hood open NISSAN NOTE 2016 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1390 of 3641

![NISSAN NOTE 2016 Service User Guide P0196 EOT SENSOREC-263

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

If it is below 80°

C (176°F), warm engine up until “COOLAN TEMP/S” indicates more than 80° C (176°F).

NISSAN NOTE 2016 Service User Guide P0196 EOT SENSOREC-263

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

If it is below 80°

C (176°F), warm engine up until “COOLAN TEMP/S” indicates more than 80° C (176°F).](/img/5/57363/w960_57363-1389.png)

P0196 EOT SENSOREC-263

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

If it is below 80°

C (176°F), warm engine up until “COOLAN TEMP/S” indicates more than 80° C (176°F).

Then perform the following steps.

3. Turn ignition switch OFF and soak the vehicle in a cool place.

4. Turn ignition switch ON.

NOTE:

Do not turn ignition switch OFF until step 8.

5. Select “DATA MONITOR” mode of “ENGINE” using CONSULT.

6. Check the following.

If they are within the specifi ed range, perform the following steps.

If they are out of the specified range, soak the vehicle to meet the above conditions. Then perform the fol-

lowing steps.

NOTE:

• Do not turn ignition switch OFF.

• If it is supposed to need a long period of time, do not deplete the battery.

7. Start engine and let it idle for 5 minutes.

8. Check 1st trip DTC.

With GST

Follow the procedure “With CONSULT” above.

Is 1st trip DTC detected?

YES >> Proceed to EC-264, "Diagnosis Procedure".

NO >> GO TO 5.

5.PERFORM COMPONENT FUNCTION CHECK (FOR MALFUNCTION B)

Perform component function check. Refer to EC-264, "

Component Function Check".

NOTE:

Use the component function check to check the overall function of the EOT sensor circuit. During this check, a

1st trip DTC might not be confirmed.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Proceed to EC-264, "

Diagnosis Procedure".

6.PRECONDITIONING

If DTC CONFIRMATION PROCEDURE has been previously conducted, always perform the following proce-

dure before conducti ng the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

• Before performing the following procedure, do not add fuel.

• Before performing the following procedure, check that fuel level is between 1/4 and 4/4.

• Before performing the following procedure, confirm that battery voltage is 11 V or more at idle.

>> GO TO 7.

7.PERFORM DTC CONFIRMATION PROCEDURE B

1. Start engine and let it idle for 60 minutes.

2. Move the vehicle to a cool place. NOTE:

Cool the vehicle in an environment of ambient air temperature between −10° C (14 °F) and 35 °C (95° F).

3. Turn ignition switch OFF and soak the vehicle for 12 hours.

CAUTION:

Never turn ignition sw itch ON during soaking.

NOTE:

The vehicle must be cooled with the hood open.

COOLAN TEMP/S Below 40°C (104 °F)

INT/A TEMP SE Below 40°C (104 °F)

Difference between “COOLAN TEMP/S” and “INT/A TEMP SE” Within 6 °C (11 °F)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1412 of 3641

![NISSAN NOTE 2016 Service User Guide P0420 THREE WAY CATALYST FUNCTIONEC-285

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0420 THREE WAY CATALYST FUNCTION

DTC LogicINFOID:0000000012431487

DTC DETECTION LOGIC

The EC NISSAN NOTE 2016 Service User Guide P0420 THREE WAY CATALYST FUNCTIONEC-285

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0420 THREE WAY CATALYST FUNCTION

DTC LogicINFOID:0000000012431487

DTC DETECTION LOGIC

The EC](/img/5/57363/w960_57363-1411.png)

P0420 THREE WAY CATALYST FUNCTIONEC-285

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0420 THREE WAY CATALYST FUNCTION

DTC LogicINFOID:0000000012431487

DTC DETECTION LOGIC

The ECM monitors the switching frequency ratio of air fuel ratio (A/F)

sensor 1 and heated oxygen sensor 2.

A three way catalyst (manifold) with high oxygen storage capacity

will indicate a low switching frequency of heated oxygen sensor 2.

As oxygen storage capacity decreases, the heated oxygen sensor 2

switching frequency will increase.

When the frequency ratio of air fuel ratio (A/F) sensor 1 and heated

oxygen sensor 2 approaches a specified limit value, the three way

catalyst (manifold) malfunction is diagnosed.

DTC CONFIRMATION PROCEDURE

1.INSPECTION START

Do you have CONSULT?

Do you have CONSULT?

YES >> GO TO 2.

NO >> GO TO 7.

2.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Do not hold engine speed for more than the specified minutes below.

>> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE-I

With CONSULT

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

4. Let engine idle for 1 minute.

5. Select “COOLAN TEMP/S” in “DATA MONITOR” mode with CONSULT.

6. Make sure that “COOLAN TEMP/S” indicates more than 70 °C (158° F).

If not, warm up engine and go to next step when “COOLAN TEMP/S” indication reaches to 70°C (158° F).

7. Open engine hood.

8. Select “DTC & SRT CONFIRMATION” then “SRT WORK SUPPORT” mode with CONSULT.

9. Rev engine up to 2,000 to 3,000 rpm and hold it for 3 consecutive minutes then release the accelerator pedal completely.

