Heat NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1629 of 3641

![NISSAN NOTE 2016 Service Repair Manual CO-24

< REMOVAL AND INSTALLATION >[HR16DE]

WATER OUTLET

Removal and Installation

INFOID:0000000012432149

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from NISSAN NOTE 2016 Service Repair Manual CO-24

< REMOVAL AND INSTALLATION >[HR16DE]

WATER OUTLET

Removal and Installation

INFOID:0000000012432149

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from](/img/5/57363/w960_57363-1628.png)

CO-24

< REMOVAL AND INSTALLATION >[HR16DE]

WATER OUTLET

Removal and Installation

INFOID:0000000012432149

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high-pressure

engine coolant escaping from the radi ator. Wrap a thick cloth around the radiator cap. Slowly turn it a

quarter of a turn to release built-up pressure. Carefu lly remove radiator cap by turning it all the way.

NOTE:

When removing components such as hoses, tubes/lines, etc. , cap or plug openings to prevent fluid from spill-

ing.

REMOVAL

1. Drain engine coolant. Refer to CO-8, "Draining Engine Coolant".

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on drive belt.

2. Remove air ducts and air cleaner assembly. Refer to EM-26, "

Removal and Installation".

3. Disconnect radiator hose (upper). Refer to CO-13, "

Exploded View".

4. Disconnect harness connector from engine coolant temperature sensor.

5. Disconnect harness connector from cylinder block heater (Canada only).

6. Disconnect water hoses and heater hoses from water outlet.

7. Remove water outlet.

8. Remove engine coolant temperature sens or from water outlet, if necessary.

9. Remove cylinder block heater from water outlet, if necessary (Canada only).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Do not reuse gasket.

INSPECTION AFTER INSTALLATION

• Before starting engine, check oil/fluid levels, including engine coolant and engine oil. If less than required quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

• Use procedure below to check for fuel leaks.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leaks

at connection points.

• Start engine. With engine speed increased, che ck again for fuel leaks at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no leaks of fuel, exhaust gas, or any oils/fluids, including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels, including engine oil and engine coolant. Refill to spec- ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc. Item

Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeaks Level

Engine oil LevelLeaks Level

Transmission/

transaxle fluid CVT Models

LeaksLevel/Leaks Leaks

M/T Models Level/Leaks LeaksLevel/Leaks

Other oils and fluids* LevelLeaks Level

Fuel LeaksLeaksLeaks

Exhaust gas —Leaks —

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1632 of 3641

![NISSAN NOTE 2016 Service Repair Manual LU-2

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432194

The Supplemental Res NISSAN NOTE 2016 Service Repair Manual LU-2

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432194

The Supplemental Res](/img/5/57363/w960_57363-1631.png)

LU-2

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432194

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Liquid GasketINFOID:0000000012432195

REMOVAL OF LIQUID GASKET SEALING

• After removing the bolts and nuts, separate the mating surface and remove the liquid gasket using Tool (A).

• In areas where the cutter is difficult to use, use a plastic hammer to lightly tap (1) the cutter where the liquid gasket is applied. Use a

plastic hammer to slide (2) the cutter by tapping on the side.

CAUTION:

Do not damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

1. Using suitable tool (A), remove old liquid gasket adhering to the liquid gasket application surface and the mating surface.

• Remove liquid gasket completely from the groove of the liquidgasket application surface, mounting bolts, and bolt holes.

2. Wipe the liquid gasket application surface and the mating sur- face with white gasoline (lighting and heating use) to remove

adhering moisture, grease and foreign materials.Tool number (A) : KV10111100 (J-37228)

