relay NISSAN NAVARA 2005 Repair Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1639 of 3171

HOW TO USE THIS MANUAL

GI-17

C

D

E

F

G

H

I

J

K

L

MB

GI

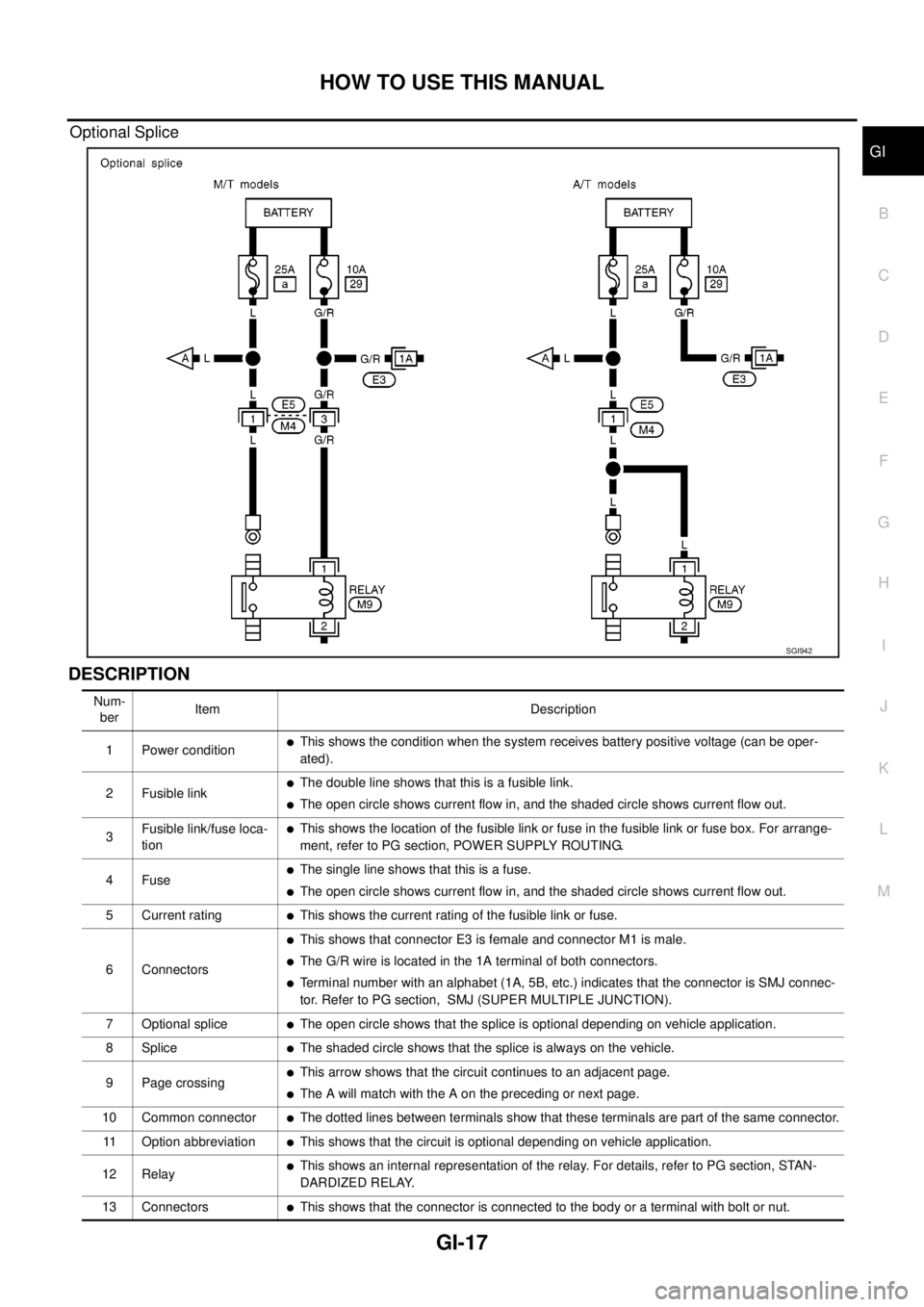

Optional Splice

DESCRIPTION

SGI942

Num-

berItem Description

1 Power condition

lThis shows the condition when the system receives battery positive voltage (can be oper-

ated).

2 Fusible link

lThe double line shows that this is a fusible link.

lThe open circle shows current flow in, and the shaded circle shows current flow out.

3Fusible link/fuse loca-

tion

lThis shows the location of the fusible link or fuse in the fusible link or fuse box. For arrange-

ment, refer to PG section, POWER SUPPLY ROUTING.

4Fuse

lThe single line shows that this is a fuse.

lThe open circle shows current flow in, and the shaded circle shows current flow out.

5 Current rating

lThis shows the current rating of the fusible link or fuse.

6 Connectors

lThis shows that connector E3 is female and connector M1 is male.

lThe G/R wire is located in the 1A terminal of both connectors.

lTerminal number with an alphabet (1A, 5B, etc.) indicates that the connector is SMJ connec-

tor. Refer to PG section, SMJ (SUPER MULTIPLE JUNCTION).

7 Optional splice

lThe open circle shows that the splice is optional depending on vehicle application.

8Splice

lThe shaded circle shows that the splice is always on the vehicle.

9 Page crossing

lThis arrow shows that the circuit continues to an adjacent page.

lThe A will match with the A on the preceding or next page.

10 Common connector

lThe dotted lines between terminals show that these terminals are part of the same connector.

11 Option abbreviation

lThis shows that the circuit is optional depending on vehicle application.

12 Relay

lThis shows an internal representation of the relay. For details, refer to PG section, STAN-

DARDIZED RELAY.

13 Connectors

lThis shows that the connector is connected to the body or a terminal with bolt or nut.

Page 1647 of 3171

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

GI-25

C

D

E

F

G

H

I

J

K

L

MB

GI

lHeat sensitive

lFreezing

lWater intrusion

lElectrical load

lCold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of the

problem.

