Time NISSAN NOTE 2008 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: NOTE, Model: NISSAN NOTE 2008Pages: 235, PDF Size: 2.29 MB

Page 153 of 235

Normal operation

The ABS will not initiate at speeds below 5 to 10

km/h (3 to 6 MPH). The speeds will vary according

to road conditions.

When the ABS senses that one or more wheels are

close to locking up, the actuator rapidly applies and

releases hydraulic pressure. This action is similar to

pumping the brakes very quickly. You may feel a

pulsation in the brake pedal and hear a noise from

the actuator under the bonnet when it is operating.

This is normal and indicates that the ABS is working

properly. However, the pulsation may indicate that

road conditions are hazardous and extra care is re-

quired while driving.When accelerating, driving on slippery surfaces or

suddenly avoiding obstacles on roads, the vehicle

might swerve or slip. The Electronic Stability Pro-

gramme (ESP) system continuously monitors and

compares the driver’s intended speed and the travel

direction. The system adjusts wheel brake pressure

and engine torque to assist in improving vehicle sta-

bility.

•When the ESP system is operating, the “SLIP”

indicator light () in the combination meter

blinks.

•When only the traction control (TCS) system in

the ESP system is operating, the “SLIP” indica-

tor light (

) in the combination meter will also

blink.

•If the “SLIP” indicator light () blinks, the

road conditions are slippery. Be sure to drive

carefully. See “Warning/indicator lights and au-

dible reminders” in the “2. Instruments and

controls” section.

•Indicator light

If a malfunction occurs in the system, the “SLIP”

indicator light (

) and the ESP indicator light

() come on in the combination meter.

As long as these indicator lights are on, the trac-

tion control function is cancelled.

The ESP system uses Active Brake Limited Slip

(ABLS) system to improve vehicle traction. The Ac-

tive Brake Limited Slip (ABLS) system works when

one of the driving wheels is spinning on a slipperysurface. The Active Brake Limited Slip (ABLS) sys-

tem, brakes the spinning wheel to distribute the driv-

ing power to the other driving wheel.

If the vehicle is operated with the ESP system turned

off, all ESP and TCS functions will be turned off.

The Active Brake Limited Slip (ABLS) system and

ABS will still operate with the ESP system off. If the

Active Brake Limited Slip (ABLS) system or the ABS

is activated, the “SLIP” indicator light (

) will

blink and you may hear a clunk noise and/or feel a

pulsation in the brake pedal. This is normal and does

not indicate a malfunction.

While the ESP system is operating, you may feel a

pulsation in the brake pedal and hear a noise or

vibration from under the bonnet. This is normal and

indicates that the ESP system is working properly.

The ESP computer has a built in diagnostic feature

that tests the system each time the engine is started

and the vehicle moves forwards or reverses at a

slow speed. When the self-test occurs, you may

hear a clunk noise and/or feel a pulsation in the

brake pedal. This is normal and is not an indication

of a malfunction.

WARNING

•The ESP system is designed to help improve

driving stability but does not prevent accidents

caused by abrupt steering operation at high

speeds, or careless or dangerous driving

techniques. Reduce vehicle speed and be es-

pecially careful when driving and cornering on

slippery surfaces. Always drive carefully.

ELECTRONIC STABILITY PROGRAMME (ESP) SYSTEM (where fitted)

Starting and driving5-29

Page 158 of 235

TEMPORARY-USE SPARE TYRE

The temporary-use spare tyre is smaller than a con-

ventional tyre and designed for emergency use only.

The tyre should be used ONLY for very short peri-

ods and NEVER be used for long drives or extended

periods.

Observe the following precautions if the temporary-

use spare tyre must be used, otherwise your vehicle

could be damaged or involved in an accident.

WARNING

•Any continuous road use of this tyre could

result in tyre failure, loss of vehicle control,

and possible personal injury.

•This tyre should not be installed on the front

axle if the vehicle must be driven in snow or

on ice. To avoid loss of vehicle control under

snowy and icy conditions, install the tempo-

rary-use spare tyre on the rear axle and use a

conventional tyre on the front axle.CAUTION

•The temporary-use spare tyre should be used

only in emergencies. It should be replaced by

the standard tyre at the first opportunity.

•Under no circumstances should you exceed

80 km/h (50 MPH); a higher speed could dam-

age the tyre.

•Avoid driving over obstacles. Also, do not take

the vehicle through an automatic car wash.

