EXT-38 NISSAN NOTE 2016 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1757 of 3641

FRONT FOG LAMPEXL-105

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

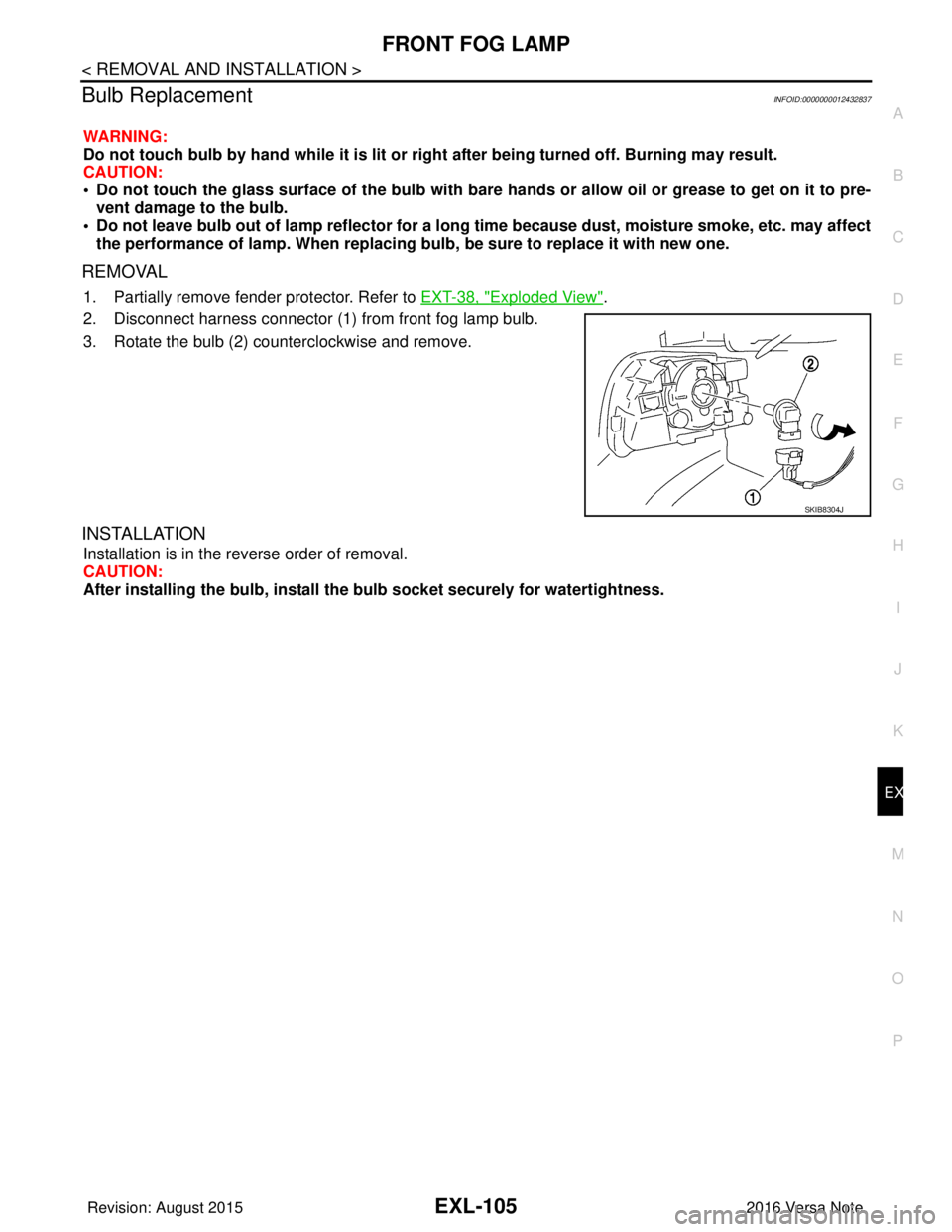

Bulb ReplacementINFOID:0000000012432837

WARNING:

Do not touch bulb by hand while it is lit or right after being turned off. Burning may result.

CAUTION:

• Do not touch the glass surface of the bulb with bare hands or allow oi l or grease to get on it to pre-

vent damage to the bulb.

• Do not leave bulb out of lamp reflector for a long time because dust, moisture smoke, etc. may affect

the performance of lamp. When replacing bulb, be sure to replace it with new one.

REMOVAL

1. Partially remove fender protector. Refer to EXT-38, "Exploded View".

2. Disconnect harness connector (1) from front fog lamp bulb.

3. Rotate the bulb (2) counterclockwise and remove.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

After installing the bulb, install the bulb socket securely for watertightness.

