diagram NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1244 of 3641

![NISSAN NOTE 2016 Service Repair Manual ENGINE CONTROL SYSTEMEC-117

< WIRING DIAGRAM > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ABBIA1687GB

Revision: August 2015

2016 Versa Note

cardiagn.com NISSAN NOTE 2016 Service Repair Manual ENGINE CONTROL SYSTEMEC-117

< WIRING DIAGRAM > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ABBIA1687GB

Revision: August 2015

2016 Versa Note

cardiagn.com](/img/5/57363/w960_57363-1243.png)

ENGINE CONTROL SYSTEMEC-117

< WIRING DIAGRAM > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ABBIA1687GB

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1245 of 3641

![NISSAN NOTE 2016 Service Repair Manual EC-118

< WIRING DIAGRAM >[HR16DE]

ENGINE CONTROL SYSTEM

ABBIA3060GB

Revision: August 2015

2016 Versa Note

cardiagn.com NISSAN NOTE 2016 Service Repair Manual EC-118

< WIRING DIAGRAM >[HR16DE]

ENGINE CONTROL SYSTEM

ABBIA3060GB

Revision: August 2015

2016 Versa Note

cardiagn.com](/img/5/57363/w960_57363-1244.png)

EC-118

< WIRING DIAGRAM >[HR16DE]

ENGINE CONTROL SYSTEM

ABBIA3060GB

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1246 of 3641

![NISSAN NOTE 2016 Service Repair Manual ENGINE CONTROL SYSTEMEC-119

< WIRING DIAGRAM > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

AABIA1415GB

Revision: August 2015

2016 Versa Note

cardiagn.com NISSAN NOTE 2016 Service Repair Manual ENGINE CONTROL SYSTEMEC-119

< WIRING DIAGRAM > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

AABIA1415GB

Revision: August 2015

2016 Versa Note

cardiagn.com](/img/5/57363/w960_57363-1245.png)

ENGINE CONTROL SYSTEMEC-119

< WIRING DIAGRAM > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

AABIA1415GB

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1420 of 3641

![NISSAN NOTE 2016 Service Repair Manual P0441 EVAP CONTROL SYSTEMEC-293

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

3. Disconnect vacuum hose connected to EVAP canister

purge volume control solenoid valve at EVAP ser NISSAN NOTE 2016 Service Repair Manual P0441 EVAP CONTROL SYSTEMEC-293

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

3. Disconnect vacuum hose connected to EVAP canister

purge volume control solenoid valve at EVAP ser](/img/5/57363/w960_57363-1419.png)

P0441 EVAP CONTROL SYSTEMEC-293

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

3. Disconnect vacuum hose connected to EVAP canister

purge volume control solenoid valve at EVAP ser-

vice port and install vacuum gauge. For the lo cation of EVAP service port, refer to FL-14, "

Exploded

View".

4. Start engine and let it idle. Never depress accelerator pedal even slightly.

5. Check vacuum gauge indication before 60 seconds pass after starting engine.

6. Rev engine up to 2,000 rpm after 100 seconds pass after starting engine.

Is the inspection result normal?

YES >> GO TO 7.

NO >> GO TO 4.

4.CHECK EVAP PURGE LINE

1. Turn ignition switch OFF.

2. Check EVAP purge line for improper connection or disconnection. Refer to EC-40, "

EVAPORATIVE EMISSION SYSTEM : System Diagram".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair EVAP purge line.

5.CHECK EVAP PURGE HOSE AND PURGE PORT

1. Disconnect purge hoses connected to EVAP service port (A )

and EVAP canister purge volume control solenoid valve ( B).

2. Blow air into each hose and EVAP purge port ( C).

3. Check that air flows freely.

Is the inspection result normal?

YES-1 >> With CONSULT: GO TO 6.

YES-2 >> Without CONSULT: GO TO 7.

NO >> Repair or clean hoses and/or purge port.

6.CHECK EVAP CANISTER PURGE VO LUME CONTROL SOLENOID VALVE

WITH CONSULT

1. Start engine.

2. Perform “PURG VOL CONT/V” in “ACTIVE TEST” mode of “ENGINE” using CONSULT. Check that

engine speed varies according to the valve opening.

