wheel NISSAN NOTE 2016 Service Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 645 of 3641

CLUTCH DISC AND CLUTCH COVERCL-19

< UNIT REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

CL

N

O P

CLUTCH DISC AND CLUTCH COVER

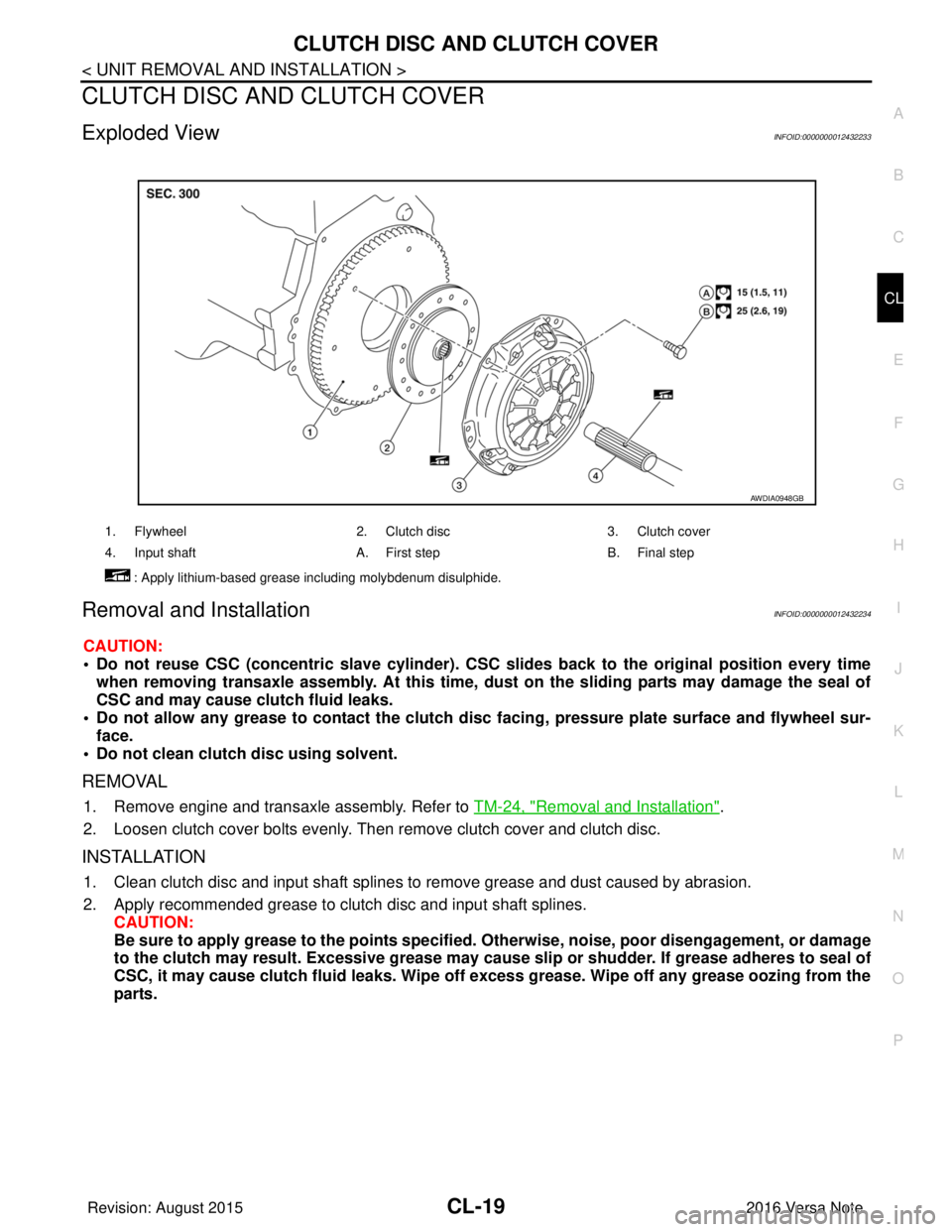

Exploded ViewINFOID:0000000012432233

Removal and InstallationINFOID:0000000012432234

CAUTION:

• Do not reuse CSC (concentric slave cylinder). CSC slides back to the original position every time

when removing transaxle assembly. At this time, du st on the sliding parts may damage the seal of

CSC and may cause clutch fluid leaks.