SKIB8304J

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1792 of 3641

FRONT BUMPEREXT-25

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

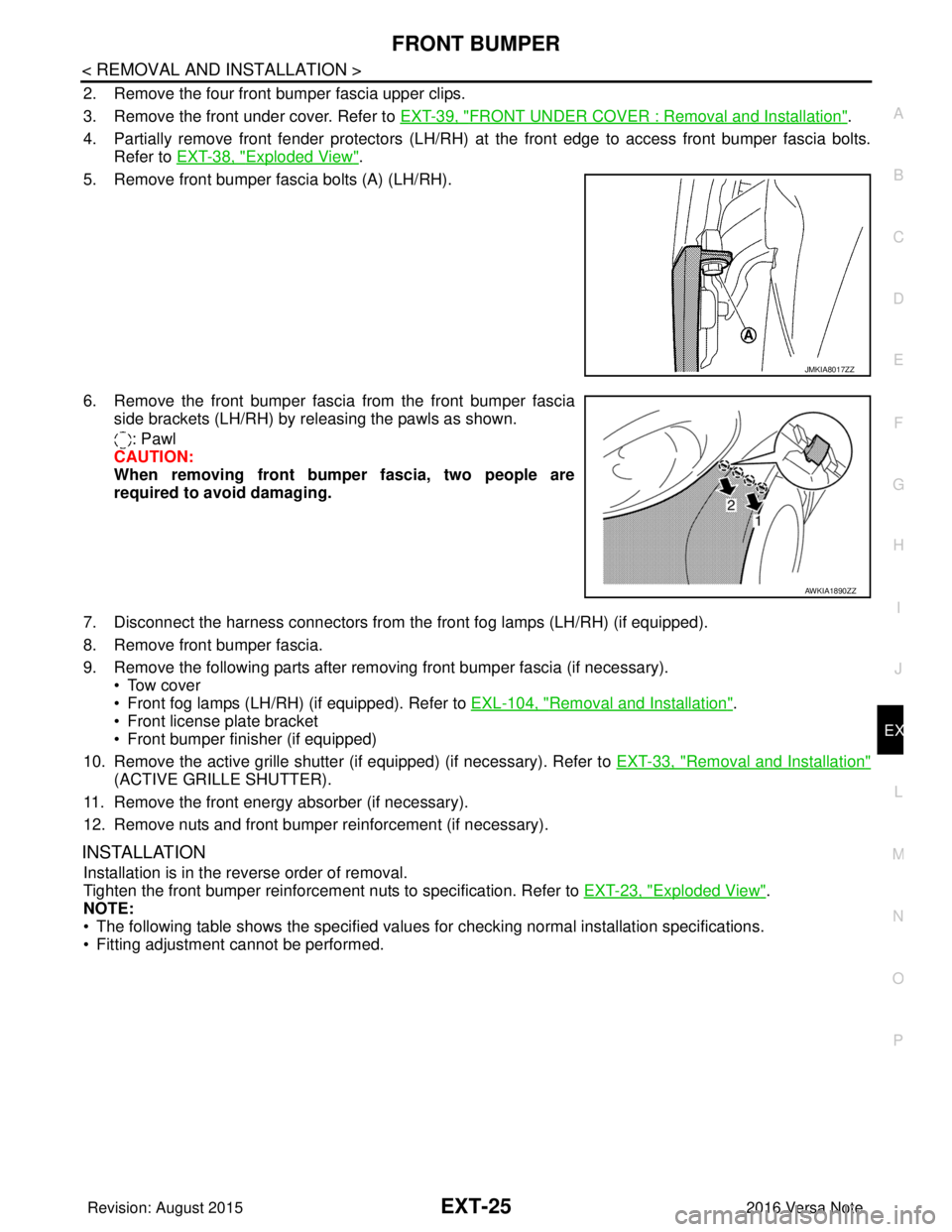

2. Remove the four front bumper fascia upper clips.

3. Remove the front under cover. Refer to EXT-39, "

FRONT UNDER COVER : Removal and Installation".

4. Partially remove front fender protectors (LH/RH) at the front edge to access front bumper fascia bolts.

Refer to EXT-38, "

Exploded View".

5. Remove front bumper fascia bolts (A) (LH/RH).

6. Remove the front bumper fasci a from the front bumper fascia

side brackets (LH/RH) by releasing the pawls as shown.

: Pawl

CAUTION:

When removing front bumper fascia, two people are

required to avoid damaging.

7. Disconnect the harness connectors from t he front fog lamps (LH/RH) (if equipped).

8. Remove front bumper fascia.

9. Remove the following parts after removing front bumper fascia (if necessary). • Tow cover

• Front fog lamps (LH/RH) (if equipped). Refer to EXL-104, "

Removal and Installation".

• Front license plate bracket

• Front bumper finisher (if equipped)

10. Remove the active grille shutter (if equipped) (if necessary). Refer to EXT-33, "

Removal and Installation"

(ACTIVE GRILLE SHUTTER).

11. Remove the front energy absorber (if necessary).

12. Remove nuts and front bumper reinforcement (if necessary).

INSTALLATION

Installation is in the reverse order of removal.

Tighten the front bumper reinforcement nuts to specification. Refer to EXT-23, "

Exploded View".

NOTE:

• The following table shows the specified values for checking normal installation specifications.

• Fitting adjustment cannot be performed.

