transmission NISSAN NAVARA 2005 Repair Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1595 of 3171

FUEL TANK

FL-11

C

D

E

F

G

H

I

J

K

L

MA

FL

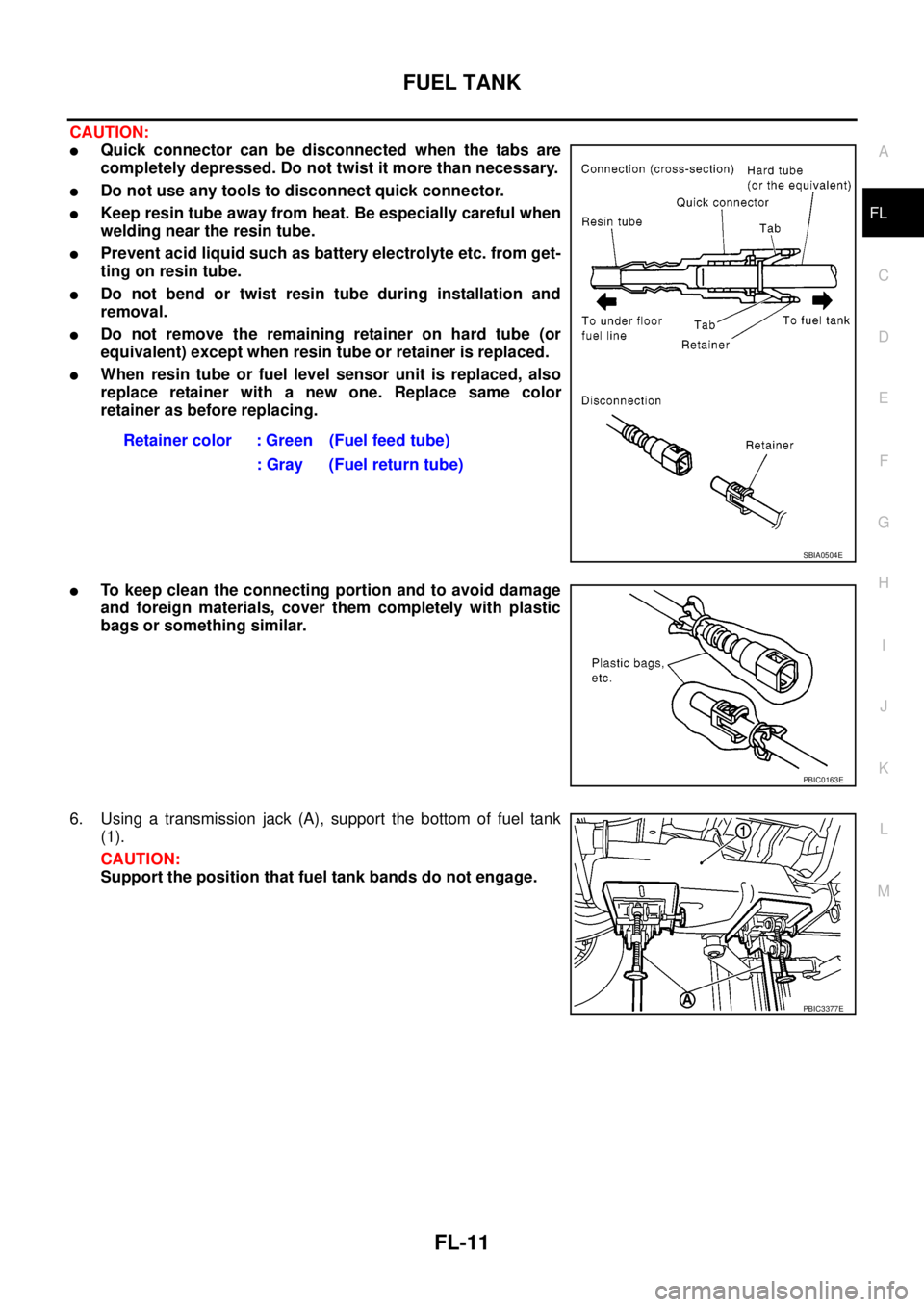

CAUTION:

lQuick connector can be disconnected when the tabs are

completely depressed. Do not twist it more than necessary.

lDo not use any tools to disconnect quick connector.

lKeep resin tube away from heat. Be especially careful when

welding near the resin tube.

lPrevent acid liquid such as battery electrolyte etc. from get-

ting on resin tube.

lDo not bend or twist resin tube during installation and

removal.

lDo not remove the remaining retainer on hard tube (or

equivalent) except when resin tube or retainer is replaced.

lWhen resin tube or fuel level sensor unit is replaced, also

replace retainer with a new one. Replace same color

retainer as before replacing.

lTo keep clean the connecting portion and to avoid damage

and foreign materials, cover them completely with plastic

bags or something similar.