• Do not allow any grease to contact the clutch di sc facing, pressure plate surface and flywheel sur-

face.

• Do not clean clutch disc using solvent.

REMOVAL

1. Remove engine and transaxle assembly. Refer to TM-24, "Removal and Installation".

2. Loosen clutch cover bolts evenly. Then remove clutch cover and clutch disc.

INSTALLATION

1. Clean clutch disc and input shaft splines to remove grease and dust caused by abrasion.

2. Apply recommended grease to clutch disc and input shaft splines. CAUTION:

Be sure to apply grease to the points specified. Otherwise, noise, poor disengagement, or damage

to the clutch may result. Excessi ve grease may cause slip or shudder. If grease adheres to seal of

CSC, it may cause clutch fluid leaks. Wipe off excess grease. Wipe off any grease oozing from the

parts.

1. Flywheel 2. Clutch disc3. Clutch cover

4. Input shaft A. First stepB. Final step

: Apply lithium-based grease including molybdenum disulphide.

AWDIA0948GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1008 of 3641

![NISSAN NOTE 2016 Service Owners Manual PREPARATIONEM-7

< PREPARATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

Commercial Service ToolsINFOID:0000000012431689

EM03470000

(J-8037)

Piston ring compressor

Installing piston assembly into cyli NISSAN NOTE 2016 Service Owners Manual PREPARATIONEM-7

< PREPARATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

Commercial Service ToolsINFOID:0000000012431689

EM03470000

(J-8037)

Piston ring compressor

Installing piston assembly into cyli](/img/5/57363/w960_57363-1007.png)

PREPARATIONEM-7

< PREPARATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

Commercial Service ToolsINFOID:0000000012431689

EM03470000

(J-8037)

Piston ring compressor

Installing piston assembly into cylinder bore

ST16610001

(J-23907)

Pulley puller Removing pilot converter

KV11103000

( — )

Pulley puller Removing crankshaft pulley

KV11105210

(J-44716)

Stopper plate Holding drive plate and flywheel static

Tool number

(TechMate No.)

Tool name

Description

S-NT044

S-NT045

NT676

AWBIA1811ZZ

Tool name

Description

Power tool Loosening nuts, screws and bolts

Quick connector release Removing fuel tube quick connectors in en- gine room

PIIB1407E

PBIC0198E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1017 of 3641

![NISSAN NOTE 2016 Service Owners Manual EM-16

< PERIODIC MAINTENANCE >[HR16DE]

DRIVE BELT

PERIODIC MAINTENANCE

DRIVE BELT

Exploded ViewINFOID:0000000012431693

Removal and InstallationINFOID:0000000012431694

REMOVAL

1. Remove engine undercov NISSAN NOTE 2016 Service Owners Manual EM-16

< PERIODIC MAINTENANCE >[HR16DE]

DRIVE BELT

PERIODIC MAINTENANCE

DRIVE BELT

Exploded ViewINFOID:0000000012431693

Removal and InstallationINFOID:0000000012431694

REMOVAL

1. Remove engine undercov](/img/5/57363/w960_57363-1016.png)

EM-16

< PERIODIC MAINTENANCE >[HR16DE]

DRIVE BELT

PERIODIC MAINTENANCE

DRIVE BELT

Exploded ViewINFOID:0000000012431693

Removal and InstallationINFOID:0000000012431694

REMOVAL

1. Remove engine undercover. Refer to

EXT-39, "FRONT UNDER COVER : Removal and Installation".

2. Remove wheel and tire (RH) using a power tool. Refer to WT-48, "

Removal and Installation".

3. Partially remove the fender protector (RH). Refer to EXT-38, "

Removal and Installation".

