clock NISSAN NAVARA 2005 Repair Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2280 of 3171

DESCRIPTION

MA-5

C

D

E

F

G

H

I

J

K

MA

B

MA

DESCRIPTIONPFP:00000

Pre-Delivery Inspection ItemsELS001K2

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

Install vehicle protection kit

Fit all accessories ordered (if applicable) (e.g. towbar, audio, navigation, air conditioner, styling kit)

UNDER HOOD — engine off

Check coolant level and cooling system for leaks

Charge battery and check terminals for condition

Check drive belts tension

Check fuel filter for water or dust (diesel only) and fuel system for leaks

Check engine oil level and for oil leaks

Check brake and clutch fluid levels and fluid lines for leaks

Check and top up washer reservoirs

Check power steering fluid level and fluid lines for leaks (if applicable)

Check air conditioning system for gas leaks (if applicable)

ON INSIDE AND OUTSIDE

Install transit fuse if removed for vehicle storage

Check instruments, gauges, lamps, horn and accessories for operation

Check wipers and washers for operation and adjustment

Check interior and door mirrors and sun visors for operation

Set radio code and set clock

Check parking brake adjustment

Check clutch pedal adjustment

Check steering lock operation

Check seat adjusters and seat belts for operation

Check all windows for operation and alignment

Check mouldings, trim and fittings for fit and alignment

Check weatherstrips for fit and adhesion

Check hood, trunk lid, door panels and fuel lid for fit and alignment

Check latches, keys, remote key, door locks and remote trunk lid and fuel lid release for operation

Check wheel nut torques

Check tyre pressure (incl. spare tyre)

Check tool kit and jack for operation

Check automatic transmission/transaxle starter inhibitor (if applicable)

Check sunroof for operation and alignment (if applicable)

UNDER BODY

Check manual transmission/transaxle, differential and transfer box for oil level and oil leaks

Tighten bolts and nuts steering linkage and gear box, axle/suspension parts, propeller and exhaust system

Check brake and clutch lines, and oil/fluid reservoirs for leaks

Remove front suspension spacer blocks (if applicable)

Check body mounting torque (if applicable)

