battery NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 3060 of 3171

TROUBLE DIAGNOSIS FOR SYMPTOMS

TF-93

C

E

F

G

H

I

J

K

L

MA

B

TF

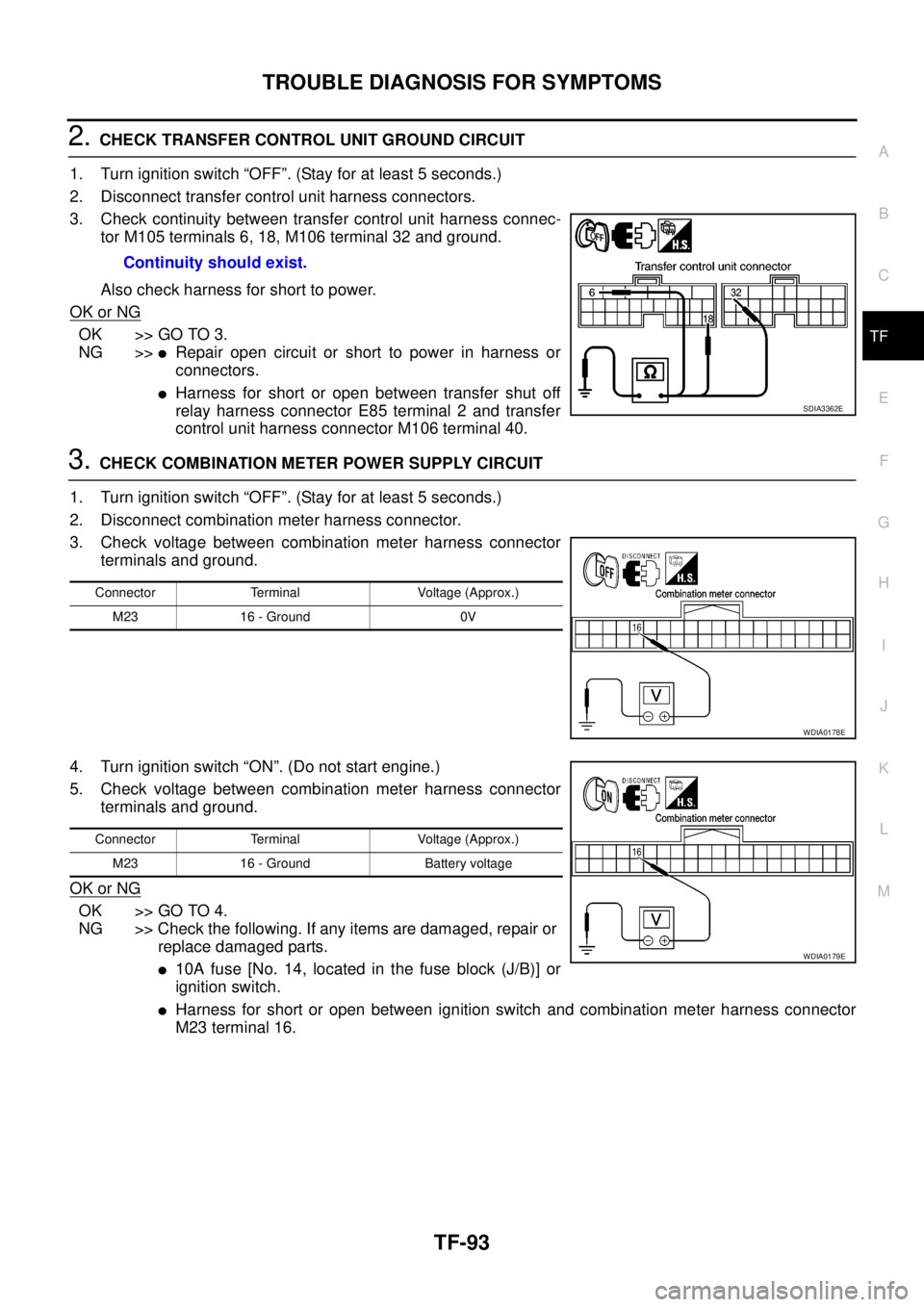

2.CHECK TRANSFER CONTROL UNIT GROUND CIRCUIT

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connectors.

3. Check continuity between transfer control unit harness connec-

tor M105 terminals 6, 18, M106 terminal 32 and ground.

Also check harness for short to power.

OK or NG

OK >> GO TO 3.

NG >>

lRepair open circuit or short to power in harness or

connectors.

lHarness for short or open between transfer shut off

relay harness connector E85 terminal 2 and transfer

control unit harness connector M106 terminal 40.

3.CHECK COMBINATION METER POWER SUPPLY CIRCUIT

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect combination meter harness connector.

3. Check voltage between combination meter harness connector

terminals and ground.

4. Turn ignition switch “ON”. (Do not start engine.)

5. Check voltage between combination meter harness connector

terminals and ground.

OK or NG

OK >> GO TO 4.

NG >> Check the following. If any items are damaged, repair or

replace damaged parts.

l10A fuse [No. 14, located in the fuse block (J/B)] or

ignition switch.

lHarness for short or open between ignition switch and combination meter harness connector

M23 terminal 16. Continuity should exist.

SDIA3362E

Connector Terminal Voltage (Approx.)

M23 16 - Ground 0V

WDIA0178E

Connector Terminal Voltage (Approx.)