4. Loosen the lock nut and then release the belt tension by turning the adjusting bolt.

5. Remove the drive belt.

INSTALLATION

1. Pull the idler pulley in the loosening direction, and then temporarily tighten the lock nut to the following

torque.

NOTE:

Do not move the lock nut from the te mporary tightened position. Go to step 2.

2. Install the drive belt on each pulley. CAUTION:

• Check that there is no engine oil, grease, or engine coolant, etc. in pulley grooves.

• Check that the belt seats securely inside the groove on each pulley.

3. Adjust drive belt tension by turning the adjusting bolt. Refer to EM-17, "

Adjustment".

CAUTION:

• Perform the belt tension adjustment with the lock nut temporarily tightened to the torque specifi-

cation listed in step 1 which preven ts the idler pulley from tilting.

• When checking immediately after in stallation, first adjust it to the specified value. Then, after

turning crankshaft two turns or more, readjust to the specified value to avoid variation in deflec-

tion between pulleys.

1. Generator 2. Water pump 3. Crankshaft pulley

4. A/C compressor 5. Tensioner idler pulley 6. Drive belt

A. Lock nut B. Adjusting bolt

ALBIA1157ZZ

Lock nut

(Temporary tightening): 4.4 N·m (0.45 kg-m, 39 in-lb)

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1053 of 3641

![NISSAN NOTE 2016 Service Owners Manual EM-52

< REMOVAL AND INSTALLATION >[HR16DE]

TIMING CHAIN

1. Remove front wheel and tire (RH). Refer to

WT-48, "Removal and Installation".

2. Remove front fender protector (RH). Refer to EXT-38, "

Rem NISSAN NOTE 2016 Service Owners Manual EM-52

< REMOVAL AND INSTALLATION >[HR16DE]

TIMING CHAIN

1. Remove front wheel and tire (RH). Refer to

WT-48, "Removal and Installation".

2. Remove front fender protector (RH). Refer to EXT-38, "

Rem](/img/5/57363/w960_57363-1052.png)

EM-52

< REMOVAL AND INSTALLATION >[HR16DE]

TIMING CHAIN

1. Remove front wheel and tire (RH). Refer to

WT-48, "Removal and Installation".

2. Remove front fender protector (RH). Refer to EXT-38, "

Removal and Installation".

3. Drain engine oil. Refer to LU-8, "

Draining".

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine oil on drive belt.

4. Drain coolant. Refer to CO-8, "

Draining Engine Coolant".

5. Remove the drive belt. Refer to EM-16, "

Removal and Installation".

6. Remove the rocker cover. Refer to EM-48, "

Removal and Installation".

7. Remove the water pump pulley. Refer to CO-18, "

Removal and Installation".

8. Support the bottom surface of engine (1) using a transmission jack (2), and then remove engine mounting insulator (RH). Refer

to EM-86, "

Exploded View".

CAUTION:

• Position a suitable jack under the engine and transaxle assembly as shown.

• Do not damage the front exhaust tube or transaxle oil pan with the jack.

9. Set No. 1 cylinder at TDC of its compression stroke:

a. Rotate crankshaft pulley (2) clockwise and align TDC mark (without paint mark) (A) to timing indicator (1) on front cover.

b. Check the matching marks on each camshaft sprocket are posi- tioned as shown.

• If not, rotate crankshaft pulley one more turn to align matchingmarks to the positions.

10. Remove crankshaft pulley:

ALBIA0894GB

(B) : White paint mark (Not use for service)

PBIC3673E

(1) : Timing chain

(2) : Camshaft sprocket (EXH)

(3) : Camshaft sprocket (INT)

(A) : Matching mark (Peripheral groove)

(B) : Pink link

(C) : Matching mark (Peripheral groove)

JPBIA4138ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1075 of 3641

![NISSAN NOTE 2016 Service Owners Manual EM-74

< REMOVAL AND INSTALLATION >[HR16DE]

OIL SEAL

2. Press in valve oil seal to the height “H” shown with Tool (A).

3. Installation of the remaining components is in the reverse order of removal NISSAN NOTE 2016 Service Owners Manual EM-74