Because this tyre’s diameter is smaller than

the diameter of a conventional tyre, the

ground clearance is reduced approximately

25 mm (1 in.).

•Avoid driving sharp turns and abrupt braking.

•Do not exceed the vehicle’s maximum load

rating or the load-carrying capacity molded

on the sidewall of the temporary-use spare

tyre.

•Do not use a snow chain on this tyre. Because

of it’s smaller size, a snow chain will not fit

properly. This could cause damage to the ve-

hicle and result in loss of the chain.

•Do not use the temporary-use spare tyre on

any other vehicle because this tyre has been

designed specifically for your vehicle.

•The vehicle must not be driven with more than

one temporary-use spare tyre at the same

time.

•Tyre tread will wear at a faster rate on the

temporary-use spare tyre than on the original.

Replace the temporary spare tyre as soon as

the tread wear indicators appear.

•Do not tow a trailer.

•As with all tyres, the temporary-use spare tyre

must be checked regularly to ensure pres-

sure is maintained.

For pressure details, see the tyre placard lo-

cated on the driver’s side centre pillar.

NCE069Z

Temporary-use spare tyre label

SPARE TYRE

6-2In case of emergency

Page 162 of 235

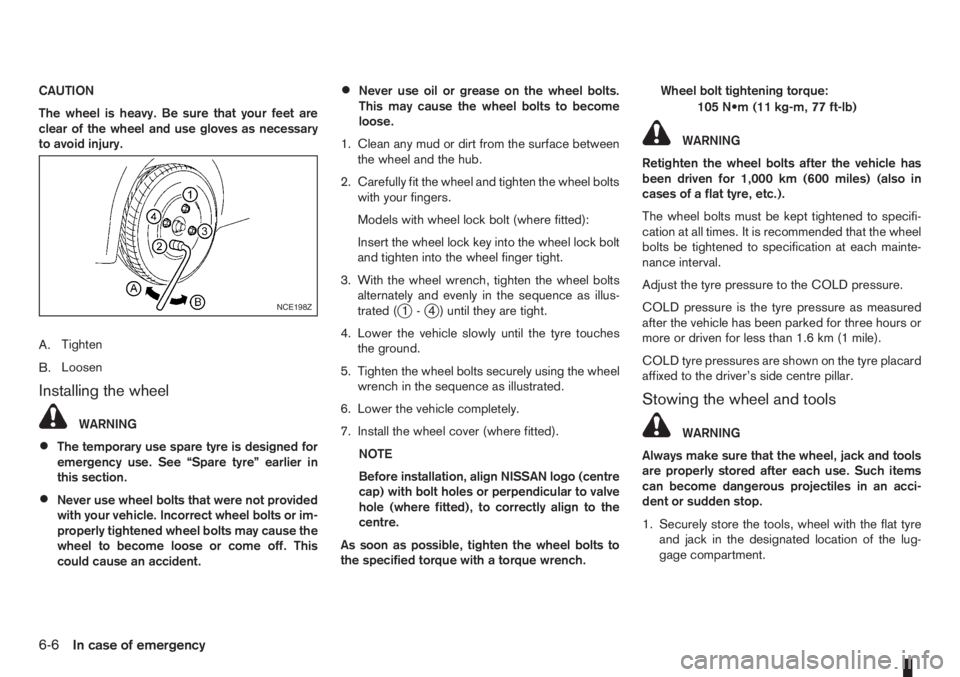

CAUTION

The wheel is heavy. Be sure that your feet are

clear of the wheel and use gloves as necessary

to avoid injury.

A.Tighten

B.Loosen

Installing the wheel

WARNING

•The temporary use spare tyre is designed for

emergency use. See “Spare tyre” earlier in

this section.

•Never use wheel bolts that were not provided

with your vehicle. Incorrect wheel bolts or im-

properly tightened wheel bolts may cause the

wheel to become loose or come off. This

could cause an accident.

•Never use oil or grease on the wheel bolts.

This may cause the wheel bolts to become

loose.

1. Clean any mud or dirt from the surface between

the wheel and the hub.

2. Carefully fit the wheel and tighten the wheel bolts

with your fingers.

Models with wheel lock bolt (where fitted):

Insert the wheel lock key into the wheel lock bolt

and tighten into the wheel finger tight.

3. With the wheel wrench, tighten the wheel bolts

alternately and evenly in the sequence as illus-

trated (

j1-j4 ) until they are tight.

