boot NISSAN NOTE 2016 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1839 of 3641

FAX-22

< UNIT DISASSEMBLY AND ASSEMBLY >

FRONT DRIVE SHAFT

Disassembly and Assembly

INFOID:0000000012431901

DISASSEMBLY (WHEEL SIDE)

1. Mount the drive shaft in a vise. CAUTION:

When mounting the drive shaft in a vise, always use aluminum or copper plates between the vise

and the drive shaft.

2. Remove the boot bands and slide the boot back.

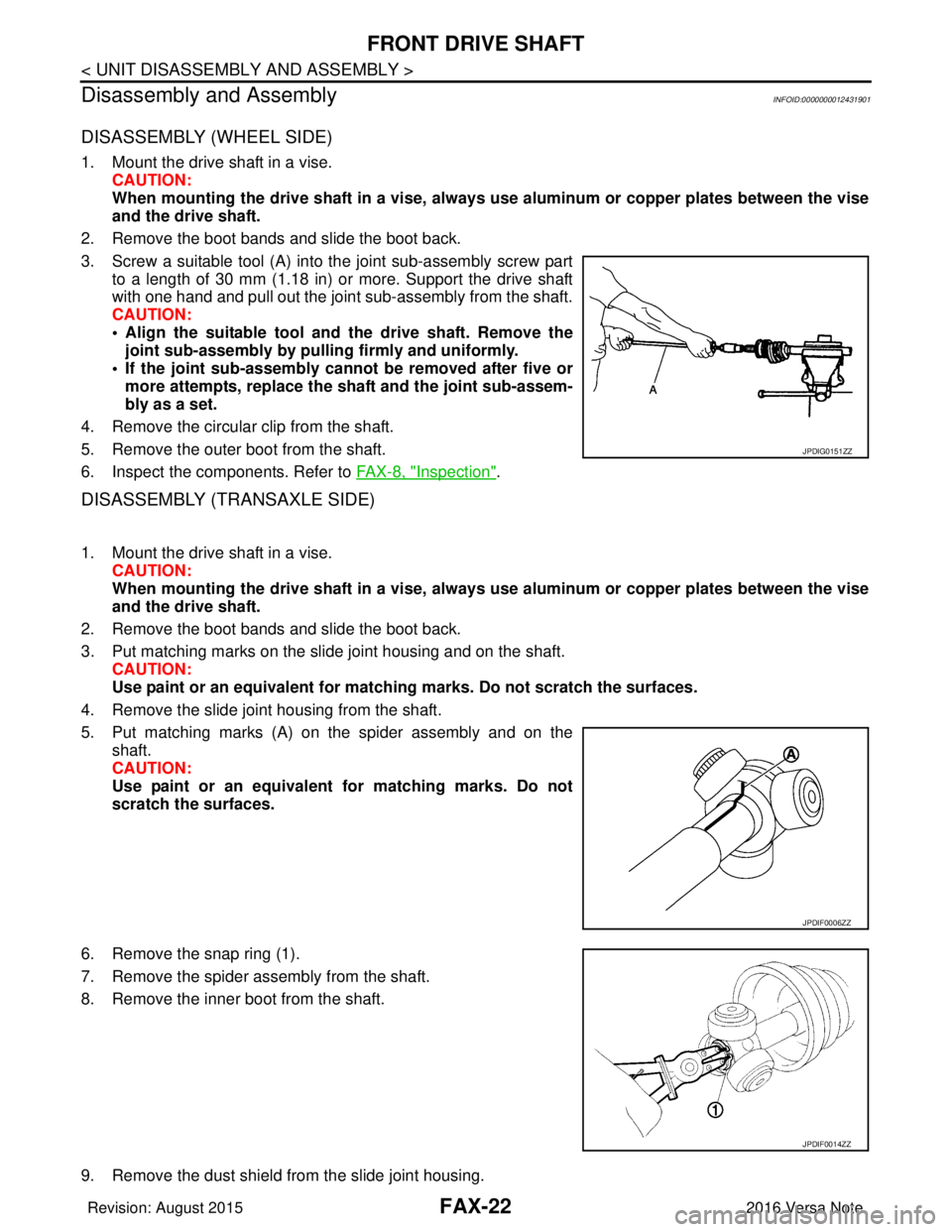

3. Screw a suitable tool (A) into the joint sub-assembly screw part to a length of 30 mm (1.18 in) or more. Support the drive shaft

with one hand and pull out the joint sub-assembly from the shaft.

CAUTION:

• Align the suitable tool and the drive shaft. Remove thejoint sub-assembly by pulli ng firmly and uniformly.

• If the joint sub-assembly cannot be removed after five or more attempts, replace the shaft and the joint sub-assem-

bly as a set.

4. Remove the circular clip from the shaft.

5. Remove the outer boot from the shaft.

6. Inspect the components. Refer to FAX-8, "

Inspection".

DISASSEMBLY (TRANSAXLE SIDE)

1. Mount the drive shaft in a vise. CAUTION:

When mounting the drive shaft in a vise, always use aluminum or copper plates between the vise

and the drive shaft.

2. Remove the boot bands and slide the boot back.

3. Put matching marks on the slide joint housing and on the shaft. CAUTION:

Use paint or an equivalent for matchi ng marks. Do not scratch the surfaces.