M23 16 - Ground Battery voltage

WDIA0179E

Page 3067 of 3171

TF-100

TRANSFER CONTROL UNIT

TRANSFER CONTROL UNIT

PFP:33084

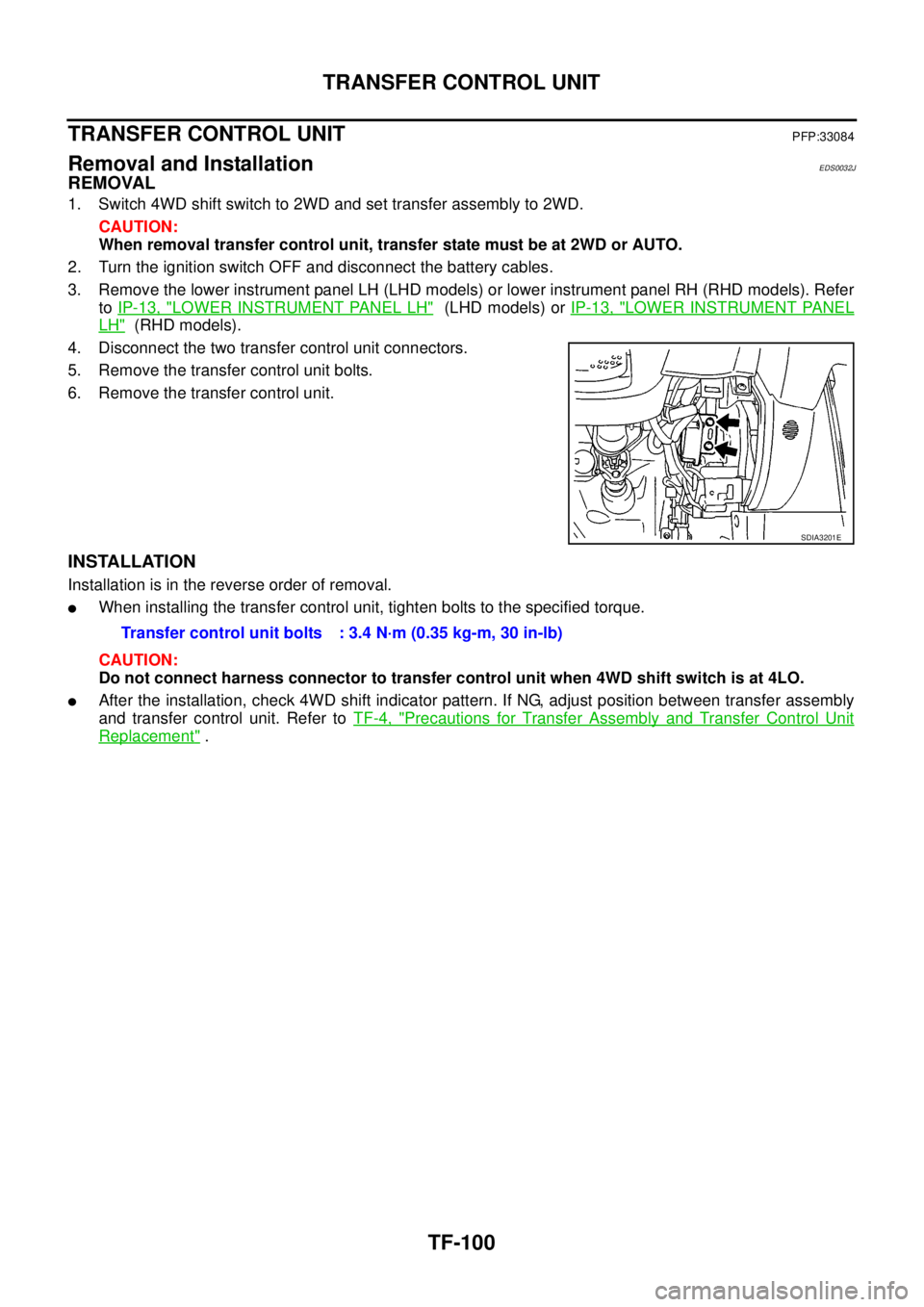

Removal and InstallationEDS0032J

REMOVAL

1. Switch 4WD shift switch to 2WD and set transfer assembly to 2WD.

CAUTION:

When removal transfer control unit, transfer state must be at 2WD or AUTO.

2. Turn the ignition switch OFF and disconnect the battery cables.

3. Remove the lower instrument panel LH (LHD models) or lower instrument panel RH (RHD models). Refer

toIP-13, "

LOWER INSTRUMENT PANEL LH"(LHD models) orIP-13, "LOWER INSTRUMENT PANEL

LH"(RHD models).

4. Disconnect the two transfer control unit connectors.

5. Remove the transfer control unit bolts.

6. Remove the transfer control unit.

INSTALLATION

Installation is in the reverse order of removal.

lWhen installing the transfer control unit, tighten bolts to the specified torque.

CAUTION:

Do not connect harness connector to transfer control unit when 4WD shift switch is at 4LO.

lAfter the installation, check 4WD shift indicator pattern. If NG, adjust position between transfer assembly

and transfer control unit. Refer toTF-4, "

Precautions for Transfer Assembly and Transfer Control Unit

Replacement".

SDIA3201E

Transfer control unit bolts : 3.4 N·m (0.35 kg-m, 30 in-lb)