4. Lower the vehicle slowly until the tyre touches

the ground.

5. Tighten the wheel bolts securely using the wheel

wrench in the sequence as illustrated.

6. Lower the vehicle completely.

7. Install the wheel cover (where fitted).

NOTE

Before installation, align NISSAN logo (centre

cap) with bolt holes or perpendicular to valve

hole (where fitted), to correctly align to the

centre.

As soon as possible, tighten the wheel bolts to

the specified torque with a torque wrench.Wheel bolt tightening torque:

105 N•m (11 kg-m, 77 ft-lb)

WARNING

Retighten the wheel bolts after the vehicle has

been driven for 1,000 km (600 miles) (also in

cases of a flat tyre, etc.).

The wheel bolts must be kept tightened to specifi-

cation at all times. It is recommended that the wheel

bolts be tightened to specification at each mainte-

nance interval.

Adjust the tyre pressure to the COLD pressure.

COLD pressure is the tyre pressure as measured

after the vehicle has been parked for three hours or

more or driven for less than 1.6 km (1 mile).

COLD tyre pressures are shown on the tyre placard

affixed to the driver’s side centre pillar.

Stowing the wheel and tools

WARNING

Always make sure that the wheel, jack and tools

are properly stored after each use. Such items

can become dangerous projectiles in an acci-

dent or sudden stop.

1. Securely store the tools, wheel with the flat tyre

and jack in the designated location of the lug-

gage compartment.

NCE198Z

6-6In case of emergency

Page 178 of 235

Your new NISSAN has been designed to have mini-

mum maintenance requirements with longer service

intervals, to save you both time and money. How-

ever, some day-to-day and regular maintenance is

essential to maintain your NISSAN’s good mechani-

cal condition, as well as its emission and engine

performance.

It is the owner’s responsibility to make sure that the

specified maintenance, as well as general mainte-

nance, is performed.

As the vehicle owner, you are the only one who can

ensure that your vehicle receives the proper mainte-

nance care.

SCHEDULED MAINTENANCE

For your convenience, the required scheduled main-

tenance items are described and listed in the sepa-

rately provided Warranty Information and Mainte-

nance booklet. You must refer to that booklet to

ensure that necessary maintenance is performed on

your NISSAN vehicle at regular intervals.

GENERAL MAINTENANCE

General maintenance includes those items which

should be checked during normal day-to-day opera-

tion of the vehicle. They are essential if your vehicle

is to continue to operate properly. It is your respon-

sibility to perform these procedures regularly as pre-

scribed.

Performing general maintenance checks requires

minimal mechanical skill and a few general automo-

tive tools.These checks or inspections can be done by your-

self, a qualified technician or, if you prefer, your

NISSAN dealer or qualified workshop.

WHERE TO GO FOR SERVICE

If maintenance service is required or your vehicle

appears to malfunction, have your vehicle checked

and tuned by an authorised NISSAN dealer or quali-

fied workshop.During the normal day-to-day operation of the ve-

hicle, general maintenance should be performed

regularly as prescribed in this section. If you detect

any unusual sounds, vibrations or smell, be sure to

check for the cause or have a NISSAN dealer or

qualified workshop do it promptly. In addition, you

should notify a NISSAN dealer or qualified work-

shop if repairs are required.

When performing any checks or maintenance work,

closely observe the “Maintenance precautions” later

in this section.

EXPLANATION OF GENERAL

MAINTENANCE ITEMS

Additional information on the following items with

an asterisk (*) is found later in this section.

The maintenance items listed here should be per-

formed from time to time, unless otherwise speci-

fied.

Outside the vehicle

Back door, doors and bonnet:

Check that the back door, all doors and the bonnet

operate properly. Also ensure that all latches lock

securely. Lubricate hinges and latches if necessary.

Make sure that the secondary latch keeps the bon-

net from opening when the primary latch is released.

When driving in areas using road salt or other cor-

rosive materials, check for lubrication frequently.

MAINTENANCE REQUIREMENTS GENERAL MAINTENANCE

8-2Maintenance and do-it-yourself

Page 179 of 235

Lights*:

Clean the headlights on a regular basis. Make sure

that the headlights, stop lights, tail lights, turn signal

lights, and other lights are all operating properly and

installed securely. Also check headlight aim.

Tyres*:

Check the pressure with a gauge periodically when

at a service station (including the spare) and adjust

to the specified pressure if necessary. Check care-

fully for damage, cuts or excessive wear.

