star stop NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1642 of 3641

![NISSAN NOTE 2016 Service Repair Manual LU-12

< REMOVAL AND INSTALLATION >[HR16DE]

OIL PUMP

3. Loosen the oil pump bolts in the reverse order as shown.

4. Remove oil pump and O-rings.

CAUTION:

• Do not reuse O-rings.

• Do not disassembl NISSAN NOTE 2016 Service Repair Manual LU-12

< REMOVAL AND INSTALLATION >[HR16DE]

OIL PUMP

3. Loosen the oil pump bolts in the reverse order as shown.

4. Remove oil pump and O-rings.

CAUTION:

• Do not reuse O-rings.

• Do not disassembl](/img/5/57363/w960_57363-1641.png)

LU-12

< REMOVAL AND INSTALLATION >[HR16DE]

OIL PUMP

3. Loosen the oil pump bolts in the reverse order as shown.

4. Remove oil pump and O-rings.

CAUTION:

• Do not reuse O-rings.

• Do not disassemble oil pump.

INSTALLATION

1. Install new O-rings on the oil pan (upper) before installing the oil pump. Refer to LU-11, "Exploded View".

CAUTION:

Do not reuse O-rings.

2. Install the oil pump.

3. Tighten the oil pump bolts to specification in the order shown.

4. Install timing chain and oil pump drive chain. Refer to EM-51,

"Removal and Installation".

5. Refill engine with new engine oil. Refer to LU-8, "

Refilling".

INSPECTION AFTER INSTALLATION

• Before starting engine, check oil/fluid levels, including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

• Use procedure below to check for fuel leaks.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leaks

at connection points.

• Start engine. With engine speed increased, che ck again for fuel leaks at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no leak s of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels, including engine oil and engine coolant. Refill to spec-

ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc.

AWBIA1122GB

AWBIA1122GB

Item Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeaks Level

Engine oil LevelLeaks Level

Transmission/

transaxle fluid CVT Models

LeaksLevel/Leaks Leaks

M/T Models Level/Leaks LeaksLevel/Leaks

Other oils and fluids* LevelLeaks Level

Fuel LeaksLeaksLeaks

Exhaust gas —Leaks —

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1644 of 3641

![NISSAN NOTE 2016 Service Repair Manual LU-14

< REMOVAL AND INSTALLATION >[HR16DE]

OIL COOLER

INSPECTION AFTER REMOVAL

Oil Cooler

Check oil cooler for cracks. Check oil cooler for clogging by blowing compressed air through engine coolant

in NISSAN NOTE 2016 Service Repair Manual LU-14

< REMOVAL AND INSTALLATION >[HR16DE]

OIL COOLER

INSPECTION AFTER REMOVAL

Oil Cooler

Check oil cooler for cracks. Check oil cooler for clogging by blowing compressed air through engine coolant

in](/img/5/57363/w960_57363-1643.png)

LU-14

< REMOVAL AND INSTALLATION >[HR16DE]

OIL COOLER

INSPECTION AFTER REMOVAL

Oil Cooler

Check oil cooler for cracks. Check oil cooler for clogging by blowing compressed air through engine coolant

inlet. If necessary, replace oil cooler.

Relief Valve

Inspect relief valve for movement, cracks and breaks by

pushing the ball. If replacement is necessary, remove

the valve by prying it out using a suitable tool. Install a new valve by tapping it in place.

INSTALLATION

Installation is in the reverse order of removal.

• Ensure that no foreign objects are adhering to the s ealing surfaces of the oil cooler and oil pan (upper).

• Tighten connector bolt after aligning cutout (1) on oil cooler with protrusion (2) on oil pan (upper) side.

CAUTION:

• Do not reuse O-ring.

• Replace relief valve if removed.

INSPECTION AFTER INSTALLATION

• Before starting engine, check oil/fluid levels, including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

• Use procedure below to check for fuel leaks.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leaks

at connection points.

• Start engine. With engine speed increased, che ck again for fuel leaks at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no leak s of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels, including engine oil and engine coolant. Refill to spec-

ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc.

AWBIA1139GB

Item Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeaks Level

Engine oil LevelLeaks Level

Transmission/

transaxle fluid CVT Models

LeaksLevel/Leaks Leaks

M/T Models Level/Leaks LeaksLevel/Leaks

Other oils and fluids* LevelLeaks Level

Fuel LeaksLeaksLeaks

Exhaust gas —Leaks —

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1674 of 3641

EXL-22

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (IPDM E/R)

ECU IDENTIFICATION

The IPDM E/R part number is displayed.

