engine NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2772 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS FOR SYSTEM

RFD-69

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

CAN Communication LineEDS003B8

DIAGNOSTIC PROCEDURE

1.CHECK CAN COMMUNICATION CIRCUIT

With CONSULT NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS FOR SYSTEM

RFD-69

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

CAN Communication LineEDS003B8

DIAGNOSTIC PROCEDURE

1.CHECK CAN COMMUNICATION CIRCUIT

With CONSULT](/img/5/57362/w960_57362-2771.png)

TROUBLE DIAGNOSIS FOR SYSTEM

RFD-69

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

CAN Communication LineEDS003B8

DIAGNOSTIC PROCEDURE

1.CHECK CAN COMMUNICATION CIRCUIT

With CONSULT-II

1. Turn ignition switch “ON” and start engine.

2. Select “SELF-DIAG RESULTS” mode for “DIFF LOCK” with in CONSULT-II.

3. Perform the self-diagnosis.

Is the

“CAN COMM CIRCUIT [U1000]”displayed?

YES >> Go toLAN-3, "Precautions When Using CONSULT-II".

NO >>INSPECTION END

SDIA1850E

Page 2773 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RFD-70

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYMPTOMS

TROUBLE DIAGNOSIS FOR SYMPTOMS

PFP:00007

DIFF LOCK Indicator Lamp Does Not Turn ONEDS003B9

SYMPTOM:

DIFF LOCK indicator lam NISSAN NAVARA 2005 Repair Workshop Manual RFD-70

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYMPTOMS

TROUBLE DIAGNOSIS FOR SYMPTOMS

PFP:00007

DIFF LOCK Indicator Lamp Does Not Turn ONEDS003B9

SYMPTOM:

DIFF LOCK indicator lam](/img/5/57362/w960_57362-2772.png)

RFD-70

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYMPTOMS

TROUBLE DIAGNOSIS FOR SYMPTOMS

PFP:00007

DIFF LOCK Indicator Lamp Does Not Turn ONEDS003B9

SYMPTOM:

DIFF LOCK indicator lamp does not turn ON for approx. 1 second when turning ignition switch to

“ON”.

DIAGNOSTIC PROCEDURE

1.CHECK SYSTEM FOR CAN COMMUNICATION LINE

Perform self-diagnosis. Refer toRFD-51, "

SELF-DIAG RESULTS MODE".

Is

“CAN COMM CIRCUIT”displayed?

YES >> Perform trouble diagnosis for CAN communication line. Refer toRFD-69, "CAN Communication

Line".

NO >> GO TO 2.

2.CHECK DIFFERENTIAL LOCK CONTROL UNIT POWER SUPPLY

1. Turn ignition switch “OFF”.

2. Disconnect differential lock control unit harness connector.

3. Check voltage between differential lock control unit harness

connector terminals and ground.

4. Turn ignition switch “ON”. (Do not start engine.)

5. Check voltage between differential lock control unit harness

connector terminals and ground.

OK or NG

OK >> GO TO 3.

NG >> Check the following. If any items are damaged, repair or

replace damaged parts.

l10A fuse [No. 3 or 19, located in fuse block (J/B)]

lHarness for short or open between battery and differential lock control unit harness connector

terminal 15

lHarness for short or open between ignition switch and differential lock control unit harness con-

nector terminals 1 and 2

lBattery and ignition switch. Refer toPG-4, "POWER SUPPLY ROUTING CIRCUIT".

Connector Terminal Voltage (Approx.)

M1071 - Ground 0V

2 - Ground 0V

15 - Ground Battery voltage

SDIA2562E

Connector Terminal Voltage (Approx.)

M1071 - Ground

Battery voltage 2 - Ground

15 - Ground

SDIA2563E

Page 2774 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS FOR SYMPTOMS

RFD-71

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

3.CHECK DIFFERENTIAL LOCK CONTROL UNIT GROUND CIRCUIT

1. Turn ignition switch “OFF”.

2. Disc NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS FOR SYMPTOMS

RFD-71

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

3.CHECK DIFFERENTIAL LOCK CONTROL UNIT GROUND CIRCUIT

1. Turn ignition switch “OFF”.

2. Disc](/img/5/57362/w960_57362-2773.png)

TROUBLE DIAGNOSIS FOR SYMPTOMS

RFD-71

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

3.CHECK DIFFERENTIAL LOCK CONTROL UNIT GROUND CIRCUIT

1. Turn ignition switch “OFF”.

2. Disconnect differential lock control unit harness connector.

3. Check continuity between differential lock control unit harness

connector M107 terminals 3, 10 and ground.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors.

