Heat NISSAN NOTE 2016 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 416 of 3641

CORROSION PROTECTIONBRM-17

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

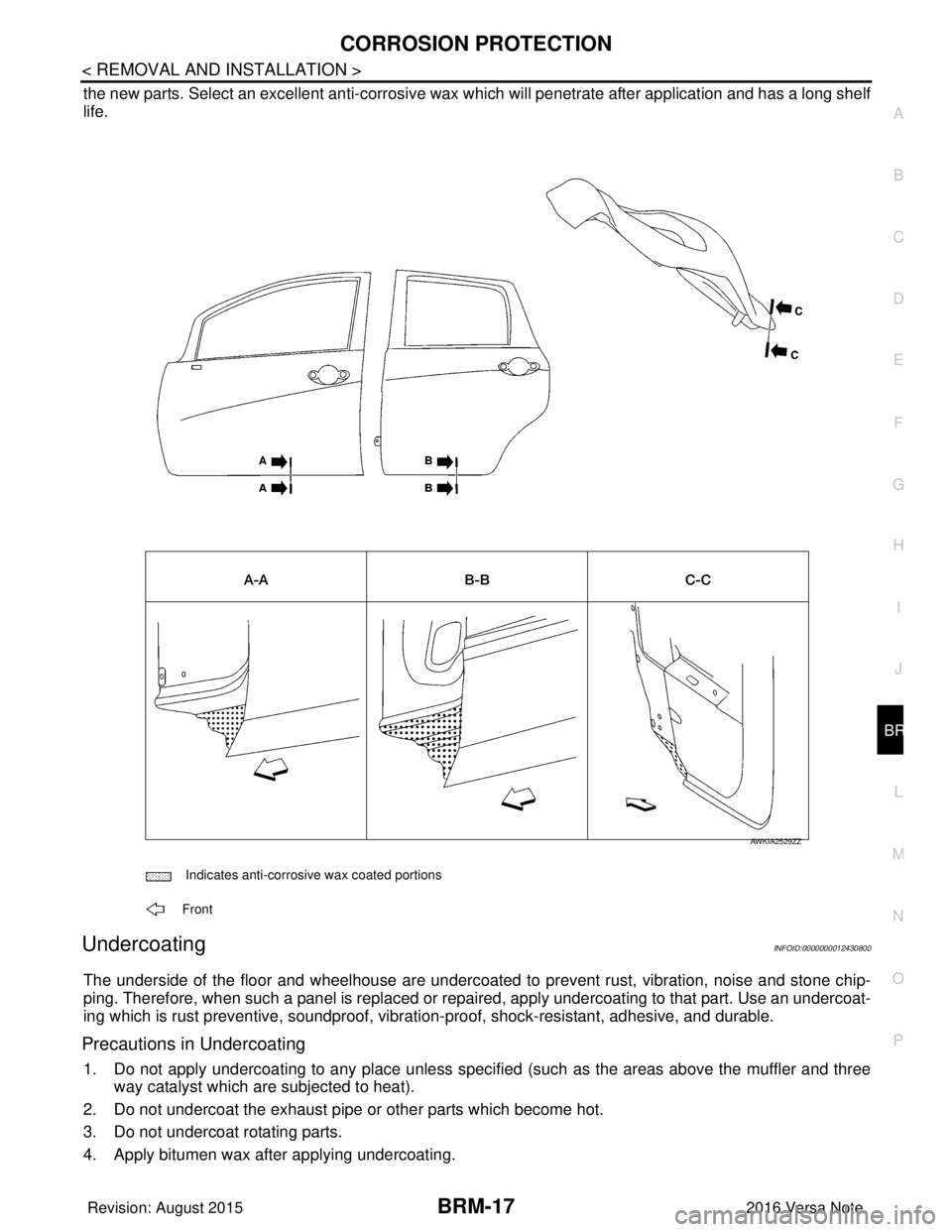

the new parts. Select an excellent anti-corrosive wax which will penetrate after application and has a long shelf

life.

UndercoatingINFOID:0000000012430800

The underside of the floor and wheelhouse are undercoated to prevent rust, vibration, noise and stone chip-

ping. Therefore, when such a panel is replaced or re paired, apply undercoating to that part. Use an undercoat-

ing which is rust preventive, soundproof, vibr ation-proof, shock-resistant, adhesive, and durable.