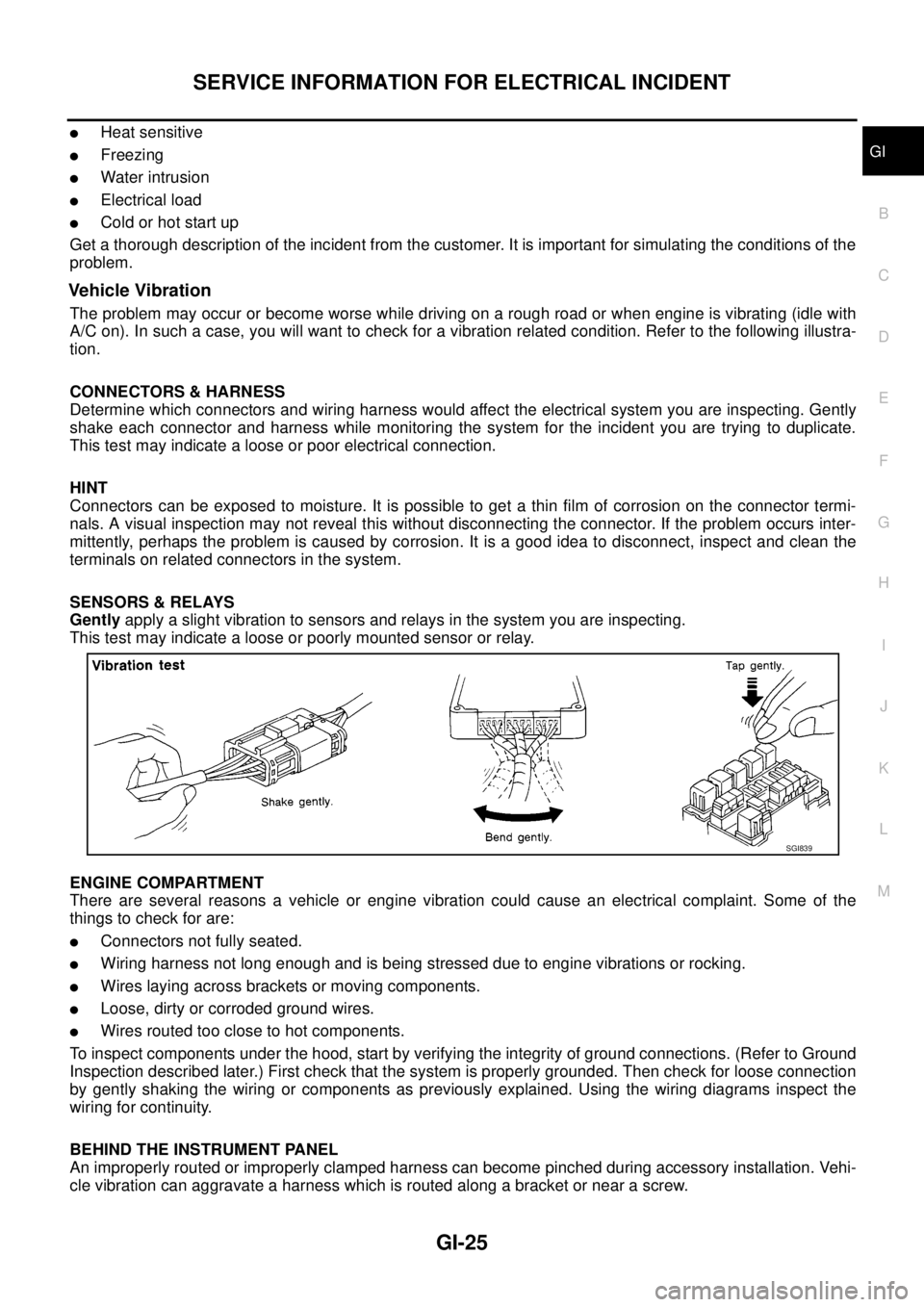

Vehicle Vibration

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vibration related condition. Refer to the following illustra-

tion.

CONNECTORS & HARNESS

Determine which connectors and wiring harness would affect the electrical system you are inspecting. Gently

shake each connector and harness while monitoring the system for the incident you are trying to duplicate.

This test may indicate a loose or poor electrical connection.

HINT

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs inter-

mittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean the

terminals on related connectors in the system.

SENSORS & RELAYS

Gentlyapply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

ENGINE COMPARTMENT

There are several reasons a vehicle or engine vibration could cause an electrical complaint. Some of the

things to check for are:

lConnectors not fully seated.

lWiring harness not long enough and is being stressed due to engine vibrations or rocking.

lWires laying across brackets or moving components.

lLoose, dirty or corroded ground wires.

lWires routed too close to hot components.

To inspect components under the hood, start by verifying the integrity of ground connections. (Refer to Ground

Inspection described later.) First check that the system is properly grounded. Then check for loose connection

by gently shaking the wiring or components as previously explained. Using the wiring diagrams inspect the

wiring for continuity.

BEHIND THE INSTRUMENT PANEL

An improperly routed or improperly clamped harness can become pinched during accessory installation. Vehi-

cle vibration can aggravate a harness which is routed along a bracket or near a screw.

SGI839

Page 1649 of 3171

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

GI-27

C

D

E

F

G

H

I

J

K

L

MB

GI

Cold or Hot Start Up

On some occasions an electrical incident may occur only when the car is started cold, or it may occur when

the car is restarted hot shortly after being turned off. In these cases you may have to keep the car overnight to

make a proper diagnosis.

CIRCUIT INSPECTION

Introduction

In general, testing electrical circuits is an easy task if it is approached in a logical and organized method.

Before beginning it is important to have all available information on the system to be tested. Also, get a thor-

ough understanding of system operation. Then you will be able to use the appropriate equipment and follow

the correct test procedure.

You may have to simulate vehicle vibrations while testing electrical components. Gently shake the wiring har-

ness or electrical component to do this.

NOTE:

Refer to “How to Check Terminal” to probe or check terminal.

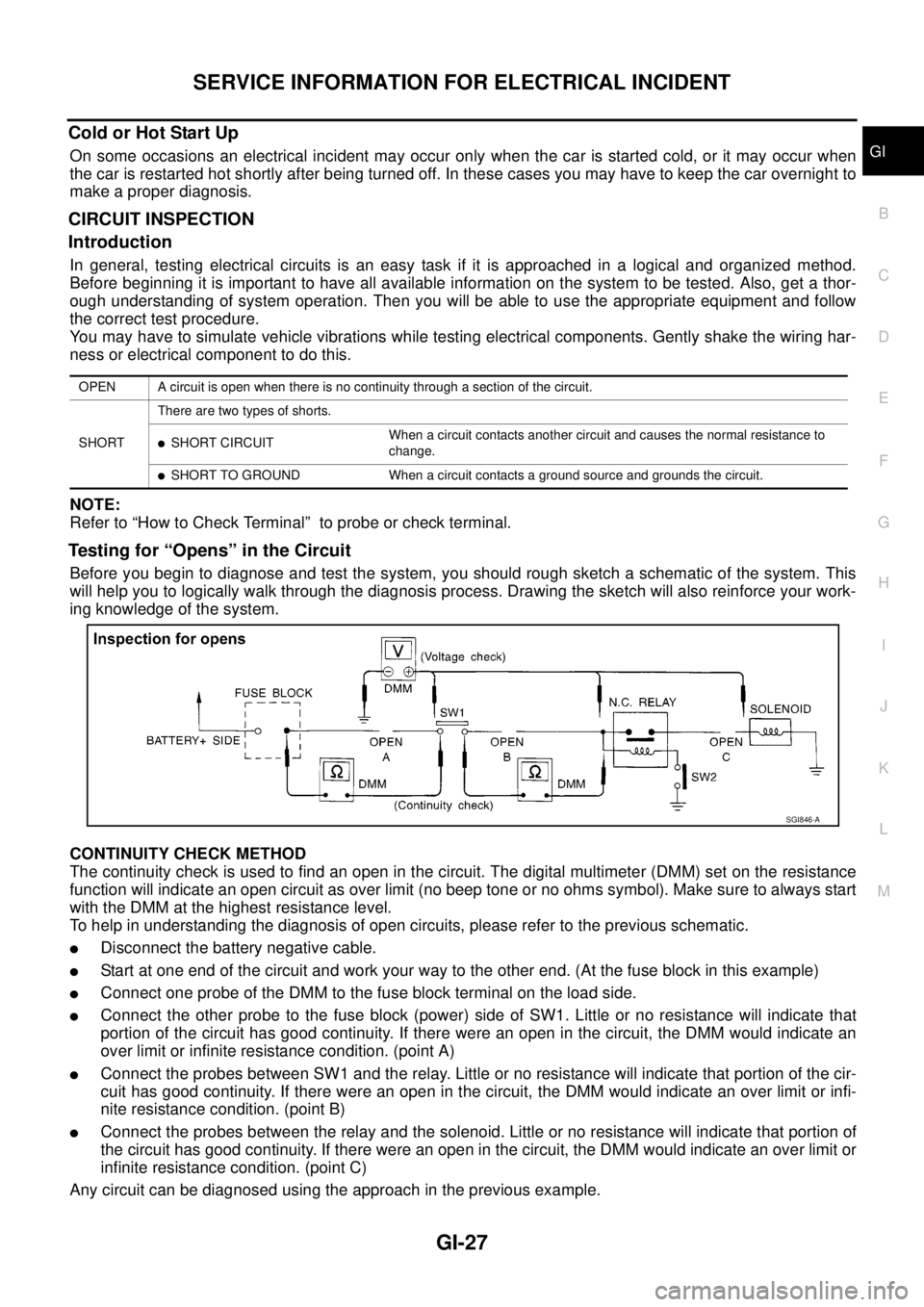

Testing for “Opens” in the Circuit

Before you begin to diagnose and test the system, you should rough sketch a schematic of the system. This

will help you to logically walk through the diagnosis process. Drawing the sketch will also reinforce your work-

ing knowledge of the system.