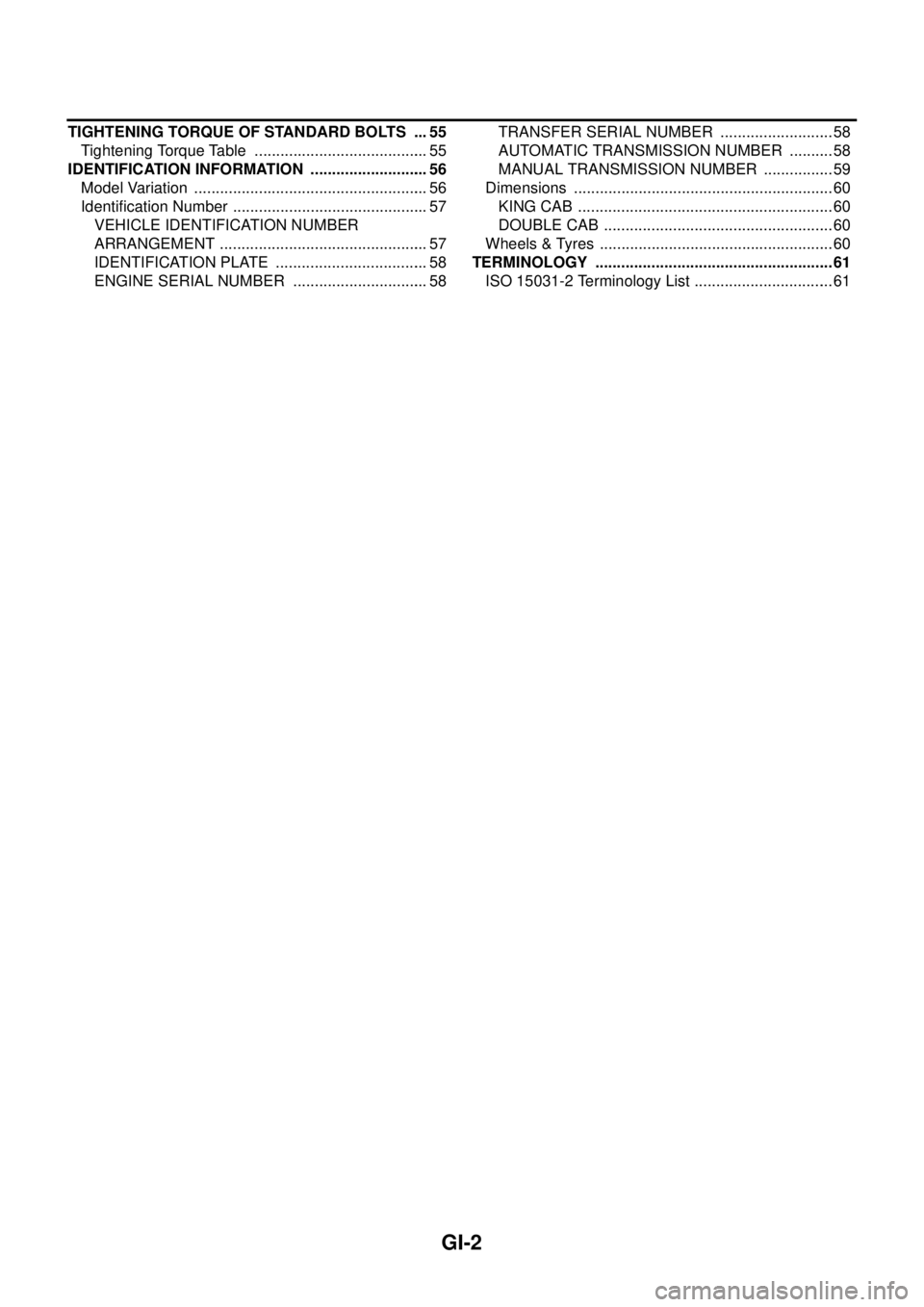

6. Using a transmission jack (A), support the bottom of fuel tank

(1).

CAUTION:

Support the position that fuel tank bands do not engage.Retainer color : Green (Fuel feed tube)

: Gray (Fuel return tube)

SBIA0504E

PBIC0163E

PBIC3377E

Page 1596 of 3171

FL-12

FUEL TANK

7. Remove fuel tank bands, and lower the transmission jack care-

fully until harness connector (A), EVAP tube (B), fuel filler hose

(E) and vent hose (F) can be disconnected.

8. Disconnect harness connector (A), EVAP tube (B), fuel filler

hose (E) and vent hose (F).

9. Supporting with hands, lower transmission jack carefully, and remove fuel tank.

CAUTION:

lPay attention not to fall fuel tank.

lMake sure that all connection points have been disconnected.

lConfirm there is no interference with vehicle.

10. Remove fuel filler tubes, fuel filler hoses and vent hoses if necessary.

INSTALLATION

Note the following, and install in the reverse order of removal.