AWBIA1249GB

JPBIA0053ZZ

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1648 of 3641

PREPARATIONEX-3

< PREPARATION >

C

DE

F

G H

I

J

K L

M A

EX

NP

O

PREPARATION

PREPARATION

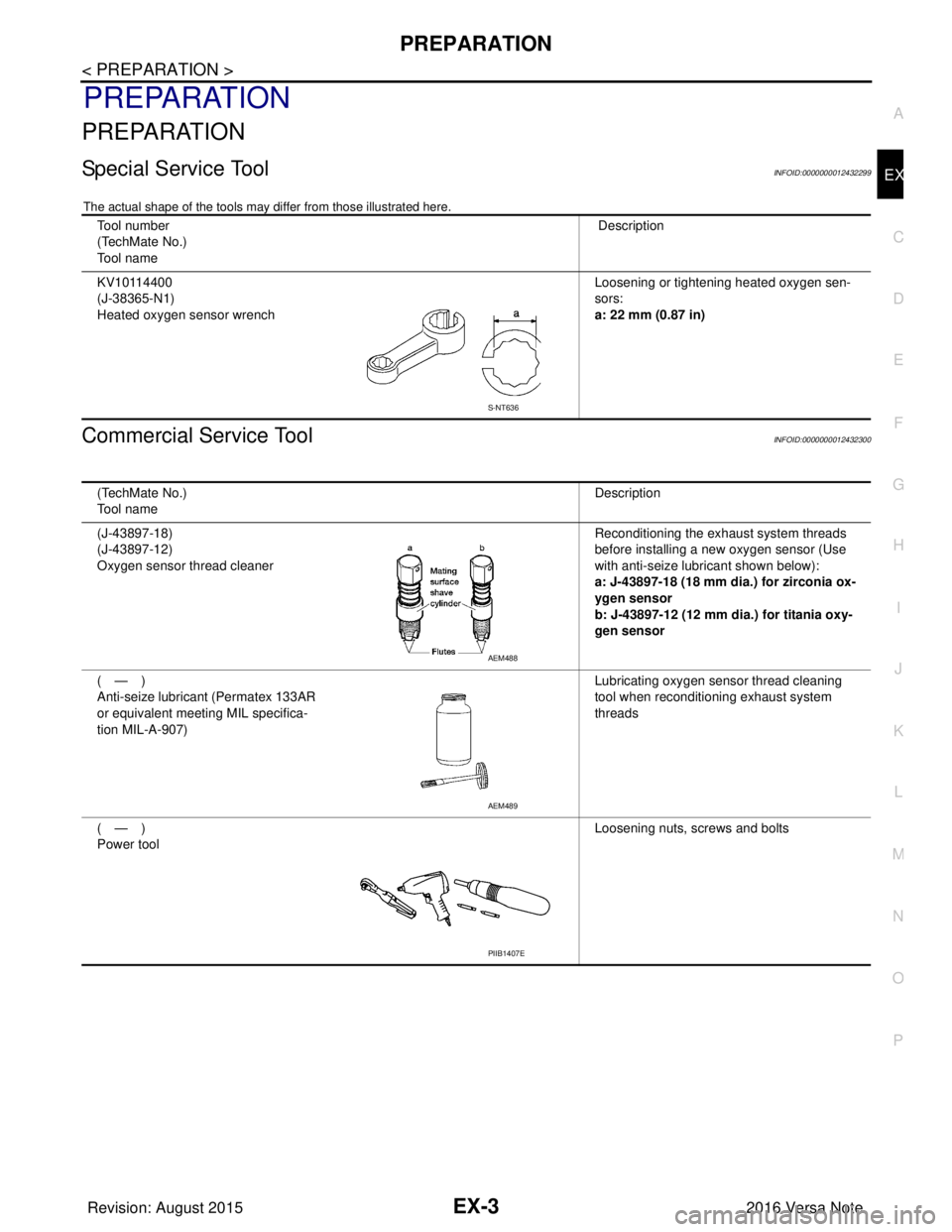

Special Service ToolINFOID:0000000012432299

The actual shape of the tools may differ from those illustrated here.

Commercial Service ToolINFOID:0000000012432300

Tool number

(TechMate No.)

Tool name

Description

KV10114400

(J-38365-N1)

Heated oxygen sensor wrench Loosening or tightening heated oxygen sen-

sors:

a: 22 mm (0.87 in)

S-NT636

(TechMate No.)

Tool name

Description

(J-43897-18)

(J-43897-12)

Oxygen sensor thread cleaner Reconditioning the exhaust system threads

before installing a new oxygen sensor (Use

with anti-seize lubricant shown below):

a: J-43897-18 (18 mm dia.) for zirconia ox-

ygen sensor

b: J-43897-12 (12 mm dia.) for titania oxy-

gen sensor

(—)

Anti-seize lubricant (Permatex 133AR

or equivalent meeting MIL specifica-

tion MIL-A-907) Lubricating oxygen sensor thread cleaning

tool when reconditioning exhaust system

threads

(—)