Page 2401 of 3171

MTC-14

PRECAUTIONS

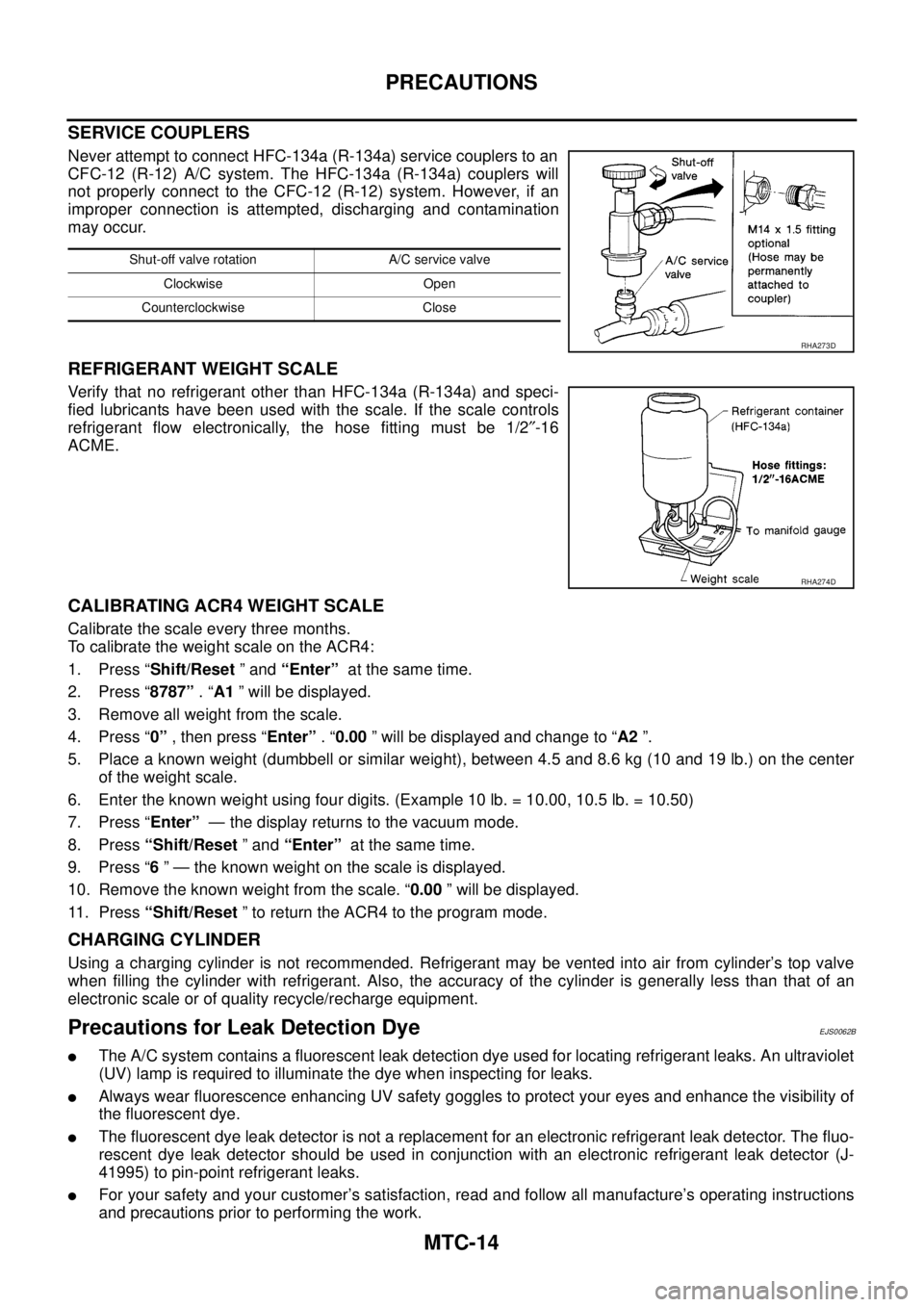

SERVICE COUPLERS

Never attempt to connect HFC-134a (R-134a) service couplers to an

CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers will

not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC-134a (R-134a) and speci-

fied lubricants have been used with the scale. If the scale controls

refrigerant flow electronically, the hose fitting must be 1/2²-16

ACME.

CALIBRATING ACR4 WEIGHT SCALE

Calibrate the scale every three months.

To calibrate the weight scale on the ACR4:

1. Press “Shift/Reset”and“Enter”at the same time.

2. Press “8787”.“A1” will be displayed.

3. Remove all weight from the scale.

4. Press “0”, then press “Enter”.“0.00” will be displayed and change to “A2”.

5. Place a known weight (dumbbell or similar weight), between 4.5 and 8.6 kg (10 and 19 lb.) on the center

of the weight scale.

6. Enter the known weight using four digits. (Example 10 lb. = 10.00, 10.5 lb. = 10.50)

7. Press “Enter”— the display returns to the vacuum mode.

8. Press“Shift/Reset”and“Enter”at the same time.

9. Press “6” — the known weight on the scale is displayed.

10. Remove the known weight from the scale. “0.00” will be displayed.

11. Press“Shift/Reset” to return the ACR4 to the program mode.

CHARGING CYLINDER

Using a charging cylinder is not recommended. Refrigerant may be vented into air from cylinder’s top valve

when filling the cylinder with refrigerant. Also, the accuracy of the cylinder is generally less than that of an

electronic scale or of quality recycle/recharge equipment.

Precautions for Leak Detection DyeEJS0062B

lThe A/C system contains a fluorescent leak detection dye used for locating refrigerant leaks. An ultraviolet

(UV) lamp is required to illuminate the dye when inspecting for leaks.

lAlways wear fluorescence enhancing UV safety goggles to protect your eyes and enhance the visibility of

the fluorescent dye.

lThe fluorescent dye leak detector is not a replacement for an electronic refrigerant leak detector. The fluo-

rescent dye leak detector should be used in conjunction with an electronic refrigerant leak detector (J-

41995) to pin-point refrigerant leaks.

lFor your safety and your customer’s satisfaction, read and follow all manufacture’s operating instructions

and precautions prior to performing the work.

Shut-off valve rotation A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

RHA274D

Page 2413 of 3171

MTC-26

AIR CONDITIONER CONTROL

AIR CONDITIONER CONTROL

PFP:27500

DescriptionEJS005FW

The front air control provides regulation of the vehicle's interior temperature. The system is based on the posi-

tion of the front air controls temperature switch selected by the driver. This is done by utilizing a microcom-

puter, also referred to as the front air control, which receives input signals from the following three sensors:

lIntake sensor

lPBR (Position Balanced Resistor).

The front air control uses these signals (including the set position of the temperature switch) to control:

lOutlet air volume

lAir temperature

lAir distribution

The front air control is used to select:

lOutlet air volume

lAir temperature/distribution

OperationEJS005FX

AIR MIX DOOR CONTROL

The air mix door is controlled so that in-vehicle temperature changed based on the position of the temperature

switch.

BLOWER SPEED CONTROL

Blower speed is controlled based on front blower switch settings.

When blower switch is turned, the blower motor starts and increases air flow volume each time the blower

switch is turned counterclockwise, and decreases air flow volume each time the blower switch is turned coun-

terclockwise.