SEF484YB

DTC No. Trouble diagnosis content DTC detecting conditionPossible cause

P0420 Catalyst system efficiency

below threshold • Three way catalyst (manifold) does not operate

properly.

• Three way catalyst (manifold) does not have

enough oxygen storage capacity. • Three way catalyst (manifold)

•Exhaust tube

• Intake air leaks

• Fuel injector

• Fuel injector leaks

•Spark plug

• Improper ignition timing

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1413 of 3641

![NISSAN NOTE 2016 Service User Guide EC-286

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P0420 THREE WAY CATALYST FUNCTION

10. Check the indication of “CATALYST”.

Which is displayed on CONSULT screen?

CMPLT >> GO TO 6.

INCMP >> GO TO 4.

4.PERFO NISSAN NOTE 2016 Service User Guide EC-286

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P0420 THREE WAY CATALYST FUNCTION

10. Check the indication of “CATALYST”.

Which is displayed on CONSULT screen?

CMPLT >> GO TO 6.

INCMP >> GO TO 4.

4.PERFO](/img/5/57363/w960_57363-1412.png)

EC-286

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P0420 THREE WAY CATALYST FUNCTION

10. Check the indication of “CATALYST”.

Which is displayed on CONSULT screen?

CMPLT >> GO TO 6.

INCMP >> GO TO 4.

4.PERFORM DTC CONFIRMATION PROCEDURE-II

1. Wait 5 seconds at idle.

2. Rev engine up to 2,000 to 3,000 rpm and maintain it unt il “INCMP” of “CATALYST” changes to “CMPLT” (It

will take approximately 5 minutes).

Does the indication change to

“CMPLT”?

YES >> GO TO 6.

NO >> GO TO 5.

5.PERFORM DTC CONFIRMATION PROCEDURE AGAIN

1. Stop engine and cool it down to less than 70 °C (158° F).

2. Perform DTC CONFIRMATION PROCEDURE again.

>> GO TO 3.

6.PERFORM DTC CONFIRMATION PROCEDURE-III

Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> Go to EC-287, "Diagnosis Procedure".

NO >> INSPECTION END

7.PERFORM COMPONENT FUNCTION CHECK

Perform component function check. Refer to EC-286, "

Component Function Check".

NOTE:

Use component function check to check the overall functi on of the three way catalyst (manifold). During this

check, a 1st trip DTC might not be confirmed.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-287, "

Diagnosis Procedure".

Component Function CheckINFOID:0000000012431488

1.PERFORM COMPONENT FUNCTION CHECK

Without CONSULT

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Restart engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

4. Let engine idle for 1 minute.

5. Open engine hood.

6. Check the voltage between ECM harness connector terminals under the following condition.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-287, "

Diagnosis Procedure".

ECM

Condition Voltage (V)

Connector +–

Te r m i n a l Te r m i n a l

F11 50

(HO2S2) 59Keeping engine speed at 2500 rpm

constant under no load The voltage fluctuation cycle takes more than 5 seconds.

• 1 cycle: 0.6 - 1.0

→ 0 - 0.3 → 0.6 - 1.0

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1672 of 3641

EXL-20

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (IPDM E/R)