SELF DIAGNOSTIC RESULT

Refer to PCS-20, "DTCIndex".

DATA MONITOR

ACTIVE TEST

Data Monitor The IPDM E/R input/output data is displayed in real time.

Active Test The IPDM E/R activates outputs to test components.

CAN Diag Support Mntr The result of transmit/receive diagnosis of CAN communication is displayed.

Direct Diagnostic Mode

Description

Monitor Item [Unit]Main

Signals Description

MOTOR FAN REQ [1/2/3/4] ×Indicates cooling fan speed signal received from ECM on CAN communication

line

AC COMP REQ [On/Off] ×Indicates A/C compressor request signal received from ECM on CAN commu-

nication line

TAIL&CLR REQ [On/Off] ×Indicates position light request signal received from BCM on CAN communica-

tion line

HL LO REQ [On/Off] ×Indicates low beam request signal received from BCM on CAN communication

line

HL HI REQ [On/Off] ×Indicates high beam request signal received from BCM on CAN communication

line

FR FOG REQ [On/Off] ×Indicates front fog light request signal received from BCM on CAN communica-

tion line

FR WIP REQ [Stop/1LOW/Low/Hi] ×Indicates front wiper request signal received from BCM on CAN communication

line

WIP AUTO STOP [STOP P/ACT P] ×Indicates condition of front wiper auto stop signal

WIP PROT [Off/BLOCK] ×Indicates condition of front wiper fail-safe operation

IGN RLY1 -REQ [On/Off] Indicates ignition switch ON signal received from BCM on CAN communication

line

IGN RLY [On/Off] ×Indicates condition of ignition relay

PUSH SW [On/Off] Indicates condition of push-button ignition switch

INTER/NP SW [On/Off] Indicates condition of CVT shift position

ST RLY CONT [On/Off] Indicates starter relay status signal received from BCM on CAN communication

line

IHBT RLY -REQ [On/Off] Indicates starter control relay signal received from BCM on CAN communication

line

ST/INHI RLY [Off/ ST /INHI] Indicates condition of starter relay and starter control relay

DETENT SW [On/Off] Indicates condition of CVT shift selector (park position switch)

DTRL REQ [Off] Indicates daytime running light request signal received from BCM on CAN com-

munication line

THFT HRN REQ [On/Off] Indicates theft warning horn request signal received from BCM on CAN commu-

nication line

HORN CHIRP [On/Off] Indicates horn reminder signal received from BCM on CAN communication line

Te s t i t e m D e s c r i p t i o n

HORN This test is able to check horn operation [On].

FRONT WIPER This test is able to check wiper motor operation [Hi/Lo/Off].

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1786 of 3641

SQUEAK AND RATTLE TROUBLE DIAGNOSESEXT-19

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and the instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar finisher

4. Instrument panel to windshield

5. Instrument panel pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shift selector assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the ar eas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-50397) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, se curing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the cons ole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1875 of 3641