Power tool Loosening nuts, screws and bolts

AEM488

AEM489

PIIB1407E

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1650 of 3641

EXHAUST SYSTEMEX-5

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EX

NP

O

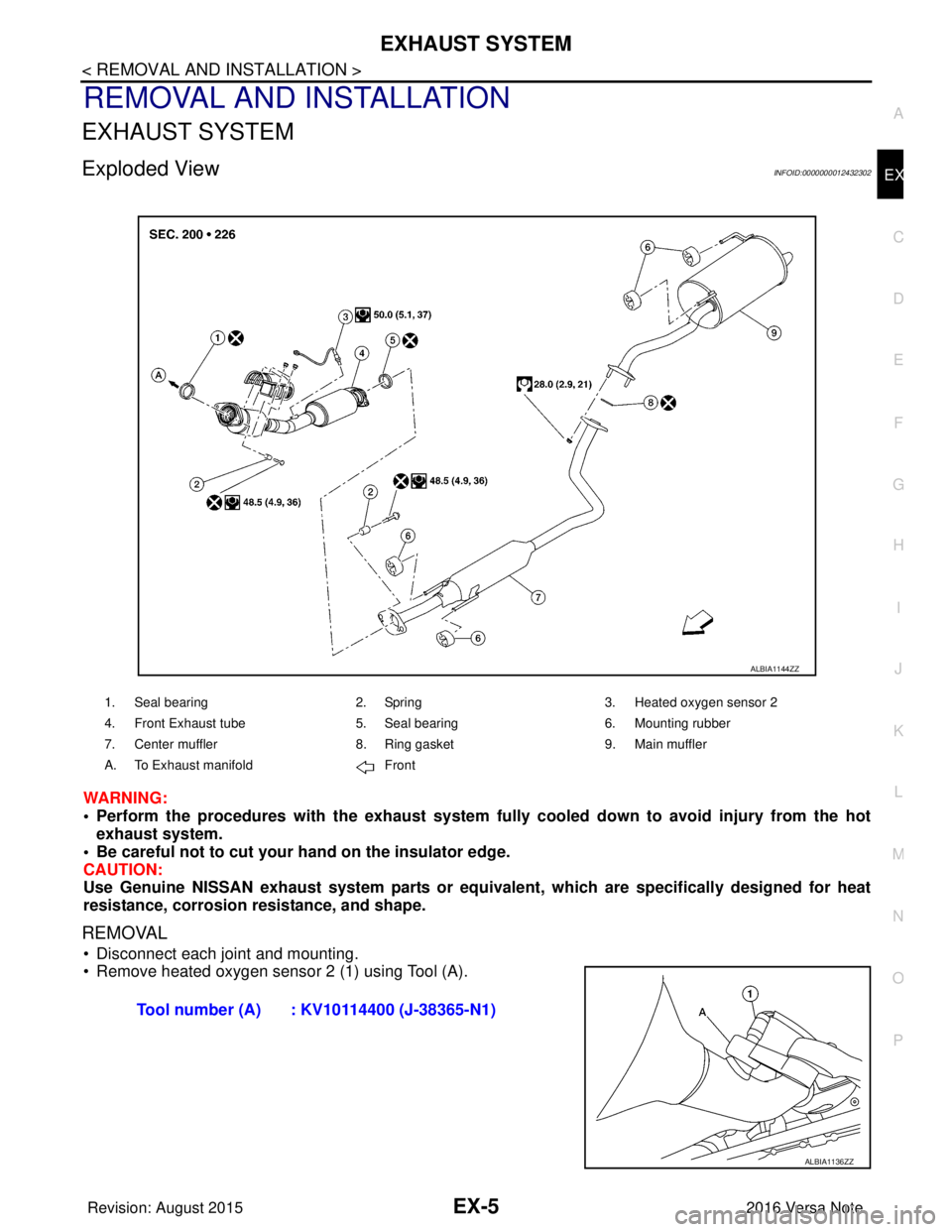

REMOVAL AND INSTALLATION

EXHAUST SYSTEM

Exploded ViewINFOID:0000000012432302

WARNING:

• Perform the procedures with the exhaust system full

y cooled down to avoid injury from the hot

exhaust system.

• Be careful not to cut your hand on the insulator edge.

CAUTION:

Use Genuine NISSAN exhaust system parts or equivalent, which are specifically designed for heat

resistance, corrosion resistance, and shape.

REMOVAL

• Disconnect each joint and mounting.

• Remove heated oxygen sensor 2 (1) using Tool (A).

1. Seal bearing 2. Spring3. Heated oxygen sensor 2

4. Front Exhaust tube 5. Seal bearing6. Mounting rubber

7. Center muffler 8. Ring gasket9. Main muffler

A. To Exhaust manifold Front

ALBIA1144ZZ

Tool number (A) : KV10114400 (J-38365-N1)

ALBIA1136ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1651 of 3641

EX-6

< REMOVAL AND INSTALLATION >

EXHAUST SYSTEM

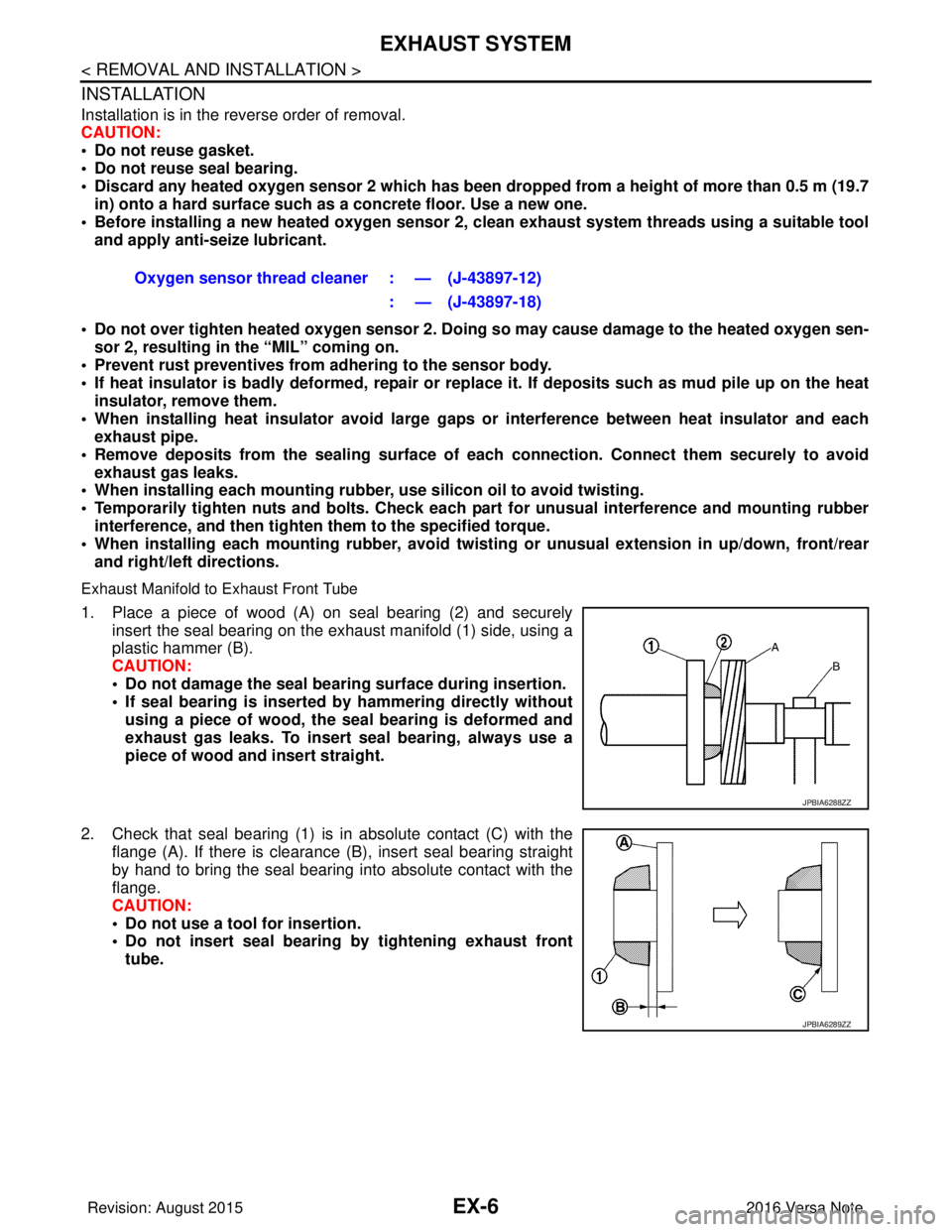

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse gasket.