Precautions in Undercoating

1. Do not apply undercoating to any place unless specif ied (such as the areas above the muffler and three

way catalyst which are subjected to heat).

2. Do not undercoat the exhaust pipe or other parts which become hot.

3. Do not undercoat rotating parts.

4. Apply bitumen wax after applying undercoating.

Indicates anti-corrosive wax coated portions

Front

AWKIA2529ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 656 of 3641

COMPONENT PARTSDEF-5

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

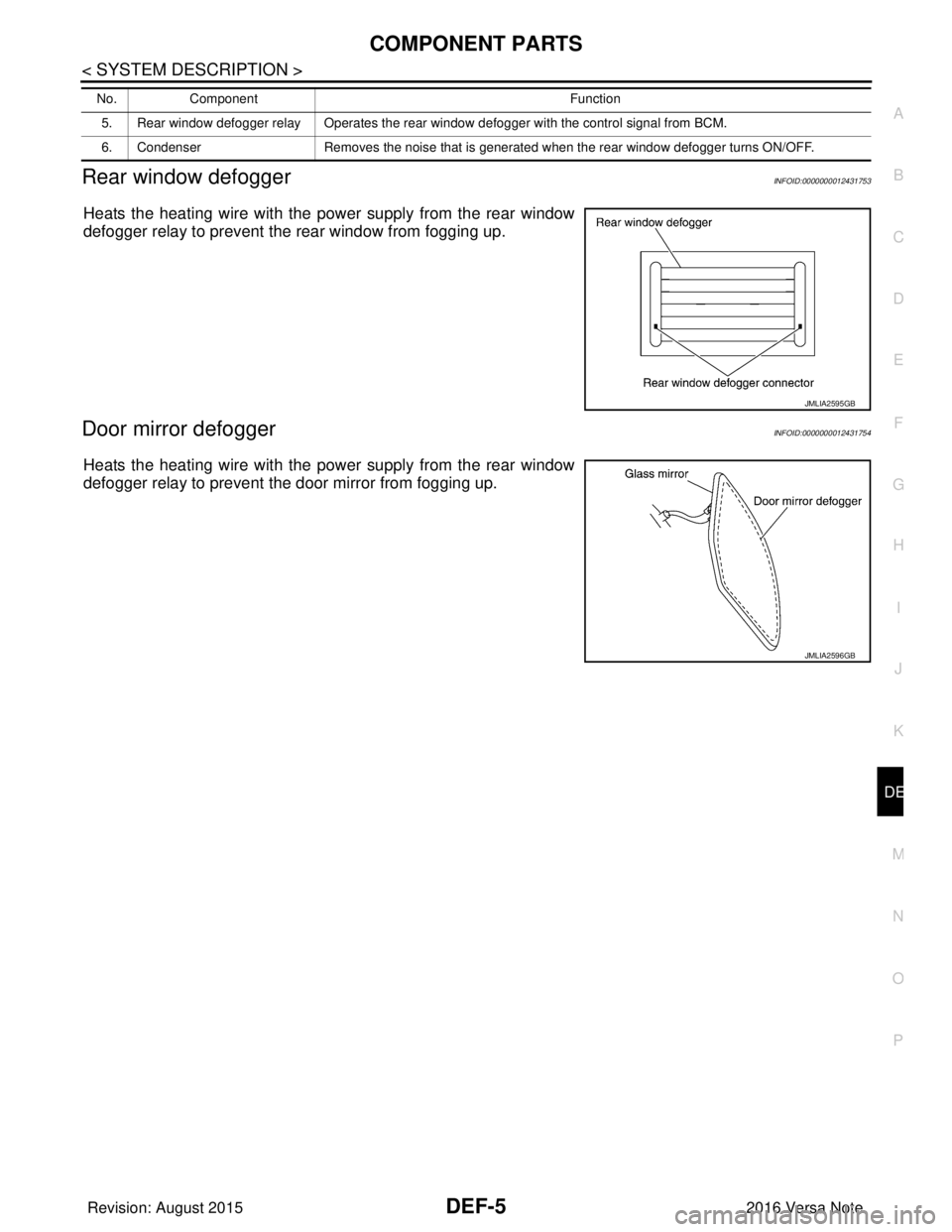

Rear window defoggerINFOID:0000000012431753

Heats the heating wire with the pow er supply from the rear window

defogger relay to prevent the rear window from fogging up.