CONTINUITY CHECK METHOD

The continuity check is used to find an open in the circuit. The digital multimeter (DMM) set on the resistance

function will indicate an open circuit as over limit (no beep tone or no ohms symbol). Make sure to always start

with the DMM at the highest resistance level.

To help in understanding the diagnosis of open circuits, please refer to the previous schematic.

lDisconnect the battery negative cable.

lStart at one end of the circuit and work your way to the other end. (At the fuse block in this example)

lConnect one probe of the DMM to the fuse block terminal on the load side.

lConnect the other probe to the fuse block (power) side of SW1. Little or no resistance will indicate that

portion of the circuit has good continuity. If there were an open in the circuit, the DMM would indicate an

over limit or infinite resistance condition. (point A)

lConnect the probes between SW1 and the relay. Little or no resistance will indicate that portion of the cir-

cuit has good continuity. If there were an open in the circuit, the DMM would indicate an over limit or infi-

nite resistance condition. (point B)

lConnect the probes between the relay and the solenoid. Little or no resistance will indicate that portion of

the circuit has good continuity. If there were an open in the circuit, the DMM would indicate an over limit or

infinite resistance condition. (point C)

Any circuit can be diagnosed using the approach in the previous example.

OPEN A circuit is open when there is no continuity through a section of the circuit.

SHORTThere are two types of shorts.

lSHORT CIRCUITWhen a circuit contacts another circuit and causes the normal resistance to

change.

lSHORT TO GROUND When a circuit contacts a ground source and grounds the circuit.

SGI846-A

Page 1650 of 3171

GI-28

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

VOLTAGE CHECK METHOD

To help in understanding the diagnosis of open circuits please refer to the previous schematic.

In any powered circuit, an open can be found by methodically checking the system for the presence of voltage.

This is done by switching the DMM to the voltage function.

lConnect one probe of the DMM to a known good ground.

lBegin probing at one end of the circuit and work your way to the other end.

lWith SW1 open, probe at SW1 to check for voltage.

voltage; open is further down the circuit than SW1.

no voltage; open is between fuse block and SW1 (point A).

lClose SW1 and probe at relay.

voltage; open is further down the circuit than the relay.

no voltage; open is between SW1 and relay (point B).

lClose the relay and probe at the solenoid.

voltage; open is further down the circuit than the solenoid.

no voltage; open is between relay and solenoid (point C).

Any powered circuit can be diagnosed using the approach in the previous example.

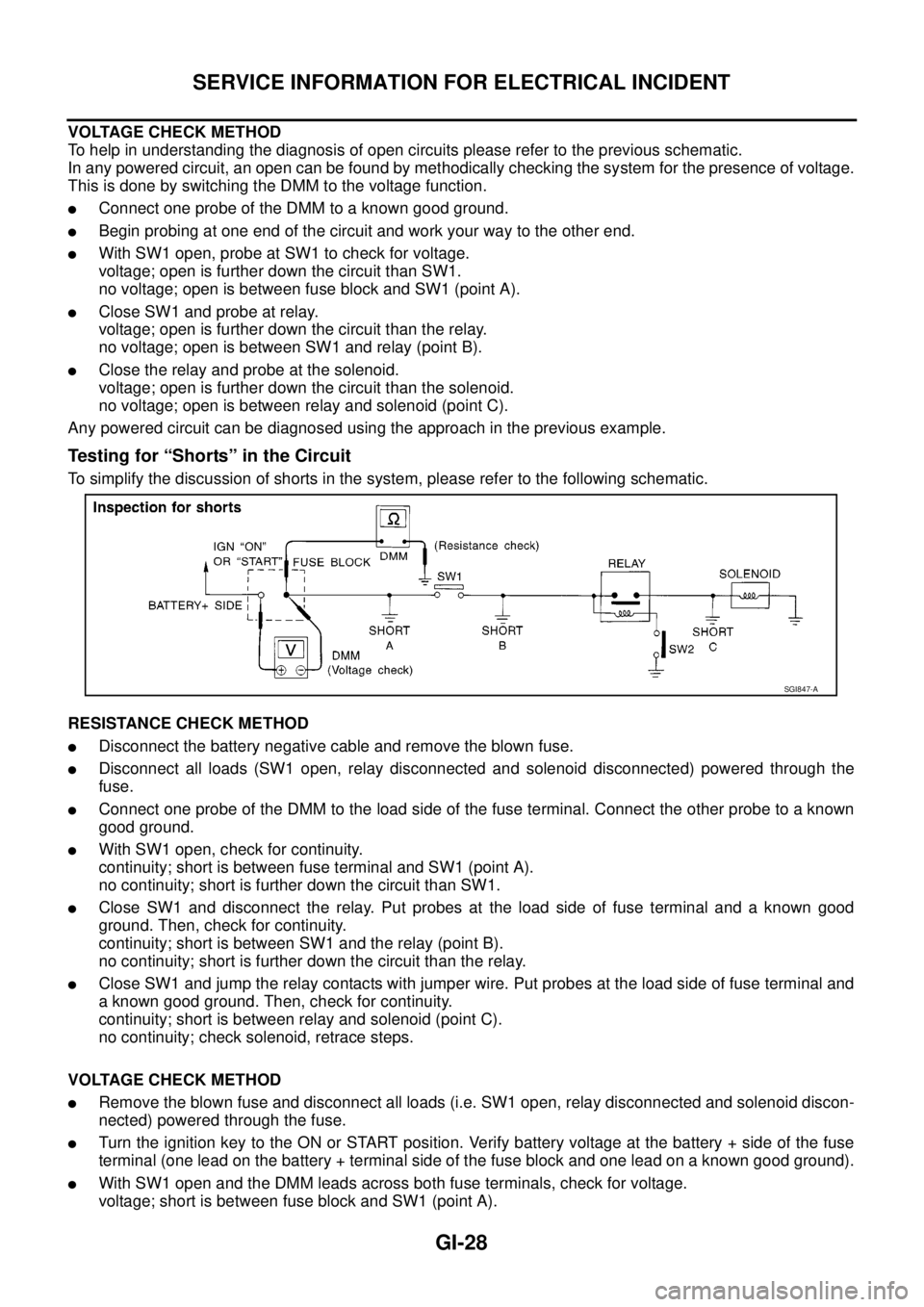

Testing for “Shorts” in the Circuit

To simplify the discussion of shorts in the system, please refer to the following schematic.

RESISTANCE CHECK METHOD

lDisconnect the battery negative cable and remove the blown fuse.

lDisconnect all loads (SW1 open, relay disconnected and solenoid disconnected) powered through the

fuse.

lConnect one probe of the DMM to the load side of the fuse terminal. Connect the other probe to a known

good ground.

lWith SW1 open, check for continuity.

continuity; short is between fuse terminal and SW1 (point A).

no continuity; short is further down the circuit than SW1.

lClose SW1 and disconnect the relay. Put probes at the load side of fuse terminal and a known good

ground. Then, check for continuity.

continuity; short is between SW1 and the relay (point B).

no continuity; short is further down the circuit than the relay.

lClose SW1 and jump the relay contacts with jumper wire. Put probes at the load side of fuse terminal and

a known good ground. Then, check for continuity.

continuity; short is between relay and solenoid (point C).

no continuity; check solenoid, retrace steps.

VOLTAGE CHECK METHOD

lRemove the blown fuse and disconnect all loads (i.e. SW1 open, relay disconnected and solenoid discon-

nected) powered through the fuse.

lTurn the ignition key to the ON or START position. Verify battery voltage at the battery + side of the fuse

terminal (one lead on the battery + terminal side of the fuse block and one lead on a known good ground).

lWith SW1 open and the DMM leads across both fuse terminals, check for voltage.

voltage; short is between fuse block and SW1 (point A).