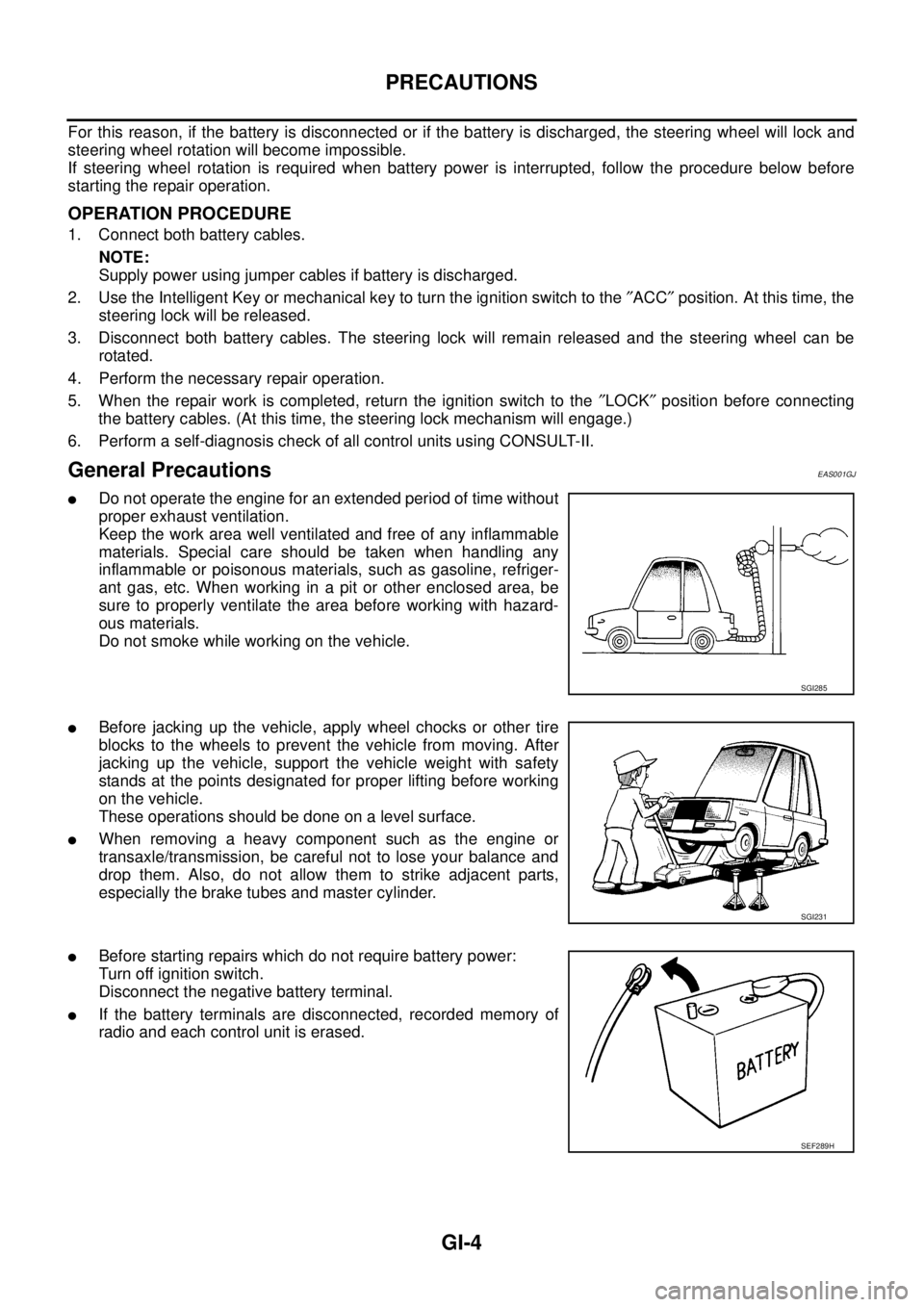

lSurely clamp fuel hoses and insert hose to the length below.

lBe sure hose clamp is not positioned on swelled area of fuel tube.

lTighten fuel hose clamp so that the flange (A) of bolt head is on

the paint mark (B) on the band.

lFit mounting band pin to the vehicle side securely.

lBefore fixing the fuel tank, temporarily install the fuel filler tube.

CAUTION:

Use genuine fuel filler tube mounting bolts or equivalent. Make sure to tighten them to the speci-

fied torque.

lConnect quick connector as follows.

1. Check connection for damage and foreign materials.

2. Align the connector with the tube, then insert connector straight into tube until a click is heard.

3. After connecting, make sure that the connection is secure by following the steps below.

lVisually confirm that the two tabs are connected to connector.

C : Fuel feed tube

D : Fuel return tube

PBIC3375E

Fuel filler hose : 35 mm (1.38 in)

The other hose : 25 mm (0.98 in)

PBIC4058E

Page 1624 of 3171

GI-2

TIGHTENING TORQUE OF STANDARD BOLTS .... 55

Tightening Torque Table ......................................... 55

IDENTIFICATION INFORMATION ............................ 56

Model Variation ....................................................... 56

Identification Number .............................................. 57

VEHICLE IDENTIFICATION NUMBER

ARRANGEMENT ................................................. 57

IDENTIFICATION PLATE .................................... 58

ENGINE SERIAL NUMBER ................................ 58TRANSFER SERIAL NUMBER ........................... 58

AUTOMATIC TRANSMISSION NUMBER ........... 58

MANUAL TRANSMISSION NUMBER ................. 59

Dimensions ............................................................. 60

KING CAB ............................................................ 60

DOUBLE CAB ...................................................... 60

Wheels & Tyres ....................................................... 60

TERMINOLOGY ........................................................ 61

ISO 15031-2 Terminology List ................................. 61

Page 1626 of 3171

GI-4

PRECAUTIONS

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the²ACC²position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the²LOCK²position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-II.

General PrecautionsEAS001GJ

lDo not operate the engine for an extended period of time without

proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any

inflammable or poisonous materials, such as gasoline, refriger-

ant gas, etc. When working in a pit or other enclosed area, be

sure to properly ventilate the area before working with hazard-

ous materials.