Tyre rotation*:

Tyres should be rotated at least every 10,000 km

(6,000 miles). However, the timing for tyre rotation

may vary according to your driving habits and road

surface conditions.

Wheel alignment and balance:

If the vehicle pull to either side while driving on a

straight and level road, or if you detect uneven or

abnormal tyre wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at

normal highway speeds, wheel balancing may be

needed.

Wheel bolts:

When checking the tyres, make sure no wheel bolts

are missing, and check for any loose wheel bolts.

Tighten if necessary.Windscreen:

Clean the windscreen on a regular basis. Check the

windscreen at least every six months for cracks or

other damage. Have a damaged windscreen re-

paired by a qualified repair facility.

Wiper blades*:

Check for cracks or wear if they do not wipe prop-

erly.

Under the bonnet and vehicle

The maintenance items listed here should be

checked periodically, e.g. each time you check the

engine oil or refuel.

Battery*:

Check if the green indicator on the top of the main-

tenance free battery is visible. If it is not visible,

replace the battery as soon as possible.

Vehicles operated in high temperatures or under

severe conditions, check the fluid level frequently.

Brake and clutch fluid level*:

Make sure that the brake and clutch fluid level is

between the MAX and MIN lines on the reservoir.

Engine coolant level*:

Check the coolant level when the engine is cold.

Engine drive belts*:

Make sure that the drive belts are not frayed, worn,

cracked or oily.Engine oil level*:

Check the level after parking the vehicle on a level

surface and turning off the engine.

Fluid leaks:

Check under the vehicle for fuel, oil, water or other

fluid leaks after the vehicle has been parked for a

while. Water dripping from the air conditioner after

use is normal. If you should notice any leaks or if

petrol fumes are evident, check for the cause and

have it corrected immediately.

Window washer fluid*:

Check that there is adequate fluid in the tank.

Inside the vehicle

The maintenance items listed here should be

checked on a regular basis, such as when perform-

ing periodic maintenance, cleaning the vehicle, etc.

Accelerator pedal:

Check the pedal for smooth operation and make

sure that the pedal does not catch or require uneven

effort. Keep the floor mats away from the pedal.

Brake pedal*:

Check the pedal for smooth operation. If the brake

pedal suddenly goes down further than normal, the

pedal feels spongy or the vehicle seems to take

longer to stop, contact a NISSAN dealer or qualified

workshop immediately. Keep the floor mat away

from the pedal.

Maintenance and do-it-yourself8-3

Page 183 of 235

WARNING

•To avoid the danger of being scalded, never

change the coolant when the engine is hot.

•Avoid direct skin contact with used coolant. If

skin contact is made, wash thoroughly with

soap or hand cleaner and plenty of water as

soon as possible.

•Keep coolant out of reach of children and

pets.

NISSAN GREEN PROGRAM

Engine coolant must be disposed of properly.

Check your local regulations.

CR14DE or HR16DE engine

1. Set the heater or air conditioner temperature

control to the maximum “HOT” position.

2. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

3. Open the radiator cap

j1 (where fitted) or en-

gine coolant reservoir cap to help to drain the

coolant.

4. Slacken off the radiator lower hose clip

j2and

remove the lower hosej3 to drain the coolant.

5. Flush the cooling system by running clean water

through the radiator filler opening (where fitted)

or engine coolant reservoir.

6. Install the radiator lower hose on the radiator

securely.7. Fill the radiator through the filler opening (where

applicable) slowly with coolant and fill the cool-

ant reservoir up to the MAX level. See “Capaci-

ties and recommended fuel/lubricants” in the

“9. Technical information” section for cooling

system capacity.

8. Install the radiator cap (where fitted) and the en-

gine coolant reservoir cap.

9. Start the engine, and warm it up until the radiator

fan operates. Then rev the engine two or three

times under no load. Observe the coolant tem-

perature warning light for signs of overheating.

10. Stop the engine. After it has completely cooled

down, refill the radiator up to the filler opening

(where fitted). If the coolant level lowered, fill

the engine coolant reservoir up to the MAX level.

11. Check radiator lower hose for any signs of leak-

age.

12. Close the bonnet.

K9K engine

1. Set the heater or air conditioner temperature

control to the maximum “HOT” position.

2. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

3. Disconnect the radiator lower hose

j1 and open

the drain plugj2 on the engine block.

4. Open the engine coolant reservoir cap to help to

drain the coolant.

