NISSAN NAVARA 2005 Repair Workshop Manual

NAVARA 2005

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57362/w960_57362-0.png

NISSAN NAVARA 2005 Repair Workshop Manual

Trending: reset, diagnostic menu, coolant, diagram, check engine light, rear view mirror, coolant level

Page 321 of 3171

ASSEMBLY

AT-313

D

E

F

G

H

I

J

K

L

MA

B

AT

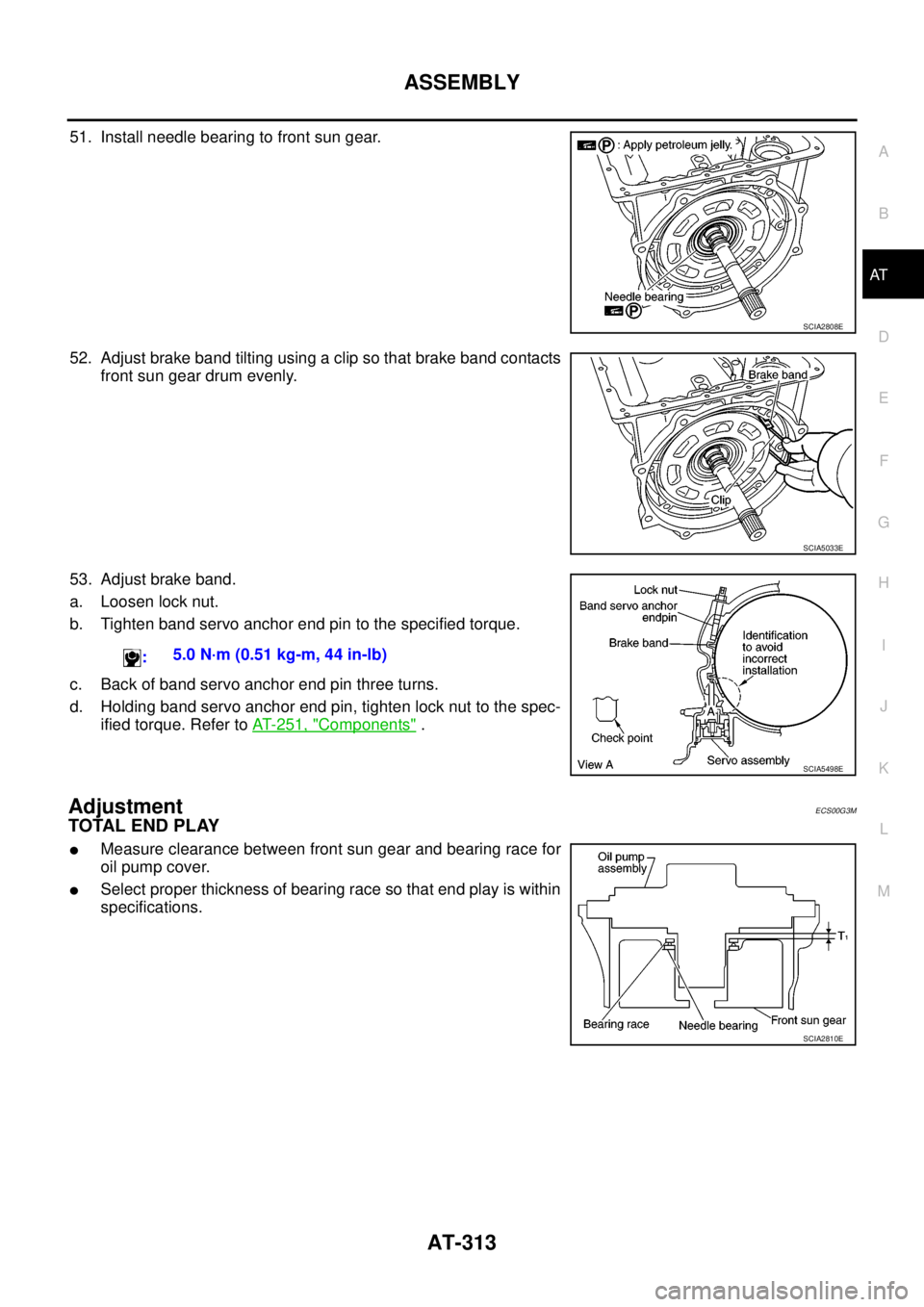

51. Install needle bearing to front sun gear.

52. Adjust brake band tilting using a clip so that brake band contacts

front sun gear drum evenly.

53. Adjust brake band.

a. Loosen lock nut.

b. Tighten band servo anchor end pin to the specified torque.

c. Back of band servo anchor end pin three turns.

d. Holding band servo anchor end pin, tighten lock nut to the spec-

ified torque. Refer toAT- 2 5 1 , "

Components".

AdjustmentECS00G3M

TOTAL END PLAY

lMeasure clearance between front sun gear and bearing race for

oil pump cover.

lSelect proper thickness of bearing race so that end play is within

specifications.

SCIA2808E

SCIA5033E

:5.0N·m(0.51kg-m,44in-lb)