4. Remove the slide joint housing from the shaft.

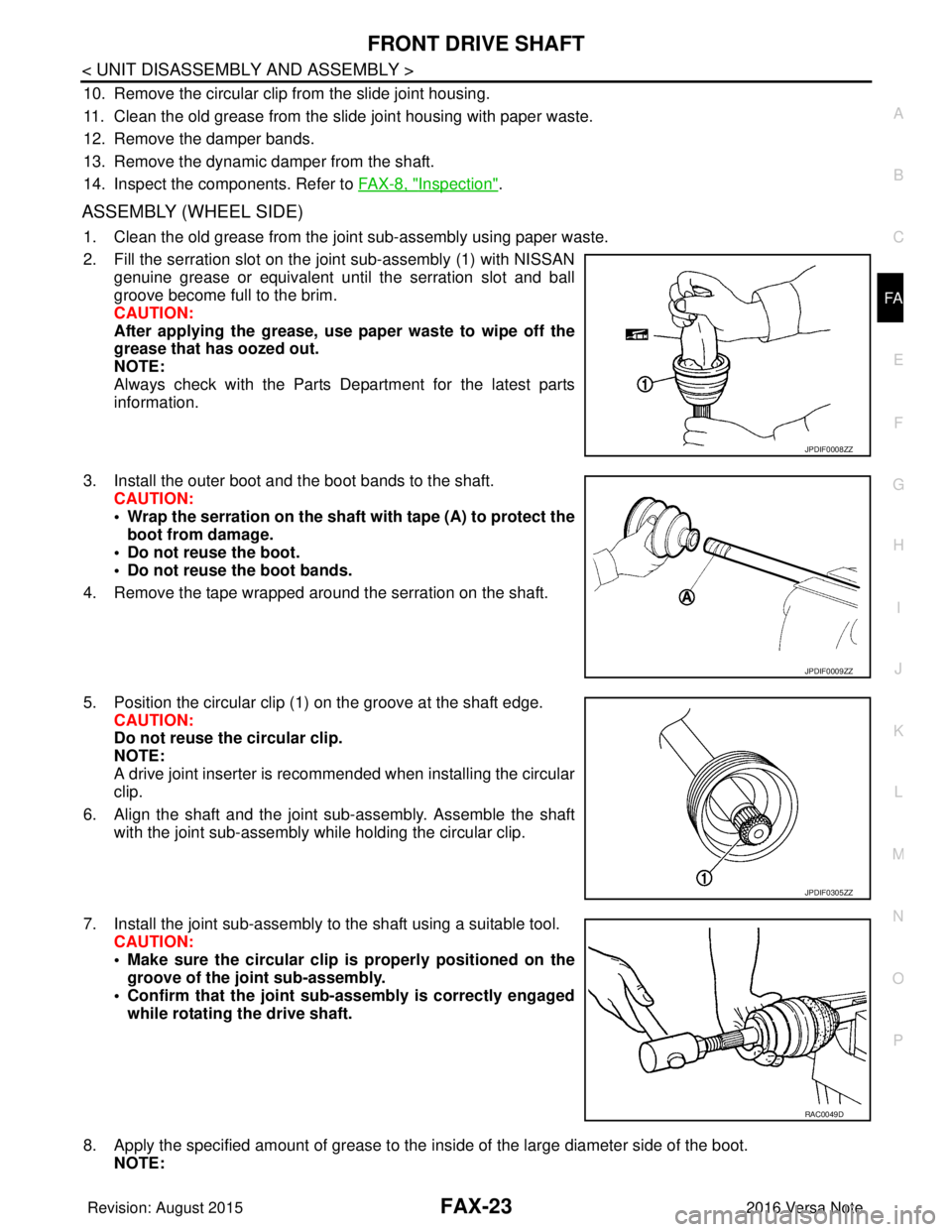

5. Put matching marks (A) on the spider assembly and on the shaft.

CAUTION:

Use paint or an equivalent fo r matching marks. Do not

scratch the surfaces.

6. Remove the snap ring (1).

7. Remove the spider assembly from the shaft.

8. Remove the inner boot from the shaft.

9. Remove the dust shield from the slide joint housing.

JPDIG0151ZZ

JPDIF0006ZZ

JPDIF0014ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1840 of 3641

FRONT DRIVE SHAFTFAX-23

< UNIT DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

10. Remove the circular clip from the slide joint housing.

11. Clean the old grease from the slide joint housing with paper waste.

12. Remove the damper bands.

13. Remove the dynamic damper from the shaft.

14. Inspect the components. Refer to FA X - 8 , "

Inspection".

ASSEMBLY (WHEEL SIDE)