5. Flush the cooling system by running fresh water

through the radiator.

6. Install the radiator lower hose to the radiator and

securely tighten the engine block drain plug.

7. Fill the reservoir up to the MAX level with cool-

ant. See “Capacities and recommended

fuel/lubricants” in the “9. Technical information”

section for cooling system capacity.

8. Install the engine coolant reservoir cap.

9. Start the engine and run the engine at about

2,000 rpm for 1 minute.

10. Stop the engine and check coolant level, allow

to cool and refill up to the MAX level.

11. Warm up the engine at about 2,000 rpm until it

reaches the normal operational temperature

(fan cycles).

Check heater core (below instrument panel) for

gurgling, refill if necessary.

NDI671Z

K9K engine

Maintenance and do-it-yourself8-7

Page 186 of 235

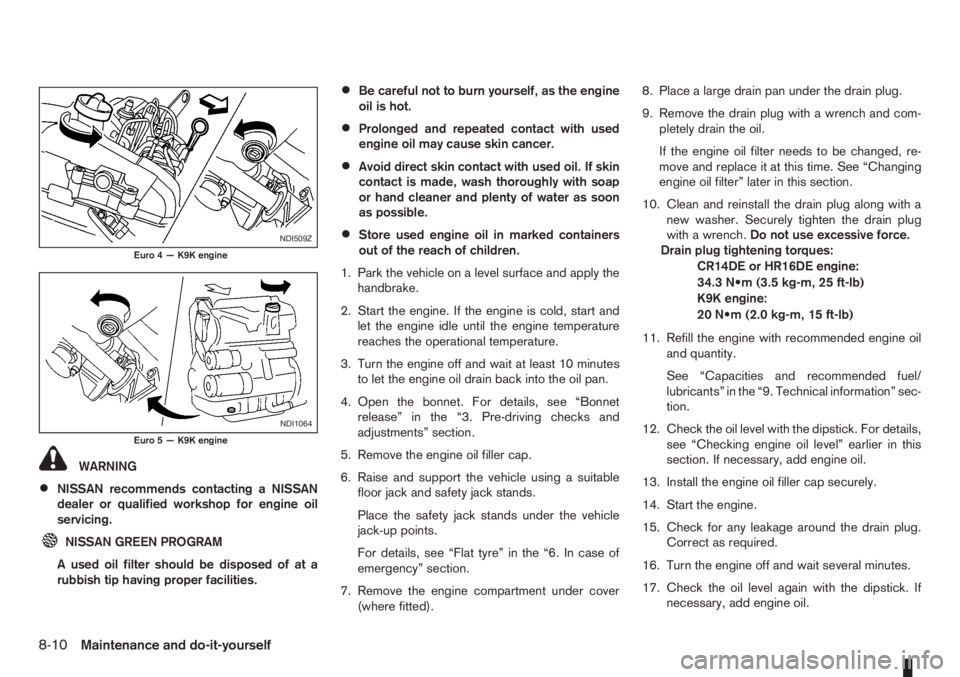

WARNING

•NISSAN recommends contacting a NISSAN

dealer or qualified workshop for engine oil

servicing.

NISSAN GREEN PROGRAM

A used oil filter should be disposed of at a

rubbish tip having proper facilities.

•Be careful not to burn yourself, as the engine

oil is hot.

•Prolonged and repeated contact with used

engine oil may cause skin cancer.

•Avoid direct skin contact with used oil. If skin

contact is made, wash thoroughly with soap

or hand cleaner and plenty of water as soon

as possible.

•Store used engine oil in marked containers

out of the reach of children.

1. Park the vehicle on a level surface and apply the

handbrake.

2. Start the engine. If the engine is cold, start and

let the engine idle until the engine temperature

reaches the operational temperature.

3. Turn the engine off and wait at least 10 minutes

to let the engine oil drain back into the oil pan.

4. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

5. Remove the engine oil filler cap.

6. Raise and support the vehicle using a suitable

floor jack and safety jack stands.

Place the safety jack stands under the vehicle

jack-up points.

For details, see “Flat tyre” in the “6. In case of

emergency” section.

7. Remove the engine compartment under cover

(where fitted).8. Place a large drain pan under the drain plug.

9. Remove the drain plug with a wrench and com-

pletely drain the oil.

If the engine oil filter needs to be changed, re-

move and replace it at this time. See “Changing

engine oil filter” later in this section.