• Do not reuse seal bearing.

• Discard any heated oxygen sensor 2 which has been dropped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a concrete floor. Use a new one.

• Before installing a new heated o xygen sensor 2, clean exhaust system threads using a suitable tool

and apply anti-seize lubricant.

• Do not over tighten heated oxygen sensor 2. Doin g so may cause damage to the heated oxygen sen-

sor 2, resulting in the “MIL” coming on.

• Prevent rust preventives from adhering to the sensor body.

• If heat insulator is badly deformed, repair or re place it. If deposits such as mud pile up on the heat

insulator, remove them.

• When installing heat insulator avoid large gaps or interference between heat insulator and each

exhaust pipe.

• Remove deposits from the sealing surface of each connection. Connect them securely to avoid

exhaust gas leaks.

• When installing each mounting rubber, use silicon oil to avoid twisting.

• Temporarily tighten nuts and bolts. Check each part for unusual interference and mounting rubber interference, and then tighten them to the specified torque.

• When installing each mounting rubber, avoid twisting or unus ual extension in up/down, front/rear

and right/left directions.

Exhaust Manifold to Exhaust Front Tube

1. Place a piece of wood (A) on seal bearing (2) and securely insert the seal bearing on the exhaust manifold (1) side, using a

plastic hammer (B).

CAUTION:

• Do not damage the seal bearing surface during insertion.

• If seal bearing is inserted by hammering directly without

using a piece of wood, the seal bearing is deformed and

exhaust gas leaks. To insert seal bearing, always use a

piece of wood and insert straight.

2. Check that seal bearing (1) is in absolute contact (C) with the flange (A). If there is clearance (B), insert seal bearing straight

by hand to bring the seal bearing into absolute contact with the

flange.

CAUTION:

• Do not use a tool for insertion.

• Do not insert seal bearing by tightening exhaust front

tube. Oxygen sensor thread cleaner : — (J-43897-12)

: — (J-43897-18)