1. Clean the old grease from the joint sub-assembly using paper waste.

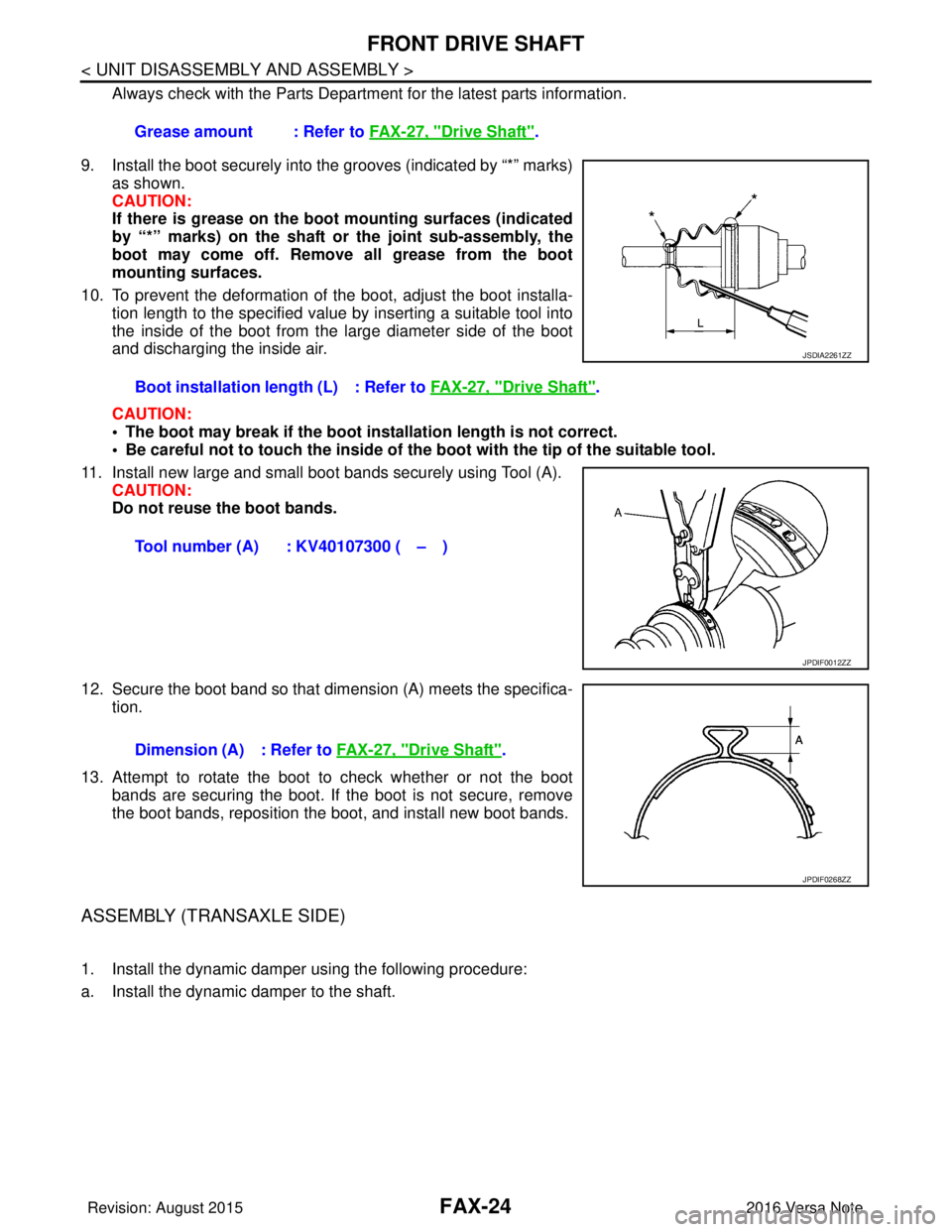

2. Fill the serration slot on the joint sub-assembly (1) with NISSAN

genuine grease or equivalent until the serration slot and ball

groove become full to the brim.

CAUTION:

After applying the grease, use paper waste to wipe off the

grease that has oozed out.

NOTE:

Always check with the Parts Department for the latest parts

information.

3. Install the outer boot and the boot bands to the shaft. CAUTION:

• Wrap the serration on the shaft with tape (A) to protect theboot from damage.

• Do not reuse the boot.

• Do not reuse the boot bands.

4. Remove the tape wrapped around the serration on the shaft.

5. Position the circular clip (1) on the groove at the shaft edge. CAUTION:

Do not reuse the circular clip.

NOTE:

A drive joint inserter is recommended when installing the circular

clip.

6. Align the shaft and the joint sub-assembly. Assemble the shaft with the joint sub-assembly while holding the circular clip.

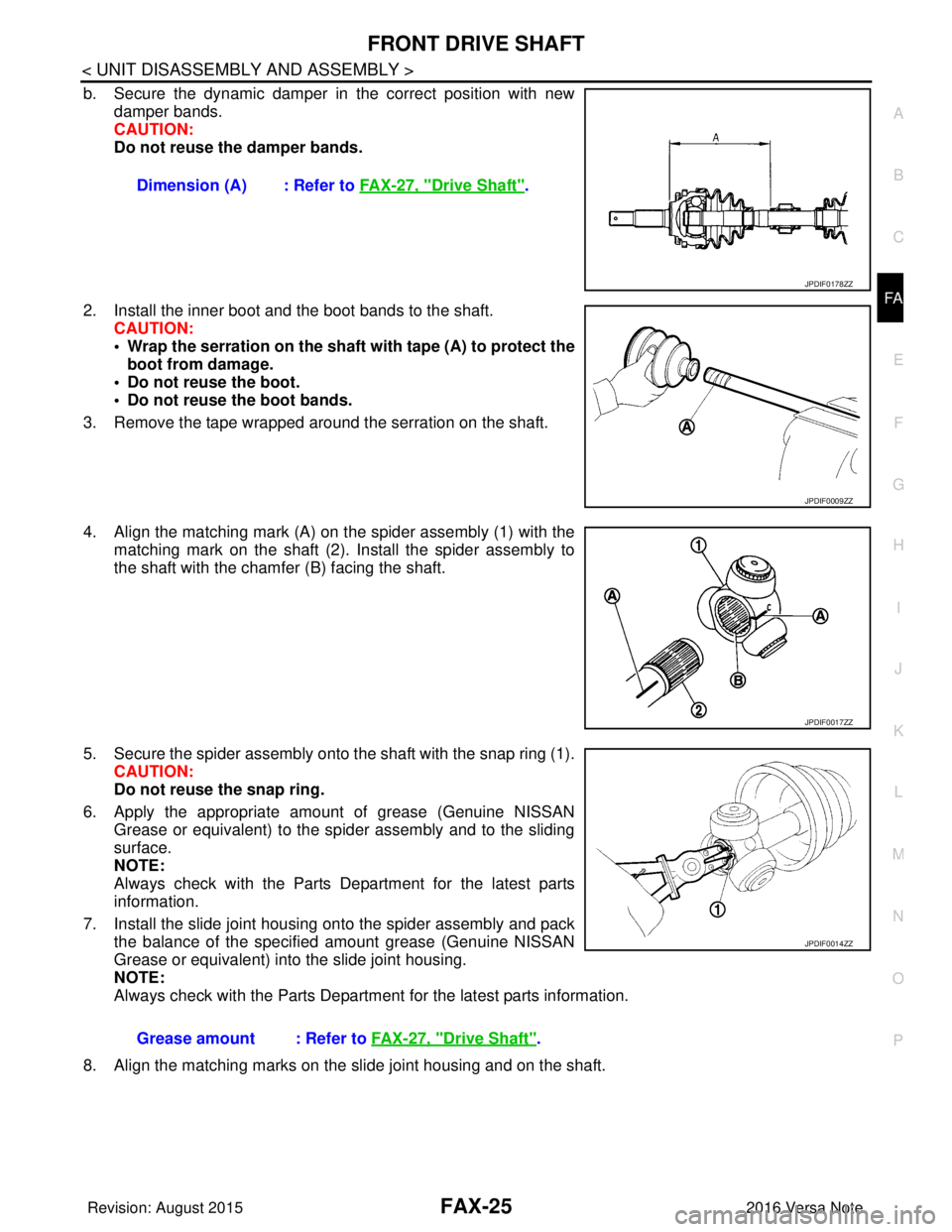

7. Install the joint sub-assembly to the shaft using a suitable tool. CAUTION:

• Make sure the circular clip is properly positioned on the

groove of the joint sub-assembly.

• Confirm that the joint sub-assembly is correctly engaged

while rotating the drive shaft.

8. Apply the specified amount of grease to the inside of the large diameter side of the boot.

NOTE:

JPDIF0008ZZ

JPDIF0009ZZ

JPDIF0305ZZ

RAC0049D

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1841 of 3641

FAX-24

< UNIT DISASSEMBLY AND ASSEMBLY >

FRONT DRIVE SHAFT

Always check with the Parts Department for the latest parts information.