4.CHECK COMBINATION METER POWER SUPPLY CIRCUIT

1. Turn ignition switch “OFF”.

2. Disconnect combination meter harness connector.

3. Check voltage between combination meter harness connector

terminal and ground.

4. Turn ignition switch “ON”. (Do not start engine.)

5. Check voltage between combination meter harness connector

terminal and ground.

OK or NG

OK >> GO TO 5.

NG >> Check the following. If any items are damaged, repair or

replace damaged parts.

l10A fuse [No.14, located in the fuse block (J/B)]

lHarness for short or open between ignition switch and combination meter harness connector

terminal 16.

lIgnition switch. Refer toPG-4, "POWER SUPPLY ROUTING CIRCUIT". Continuity should exist.

SDIA2564E

Connector Terminal Voltage (Approx.)

M23 16 - Ground 0V

WDIA0250E

Connector Terminal Voltage (Approx.)

M23 16 - Ground 0V

WDIA0251E

Page 2775 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual RFD-72

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYMPTOMS

5.CHECK HARNESS BETWEEN DIFFERENTIAL LOCK CONTROL UNIT AND COMBINATION METER

1. Turn ignition switch “OFF”.

2. Disconne NISSAN NAVARA 2005 Repair Workshop Manual RFD-72

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYMPTOMS

5.CHECK HARNESS BETWEEN DIFFERENTIAL LOCK CONTROL UNIT AND COMBINATION METER

1. Turn ignition switch “OFF”.

2. Disconne](/img/5/57362/w960_57362-2774.png)

RFD-72

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

TROUBLE DIAGNOSIS FOR SYMPTOMS

5.CHECK HARNESS BETWEEN DIFFERENTIAL LOCK CONTROL UNIT AND COMBINATION METER

1. Turn ignition switch “OFF”.

2. Disconnect differential lock control unit harness connector and combination meter harness connector.

3. Check continuity between differential lock control unit harness

connector M107 terminal 21 and combination meter harness

connector M23 terminal 25.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.CHECK INDICATOR LAMP CIRCUIT

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Connect combination meter harness connector.

3. Disconnect differential lock control unit harness connector.

4. Turn ignition switch “ON”. (Do not start engine.)

5. Ground the following terminals using suitable wiring.

–Differential lock control unit harness connector M107 terminal 21

and ground.

Do indicator lamps turn on?

OK >> GO TO 7.

NG >> Replace combination meter. Refer toDI-27, "

Removal

and Installation of Combination Meter".

7.CHECK SYMPTOM

Check again.

OK or NG

OK >>INSPECTION END

NG >> GO TO 8.

8.CHECK DIFFERENTIAL LOCK CONTROL UNIT

Check differential lock control unit input/output signal. Refer toRFD-48, "

Differential Lock Control Unit Input/

Output Signal Reference Values".

OK or NG

OK >>INSPECTION END

NG >> Check differential lock control unit pin terminals for damage or loose connection with harness con-

nector. If any items are damaged, repair or replace damaged parts. Continuity should exist.

WDIA0252E

SDIA3453E

Page 2776 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS FOR SYMPTOMS

RFD-73

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DIFF LOCK Indicator Lamp Does Not ChangeEDS003BA

SYMPTOM:

DIFF LOCK indicator lamp does not chan NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS FOR SYMPTOMS

RFD-73

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DIFF LOCK Indicator Lamp Does Not ChangeEDS003BA

SYMPTOM:

DIFF LOCK indicator lamp does not chan](/img/5/57362/w960_57362-2775.png)

TROUBLE DIAGNOSIS FOR SYMPTOMS

RFD-73

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DIFF LOCK Indicator Lamp Does Not ChangeEDS003BA

SYMPTOM:

DIFF LOCK indicator lamp does not change when turning differential lock mode switch to “ON” after

engine start.

