lock NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 3116 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual FRONT WIPER AND WASHER SYSTEM

WW-5

C

D

E

F

G

H

I

J

L

MA

B

WW

With the ignition switch in ON or START position, power is supplied

lthrough 10A fuse [No. 15, located in fuse block (J/B)]

lto combination NISSAN NAVARA 2005 Repair Workshop Manual FRONT WIPER AND WASHER SYSTEM

WW-5

C

D

E

F

G

H

I

J

L

MA

B

WW

With the ignition switch in ON or START position, power is supplied

lthrough 10A fuse [No. 15, located in fuse block (J/B)]

lto combination](/img/5/57362/w960_57362-3115.png)

FRONT WIPER AND WASHER SYSTEM

WW-5

C

D

E

F

G

H

I

J

L

MA

B

WW

With the ignition switch in ON or START position, power is supplied

lthrough 10A fuse [No. 15, located in fuse block (J/B)]

lto combination switch terminal 2,

lthrough 10A fuse [No. 1, located in fuse block (J/B)]

lto BCM terminal 3.

Ground is supplied

lto BCM terminal 55 and

lto combination switch terminal 9

lthrough grounds M21, M80 and M83,

lto IPDM E/R terminals 38 and 59 and

lto front wiper motor terminal 2

lthrough grounds E21, E41 and E61.

LOW SPEED WIPER OPERATION

When the ignition switch is in the ON or START position, and the front wiper switch is turned to the low posi-

tion, the BCM detects a low speed wiper ON request through the combination switch (wiper switch) reading

function.

The BCM then sends a front wiper (low) request signal with CAN communication.

lfrom BCM terminals 21 and 22

lto IPDM E/R terminals 39 and 40.

When IPDM E/R receives front wiper (low) request signal, it supplies ground to energize the front wiper main

relay.

With the front wiper LOW/ HIGH relay energized, power is supplied

lthrough front wiper main relay

lthrough front wiper LOW/HIGH relay

lthrough IPDM E/R terminal 32

lto front wiper motor terminal 1.

Ground is supplied

lto front wiper motor terminal 2

lthrough grounds E21, E41 and E61.

With power and ground supplied, the front wiper motor operates at low speed.

HI SPEED WIPER OPERATION

When the ignition switch is in the ON or START position, and the front wiper switch is turned to the high posi-

tion, the BCM detects a high speed wiper ON request through the combination switch (wiper switch) reading

function.

The BCM then sends a front wiper (high) request signal with CAN communication.

lfrom BCM terminals 21 and 22

lto IPDM E/R terminals 39 and 40.

When IPDM E/R receives front wiper (high) request signal, it supplies ground to energize the front wiper main

relays.

With the front wiper LOW/HIGH relays energized, power is supplied

lthrough front wiper main relay

lthrough front wiper LOW/HIGH relay

lthrough IPDM E/R terminal 35

lto front wiper motor terminal 4.

Ground is supplied

lto front wiper motor terminal 2

lthrough grounds E21, E41 and E61.

With power and ground supplied, the front wiper motor operates at high speed.

Page 3117 of 3171

WW-6

FRONT WIPER AND WASHER SYSTEM

INTERMITTENT OPERATION

When front wiper switch is turned to INT position, wiper performs intermittent operation, low-speed operation,

and high-speed operation according to water drop increase rate on windshield detected by light and rain sen-

sor. If light and rain sensor malfunctions, it operates as vehicle speed sensing wiper during driving and oper-

ates intermittent operation according to INT-volume switch with vehicle stopped. During this time, BCM

controls each operation.

The BCM then sends a front wiper (HI or LOW) request signal with CAN communication.

lfrom BCM terminals 21 and 22

lto IPDM E/R terminals 39 and 40.

When the BCM determines that combination switch status is front wiper intermittent ON, it performs the follow-

ing operations.

lBCM detects intermittent wiper dial position.

lBCM sends front wiper request signal (HI or LOW) to IPDM E/R at calculated operation interval.