Do not smoke while working on the vehicle.

lBefore jacking up the vehicle, apply wheel chocks or other tire

blocks to the wheels to prevent the vehicle from moving. After

jacking up the vehicle, support the vehicle weight with safety

stands at the points designated for proper lifting before working

on the vehicle.

These operations should be done on a level surface.

lWhen removing a heavy component such as the engine or

transaxle/transmission, be careful not to lose your balance and

drop them. Also, do not allow them to strike adjacent parts,

especially the brake tubes and master cylinder.

lBefore starting repairs which do not require battery power:

Turn off ignition switch.

Disconnect the negative battery terminal.

lIf the battery terminals are disconnected, recorded memory of

radio and each control unit is erased.

SGI285

SGI231

SEF289H

Page 1627 of 3171

PRECAUTIONS

GI-5

C

D

E

F

G

H

I

J

K

L

MB

GI

lTo prevent serious burns:

Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

lDispose of drained oil or the solvent used for cleaning parts in

an appropriate manner.

lDo not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel

spray and possibly a fire.

lClean all disassembled parts in the designated liquid or solvent

prior to inspection or assembly.

lReplace oil seals, gaskets, packings, O-rings, locking washers, cotter pins, self-locking nuts, etc. with new

ones.

lReplace inner and outer races of tapered roller bearings and needle bearings as a set.

lArrange the disassembled parts in accordance with their assembled locations and sequence.

lDo not touch the terminals of electrical components which use microcomputers (such as ECM).

Static electricity may damage internal electronic components.

lAfter disconnecting vacuum or air hoses, attach a tag to indicate the proper connection.

lUse only the fluids and lubricants specified in this manual.

lUse approved bonding agent, sealants or their equivalents when required.

lUse tools and recommended special tools where specified for safe and efficient service repairs.

lWhen repairing the fuel, oil, water, vacuum or exhaust systems, check all affected lines for leaks.

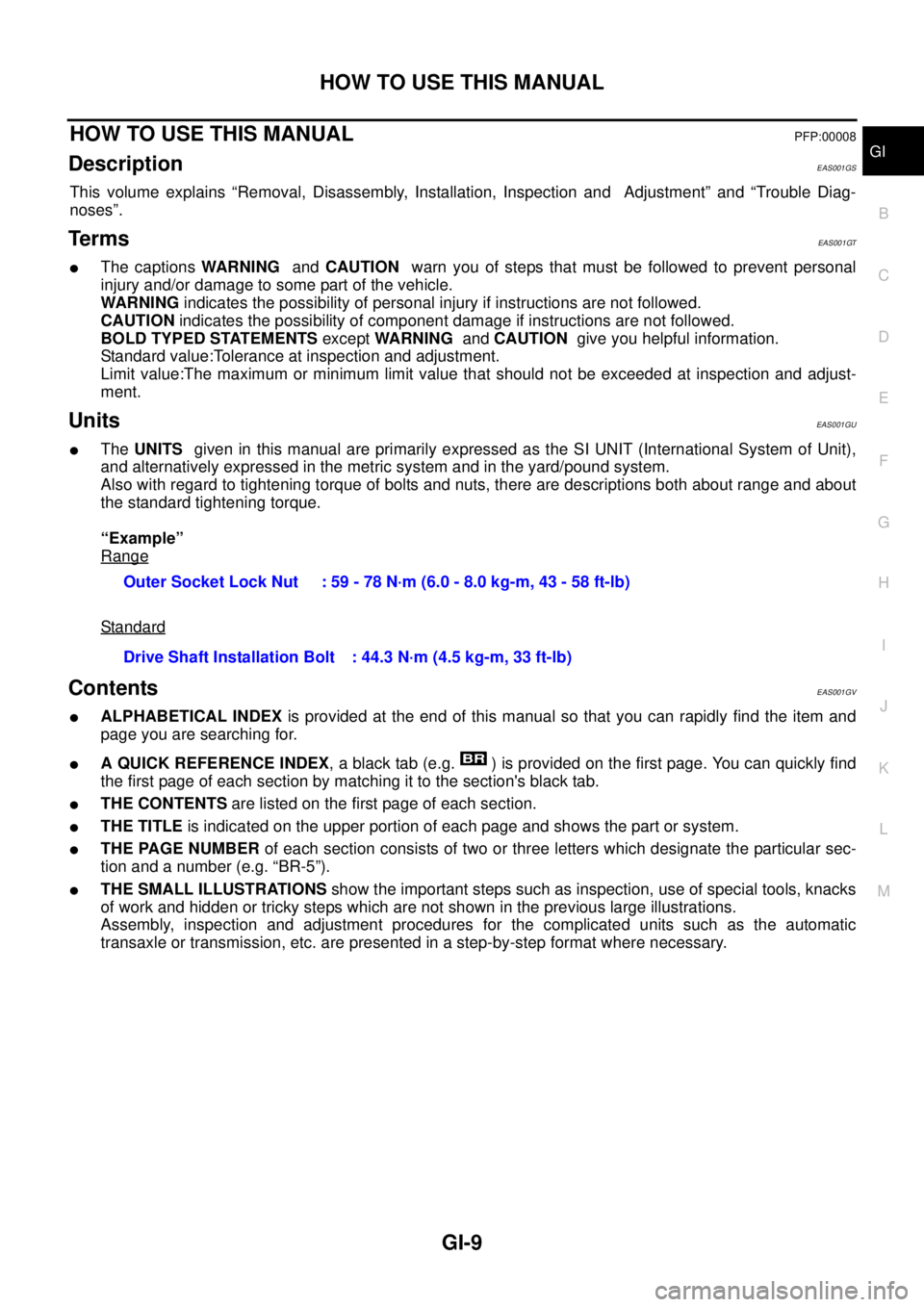

lBefore servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate cov-

ers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic trouble codes, do not carelessly disconnect the harness

connectors which are related to the engine control system and TCM (transmission control module)

system. The connectors should be disconnected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