SCIA5498E

SCIA2810E

Page 322 of 3171

AT-314

ASSEMBLY

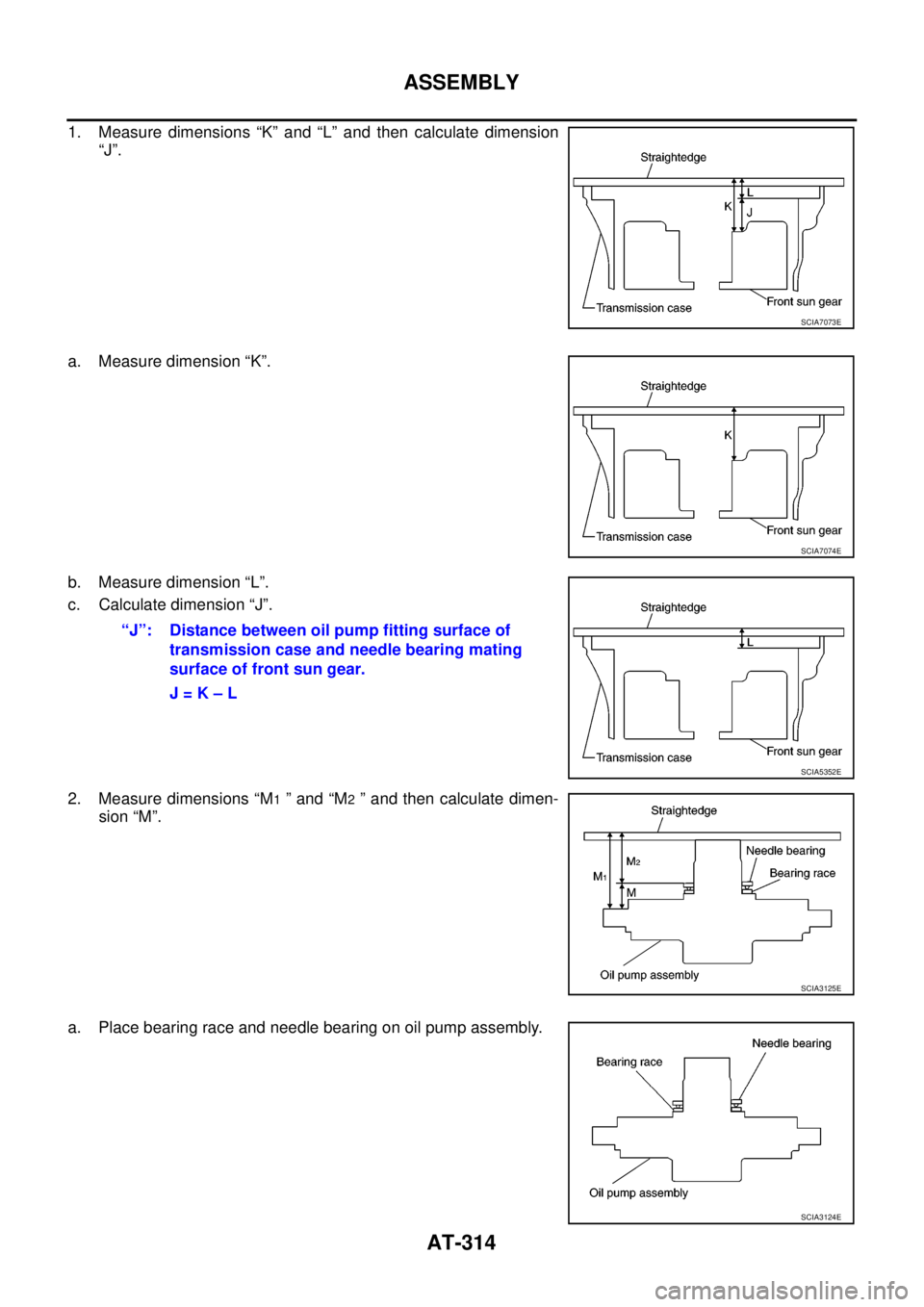

1. Measure dimensions “K” and “L” and then calculate dimension

“J”.

a. Measure dimension “K”.

b. Measure dimension “L”.

c. Calculate dimension “J”.

2. Measure dimensions “M

1”and“M2” and then calculate dimen-

sion “M”.

a. Place bearing race and needle bearing on oil pump assembly.

SCIA7073E

SCIA7074E

“J”: Distance between oil pump fitting surface of

transmission case and needle bearing mating

surface of front sun gear.

J=K–L

SCIA5352E

SCIA3125E

SCIA3124E

Page 323 of 3171

ASSEMBLY

AT-315

D

E

F

G

H

I

J

K

L

MA

B

AT

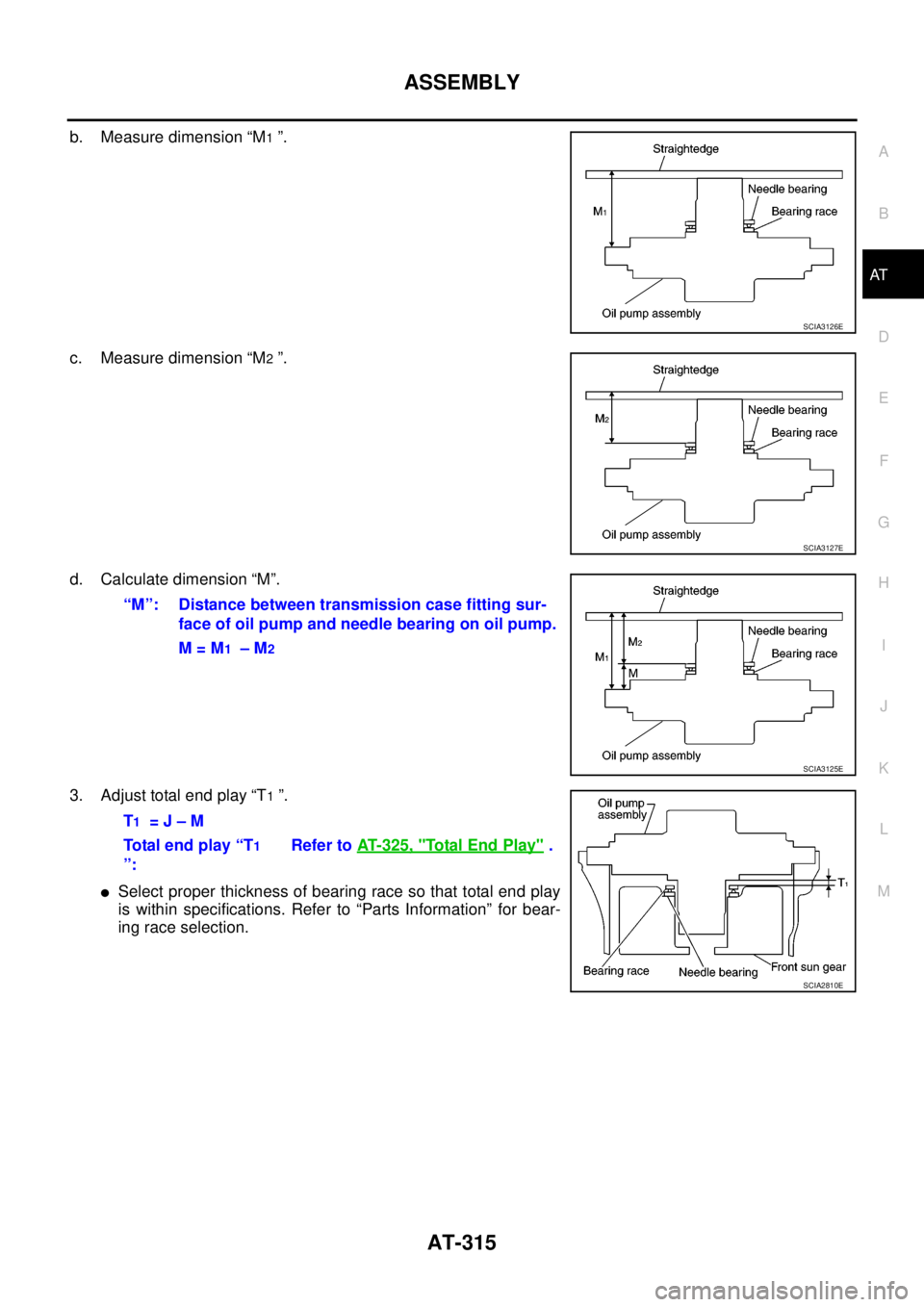

b. Measure dimension “M1”.