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000012542316

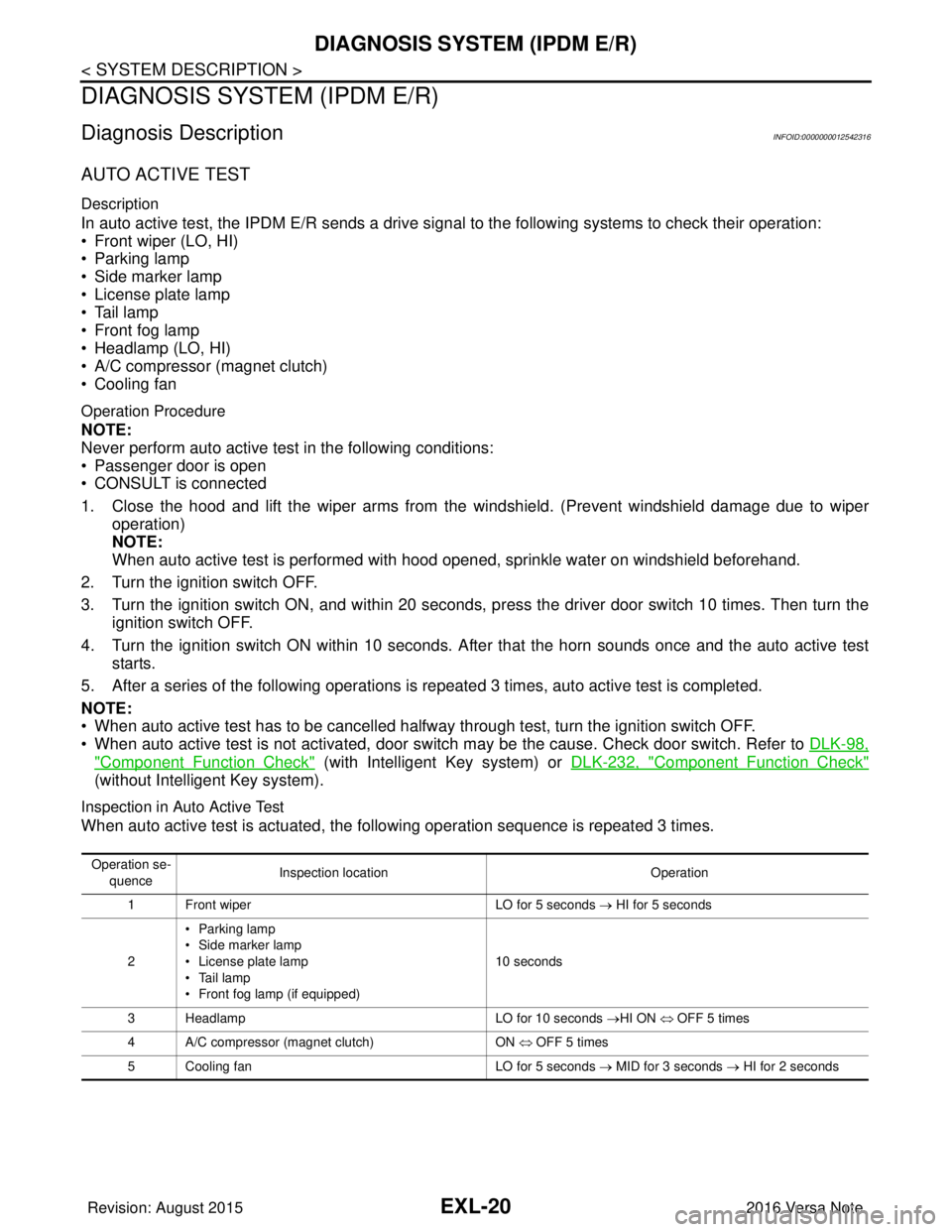

AUTO ACTIVE TEST

Description

In auto active test, the IPDM E/R sends a drive signal to the following systems to check their operation:

• Front wiper (LO, HI)

• Parking lamp

• Side marker lamp

• License plate lamp

• Tail lamp

• Front fog lamp

• Headlamp (LO, HI)

• A/C compressor (magnet clutch)

• Cooling fan

Operation Procedure

NOTE:

Never perform auto active test in the following conditions:

• Passenger door is open

• CONSULT is connected

1. Close the hood and lift the wiper arms from the windshield. (Prevent windshield damage due to wiper

operation)

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn the ignition switch OFF.

3. Turn the ignition switch ON, and within 20 seconds, pr ess the driver door switch 10 times. Then turn the

ignition switch OFF.

4. Turn the ignition switch ON within 10 seconds. Af ter that the horn sounds once and the auto active test

starts.

5. After a series of the following operations is repeated 3 times, auto active test is completed.

NOTE:

• When auto active test has to be cancelled halfw ay through test, turn the ignition switch OFF.

• When auto active test is not activated, door swit ch may be the cause. Check door switch. Refer to DLK-98,

"ComponentFunctionCheck" (with Intelligent Key system) or DLK-232, "ComponentFunctionCheck"

(without Intelligent Key system).

Inspection in Auto Active Test

When auto active test is actuated, the following operation sequence is repeated 3 times.