When IPDM E/R receives front wiper request signal (HI or LOW), it supplies ground to energize the front wiper

main relay and front wiper LOW/HIGH relay. It then sends an auto-stop signal to the BCM, and conducts inter-

mittent front wiper motor operation.

AUTO STOP OPERATION

When the wiper arms are not located at the base of the windshield, and the wiper switch is turned OFF, the

wiper motor will continue to operate until the wiper arms reach the windshield base. When the wiper arms

reach the base of windshield, front wiper motor terminals 2 and 5 are connected.

Ground is supplied

lto IPDM E/R terminal 43

lthrough front wiper motor terminal 5

lthrough front wiper motor terminal 2

lthrough grounds E21, E41 and E61.

The IPDM E/R sends an auto stop operation signal to the BCM with CAN communication.

When the BCM receives an auto stop operation signal, the BCM sends wiper stop signal to the IPDM E/R over

CAN communication lines. The IPDM E/R then de-energizes the front wiper main relay.

The wiper motor will then stop the wiper arms at the STOP position.

FRONT WASHER OPERATION

When the ignition switch is in the ON or START position, and the front washer switches are OFF, the front

washer motor is supplied power

lthrough 10A fuse [No. 15, located in fuse block (J/B)]

lthrough combination switch (wiper switch) terminal 2

lthrough combination switch (wiper switch) terminal 4

lto front washer motor terminal 1.

When the front wiper switch is in the front washer position, the BCM detects a front washer signal request

through the combination switch (wiper switch) reading function.

Combination switch ground is supplied

lto front washer motor terminal 2

lthrough combination switch (wiper switch) terminal 3

lthrough combination switch (wiper switch) terminal 9

lthrough grounds M21, M80 and M83.

With ground supplied, the front washer motor is operated in the front direction.

When the BCM detects that front washer motor has operated for 0.4 seconds or longer, the BCM uses CAN

communication and sends a wiper request signal to the IPDM E/R for low speed operation of wipers.

When the BCM detects that the washer switch is OFF, low speed operation cycles approximately 3 times and

then stops.