When engine coolant temperature is low, the blower motor operation is delayed to prevent cool air from flow-

ing.

INTAKE DOORS CONTROL

The intake doors are controlled by the recirculation switch setting, and the mode (defroster) switch setting.

MODE DOOR CONTROL

The mode door is controlled by the position of the mode switch.

DEFROSTER DOOR CONTROL

The defroster door is controlled by: Turning the defroster dial to front defroster.

Page 2436 of 3171

TROUBLE DIAGNOSIS

MTC-49

C

D

E

F

G

H

I

K

L

MA

B

MTC

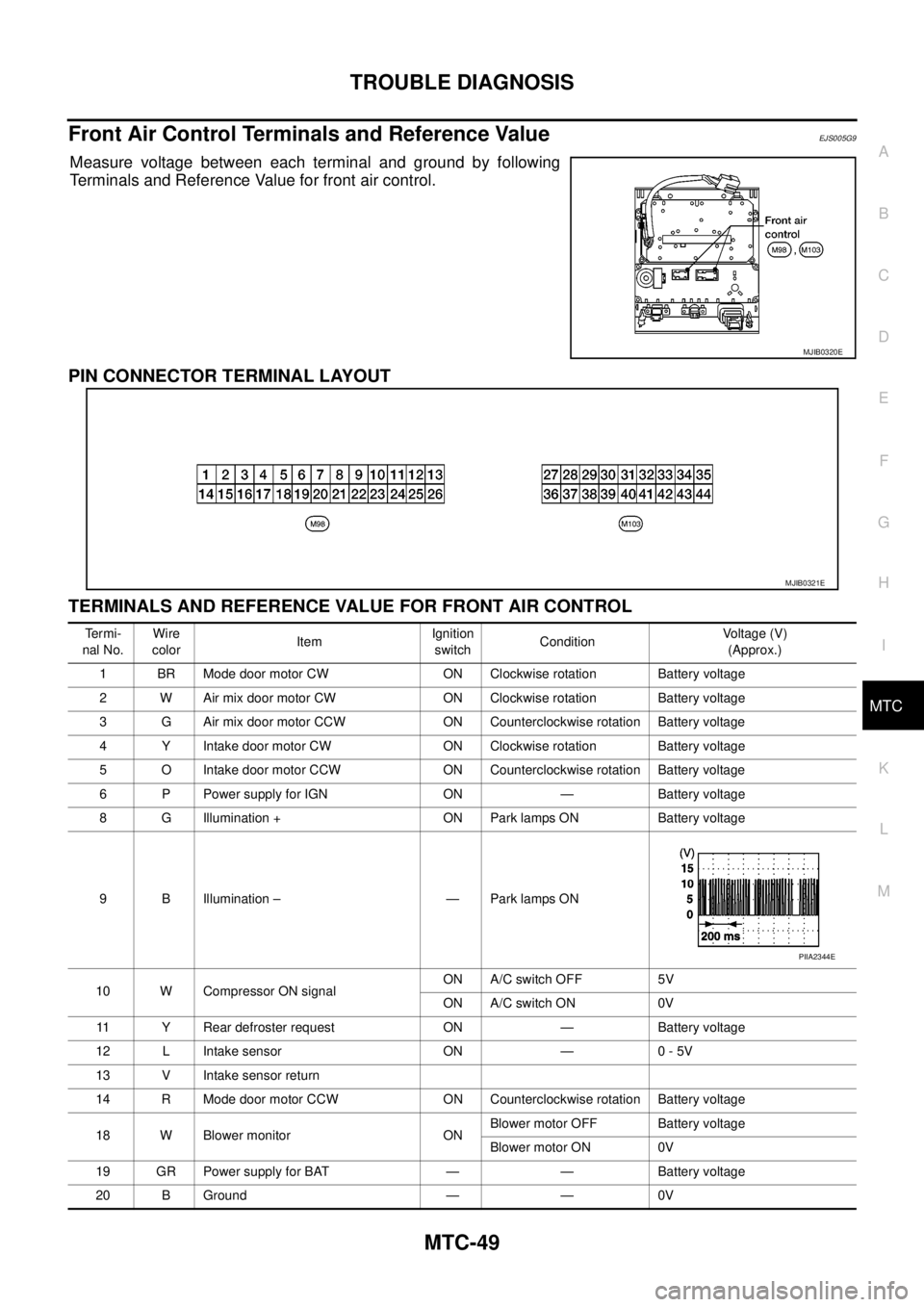

Front Air Control Terminals and Reference ValueEJS005G9

Measure voltage between each terminal and ground by following

Terminals and Reference Value for front air control.