Door mirror defoggerINFOID:0000000012431754

Heats the heating wire with the pow er supply from the rear window

defogger relay to prevent the door mirror from fogging up.

5. Rear window defogger relay Operates the rear window defogger with the control signal from BCM.

6. Condenser Removes the noise that is generated when the rear window defogger turns ON/OFF.

No.

Component Function

JMLIA2595GB

JMLIA2596GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 675 of 3641

DEF-24

< DTC/CIRCUIT DIAGNOSIS >

REAR WINDOW DEFOGGER POWER SUPPLY AND GROUND CIRCUIT

REAR WINDOW DEFOGGER POWER SUPPLY AND GROUND CIRCUIT

DescriptionINFOID:0000000012431771

Heats the heating wire with the power supply from the rear window defogger relay to prevent the rear window

from fogging up.

Component Function CheckINFOID:0000000012431772

1. CHECK REAR WINDOW DEFOGGER

Check that the heating wire of rear window defogger is heated when turning the rear window defogger switch

ON.

Is the inspection result normal?

YES >> Rear window defogger is OK.

NO >> Refer to DEF-24, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000012431773

Regarding Wiring Diagram information, refer to DEF-12, "Wiring Diagram".

1. CHECK FUSES

Check if any of the following fuses in fuse block (J/B) are blown.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace the blown fuse after repairing the affected circuit.

2. CHECK REAR WINDOW DEFOGGER POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between rear window defogger relay connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Check the following: • Rear window defogger relay.

• Battery power supply circuit.

3. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between rear window defogger connector and ground.

COMPONENT PARTS AMPEREFUSE NO.

Fuse block (J/B) 20A

9

20A 11

Te r m i n a l s

Condition of rear window de-fogger switch Voltage (V)

(Approx.)

(+)

(–)

Rear window defogger relay

connector Te r m i n a l

M14 3, 6Ground ON Battery

voltage

OFF 0

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 677 of 3641

DEF-26

< DTC/CIRCUIT DIAGNOSIS >

DRIVER SIDE DOOR MIRROR DEFOGGER

DRIVER SIDE DOOR MIRROR DEFOGGER

DescriptionINFOID:0000000012431775

Heats the heating wire with the power supply from the rear window defogger relay to prevent the door mirror

from fogging up.

Component Function CheckINFOID:0000000012431776

1. CHECK DOOR MIRROR DEFOGGER LH

Check that heating wire of door mirror defogger LH is heated when turning the rear window defogger switch

ON.

Is the inspection result normal?

YES >> Door mirror defogger is OK.

NO >> Refer to DEF-26, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000012431777

Regarding Wiring Diagram information, refer to DEF-12, "Wiring Diagram".

1. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect door mirror LH.

3. Turn ignition switch ON.

4. Check voltage between door mirror LH connector and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace harness.

2. CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between door mirror LH connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness.

3. CHECK DOOR MIRROR DEFOGGER LH

Check door mirror defogger LH.

Refer to DEF-27, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace door mirror. Refer to MIR-15, "

Removal and Installation".

4. CHECK INTERMITTENT INCIDENT

Te r m i n a l s

Condition of rear window

defogger switch Voltage (V)

(Approx.)

(+)

(–)

Door mirror LH connector Terminal

D4 5Ground ON

Battery voltage

OFF 0

Door mirror LH connector Terminal

GroundContinuity

D4 4 Yes

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 679 of 3641

DEF-28

< DTC/CIRCUIT DIAGNOSIS >

PASSENGER SIDE DOOR MIRROR DEFOGGER

PASSENGER SIDE DOOR MIRROR DEFOGGER

DescriptionINFOID:0000000012431779

Heats the heating wire with the power supply from the rear window defogger relay to prevent the door mirror

from fogging up.

Component Function CheckINFOID:0000000012431780

1.CHECK DOOR MIRROR DEFOGGER RH

Check that the heating wire of door mirror defogger RH is heated when turning the rear window defogger

switch ON.

Is the inspection result normal?

YES >> Door mirror defogger RH is OK.