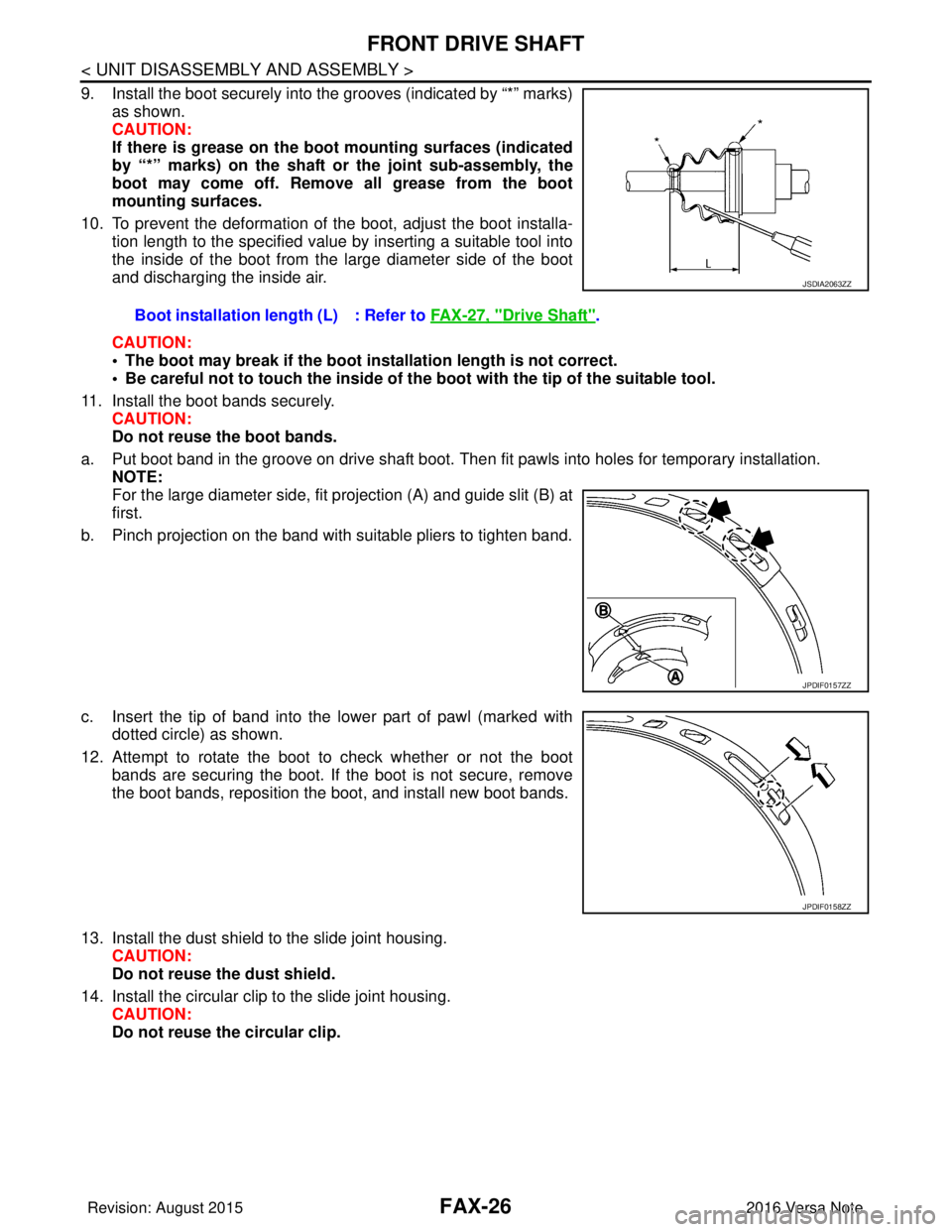

9. Install the boot securely into the grooves (indicated by “*” marks) as shown.

CAUTION:

If there is grease on the boot mounting surfaces (indicated

by “*” marks) on the shaft or the joint sub-assembly, the

boot may come off. Remove all grease from the boot

mounting surfaces.

10. To prevent the deformation of the boot, adjust the boot installa- tion length to the specified value by inserting a suitable tool into

the inside of the boot from the large diameter side of the boot

and discharging the inside air.

CAUTION:

• The boot may break if the boot installation length is not correct.

• Be careful not to touch the inside of the boot with the tip of the suitable tool.

11. Install new large and small boot bands securely using Tool (A). CAUTION:

Do not reuse the boot bands.

12. Secure the boot band so that dimension (A) meets the specifica- tion.

13. Attempt to rotate the boot to check whether or not the boot bands are securing the boot. If the boot is not secure, remove

the boot bands, reposition the boot, and install new boot bands.

ASSEMBLY (TRANSAXLE SIDE)

1. Install the dynamic damper using the following procedure:

a. Install the dynamic damper to the shaft. Grease amount : Refer to

FAX-27, "

Drive Shaft".

Boot installation length (L) : Refer to FAX-27, "

Drive Shaft".

Tool number (A) : KV40107300 ( – )

JSDIA2261ZZ

JPDIF0012ZZ

Dimension (A) : Refer to FAX-27, "Drive Shaft".

JPDIF0268ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1842 of 3641

FRONT DRIVE SHAFTFAX-25

< UNIT DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

b. Secure the dynamic damper in the correct position with new

damper bands.

CAUTION:

Do not reuse the damper bands.

2. Install the inner boot and the boot bands to the shaft. CAUTION:

• Wrap the serration on the shaft with tape (A) to protect theboot from damage.

• Do not reuse the boot.

• Do not reuse the boot bands.

3. Remove the tape wrapped around the serration on the shaft.

4. Align the matching mark (A) on the spider assembly (1) with the matching mark on the shaft (2). Install the spider assembly to

the shaft with the chamfer (B) facing the shaft.

5. Secure the spider assembly onto the shaft with the snap ring (1). CAUTION:

Do not reuse the snap ring.

6. Apply the appropriate amount of grease (Genuine NISSAN Grease or equivalent) to the spider assembly and to the sliding

surface.

NOTE:

Always check with the Parts Department for the latest parts

information.

7. Install the slide joint housing onto the spider assembly and pack the balance of the specified amount grease (Genuine NISSAN

Grease or equivalent) into the slide joint housing.

NOTE:

Always check with the Parts Department for the latest parts information.

8. Align the matching marks on the slide joint housing and on the shaft. Dimension (A) : Refer to

FAX-27, "

Drive Shaft".

