boot NISSAN NOTE 2016 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2086 of 3641

IP-18

< REMOVAL AND INSTALLATION >

CENTER CONSOLE ASSEMBLY

CENTER CONSOLE ASSEMBLY

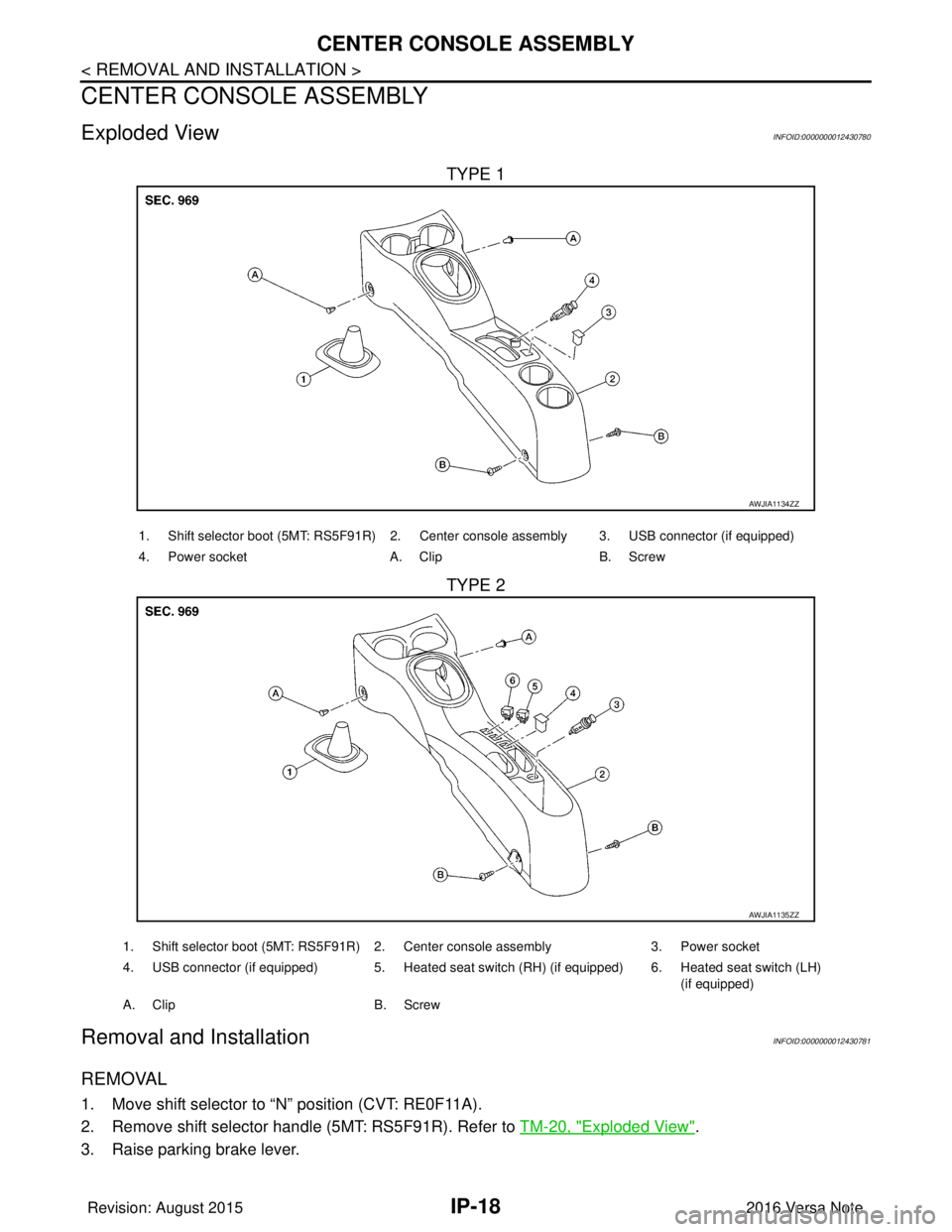

Exploded ViewINFOID:0000000012430780

TYPE 1

TYPE 2

Removal and InstallationINFOID:0000000012430781

REMOVAL

1. Move shift selector to “N” position (CVT: RE0F11A).

2. Remove shift selector handle (5MT: RS5F91R). Refer to TM-20, "

Exploded View".