c. Measure dimension “M

2”.

d. Calculate dimension “M”.

3. Adjust total end play “T

1”.

lSelect proper thickness of bearing race so that total end play

is within specifications. Refer to “Parts Information” for bear-

ing race selection.

SCIA3126E

SCIA3127E

“M”: Distance between transmission case fitting sur-

face of oil pump and needle bearing on oil pump.

M=M

1–M2

SCIA3125E

T1=J–M

Total end play “T

1

”:Refer toAT- 3 2 5 , "

To ta l E n d P l a y".

SCIA2810E

Page 324 of 3171

AT-316

ASSEMBLY

Assembly (2)

ECS00G3N

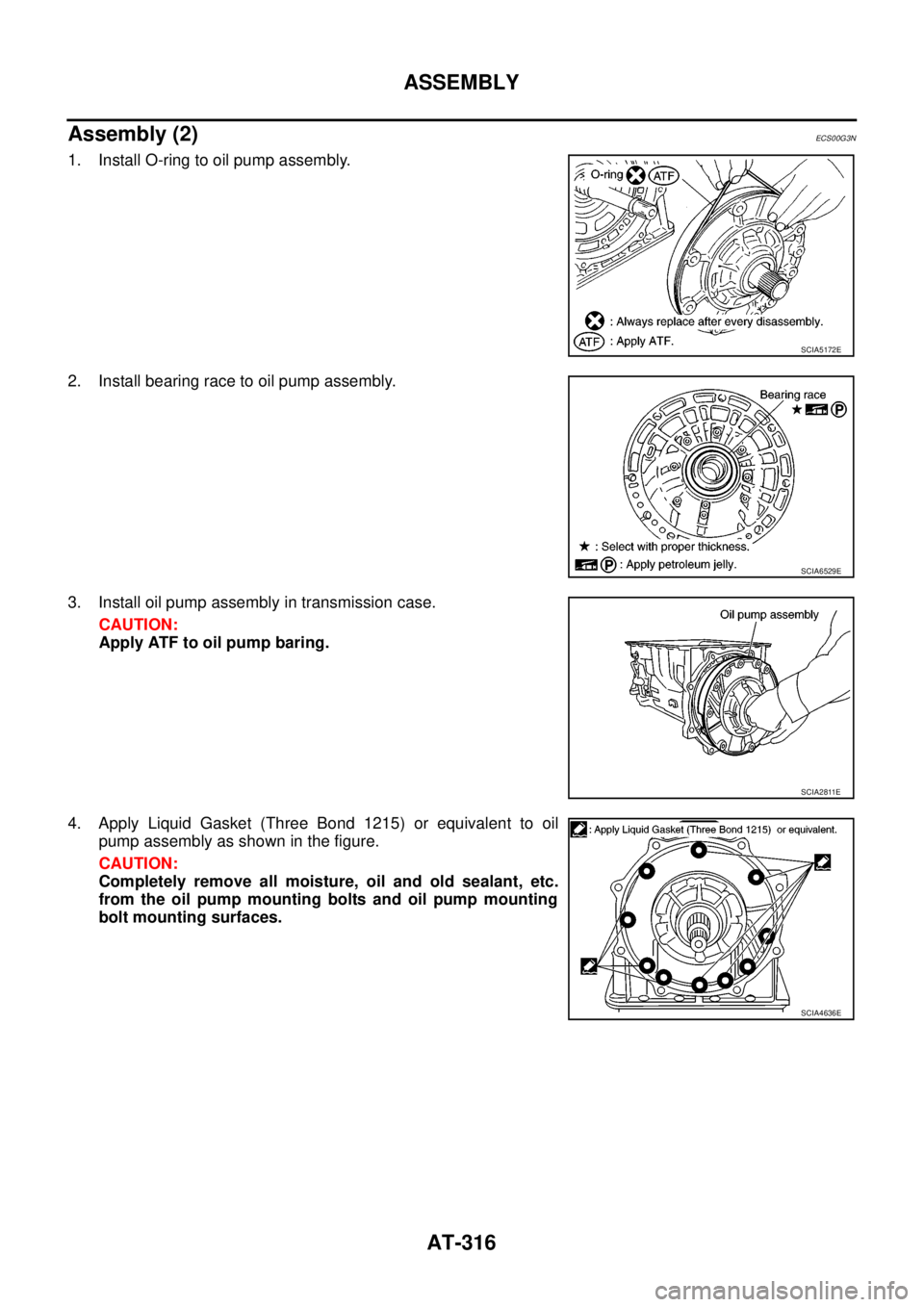

1. Install O-ring to oil pump assembly.

2. Install bearing race to oil pump assembly.

3. Install oil pump assembly in transmission case.

CAUTION:

Apply ATF to oil pump baring.

4. Apply Liquid Gasket (Three Bond 1215) or equivalent to oil

pump assembly as shown in the figure.

CAUTION:

Completely remove all moisture, oil and old sealant, etc.

from the oil pump mounting bolts and oil pump mounting

bolt mounting surfaces.