Precautions for Three Way CatalystEAS001GL

If a large amount of unburned fuel flows into the catalyst, the catalyst temperature will be excessively high. To

prevent this, follow the instructions.

lUse unleaded gasoline only. Leaded gasoline will seriously damage the three way catalyst.

lWhen checking for ignition spark or measuring engine compression, make tests quickly and only when

necessary.

lDo not run engine when the fuel tank level is low, otherwise the engine may misfire, causing damage to

the catalyst.

Do not place the vehicle on flammable material. Keep flammable material off the exhaust pipe and the three

way catalyst.

Precautions for FuelEAS001GM

GASOLINE ENGINE

Use unleaded gasoline with an octane rating of at least 95 (RON).

SGI233

SGI234

Page 1631 of 3171

HOW TO USE THIS MANUAL

GI-9

C

D

E

F

G

H

I

J

K

L

MB

GI

HOW TO USE THIS MANUALPFP:00008

DescriptionEAS001GS

This volume explains “Removal, Disassembly, Installation, Inspection and Adjustment” and “Trouble Diag-

noses”.

TermsEAS001GT

lThe captionsWARNINGandCAUTIONwarn you of steps that must be followed to prevent personal

injury and/or damage to some part of the vehicle.

WARNINGindicates the possibility of personal injury if instructions are not followed.

CAUTIONindicates the possibility of component damage if instructions are not followed.

BOLD TYPED STATEMENTSexceptWARNINGandCAUTIONgive you helpful information.

Standard value:Tolerance at inspection and adjustment.

Limit value:The maximum or minimum limit value that should not be exceeded at inspection and adjust-

ment.

UnitsEAS001GU

lTheUNITSgiven in this manual are primarily expressed as the SI UNIT (International System of Unit),

and alternatively expressed in the metric system and in the yard/pound system.

Also with regard to tightening torque of bolts and nuts, there are descriptions both about range and about

the standard tightening torque.

“Example”

Range

Standard

ContentsEAS001GV

lALPHABETICAL INDEXis provided at the end of this manual so that you can rapidly find the item and

page you are searching for.

lA QUICK REFERENCE INDEX, a black tab (e.g. ) is provided on the first page. You can quickly find

the first page of each section by matching it to the section's black tab.

lTHE CONTENTSare listed on the first page of each section.

lTHE TITLEis indicated on the upper portion of each page and shows the part or system.

lTHE PAGE NUMBERof each section consists of two or three letters which designate the particular sec-

tion and a number (e.g. “BR-5”).

lTHE SMALL ILLUSTRATIONSshow the important steps such as inspection, use of special tools, knacks

of work and hidden or tricky steps which are not shown in the previous large illustrations.

Assembly, inspection and adjustment procedures for the complicated units such as the automatic

transaxle or transmission, etc. are presented in a step-by-step format where necessary.Outer Socket Lock Nut : 59 - 78 N·m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

Drive Shaft Installation Bolt : 44.3 N·m (4.5 kg-m, 33 ft-lb)

Page 1645 of 3171

HOW TO USE THIS MANUAL

GI-23

C

D

E

F

G

H

I

J

K

L

MB

GI

AbbreviationsEAS001GZ

The followingABBREVIATIONSare used:

ABBREVIATION DESCRIPTION

A/C Air Conditioner

A/T Automatic Transaxle/Transmission

ATF Automatic Transmission Fluid

D

1Drive range 1st gear

D

2Drive range 2nd gear

D

3Drive range 3rd gear

D

4Drive range 4th gear

FR, RR Front, Rear

LH, RH Left-Hand, Right-Hand

M/T Manual Transaxle/Transmission

OD Overdrive

P/S Power Steering

SAE Society of Automotive Engineers, Inc.