3. Raise parking brake lever.

AWJIA1134ZZ

1. Shift selector boot (5MT: RS5F91R) 2. Center console assembly 3. USB connector (if equipped)

4. Power socket A. Clip B. Screw

AWJIA1135ZZ

1. Shift selector boot (5MT: RS5F91R) 2. Center console assembly 3. Power socket

4. USB connector (if equipped) 5. Heated seat switch (RH) (if equipped) 6. Heated seat switch (LH) (if equipped)

A. Clip B. Screw

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2323 of 3641

MA-8

< PERIODIC MAINTENANCE >

PERIODIC MAINTENANCE

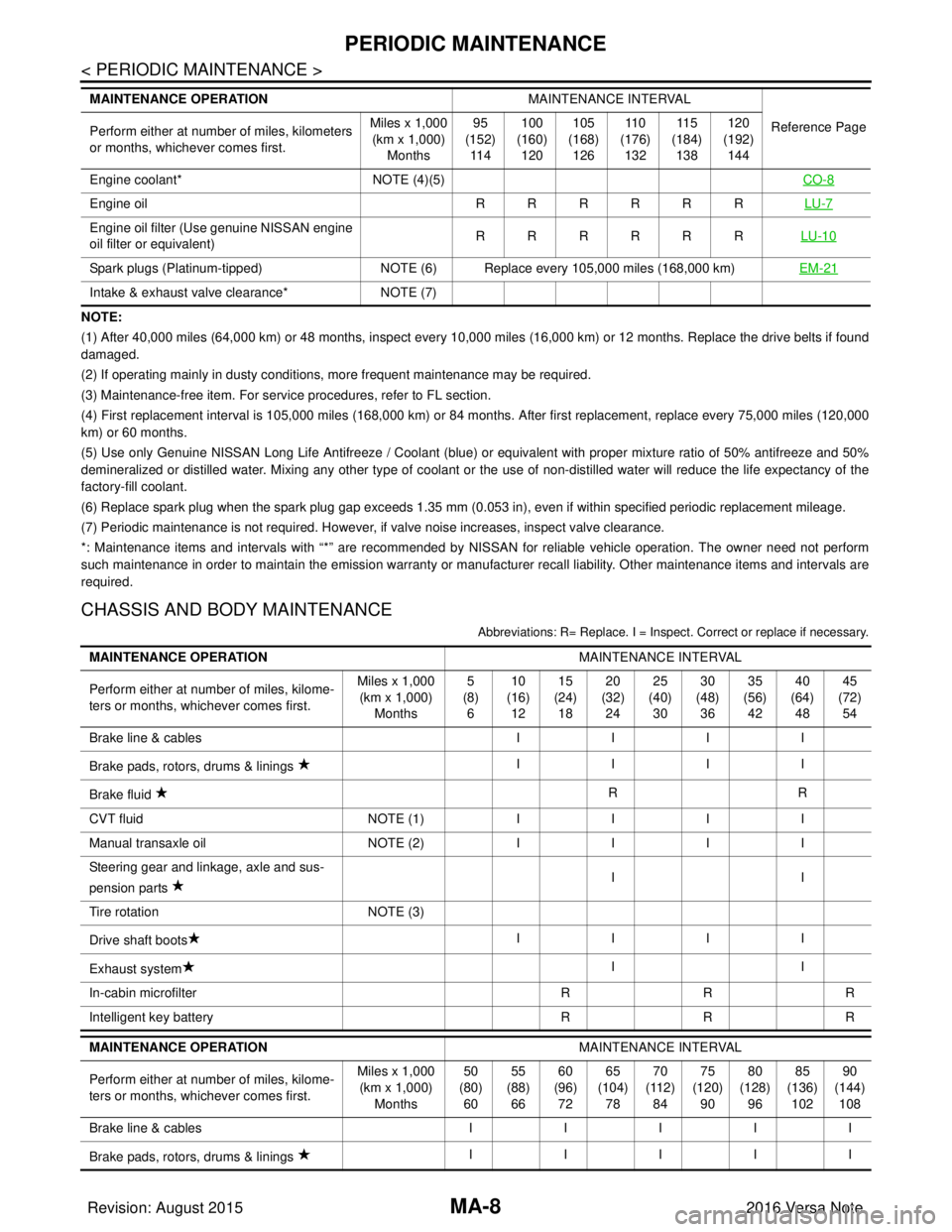

NOTE:

(1) After 40,000 miles (64,000 km) or 48 months, inspect every 10,000 miles (16,000 km) or 12 months. Replace the drive belts if found

damaged.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required.

(3) Maintenance-free item. For service procedures, refer to FL section.

(4) First replacement interval is 105,000 miles (168,000 km) or 84 months. After first replacement, replace every 75,000 miles (120,000

km) or 60 months.

(5) Use only Genuine NISSAN Long Life Antifreeze / Coolant (blue) or equivalent with proper mixture ratio of 50% antifreeze and 50%

demineralized or distilled water. Mixing any other type of coolant or the use of non-distilled water will reduce the life expec tancy of the

factory-fill coolant.

(6) Replace spark plug when the spark plug gap exceeds 1.35 mm (0.053 in), even if within specified periodic replacement mileag e.

(7) Periodic maintenance is not required. However, if valve noise increases, inspect valve clearance.

*: Maintenance items and intervals with “*” are recommended by NISSAN for reli able vehicle operation. The owner need not perform

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and inter vals are

required.

CHASSIS AND BODY MAINTENANCE

Abbreviations: R= Replace. I = Inspec t. Correct or replace if necessary.

Engine coolant* NOTE (4)(5) CO-8

Engine oil RRRRRRLU-7

Engine oil filter (Use genuine NISSAN engine

oil filter or equivalent) RRRRRR

LU-10

Spark plugs (Platinum-tipped)NOTE (6) Replace every 105,000 miles (168,000 km) EM-21

Intake & exhaust valve clearance*NOTE (7)

MAINTENANCE OPERATION

MAINTENANCE INTERVAL

Reference Page

Perform either at number of miles, kilometers

or months, whichever comes first. Miles x 1,000

(km x 1,000)

Months 95

(152)

11 4 100

(160)

120 105

(168)

126 11 0

(176)

132 11 5

(184)

138 120

(192)

144

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilome-

ters or months, whichever comes first. Miles x 1,000

(km x 1,000)

Months 5

(8)

6 10

(16)

12 15

(24)

18 20

(32)

24 25

(40)

30 30

(48)

36 35

(56)

42 40

(64)

48 45

(72)

54

Brake line & cables IIII

Brake pads, rotors, drums & linings IIII

Brake fluid RR

CVT fluid NOTE (1)IIII

Manual transaxle oil NOTE (2)IIII

Steering gear and linkage, axle and sus-

pension parts II

Tire rotation NOTE (3)