SCIA5172E

SCIA6529E

SCIA2811E

SCIA4636E

Page 325 of 3171

ASSEMBLY

AT-317

D

E

F

G

H

I

J

K

L

MA

B

AT

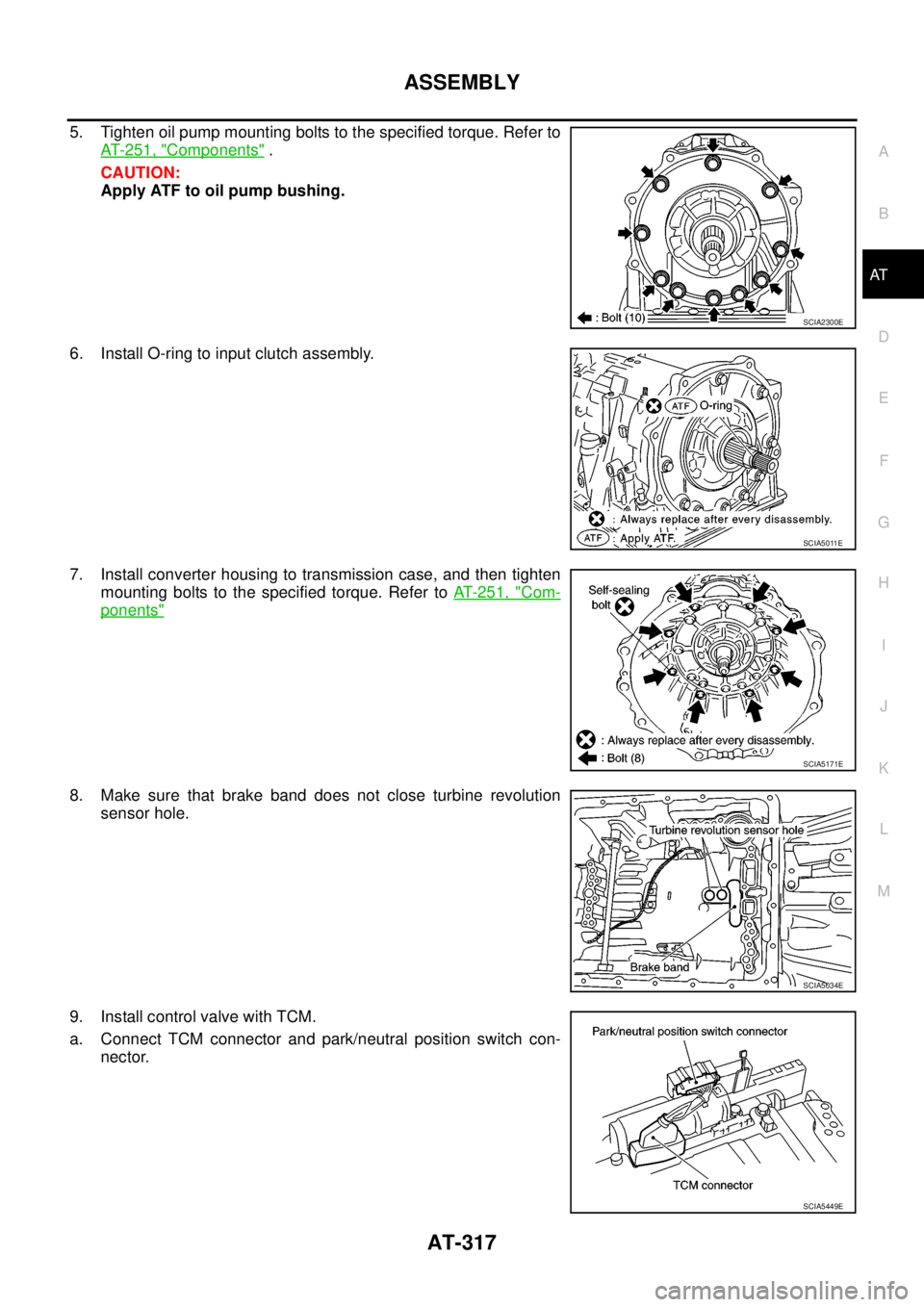

5. Tighten oil pump mounting bolts to the specified torque. Refer to

AT- 2 5 1 , "

Components".

CAUTION:

Apply ATF to oil pump bushing.

6. Install O-ring to input clutch assembly.

7. Install converter housing to transmission case, and then tighten

mounting bolts to the specified torque. Refer toAT- 2 5 1 , "

Com-

ponents"

8. Make sure that brake band does not close turbine revolution

sensor hole.

9. Install control valve with TCM.

a. Connect TCM connector and park/neutral position switch con-

nector.