DIAGNOSTIC PROCEDURE

1.CHECK DIFF LOCK INDICATOR LAMP

Confirm DIFF LOCK indicator lamp when ignition switch is turned to ON.

Does DIFF LOCK indicator lamp turn on?

YES >> GO TO 2.

NO >> Go toRFD-70, "

DIFF LOCK Indicator Lamp Does Not Turn ON".

2.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer toRFD-51, "

SELF-DIAG RESULTS MODE".

Is any malfunction detected by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 3.

3.CHECK SYSTEM FOR DIFFERENTIAL LOCK MODE SWITCH

Perform trouble diagnosis for differential lock mode switch system. Refer toRFD-56, "

Differential Lock Mode

Switch".

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.CHECK SYMPTOM

Check again.

OK or NG

OK >>INSPECTION END

NG >> GO TO 5.

5.CHECK DIFFERENTIAL LOCK CONTROL UNIT

Check differential lock control unit input/output signal. Refer toRFD-48, "

Differential Lock Control Unit Input/

Output Signal Reference Values".

OK or NG

OK >>INSPECTION END

NG >> Check differential lock control unit pin terminals for damage or loose connection with harness con-

nector. If any items are damaged, repair or replace damaged parts.

Page 2807 of 3171

RSU-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

PrecautionsEES002JD

lWhen installing rubber parts, final tightening must be carried out under unladen condition* with

tires on ground.

*Fuel, radiator coolant, and engine oil are full. Spare tire, jack, hand tools, and mats are in their

designated positions. Oil will shorten the life of rubber bushings, so wipe off any spilled oil imme-

diately.

lLock nuts are not reusable. Always use new lock nuts for installation. New lock nuts are pre-oiled,

do not apply any additional lubrication.

Page 2810 of 3171

REAR SUSPENSION ASSEMBLY

RSU-5

C

D

F

G

H

I

J

K

L

MA

B

RSU

CAUTION:

When installing the components with rubber bushings, the final tightening of the nuts and bolts must

be done with the vehicle in an unladen condition (the fuel, engine coolant, and engine oil full; the

spare tire, jack, hand tools and mats in their designated positions) with the tires on the ground.