Drive shaft boots IIII

Exhaust system II

In-cabin microfilter RRR

Intelligent key battery RRR

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilome-

ters or months, whichever comes first. Miles x 1,000

(km x 1,000) Months 50

(80) 60 55

(88) 66 60

(96) 72 65

(104) 78 70

(112) 84 75

(120) 90 80

(128) 96 85

(136) 102 90

(144) 108

Brake line & cables III II

Brake pads, rotors, drums & linings IIIII

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2324 of 3641

PERIODIC MAINTENANCEMA-9

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

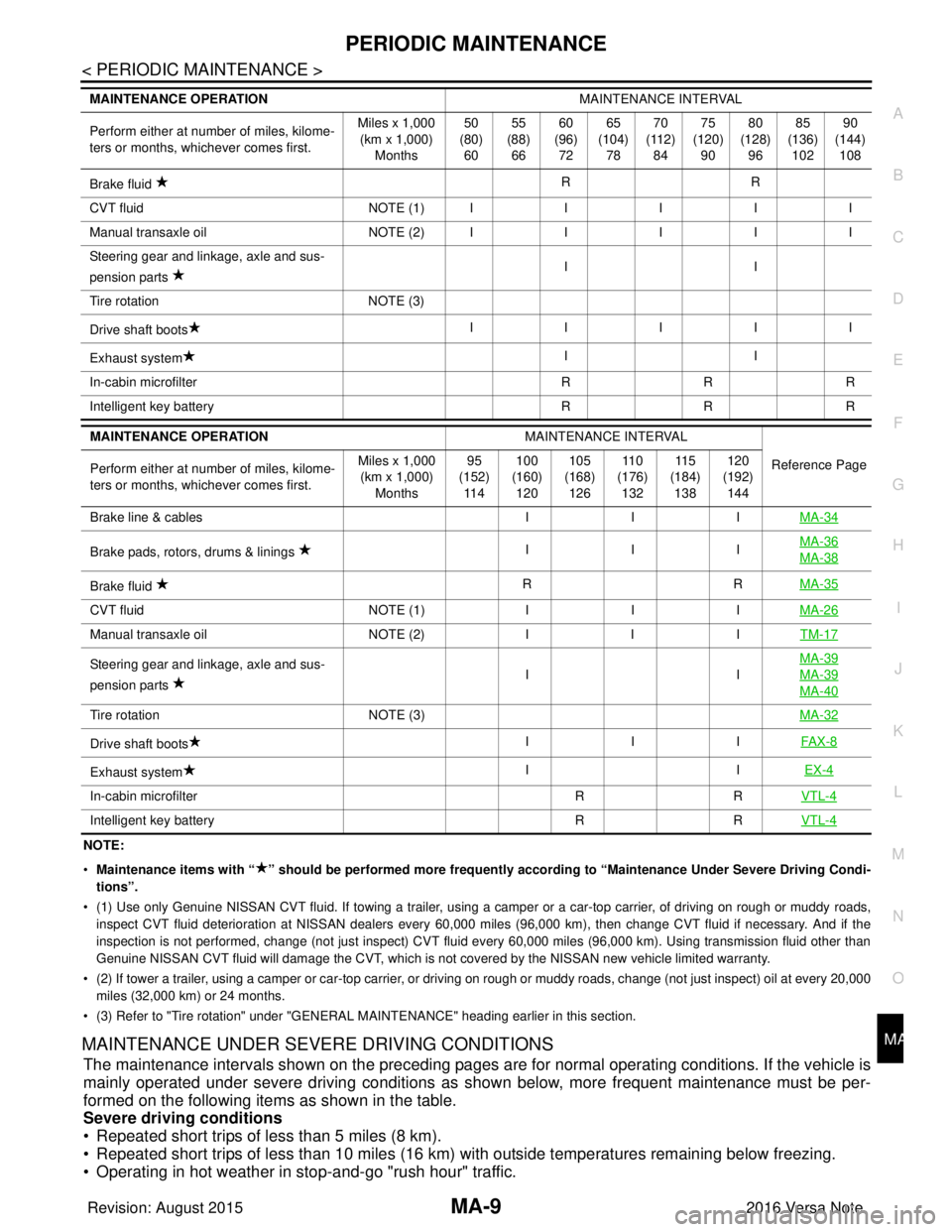

NOTE:

•

Maintenance items with “ ” shoul d be performed more frequently according to “Maintenance Under Severe Driving Condi-

tions”.

• (1) Use only Genuine NISSAN CVT fluid. If towing a trailer, using a camper or a car-top carrier, of driving on rough or muddy roads,

inspect CVT fluid deterioration at NISSAN dealers every 60,000 miles (96,000 km), then change CVT fluid if necessary. And if th e

inspection is not performed, change (not just inspect) CVT fluid every 60,000 miles (96,000 km). Using transmission fluid other than

Genuine NISSAN CVT fluid will damage the CVT, which is not covered by the NISSAN new vehicle limited warranty.

• (2) If tower a trailer, using a camper or car-top carrier, or driving on rough or muddy roads, change (not just inspect) oil a t every 20,000

miles (32,000 km) or 24 months.

• (3) Refer to "Tire rotation" under "GENERAL MAINTENANCE" heading earlier in this section.

MAINTENANCE UNDER SEVERE DRIVING CONDITIONS

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle is

mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

Severe driving conditions

• Repeated short trips of less than 5 miles (8 km).

• Repeated short trips of less than 10 miles (16 km) wi th outside temperatures remaining below freezing.

• Operating in hot weather in stop-and-go "rush hour" traffic.

Brake fluid RR

C VT flu id NO TE (1)IIIII

M anu al t ra nsa xle o il NO TE (2)IIIII

Steering gear and linkage, axle and sus-

pension parts II

Tire rotation NOTE (3)

Drive shaft boots IIIII

Exhaust system II

In-cabin microfilter RRR

Intelligent key battery RRR

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference Page

Perform either at number of miles, kilome-

ters or months, whichever comes first. Miles x 1,000

(km x 1,000) Months 95

(152) 11 4 100

(160) 120 105

(168) 126 11 0

(176) 132 11 5

(184) 138 120

(192) 144

Brake line & cables IIIMA-34

Brake pads, rotors, drums & linings IIIMA-36MA-38

Brake fluid

RR

MA-35

CVT fluid NOTE (1)IIIMA-26

Manual transaxle oil NOTE (2)IIITM-17

Steering gear and linkage, axle and sus-

pension parts IIMA-39MA-39

MA-40

Tire rotation

NOTE (3) MA-32

Drive shaft boots III

FAX-8

Exhaust system II

EX-4

In-cabin microfilter RRVTL-4

Intelligent key battery RRVTL-4

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilome-

ters or months, whichever comes first. Miles x 1,000

(km x 1,000)