SCIA2300E

SCIA5011E

SCIA5171E

SCIA5034E

SCIA5449E

Page 326 of 3171

AT-318

ASSEMBLY

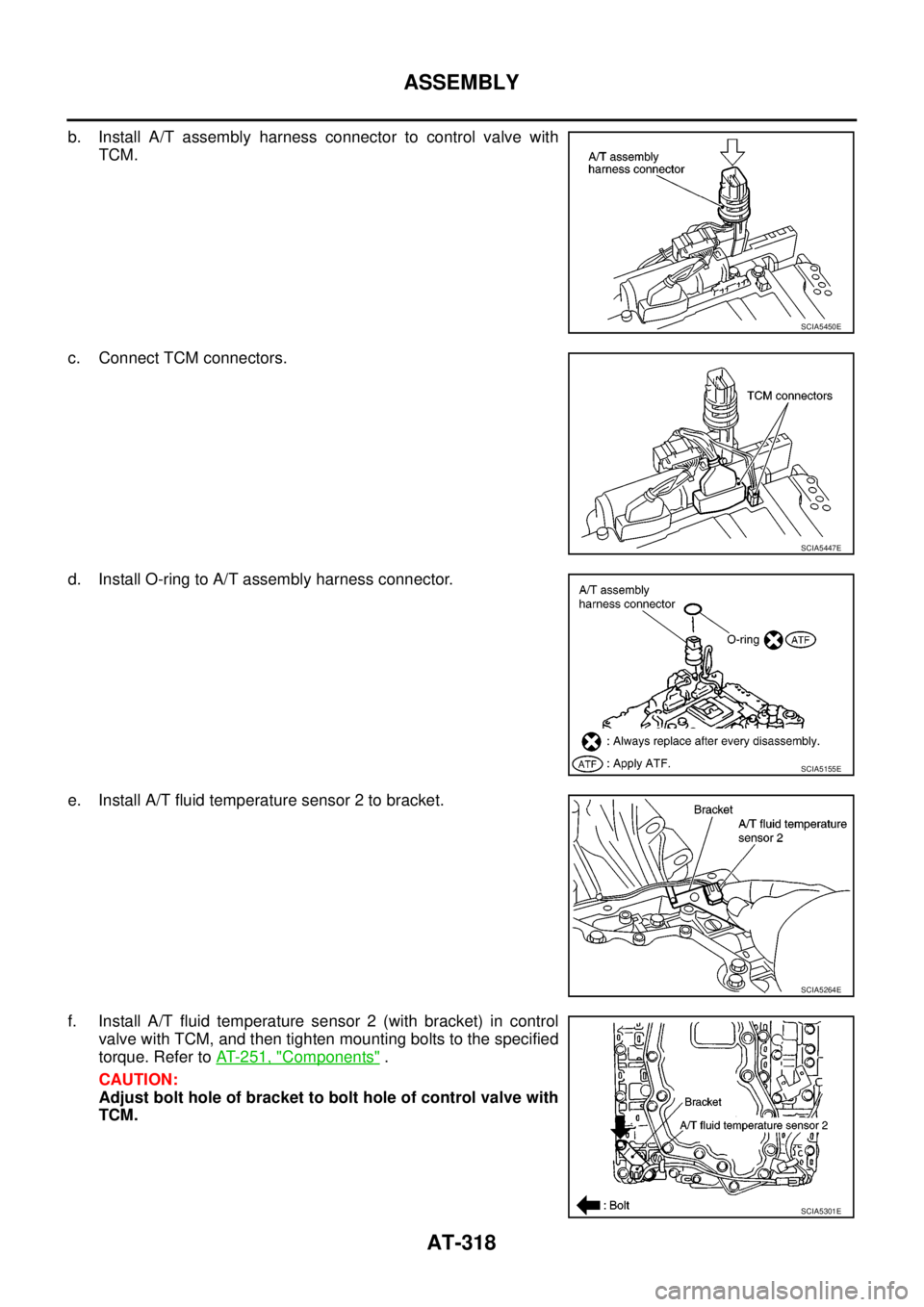

b. Install A/T assembly harness connector to control valve with

TCM.

c. Connect TCM connectors.

d. Install O-ring to A/T assembly harness connector.

e. Install A/T fluid temperature sensor 2 to bracket.

f. Install A/T fluid temperature sensor 2 (with bracket) in control

valve with TCM, and then tighten mounting bolts to the specified

torque. Refer toAT- 2 5 1 , "

Components".

CAUTION:

Adjust bolt hole of bracket to bolt hole of control valve with

TCM.

SCIA5450E

SCIA5447E

SCIA5155E

SCIA5264E

SCIA5301E

Page 327 of 3171

ASSEMBLY

AT-319

D

E

F

G

H

I

J

K

L

MA

B

AT

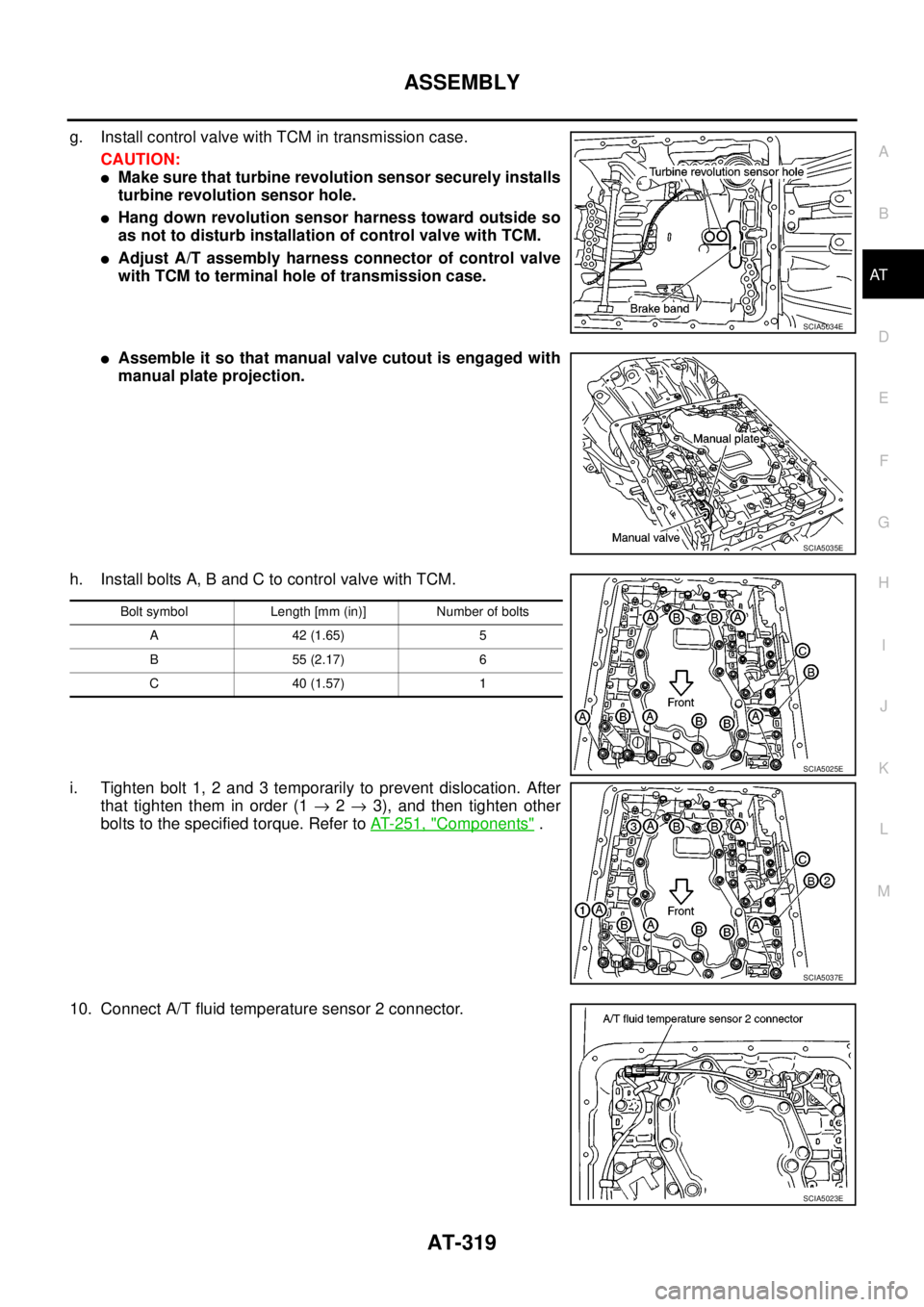

g. Install control valve with TCM in transmission case.