Does engine speed vary according to the valve opening?

YES >> GO TO 8.

NO >> GO TO 7. Vacuum should not exist.

Vacuum should exist.

SEF367U

SEF368U

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1421 of 3641

![NISSAN NOTE 2016 Service Repair Manual EC-294

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P0441 EVAP CONTROL SYSTEM

7.CHECK EVAP CANISTER PURGE VO

LUME CONTROL SOLENOID VALVE

Check the EVAP canister purge volume control solenoid valve. Refer to EC- NISSAN NOTE 2016 Service Repair Manual EC-294

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P0441 EVAP CONTROL SYSTEM

7.CHECK EVAP CANISTER PURGE VO

LUME CONTROL SOLENOID VALVE

Check the EVAP canister purge volume control solenoid valve. Refer to EC-](/img/5/57363/w960_57363-1420.png)

EC-294

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P0441 EVAP CONTROL SYSTEM

7.CHECK EVAP CANISTER PURGE VO

LUME CONTROL SOLENOID VALVE

Check the EVAP canister purge volume control solenoid valve. Refer to EC-298, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 8.

NO >> Replace EVAP canister purge volume control solenoid valve. Refer to FL-14, "

Exploded View".

8.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR CONNECTOR

1. Disconnect EVAP control system pressure sensor harness connector.

2. Check that water is not inside connectors.

Is the inspection result normal?

YES >> GO TO 9.

NO >> Replace EVAP control system pressure sensor. Refer to FL-19, "

Removal and Installation".

9.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR FUNCTION

Refer to EC-315, "

DTC Logic" for DTC P0452, EC-318, "DTC Logic" for DTC P0453.

Is the inspection result normal?

YES >> GO TO 10.

NO >> Replace EVAP control system pressure sensor. Refer to FL-19, "

Removal and Installation".

10.CHECK RUBBER TUBE FOR CLOGGING

1. Disconnect rubber tube connected to EV AP canister vent control valve.

2. Check the rubber tube for clogging.

Is the inspection result normal?

YES >> GO TO 11.

NO >> Clean the rubber tube using an air blower.

11 .CHECK EVAP CANISTER VENT CONTROL VALVE

Check the EVAP canister vent control valve. Refer to EC-304, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 12.

NO >> Replace EVAP canister vent control valve. Refer to FL-17, "

Removal and Installation".

12.CHECK EVAP PURGE LINE

Inspect EVAP purge line (pipe and rubber tube). Check for evidence of leaks.

Refer to EC-40, "

EVAPORATIVE EMISSION SYSTEM : System Diagram".

Is the inspection result normal?

YES >> GO TO 13.

NO >> Repair or replace malfunctioning part.

13.CLEAN EVAP PURGE LINE

Clean EVAP purge line (pipe and rubber tube) using air blower.

>> GO TO 14.

14.CHECK INTERMITTENT INCIDENT

Perform GI-42, "

Intermittent Incident".

>> INSPECTION END

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1653 of 3641

EXL-1

DRIVER CONTROLS

C

DE

F

G H

I

J

K

M

SECTION EXL

A

B

EXL

N

O P

CONTENTS

EXTERIOR LIGHTING SYSTEM

PRECAUTION ....... ........................................4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution for Work ..................................................4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

SYSTEM DESCRIPTION ..............................6

COMPONENT PARTS ................................... .....6

Component Parts Location .................................. ......6

Component Description .............................................6

SYSTEM ..............................................................8

HEADLAMP SYSTEM .................................................8

HEADLAMP SYSTEM : Syst em Diagram .................8

HEADLAMP SYSTEM : System Description ....... ......8

DAYTIME RUNNING LIGHT SYSTEM ........................9

DAYTIME RUNNING LIGHT SYSTEM : System

Diagram ............................................................... ......

9

DAYTIME RUNNING LIGHT SYSTEM : System

Description ................................................................