Months 50

(80)

60 55

(88)

66 60

(96)

72 65

(104)

78 70

(112)

84 75

(120)

90 80

(128)

96 85

(136)

102 90

(144)

108

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2325 of 3641

MA-10

< PERIODIC MAINTENANCE >

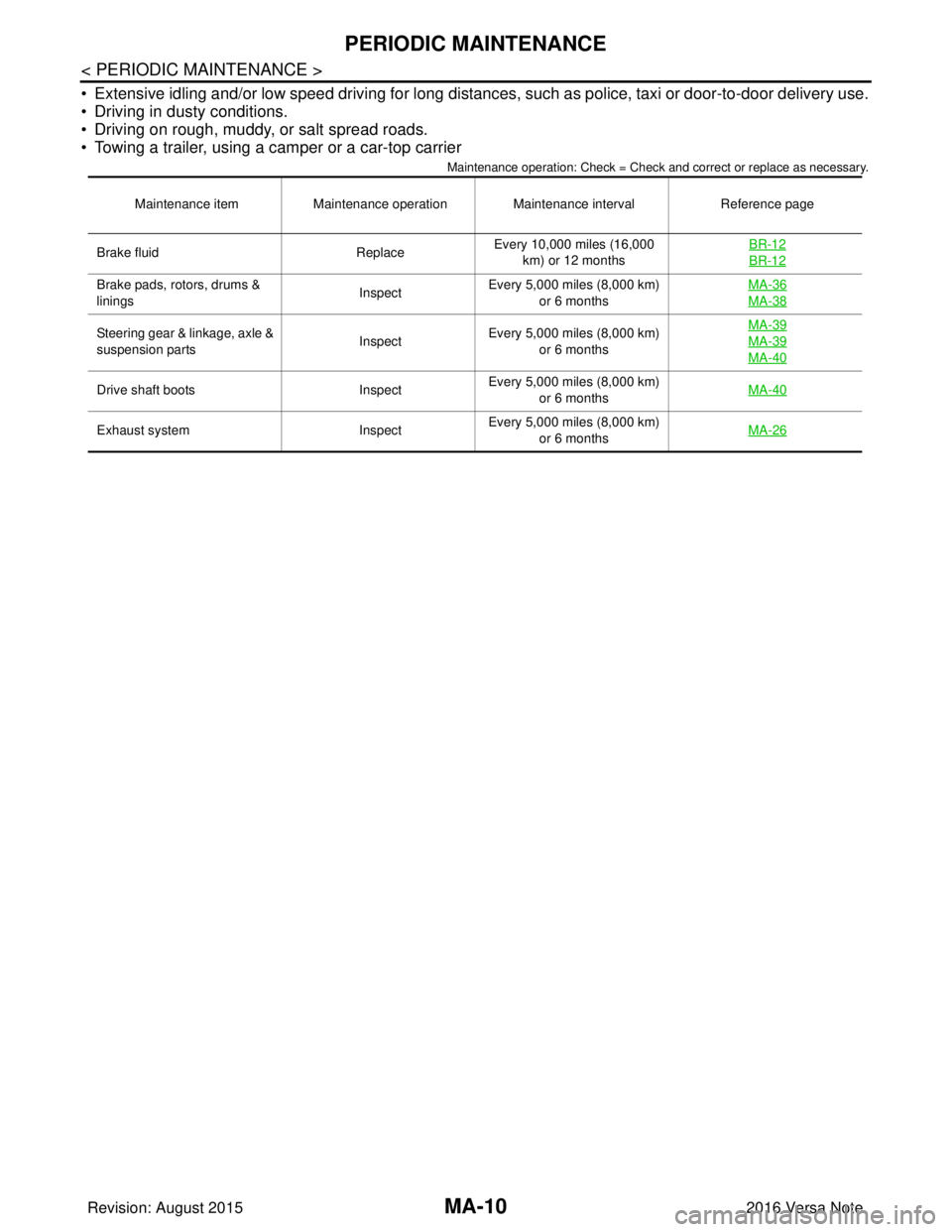

PERIODIC MAINTENANCE

• Extensive idling and/or low speed driving for long distances, such as police, taxi or door-to-door delivery use.

• Driving in dusty conditions.

• Driving on rough, muddy, or salt spread roads.

• Towing a trailer, using a camper or a car-top carrier

Maintenance operation: Check = Check and correct or replace as necessary.

Maintenance itemMaintenance operation Maintenance interval Reference page

Brake fluid ReplaceEvery 10,000 miles (16,000

km) or 12 months BR-12

BR-12

Brake pads, rotors, drums &

linings

InspectEvery 5,000 miles (8,000 km)

or 6 months MA-36

MA-38

Steering gear & linkage, axle &

suspension parts

InspectEvery 5,000 miles (8,000 km)

or 6 months MA-39MA-39

MA-40

Drive shaft boots

InspectEvery 5,000 miles (8,000 km)

or 6 months MA-40

Exhaust system

InspectEvery 5,000 miles (8,000 km)