CAUTION:

lMake sure that turbine revolution sensor securely installs

turbine revolution sensor hole.

lHang down revolution sensor harness toward outside so

as not to disturb installation of control valve with TCM.

lAdjust A/T assembly harness connector of control valve

with TCM to terminal hole of transmission case.

lAssemble it so that manual valve cutout is engaged with

manual plate projection.

h. Install bolts A, B and C to control valve with TCM.

i. Tighten bolt 1, 2 and 3 temporarily to prevent dislocation. After

that tighten them in order (1®2®3), and then tighten other

bolts to the specified torque. Refer toAT- 2 5 1 , "

Components".

10. Connect A/T fluid temperature sensor 2 connector.

SCIA5034E

SCIA5035E

Bolt symbol Length [mm (in)] Number of bolts

A42(1.65) 5

B55(2.17) 6

C40(1.57) 1

SCIA5025E

SCIA5037E

SCIA5023E

Page 328 of 3171

AT-320

ASSEMBLY

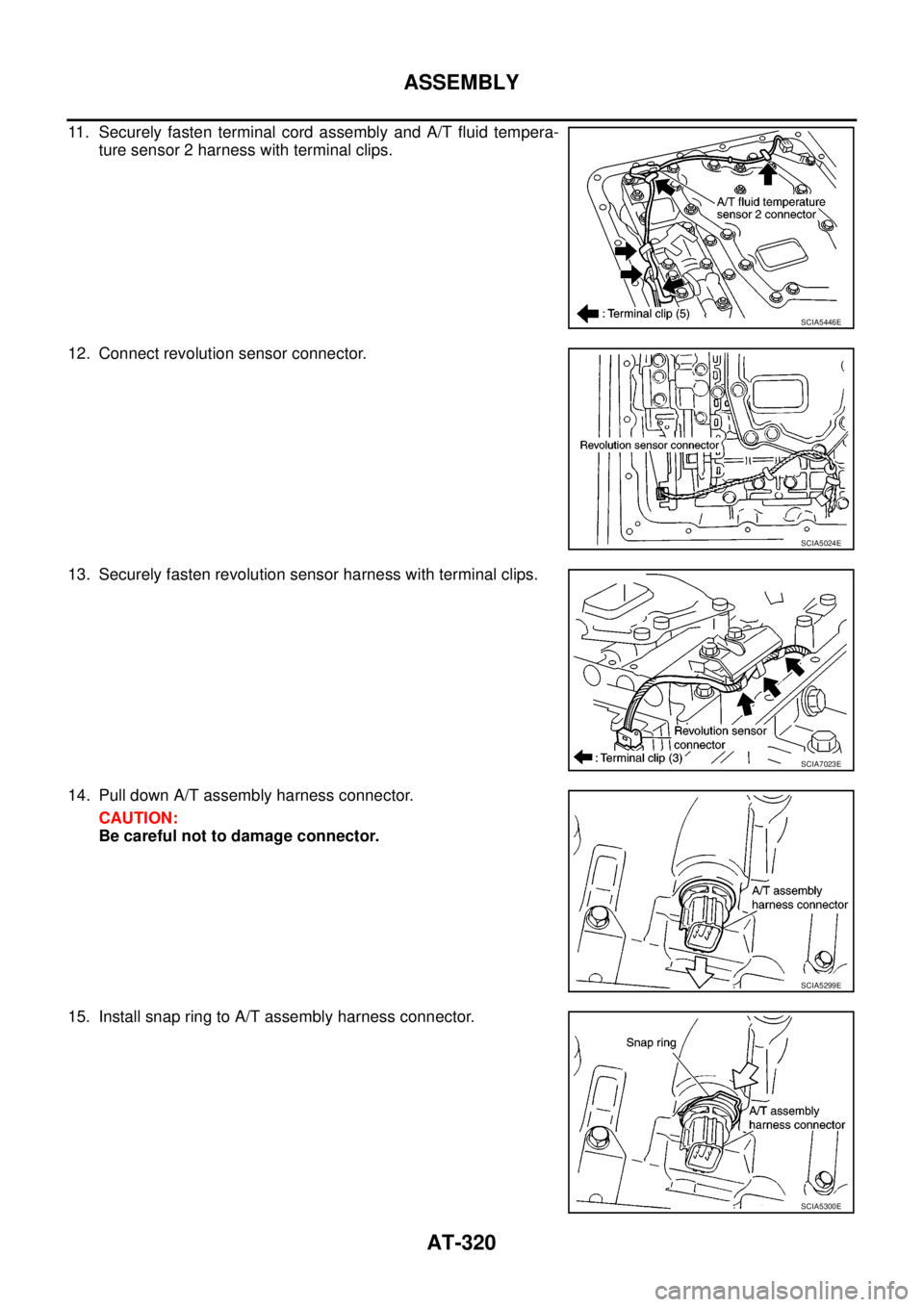

11. Securely fasten terminal cord assembly and A/T fluid tempera-

ture sensor 2 harness with terminal clips.

12. Connect revolution sensor connector.

13. Securely fasten revolution sensor harness with terminal clips.

14. Pull down A/T assembly harness connector.

CAUTION:

Be careful not to damage connector.