JPBIA6288ZZ

JPBIA6289ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1810 of 3641

ROOF SIDE MOLDINGEXT-43

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

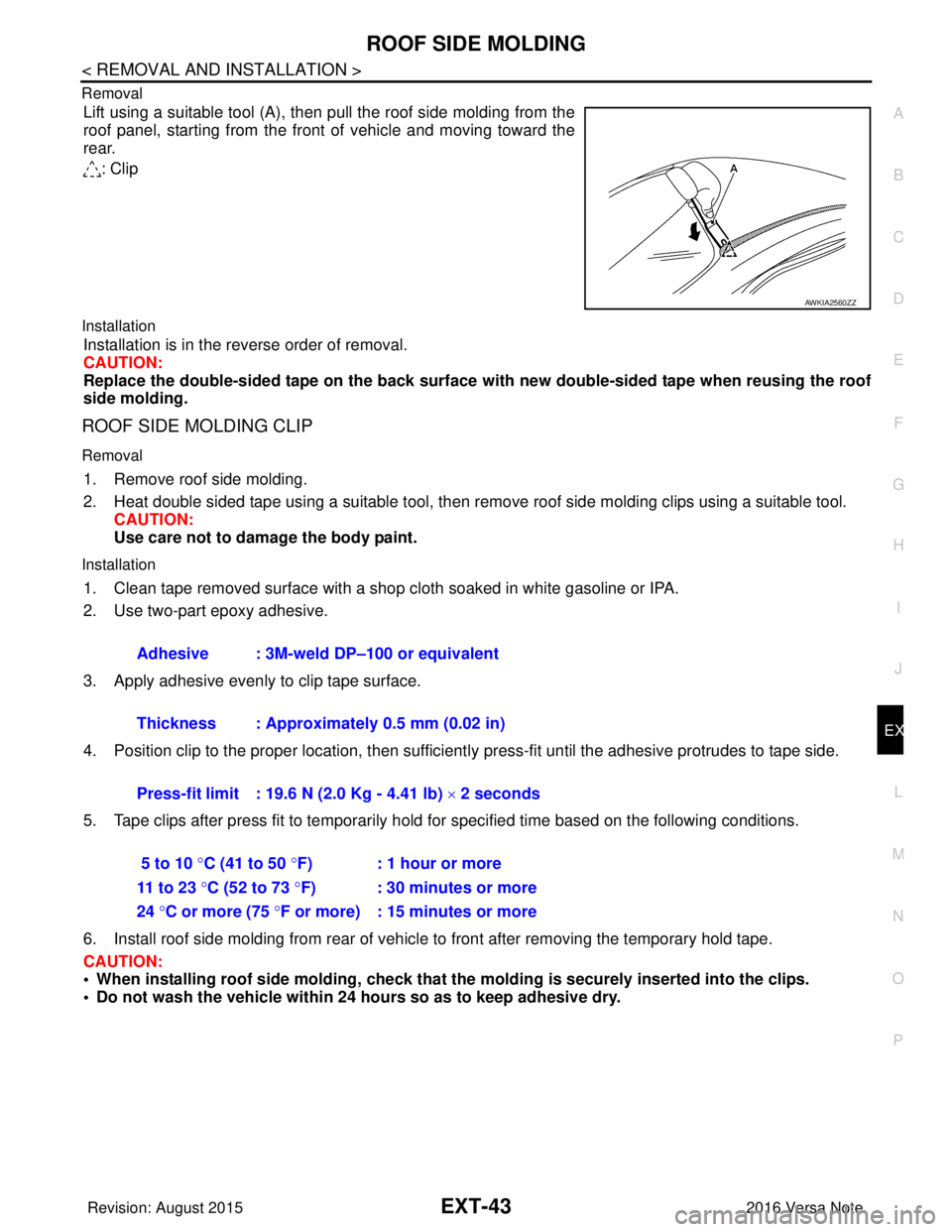

Removal

Lift using a suitable tool (A), then pull the roof side molding from the

roof panel, starting from the front of vehicle and moving toward the

rear.

: Clip

Installation

Installation is in the reverse order of removal.

CAUTION:

Replace the double-sided tape on the back surface with new double-sided tape when reusing the roof

side molding.

ROOF SIDE MOLDING CLIP

Removal

1. Remove roof side molding.

2. Heat double sided tape using a suitable tool, then remove roof side molding clips using a suitable tool.

CAUTION:

Use care not to damage the body paint.

Installation

1. Clean tape removed surface with a shop cloth soaked in white gasoline or IPA.

2. Use two-part epoxy adhesive.

3. Apply adhesive evenly to clip tape surface.

4. Position clip to the proper location, then sufficient ly press-fit until the adhesive protrudes to tape side.

5. Tape clips after press fit to temporarily hold for specified time based on the following conditions.

6. Install roof side molding from rear of vehicle to front after removing the temporary hold tape.

CAUTION:

• When installing roof side moldin g, check that the molding is securely inserted into the clips.

• Do not wash the vehicle within 24 hours so as to keep adhesive dry.

AWKIA2560ZZ

Adhesive : 3M-weld DP–100 or equivalent

Thickness : Approximately 0.5 mm (0.02 in)