JPDIF0178ZZ

JPDIF0009ZZ

JPDIF0017ZZ

Grease amount : Refer to FAX-27, "Drive Shaft".

JPDIF0014ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1843 of 3641

FAX-26

< UNIT DISASSEMBLY AND ASSEMBLY >

FRONT DRIVE SHAFT

9. Install the boot securely into the grooves (indicated by “*” marks)as shown.

CAUTION:

If there is grease on the boot mounting surfaces (indicated

by “*” marks) on the shaft or the joint sub-assembly, the

boot may come off. Remove all grease from the boot

mounting surfaces.

10. To prevent the deformation of the boot, adjust the boot installa- tion length to the specified value by inserting a suitable tool into

the inside of the boot from the large diameter side of the boot

and discharging the inside air.

CAUTION:

• The boot may break if the boot installation length is not correct.

• Be careful not to touch the inside of the boot with the tip of the suitable tool.

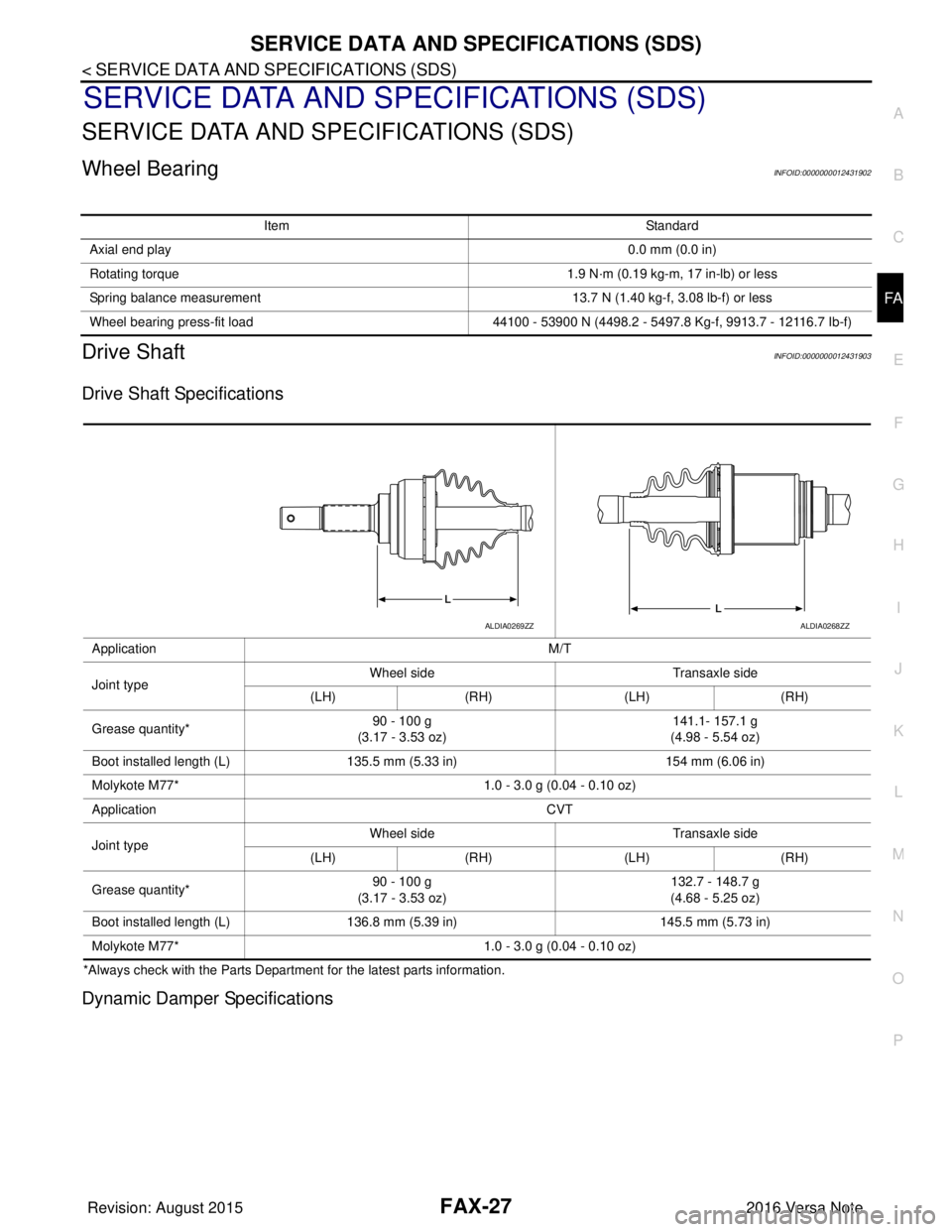

11. Install the boot bands securely. CAUTION:

Do not reuse the boot bands.

a. Put boot band in the groove on drive shaft boot. Then fit pawls into holes for temporary installation. NOTE:

For the large diameter side, fit projection (A) and guide slit (B) at

first.

b. Pinch projection on the band with suitable pliers to tighten band.

c. Insert the tip of band into the lower part of pawl (marked with dotted circle) as shown.

12. Attempt to rotate the boot to check whether or not the boot bands are securing the boot. If the boot is not secure, remove

the boot bands, reposition the boot, and install new boot bands.

13. Install the dust shield to the slide joint housing. CAUTION:

Do not reuse the dust shield.

14. Install the circular clip to the slide joint housing. CAUTION:

Do not reuse the circular clip.Boot installation length (L) : Refer to

FAX-27, "

Drive Shaft".