15. Install snap ring to A/T assembly harness connector.

SCIA5446E

SCIA5024E

SCIA7023E

SCIA5299E

SCIA5300E

Page 329 of 3171

ASSEMBLY

AT-321

D

E

F

G

H

I

J

K

L

MA

B

AT

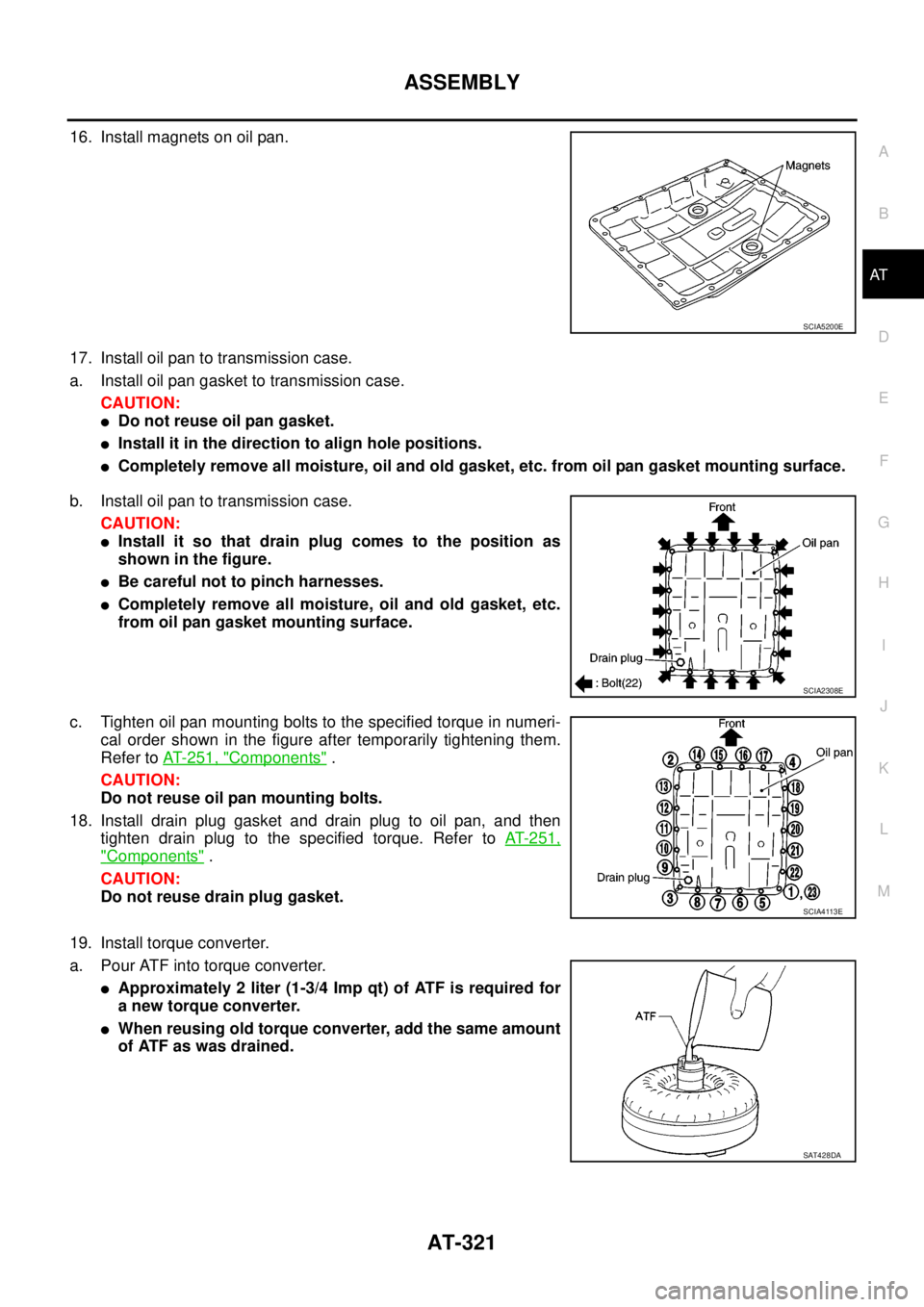

16. Install magnets on oil pan.

17. Install oil pan to transmission case.

a. Install oil pan gasket to transmission case.

CAUTION:

lDo not reuse oil pan gasket.

lInstall it in the direction to align hole positions.

lCompletely remove all moisture, oil and old gasket, etc. from oil pan gasket mounting surface.

b. Install oil pan to transmission case.

CAUTION:

lInstall it so that drain plug comes to the position as

shown in the figure.

lBe careful not to pinch harnesses.

lCompletely remove all moisture, oil and old gasket, etc.

from oil pan gasket mounting surface.