On-Vehicle Inspection and ServiceEES002JH

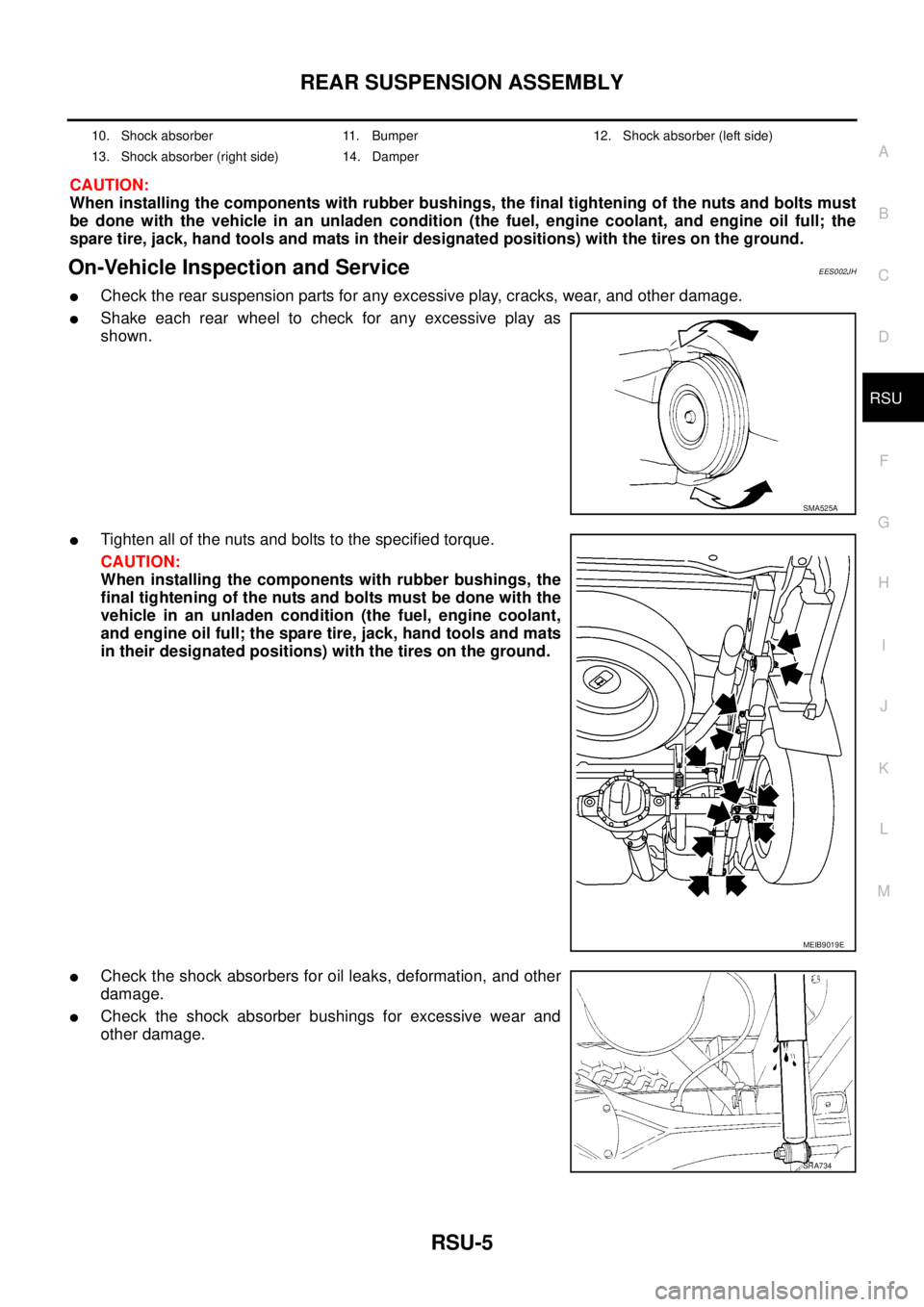

lCheck the rear suspension parts for any excessive play, cracks, wear, and other damage.