Page 3133 of 3171

WW-22

FRONT WIPER AND WASHER SYSTEM

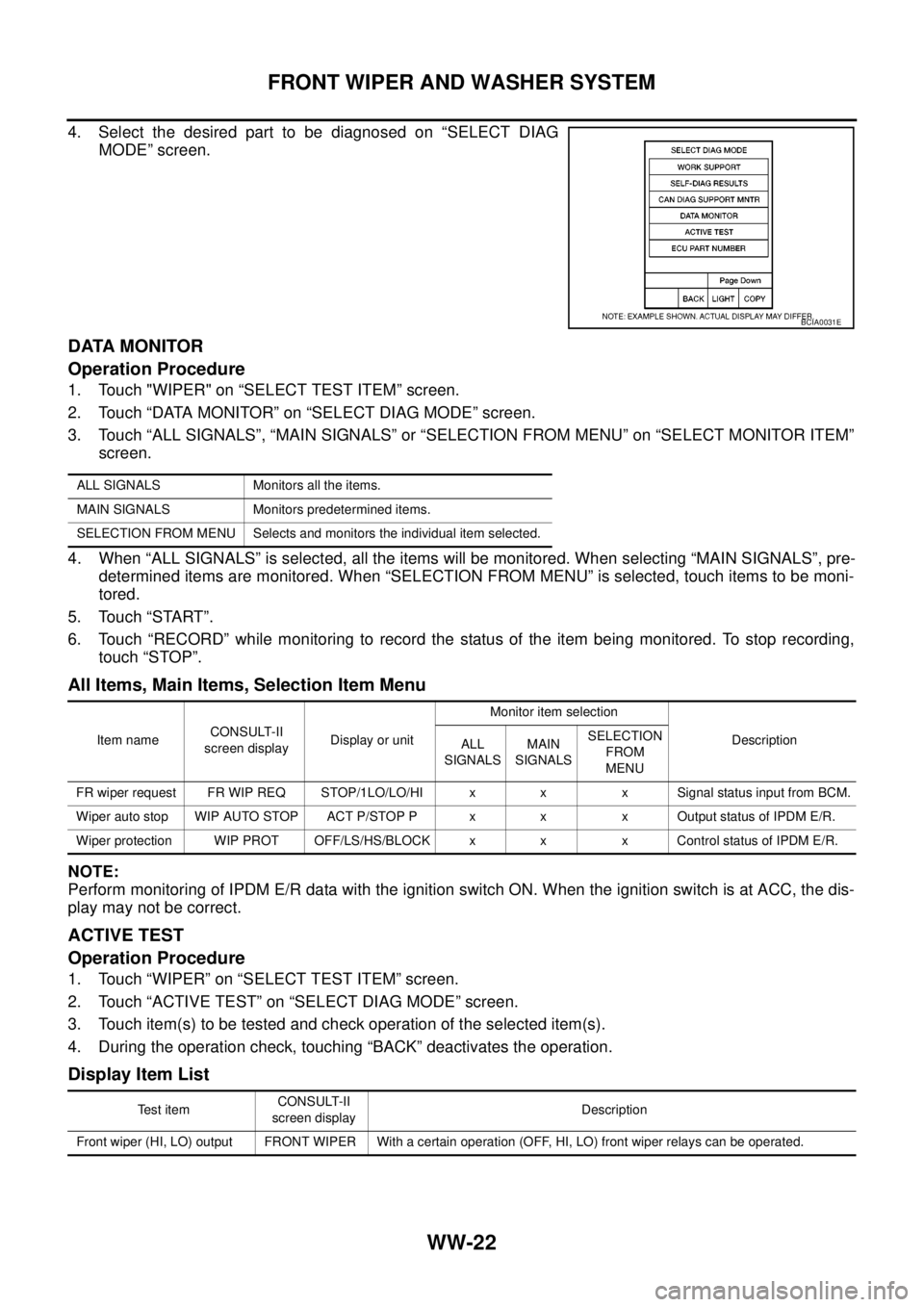

4. Select the desired part to be diagnosed on “SELECT DIAG

MODE” screen.

DATA MONITOR

Operation Procedure

1. Touch "WIPER" on “SELECT TEST ITEM” screen.

2. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

3. Touch “ALL SIGNALS”, “MAIN SIGNALS” or “SELECTION FROM MENU” on “SELECT MONITOR ITEM”

screen.

4. When “ALL SIGNALS” is selected, all the items will be monitored. When selecting “MAIN SIGNALS”, pre-

determined items are monitored. When “SELECTION FROM MENU” is selected, touch items to be moni-

tored.

5. Touch “START”.

6. Touch “RECORD” while monitoring to record the status of the item being monitored. To stop recording,

touch “STOP”.

All Items, Main Items, Selection Item Menu

NOTE:

Perform monitoring of IPDM E/R data with the ignition switch ON. When the ignition switch is at ACC, the dis-

play may not be correct.

ACTIVE TEST

Operation Procedure

1. Touch “WIPER” on “SELECT TEST ITEM” screen.

2. Touch “ACTIVE TEST” on “SELECT DIAG MODE” screen.

3. Touch item(s) to be tested and check operation of the selected item(s).

4. During the operation check, touching “BACK” deactivates the operation.

Display Item List

BCIA0031E

ALL SIGNALS Monitors all the items.

MAIN SIGNALS Monitors predetermined items.

SELECTION FROM MENU Selects and monitors the individual item selected.

Item nameCONSULT-II

screen displayDisplay or unitMonitor item selection

Description

ALL

SIGNALSMAIN

SIGNALSSELECTION

FROM

MENU

FR wiper request FR WIP REQ STOP/1LO/LO/HI x x x Signal status input from BCM.

Wiper auto stop WIP AUTO STOP ACT P/STOP P x x x Output status of IPDM E/R.