< REMOVAL AND INSTALLATION >[HR16DE]

OIL SEAL

2. Press in valve oil seal to the height “H” shown with Tool (A).

3. Installation of the remaining components is in the reverse order of removal](/img/5/57363/w960_57363-1074.png)

EM-74

< REMOVAL AND INSTALLATION >[HR16DE]

OIL SEAL

2. Press in valve oil seal to the height “H” shown with Tool (A).

3. Installation of the remaining components is in the reverse order of removal.

FRONT OIL SEAL

FRONT OIL SEAL : Remo

val and InstallationINFOID:0000000012431724

REMOVAL

1. Remove front fender protector (RH). Refer to EXT-38, "Removal and Installation".

2. Remove drive belt. Refer to EM-16, "

Removal and Installation".

3. Remove crankshaft pulley. Refer to EM-51, "

Exploded View".

4. Remove front oil seal using suitable tool. CAUTION:

Be careful not to damage front cover and crankshaft.

5. Installation of the remaining components is in the reverse order of removal.

INSTALLATION

1. Apply new engine oil to new front oil seal joint surface and seal lip.

2. Install front oil seal so that each seal lip is oriented as shown.

• Press-fit front oil seal using a suitable drift.CAUTION:

• Be careful not to damage front cover and crankshaft.

• Press-fit oil seal straight to avoid causing burrs or tilting.

3. Installation of the remaining components is in the reverse order of removal.

REAR OIL SEAL

REAR OIL SEAL : Removal and InstallationINFOID:0000000012431725

REMOVAL

1. Remove engine and transaxle assembly. Refer to TM-24, "Removal and Installation" (M/T models) and

TM-259, "

Removal and Installation" (CVT models).

2. Remove clutch cover and clutch disk (M/T models). Refer to CL-19, "

Removal and Installation".

3. Remove flywheel (M/T models) or drive plate (CVT models). Refer to EM-93, "

Exploded View".

4. Remove rear oil seal using suitable tool. Height “H” : 13.2 - 13.8 mm (0.520 - 0.543 in)

Tool number (A) : KV10115600 (J-38958)

PBIC3211J

(A) : Dust seal lip

(B) : Oil seal lip

: Engine outside

: Engine inside

PBIC3485J

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1088 of 3641

![NISSAN NOTE 2016 Service Owners Manual ENGINE ASSEMBLYEM-87

< UNIT REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

CAUTION:

Check that the stud bolt (*2) is tigh

t at the specified torque before tightening the nut (*1) NISSAN NOTE 2016 Service Owners Manual ENGINE ASSEMBLYEM-87

< UNIT REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

CAUTION:

Check that the stud bolt (*2) is tigh

t at the specified torque before tightening the nut (*1)](/img/5/57363/w960_57363-1087.png)

ENGINE ASSEMBLYEM-87

< UNIT REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

CAUTION:

Check that the stud bolt (*2) is tigh

t at the specified torque before tightening the nut (*1) shown. [Stud

bolt (*2) may be loosened after loosening the nut (*1)]

Removal and InstallationINFOID:0000000012431732

WARNING:

• Position the vehicle on a flat and solid surface.

• Place chocks at front and back of rear wheels.

• Attach proper slingers and bolts described in PARTS CATALOG if engine is not already equipped.

CAUTION:

• Always be careful to work safely.

• Do not start working until exhaust system and coolant are cool enough.

• If items or work required are not covered by th e engine section, refer to the applicable sections.

• Always use the support poin t specified for lifting.

• Use either 2-pole lift type or separate type lift. If board-on type must be used, support the rear axle

jacking point with a transmission jack or similar to ol before starting work, in preparation for the

backward shift of center of gravity.

• For supporting points for lifting and j acking point at rear axle, refer to GI-29, "

2-Pole Lift".

NOTE:

• When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from

spilling.