10. Clean and reinstall the drain plug along with a

new washer. Securely tighten the drain plug

with a wrench.Do not use excessive force.

Drain plug tightening torques:

CR14DE or HR16DE engine:

34.3 N•m (3.5 kg-m, 25 ft-lb)

K9K engine:

20 N•m (2.0 kg-m, 15 ft-lb)

11. Refill the engine with recommended engine oil

and quantity.

See “Capacities and recommended fuel/

lubricants” in the “9. Technical information” sec-

tion.

12. Check the oil level with the dipstick. For details,

see “Checking engine oil level” earlier in this

section. If necessary, add engine oil.

13. Install the engine oil filler cap securely.

14. Start the engine.

15. Check for any leakage around the drain plug.

Correct as required.

16. Turn the engine off and wait several minutes.

17. Check the oil level again with the dipstick. If

necessary, add engine oil.NDI509Z

Euro 4 — K9K engine

NDI1064

Euro 5 — K9K engine

8-10Maintenance and do-it-yourself

Page 188 of 235

8. Turn the engine off and wait several minutes.

Check the oil level and add engine oil, if neces-

sary.

9. Install the engine compartment under cover

(where fitted).

10. Lower the vehicle carefully to the ground.

11. Close the bonnet.

PROTECT THE ENVIRONMENT

NISSAN GREEN PROGRAM

It is illegal to pollute drains, water courses and soil.

Use authorised waste collection facilities, including

civic amenity sites and garages providing facilities

for the disposal of used oil and used oil filters. If in

doubt, contact your local authority for advice on dis-

posal.

The regulations concerning the pollution of the

environment will vary from country to country.

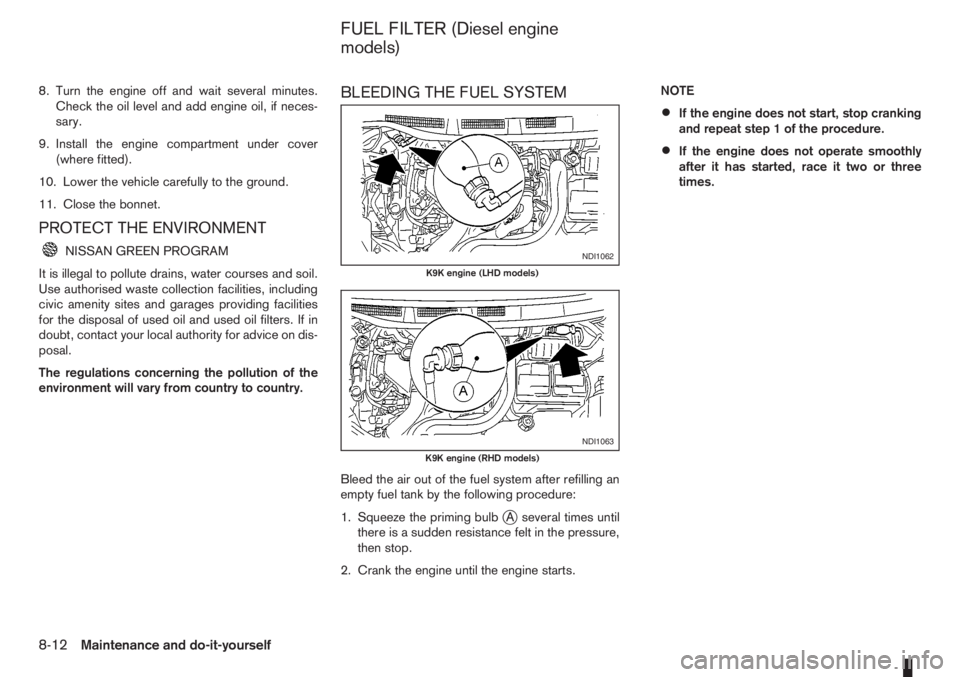

BLEEDING THE FUEL SYSTEM

Bleed the air out of the fuel system after refilling an

empty fuel tank by the following procedure:

1. Squeeze the priming bulb

jA several times until

there is a sudden resistance felt in the pressure,

then stop.

2. Crank the engine until the engine starts.NOTE

•If the engine does not start, stop cranking

and repeat step 1 of the procedure.

•If the engine does not operate smoothly

after it has started, race it two or three

times.