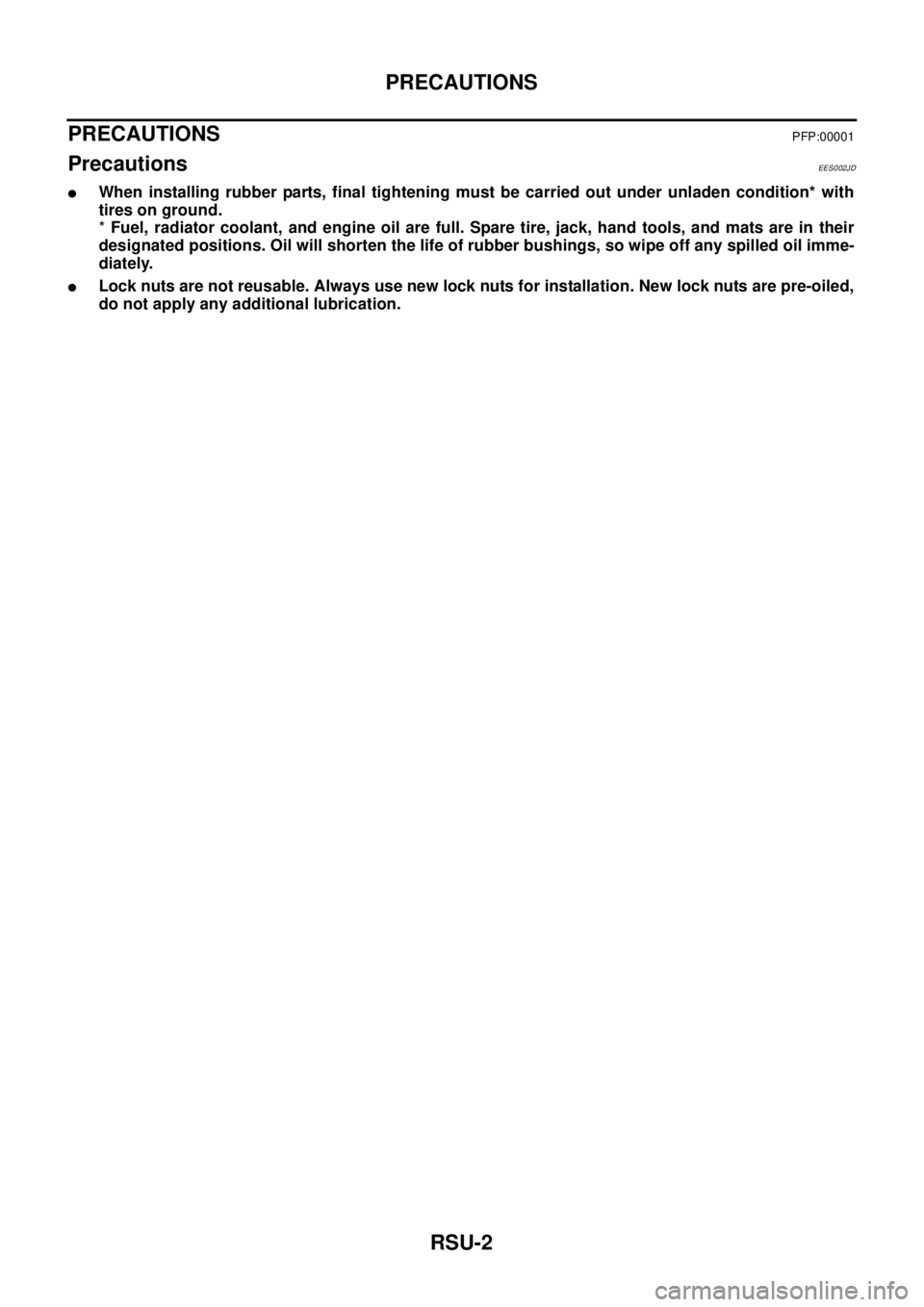

lShake each rear wheel to check for any excessive play as

shown.

lTighten all of the nuts and bolts to the specified torque.

CAUTION:

When installing the components with rubber bushings, the

final tightening of the nuts and bolts must be done with the

vehicle in an unladen condition (the fuel, engine coolant,

and engine oil full; the spare tire, jack, hand tools and mats

in their designated positions) with the tires on the ground.

lCheck the shock absorbers for oil leaks, deformation, and other

damage.

lCheck the shock absorber bushings for excessive wear and

other damage.

10. Shock absorber 11. Bumper 12. Shock absorber (left side)

13. Shock absorber (right side) 14. Damper

SMA525A

MEIB9019E

SRA734

Page 2813 of 3171

RSU-8

LEAF SPRING

CAUTION:

When installing the components with rubber bushings, the final tightening of the nuts and bolts must

be done with the vehicle in an unladen condition (the fuel, engine coolant, and engine oil full; the

spare tire, jack, hand tools and mats in their designated positions) with the tires on the ground.