SDS Service Data and Specifications

SST Special Service Tools

2WD 2-Wheel Drive

2

22nd range 2nd gear

2

12nd range 1st gear

1

21st range 2nd gear

1

11st range 1st gear

Page 1646 of 3171

GI-24

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

PFP:00000

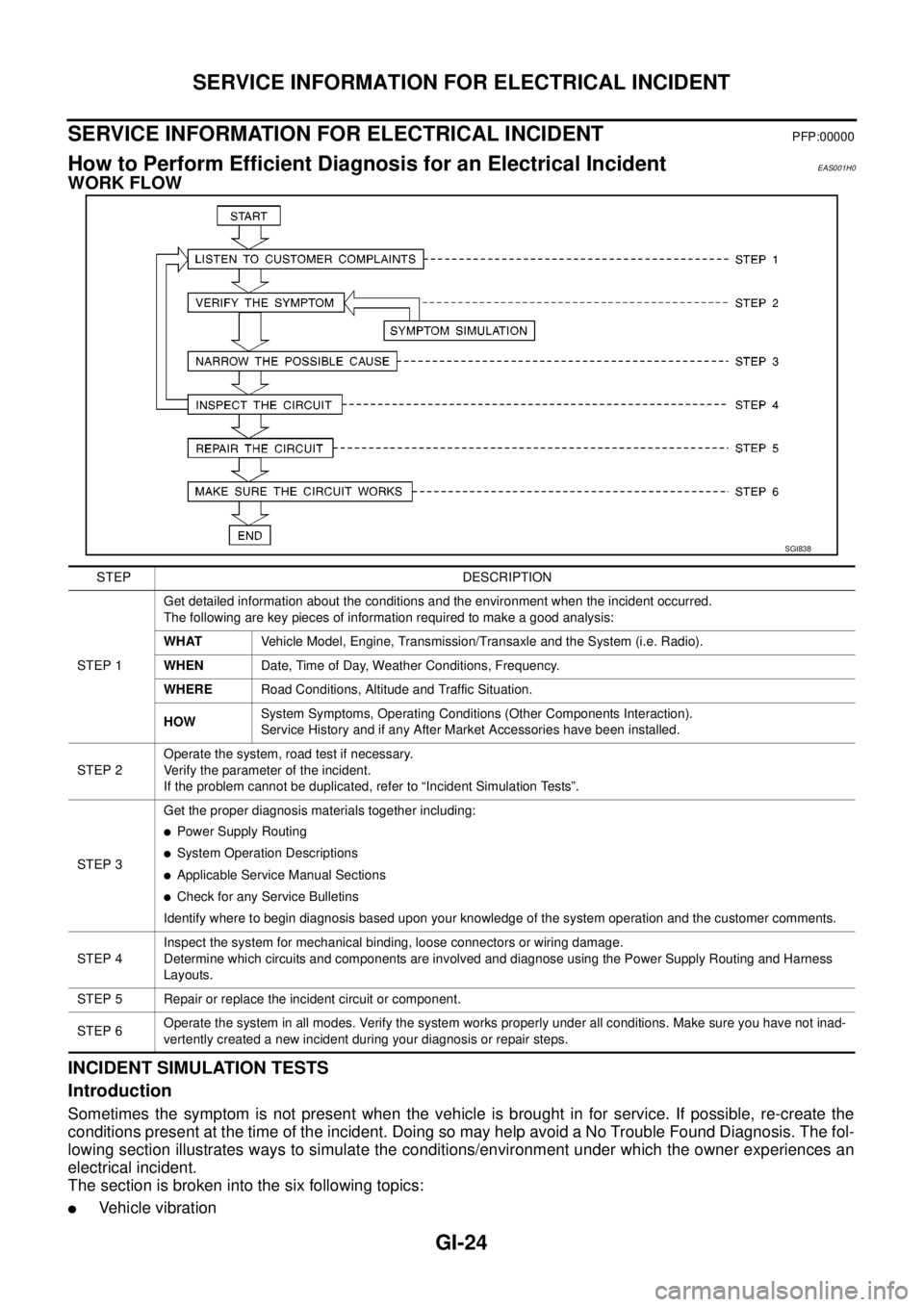

How to Perform Efficient Diagnosis for an Electrical IncidentEAS001H0

WORK FLOW

INCIDENT SIMULATION TESTS

Introduction

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doing so may help avoid a No Trouble Found Diagnosis. The fol-

lowing section illustrates ways to simulate the conditions/environment under which the owner experiences an

electrical incident.

The section is broken into the six following topics:

lVehicle vibration

SGI838

STEP DESCRIPTION

STEP 1Get detailed information about the conditions and the environment when the incident occurred.

The following are key pieces of information required to make a good analysis:

WHATVehicle Model, Engine, Transmission/Transaxle and the System (i.e. Radio).

WHENDate, Time of Day, Weather Conditions, Frequency.

WHERERoad Conditions, Altitude and Traffic Situation.

HOWSystem Symptoms, Operating Conditions (Other Components Interaction).

Service History and if any After Market Accessories have been installed.

STEP 2Operate the system, road test if necessary.

Verify the parameter of the incident.

If the problem cannot be duplicated, refer to “Incident Simulation Tests”.

STEP 3Get the proper diagnosis materials together including:

lPower Supply Routing

lSystem Operation Descriptions

lApplicable Service Manual Sections

lCheck for any Service Bulletins

Identify where to begin diagnosis based upon your knowledge of the system operation and the customer comments.

STEP 4Inspect the system for mechanical binding, loose connectors or wiring damage.

Determine which circuits and components are involved and diagnose using the Power Supply Routing and Harness

Layouts.

STEP 5 Repair or replace the incident circuit or component.

STEP 6Operate the system in all modes. Verify the system works properly under all conditions. Make sure you have not inad-

vertently created a new incident during your diagnosis or repair steps.

Page 1675 of 3171

TOW TRUCK TOWING

GI-53

C

D

E

F

G

H

I

J

K

L

MB

GI

TOW TRUCK TOWINGPFP:00000

To w Tr u c k To w i n gEAS001DI

WARNING:

lNever get under the vehicle while it is supported only by the jack. Always use safety stands to

support the frame when you have to get under the vehicle.

lPlace wheel chocks at both front and back of the wheels on the ground.