Page 3115 of 3171

WW-4

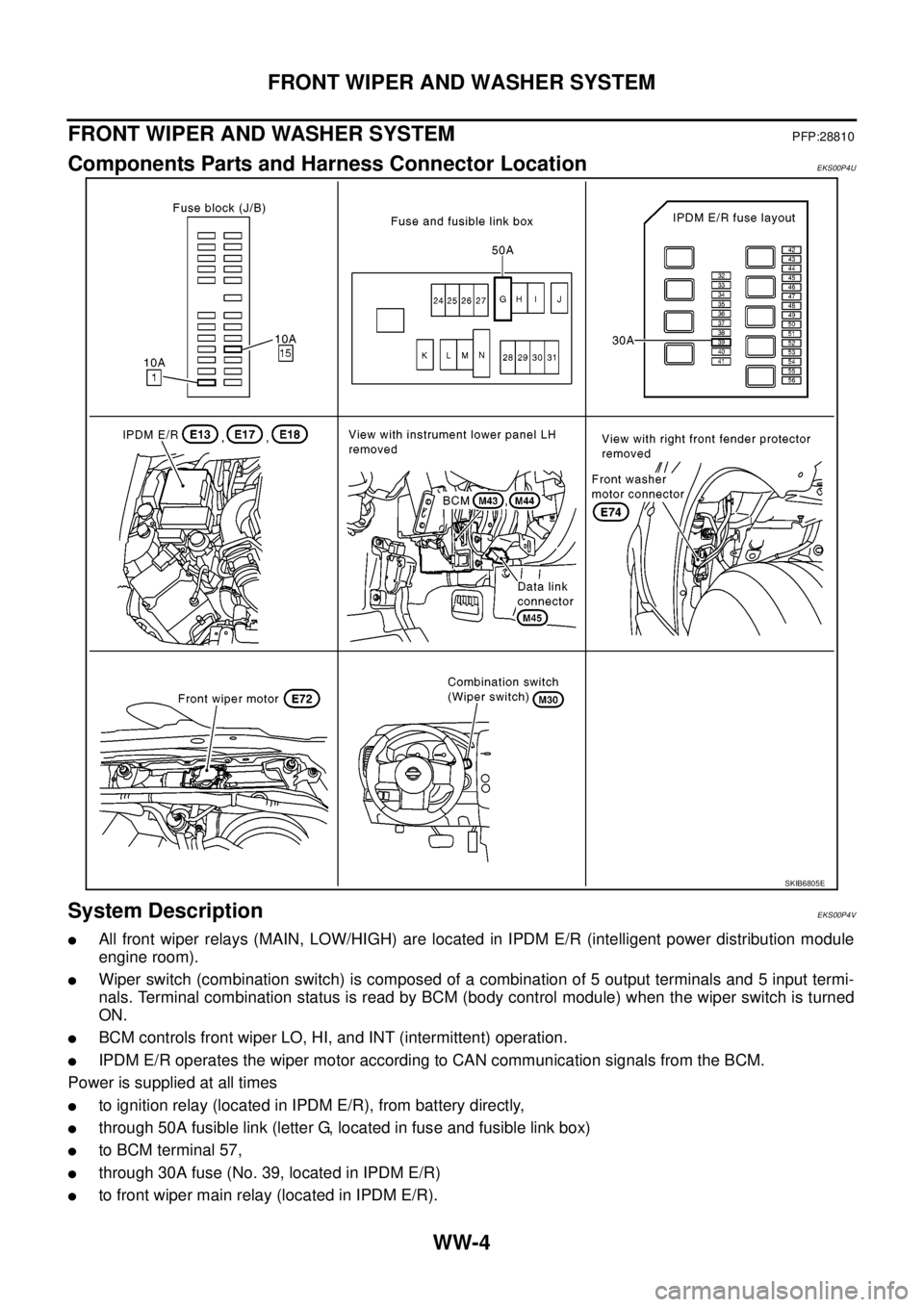

FRONT WIPER AND WASHER SYSTEM

FRONT WIPER AND WASHER SYSTEM

PFP:28810

Components Parts and Harness Connector LocationEKS00P4U

System DescriptionEKS00P4V

lAll front wiper relays (MAIN, LOW/HIGH) are located in IPDM E/R (intelligent power distribution module

engine room).

lWiper switch (combination switch) is composed of a combination of 5 output terminals and 5 input termi-

nals. Terminal combination status is read by BCM (body control module) when the wiper switch is turned

ON.

lBCM controls front wiper LO, HI, and INT (intermittent) operation.

lIPDM E/R operates the wiper motor according to CAN communication signals from the BCM.

Power is supplied at all times

lto ignition relay (located in IPDM E/R), from battery directly,

lthrough 50A fusible link (letter G, located in fuse and fusible link box)

lto BCM terminal 57,

lthrough 30A fuse (No. 39, located in IPDM E/R)

lto front wiper main relay (located in IPDM E/R).