JMKIA8017ZZ

AWKIA1890ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1805 of 3641

EXT-38

< REMOVAL AND INSTALLATION >

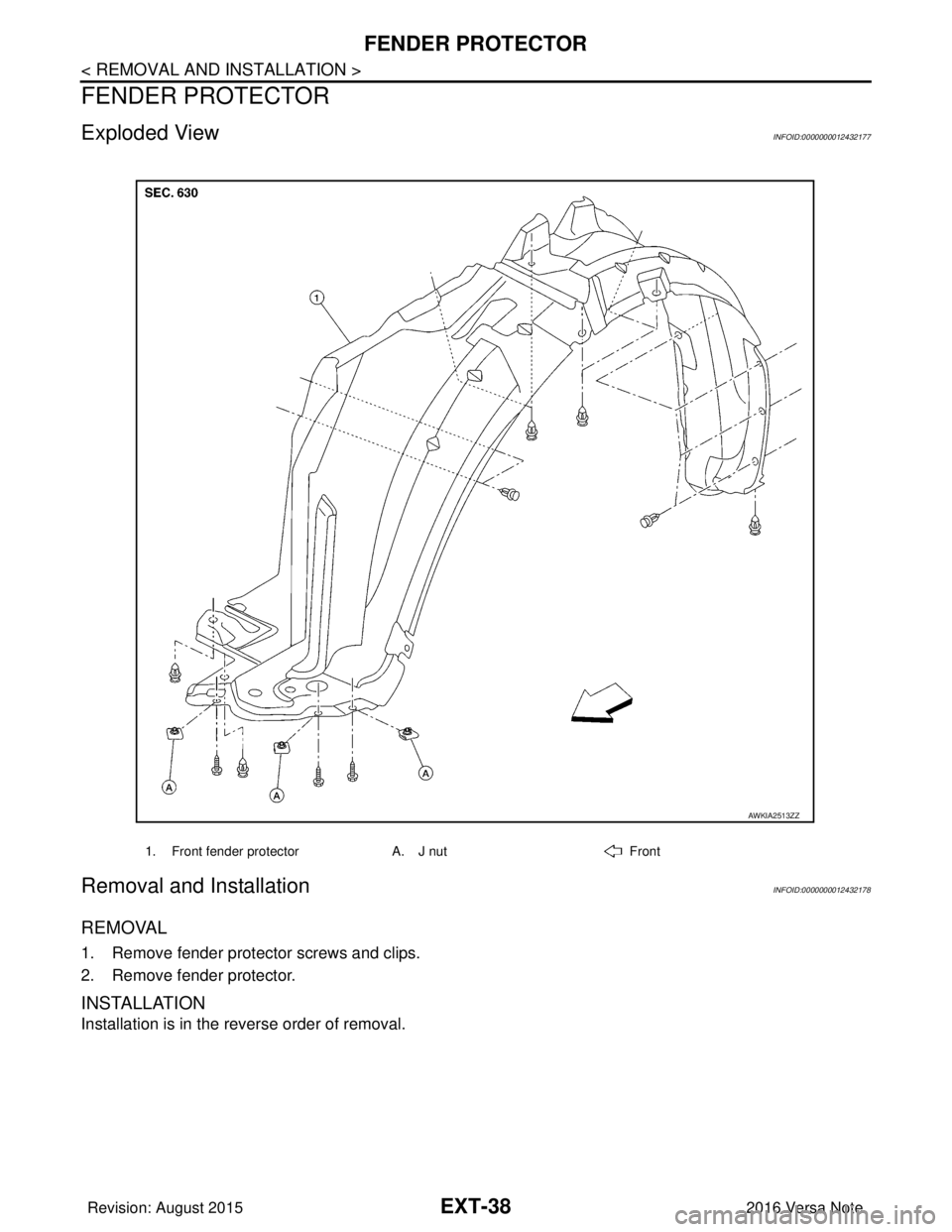

FENDER PROTECTOR

FENDER PROTECTOR

Exploded ViewINFOID:0000000012432177

Removal and InstallationINFOID:0000000012432178

REMOVAL

1. Remove fender protector screws and clips.

2. Remove fender protector.

INSTALLATION

Installation is in the reverse order of removal.