Operation se-

quence Inspection location

Operation

1 Front wiper LO for 5 seconds → HI for 5 seconds

2 •Parking lamp

• Side marker lamp

• License plate lamp

• Tail lamp

• Front fog lamp (if equipped) 10 seconds

3 Headlamp LO for 10 seconds →HI ON ⇔ OFF 5 times

4 A/C compressor (magnet clutch) ON ⇔ OFF 5 times

5 Cooling fan LO for 5 seconds → MID for 3 seconds → HI for 2 seconds

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1899 of 3641

HOW TO READ WIRING DIAGRAMSGI-11

< HOW TO USE THIS MANUAL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

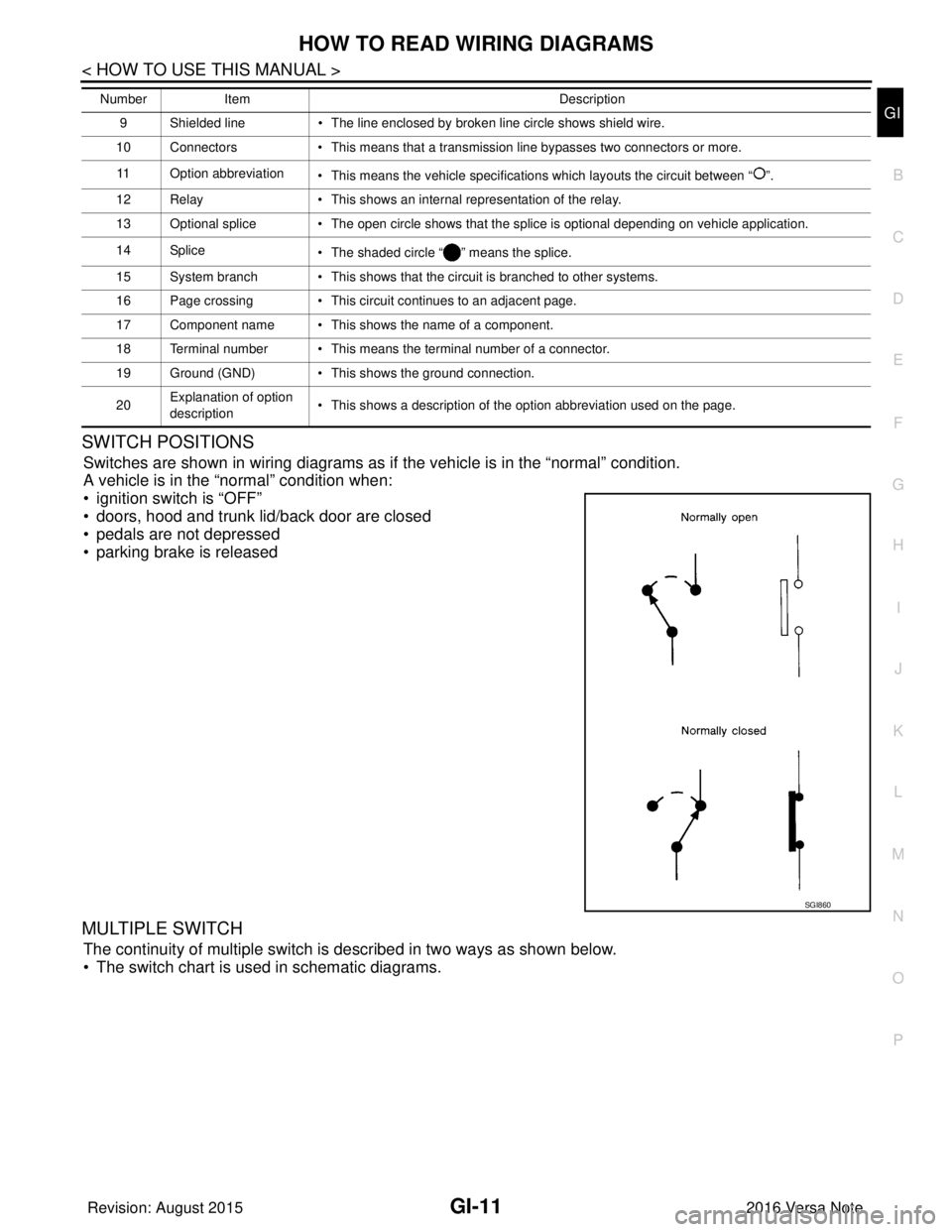

SWITCH POSITIONS

Switches are shown in wiring diagrams as if the vehicle is in the “normal” condition.

A vehicle is in the “normal” condition when:

• ignition switch is “OFF”

• doors, hood and trunk lid/back door are closed

• pedals are not depressed

• parking brake is released

MULTIPLE SWITCH

The continuity of multiple switch is described in two ways as shown below.

• The switch chart is used in schematic diagrams.

9 Shielded line • The line enclosed by broken line circle shows shield wire.

10 Connectors • This means that a transmission line bypasses two connectors or more.

11 Option abbreviation • This means the vehicle specifications which layouts the circuit between “ ”.

12 Relay • This shows an internal representation of the relay.

13 Optional splice • The open circle shows that the splice is optional depending on vehicle application.

14 Splice • The shaded circle “ ” means the splice.

15 System branch • This shows that the circuit is branched to other systems.

16 Page crossing • This circuit continues to an adjacent page.

17 Component name • This shows the name of a component.

18 Terminal number • This means the terminal number of a connector.

19 Ground (GND) • This shows the ground connection.

20 Explanation of option

description • This shows a description of the option abbreviation used on the page.