9

FRONT FOG LAMP SYSTEM .....................................9

FRONT FOG LAMP SYSTEM : System Diagram ......9

FRONT FOG LAMP SYSTEM : System Descrip-

tion ..........................................................................

10

TURN SIGNAL AND HAZARD WARNING LAMP

SYSTEM ................................................................ ....

10

TURN SIGNAL AND HAZARD WARNING LAMP

SYSTEM : System Diagram ....................................

10

TURN SIGNAL AND HAZARD WARNING LAMP

SYSTEM : System Description ...............................

10

PARKING, LICENSE PLATE AND TAIL LAMP

SYSTEM .......................................... ...........................

10

PARKING, LICENSE PLATE AND TAIL LAMP

SYSTEM : System Diagram ................................ ....

11

PARKING, LICENSE PLATE AND TAIL LAMP

SYSTEM : System Description ................................

11

DIAGNOSIS SYSTEM (BCM) (WITH INTELLI-

GENT KEY SYSTEM) .......................................

12

COMMON ITEM ..................................................... ....12

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) .....................................................

12

HEADLAMP ........................................................... ....13

HEADLAMP : CONSULT Function (BCM - HEAD

LAMP) ......................................................................

13

FLASHER ............................................................... ....13

FLASHER : CONSULT Function (BCM - FLASH-

ER) ..........................................................................

14

COMB SW .............................................................. ....14

COMB SW : CONSULT Function (BCM - COMB

SW) ..........................................................................

14

BATTERY SAVER ................................................. ....15

BATTERY SAVER : CONSULT Function (BCM -

BATTERY SAVER) ..................................................

15

DIAGNOSIS SYSTEM (BCM) (WITHOUT IN-

TELLIGENT KEY SYSTEM) .............................

16

COMMON ITEM ..................................................... ....16

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) .....................................................

16

HEADLAMP ........................................................... ....17

HEADLAMP : CONSULT Function (BCM - HEAD

LAMP) ......................................................................

17

FLASHER ............................................................... ....17

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1654 of 3641

EXL-2

FLASHER : CONSULT Function (BCM - FLASH-

ER) .........................................................................

17

COMB SW .............................................................. ...18

COMB SW : CONSULT Function (BCM - COMB

SW) .........................................................................

18

BATTERY SAVER ................................................. ...18

BATTERY SAVER : CONSULT Function (BCM -

BATTERY SAVER) .................................................

18

DIAGNOSIS SYSTEM (IPDM E/R) ................. ...20

Diagnosis Description .......................................... ...20

CONSULT Function (IPDM E/R) ............................21

ECU DIAGNOSIS INFORMATION ..............24

BCM, IPDM E/R .............................................. ...24

List of ECU Reference ......................................... ...24

WIRING DIAGRAM .....................................25

HEADLAMP .................................................... ...25

Wiring Diagram - For USA ................................... ...25

Wiring Diagram - For Canada .................................31

DAYTIME LIGHT SYSTEM ............................. ...37

Wiring Diagram .................................................... ...37

FRONT FOG LAMP ...........................................43

Wiring Diagram .................................................... ...43

TURN SIGNAL AND HAZARD WARNING

LAMP SYSTEM .............................................. ...

48

Wiring Diagram .................................................... ...48

PARKING, LICENSE PLATE AND TAIL

LAMPS SYSTEM ............................................ ...

55

Wiring Diagram .................................................... ...55

STOP LAMP ......................................................63

Wiring Diagram .................................................... ...63

BACK-UP LAMP ................................................67

Wiring Diagram .................................................... ...67

BASIC INSPECTION ...................................71

DIAGNOSIS AND REPAIR WORKFLOW ...... ...71

Work Flow ............................................................ ...71

DTC/CIRCUIT DIAGNOSIS ...................... ...74

POWER SUPPLY AND GROUND CIRCUIT .. ...74

BCM (BODY CONTROL SYSTEM) (WITH INTEL-

LIGENT KEY SYSTEM) ..... .......................................

74

BCM (BODY CONTROL S YSTEM) (WITH INTEL-

LIGENT KEY SYSTEM) : Dia gnosis Procedure .....