NO >> Refer to DEF-28, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000012431781

Regarding Wiring Diagram information, refer to DEF-12, "Wiring Diagram".

1. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect door mirror RH.

3. Turn ignition switch ON.

4. Check voltage between door mirror RH connector and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace harness.

2. CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between door mirror RH connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness.

3. CHECK PASSENGER SIDE DOOR MIRROR DEFOGGER

Check door mirror defogger RH.

Refer to DEF-29, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace door mirror RH. Refer to MIR-17, "

Removal and Installation".

4. CHECK INTERMITTENT INCIDENT

Te r m i n a l s

Condition of rear window de-

fogger switch Voltage (V)

(Approx.)

(+)

(–)

Door mirror RH connector Terminal

D107 5Ground ON

Battery voltage

OFF 0

Door mirror RH connector Terminal

GroundContinuity

D107 4 Yes

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 688 of 3641

FILAMENTDEF-37

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

• Ruler 30 cm (11.8 in) long

• Drawing pen

• Heat gun

• Alcohol

• Cloth

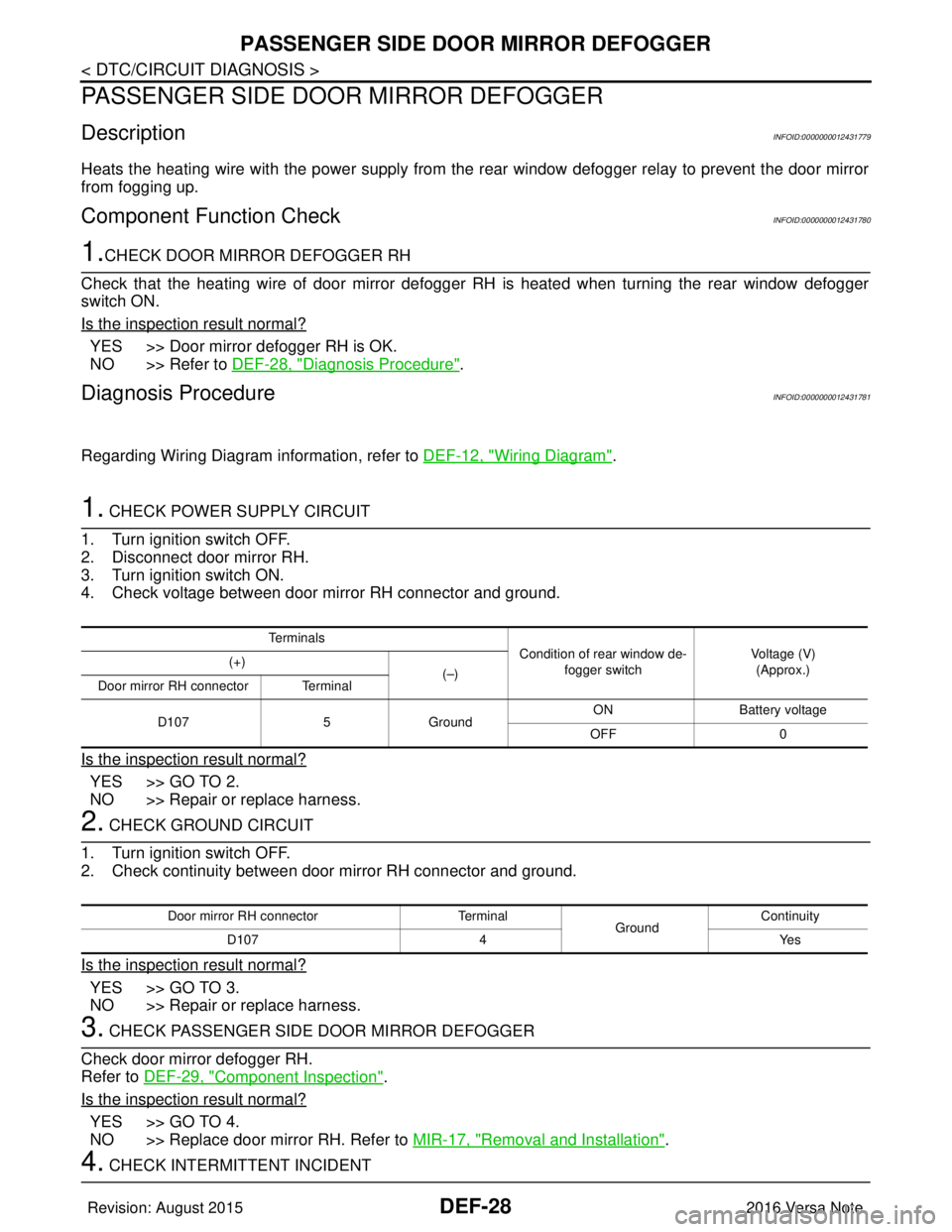

REPAIRING PROCEDURE

1. Wipe broken heat wire and its surrounding area clean with a cloth dampened in alcohol.

2. Apply a small amount of conductive silver composition to tip of drawing pen.

NOTE:

Shake silver composition container before use.

3. Place ruler on glass along broken line. Deposit conductive silver composition on break with drawing pen. Slightly overlap existing

heat wire on both sides [preferably 5 mm (0.20 in)] of the break.

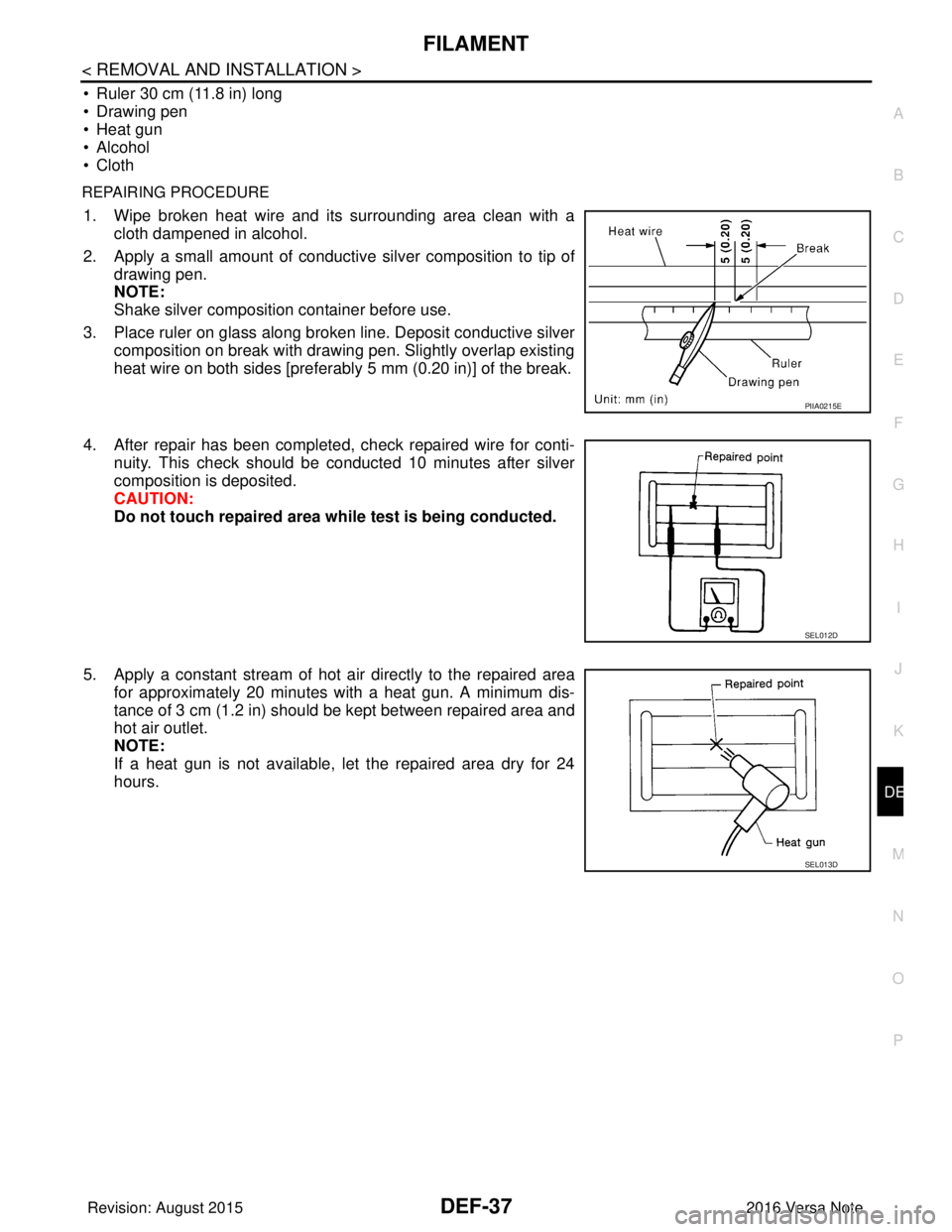

4. After repair has been completed, check repaired wire for conti- nuity. This check should be conducted 10 minutes after silver

composition is deposited.