PIN CONNECTOR TERMINAL LAYOUT

TERMINALS AND REFERENCE VALUE FOR FRONT AIR CONTROL

MJIB0320E

MJIB0321E

Te r m i -

nal No.Wire

colorItemIgnition

switchConditionVoltage (V)

(Approx.)

1 BR Mode door motor CW ON Clockwise rotation Battery voltage

2 W Air mix door motor CW ON Clockwise rotation Battery voltage

3 G Air mix door motor CCW ON Counterclockwise rotation Battery voltage

4 Y Intake door motor CW ON Clockwise rotation Battery voltage

5 O Intake door motor CCW ON Counterclockwise rotation Battery voltage

6 P Power supply for IGN ON — Battery voltage

8 G Illumination + ON Park lamps ON Battery voltage

9 B Illumination – — Park lamps ON

10 W Compressor ON signalON A/C switch OFF 5V

ON A/C switch ON 0V

11 Y Rear defroster request ON — Battery voltage

12 L Intake sensor ON — 0 - 5V

13 V Intake sensor return

14 R Mode door motor CCW ON Counterclockwise rotation Battery voltage

18 W Blower monitor ONBlower motor OFF Battery voltage

Blower motor ON 0V

19 GR Power supply for BAT — — Battery voltage

20 B Ground — — 0V

PIIA2344E

Page 2440 of 3171

TROUBLE DIAGNOSIS

MTC-53

C

D

E

F

G

H

I

K

L

MA

B

MTC

Operational CheckEJS005GB

The purpose of the operational check is to confirm that the system operates properly.

CHECKING BLOWER

1. Turn blower control switch clockwise. Blower should operate on

low speed. The blower symbol should have one blade lit (on dis-

play).

2. Turn the blower control switch again, and continue checking

blower speed and blower symbol until all speeds are checked.

3. Leave blower on MAX speed.

If NG, go to trouble diagnosis procedure for

If OK, continue with next check.

CHECKING DISCHARGE AIR

1. Turn the mode switch.

2. Each position indicator should change shape (on display, if

equipped).

3. Confirm that discharge air comes out according to the air distri-

bution table.

Mode door position is checked in the next step.

If NG, go to trouble diagnosis procedure forMTC-58, "

Mode Door

Motor Circuit".

If OK, continue with next check.

NOTE:

Confirm that the compressor clutch is engaged (sound or visual

inspection) and intake door position is at fresh when the DEF or D/F

is selected.

CHECKING RECIRCULATION

1. Press recirculation ( ) switch one time. Recirculation indica-

tor should illuminate.

2. Press recirculation ( ) switch one more time. Recirculation

indicator should go off.

3. Listen for intake door position change (blower sound should

change slightly).

If NG, go to trouble diagnosis procedure forMTC-68, "

Intake Door

Motor Circuit".

If OK, continue with next check.

NOTE:

Confirm that the compressor clutch is engaged (sound or visual

inspection) and intake door position is at fresh when the DEF or D/F is selected.Conditions : Engine running and at normal operating temperature