1. Front fender protectorA. J nutFront

AWKIA2513ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2051 of 3641

HA-26

< REMOVAL AND INSTALLATION >

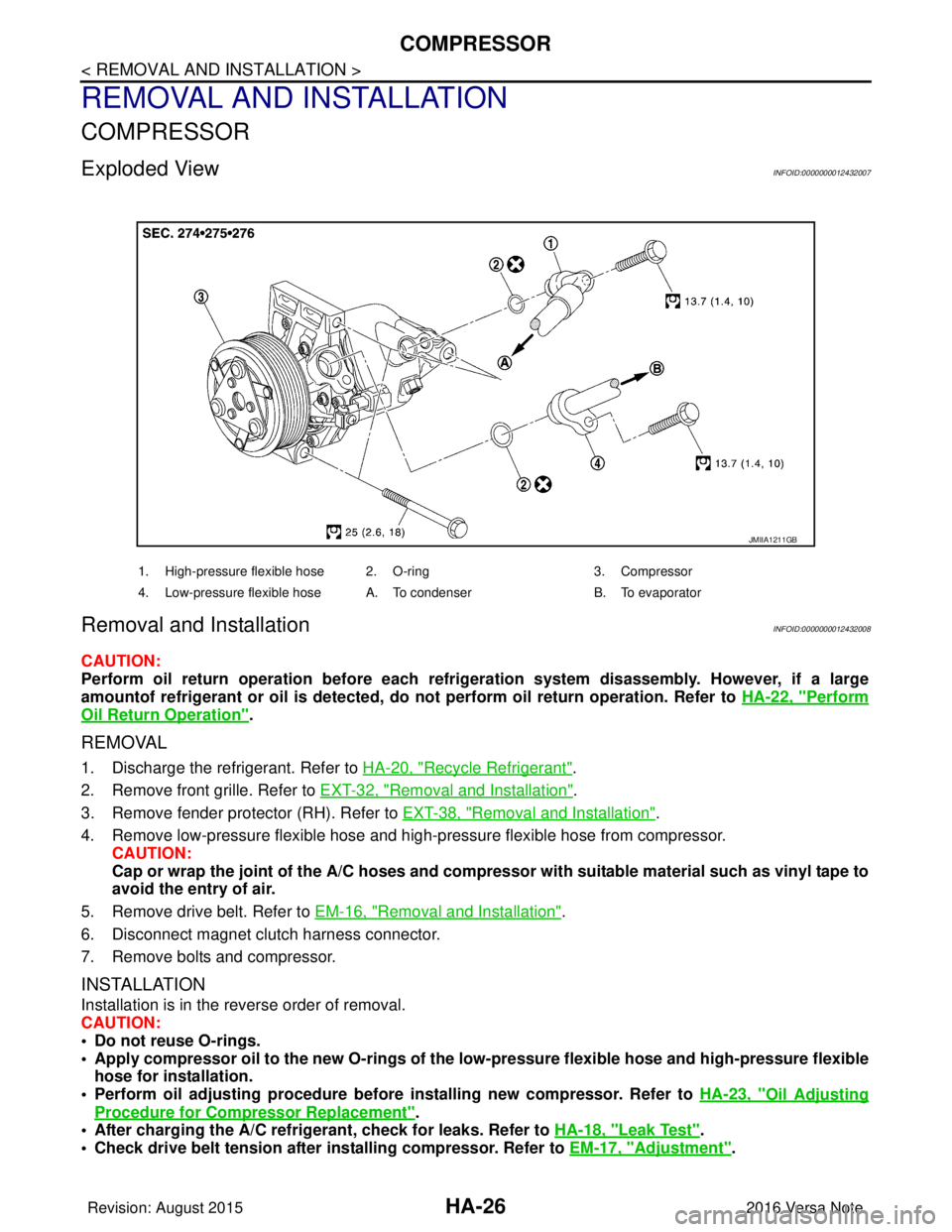

COMPRESSOR

REMOVAL AND INSTALLATION

COMPRESSOR

Exploded ViewINFOID:0000000012432007

Removal and InstallationINFOID:0000000012432008

CAUTION:

Perform oil return operation before each refrigeration system disassembly. However, if a large

amountof refrigerant or oil is detected, do not perform oil return operation. Refer to HA-22, "

Perform

Oil Return Operation".

REMOVAL

1. Discharge the refrigerant. Refer to HA-20, "Recycle Refrigerant".

2. Remove front grille. Refer to EXT-32, "

Removal and Installation".

3. Remove fender protector (RH). Refer to EXT-38, "

Removal and Installation".

4. Remove low-pressure flexible hose and high-pressure flexible hose from compressor. CAUTION:

Cap or wrap the joint of the A/C hoses and compr essor with suitable material such as vinyl tape to

avoid the entry of air.

5. Remove drive belt. Refer to EM-16, "

Removal and Installation".

6. Disconnect magnet clutch harness connector.

7. Remove bolts and compressor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-rings.

• Apply compressor oil to the new O-rings of the low-pressure flexible hose an d high-pressure flexible

hose for installation.

• Perform oil adjusting procedure before installing new compressor. Refer to HA-23, "

Oil Adjusting

Procedure for Compressor Replacement".

• After charging the A/C refrig erant, check for leaks. Refer to HA-18, "

Leak Test".

• Check drive belt tension after installing compressor. Refer to EM-17, "

Adjustment".