SKIB6805E

Page 3126 of 3171

FRONT WIPER AND WASHER SYSTEM

WW-15

C

D

E

F

G

H

I

J

L

MA

B

WW

Terminals and Reference Values for BCMEKS00P4Z

Te r m i n a l

No.Wire

colorSignal nameMeasuring condition

Reference value

Ignition

switchOperation or condition

3 Y Ignition switch (ON) ON — Battery voltage

6 G Combination switch output 3 ONLighting, turn, wiper OFF

Wiper dial position 4

7 GR Combination switch output 4 ONLighting, turn, wiper OFF

Wiper dial position 4

8 LG Combination switch output 1 ONLighting, turn, wiper OFF

Wiper dial position 4

9 BR Combination switch output 2 ONLighting, turn, wiper OFF

Wiper dial position 4

10 O Combination switch output 5 ONLighting, turn, wiper OFF

Wiper dial position 4

21 P CAN-L—— —

22 L CAN-H—— —

24 R Light and rain sensor signal — Ignition switchON

OFF Battery voltage

36 P Combination switch input 5 ONLighting, turn, wiper OFF

Wiper dial position 4

Approx. 0V 37 L Combination switch input 2 ONLighting, turn, wiper OFF

Wiper dial position 4

38 V Combination switch input 3 ONLighting, turn, wiper OFF

Wiper dial position 4

39 SB Combination switch input 4 ONLighting, turn, wiper OFF

Wiper dial position 4

40 R Combination switch input 1 ONLighting, turn, wiper OFF

Wiper dial position 4

42 V Room lamp power supply OFF — Battery voltage

55 B Ground ON — Approx. 0V

57 W Battery power supply (fusible link) OFF — Battery voltage

PKIB4958J

PKIC1618E

Page 3127 of 3171

WW-16

FRONT WIPER AND WASHER SYSTEM

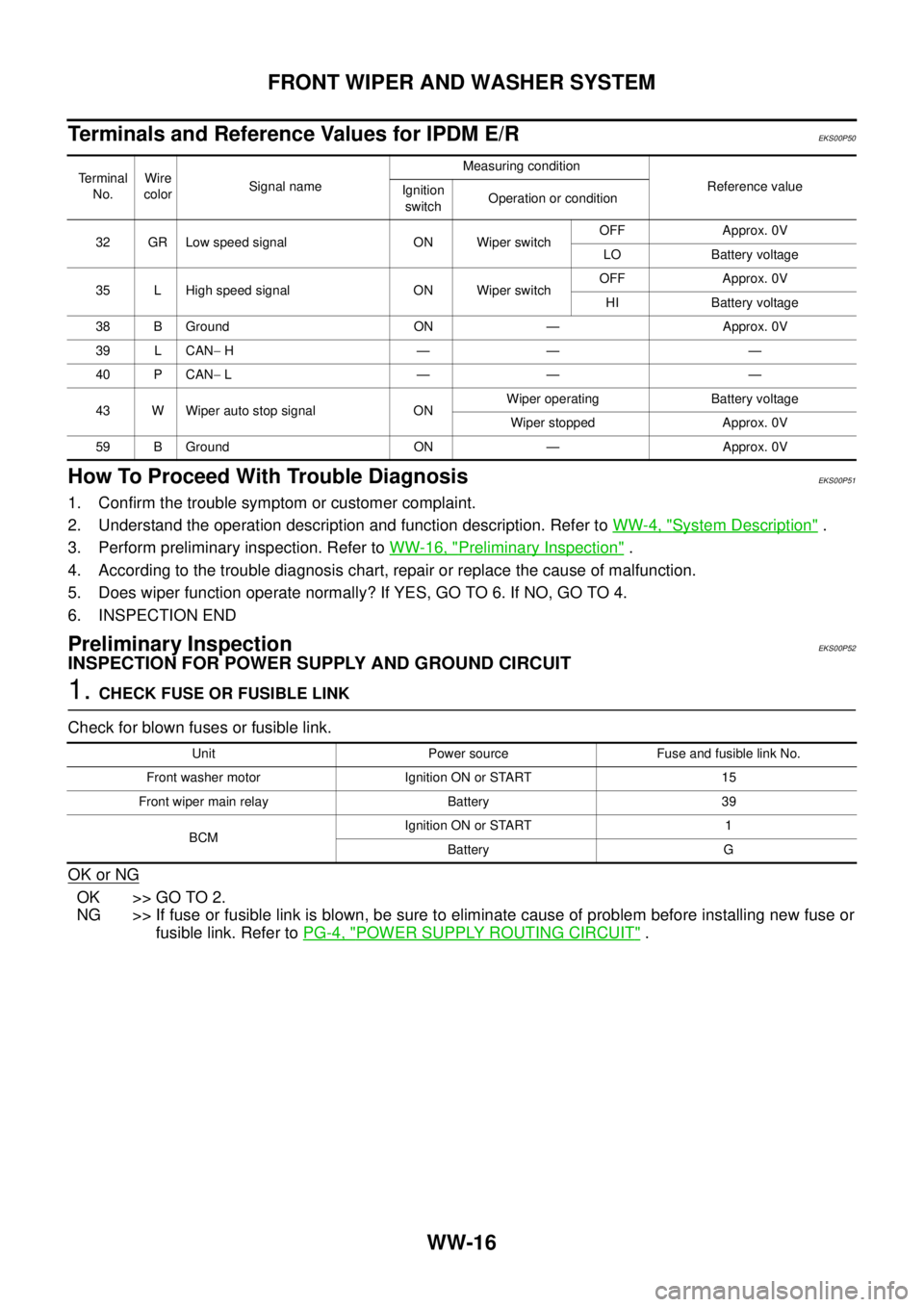

Terminals and Reference Values for IPDM E/R

EKS00P50

How To Proceed With Trouble DiagnosisEKS00P51

1. Confirm the trouble symptom or customer complaint.

2. Understand the operation description and function description. Refer toWW-4, "

System Description".

3. Perform preliminary inspection. Refer toWW-16, "

Preliminary Inspection".

4. According to the trouble diagnosis chart, repair or replace the cause of malfunction.

5. Does wiper function operate normally? If YES, GO TO 6. If NO, GO TO 4.

6. INSPECTION END

Preliminary InspectionEKS00P52

INSPECTION FOR POWER SUPPLY AND GROUND CIRCUIT

1.CHECK FUSE OR FUSIBLE LINK

Check for blown fuses or fusible link.

OK or NG

OK >> GO TO 2.

NG >> If fuse or fusible link is blown, be sure to eliminate cause of problem before installing new fuse or

fusible link. Refer toPG-4, "

POWER SUPPLY ROUTING CIRCUIT".

Te r m i n a l

No.Wire

colorSignal nameMeasuring condition

Reference value

Ignition

switchOperation or condition

32 GR Low speed signal ON Wiper switchOFF Approx. 0V

LO Battery voltage

35 L High speed signal ON Wiper switchOFF Approx. 0V

HI Battery voltage

38 B Ground ON — Approx. 0V

39 L CAN-H—— —

40 P CAN-L—— —

43 W Wiper auto stop signal ONWiper operating Battery voltage

Wiper stopped Approx. 0V

59 B Ground ON — Approx. 0V

Unit Power source Fuse and fusible link No.