MJIB0223E

MJIB0224E

MJIB0284E

MJIB0225E

Page 2441 of 3171

MTC-54

TROUBLE DIAGNOSIS

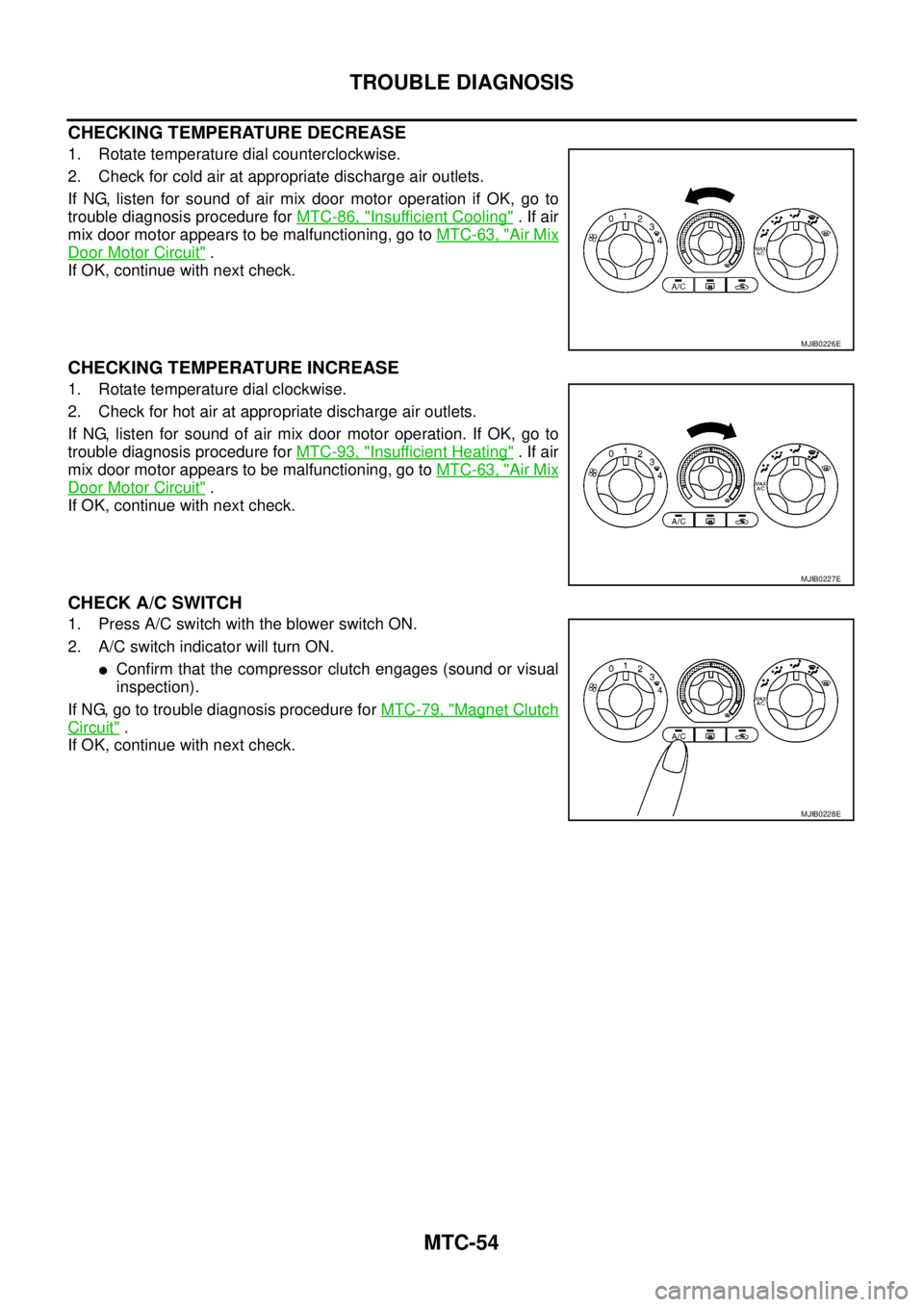

CHECKING TEMPERATURE DECREASE

1. Rotate temperature dial counterclockwise.

2. Check for cold air at appropriate discharge air outlets.

If NG, listen for sound of air mix door motor operation if OK, go to

trouble diagnosis procedure forMTC-86, "

Insufficient Cooling".Ifair

mix door motor appears to be malfunctioning, go toMTC-63, "

Air Mix

Door Motor Circuit".

If OK, continue with next check.

CHECKING TEMPERATURE INCREASE

1. Rotate temperature dial clockwise.

2. Check for hot air at appropriate discharge air outlets.

If NG, listen for sound of air mix door motor operation. If OK, go to

trouble diagnosis procedure forMTC-93, "

Insufficient Heating".Ifair

mix door motor appears to be malfunctioning, go toMTC-63, "

Air Mix

Door Motor Circuit".

If OK, continue with next check.

CHECK A/C SWITCH

1. Press A/C switch with the blower switch ON.

2. A/C switch indicator will turn ON.

lConfirm that the compressor clutch engages (sound or visual

inspection).

If NG, go to trouble diagnosis procedure forMTC-79, "

Magnet Clutch

Circuit".

If OK, continue with next check.

MJIB0226E

MJIB0227E

MJIB0228E

Page 2504 of 3171

DUCTS AND GRILLES

MTC-117

C

D

E

F

G

H

I

K

L

MA

B

MTC

NOTE:

To remove the overhead console front and rear grilles, turn the grille counter-clockwise to release the

grille from the overhead console trim panel.

Installation

Installation is in the reverse order of removal.