Press-fit limit : 19.6 N (2.0 Kg - 4.41 lb) × 2 seconds

5 to 10 °C (41 to 50 °F) : 1 hour or more

11 to 23 °C (52 to 73 °F) : 30 minutes or more

24 °C or more (75 °F or more) : 15 minutes or more

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1812 of 3641

DOOR SASH TAPEEXT-45

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

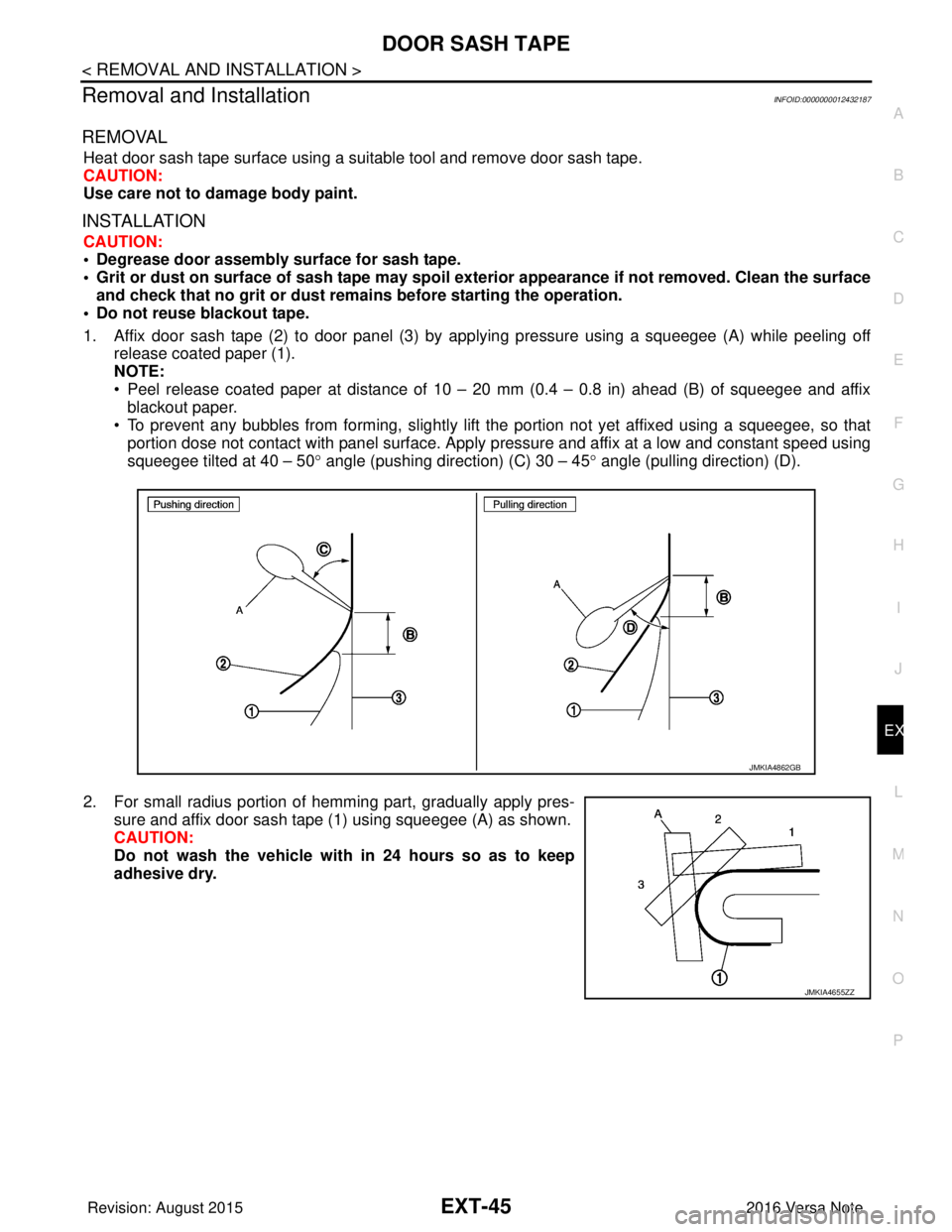

Removal and InstallationINFOID:0000000012432187

REMOVAL

Heat door sash tape surface using a suitable tool and remove door sash tape.

CAUTION:

Use care not to damage body paint.

INSTALLATION

CAUTION:

• Degrease door assembly surface for sash tape.

• Grit or dust on surface of sash tape may spoil exterior appearance if not removed. Clean the surface

and check that no grit or dust rema ins before starting the operation.

• Do not reuse blackout tape.

1. Affix door sash tape (2) to door panel (3) by applying pressure using a squeegee (A) while peeling off release coated paper (1).

NOTE:

• Peel release coated paper at distance of 10 – 20 mm (0.4 – 0.8 in) ahead (B) of squeegee and affixblackout paper.

• To prevent any bubbles from forming, slightly lift the portion not yet affixed using a squeegee, so that

portion dose not contact with panel surface. Apply pressure and affix at a low and constant speed using

squeegee tilted at 40 – 50 ° angle (pushing direction) (C) 30 – 45° angle (pulling direction) (D).

2. For small radius portion of hemming part, gradually apply pres- sure and affix door sash tape (1) using squeegee (A) as shown.

CAUTION:

Do not wash the vehicle with in 24 hours so as to keep

adhesive dry.

JMKIA4862GB

JMKIA4655ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1816 of 3641

REAR SPOILEREXT-49

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

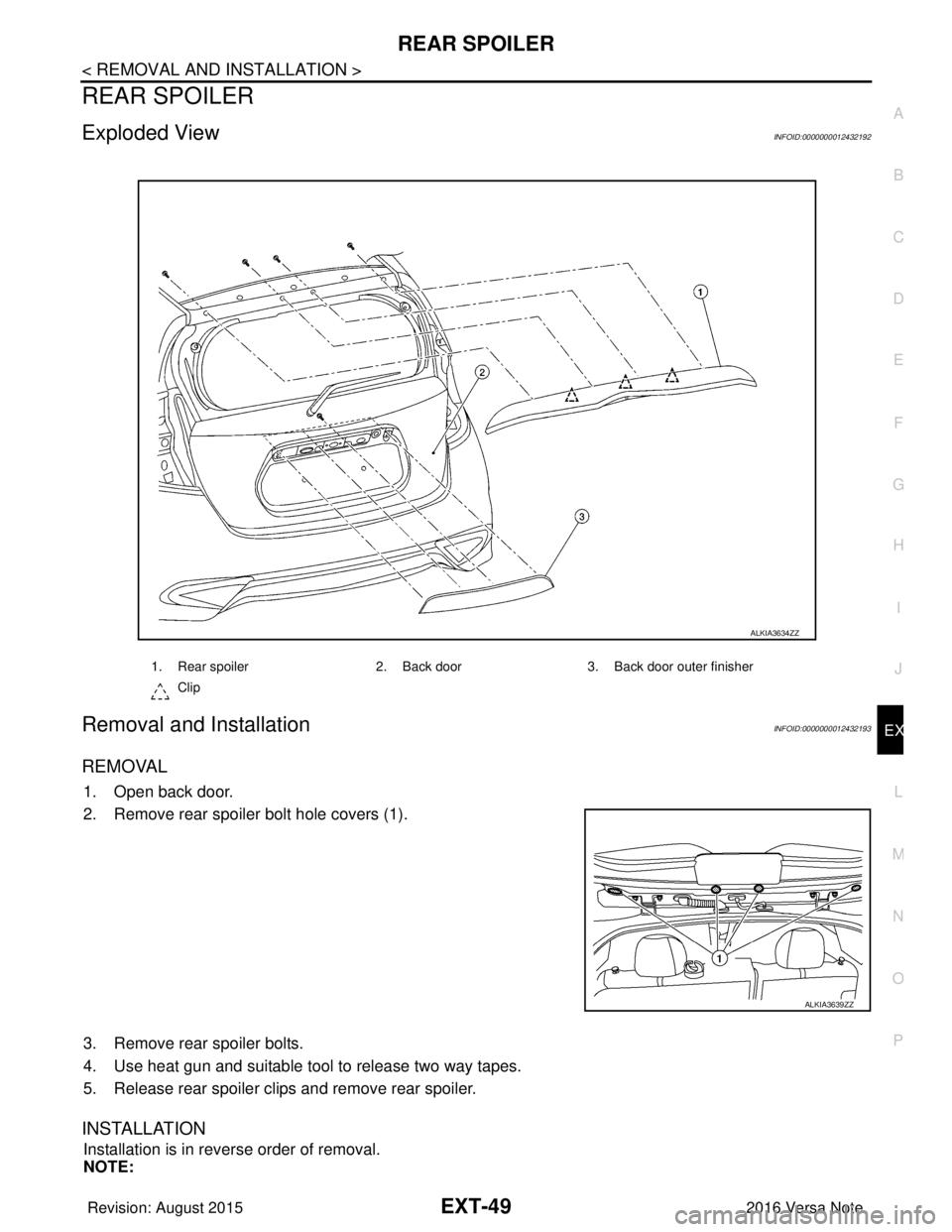

REAR SPOILER

Exploded ViewINFOID:0000000012432192

Removal and InstallationINFOID:0000000012432193

REMOVAL

1. Open back door.

2. Remove rear spoiler bolt hole covers (1).

3. Remove rear spoiler bolts.

4. Use heat gun and suitable tool to release two way tapes.

5. Release rear spoiler clips and remove rear spoiler.

INSTALLATION

Installation is in reverse order of removal.