CAUTION:

lAll applicable local laws regarding the towing operation must be obeyed.

lIt is necessary to use proper towing equipment to avoid possible damage during towing opera-

tion. Towing is in accordance with Towing Procedure Manual at dealer.

lAlways attach safety chains before towing.

lWhen towing, make sure that the transmission, steering system and powertrain are in good order.

If any unit is damaged, dollies must be used.

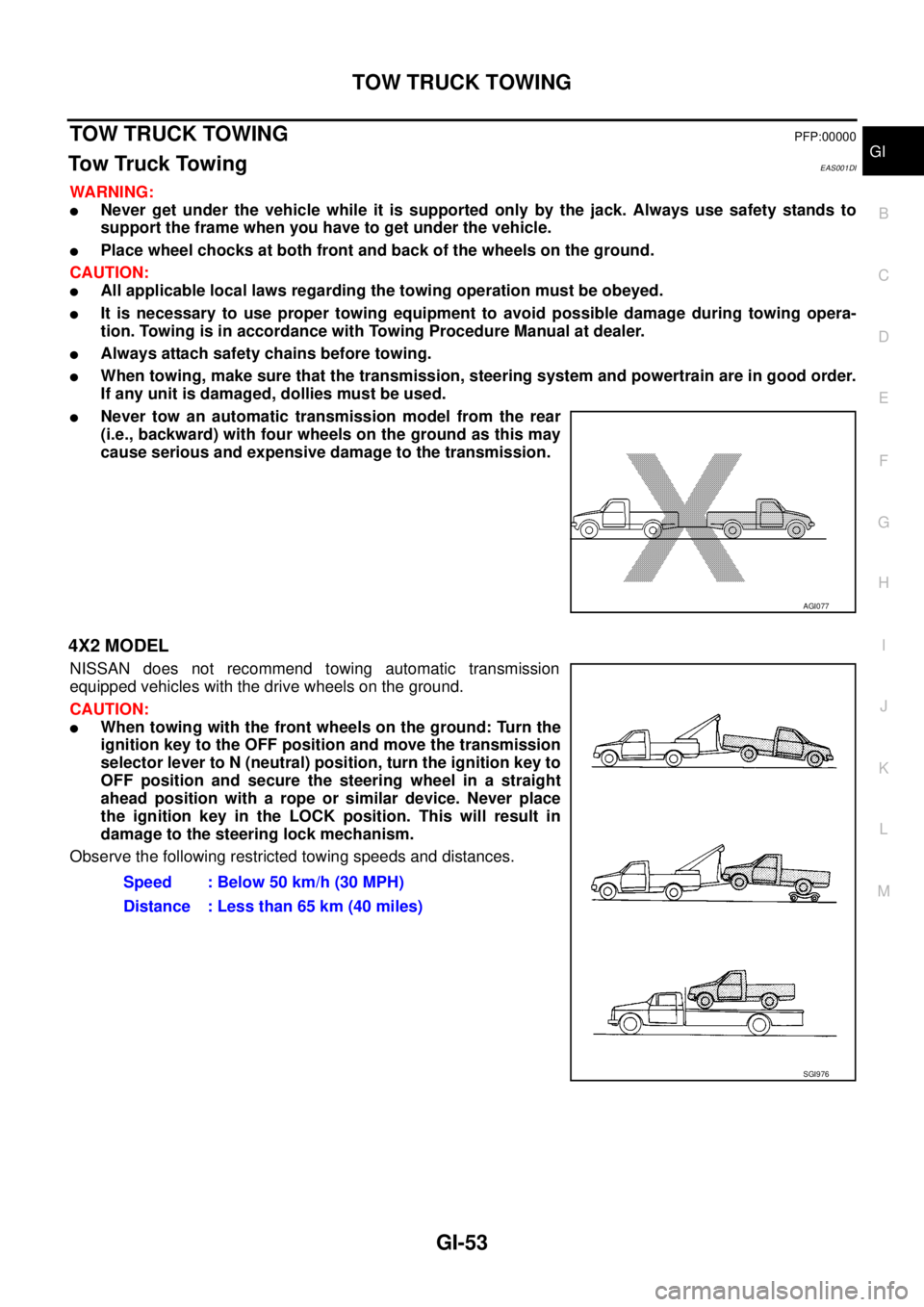

lNever tow an automatic transmission model from the rear

(i.e., backward) with four wheels on the ground as this may

cause serious and expensive damage to the transmission.

4X2 MODEL

NISSAN does not recommend towing automatic transmission

equipped vehicles with the drive wheels on the ground.

CAUTION:

lWhen towing with the front wheels on the ground: Turn the

ignition key to the OFF position and move the transmission

selector lever to N (neutral) position, turn the ignition key to

OFF position and secure the steering wheel in a straight

ahead position with a rope or similar device. Never place

the ignition key in the LOCK position. This will result in

damage to the steering lock mechanism.

Observe the following restricted towing speeds and distances.