Number

Item Description

SGI860

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2049 of 3641

HA-24

< PERIODIC MAINTENANCE >

PERFORMANCE TEST

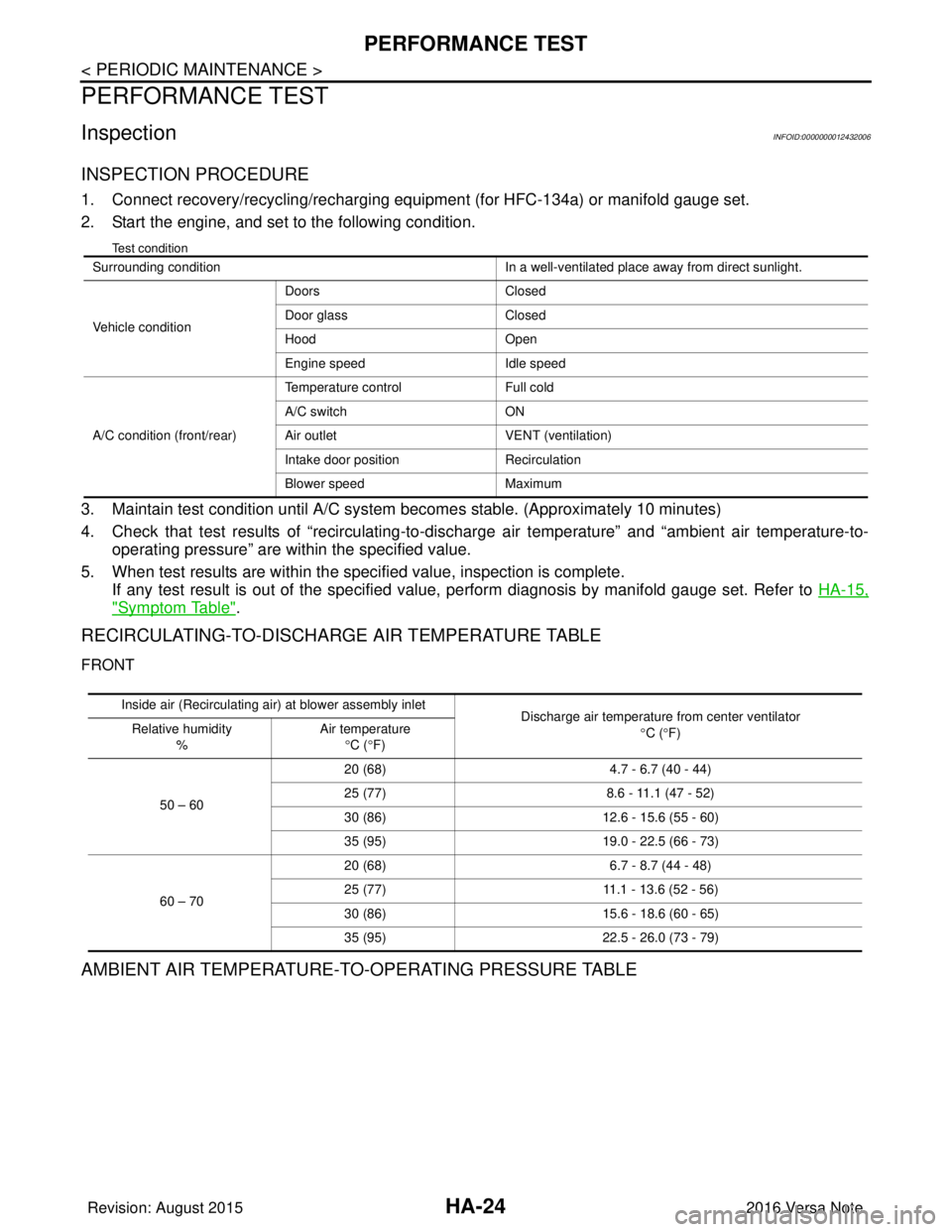

PERFORMANCE TEST

InspectionINFOID:0000000012432006

INSPECTION PROCEDURE

1. Connect recovery/recycling/recharging equipment (for HFC-134a) or manifold gauge set.

2. Start the engine, and set to the following condition.

Test condition

3. Maintain test condition until A/C system becomes stable. (Approximately 10 minutes)

4. Check that test results of “recirculating-to-disc harge air temperature” and “ambient air temperature-to-

operating pressure” are within the specified value.

5. When test results are within the spec ified value, inspection is complete.

If any test result is out of the specified val ue, perform diagnosis by manifold gauge set. Refer to HA-15,

"Symptom Table".

RECIRCULATING-TO-DISCHARGE AIR TEMPERATURE TABLE

FRONT

AMBIENT AIR TEMPERATURE-TO-OPERATING PRESSURE TABLE

Surrounding condition In a well-ventilated place away from direct sunlight.

Vehicle condition Doors

Closed

Door glass Closed

Hood Open

Engine speed Idle speed

A/C condition (front/rear) Temperature control

Full cold

A/C switch ON

Air outlet VENT (ventilation)

Intake door position Recirculation

Blower speed Maximum

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature from center ventilator

°C ( °F)

Relative humidity

% Air temperature

°C ( °F)

50 – 60 20 (68)

4.7 - 6.7 (40 - 44)

25 (77) 8.6 - 11.1 (47 - 52)

30 (86) 12.6 - 15.6 (55 - 60)

35 (95) 19.0 - 22.5 (66 - 73)

60 – 70 20 (68)

6.7 - 8.7 (44 - 48)

25 (77) 11.1 - 13.6 (52 - 56)

30 (86) 15.6 - 18.6 (60 - 65)

35 (95) 22.5 - 26.0 (73 - 79)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2320 of 3641