JMIIA1211GB

1. High-pressure flexible hose 2. O-ring 3. Compressor

4. Low-pressure flexible hose A. To condenser B. To evaporator

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2328 of 3641

ENGINE MAINTENANCEMA-13

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

ENGINE MAINTENANCE

DRIVE BELT

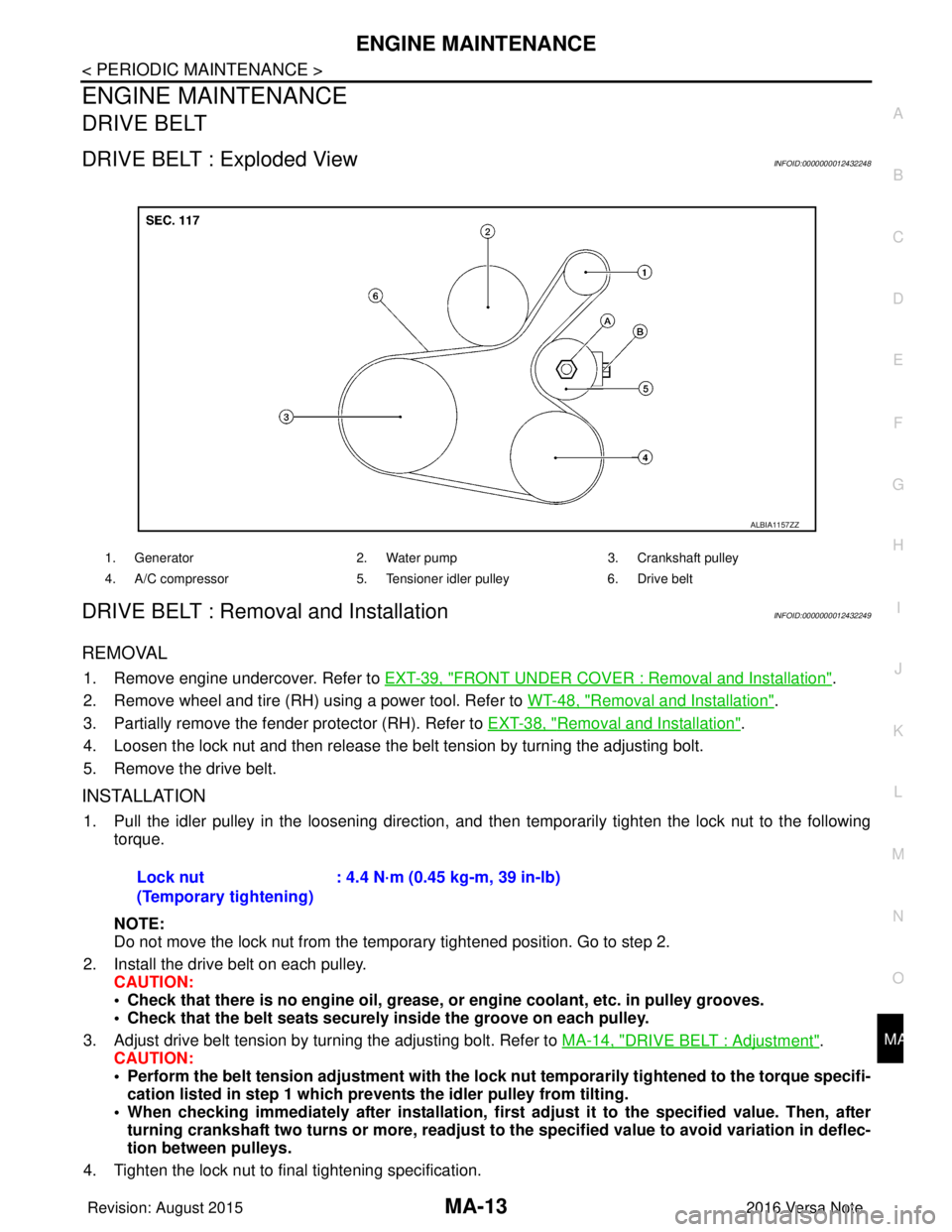

DRIVE BELT : Exploded ViewINFOID:0000000012432248

DRIVE BELT : Removal and InstallationINFOID:0000000012432249

REMOVAL

1. Remove engine undercover. Refer to

EXT-39, "FRONT UNDER COVER : Removal and Installation".

2. Remove wheel and tire (RH) using a power tool. Refer to WT-48, "

Removal and Installation".

3. Partially remove the fender protector (RH). Refer to EXT-38, "

Removal and Installation".

4. Loosen the lock nut and then release the belt tension by turning the adjusting bolt.

5. Remove the drive belt.

INSTALLATION

1. Pull the idler pulley in the loosening direction, and then temporarily tighten the lock nut to the following

torque.

NOTE:

Do not move the lock nut from the temporary tightened position. Go to step 2.

2. Install the drive belt on each pulley. CAUTION:

• Check that there is no engine oil, grease, or engine coolant, etc. in pulley grooves.

• Check that the belt seats securely inside the groove on each pulley.

3. Adjust drive belt tension by turning the adjusting bolt. Refer to MA-14, "

DRIVE BELT : Adjustment".

CAUTION:

• Perform the belt tension adjustment with the lock nut temporarily tightened to the torque specifi-

cation listed in step 1 which preven ts the idler pulley from tilting.

• When checking immediately after in stallation, first adjust it to the specified value. Then, after

turning crankshaft two turns or more, readjust to the specified value to avoid variation in deflec-

tion between pulleys.

4. Tighten the lock nut to final tightening specification.

1. Generator 2. Water pump3. Crankshaft pulley

4. A/C compressor 5. Tensioner idler pulley6. Drive belt

ALBIA1157ZZ

Lock nut

(Temporary tightening): 4.4 N·m (0.45 kg-m, 39 in-lb)