Page 2522 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

MTC-135

C

D

E

F

G

H

I

K

L

MA

B

MTC

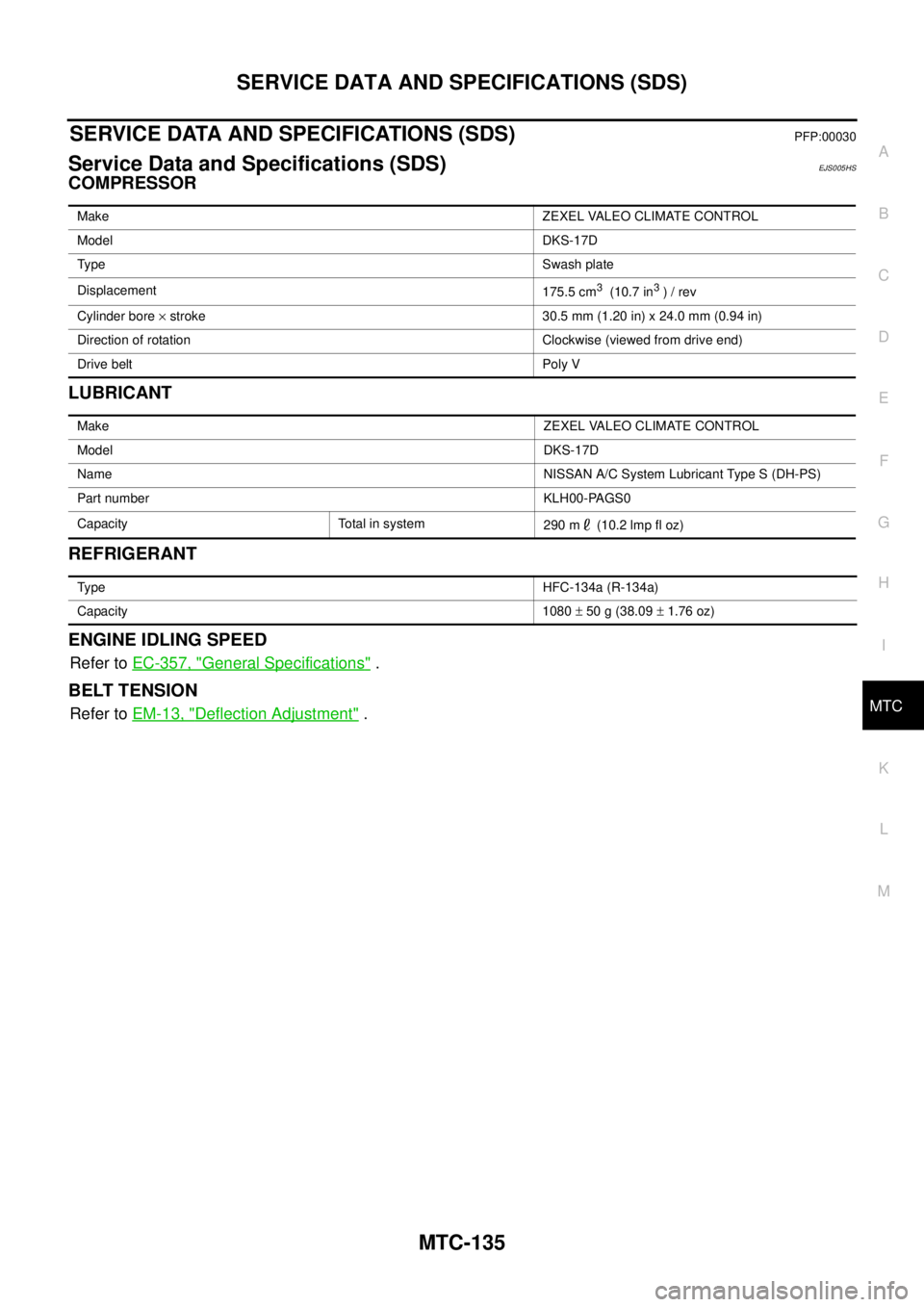

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Service Data and Specifications (SDS)EJS005HS

COMPRESSOR

LUBRICANT

REFRIGERANT

ENGINE IDLING SPEED

Refer toEC-357, "General Specifications".

BELT TENSION

Refer toEM-13, "Deflection Adjustment".

MakeZEXEL VALEO CLIMATE CONTROL

ModelDKS-17D

Ty p eSwash plate

Displacement

175.5 cm

3(10.7 in3)/rev

Cylinder bore´stroke 30.5 mm (1.20 in) x 24.0 mm (0.94 in)

Direction of rotation Clockwise (viewed from drive end)

Drive belt Poly V

MakeZEXEL VALEO CLIMATE CONTROL

ModelDKS-17D

NameNISSAN A/C System Lubricant Type S (DH-PS)

Part number KLH00-PAGS0

Capacity Total in system

290m (10.2lmpfloz)

Ty p eHFC-134a (R-134a)

Capacity 1080±50g(38.09±1.76 oz)