GENERAL MAINTENANCEMA-5

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

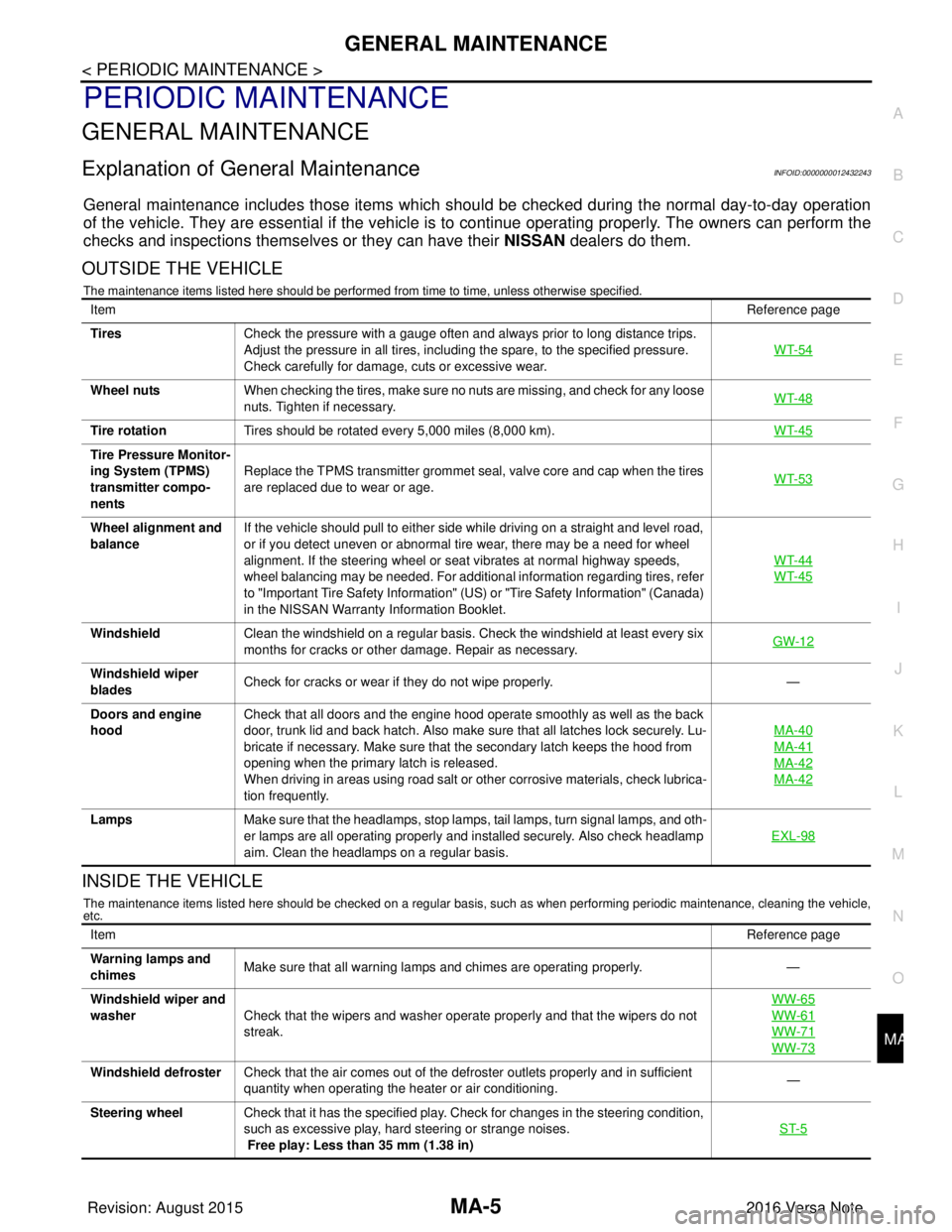

PERIODIC MAINTENANCE

GENERAL MAINTENANCE

Explanation of Gene

ral MaintenanceINFOID:0000000012432243

General maintenance includes those items which shoul d be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operati ng properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Tires Check the pressure with a gauge often and always prior to long distance trips.

Adjust the pressure in all tires, including the spare, to the specified pressure.

Check carefully for damage, cuts or excessive wear. WT-54

Wheel nuts

When checking the tires, make sure no nuts are missing, and check for any loose

nuts. Tighten if necessary. WT-48

Tire rotation

Tires should be rotated every 5,000 miles (8,000 km). WT-45

Tire Pressure Monitor-

ing System (TPMS)

transmitter compo-

nentsReplace the TPMS transmitter grommet seal, valve core and cap when the tires

are replaced due to wear or age.

WT-53

Wheel alignment and

balanceIf the vehicle should pull to either side while driving on a straight and level road,

or if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed. For additional information regarding tires, refer

to "Important Tire Safety Information" (US) or "Tire Safety Information" (Canada)

in the NISSAN Warranty

Information Booklet. WT-44

WT-45

Windshield

Clean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary. GW-12

Windshield wiper

bladesCheck for cracks or wear if they do not wipe properly.

—

Doors and engine

hood Check that all doors and the engine hood operate smoothly as well as the back

door, trunk lid and back hatch. Also make sure that all latches lock securely. Lu-

bricate if necessary. Make sure that the secondary latch keeps the hood from

opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check lubrica-

tion frequently. MA-40

MA-41

MA-42

MA-42

Lamps

Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and oth-

er lamps are all operating properly and installed securely. Also check headlamp

aim. Clean the headlamps on a regular basis. EXL-98

Item

Reference page

Warning lamps and

chimes Make sure that all warning lamps and chimes are operating properly.