SGI847-A

Page 1651 of 3171

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

GI-29

C

D

E

F

G

H

I

J

K

L

MB

GI

no voltage; short is further down the circuit than SW1.

lWith SW1 closed, relay and solenoid disconnected and the DMM leads across both fuse terminals, check

for voltage.

voltage; short is between SW1 and the relay (point B).

no voltage; short is further down the circuit than the relay.

lWith SW1 closed, relay contacts jumped with fused jumper wire check for voltage.

voltage; short is down the circuit of the relay or between the relay and the disconnected solenoid (point C).

no voltage; retrace steps and check power to fuse block.

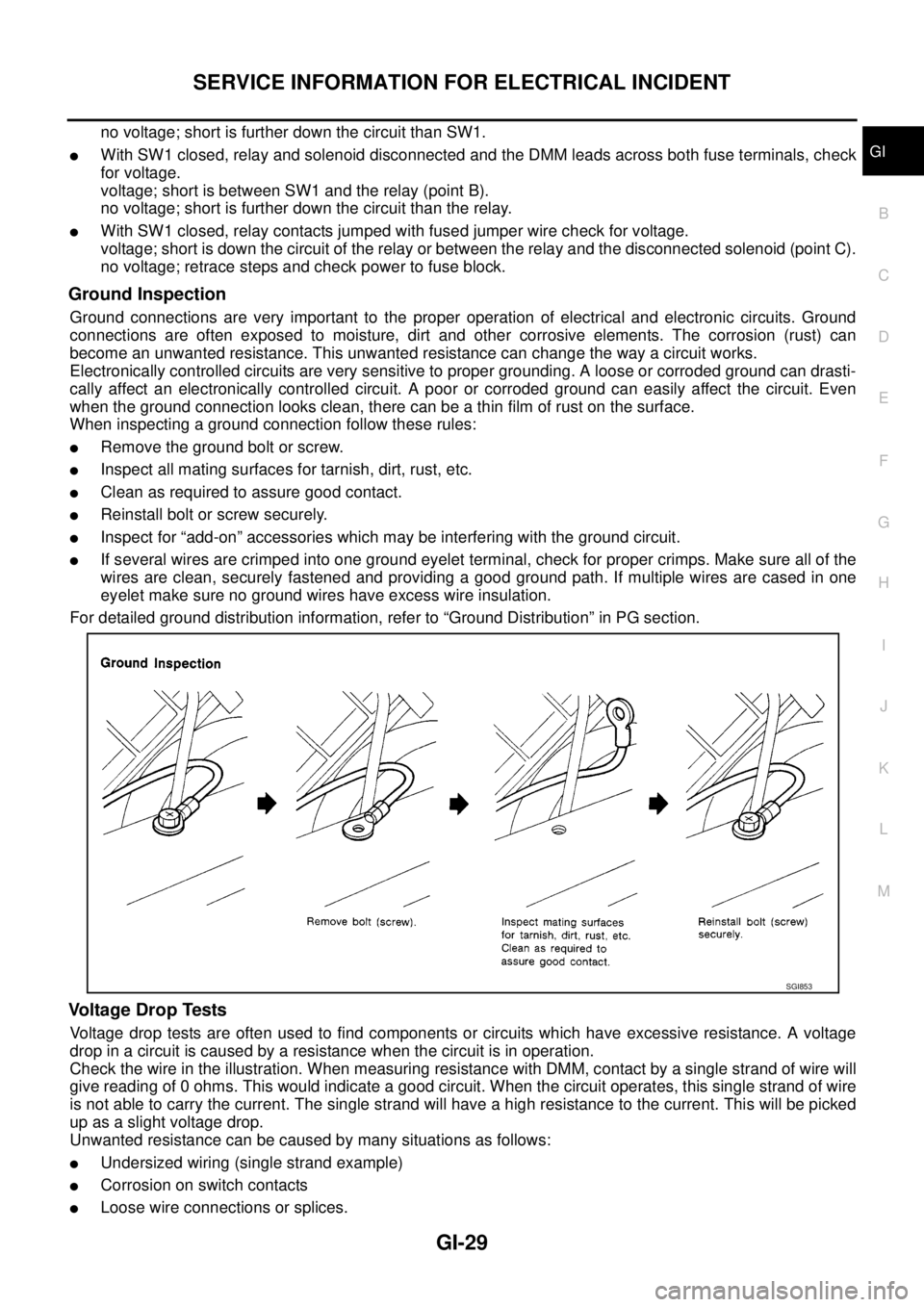

Ground Inspection

Ground connections are very important to the proper operation of electrical and electronic circuits. Ground

connections are often exposed to moisture, dirt and other corrosive elements. The corrosion (rust) can

become an unwanted resistance. This unwanted resistance can change the way a circuit works.

Electronically controlled circuits are very sensitive to proper grounding. A loose or corroded ground can drasti-

cally affect an electronically controlled circuit. A poor or corroded ground can easily affect the circuit. Even

when the ground connection looks clean, there can be a thin film of rust on the surface.

When inspecting a ground connection follow these rules:

lRemove the ground bolt or screw.

lInspect all mating surfaces for tarnish, dirt, rust, etc.

lClean as required to assure good contact.

lReinstall bolt or screw securely.

lInspect for “add-on” accessories which may be interfering with the ground circuit.

lIf several wires are crimped into one ground eyelet terminal, check for proper crimps. Make sure all of the

wires are clean, securely fastened and providing a good ground path. If multiple wires are cased in one

eyelet make sure no ground wires have excess wire insulation.

For detailed ground distribution information, refer to “Ground Distribution” in PG section.

Voltage Drop Tests

Voltage drop tests are often used to find components or circuits which have excessive resistance. A voltage

drop in a circuit is caused by a resistance when the circuit is in operation.

Check the wire in the illustration. When measuring resistance with DMM, contact by a single strand of wire will

give reading of 0 ohms. This would indicate a good circuit. When the circuit operates, this single strand of wire

is not able to carry the current. The single strand will have a high resistance to the current. This will be picked

up as a slight voltage drop.

Unwanted resistance can be caused by many situations as follows:

lUndersized wiring (single strand example)

lCorrosion on switch contacts

lLoose wire connections or splices.