JSDIA2063ZZ

JPDIF0157ZZ

JPDIF0158ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1844 of 3641

SERVICE DATA AND SPECIFICATIONS (SDS)FAX-27

< SERVICE DATA AND SPECIFICATIONS (SDS)

CEF

G H

I

J

K L

M A

B

FA X

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Wheel BearingINFOID:0000000012431902

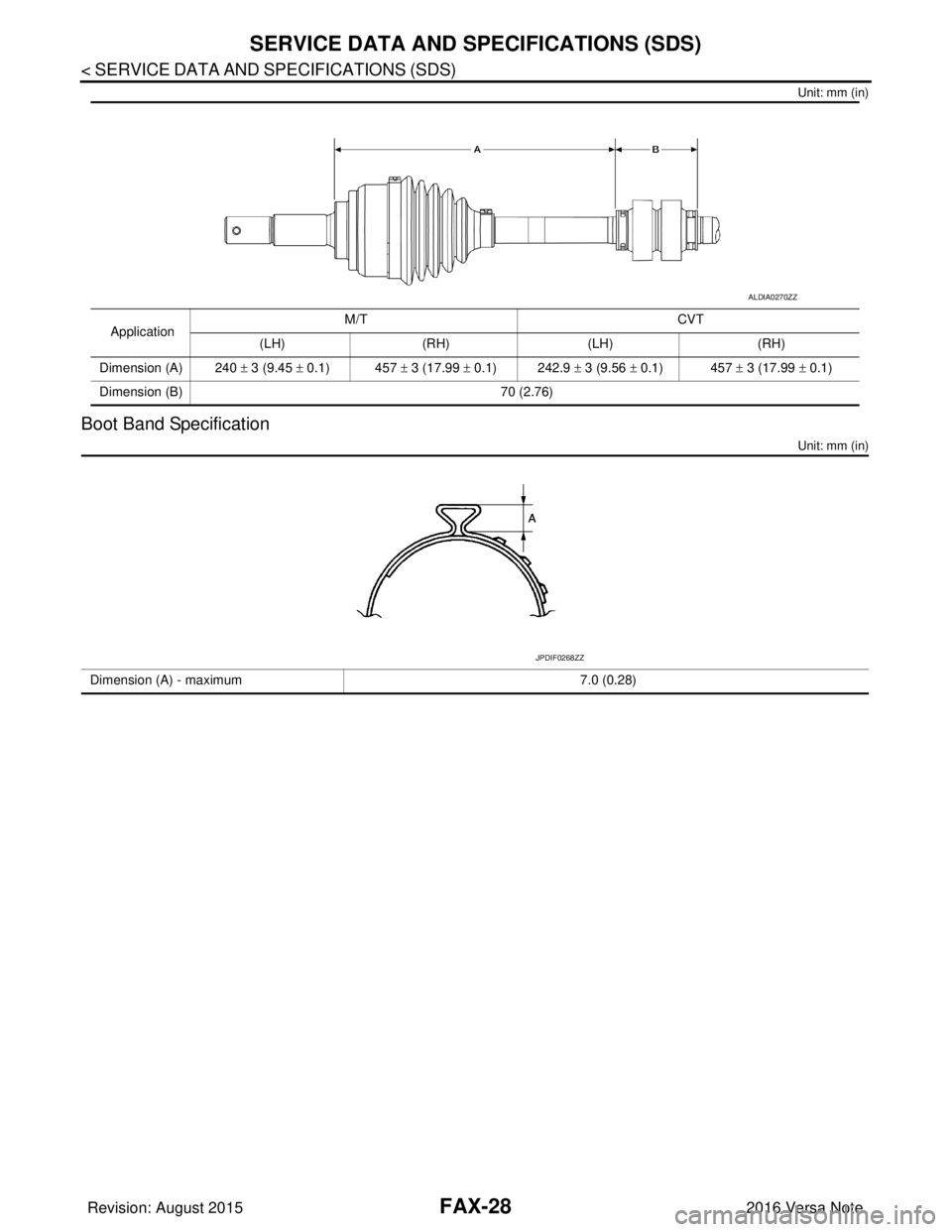

Drive ShaftINFOID:0000000012431903

Drive Shaft Specifications

*Always check with the Parts Departme nt for the latest parts information.

Dynamic Damper Specifications

Item Standard

Axial end play 0.0 mm (0.0 in)

Rotating torque 1.9 N·m (0.19 kg-m, 17 in-lb) or less

Spring balance measurement 13.7 N (1.40 kg-f, 3.08 lb-f) or less

Wheel bearing press-fit load 44100 - 53900 N (4498.2 - 5497.8 Kg-f, 9913.7 - 12116.7 Ib-f)

Application M/T

Joint type Wheel side

Transaxle side

(LH) (RH) (LH)(RH)

Grease quantity* 90 - 100 g

(3.17 - 3.53 oz) 141.1- 157.1 g

(4.98 - 5.54 oz)

Boot installed length (L) 135.5 mm (5.33 in) 154 mm (6.06 in)

Molykote M77* 1.0 - 3.0 g (0.04 - 0.10 oz)

Application CVT

Joint type Wheel side

Transaxle side

(LH) (RH) (LH)(RH)

Grease quantity* 90 - 100 g

(3.17 - 3.53 oz) 132.7 - 148.7 g

(4.68 - 5.25 oz)

Boot installed length (L) 136.8 mm (5.39 in) 145.5 mm (5.73 in)

Molykote M77* 1.0 - 3.0 g (0.04 - 0.10 oz)

ALDIA0269ZZALDIA0268ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1845 of 3641

FAX-28

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Unit: mm (in)

Boot Band Specification

Unit: mm (in)

ApplicationM/T

CVT

(LH) (RH) (LH) (RH)

Dimension (A) 240 ± 3 (9.45 ± 0.1) 457 ± 3 (17.99 ± 0.1) 242.9 ± 3 (9.56 ± 0.1) 457 ± 3 (17.99 ± 0.1)

Dimension (B) 70 (2.76)

ALDIA0270ZZ

Dimension (A) - maximum 7.0 (0.28)