74

BCM (BODY CONTROL SYST EM) (WITHOUT IN-

TELLIGENT KEY SYSTEM) . ....................................

74

BCM (BODY CONTROL SYSTEM) (WITHOUT

INTELLIGENT KEY SYSTEM) : Diagnosis Proce-

dure ...................................................................... ...

74

IPDM E/R ................................................................ ...75

IPDM E/R : Diagnosis Procedure ............................75

HEADLAMP (HI) CIRCUIT ................................77

Description ........................................................... ...77

Component Function Check ...................................77

Diagnosis Procedure ...............................................77

HEADLAMP (LO) CIRCUIT ...............................79

Description ........................................................... ...79

Component Function Check ...................................79

Diagnosis Procedure ...............................................79

PARKING LAMP CIRCUIT ................................82

Description ........................................................... ...82

Component Function Check ...................................82

Diagnosis Procedure ...............................................82

TURN SIGNAL LAMP CIRCUIT ........................85

Description ........................................................... ...85

Component Function Check ...................................85

Diagnosis Procedure ...............................................85

FRONT FOG LAMP CIRCUIT ...........................88

Component Function Check ................................ ...88

Diagnosis Procedure ...............................................88

Component Inspection ............................................90

SYMPTOM DIAGNOSIS ............................91

EXTERIOR LIGHTING SYSTEM SYMPTOMS ...91

Symptom Table .................................................... ...91

BOTH SIDE HEADLAMPS DO NOT SWITCH

TO HIGH BEAM .................................................

93

Description ........................................................... ...93

Diagnosis Procedure ...............................................93

BOTH SIDE HEADLAMPS (LO) ARE NOT

TURNED ON ......................................................

94

Description ..............................................................94

Diagnosis Procedure ...............................................94

PARKING, LICENSE PLATE AND TAIL

LAMPS ARE NOT TURNED ON .......................

95

Description ........................................................... ...95

Diagnosis Procedure ...............................................95

BOTH SIDE FRONT FOG LAMPS ARE NOT

TURNED ON ......................................................