SGI853

Page 1733 of 3171

REAR WINDOW DEFOGGER

GW-47

C

D

E

F

G

H

J

K

L

MA

B

GW

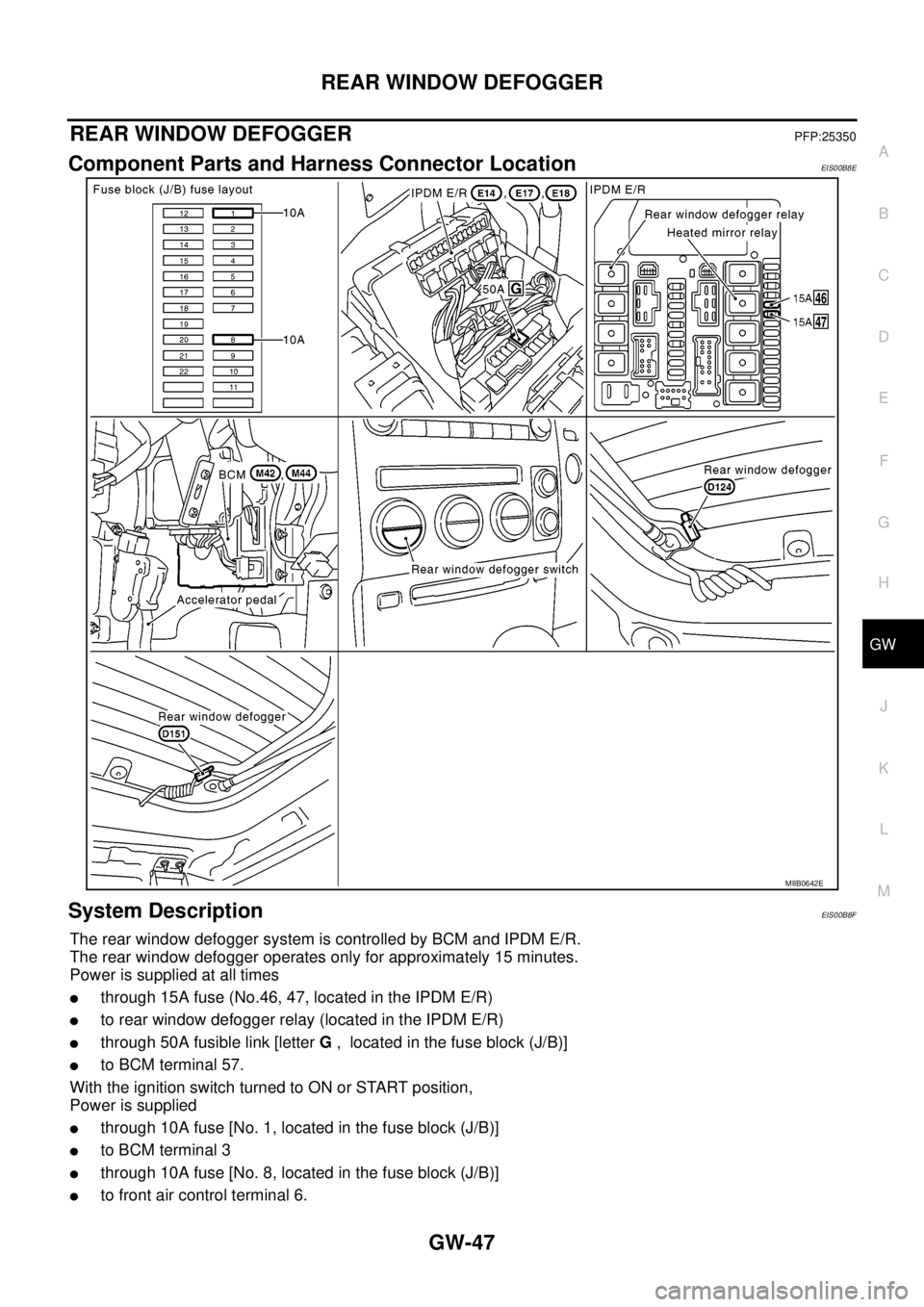

REAR WINDOW DEFOGGERPFP:25350

Component Parts and Harness Connector LocationEIS00B8E

System DescriptionEIS00B8F

The rear window defogger system is controlled by BCM and IPDM E/R.

The rear window defogger operates only for approximately 15 minutes.

Power is supplied at all times

lthrough 15A fuse (No.46, 47, located in the IPDM E/R)

lto rear window defogger relay (located in the IPDM E/R)

lthrough 50A fusible link [letterG, located in the fuse block (J/B)]

lto BCM terminal 57.

WiththeignitionswitchturnedtoONorSTARTposition,

Power is supplied

lthrough 10A fuse [No. 1, located in the fuse block (J/B)]

lto BCM terminal 3

lthrough 10A fuse [No. 8, located in the fuse block (J/B)]

lto front air control terminal 6.

MIIB0642E

Page 1734 of 3171

GW-48

REAR WINDOW DEFOGGER

Ground is supplied

lto BCM terminal 55

lto front air control terminal 20

lthrough body grounds M21, M80 and M83

lto IPDM E/R terminals 38 and 59

lthrough body grounds E21, E41 and E61.

When front air control (rear window defogger switch) is turned to ON,

Ground is supplied

lto BCM terminal 20

lthrough front air control terminal 11

lthrough front air control terminal 20

lthrough body grounds M21, M80 and M83.

Then rear window defogger switch is illuminated.

Then BCM recognizes that rear window defogger switch is turned to ON.

Then it sends rear window defogger switch signals to IPDM E/R via DATA LINE (CAN H, CAN L).

When display panel receives rear window defogger switch signals it illuminates on the screen.

When IPDM E/R receives rear window defogger switch signals,

Ground is supplied

lto rear window defogger relay (located in the IPDM E/R)

lthrough IPDM E/R terminals 38 and 59

lthrough body grounds E21, E41 and E61

and then rear window defogger relay and heated mirror is energized.

Power is supplied

lthrough IPDM E/R terminal 60

lto rear window defogger terminal 1.

Ground is supplied

lto rear window window defogger terminal 2

lthrough body ground D152.

With power and ground supplied, rear window defogger filaments heat and defog the rear window.

CAN Communication System DescriptionEIS00B8G

Refer toLAN-23, "CAN COMMUNICATION".

Page 1745 of 3171

REAR WINDOW DEFOGGER

GW-59

C

D

E

F

G

H

J

K

L

MA

B

GW

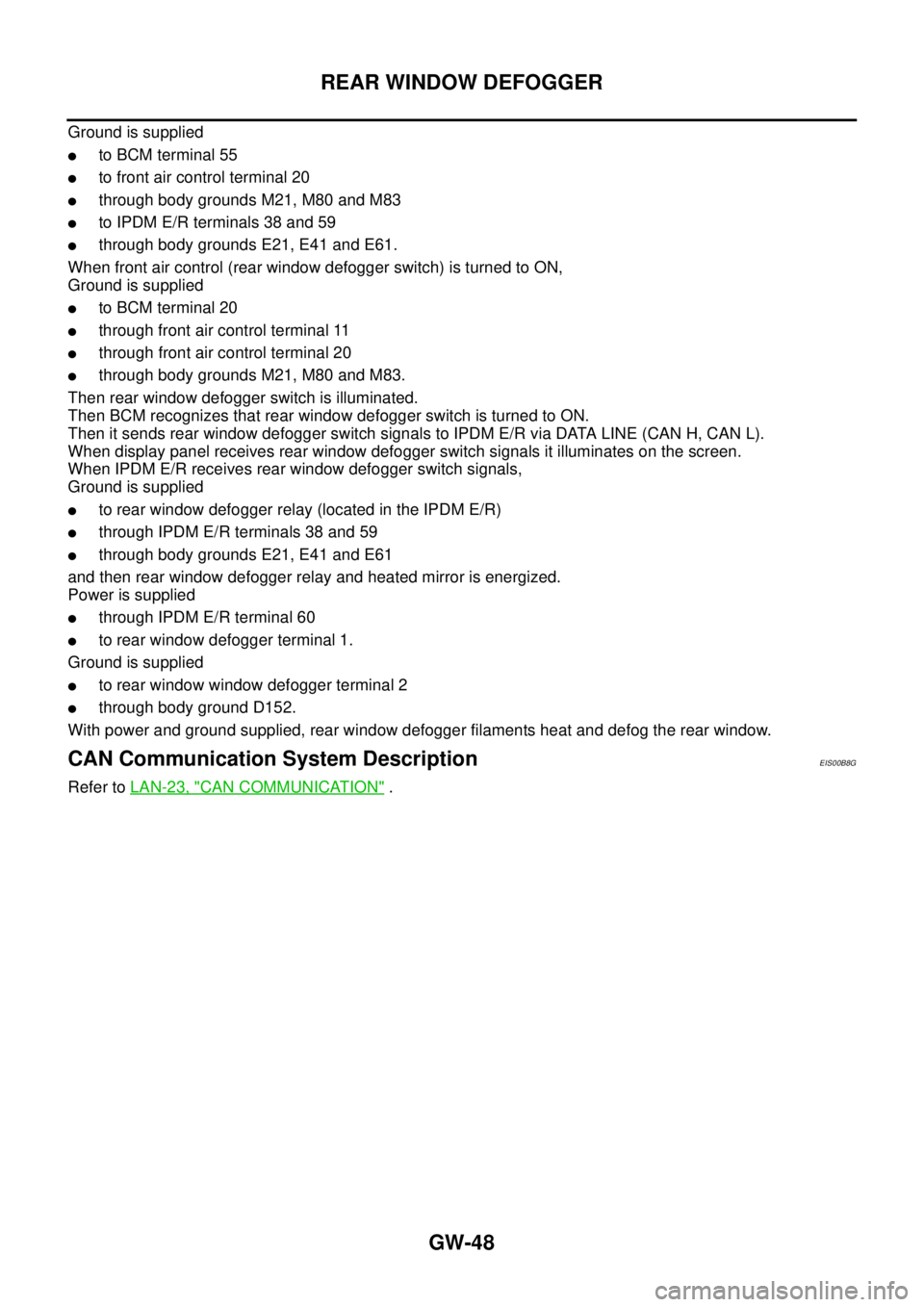

Rear Window Defogger Power Supply Circuit CheckEIS00B8Q

1.CHECK FUSE

lCheck 15A fuse (No.46, 47, located in the IPDM E/R)

NOTE:

Refer toGW-47, "

Component Parts and Harness Connector Location".