REMOVAL

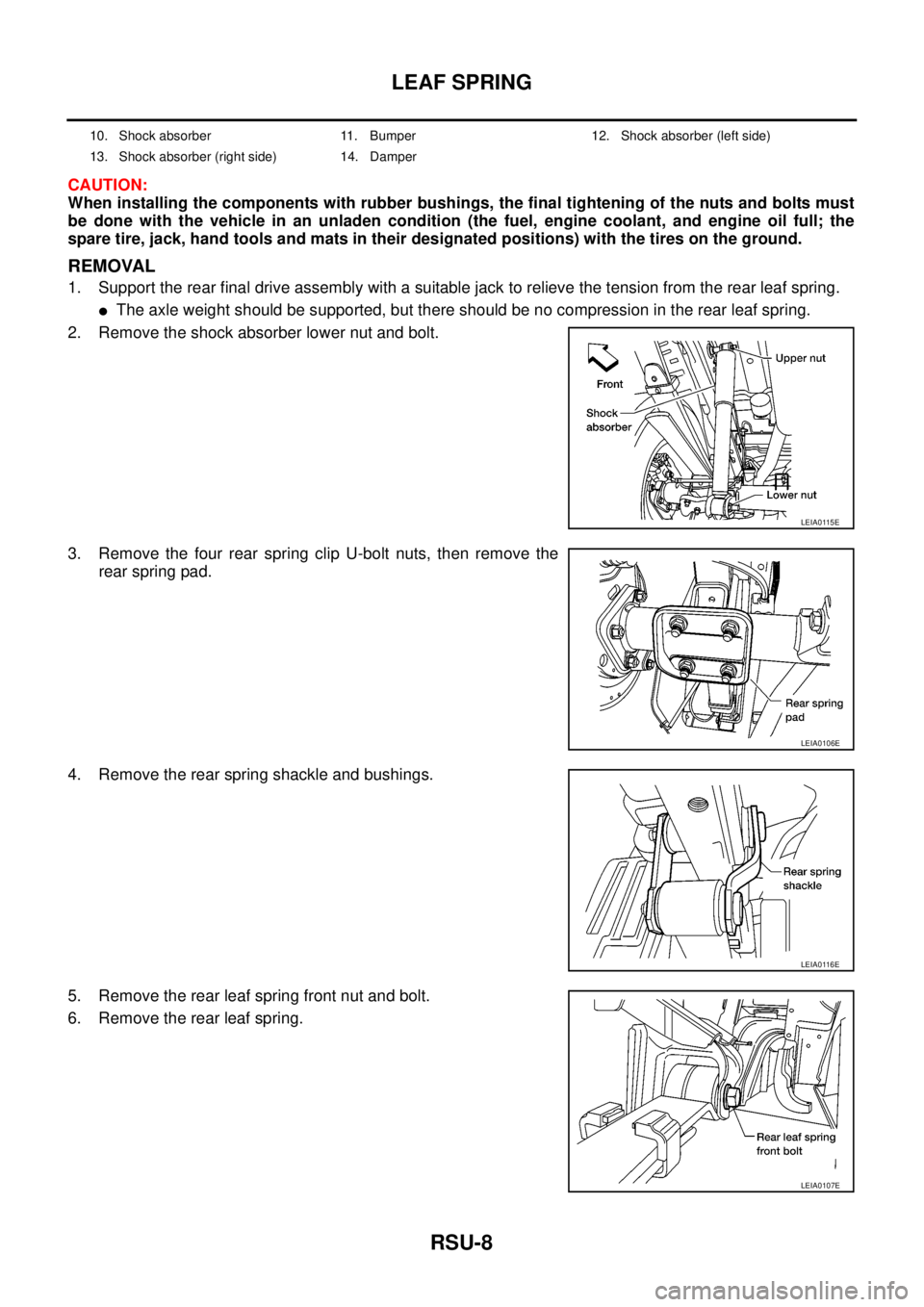

1. Support the rear final drive assembly with a suitable jack to relieve the tension from the rear leaf spring.

lThe axle weight should be supported, but there should be no compression in the rear leaf spring.

2. Remove the shock absorber lower nut and bolt.

3. Remove the four rear spring clip U-bolt nuts, then remove the

rear spring pad.