NOTE:

1. Rear spoiler 2. Back door3. Back door outer finisher

Clip

ALKIA3634ZZ

ALKIA3639ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1871 of 3641

FUEL SYSTEMFL-5

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M A

FL

NP

O

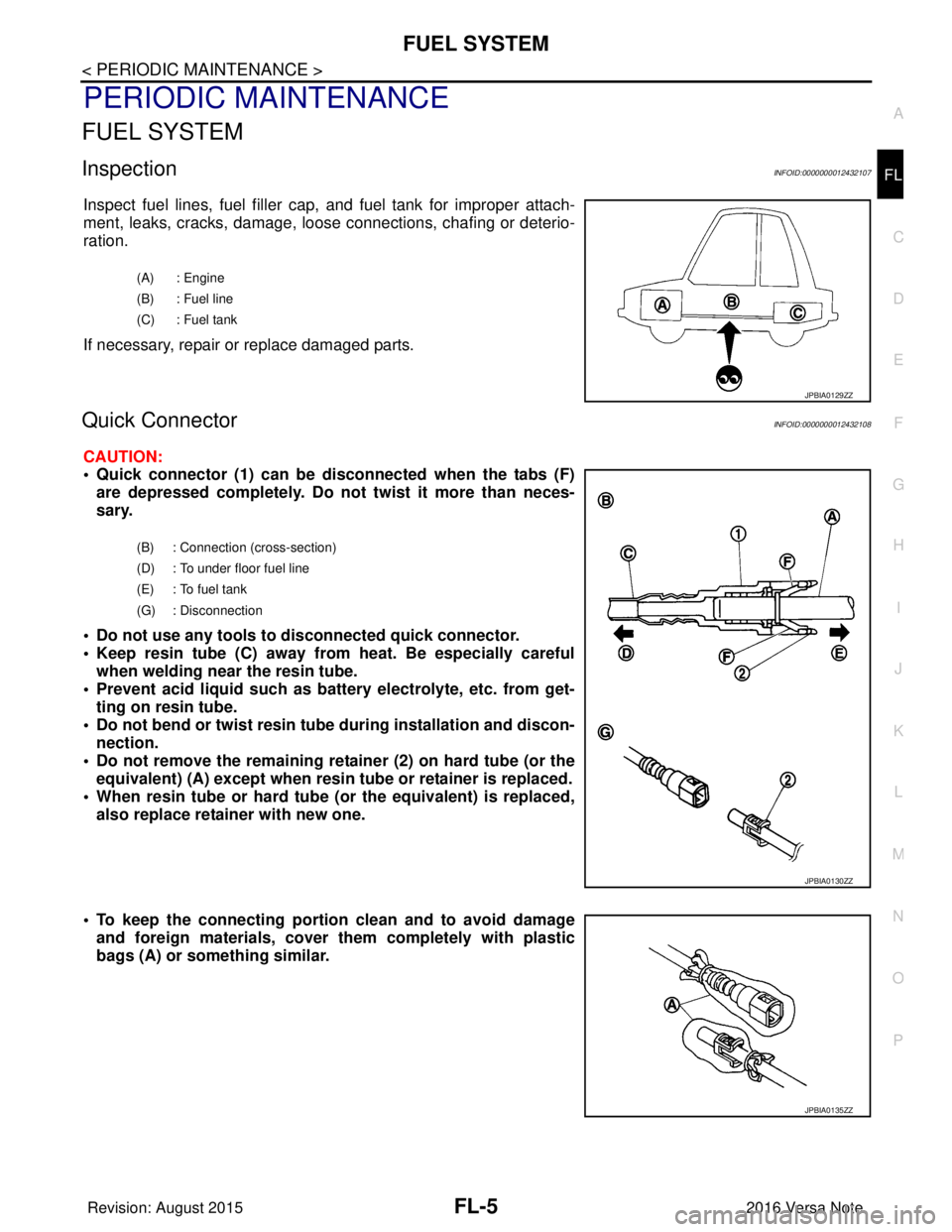

PERIODIC MAINTENANCE

FUEL SYSTEM

InspectionINFOID:0000000012432107

Inspect fuel lines, fuel filler cap,

and fuel tank for improper attach-

ment, leaks, cracks, damage, loos e connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

Quick ConnectorINFOID:0000000012432108

CAUTION:

• Quick connector (1) can be di sconnected when the tabs (F)

are depressed completely. Do not twist it more than neces-

sary.

• Do not use any tools to di sconnected quick connector.

• Keep resin tube (C) away from heat. Be especially careful when welding near the resin tube.

• Prevent acid liquid such as battery electrolyte, etc. from get- ting on resin tube.

• Do not bend or twist resin tube during installation and discon-

nection.