JPDIF0268ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1851 of 3641

FSU-6

< PERIODIC MAINTENANCE >

FRONT SUSPENSION ASSEMBLY

PERIODIC MAINTENANCE

FRONT SUSPENSION ASSEMBLY

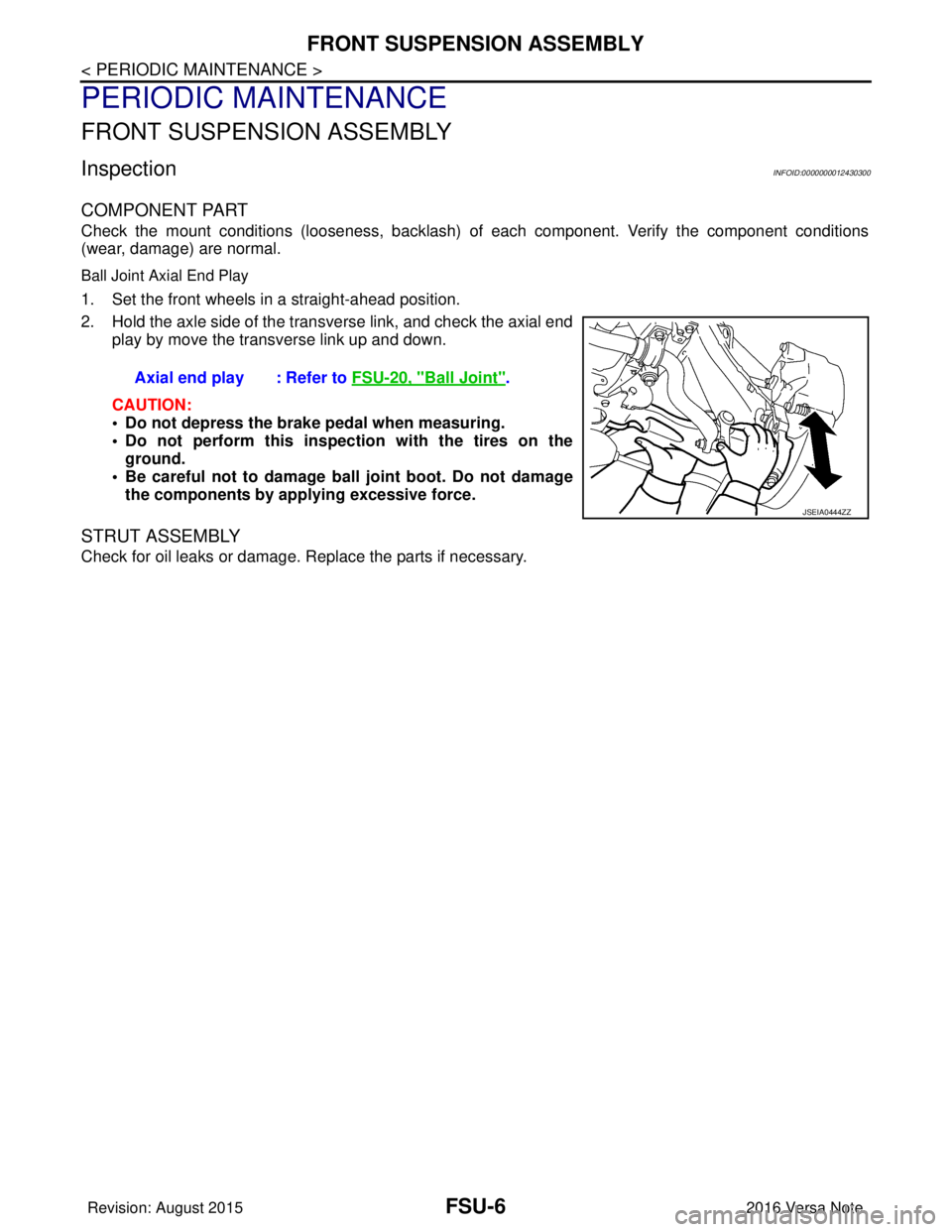

InspectionINFOID:0000000012430300

COMPONENT PART

Check the mount conditions (looseness, backlash) of each component. Verify the component conditions

(wear, damage) are normal.

Ball Joint Axial End Play

1. Set the front wheels in a straight-ahead position.

2. Hold the axle side of the tran sverse link, and check the axial end

play by move the transverse link up and down.

CAUTION:

• Do not depress the brake pedal when measuring.

• Do not perform this inspect ion with the tires on the

ground.

• Be careful not to damage ball joint boot. Do not damage the components by applying excessive force.

STRUT ASSEMBLY

Check for oil leaks or damage. Replace the parts if necessary.Axial end play : Refer to

FSU-20, "

Ball Joint".