1. Engine mounting (RH) stay 2. Engine mount (RH) stay 3. Engine mounting insulator (RH)

4. Rear engine mounting bracket 5. Rear torque rod 6. Engine mounting bracket (LH)

7. Mass damper 8. Engine mounting insulator (LH) 9. Engine mounting bracket (LH)

10. Engine mount bracket (LH) A. Front mark B. Transaxle (upper)

C. Transaxle (lower) D. M/T models

AWBIA1587ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1089 of 3641

![NISSAN NOTE 2016 Service Owners Manual EM-88

< UNIT REMOVAL AND INSTALLATION >[HR16DE]

ENGINE ASSEMBLY

• Remove the engine and the transaxle assembly from the vehicle downward. Separate the engine and the

transaxle.

REMOVAL

1. Release fu NISSAN NOTE 2016 Service Owners Manual EM-88

< UNIT REMOVAL AND INSTALLATION >[HR16DE]

ENGINE ASSEMBLY

• Remove the engine and the transaxle assembly from the vehicle downward. Separate the engine and the

transaxle.

REMOVAL

1. Release fu](/img/5/57363/w960_57363-1088.png)

EM-88

< UNIT REMOVAL AND INSTALLATION >[HR16DE]

ENGINE ASSEMBLY

• Remove the engine and the transaxle assembly from the vehicle downward. Separate the engine and the

transaxle.

REMOVAL

1. Release fuel pressure. Refer to EC-137, "Work Procedure".

2. Drain engine coolant from radiator. Refer to CO-8, "

Draining Engine Coolant".

CAUTION:

• Perform this step when the engine is cold.

• Do not spill engine coolant on drive belts.

3. Remove the following parts: • Front wheels and tires (RH/LH). Refer to WT-48, "

Removal and Installation".

• Front fender protector (RH/LH). Refer to EXT-38, "

Exploded View".

• Drive belt. Refer to EM-16, "

Removal and Installation".

• Battery and battery tray. Refer to PG-70, "

Exploded View".

• Air duct (inlet), air duct, and air cleaner case assembly. Refer to EM-26, "

Removal and Installation".

• Radiator hose (upper and lower). Refer to CO-13, "

Exploded View".

• Exhaust front tube. Refer to EX-5, "

Exploded View".

4. Disconnect engine room harness connector at the ECM and CVT (if equipped). CAUTION:

Protect connectors against foreign materials during the operation by wrapping in a plastic bag.

5. Disconnect heater hoses. Refer to CO-13, "

Exploded View".

6. Disconnect fuel feed hose at engine side. Refer to EM-40, "

Exploded View".

7. Disconnect control linkage cable from transaxle. Refer to TM-20, "

Exploded View" (M/T models) and TM-

234, "Exploded View" (CVT models).

8. Disconnect clutch tube on transaxle side from clutch damper (M/T models). Refer to CL-15, "

Exploded

View".

9. Remove generator. Refer to CHG-29, "

Exploded View".

10. Disconnect vacuum hose at engine side.

11. Remove EVAP hoses at engine side.

12. Remove A/C compressor from the engine with the piping connected. Temporarily position the A/C com-

pressor on the vehicle side with a rope without placing a heavy load on the piping.

13. Remove ground cable at transaxle side.

14. Remove drive shafts (RH/LH). Refer to FAX-19, "

Removal and Installation".

15. Remove rear torque rod (1).

16. When engine can be hoisted, install engine slinger to cylinder head front left side (A) and rear right side (B) and support the

engine position with a suitable tool.

(2) : Rear engine mounting bracket

: Front

JSBIA0643ZZ

: Engine front

Slinger (A) bolts : 65 N·m (6.6 kg-m, 48 ft-lb)

Slinger (B) bolts : 25 N·m (2.6 kg-m, 18 ft-lb)

AWBIA1134GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1092 of 3641

![NISSAN NOTE 2016 Service Owners Manual ENGINE UNITEM-91

< UNIT DISASSEMBLY AND ASSEMBLY > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

UNIT DISASSEMBLY AND ASSEMBLY

ENGINE UNIT

SettingINFOID:0000000012431733

NOTE:

The following procedures expl NISSAN NOTE 2016 Service Owners Manual ENGINE UNITEM-91

< UNIT DISASSEMBLY AND ASSEMBLY > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

UNIT DISASSEMBLY AND ASSEMBLY

ENGINE UNIT

SettingINFOID:0000000012431733

NOTE:

The following procedures expl](/img/5/57363/w960_57363-1091.png)

ENGINE UNITEM-91

< UNIT DISASSEMBLY AND ASSEMBLY > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

UNIT DISASSEMBLY AND ASSEMBLY

ENGINE UNIT

SettingINFOID:0000000012431733

NOTE:

The following procedures explain how to disassemble the engine with the engine stand fastened to the bell

housing. Some steps may be different if using a different type of engine stand.

1. Install engine to engine stand:

a. On (M/T models), remove flywheel.

• Secure flywheel using suitable tool and remove bolts.

CAUTION:

• Do not disassemble flywheel.

• Do not place flywheel with signal plate facing down.

• When handling signal plate, take care not to damage or scratch it.

• Handle signal plate in a manner that prevents it from becoming magnetized.

b. On (CVT models), remove driveplate. • Secure driveplate using suitable tool and remove bolts.

CAUTION:

• Do not disassemble flywheel.

• Do not place flywheel or drive plat e with signal plate facing down.

• When handling signal plate, take care not to damage or scratch it.

• Handle signal plate in a manner that prevents it from becoming magnetized.

c. Lift the engine with a hoist to install it onto a widely used engine stand. CAUTION:

• Use the engine stand that has a load capacity approximately 150 kg (331 lb) or more large

enough for supporting the engine weight.

• If the load capacity of stand is not adequate, remove the following parts beforehand to reduce the poten- tial risk of overturning stand.

- Intake manifold. Refer to EM-28, "

Exploded View".

- Exhaust manifold. Refer to EM-31, "

Removal and Installation".

- Rocker cover. Refer to EM-48, "

Exploded View".

CAUTION:

Before removing the hanging chains, check the engine stand is stable and there is no risk of over-

turning.

NOTE:

The figure shows an example of widely used engine stand (A)

that can support the mating surface of transaxle with flywheel

removed.

2. Drain engine oil. Refer to LU-8, "

Draining".

CAUTION:

• Be sure to clean drain plug and in stall with new drain plug washer.

• Do not reuse drain plug washer. Tool number : KV11105210 (J-44716)

Tool number : KV11105210 (J-44716)

PBIC3227J

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1095 of 3641

![NISSAN NOTE 2016 Service Owners Manual EM-94

< UNIT DISASSEMBLY AND ASSEMBLY >[HR16DE]

CYLINDER BLOCK

Disassembly and Assembly

INFOID:0000000012431737

DISASSEMBLY

NOTE:

The following procedures explain how to disassem ble the engine with t NISSAN NOTE 2016 Service Owners Manual EM-94

< UNIT DISASSEMBLY AND ASSEMBLY >[HR16DE]

CYLINDER BLOCK

Disassembly and Assembly

INFOID:0000000012431737

DISASSEMBLY

NOTE:

The following procedures explain how to disassem ble the engine with t](/img/5/57363/w960_57363-1094.png)

EM-94

< UNIT DISASSEMBLY AND ASSEMBLY >[HR16DE]

CYLINDER BLOCK

Disassembly and Assembly

INFOID:0000000012431737

DISASSEMBLY

NOTE:

The following procedures explain how to disassem ble the engine with the engine stand fastened to the bell

housing. Some steps may be different if using a different type of engine stand.

1. Remove cylinder head. Refer to EM-76, "

Exploded View".

2. Remove knock sensor. CAUTION:

Carefully handle knock sensor avoiding shocks.

3. Remove the crankshaft position sensor cover (3), and then crankshaft position sensor (POS) (2).

CAUTION:

• Avoid impacts such as a dropping.

• Do not disassemble.

• Keep sensor away from metal particles.

• Do not place the sensor in a location where it is exposed

to magnetism.

• Do not reuse O-ring.