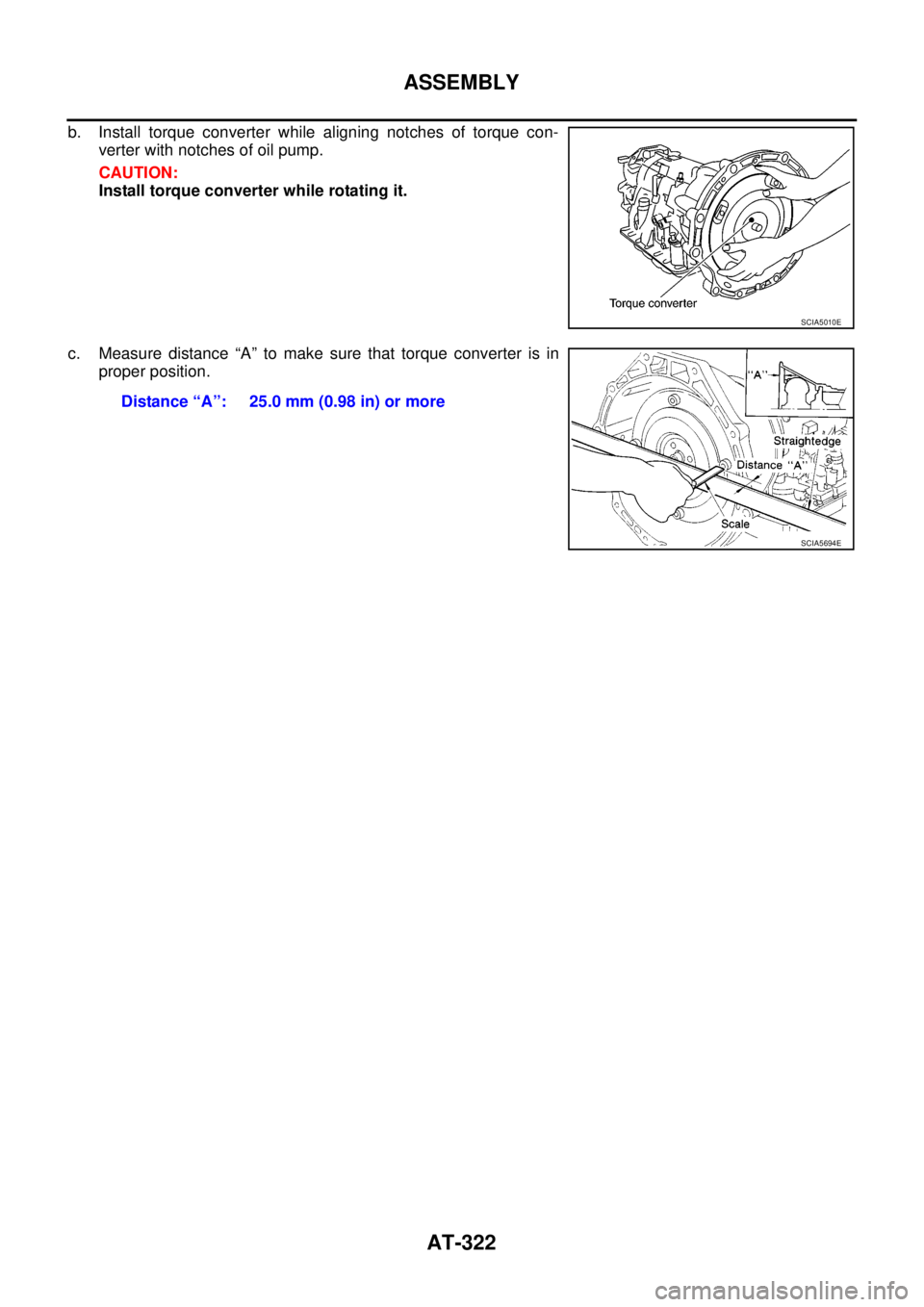

c. Tighten oil pan mounting bolts to the specified torque in numeri-

cal order shown in the figure after temporarily tightening them.

Refer toAT- 2 5 1 , "

Components".

CAUTION:

Do not reuse oil pan mounting bolts.

18. Install drain plug gasket and drain plug to oil pan, and then

tighten drain plug to the specified torque. Refer toAT-251,

"Components".

CAUTION:

Do not reuse drain plug gasket.

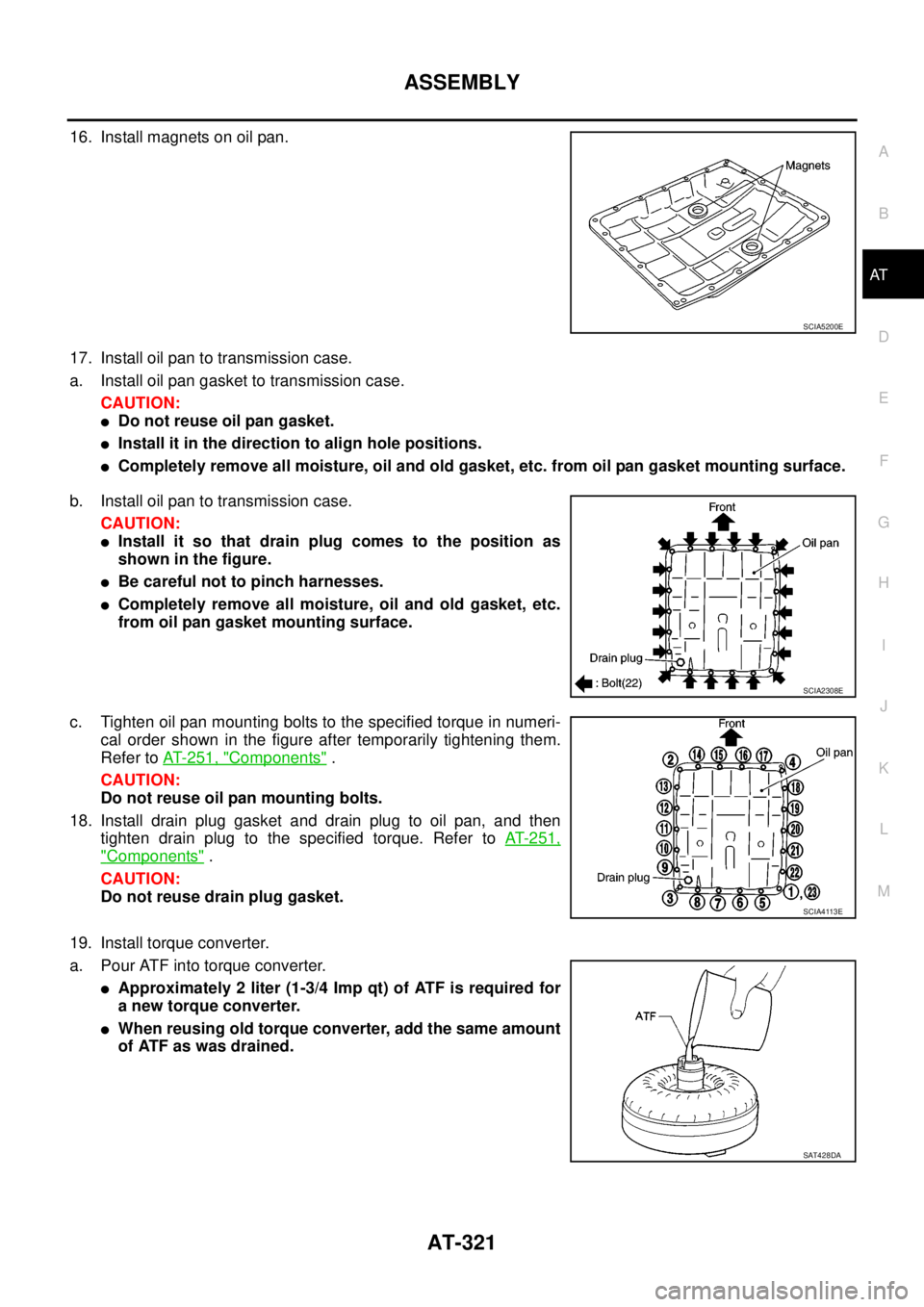

19. Install torque converter.

a. Pour ATF into torque converter.

lApproximately 2 liter (1-3/4 Imp qt) of ATF is required for

a new torque converter.

lWhen reusing old torque converter, add the same amount

of ATF as was drained.

SCIA5200E

SCIA2308E

SCIA4113E

SAT428DA

Page 330 of 3171

AT-322

ASSEMBLY

b. Install torque converter while aligning notches of torque con-

verter with notches of oil pump.

CAUTION:

Install torque converter while rotating it.

c. Measure distance “A” to make sure that torque converter is in

proper position.

SCIA5010E

Distance “A”: 25.0 mm (0.98 in) or more

SCIA5694E

Trending: radio antenna, EC_main, trailer, relay, service, light, coolant