JSEIA0444ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1855 of 3641

FSU-10

< REMOVAL AND INSTALLATION >

TRANSVERSE LINK

TRANSVERSE LINK

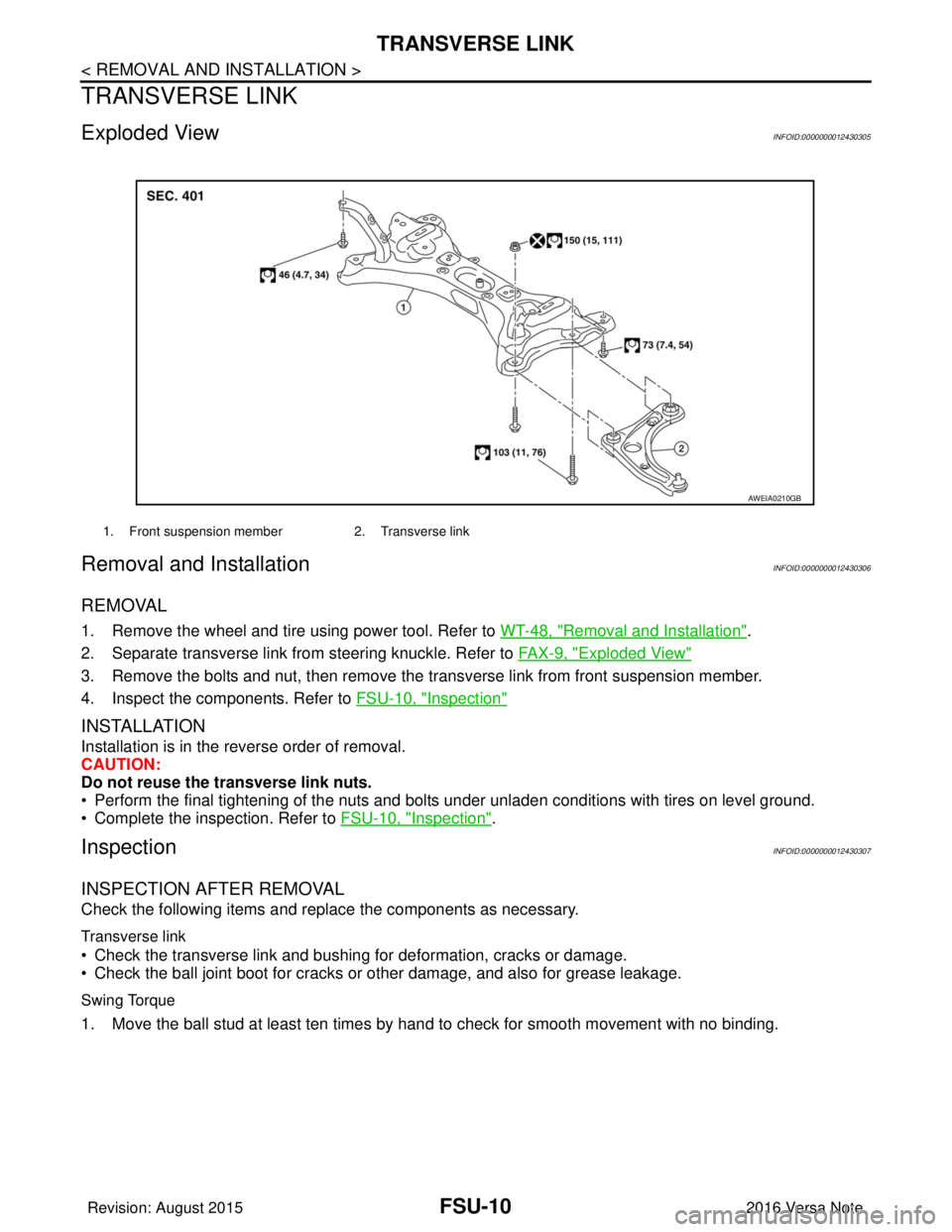

Exploded ViewINFOID:0000000012430305

Removal and InstallationINFOID:0000000012430306

REMOVAL

1. Remove the wheel and tire using power tool. Refer to WT-48, "Removal and Installation".

2. Separate transverse link from steering knuckle. Refer to FA X - 9 , "

Exploded View"

3. Remove the bolts and nut, then remove the transverse link from front suspension member.

4. Inspect the components. Refer to FSU-10, "

Inspection"

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Do not reuse the transverse link nuts.

• Perform the final tightening of the nuts and bolts under unladen conditions with tires on level ground.

• Complete the inspection. Refer to FSU-10, "

Inspection".

InspectionINFOID:0000000012430307

INSPECTION AFTER REMOVAL

Check the following items and replace the components as necessary.

Transverse link

• Check the transverse link and bushing for deformation, cracks or damage.

• Check the ball joint boot for cracks or other damage, and also for grease leakage.

Swing Torque

1. Move the ball stud at least ten times by hand to check for smooth movement with no binding.

1. Front suspension member2. Transverse link

AWEIA0210GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1893 of 3641

HOW TO USE THIS MANUALGI-5

< HOW TO USE THIS MANUAL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

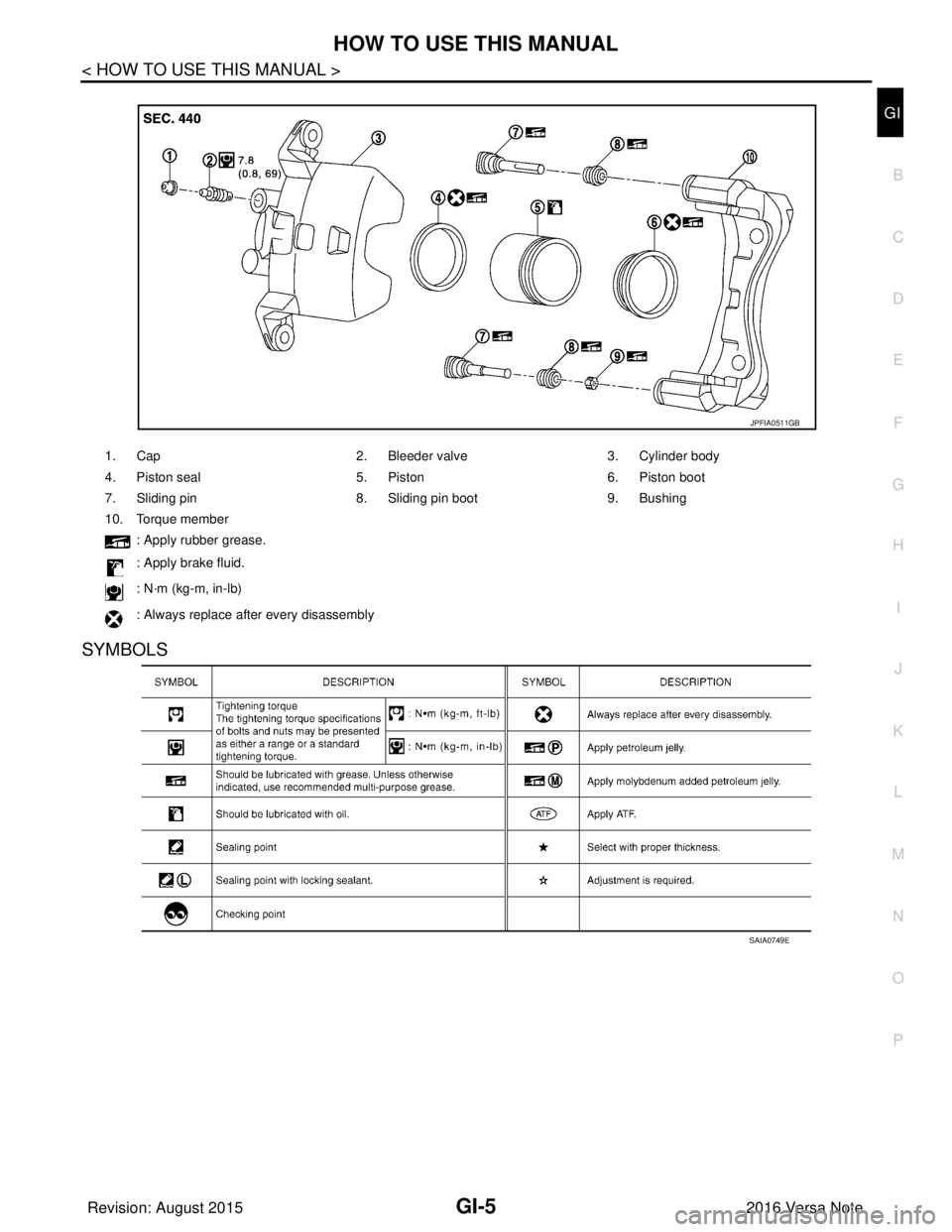

SYMBOLS

1. Cap 2. Bleeder valve3. Cylinder body

4. Piston seal 5. Piston6. Piston boot

7. Sliding pin 8. Sliding pin boot9. Bushing

10. Torque member

: Apply rubber grease.

: Apply brake fluid.

: N·m (kg-m, in-lb)

: Always replace after every disassembly

JPFIA0511GB

SAIA0749E

Revision: August 2015 2016 Versa Note

cardiagn.com