Front washer motor Ignition ON or START 15

Front wiper main relay Battery 39

BCMIgnition ON or START 1

Battery G

Page 3128 of 3171

FRONT WIPER AND WASHER SYSTEM

WW-17

C

D

E

F

G

H

I

J

L

MA

B

WW

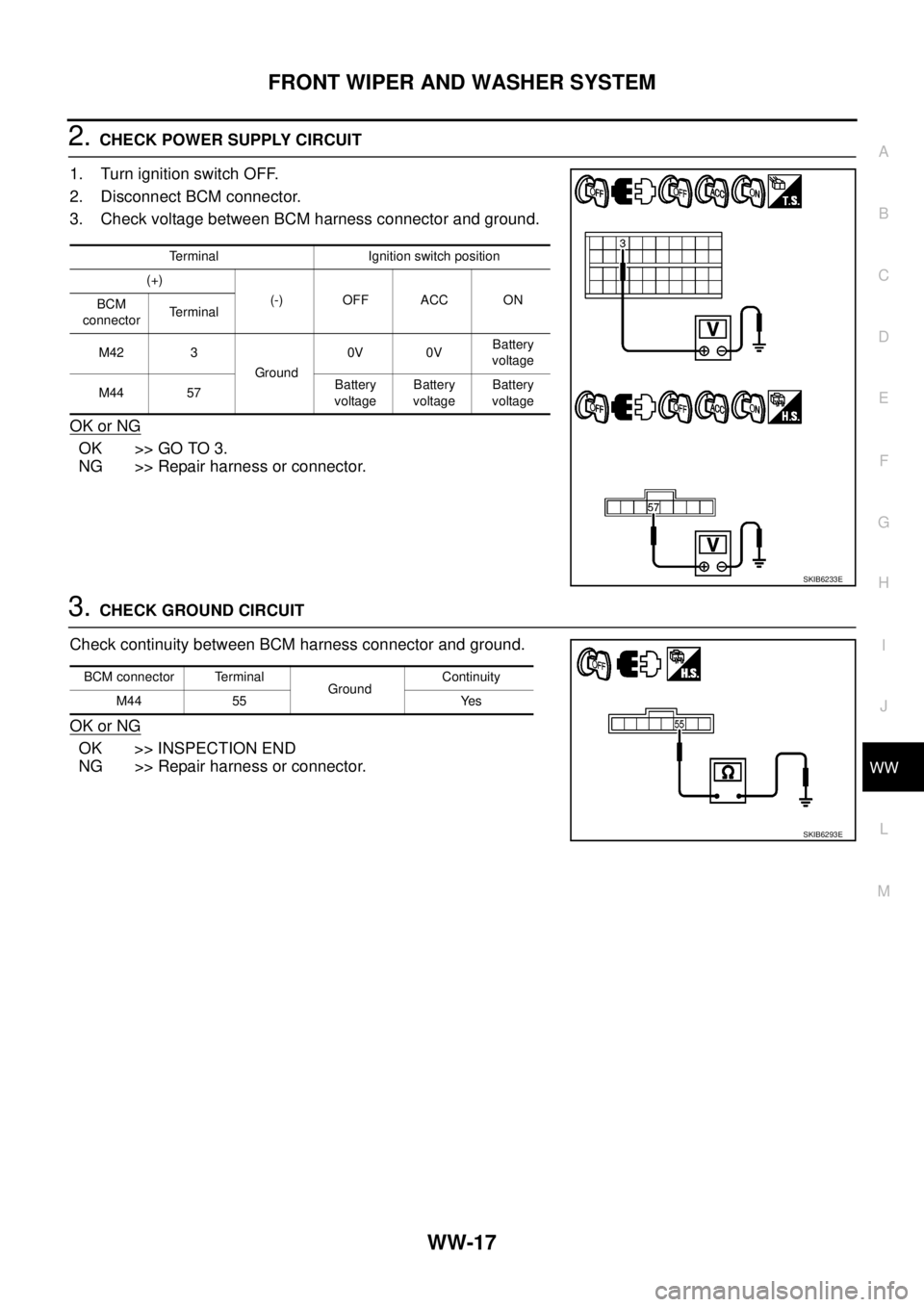

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check voltage between BCM harness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

OK or NG

OK >> INSPECTION END

NG >> Repair harness or connector.

Terminal Ignition switch position

(+)

(-) OFF ACC ON

BCM

connectorTerminal

M42 3

Ground0V 0VBattery

voltage

M44 57Battery

voltageBattery

voltageBattery

voltage

SKIB6233E

BCM connector Terminal

GroundContinuity

M44 55 Yes

SKIB6293E

Page 3135 of 3171

WW-24

FRONT WIPER AND WASHER SYSTEM

4.CHECK LIGHT AND RAIN SENSOR GROUND CIRCUIT

Check continuity between light and rain sensor harness connector

and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair harness or connector.

5.CHECK LIGHT AND RAIN SENSOR POWER SUPPLY CIRCUIT

1. Check continuity between BCM harness connector (A) and light

and rain sensor harness connector (B).

2. Check continuity between BCM harness connector (A) and

ground.

OK or NG

OK >> GO TO 6.

NG >> Repair harness or connector.

6.CHECK LIGHT AND RAIN SENSOR POWER SUPPLY

1. Connect BCM connector.

2. Turn ignition switch ON.

3. Check voltage between light and rain sensor harness connector

and ground.

OK or NG

OK >> Replace light and rain sensor. Refer toLT-65, "Removal

and Installation of Light and Rain Sensor".

NG >> Replace BCM. Refer toBCS-17, "

Removal and Installation of BCM".