—

Windshield wiper and

washer Check that the wipers and washer operate properly and that the wipers do not

streak. WW-65

WW-61

WW-71

WW-73

Windshield defroster

Check that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioning. —

Steering wheel Check that it has the specified play. Check for changes in the steering condition,

such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in) ST-5

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2512 of 3641

![NISSAN NOTE 2016 Service User Guide PCS

DIAGNOSIS SYSTEM (IPDM E/R)PCS-9

< SYSTEM DESCRIPTION > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000012433271

AUTO ACTIVE TEST

Descripti NISSAN NOTE 2016 Service User Guide PCS

DIAGNOSIS SYSTEM (IPDM E/R)PCS-9

< SYSTEM DESCRIPTION > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000012433271

AUTO ACTIVE TEST

Descripti](/img/5/57363/w960_57363-2511.png)

PCS

DIAGNOSIS SYSTEM (IPDM E/R)PCS-9

< SYSTEM DESCRIPTION > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000012433271

AUTO ACTIVE TEST

Description

In auto active test, the IPDM E/R

sends a drive signal to the following systems to check their operation:

• Front wiper (LO, HI)

• Parking lamp

• Side marker lamp

• License plate lamp

• Tail lamp

• Front fog lamp

• Headlamp (LO, HI)

• A/C compressor (magnet clutch)

• Cooling fan

Operation Procedure

NOTE:

Never perform auto active test in the following conditions:

• Passenger door is open

• CONSULT is connected

1. Close the hood and lift the wiper arms from the windshield. (Prevent windshield damage due to wiper

operation)

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn the ignition switch OFF.

3. Turn the ignition switch ON, and within 20 seconds, pr ess the driver door switch 10 times. Then turn the

ignition switch OFF.

4. Turn the ignition switch ON within 10 seconds. Af ter that the horn sounds once and the auto active test

starts.

5. After a series of the following operations is repeated 3 times, auto active test is completed.

NOTE:

• When auto active test has to be cancelled halfw ay through test, turn the ignition switch OFF.

• When auto active test is not activated, door swit ch may be the cause. Check door switch. Refer to DLK-98,

"ComponentFunctionCheck" (with Intelligent Key system) or DLK-232, "ComponentFunctionCheck"

(without Intelligent Key system).

Inspection in Auto Active Test

When auto active test is actuated, the following operation sequence is repeated 3 times.

Operation se-

quence Inspection location

Operation

1 Front wiper LO for 5 seconds → HI for 5 seconds

2 •Parking lamp

• Side marker lamp

• License plate lamp

• Tail lamp

• Front fog lamp (if equipped) 10 seconds

3 Headlamp LO for 10 seconds →HI ON ⇔ OFF 5 times

4 A/C compressor (magnet clutch) ON ⇔ OFF 5 times

5 Cooling fan LO for 5 seconds → MID for 3 seconds → HI for 2 seconds

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2984 of 3641

![NISSAN NOTE 2016 Service User Guide DIAGNOSIS SYSTEM (IPDM E/R)SEC-127

< SYSTEM DESCRIPTION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000012542533

AU NISSAN NOTE 2016 Service User Guide DIAGNOSIS SYSTEM (IPDM E/R)SEC-127

< SYSTEM DESCRIPTION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000012542533

AU](/img/5/57363/w960_57363-2983.png)

DIAGNOSIS SYSTEM (IPDM E/R)SEC-127

< SYSTEM DESCRIPTION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000012542533

AUTO ACTIVE TEST

Description

In auto active test, the IPDM E/R sends a drive signal to the following systems to check their operation:

• Front wiper (LO, HI)

• Parking lamp

• Side marker lamp

• License plate lamp

• Tail lamp

• Front fog lamp

• Headlamp (LO, HI)

• A/C compressor (magnet clutch)

• Cooling fan

Operation Procedure

NOTE:

Never perform auto active test in the following conditions:

• Passenger door is open

• CONSULT is connected

1. Close the hood and lift the wiper arms from the windshield. (Prevent windshield damage due to wiper

operation)

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn the ignition switch OFF.

3. Turn the ignition switch ON, and within 20 seconds, pr ess the driver door switch 10 times. Then turn the

ignition switch OFF.

4. Turn the ignition switch ON within 10 seconds. Af ter that the horn sounds once and the auto active test

starts.

5. After a series of the following operations is repeated 3 times, auto active test is completed.

NOTE:

• When auto active test has to be cancelled halfw ay through test, turn the ignition switch OFF.

• When auto active test is not activated, door swit ch may be the cause. Check door switch. Refer to DLK-98,

"ComponentFunctionCheck" (with Intelligent Key system) or DLK-232, "ComponentFunctionCheck"

(without Intelligent Key system).

Inspection in Auto Active Test

When auto active test is actuated, the following operation sequence is repeated 3 times.