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2329 of 3641

MA-14

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE

5. Check that belt tension is within the specification using suitable tool. Refer to EM-116, "Drive Belt".

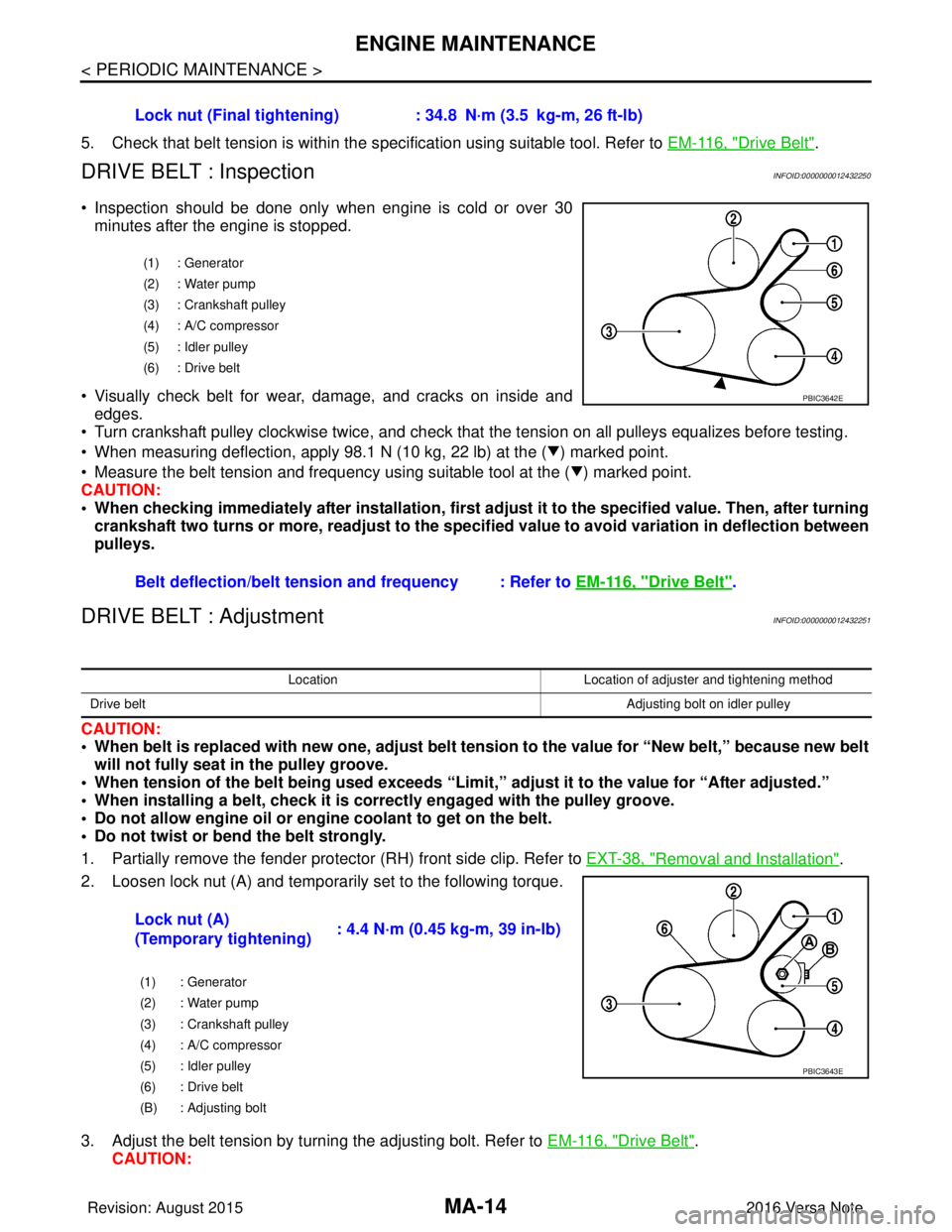

DRIVE BELT : InspectionINFOID:0000000012432250

• Inspection should be done only when engine is cold or over 30

minutes after the engine is stopped.

• Visually check belt for wear, damage, and cracks on inside and edges.

• Turn crankshaft pulley clockwise twice, and check that the tension on all pulleys equalizes before testing.

• When measuring deflection, apply 98.1 N (10 kg, 22 lb) at the ( ) marked point.

• Measure the belt tension and frequency using suitable tool at the ( ) marked point.

CAUTION:

• When checking immediately after installation, first ad just it to the specified value. Then, after turning

crankshaft two turns or more, readjust to the speci fied value to avoid variation in deflection between

pulleys.

DRIVE BELT : AdjustmentINFOID:0000000012432251

CAUTION:

• When belt is replaced with new one, adjust belt tension to the value for “New belt,” because new belt will not fully seat in the pulley groove.

• When tension of the belt being used exceeds “Limit,” adjust it to the value for “After adjusted.”

• When installing a belt, check it is co rrectly engaged with the pulley groove.

• Do not allow engine oil or engine coolant to get on the belt.

• Do not twist or bend the belt strongly.

1. Partially remove the fender protector (RH) front side clip. Refer to EXT-38, "

Removal and Installation".

2. Loosen lock nut (A) and temporarily set to the following torque.

3. Adjust the belt tension by turning the adjusting bolt. Refer to EM-116, "

Drive Belt".

CAUTION: Lock nut (Final tightening) :

34.8 N·m (3.5 kg-m, 26 ft-lb)

(1) : Generator

(2) : Water pump

(3) : Crankshaft pulley

(4) : A/C compressor

(5) : Idler pulley

(6) : Drive belt

Belt deflection/belt tension and frequency : Refer to EM-116, "Drive Belt".

PBIC3642E

LocationLocation of adjuster and tightening method

Drive belt Adjusting bolt on idler pulley

Lock nut (A)

(Temporary tightening): 4.4 N·m (0.45 kg-m, 39 in-lb)

(1) : Generator

(2) : Water pump

(3) : Crankshaft pulley

(4) : A/C compressor

(5) : Idler pulley

(6) : Drive belt

(B) : Adjusting bolt

PBIC3643E

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 3264 of 3641

![NISSAN NOTE 2016 Service User Guide 5TH MAIN GEAR ASSEMBLYTM-23

< REMOVAL AND INSTALLATION > [5MT: RS5F91R]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

5TH MAIN GEAR ASSEMBLY

Removal and InstallationINFOID:0000000012430959

REMOVAL

1. Move the shift NISSAN NOTE 2016 Service User Guide 5TH MAIN GEAR ASSEMBLYTM-23

< REMOVAL AND INSTALLATION > [5MT: RS5F91R]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

5TH MAIN GEAR ASSEMBLY

Removal and InstallationINFOID:0000000012430959

REMOVAL

1. Move the shift](/img/5/57363/w960_57363-3263.png)

5TH MAIN GEAR ASSEMBLYTM-23

< REMOVAL AND INSTALLATION > [5MT: RS5F91R]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

5TH MAIN GEAR ASSEMBLY

Removal and InstallationINFOID:0000000012430959

REMOVAL

1. Move the shift selector to the 3rd gear position.

2. Disconnect the shifter cable and the selector cable fr om shifter lever A and selector lever. Refer to TM-20,

"Removal and Installation".

CAUTION:

Do not move shifter lever A and selector lever to disconnect each cable.

3. Drain gear oil. Refer to TM-17, "

Draining".

4. Remove fender protector (LH). Refer to EXT-38, "

Removal and Installation".

5. Remove the harness clamp (A) from rear housing (1).

6. Remove rear housing and O-ring. CAUTION:

Remove in direction of input shaft ( ) as shown. Rear

housing gear oil channel is inserted to input shaft center

hole.

7. Remove 5th main gear assembly. Refer to step 5 through 8 of “Disassembly of TRANSAXLE ASSEMBLY”. Refer to TM-30,

"Disassembly".