or 6 months MA-26

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2354 of 3641

CHASSIS AND BODY MAINTENANCEMA-39

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

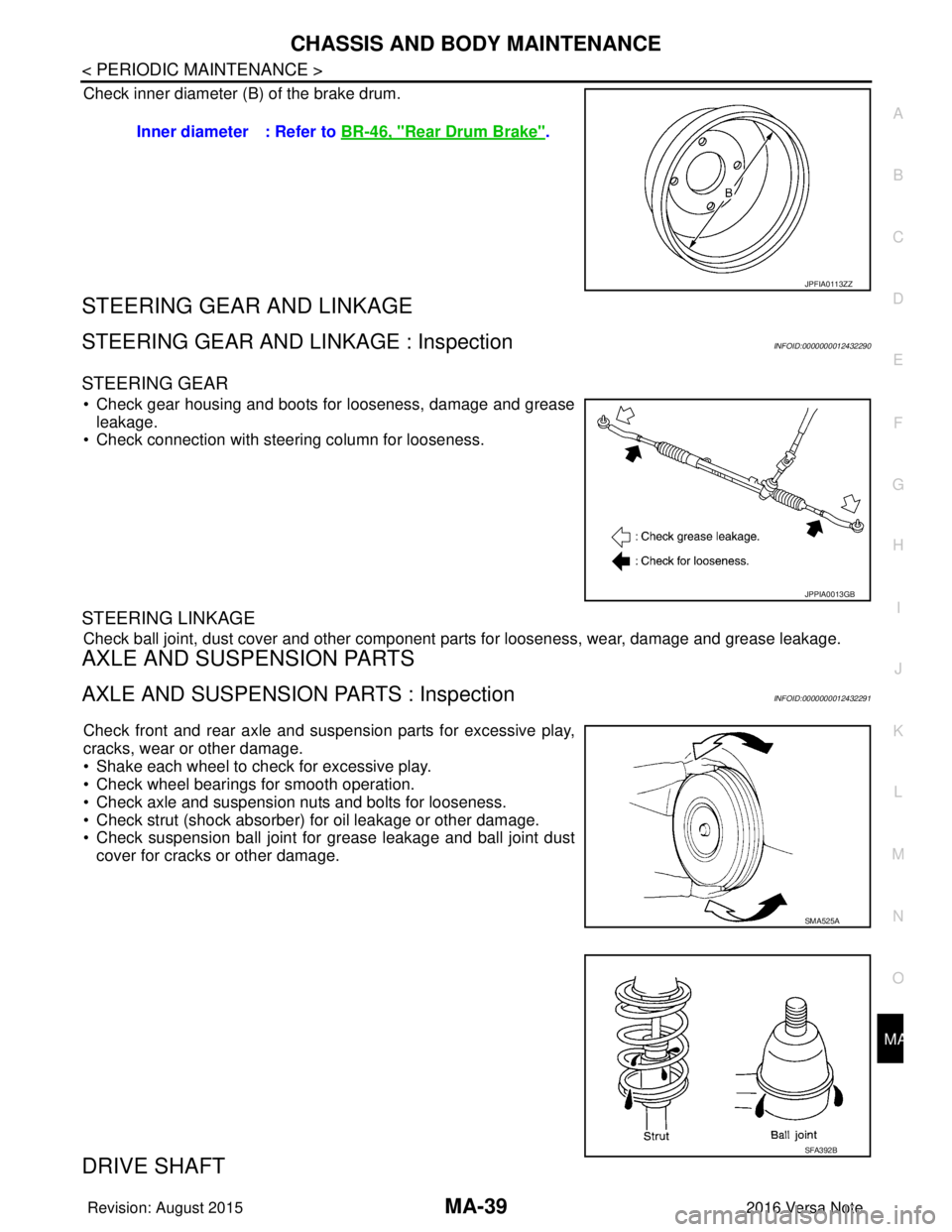

Check inner diameter (B) of the brake drum.

STEERING GEAR AND LINKAGE

STEERING GEAR AND LINKAGE : InspectionINFOID:0000000012432290

STEERING GEAR

• Check gear housing and boots for looseness, damage and grease

leakage.

• Check connection with steering column for looseness.

STEERING LINKAGE

Check ball joint, dust cover and other component parts for looseness, wear, damage and grease leakage.