Wiper protection WIP PROT OFF/LS/HS/BLOCK x x x Control status of IPDM E/R.

Te s t i t e mCONSULT-II

screen displayDescription

Front wiper (HI, LO) output FRONT WIPER With a certain operation (OFF, HI, LO) front wiper relays can be operated.

Page 3139 of 3171

WW-28

FRONT WIPER AND WASHER SYSTEM

Front Wiper Does Not Return to Stop Position (After Front Wiper for 10 Sec-

onds, They Stop for 20 seconds, and After Repeating the Operations Five

Times, They Become Inoperative)

EKS00P57

CAUTION:

lWhen auto stop signal has not varied for 10 seconds or longer while IPDM E/R is operating front

wipers, IPDM E/R considers front wipers are locked, and stops wiper output. That causes this

symptom.

lThis status can be checked by “DATA MONITOR” of “IPDM E/R” on which “WIPER PROTECTION”

ITEMS SHOWS “BLOCK”.

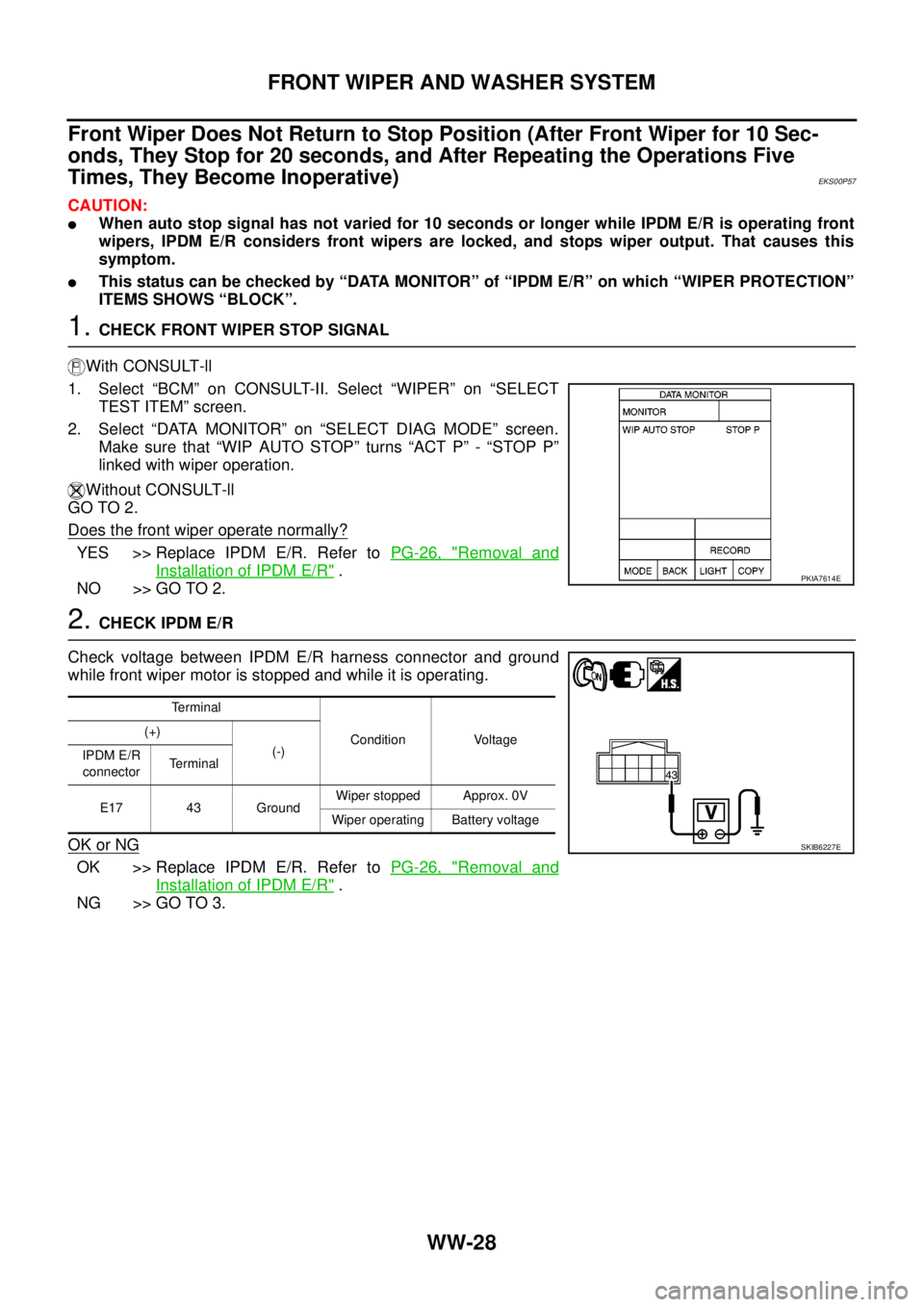

1.CHECK FRONT WIPER STOP SIGNAL

With CONSULT-ll

1. Select “BCM” on CONSULT-II. Select “WIPER” on “SELECT

TEST ITEM” screen.

2. Select “DATA MONITOR” on “SELECT DIAG MODE” screen.

Make sure that “WIP AUTO STOP” turns “ACT P” - “STOP P”

linked with wiper operation.

Without CONSULT-ll

GO TO 2.

Does the front wiper operate normally?

YES >> Replace IPDM E/R. Refer toPG-26, "Removal and

Installation of IPDM E/R".

NO >> GO TO 2.

2.CHECK IPDM E/R

Check voltage between IPDM E/R harness connector and ground

while front wiper motor is stopped and while it is operating.

OK or NG

OK >> Replace IPDM E/R. Refer toPG-26, "Removal and

Installation of IPDM E/R".

NG >> GO TO 3.

PKIA7614E

Terminal

Condition Voltage (+)

(-)

IPDM E/R

connectorTerminal

E17 43 GroundWiper stopped Approx. 0V

Wiper operating Battery voltage

SKIB6227E

Page 3151 of 3171

WW-40