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse, refer toPG-

4, "POWER SUPPLY ROUTING CIRCUIT".

2.CHECK REAR WINDOW DEFOGGER RELAY OUTPUT SIGNAL

1. Turn ignition switch ON.

2. Check voltage between IPDM E/R connector and ground.

OK or NG

OK >> Check the condition of harness and connector.

NG >> Repair IPDM E/R.

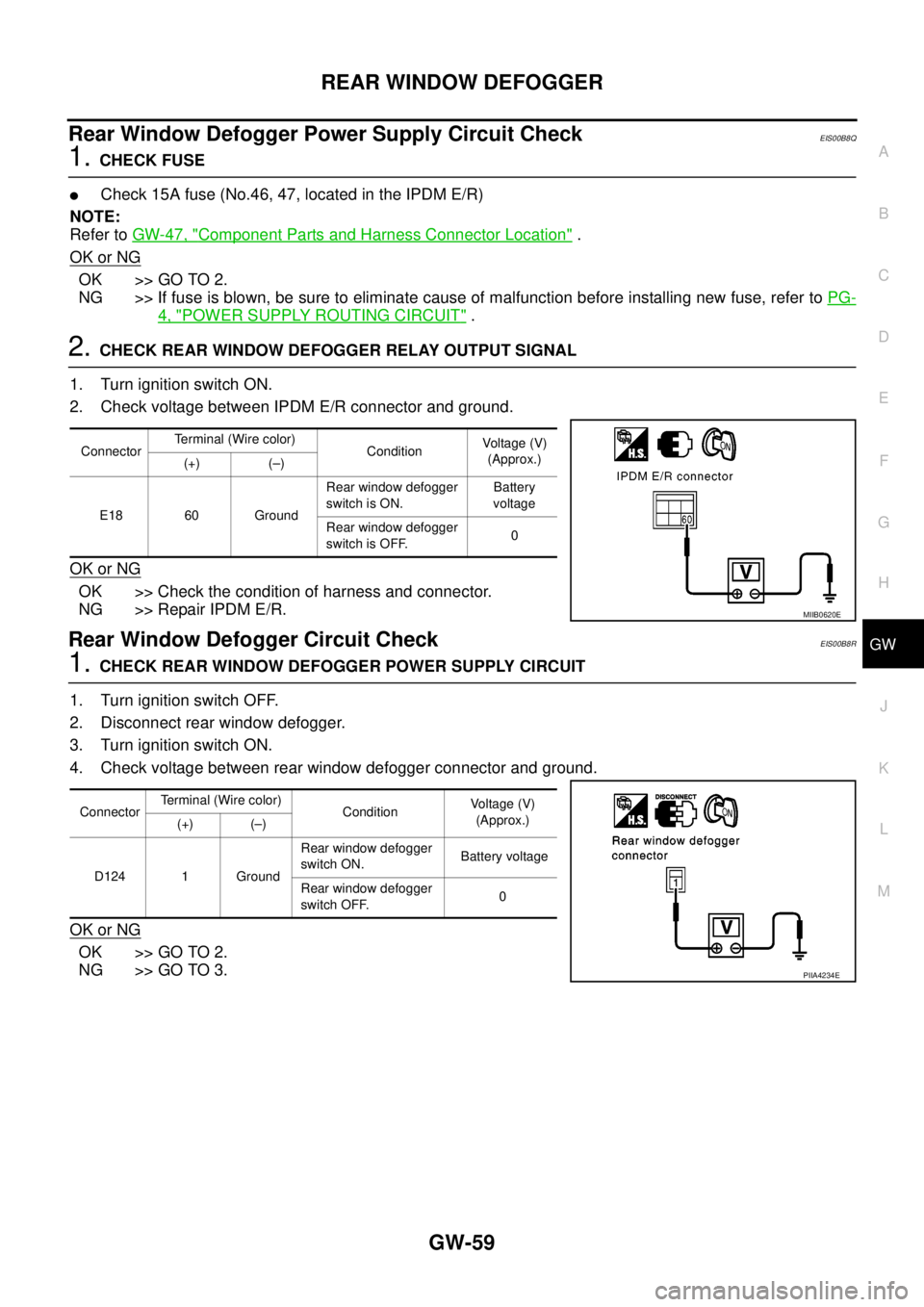

Rear Window Defogger Circuit CheckEIS00B8R

1.CHECK REAR WINDOW DEFOGGER POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear window defogger.

3. Turn ignition switch ON.

4. Check voltage between rear window defogger connector and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

ConnectorTerminal (Wire color)

ConditionVoltag e (V)

(Approx.)

(+) (–)

E18 60 GroundRear window defogger

switch is ON.Battery

voltage

Rear window defogger

switch is OFF.0

MIIB0620E

ConnectorTerminal (Wire color)

ConditionVo l ta g e (V )

(Approx.)

(+) (–)