CAUTION:

Do not touch repaired area wh ile test is being conducted.

5. Apply a constant stream of hot air directly to the repaired area for approximately 20 minutes with a heat gun. A minimum dis-

tance of 3 cm (1.2 in) should be kept between repaired area and

hot air outlet.

NOTE:

If a heat gun is not available, let the repaired area dry for 24

hours.

PIIA0215E

SEL012D

SEL013D

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1007 of 3641

![NISSAN NOTE 2016 Service User Guide EM-6

< PREPARATION >[HR16DE]

PREPARATION

PREPARATION

PREPARATION

Special Service ToolsINFOID:0000000012431688

The actual shape of the tools may differ from those illustrated here.

Tool number

(TechMat NISSAN NOTE 2016 Service User Guide EM-6

< PREPARATION >[HR16DE]

PREPARATION

PREPARATION

PREPARATION

Special Service ToolsINFOID:0000000012431688

The actual shape of the tools may differ from those illustrated here.

Tool number

(TechMat](/img/5/57363/w960_57363-1006.png)

EM-6

< PREPARATION >[HR16DE]

PREPARATION

PREPARATION

PREPARATION

Special Service ToolsINFOID:0000000012431688

The actual shape of the tools may differ from those illustrated here.

Tool number

(TechMate No.)

Tool nameDescription

K V 1 0 1111 0 0

(J-37228)

Seal cutter Removing oil pan (lower and upper) etc.

KV10116200

(J-26336-B)

Valve spring compressor

1. KV10115900

(J-26336-20)

Attachment

2. KV10109220

( — )

Adapter Disassembling and assembling valve mecha-

nism

Part (1) is a component of KV10116200, but

Part (2) is not so.

KV10112100

(BT-8653-A)

Angle wrench Tightening bolts for main bearing cap, cylinder

head, etc.

KV10117100

( — )

Heated oxygen sensor wrench Loosening or tightening heated oxygen sen-

sor 1

For 22 mm (0.87 in) width hexagon nut

KV10107902

(J-38959)

Valve oil seal puller Removing valve oil seal

KV10115600

(J-38958)

Valve oil seal drift Installing valve oil seal

Use side A.

a: 20 (0.79) dia. d: 8 (0.31) dia.

b: 13 (0.51) dia. e: 10.7 (0.421)

c: 10.3 (0.406) dia. f: 5 (0.20)

Unit: mm (in)

S-NT046

PBIC1650E

S-NT014

NT379

NT011

S-NT603

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1009 of 3641

![NISSAN NOTE 2016 Service User Guide EM-8

< PREPARATION >[HR16DE]

PREPARATION

Spark plug wrench

Removing and installing spark plug

a: 14 mm (0.55 in)

Pulley holder Crankshaft pulley removing and installing

Valve seat cutter set Finishing NISSAN NOTE 2016 Service User Guide EM-8

< PREPARATION >[HR16DE]

PREPARATION

Spark plug wrench

Removing and installing spark plug

a: 14 mm (0.55 in)

Pulley holder Crankshaft pulley removing and installing

Valve seat cutter set Finishing](/img/5/57363/w960_57363-1008.png)

EM-8

< PREPARATION >[HR16DE]

PREPARATION

Spark plug wrench

Removing and installing spark plug

a: 14 mm (0.55 in)

Pulley holder Crankshaft pulley removing and installing

Valve seat cutter set Finishing valve seat dimensions

Piston ring expander Removing and installing piston ring

Valve guide drift Removing and installing valve guide

Valve guide reamer (1): Reaming valve guide inner hole

(2): Reaming hole for oversize valve guide

(J-43897-18)

(J-43897-12)

Oxygen sensor thread cleaner Reconditioning the exhaust system threads

before installing a new air fuel ratio sensor

(Use with anti-seize lubricant shown below.)