HEADLAMP WASHER

OUTLINE

Power is supplied at all times

lto ignition relay (located in IPDM E/R), from battery directly,

lthrough 50A fusible link (letter G, located in fuse and fusible link box),

lto BCM terminal 57,

lthrough 20A fuse (No. 53, located in IPDM E/R)

lto CPU (central processing unit) (located in IPDM E/R).

With the ignition switch in the ON or START position, power is supplied

lto ignition relay (located in IPDM E/R),

lthrough 10A fuse [No. 1, located in fuse block (J/B)]

lto BCM terminal 3,

lthrough 10A fuse [No. 15, located in fuse block (J/B)]

lto combination switch terminal 2.

Ground is supplied

lto BCM terminal 55 and

lto combination switch terminal 9

lthrough grounds M21, M80 and M83,

lto IPDM E/R terminals 38 and 59

lthrough grounds E21, E41 and E61.

When the headlamp washer switch is ON, ground is supplied

lto BCM terminal 35

lthrough headlamp washer switch terminal 1

lthrough headlamp washer switch terminal 2

lthrough ground M21, M80 and M83.

HEADLAMP WASHER OPERATION

With the headlamp washer switch in the ON position, the BCM receives input signal requesting. This input sig-

nal is communicated to the IPDM E/R via the CAN communication. The CPU located in the IPDM E/R controls

the headlamp washer relay coil, which when energized, power is supplied

lthrough 10A fuse (No. 38, located in IPDM E/R)

lthrough IPDM E/R terminal 27

lto headlamp washer relay terminals 2 and 5,

lthrough headlamp washer relay terminal 1

lto IPDM E/R terminal 5,

lthrough headlamp washer relay terminal 3

lto headlamp washer motor terminal 1.

Ground is supplied

lto headlamp washer motor terminal 2

lthrough grounds E21, E41 and E61.

With power and ground supplied, headlamp washer operates.