• Do not remove the remaining retainer (2) on hard tube (or the equivalent) (A) except when resin tu be or retainer is replaced.

• When resin tube or hard tube (or the equivalent) is replaced, also replace retainer with new one.

• To keep the connecting portion clean and to avoid damage and foreign materials, cover them completely with plastic

bags (A) or something similar.

(A) : Engine

(B) : Fuel line

(C) : Fuel tank

JPBIA0129ZZ

(B) : Connection (cross-section)

(D) : To under floor fuel line

(E) : To fuel tank

(G) : Disconnection

JPBIA0130ZZ

JPBIA0135ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1873 of 3641

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLYFL-7

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

FL

NP

O

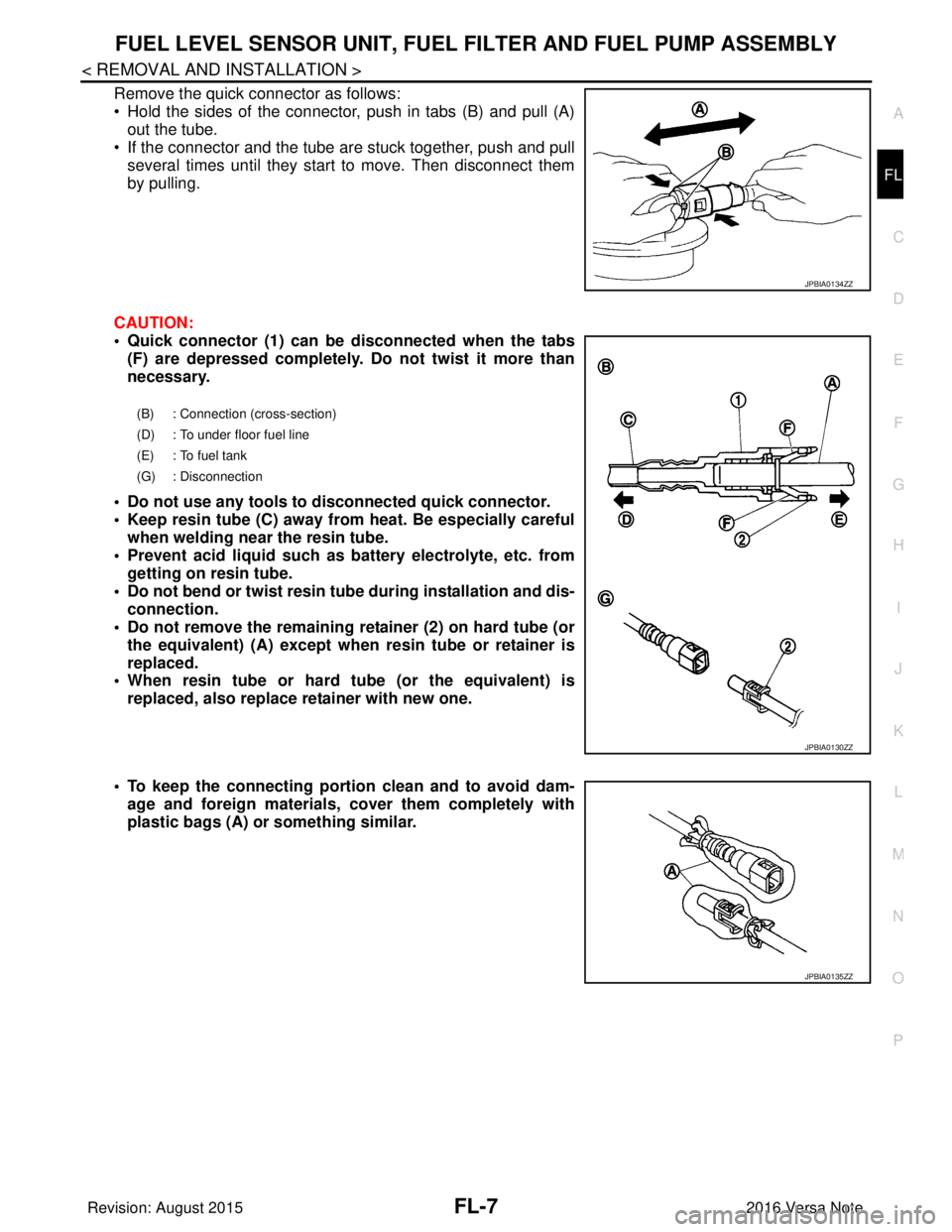

Remove the quick connector as follows:

• Hold the sides of the connector, push in tabs (B) and pull (A)

out the tube.

• If the connector and the tube are stuck together, push and pull several times until they start to move. Then disconnect them

by pulling.

CAUTION:

• Quick connector (1) can be disconnected when the tabs (F) are depressed completely. Do not twist it more than

necessary.

• Do not use any tools to disconnected quick connector.

• Keep resin tube (C) away from heat. Be especially careful when welding near the resin tube.

• Prevent acid liquid such as battery electrolyte, etc. from

getting on resin tube.

• Do not bend or twist resin tube during installation and dis- connection.

• Do not remove the remaining retainer (2) on hard tube (or

the equivalent) (A) except when resin tube or retainer is

replaced.

• When resin tube or hard tube (or the equivalent) is

replaced, also replace retainer with new one.

• To keep the connecting portio n clean and to avoid dam-

age and foreign materials, cover them completely with

plastic bags (A) or something similar.

JPBIA0134ZZ

(B) : Connection (cross-section)

(D) : To under floor fuel line

(E) : To fuel tank

(G) : Disconnection

JPBIA0130ZZ

JPBIA0135ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com