Light and rain

sensor connectorTerminal

GroundContinuity

R3 3 Yes

PKIC1375E

AB

Continuity

Connector Terminal Connector Terminal

M43 42 R3 1 Yes

A

GroundContinuity

Connector Terminal

M43 42 No

PKIC1376E

Terminal

Voltage (+)

(-)

Light and rain sensor

connectorTe r m i n a l

R3 1 Ground Battery voltage

SKIB6406E

Page 3138 of 3171

FRONT WIPER AND WASHER SYSTEM

WW-27

C

D

E

F

G

H

I

J

L

MA

B

WW

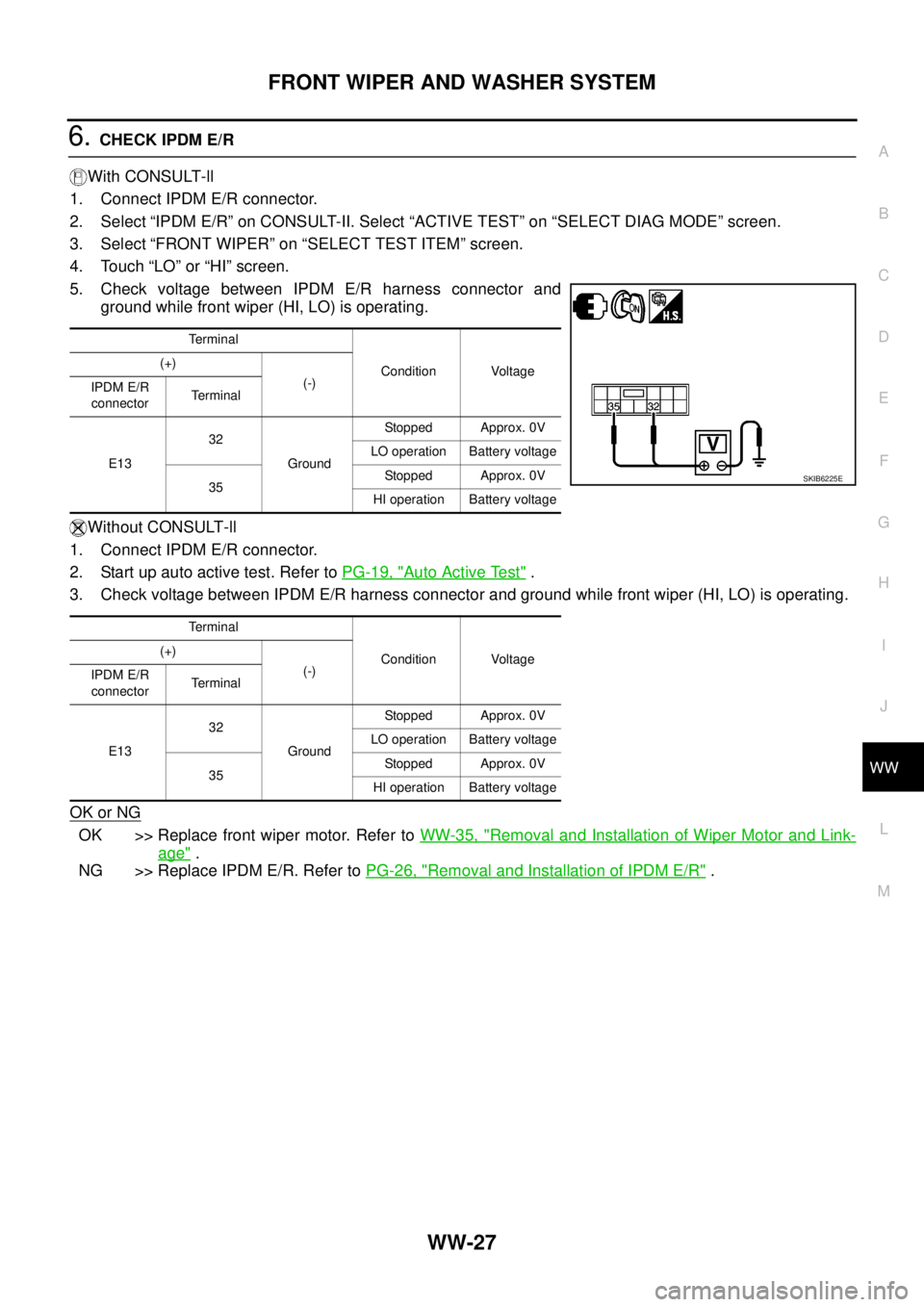

6.CHECK IPDM E/R

With CONSULT-ll

1. Connect IPDM E/R connector.

2. Select “IPDM E/R” on CONSULT-II. Select “ACTIVE TEST” on “SELECT DIAG MODE” screen.

3. Select “FRONT WIPER” on “SELECT TEST ITEM” screen.

4. Touch “LO” or “HI” screen.

5. Check voltage between IPDM E/R harness connector and

ground while front wiper (HI, LO) is operating.

Without CONSULT-ll

1. Connect IPDM E/R connector.

2. Start up auto active test. Refer toPG-19, "

Auto Active Test".

3. Check voltage between IPDM E/R harness connector and ground while front wiper (HI, LO) is operating.

OK or NG

OK >> Replace front wiper motor. Refer toWW-35, "Removal and Installation of Wiper Motor and Link-

age".

NG >> Replace IPDM E/R. Refer toPG-26, "

Removal and Installation of IPDM E/R".