AXLE AND SUSPENSION PARTS

AXLE AND SUSPENSION PARTS : InspectionINFOID:0000000012432291

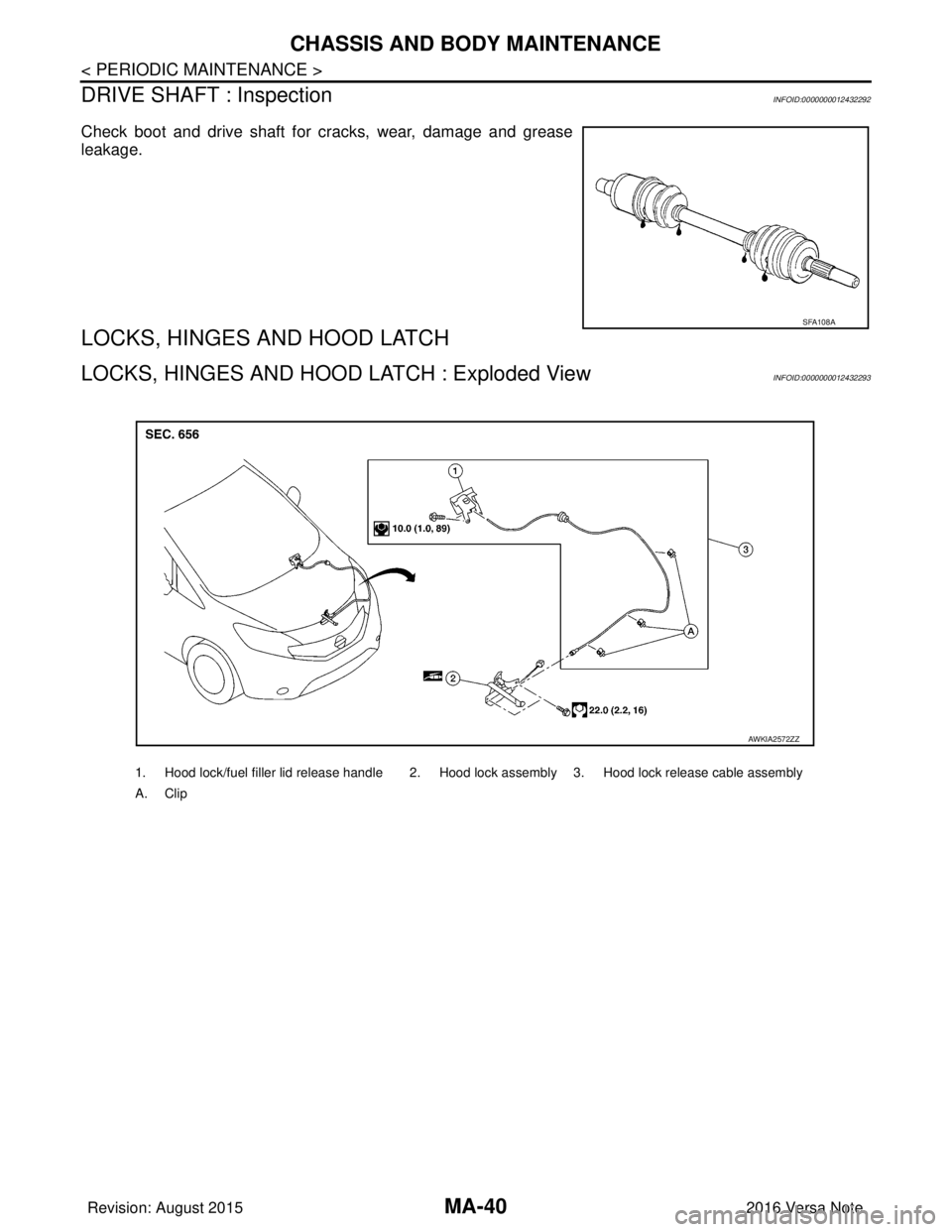

Check front and rear axle and suspension parts for excessive play,

cracks, wear or other damage.

• Shake each wheel to check for excessive play.

• Check wheel bearings for smooth operation.

• Check axle and suspension nuts and bolts for looseness.

• Check strut (shock absorber) for oil leakage or other damage.

• Check suspension ball joint for grease leakage and ball joint dust

cover for cracks or other damage.

DRIVE SHAFT

Inner diameter : Refer to BR-46, "Rear Drum Brake".

JPFIA0113ZZ

JPPIA0013GB

SMA525A

SFA392B

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2355 of 3641

MA-40

< PERIODIC MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

DRIVE SHAFT : Inspection

INFOID:0000000012432292

Check boot and drive shaft for cracks, wear, damage and grease

leakage.

LOCKS, HINGES AND HOOD LATCH

LOCKS, HINGES AND HOOD LATCH : Exploded ViewINFOID:0000000012432293

SFA108A

1. Hood lock/fuel filler lid release handle 2. Hood lock assembly 3. Hood lock release cable assembly

A. Clip

AWKIA2572ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3187 of 3641

PRECAUTIONSSTC-3

< PRECAUTION >

C

DE

F

H I

J

K L

M A

B

STC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431939

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Service Notice and Precautions for EPS SystemINFOID:0000000012431940

• Check the following item when performing the trouble diagnosis:

- Check for possible causes of the malfunction by inte rviewing the customer as to what conditions were

present when the symptom occurred.

- Check if the steering wheel and the EPS control unit are genuine parts.

- Check if the air pressure and size of each tire is correct.

- Check if the installation of the links and suspension components are correct.

- Check if the tires are worn evenly, indicating the wheel alignment is correct.

- Check if the installation of the steering column and t he steering gear are correct. Check for loose bolts, dam-

aged links, cracked boots and leaking grease, etc.

- Check for damage or modification to suspension or body resulting in increased weight or altered ground clearance.

- Check if the battery voltage is proper.

- Check the EPS control unit harness to be sure the harness connectors are fully seated.

• Before connecting or disconnecting the EPS control uni t harness connector, turn ignition switch “OFF” and

disconnect the battery cable from the negative terminal. Battery voltage is applied to the EPS control unit

even if ignition switch is turned “OFF”.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3224 of 3641