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLYFL-9

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

FL

NP

O

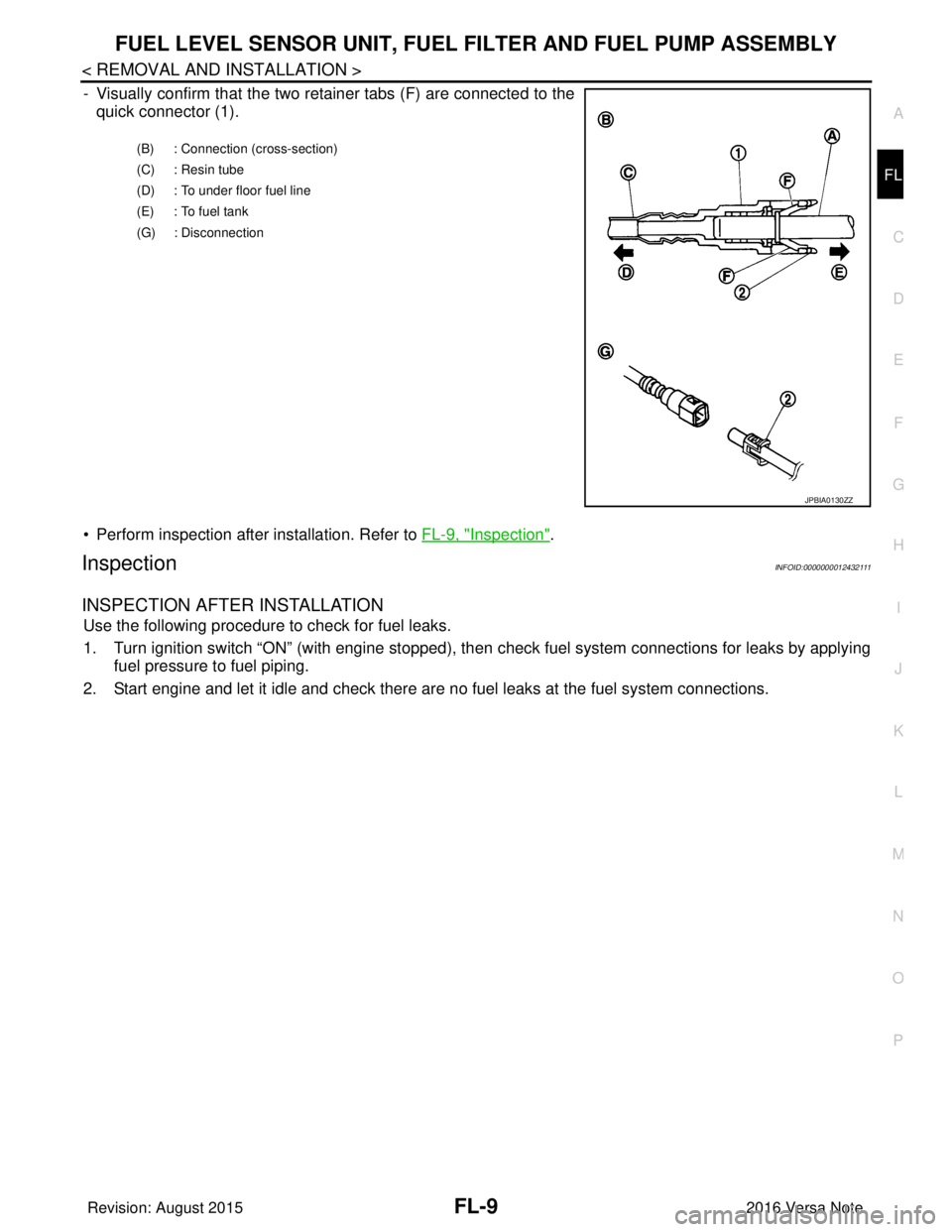

- Visually confirm that the two retainer tabs (F) are connected to the

quick connector (1).

• Perform inspection after installation. Refer to FL-9, "

Inspection".

InspectionINFOID:0000000012432111

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leaks.

1. Turn ignition switch “ON” (with engine stopped), then check fuel system connections for leaks by applying

fuel pressure to fuel piping.

2. Start engine and let it idle and check there are no fuel leaks at the fuel system connections.

(B) : Connection (cross-section)

(C) : Resin tube

(D) : To under floor fuel line

(E) : To fuel tank

(G) : Disconnection

JPBIA0130ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1879 of 3641

FUEL TANKFL-13

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

FL

NP

O

17. If replacing the fuel tank, remove the fuel level sensor unit, fuel filter and fuel pump assembly to transfer to

the new fuel tank.

CAUTION:

Do not reuse O-ring.

INSTALLATION

Installation is in the reverse order of removal.

Fuel Filler Hose

• Insert fuel filler hose to the length below.

• Be sure hose clamp is not placed on swelled area of fuel filler tube.

• Install fuel filler hose to fuel t ank, paying attention to install mark.

EVAP Hose

1. Check connections for damage or foreign material.

2. Align the matching side connection part with the center of shaft, and insert connector straight until a "click"

sound is heard.

InspectionINFOID:0000000012432114

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leaks.

1. Turn ignition switch “ON” (with engine stopped), then check fuel system connections for leaks by applying

fuel pressure to fuel piping.

2. Start engine and let it idle and check there are no fuel leaks at the fuel system connections.

Fuel filler hose : 35 mm (1.38 in)

Vent hose : 25 mm (0.98 in)