INSTALLATION

Installation is in the reverse order of removal.

• Shift into 3rd with shifter lever to install the 5th main gear assembly, referring to Step 36 to 39 of “Assemblyof TRANSAXLE ASSEMBLY” Refer to TM-36, "

Assembly".

• Install O-ring and the rear housing to the transaxle case and tighten the bolts to the specified torque. Refer to TM-26, "

Exploded View".

CAUTION:

• Do not reuse O-ring.

• Do not pinch O-ring when installing rear housing.

• Refill gear oil. Refer to TM-17, "

Refilling".

InspectionINFOID:0000000012430960

INSPECTION AFTER INSTALLATION

• Check the operation of the control linkage. Refer to TM-21, "Inspection".

• Check the gear oil level and for oil leaks. Refer to TM-17, "

Inspection".

JPDIC0734ZZ

SCIA1709J

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3498 of 3641

![NISSAN NOTE 2016 Service User Guide CVT FLUID FILTERTM-257

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

CVT FLUID FILTER

Exploded ViewINFOID:0000000012431220

Removal and InstallationINFOID:0000000012431221 NISSAN NOTE 2016 Service User Guide CVT FLUID FILTERTM-257

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

CVT FLUID FILTER

Exploded ViewINFOID:0000000012431220

Removal and InstallationINFOID:0000000012431221](/img/5/57363/w960_57363-3497.png)

CVT FLUID FILTERTM-257

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

CVT FLUID FILTER

Exploded ViewINFOID:0000000012431220

Removal and InstallationINFOID:0000000012431221

REMOVAL

1. Remove fender protector (LH). Refer to EXT-38, "Removal and Installation".

2. Remove fluid filter cover bolt (A).

1. Transaxle assembly 2. CVT fluid filter3. Fluid filter cover

: Always replace after every disassembly.

: N·m (kg-m, in-lb)

: Apply CVT fluid

JSDIA5448GB

JSDIA5047ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3621 of 3641

WW-56

< REMOVAL AND INSTALLATION >

WASHER TANK

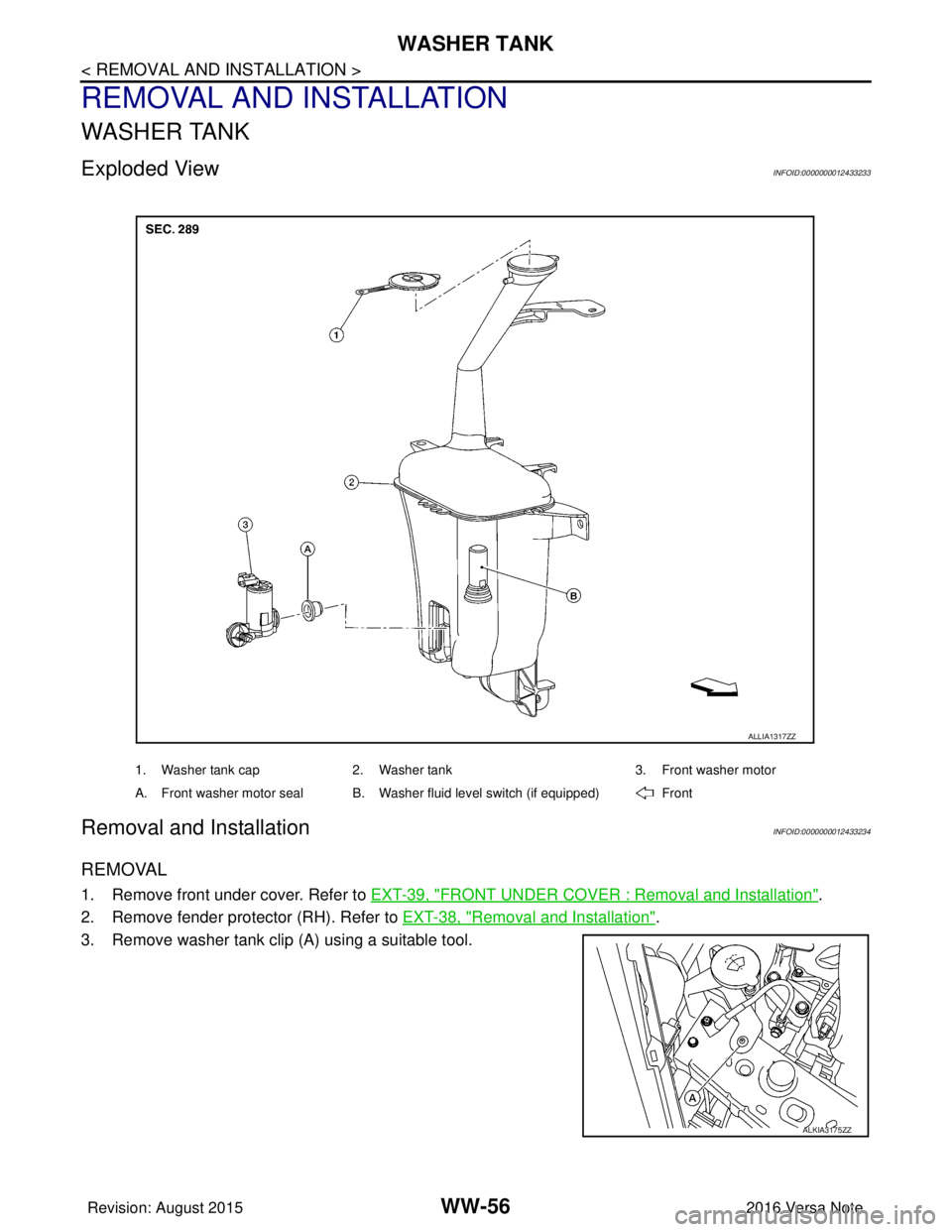

REMOVAL AND INSTALLATION

WASHER TANK

Exploded ViewINFOID:0000000012433233

Removal and InstallationINFOID:0000000012433234

REMOVAL

1. Remove front under cover. Refer to EXT-39, "FRONT UNDER COVER : Removal and Installation".

2. Remove fender protector (RH). Refer to EXT-38, "

Removal and Installation".