D124 1 GroundRear window defogger

switch ON.Battery voltage

Rear window defogger

switch OFF.0

PIIA4234E

Page 1755 of 3171

IDX-3

A

C

D

E

F

G

H

I

J

K

L B

IDX

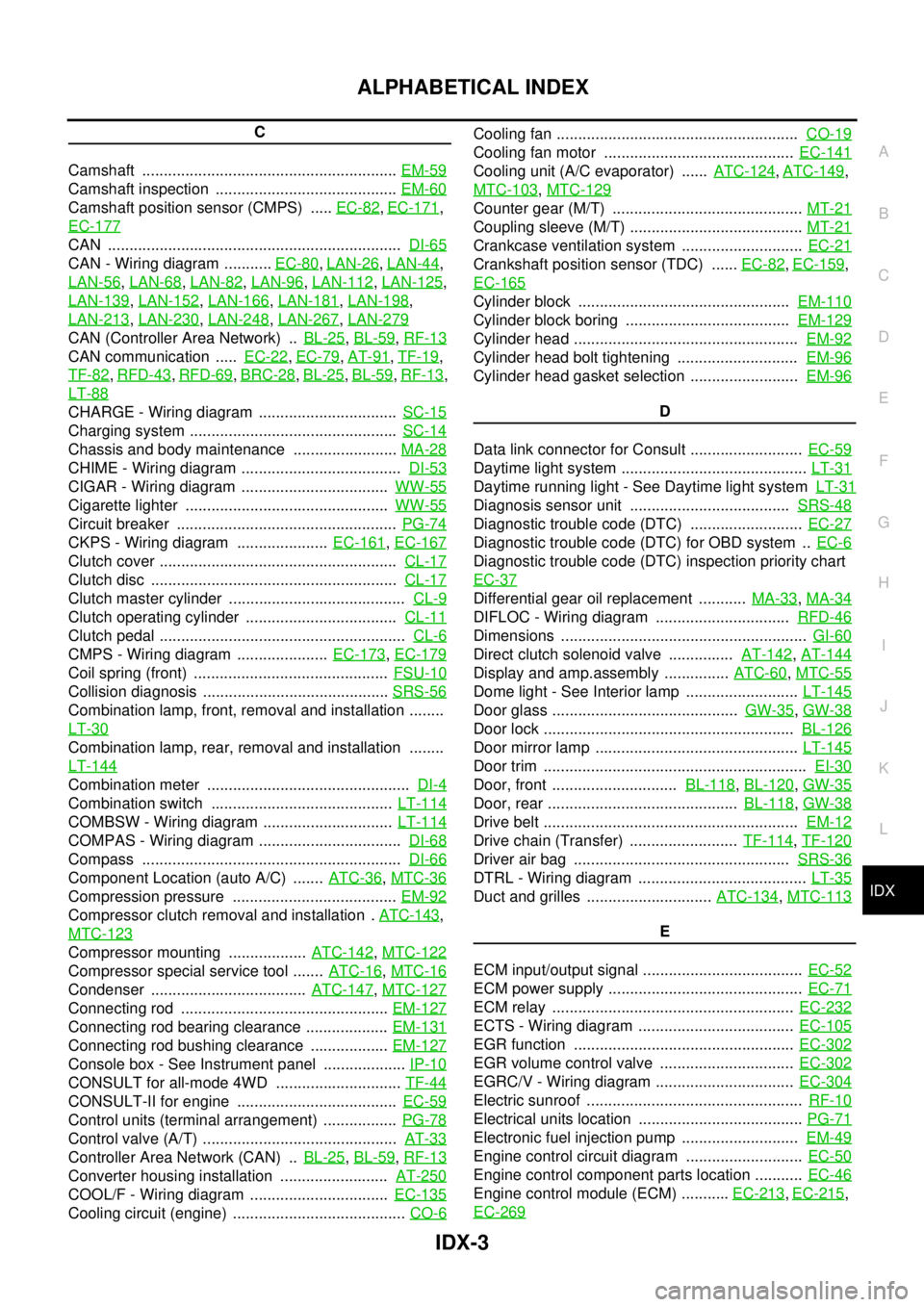

ALPHABETICAL INDEX

C

Camshaft ...........................................................EM-59

Camshaft inspection ..........................................EM-60

Camshaft position sensor (CMPS) .....EC-82,EC-171,

EC-177

CAN ....................................................................DI-65

CAN - Wiring diagram ...........EC-80,LAN-26,LAN-44,

LAN-56

,LAN-68,LAN-82,LAN-96,LAN-112,LAN-125,

LAN-139

,LAN-152,LAN-166,LAN-181,LAN-198,

LAN-213

,LAN-230,LAN-248,LAN-267,LAN-279

CAN (Controller Area Network) ..BL-25,BL-59,RF-13

CAN communication .....EC-22,EC-79,AT-91,TF-19,

TF-82

,RFD-43,RFD-69,BRC-28,BL-25,BL-59,RF-13,

LT-88

CHARGE - Wiring diagram ................................SC-15

Charging system ................................................SC-14

Chassis and body maintenance ........................MA-28

CHIME - Wiring diagram .....................................DI-53

CIGAR - Wiring diagram ..................................WW-55

Cigarette lighter ...............................................WW-55

Circuit breaker ...................................................PG-74

CKPS - Wiring diagram .....................EC-161,EC-167

Clutch cover .......................................................CL-17

Clutch disc .........................................................CL-17

Clutch master cylinder .........................................CL-9

Clutch operating cylinder ...................................CL-11

Clutch pedal .........................................................CL-6

CMPS - Wiring diagram .....................EC-173,EC-179

Coil spring (front) .............................................FSU-10

Collision diagnosis ...........................................SRS-56

Combination lamp, front, removal and installation ........

LT-30

Combination lamp, rear, removal and installation ........