4. Remove the rear spring shackle and bushings.

5. Remove the rear leaf spring front nut and bolt.

6. Remove the rear leaf spring.

10. Shock absorber 11. Bumper 12. Shock absorber (left side)

13. Shock absorber (right side) 14. Damper

LEIA0115E

LEIA0106E

LEIA0116E

LEIA0107E

Page 2815 of 3171

RSU-10

LEAF SPRING

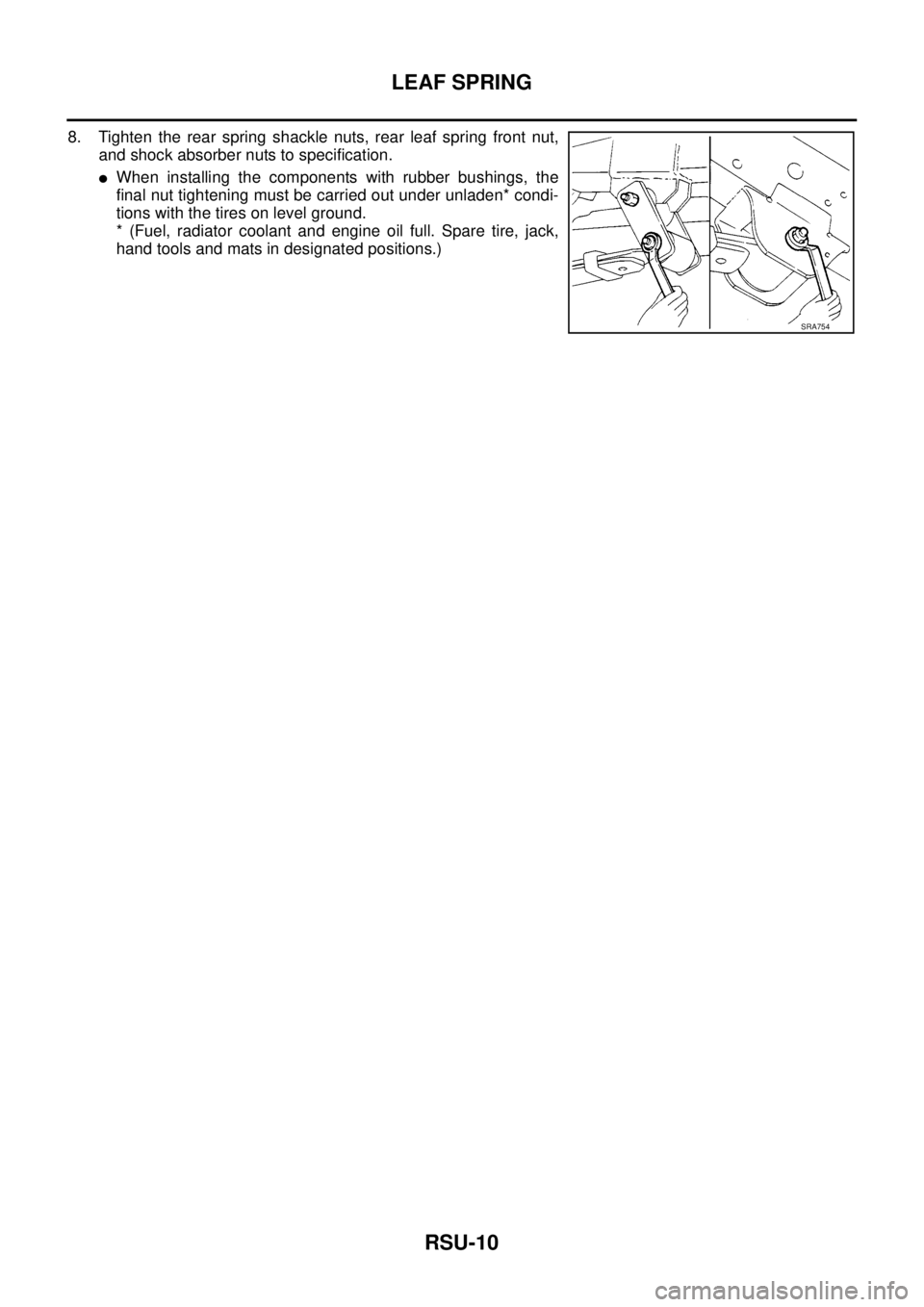

8. Tighten the rear spring shackle nuts, rear leaf spring front nut,

and shock absorber nuts to specification.

lWhen installing the components with rubber bushings, the

final nut tightening must be carried out under unladen* condi-

tions with the tires on level ground.

* (Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.)