3. Remove washer tank clip (A) using a suitable tool.

1. Washer tank cap 2. Washer tank 3. Front washer motor

A. Front washer motor seal B. Washer fluid level switch (if equipped) Front

ALLIA1317ZZ

ALKIA3175ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3623 of 3641

WW-58

< REMOVAL AND INSTALLATION >

FRONT WASHER MOTOR

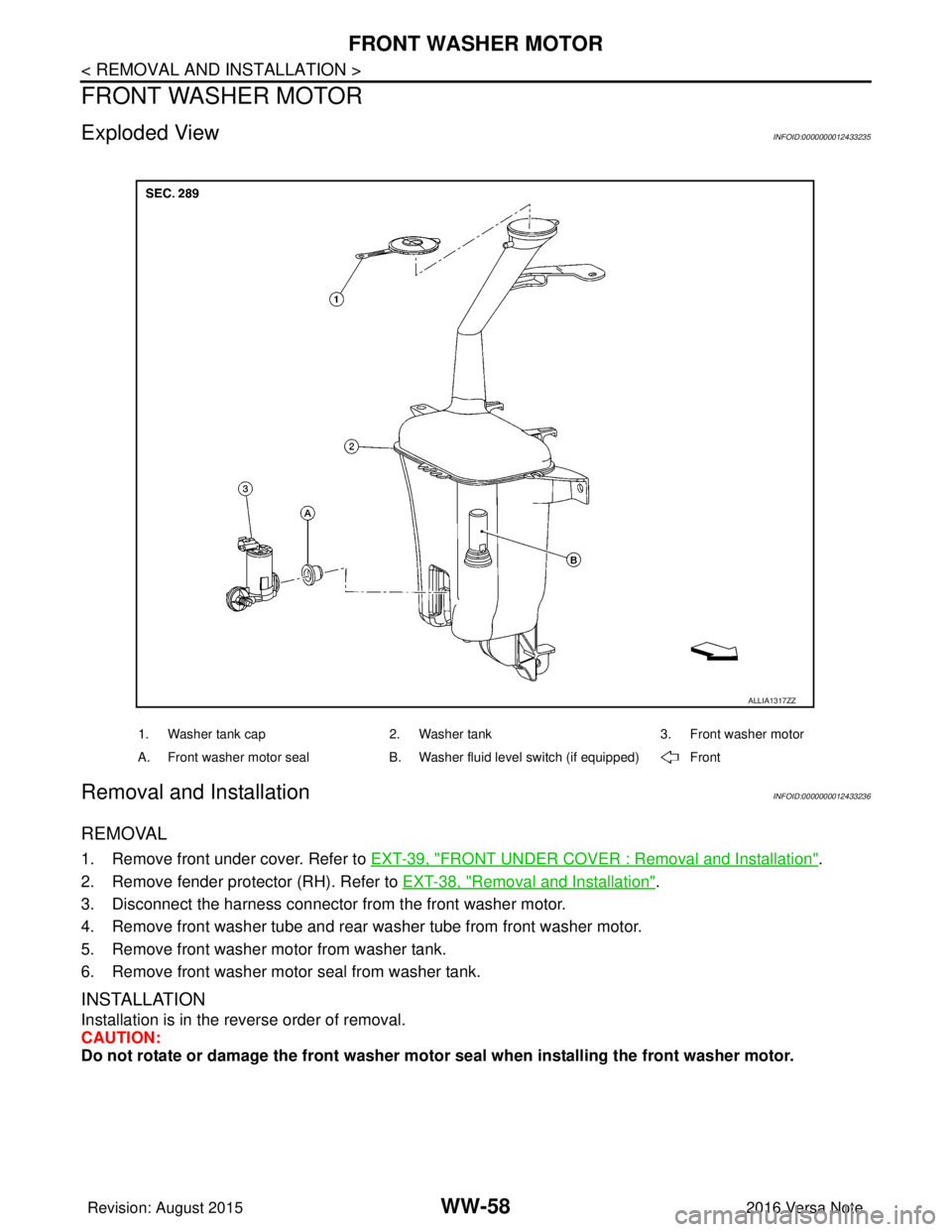

FRONT WASHER MOTOR

Exploded ViewINFOID:0000000012433235

Removal and InstallationINFOID:0000000012433236

REMOVAL

1. Remove front under cover. Refer to EXT-39, "FRONT UNDER COVER : Removal and Installation".

2. Remove fender protector (RH). Refer to EXT-38, "

Removal and Installation".

3. Disconnect the harness connector from the front washer motor.

4. Remove front washer tube and rear wa sher tube from front washer motor.

5. Remove front washer motor from washer tank.

6. Remove front washer motor seal from washer tank.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Do not rotate or damage the front washer moto r seal when installing the front washer motor.

1. Washer tank cap 2. Washer tank 3. Front washer motor

A. Front washer motor seal B. Washer fluid level switch (if equipped) Front

ALLIA1317ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com