Page 2650 of 3171

POWER STEERING GEAR AND LINKAGE

PS-23

C

D

E

F

H

I

J

K

L

MA

B

PS

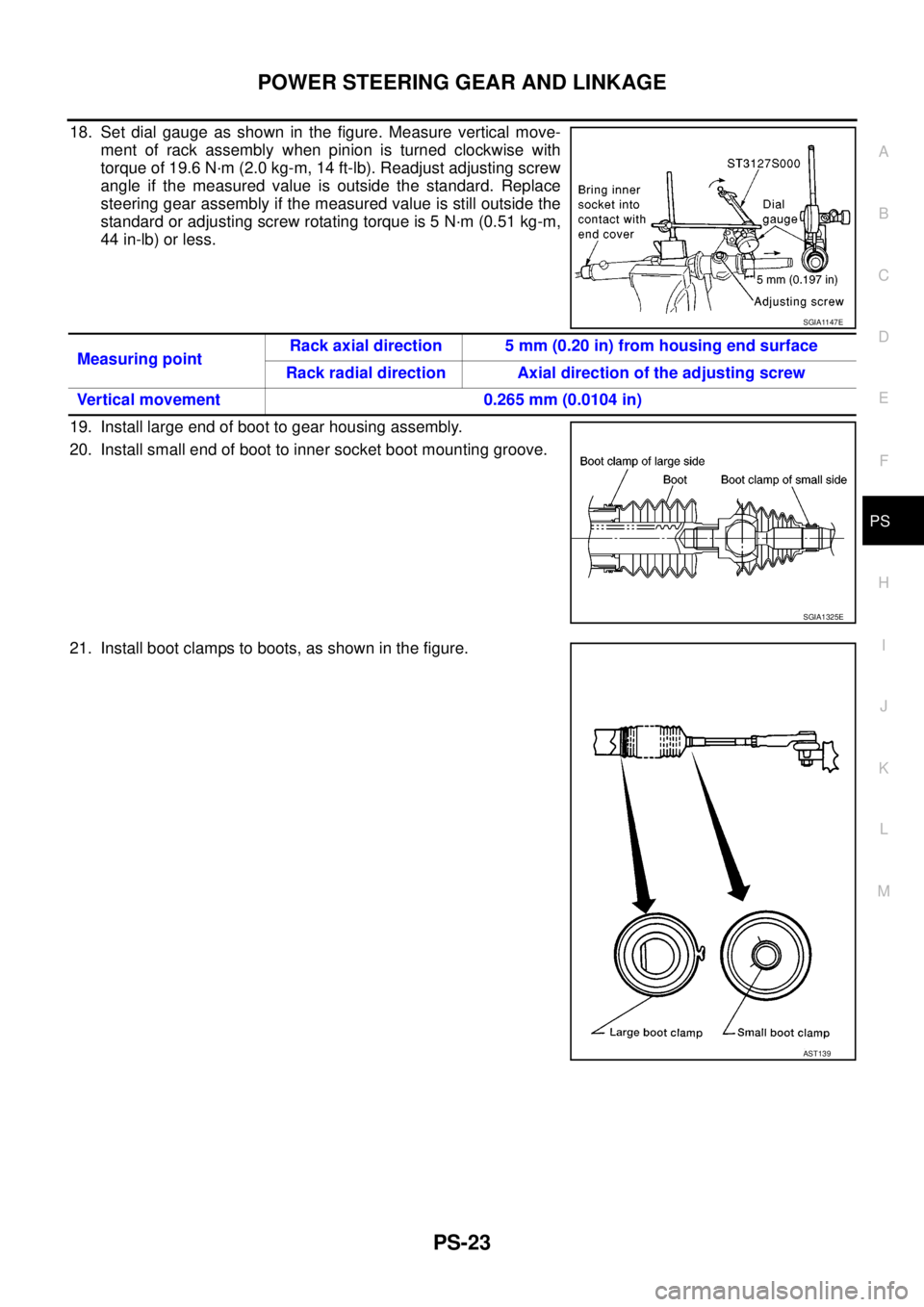

18. Set dial gauge as shown in the figure. Measure vertical move-

ment of rack assembly when pinion is turned clockwise with

torque of 19.6 N·m (2.0 kg-m, 14 ft-lb). Readjust adjusting screw

angle if the measured value is outside the standard. Replace

steering gear assembly if the measured value is still outside the

standard or adjusting screw rotating torque is 5 N·m (0.51 kg-m,

44 in-lb) or less.

19. Install large end of boot to gear housing assembly.

20. Install small end of boot to inner socket boot mounting groove.

21. Install boot clamps to boots, as shown in the figure.

SGIA1147E

Measuring pointRack axial direction 5 mm (0.20 in) from housing end surface

Rack radial direction Axial direction of the adjusting screw

Vertical movement 0.265 mm (0.0104 in)