4. Remove oil pan (upper and lower). Refer to EM-34

.

5. Remove piston and connecting rod assembly: • Before removing piston and connecting rod assembly, check the connecting rod side clearance. Refer toEM-102, "

Inspection".

a. Position crankshaft pin corresponding to connecting rod to be removed onto the bottom dead center.

b. Remove connecting rod cap.

c. Using a hammer handle or similar tool, push piston and connect- ing rod assembly out through the cylinder head side.

CAUTION:

• Do not damage mating surface with connecting rod cap.

• Do not damage the cylinder wall or crankshaft pin.

6. Remove connecting rod bearings. CAUTION:

Identify original positions for installation, an d store the bearings without mixing them up.

10. Oil temperature sensor 11. Oil pressure sensor12. Oil jet

13. Top ring 14. Second ring15. Oil rings

16. Piston 17. Piston pin18. Connecting rod

19. Connecting rod bearing (upper) 20. Main bearing (upper) 21. Thrust bearing

22. Crankshaft key 23. Connecting rod bolt24. Connecting rod cap

25. Connecting rod bearing (lower) 26. Main bearing (lower) 27. Crankshaft

28. Pilot converter (CVT models) 29. Signal plate30. Rear oil seal

31. Drive plate (CVT models) 32. Reinforce plate (CVT models) 33. Flywheel (M/T models)

34. Main bearing cap 35. Main bearing cap bolt A. Refer to ASSEMBLY

B. Chamfered Crankshaft side

(1) O-ring

(4) Cylinder block

: Engine front

JPBIA4202ZZ

KBIA3365J

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1102 of 3641

![NISSAN NOTE 2016 Service Owners Manual CYLINDER BLOCKEM-101

< UNIT DISASSEMBLY AND ASSEMBLY > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

Install the rear oil seal after installing the oil pan (upper).

17. Install rear oil seal. Refer to EM- NISSAN NOTE 2016 Service Owners Manual CYLINDER BLOCKEM-101

< UNIT DISASSEMBLY AND ASSEMBLY > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

Install the rear oil seal after installing the oil pan (upper).

17. Install rear oil seal. Refer to EM-](/img/5/57363/w960_57363-1101.png)

CYLINDER BLOCKEM-101

< UNIT DISASSEMBLY AND ASSEMBLY > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

Install the rear oil seal after installing the oil pan (upper).

17. Install rear oil seal. Refer to EM-74, "

REAR OIL SEAL : Removal and Installation".

18. Install flywheel (M/T models) or drive plate (CVT models).

M/T models

• Secure crankshaft with a stopper plate and tighten bolts crosswise over several times.

CVT models

• Secure crankshaft with a stopper plate and tighten bolts crosswise over several times.

CAUTION:

Do not damage or scratch and contact surface for clutch disc of flywheel.

19. Install knock sensor (1).

• Install connectors so that they are positioned toward the rearof the engine.

CAUTION:

• Do not tighten bolt while holding the connector.

• If any impact by dropping is applied to knock sensor,

replace it with a new one.

NOTE:

• Check that there is no foreign material on the cylinder block

mating surface and the back surface of knock sensor.

• Check that knock sensor does not interfere with other parts.

20. Install crankshaft position sensor (POS) (2) and O-ring (1) and then install the crankshaft position sensor cover (3) on the cylin-

der block (4).

• Tighten bolts with sensor inserted completely.

CAUTION:

• Avoid impacts such as a dropping.

• Do not disassemble.

• Keep sensor away from metal particles.

• Do not place the sensor in a location where it is exposedto magnetism.

• Do not reuse O-ring.

21. For the oil level gauge guide (1), secure in position (B) shown to the water inlet clip (A) after inserting to the cylinder block side.

22. Assembly of the remaining components is in the reverse order of disassembly.

Tool number : KV11105210 (J-44716)

Tool number : KV11105210 (J-44716)

: Engine front

: Engine front

PBIC3754E

JPBIA4202ZZ

PBIC3755E

Revision: August 2015

2016 Versa Note

cardiagn.com