A: [18 mm (0.71 in) dia.] for zirconia heated

oxygen sensor

B: [12 mm (0.47 in) dia.] for titania heated

oxygen sensor

C: Mating surface shave cylinder

D: Flutes

Tool name

Description

JPBIA0399ZZ

NT035

S-NT048

S-NT030

PBIC4012E

PBIC4013E

JPBIA0238ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1032 of 3641

![NISSAN NOTE 2016 Service User Guide EXHAUST MANIFOLDEM-31

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

EXHAUST MANIFOLD

Exploded ViewINFOID:0000000012431707

Removal and InstallationINFOID:0000000012431708

REMOVA NISSAN NOTE 2016 Service User Guide EXHAUST MANIFOLDEM-31

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

EXHAUST MANIFOLD

Exploded ViewINFOID:0000000012431707

Removal and InstallationINFOID:0000000012431708

REMOVA](/img/5/57363/w960_57363-1031.png)

EXHAUST MANIFOLDEM-31

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

EXHAUST MANIFOLD

Exploded ViewINFOID:0000000012431707

Removal and InstallationINFOID:0000000012431708

REMOVAL

1. Remove air duct (inlet), air duct and air cleaner assembly. Refer to

EM-26, "Exploded View".

2. Remove exhaust front tube. Refer to EX-5, "

Exploded View".

3. Remove harness bracket from the cylinder head on the right rear side.

4. Remove exhaust manifold upper and lower covers.

5. Disconnect air fuel ratio sensor 1 harness connector.

AWBIA1603ZZ

1. Exhaust manifold cover (upper) 2. Harness bracket 3. Air-fuel ratio sensor 1

4. Exhaust manifold stay 5. Heat insulator6. Exhaust manifold

7. Exhaust manifold cover (lower) 8. Exhaust maifold gasket Engine front

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1042 of 3641

![NISSAN NOTE 2016 Service User Guide FUEL INJECTOR AND FUEL TUBEEM-41

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

3. Disconnect fuel feed hose from

fuel tube. Disconnect quick con-

nector:

NOTE:

There is no fue NISSAN NOTE 2016 Service User Guide FUEL INJECTOR AND FUEL TUBEEM-41

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

3. Disconnect fuel feed hose from

fuel tube. Disconnect quick con-

nector:

NOTE:

There is no fue](/img/5/57363/w960_57363-1041.png)

FUEL INJECTOR AND FUEL TUBEEM-41

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

3. Disconnect fuel feed hose from

fuel tube. Disconnect quick con-

nector:

NOTE:

There is no fuel return path.

a. Remove quick connector cap (engine side) (1) from quick con- nector connection.

b. Disconnect fuel feed hose from hose clamp.

c. With the sleeve (B) side of quick connector release (A) facing quick connector (2), install quick connector release (A) onto fuel

tube (1) as shown.

d. Insert quick connector release (A) into quick connector (2) until sleeve (B) contacts and goes no further. Hold quick connector

release (A) in that position (D).

CAUTION:

Inserting quick connector re lease hard will not disconnect

quick connector. Hold qui ck connector release where it

contacts and goes no further.

e. Draw and pull out quick connector (E) straight up from fuel tube (1).

CAUTION:

• Pull quick connector up (E) from holding position (C) as shown.

• Do not pull with lateral force applied. O-ring inside quick connector may be damaged.

• Prepare container and cloth be forehand as fuel will leak out.

• Discard O-ring, do not reuse.

• Avoid fire and sparks.

• Keep parts away from heat source. Be especi ally careful when welding is performed.

• Do not expose parts to battery electrolyte or other acids.

• Do not bend or twist connection between quick connector and fuel feed tube during installation

or removal.

• Be sure to cover openings of disconnected fuel feed hose

(A) and fuel tube (C) with plug or plastic bag (B) to avoid

fuel leaks and entry of foreign material.

4. Disconnect fuel feed hose from fuel pipe as follows:

(1) : Quick connector cap (engine side)

JPBIA4130ZZ

JPBIA4131ZZ

JPBIA2255ZZ

JSBIA1295ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com