Te r m i n a l

Condition Voltage (+)

(-)

IPDM E/R

connectorTerminal

E1332

GroundStopped Approx. 0V

LO operation Battery voltage

35Stopped Approx. 0V

HI operation Battery voltage

Te r m i n a l

Condition Voltage (+)

(-)

IPDM E/R

connectorTerminal

E1332

GroundStopped Approx. 0V

LO operation Battery voltage

35Stopped Approx. 0V

HI operation Battery voltage

SKIB6225E

Page 3139 of 3171

WW-28

FRONT WIPER AND WASHER SYSTEM

Front Wiper Does Not Return to Stop Position (After Front Wiper for 10 Sec-

onds, They Stop for 20 seconds, and After Repeating the Operations Five

Times, They Become Inoperative)

EKS00P57

CAUTION:

lWhen auto stop signal has not varied for 10 seconds or longer while IPDM E/R is operating front

wipers, IPDM E/R considers front wipers are locked, and stops wiper output. That causes this

symptom.

lThis status can be checked by “DATA MONITOR” of “IPDM E/R” on which “WIPER PROTECTION”

ITEMS SHOWS “BLOCK”.

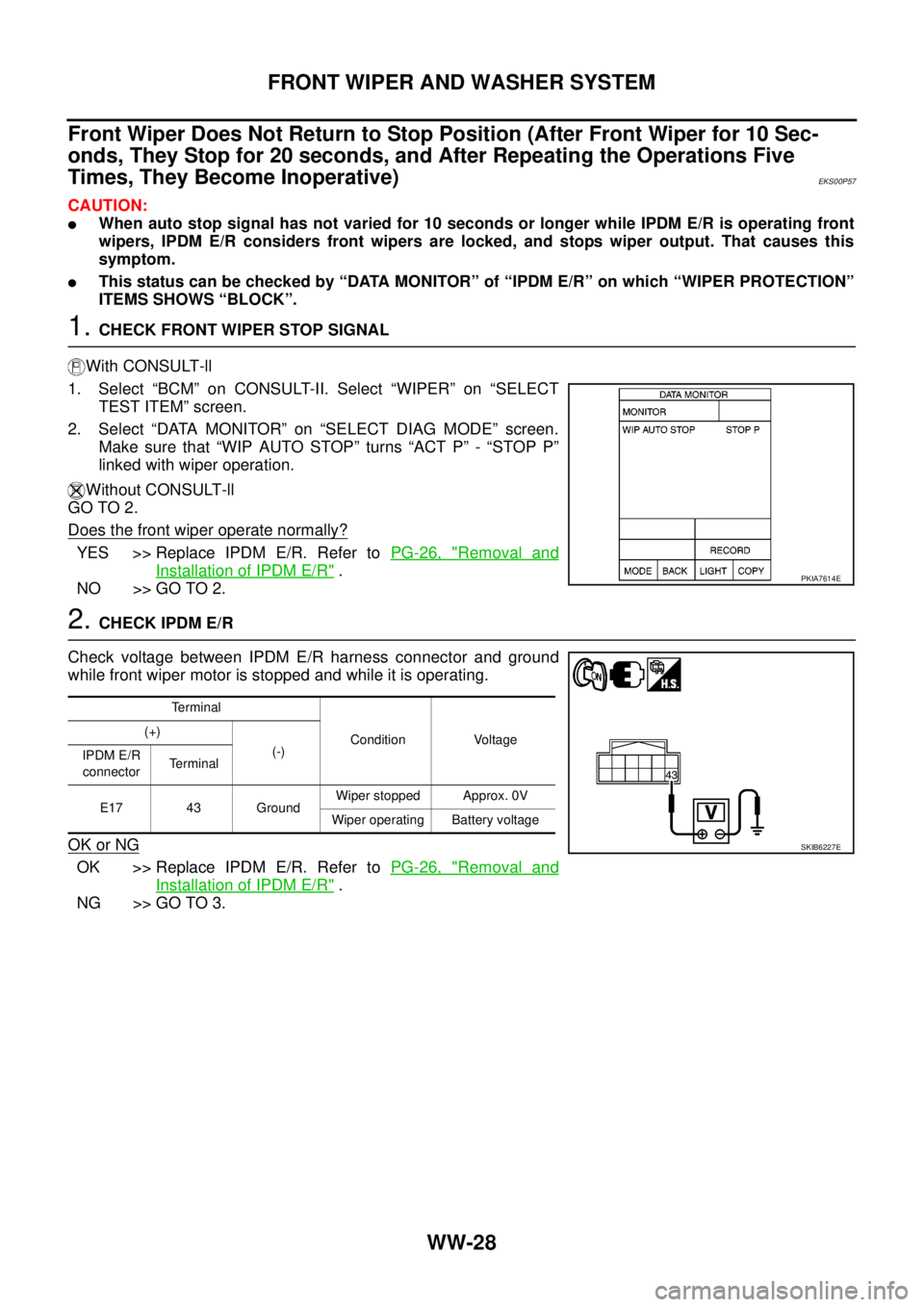

1.CHECK FRONT WIPER STOP SIGNAL

With CONSULT-ll

1. Select “BCM” on CONSULT-II. Select “WIPER” on “SELECT

TEST ITEM” screen.

2. Select “DATA MONITOR” on “SELECT DIAG MODE” screen.

Make sure that “WIP AUTO STOP” turns “ACT P” - “STOP P”

linked with wiper operation.

Without CONSULT-ll

GO TO 2.

Does the front wiper operate normally?

YES >> Replace IPDM E/R. Refer toPG-26, "Removal and

Installation of IPDM E/R".

NO >> GO TO 2.

2.CHECK IPDM E/R

Check voltage between IPDM E/R harness connector and ground

while front wiper motor is stopped and while it is operating.

OK or NG

OK >> Replace IPDM E/R. Refer toPG-26, "Removal and

Installation of IPDM E/R".

NG >> GO TO 3.