SGIA1325E

AST139

Page 2681 of 3171

RF-4

SQUEAK AND RATTLE TROUBLE DIAGNOSES

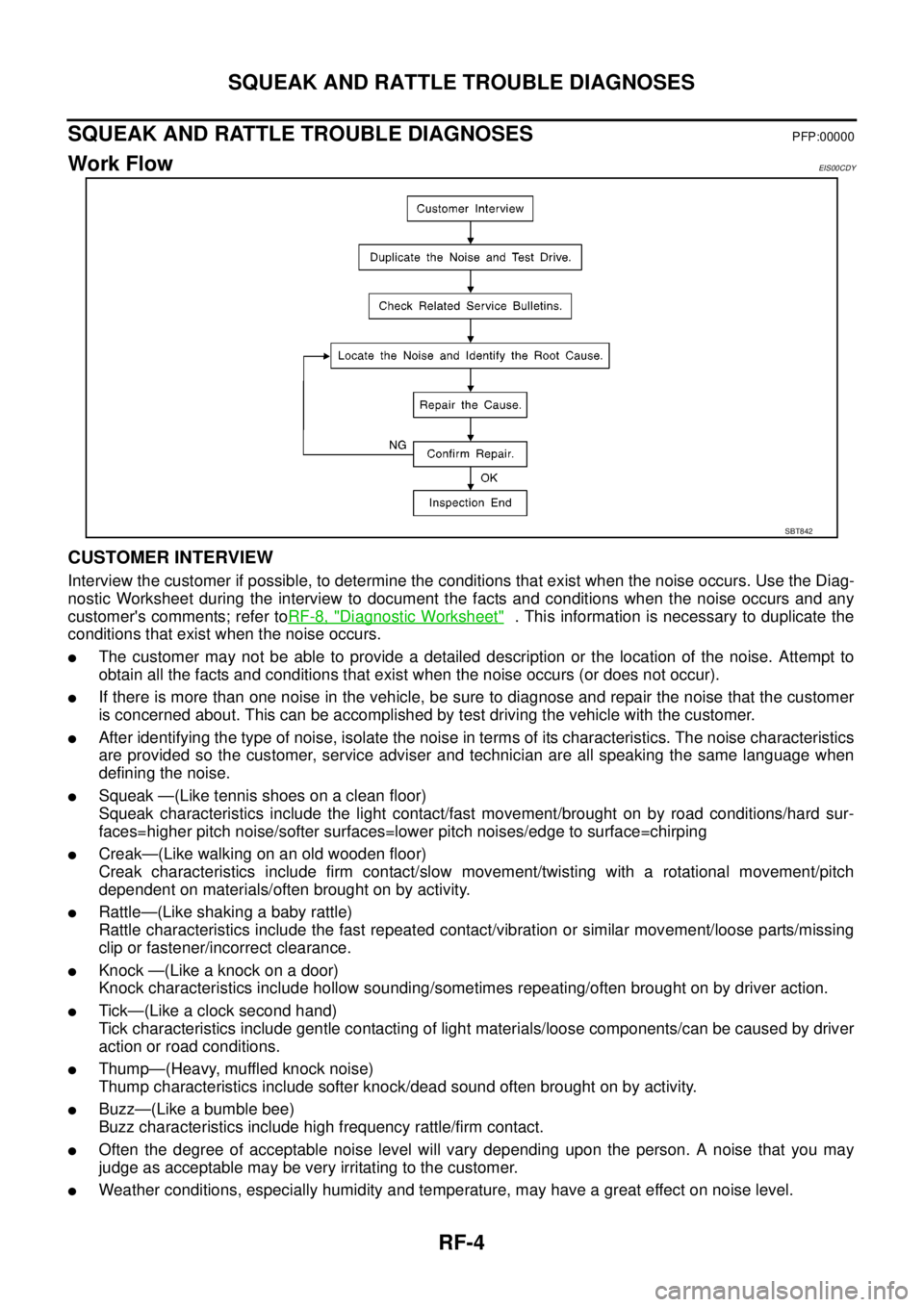

SQUEAK AND RATTLE TROUBLE DIAGNOSES

PFP:00000

Work FlowEIS00CDY

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer toRF-8, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

lThe customer may not be able to provide a detailed description or the location of the noise. Attempt to

obtain all the facts and conditions that exist when the noise occurs (or does not occur).

lIf there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer

is concerned about. This can be accomplished by test driving the vehicle with the customer.

lAfter identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

lSqueak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard sur-

faces=higher pitch noise/softer surfaces=lower pitch noises/edge to surface=chirping

lCreak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch

dependent on materials/often brought on by activity.

lRattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contact/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

lKnock —(Like a knock on a door)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

lTick—(Like a clock second hand)

Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

lThump—(Heavy, muffled knock noise)

Thump characteristics include softer knock/dead sound often brought on by activity.

lBuzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

lOften the degree of acceptable noise level will vary depending upon the person. A noise that you may

judge as acceptable may be very irritating to the customer.

lWeather conditions, especially humidity and temperature, may have a great effect on noise level.

SBT842