PREPARATIONST-3

< PREPARATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

PREPARATION

PREPARATION

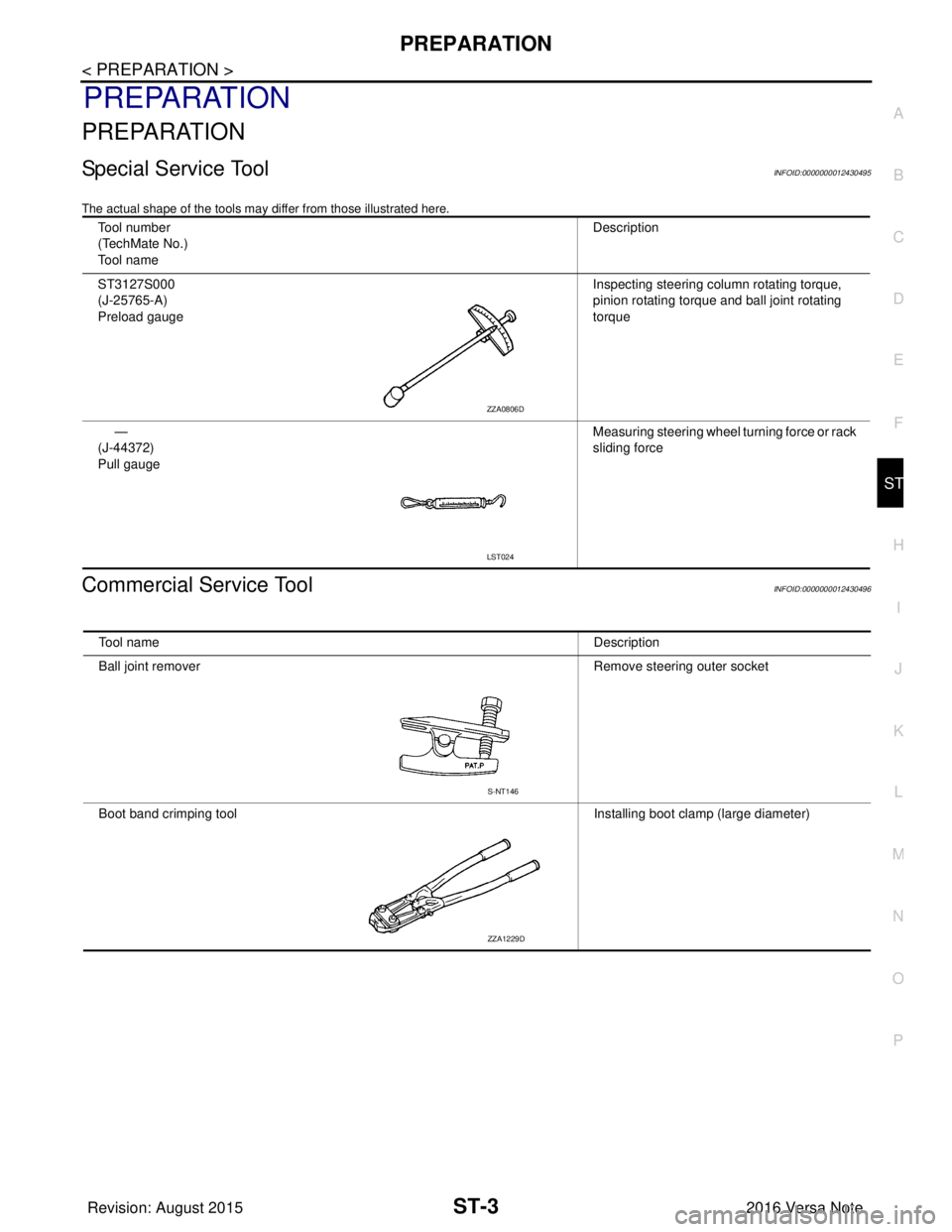

Special Service ToolINFOID:0000000012430495

The actual shape of the tools may di ffer from those illustrated here.

Commercial Service ToolINFOID:0000000012430496

Tool number

(TechMate No.)

Tool name Description

ST3127S000

(J-25765-A)

Preload gauge Inspecting steering column rotating torque,

pinion rotating torque and ball joint rotating

torque

—

(J-44372)

Pull gauge Measuring steering wheel turning force or rack

sliding force

ZZA0806D

LST024

Tool name

Description

Ball joint remover Remove steering outer socket

Boot band crimping tool Installing boot clamp (large diameter)

S-NT146

ZZA1229D

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3237 of 3641

ST-16

< UNIT DISASSEMBLY AND ASSEMBLY >

STEERING GEAR AND LINKAGE

UNIT DISASSEMBLY AND ASSEMBLY

STEERING GEAR AND LINKAGE

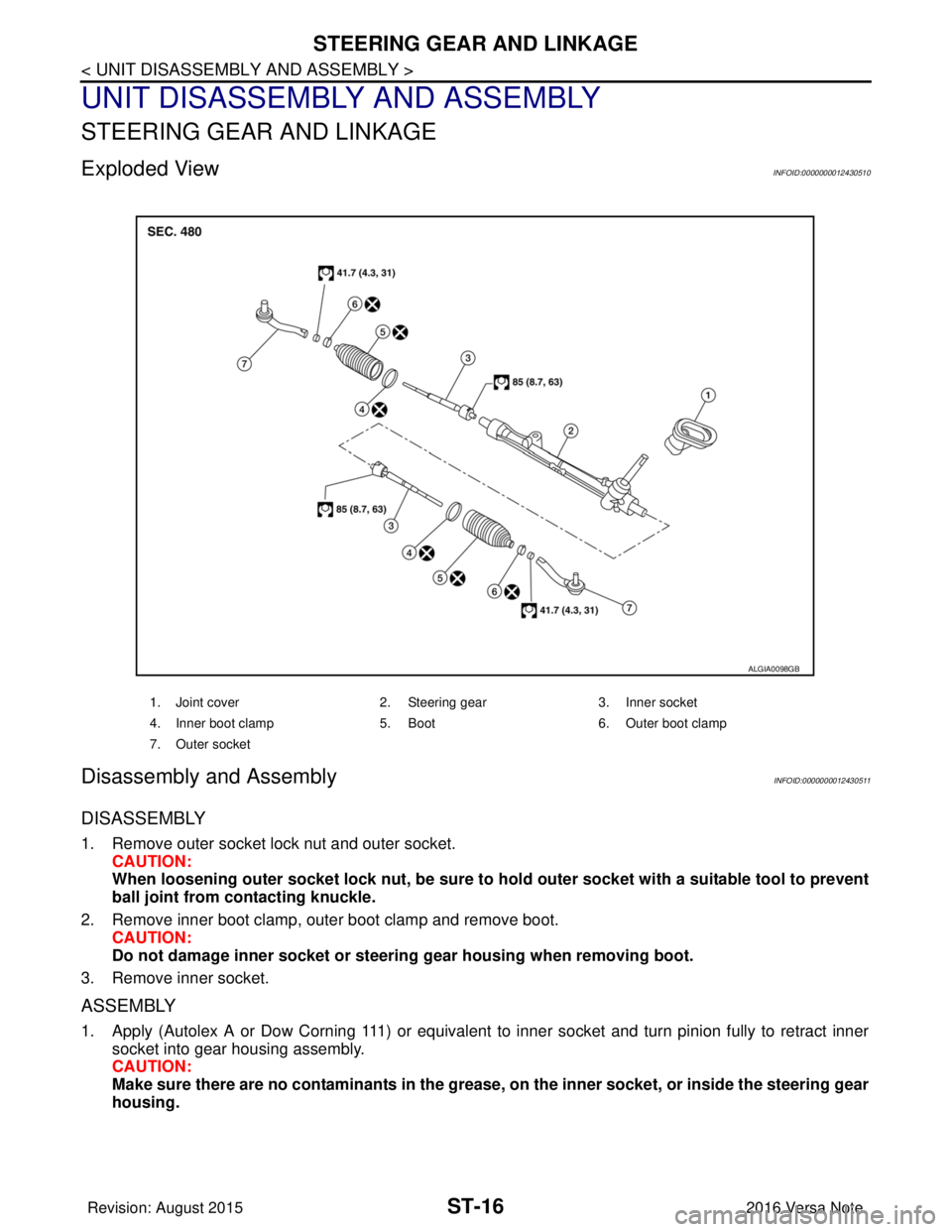

Exploded ViewINFOID:0000000012430510

Disassembly and AssemblyINFOID:0000000012430511

DISASSEMBLY

1. Remove outer socket lock nut and outer socket.CAUTION:

When loosening outer socket lock nut, be sure to hold outer socket with a suitable tool to prevent

ball joint from contacting knuckle.