LT-144

Combination meter ...............................................DI-4

Combination switch ..........................................LT-114

COMBSW - Wiring diagram ..............................LT-114

COMPAS - Wiring diagram .................................DI-68

Compass ............................................................DI-66

Component Location (auto A/C) .......ATC-36,MTC-36

Compression pressure ......................................EM-92

Compressor clutch removal and installation .ATC-143,

MTC-123

Compressor mounting ..................ATC-142,MTC-122

Compressor special service tool .......ATC-16,MTC-16

Condenser ....................................ATC-147,MTC-127

Connecting rod ................................................EM-127

Connecting rod bearing clearance ...................EM-131

Connecting rod bushing clearance ..................EM-127

Console box - See Instrument panel ...................IP-10

CONSULT for all-mode 4WD .............................TF-44

CONSULT-II for engine .....................................EC-59

Control units (terminal arrangement) .................PG-78

Control valve (A/T) .............................................AT-33

Controller Area Network (CAN) ..BL-25,BL-59,RF-13

Converter housing installation .........................AT-250

COOL/F - Wiring diagram ................................EC-135

Cooling circuit (engine) ........................................CO-6

Cooling fan ........................................................CO-19

Cooling fan motor ............................................EC-141

Cooling unit (A/C evaporator) ......ATC-124,ATC-149,

MTC-103

,MTC-129

Counter gear (M/T) ............................................MT-21

Coupling sleeve (M/T) ........................................MT-21

Crankcase ventilation system ............................EC-21

Crankshaft position sensor (TDC) ......EC-82,EC-159,

EC-165

Cylinder block .................................................EM-110

Cylinder block boring ......................................EM-129

Cylinder head ....................................................EM-92

Cylinder head bolt tightening ............................EM-96

Cylinder head gasket selection .........................EM-96

D

Data link connector for Consult ..........................EC-59

Daytime light system ...........................................LT-31

Daytime running light - See Daytime light systemLT-31

Diagnosis sensor unit .....................................SRS-48

Diagnostic trouble code (DTC) ..........................EC-27

Diagnostic trouble code (DTC) for OBD system ..EC-6

Diagnostic trouble code (DTC) inspection priority chart

EC-37

Differential gear oil replacement ...........MA-33,MA-34

DIFLOC - Wiring diagram ...............................RFD-46

Dimensions .........................................................GI-60

Direct clutch solenoid valve ...............AT-142,AT-144

Display and amp.assembly ...............ATC-60,MTC-55

Dome light - See Interior lamp ..........................LT-145

Door glass ...........................................GW-35,GW-38

Door lock ..........................................................BL-126

Door mirror lamp ...............................................LT-145

Door trim .............................................................EI-30

Door, front .............................BL-118,BL-120,GW-35

Door, rear ............................................BL-118,GW-38

Drive belt ...........................................................EM-12

Drive chain (Transfer) .........................TF-114,TF-120

Driver air bag ..................................................SRS-36

DTRL - Wiring diagram .......................................LT-35

Duct and grilles .............................ATC-134,MTC-113

E

ECM input/output signal .....................................EC-52

ECM power supply .............................................EC-71

ECM relay ........................................................EC-232

ECTS - Wiring diagram ....................................EC-105

EGR function ...................................................EC-302

EGR volume control valve ...............................EC-302

EGRC/V - Wiring diagram ................................EC-304

Electric sunroof ..................................................RF-10

Electrical units location ......................................PG-71

Electronic fuel injection pump ...........................EM-49

Engine control circuit diagram ...........................EC-50

Engine control component parts location ...........EC-46

Engine control module (ECM) ...........EC-213,EC-215,

EC-269

Page 1756 of 3171

IDX-4

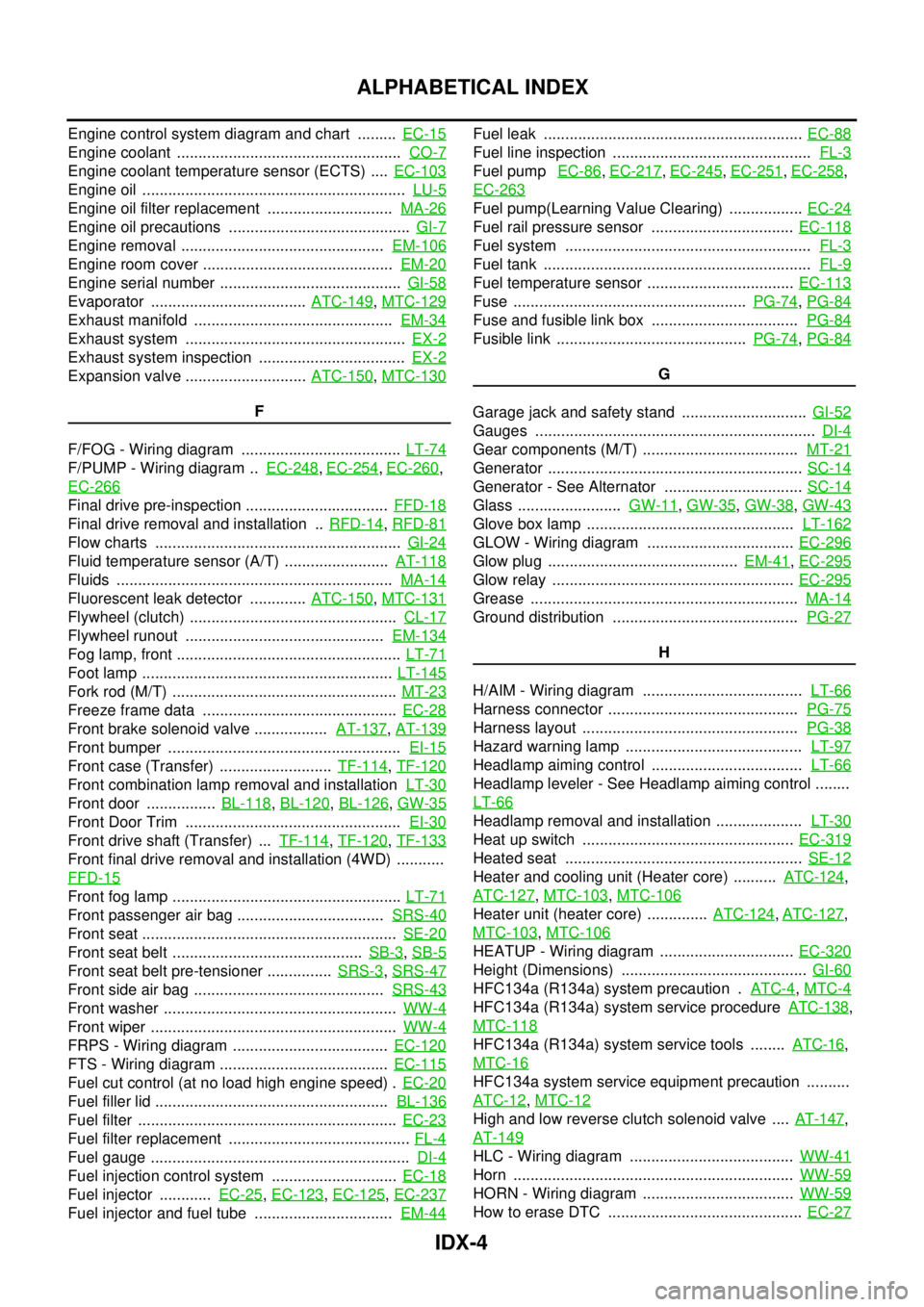

ALPHABETICAL INDEX

Engine control system diagram and chart .........EC-15

Engine coolant ....................................................CO-7

Engine coolant temperature sensor (ECTS) ....EC-103

Engine oil .............................................................LU-5

Engine oil filter replacement .............................MA-26

Engine oil precautions ..........................................GI-7

Engine removal ...............................................EM-106

Engine room cover ............................................EM-20

Engine serial number ..........................................GI-58

Evaporator ....................................ATC-149,MTC-129

Exhaust manifold ..............................................EM-34

Exhaust system ...................................................EX-2

Exhaust system inspection ..................................EX-2

Expansion valve ............................ATC-150,MTC-130

F

F/FOG - Wiring diagram .....................................LT-74

F/PUMP - Wiring diagram ..EC-248,EC-254,EC-260,

EC-266

Final drive pre-inspection .................................FFD-18

Final drive removal and installation ..RFD-14,RFD-81

Flow charts .........................................................GI-24

Fluid temperature sensor (A/T) ........................AT-118

Fluids ................................................................MA-14

Fluorescent leak detector .............ATC-150,MTC-131

Flywheel (clutch) ................................................CL-17

Flywheel runout ..............................................EM-134

Fog lamp, front ....................................................LT-71

Foot lamp ..........................................................LT-145

Fork rod (M/T) ....................................................MT-23

Freeze frame data .............................................EC-28

Front brake solenoid valve .................AT-137,AT-139

Front bumper ......................................................EI-15

Front case (Transfer) ..........................TF-114,TF-120

Front combination lamp removal and installationLT-30

Front door ................BL-118,BL-120,BL-126,GW-35

Front Door Trim ..................................................EI-30

Front drive shaft (Transfer) ...TF-114,TF-120,TF-133

Front final drive removal and installation (4WD) ...........

FFD-15

Front fog lamp .....................................................LT-71

Front passenger air bag ..................................SRS-40

Front seat ...........................................................SE-20

Front seat belt ............................................SB-3,SB-5

Front seat belt pre-tensioner ...............SRS-3,SRS-47

Front side air bag ............................................SRS-43

Front washer ......................................................WW-4

Front wiper .........................................................WW-4

FRPS - Wiring diagram ....................................EC-120

FTS - Wiring diagram .......................................EC-115

Fuel cut control (at no load high engine speed) .EC-20

Fuel filler lid ......................................................BL-136

Fuel filter ............................................................EC-23

Fuel filter replacement ..........................................FL-4

Fuel gauge ............................................................DI-4

Fuel injection control system .............................EC-18

Fuel injector ............EC-25,EC-123,EC-125,EC-237

Fuel injector and fuel tube ................................EM-44

Fuel leak ............................................................EC-88

Fuel line inspection ..............................................FL-3

Fuel pumpEC-86,EC-217,EC-245,EC-251,EC-258,

EC-263

Fuel pump(Learning Value Clearing) .................EC-24

Fuel rail pressure sensor .................................EC-118

Fuel system .........................................................FL-3

Fuel tank ..............................................................FL-9

Fuel temperature sensor ..................................EC-113

Fuse ......................................................PG-74,PG-84

Fuse and fusible link box ..................................PG-84

Fusible link ............................................PG-74,PG-84

G

Garage jack and safety stand .............................GI-52

Gauges .................................................................DI-4

Gear components (M/T) ....................................MT-21

Generator ...........................................................SC-14

Generator - See Alternator ................................SC-14

Glass ........................GW-11,GW-35,GW-38,GW-43

Glove box lamp ................................................LT-162

GLOW - Wiring diagram ..................................EC-296

Glow plug ............................................EM-41,EC-295

Glow relay ........................................................EC-295

Grease ..............................................................MA-14

Ground distribution ...........................................PG-27

H

H/AIM - Wiring diagram .....................................LT-66

Harness connector ............................................PG-75

Harness layout ..................................................PG-38

Hazard warning lamp .........................................LT-97

Headlamp aiming control ...................................LT-66

Headlamp leveler - See Headlamp aiming control ........

LT-66

Headlamp removal and installation ....................LT-30

Heat up switch .................................................EC-319

Heated seat .......................................................SE-12

Heater and cooling unit (Heater core) ..........ATC-124,

ATC-127

,MTC-103,MTC-106

Heater unit (heater core) ..............ATC-124,ATC-127,

MTC-103

,MTC-106

HEATUP - Wiring diagram ...............................EC-320

Height (Dimensions) ...........................................GI-60

HFC134a (R134a) system precaution .ATC-4,MTC-4

HFC134a (R134a) system service procedureATC-138,

MTC-118

HFC134a (R134a) system service tools ........ATC-16,

MTC-16

HFC134a system service equipment precaution ..........

ATC-12

,MTC-12

High and low reverse clutch solenoid valve ....AT-147,

AT-149

HLC - Wiring diagram ......................................WW-41

Horn .................................................................WW-59

HORN - Wiring diagram ...................................WW-59

How to erase DTC .............................................EC-27