AGI077

Speed : Below 50 km/h (30 MPH)

Distance : Less than 65 km (40 miles)

SGI976

Page 1676 of 3171

GI-54

TOW TRUCK TOWING

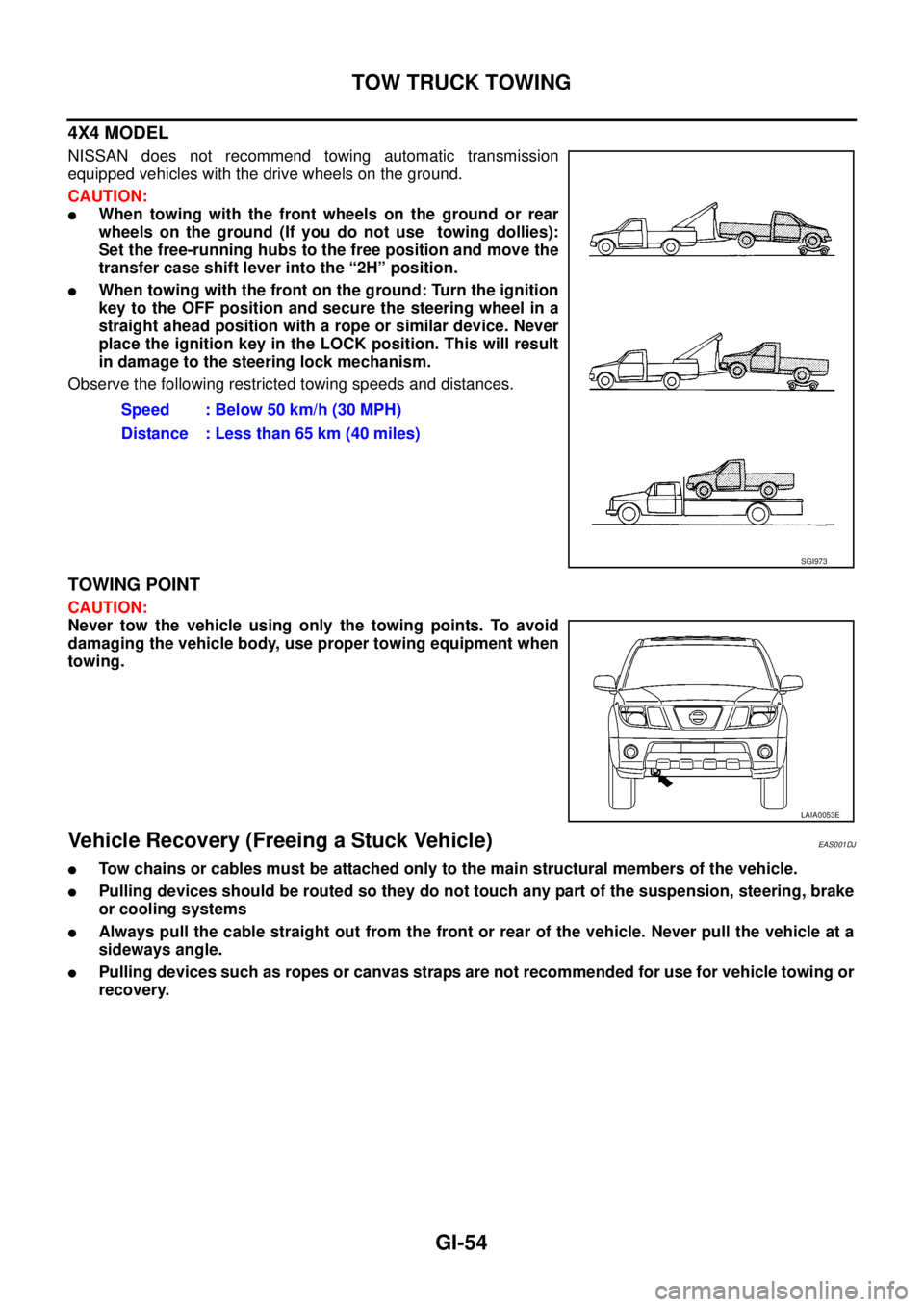

4X4 MODEL

NISSAN does not recommend towing automatic transmission

equipped vehicles with the drive wheels on the ground.

CAUTION:

lWhen towing with the front wheels on the ground or rear

wheels on the ground (If you do not use towing dollies):

Set the free-running hubs to the free position and move the

transfer case shift lever into the “2H” position.

lWhen towing with the front on the ground: Turn the ignition

key to the OFF position and secure the steering wheel in a

straight ahead position with a rope or similar device. Never

place the ignition key in the LOCK position. This will result

in damage to the steering lock mechanism.

Observe the following restricted towing speeds and distances.

TOWING POINT

CAUTION:

Never tow the vehicle using only the towing points. To avoid

damaging the vehicle body, use proper towing equipment when

towing.

Vehicle Recovery (Freeing a Stuck Vehicle)EAS001DJ

lTow chains or cables must be attached only to the main structural members of the vehicle.

lPulling devices should be routed so they do not touch any part of the suspension, steering, brake

or cooling systems

lAlways pull the cable straight out from the front or rear of the vehicle. Never pull the vehicle at a

sideways angle.

lPulling devices such as ropes or canvas straps are not recommended for use for vehicle towing or

recovery.Speed : Below 50 km/h (30 MPH)

Distance : Less than 65 km (40 miles)

SGI973

LAIA0053E