SRA754

Page 2816 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

RSU-11

C

D

F

G

H

I

J

K

L

MA

B

RSU

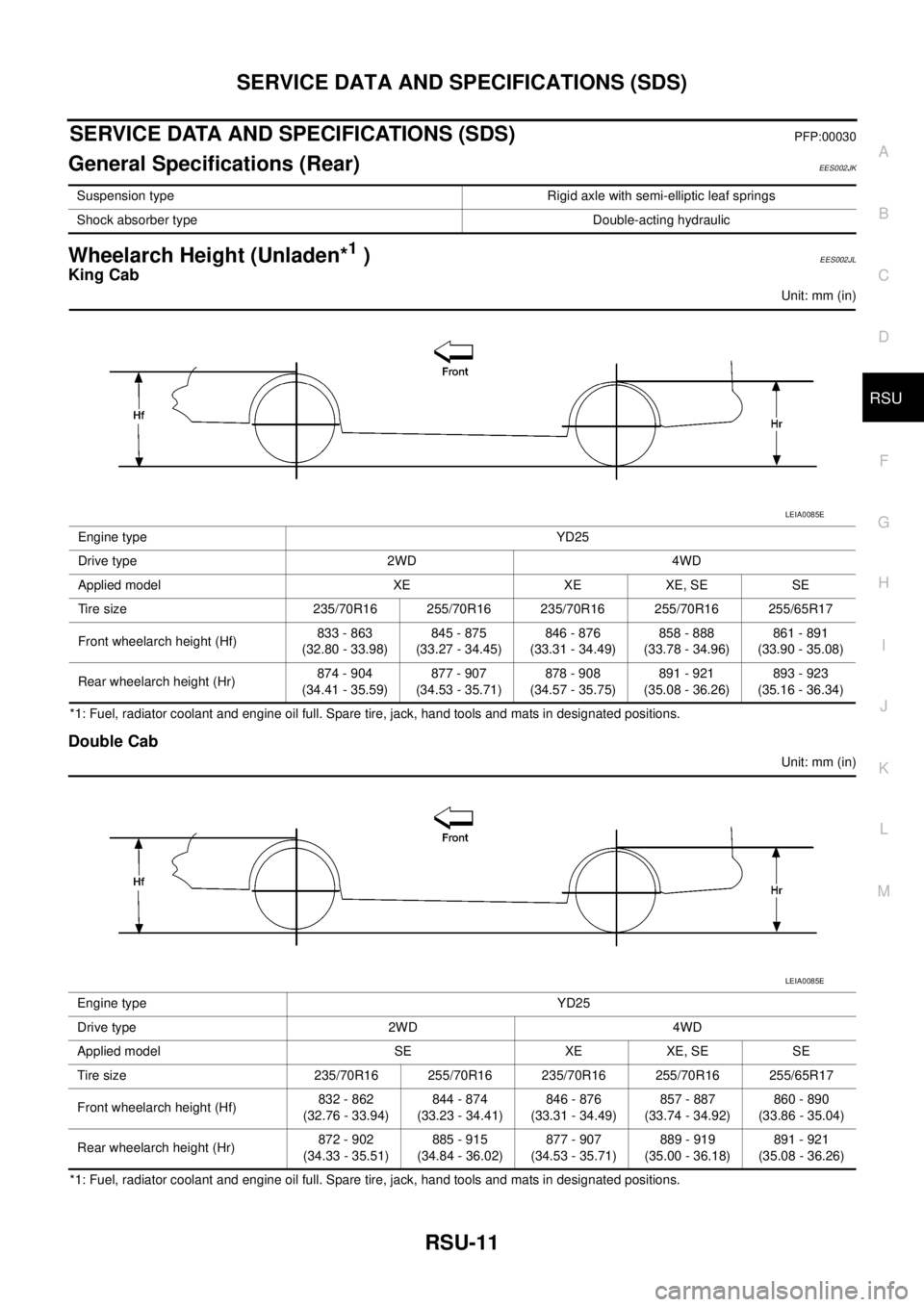

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General Specifications (Rear)EES002JK

Wheelarch Height (Unladen*1)EES002JL

King Cab

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Double Cab

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.Suspension type Rigid axle with semi-elliptic leaf springs

Shock absorber type Double-acting hydraulic

Engine type YD25

Drive type 2WD 4WD

Applied model XE XE XE, SE SE

Tire size 235/70R16 255/70R16 235/70R16 255/70R16 255/65R17

Front wheelarch height (Hf)833 - 863

(32.80 - 33.98)845 - 875

(33.27 - 34.45)846 - 876

(33.31 - 34.49)858 - 888

(33.78 - 34.96)861 - 891

(33.90 - 35.08)

Rear wheelarch height (Hr)874 - 904

(34.41 - 35.59)877 - 907

(34.53 - 35.71)878 - 908

(34.57 - 35.75)891 - 921

(35.08 - 36.26)893 - 923

(35.16 - 36.34)

LEIA0085E

Engine type YD25

Drive type 2WD 4WD

Applied model SE XE XE, SE SE

Tire size 235/70R16 255/70R16 235/70R16 255/70R16 255/65R17

Front wheelarch height (Hf)832 - 862

(32.76 - 33.94)844 - 874

(33.23 - 34.41)846 - 876

(33.31 - 34.49)857 - 887

(33.74 - 34.92)860 - 890

(33.86 - 35.04)

Rear wheelarch height (Hr)872 - 902

(34.33 - 35.51)885 - 915

(34.84 - 36.02)877 - 907

(34.53 - 35.71)889 - 919

(35.00 - 36.18)891 - 921

(35.08 - 36.26)

LEIA0085E