2. Remove inner boot clamp, outer boot clamp and remove boot. CAUTION:

Do not damage inner socket or steerin g gear housing when removing boot.

3. Remove inner socket.

ASSEMBLY

1. Apply (Autolex A or Dow Corning 111) or equivalent to inner socket and turn pinion fully to retract inner socket into gear housing assembly.

CAUTION:

Make sure there are no contaminants in the grease, on the inner socket, or inside the steering gear

housing.

1. Joint cover 2. Steering gear3. Inner socket

4. Inner boot clamp 5. Boot6. Outer boot clamp

7. Outer socket

ALGIA0098GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3238 of 3641

STEERING GEAR AND LINKAGEST-17

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

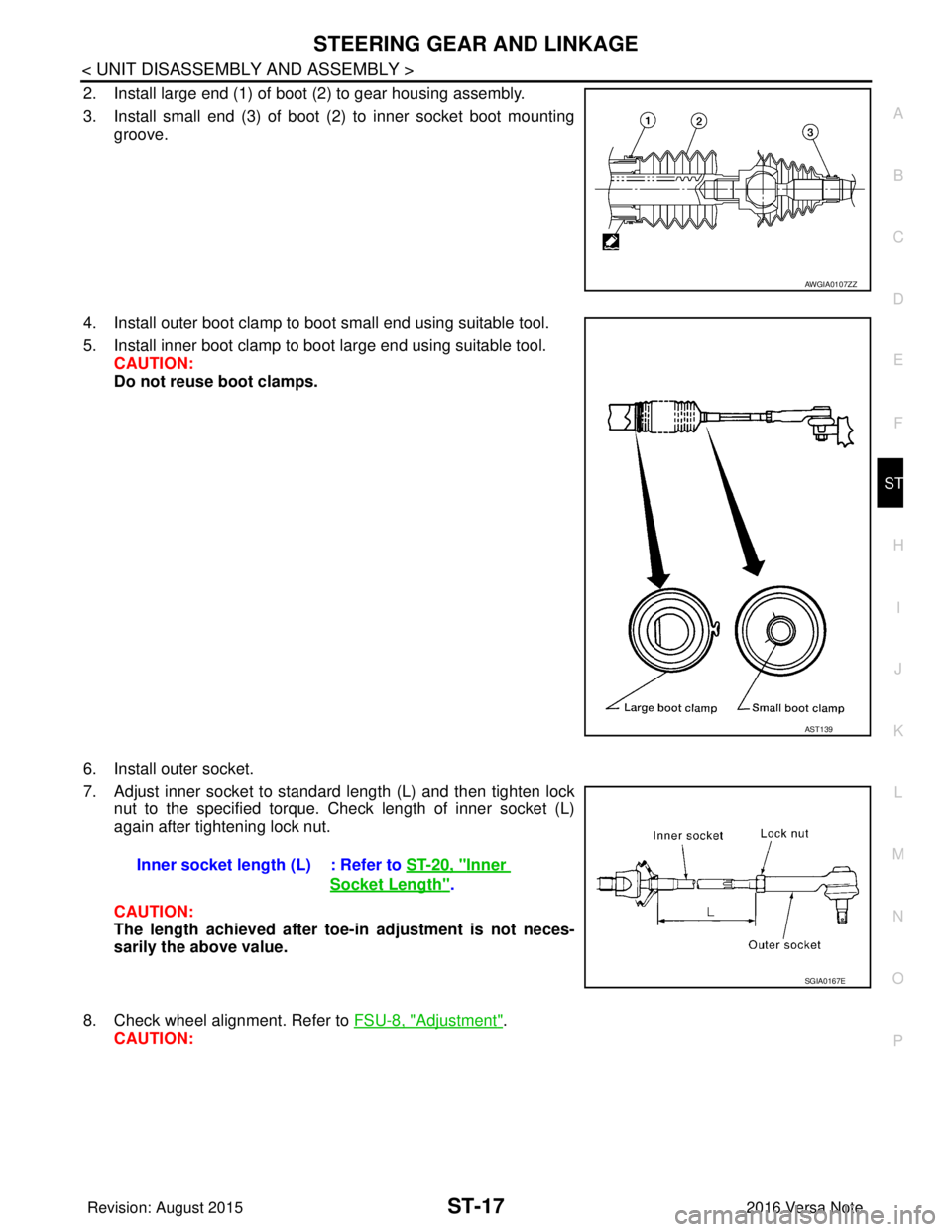

2. Install large end (1) of boot (2) to gear housing assembly.

3. Install small end (3) of boot (2) to inner socket boot mounting groove.

4. Install outer boot clamp to boot small end using suitable tool.

5. Install inner boot clamp to boot large end using suitable tool. CAUTION:

Do not reuse boot clamps.

6. Install outer socket.

7. Adjust inner socket to standard length (L) and then tighten lock nut to the specified torque. Check length of inner socket (L)

again after tightening lock nut.

CAUTION:

The length achieved after toe-in adjustment is not neces-

sarily the above value.

8. Check wheel alignment. Refer to FSU-8, "

Adjustment".

CAUTION:

AWGIA0107ZZ

AST139

Inner socket length (L) : Refer to ST-20, "Inner

Socket Length".

SGIA0167E

Revision: August 2015 2016 Versa Note

cardiagn.com