NDI1062

K9K engine (LHD models)

NDI1063

K9K engine (RHD models)

FUEL FILTER (Diesel engine

models)

8-12Maintenance and do-it-yourself

Page 192 of 235

ommends to visually check the green indicatorjA status periodically. If it is not visible, replace

the battery as soon as possible.

•If battery replacement or check is required, con-

tact a NISSAN dealer or qualified workshop.

REINITIALISATION PROCEDURE

AFTER BATTERY RECONNECTION

Power window (Driver’s side —

where fitted)

When the vehicle battery has been connected, the

system must be reinitialised as follows:

1. Push down and hold the driver’s side window

switch until the window glass is completely low-

ered then release the switch.

2.In one continuous operation, pull up and hold

the driver’s side window switch until the window

glass is completely closed and continue holding

the switch for a further 5 seconds.

3. The system is now reinitialised.

Repeat the procedure every time the vehicle battery

is connected.

If the reinitialisation procedure cannot be performed

successfully, take your vehicle to a NISSAN dealer

or qualified workshop.

JUMP-STARTING

If jump-starting is necessary, see “Jump-starting” in

the “6. In case of emergency” section. If the engine

does not start by jump starting, the battery may have

to be replaced. Contact a NISSAN dealer or quali-

fied workshop.

8-16Maintenance and do-it-yourself

Page 199 of 235

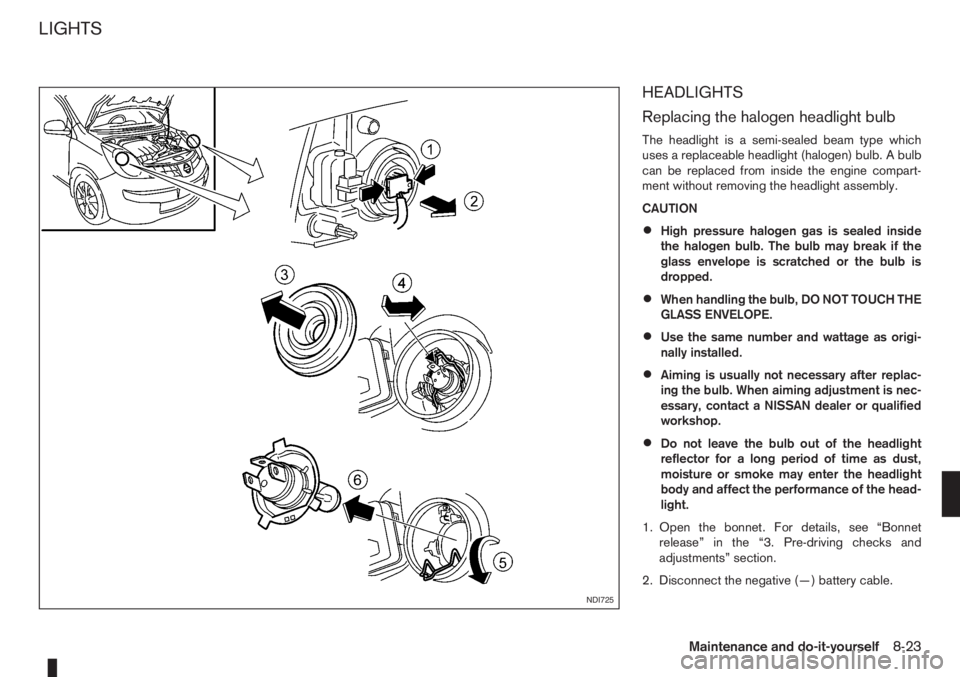

HEADLIGHTS

Replacing the halogen headlight bulb

The headlight is a semi-sealed beam type which

uses a replaceable headlight (halogen) bulb. A bulb

can be replaced from inside the engine compart-

ment without removing the headlight assembly.

CAUTION

•High pressure halogen gas is sealed inside

the halogen bulb. The bulb may break if the

glass envelope is scratched or the bulb is

dropped.

•When handling the bulb, DO NOT TOUCH THE

GLASS ENVELOPE.

•Use the same number and wattage as origi-

nally installed.

•Aiming is usually not necessary after replac-

ing the bulb. When aiming adjustment is nec-

essary, contact a NISSAN dealer or qualified

workshop.

•Do not leave the bulb out of the headlight

reflector for a long period of time as dust,

moisture or smoke may enter the headlight

body and affect the performance of the head-

light.

1. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

2. Disconnect the negative (—) battery cable.

NDI725

LIGHTS

Maintenance and do-it-yourself8-23