Operation se-

quence Inspection location

Operation

1 Front wiper LO for 5 seconds → HI for 5 seconds

2 •Parking lamp

• Side marker lamp

• License plate lamp

• Tail lamp

• Front fog lamp (if equipped) 10 seconds

3 Headlamp LO for 10 seconds →HI ON ⇔ OFF 5 times

4 A/C compressor (magnet clutch) ON ⇔ OFF 5 times

5 Cooling fan LO for 5 seconds → MID for 3 seconds → HI for 2 seconds

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3582 of 3641

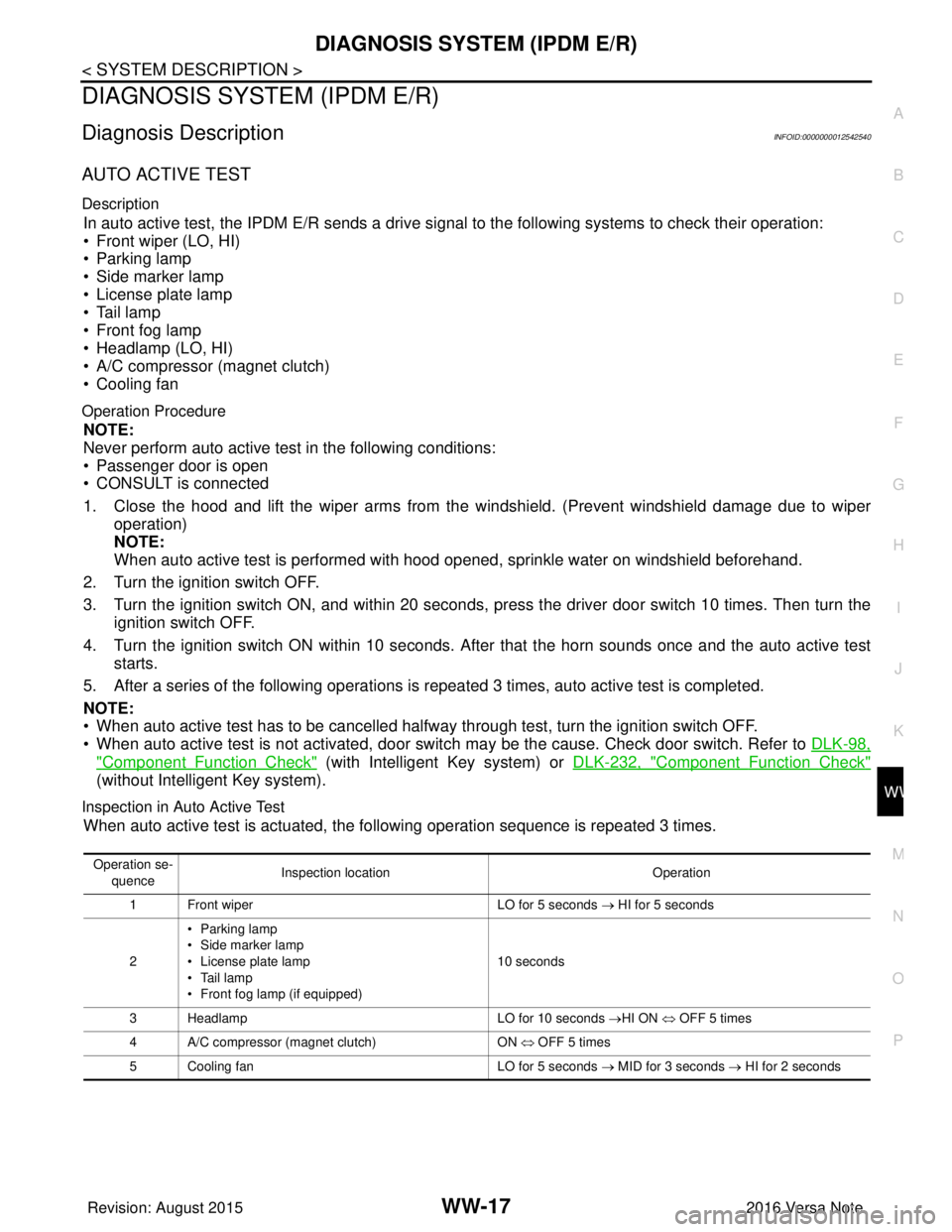

DIAGNOSIS SYSTEM (IPDM E/R)WW-17

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000012542540

AUTO ACTIVE TEST

Description

In auto active test, the IPDM E/R sends a drive signal to the following systems to check their operation:

• Front wiper (LO, HI)

• Parking lamp

• Side marker lamp

• License plate lamp

• Tail lamp

• Front fog lamp

• Headlamp (LO, HI)

• A/C compressor (magnet clutch)

• Cooling fan

Operation Procedure

NOTE:

Never perform auto active test in the following conditions:

• Passenger door is open

• CONSULT is connected

1. Close the hood and lift the wiper arms from the windshield. (Prevent windshield damage due to wiper

operation)

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn the ignition switch OFF.

3. Turn the ignition switch ON, and within 20 seconds, pr ess the driver door switch 10 times. Then turn the

ignition switch OFF.

4. Turn the ignition switch ON within 10 seconds. Af ter that the horn sounds once and the auto active test

starts.

5. After a series of the following operations is repeated 3 times, auto active test is completed.

NOTE:

• When auto active test has to be cancelled halfw ay through test, turn the ignition switch OFF.

• When auto active test is not activated, door swit ch may be the cause. Check door switch. Refer to DLK-98,

"ComponentFunctionCheck" (with Intelligent Key system) or DLK-232, "ComponentFunctionCheck"

(without Intelligent Key system).

Inspection in Auto Active Test

When auto active test is actuated, the following operation sequence is repeated 3 times.

Operation se-

quence Inspection location

Operation

1 Front wiper LO for 5 seconds → HI for 5 seconds

2 •Parking lamp

• Side marker lamp

• License plate lamp

• Tail lamp

• Front fog lamp (if equipped) 10 seconds

3 Headlamp LO for 10 seconds →HI ON ⇔ OFF 5 times

4 A/C compressor (magnet clutch) ON ⇔ OFF 5 times

5 Cooling fan LO for 5 seconds → MID for 3 seconds → HI for 2 seconds

Revision: August 2015 2016 Versa Note

cardiagn.com