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1887 of 3641

FUEL LEVEL SENSOR UNITFL-21

< DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

FL

NP

O

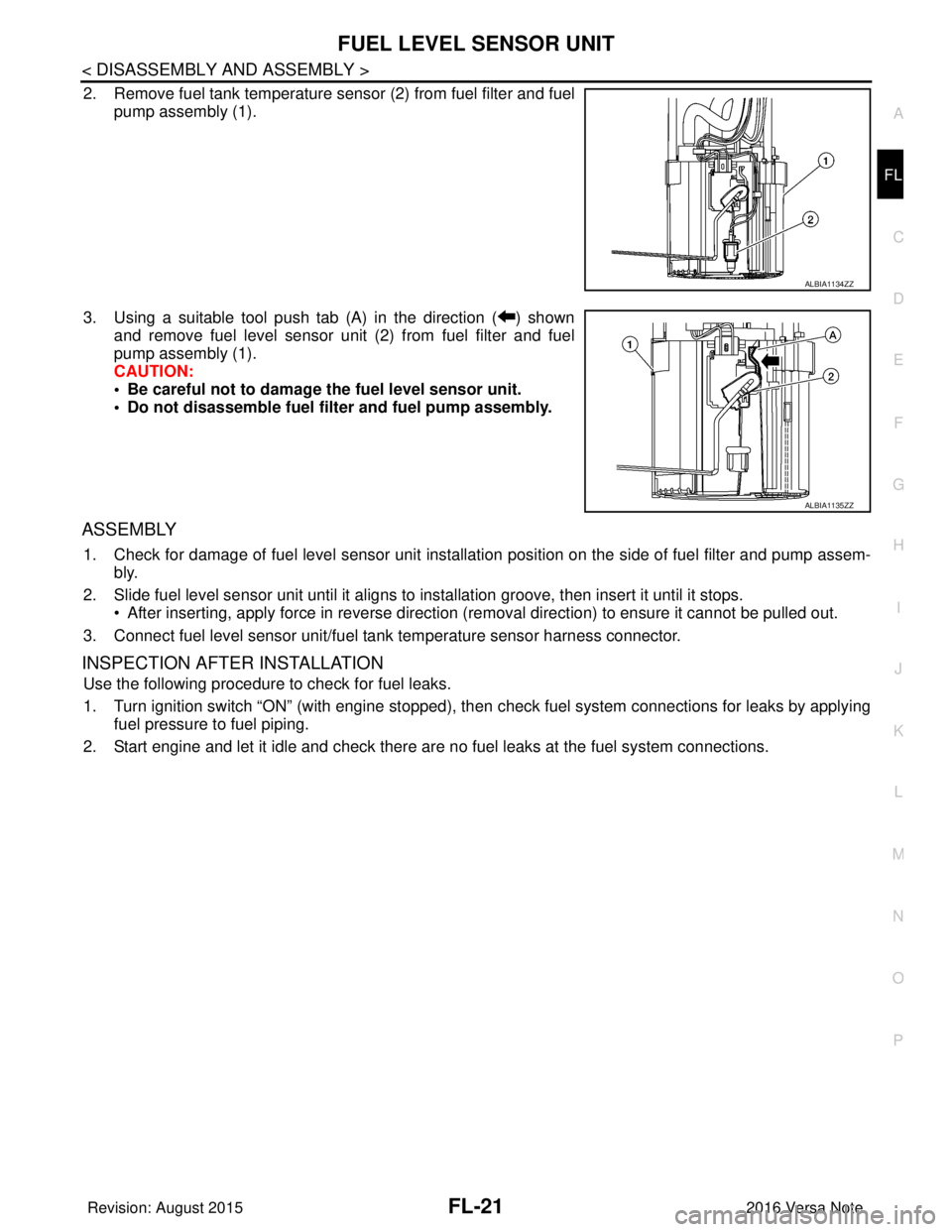

2. Remove fuel tank temperature s

ensor (2) from fuel filter and fuel

pump assembly (1).

3. Using a suitable tool push tab (A) in the direction ( ) shown and remove fuel level sensor unit (2) from fuel filter and fuel

pump assembly (1).

CAUTION:

• Be careful not to damage the fuel level sensor unit.

• Do not disassemble fuel filter and fuel pump assembly.

ASSEMBLY

1. Check for damage of fuel level sensor unit installation position on the side of fuel filter and pump assem- bly.

2. Slide fuel level sensor unit until it aligns to installation groove, then insert it until it stops. • After inserting, apply force in reverse direction (removal direction) to ensure it cannot be pulled out.

3. Connect fuel level sensor unit/fuel t ank temperature sensor harness connector.

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leaks.

1. Turn ignition switch “ON” (with engine stopped), then check fuel system connections for leaks by applying

fuel pressure to fuel piping.

2. Start engine and let it idle and check there are no fuel leaks at the fuel system connections.

ALBIA1134ZZ

ALBIA1135ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1947 of 3641

SQUEAK AND RATTLE TROUBLE DIAGNOSESGW-7

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

GW

N

O P

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and the instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar finisher

4. Instrument panel to windshield

5. Instrument panel pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shift selector assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the ar eas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-50397) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, se curing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the cons ole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1955 of 3641

OPERA WINDOWGW-15

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

GW

N

O P

When cutting glass from the vehicle, always wear safety glasses and heavy gloves to prevent

glass splinters from entering your eyes or cutting your hands.