PKIA7614E

Terminal

Condition Voltage (+)

(-)

IPDM E/R

connectorTerminal

E17 43 GroundWiper stopped Approx. 0V

Wiper operating Battery voltage

SKIB6227E

Page 3141 of 3171

WW-30

FRONT WIPER AND WASHER SYSTEM

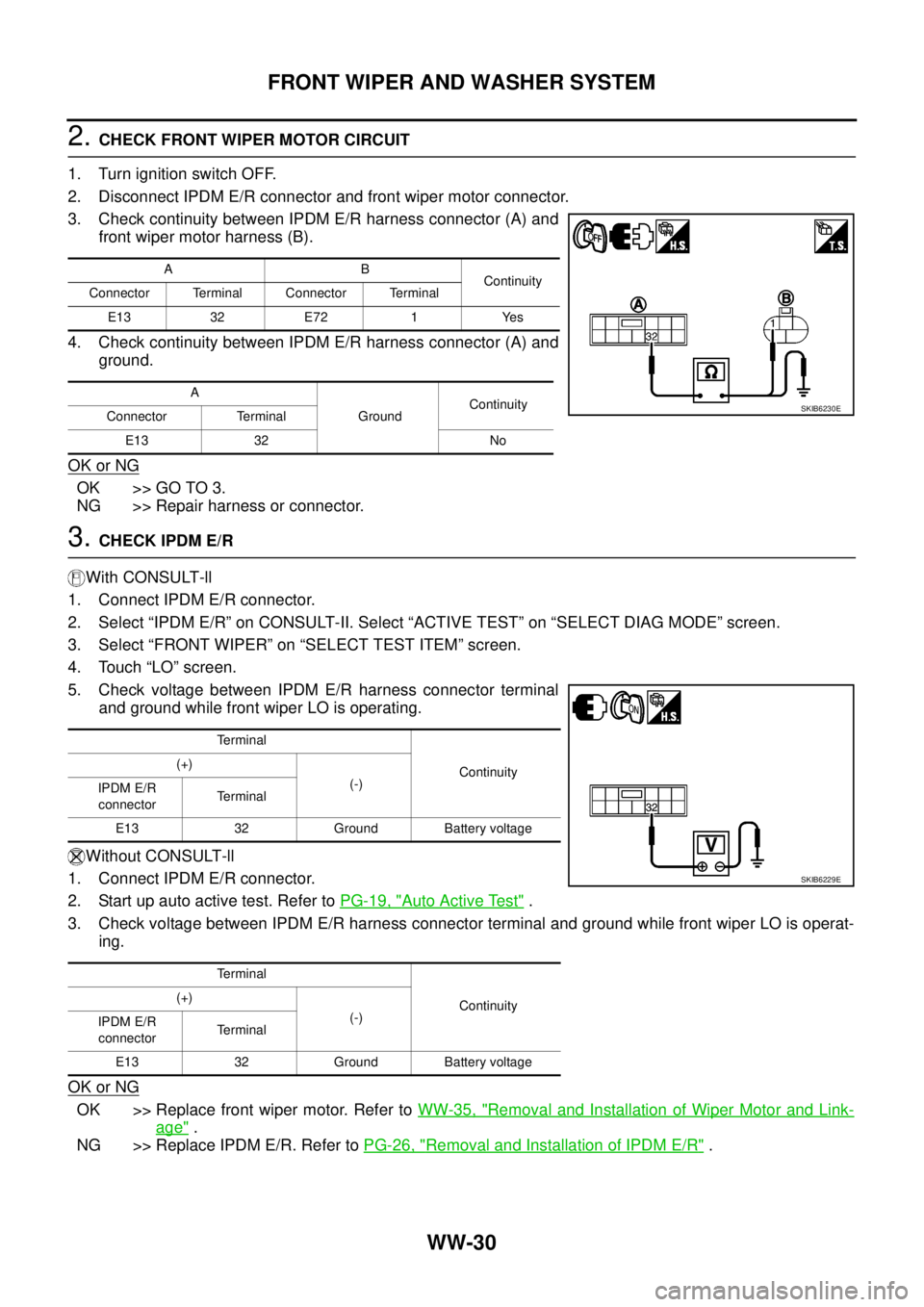

2.CHECK FRONT WIPER MOTOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector and front wiper motor connector.

3. Check continuity between IPDM E/R harness connector (A) and

front wiper motor harness (B).

4. Check continuity between IPDM E/R harness connector (A) and

ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK IPDM E/R

With CONSULT-ll

1. Connect IPDM E/R connector.

2. Select “IPDM E/R” on CONSULT-II. Select “ACTIVE TEST” on “SELECT DIAG MODE” screen.

3. Select “FRONT WIPER” on “SELECT TEST ITEM” screen.

4. Touch “LO” screen.

5. Check voltage between IPDM E/R harness connector terminal

and ground while front wiper LO is operating.

Without CONSULT-ll

1. Connect IPDM E/R connector.

2. Startupautoactivetest.RefertoPG-19, "

Auto Active Test".

3. Check voltage between IPDM E/R harness connector terminal and ground while front wiper LO is operat-

ing.

OK or NG

OK >> Replace front wiper motor. Refer toWW-35, "Removal and Installation of Wiper Motor and Link-

age".

NG >> Replace IPDM E/R. Refer toPG-26, "

Removal and Installation of IPDM E/R".

AB

Continuity

Connector Terminal Connector Terminal

E13 32 E72 1 Yes

A

GroundContinuity

Connector Terminal

E13 32 No

SKIB6230E

Terminal

Continuity (+)

(-)

IPDM E/R

connectorTerminal

E13 32 Ground Battery voltage

Terminal

Continuity (+)

(-)

IPDM E/R

connectorTerminal

E13 32 Ground Battery voltage

SKIB6229E