CAUTION:

• Be careful not to scratch the glass when removing.

• Do not set or stand the glass on its ed ge. Small chips may develop into cracks.

• Apply protective tape around the opera windo w glass to protect the painted surface from dam-

age.

INSTALLATION

• Use a Genuine NISSAN Urethane Adhesive Kit (if avail able) or equivalent and follow the instructions fur-

nished with it.

• Adhesive shall be continuously applied to assure watert ightness. Glass installation shall be finished within

five minutes after applying the adhesive.

• The start and finisher of the urethane adhesive applicati on should be located at the bottom to assure water-

tightness.

• While the urethane adhesive is curing, open a door window . This will prevent the glass from being forced out

by passenger compartment air pressure when a door is closed.

• Inform the customer that the vehicle should rema in stationary until the urethane adhesive has completely

cured (preferably 24 hours). Curing time varies with temperature and humidity.

WARNING:

• Keep heat and open flames away as primers and adhesive are flammable.

• The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Avoid

contact with skin and eyes.

• Use in an open, well ventilated lo cation. Avoid breathing the vapors. They can be harmful if inhaled.

If affected by vapor inhalation, imme diately move to an area with fresh air.

• Driving the vehicle before the urethane adhesive is completely cured may affect the performance of

the opera window glass in case of an accident.

CAUTION:

• Do not use an adhesive which is past its usable te rm. Shelf life of this product is limited to six

months after the date of manufacture. Carefully ad here to the expiration or manufacture date printed

on the box.

• Keep primers and adhesive in a cool, dry place. Id eally, they should be stored in a refrigerator.

• Do not leave primers or adhesive cartridge unattended with their caps open or off.

• The vehicle should not be driven for at least 24 hours or until the urethane adhesive is completely

cured. Curing time varies depe nding on temperature and humidity. The curing time increases under

lower temperature and lower humidity.

REPAIRING WATER LEAKS FOR OPERA WINDOW GLASS

• Leaks can be repaired without removing and reinstalling opera window glass.

• If water is leaking between the urethane adhesive materi al and body or glass, determine the extent of the

leak.

• This can be done by applying water to the opera window glass area while pushing glass outward.

• To stop the leak, apply primer (if necessary ) and then urethane adhesive to the leak point.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1978 of 3641

![NISSAN NOTE 2016 Service Repair Manual HAC-10

< SYSTEM DESCRIPTION >[MANUAL AIR CONDITIONING]

COMPONENT PARTS

A. LH side of instrument panel B. Behind center of instrument panel C. Center of instrument panel

No. Component Description

1. BC NISSAN NOTE 2016 Service Repair Manual HAC-10

< SYSTEM DESCRIPTION >[MANUAL AIR CONDITIONING]

COMPONENT PARTS

A. LH side of instrument panel B. Behind center of instrument panel C. Center of instrument panel

No. Component Description

1. BC](/img/5/57363/w960_57363-1977.png)

HAC-10

< SYSTEM DESCRIPTION >[MANUAL AIR CONDITIONING]

COMPONENT PARTS

A. LH side of instrument panel B. Behind center of instrument panel C. Center of instrument panel

No. Component Description

1. BCM The BCM receives the fan ON and A/C ON signals from the front air control and sends a com-

pressor ON request to the ECM.

2. Fuse Block (J/B) Located in the passenger compartment, behind the left lower IP, the Fuse Block (J/B) con-

tains the front blower motor relay and several fuses required for the air conditioner control

system.

3. Blower relay The blower relay controls the flow of current to fuse 20, 21 and 22 in the Fuse Block (J/B).

The relay is connected directly to ground, and is energized when the ignition switch is in the

ON or START position.

4. Front blower motor The front blower motor varies the speed at which the air flows through the ventilation system.

5. Front blower motor resistor Ground for the blower is supplied through blower resistor and the blower speed switch. As

the switch is moved from position 1 through 4, more current is allowed to flow through the

motor, for a higher speed. This is because less resistors are in the path as the switch is

moved to a higher position. When the switch is on the highest position, all resistors are by-

passed.

6. Thermo control amp. Thermo control amp. is composed of thermistor and amplifier. When the A/C switch signal is

received from the front air control, the thermo control amp. transmits the A/C ON signal to the

BCM according to evaporator fin temperature. When the thermistor detecting temperature of

the air that passes through evaporator is extremely low, the thermo control amp. sends the

A/C OFF signal to BCM, and stops the compressor.

7. Front air control The front air control controls the operation of the A/C and heating system.

AWIIA1862ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com