96

Description ..............................................................96

Diagnosis Procedure ...............................................96

PERIODIC MAINTENANCE .......................97

HEADLAMP AIMING ADJUSTMENT ............ ...97

Inspection ............................................................. ...97

Aiming Adjustment Procedure ................................98

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1660 of 3641

EXL-8

< SYSTEM DESCRIPTION >

SYSTEM

SYSTEM

HEADLAMP SYSTEM

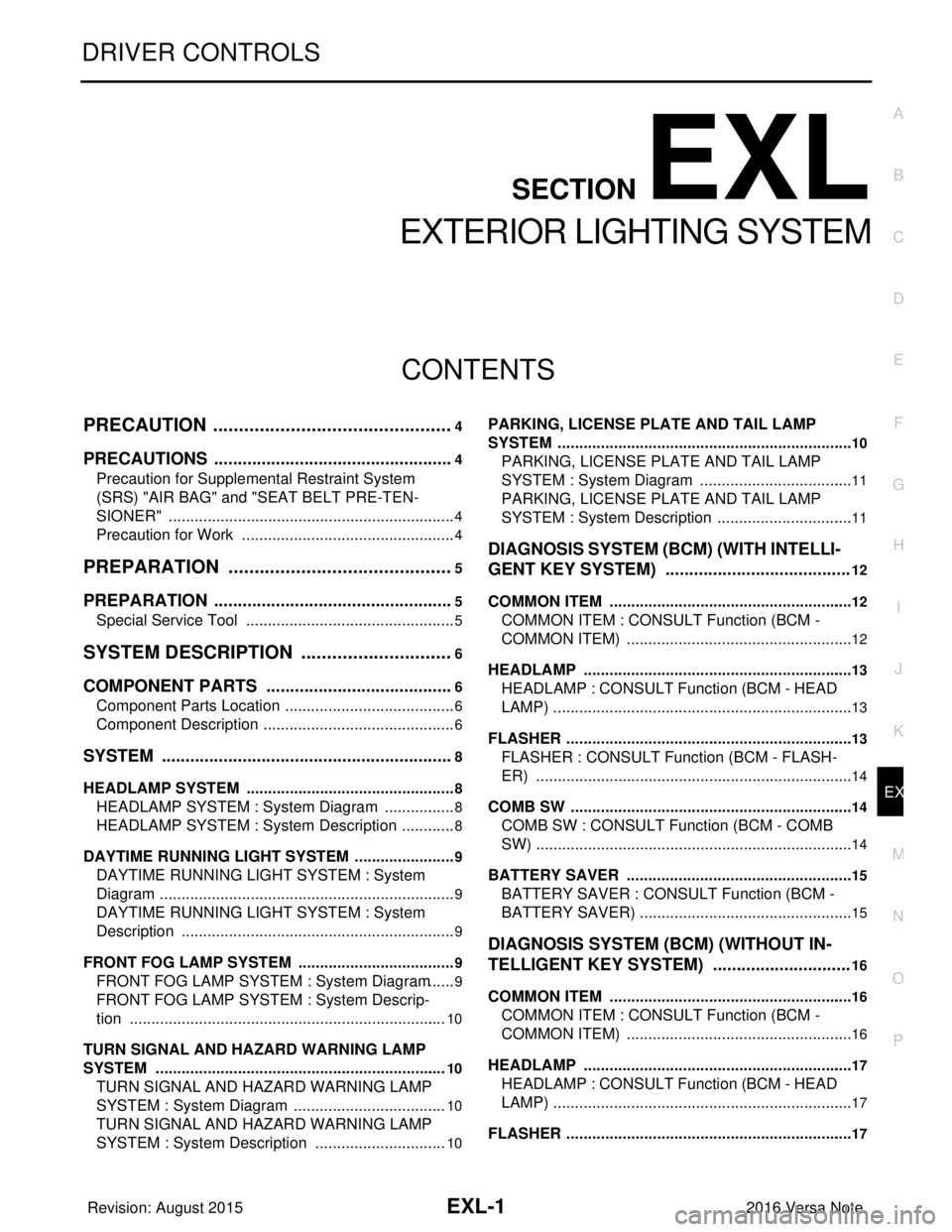

HEADLAMP SYSTEM : System Diagram INFOID:0000000012432769

System Diagram - For USA

System Diagram - For Canada

HEADLAMP SYSTEM : System DescriptionINFOID:0000000012432770

LOW BEAM OPERATION

When the lighting switch is in 2nd position, the BCM receives input requesting the headlamps to illuminate.

This input is communicated to the IPDM E/R across the CAN communication lines. The CPU of the IPDM E/R

controls the headlamp low relay coil which supplies power to the low beam headlamps.

HIGH BEAM OPERATION/FLASH-TO-PASS OPERATION

With the lighting switch in the 2nd position and placed in HIGH position, the BCM receives input requesting the

headlamp high beams to illuminate. The flash to pass f eature can be used any time and also sends a signal to

the BCM. This input is communicated to the IPDM E/R across the CAN communication lines. The CPU of the

combination meter controls the ON/OFF status off the HIGH BEAM indicator. The CPU of the IPDM E/R con-

trols the headlamp high relay coil which supplies power to the high beam headlamps.

The combination meter receives a high beam request signal (ON) through the CAN communication lines and

turns the high beam indicator lamp ON.

EXTERIOR LAMP BATTERY SAVER CONTROL

With the combination switch (lighting and turn signal switch) in the 2nd position and the ignition switch is

turned from ON or ACC to OFF, the battery saver feature is activated.

ALLIA1579GB

ALLIA1580GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1661 of 3641

SYSTEMEXL-9

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

Under this condition, the headlamps remain illuminated for 45 seconds unless the lighting switch position is

changed. If the lighting switch position is changed, then the headlamps are turned off.

This setting can be changed by CONSULT. Refer to BCS-20, "

HEADLAMP : CONSULT Function (BCM -

HEAD LAMP)" (with Intelligent Key system) or BCS-93, "HEADLAMP : CONSULT Function (BCM - HEAD

LAMP)" (without Intelligent Key system).

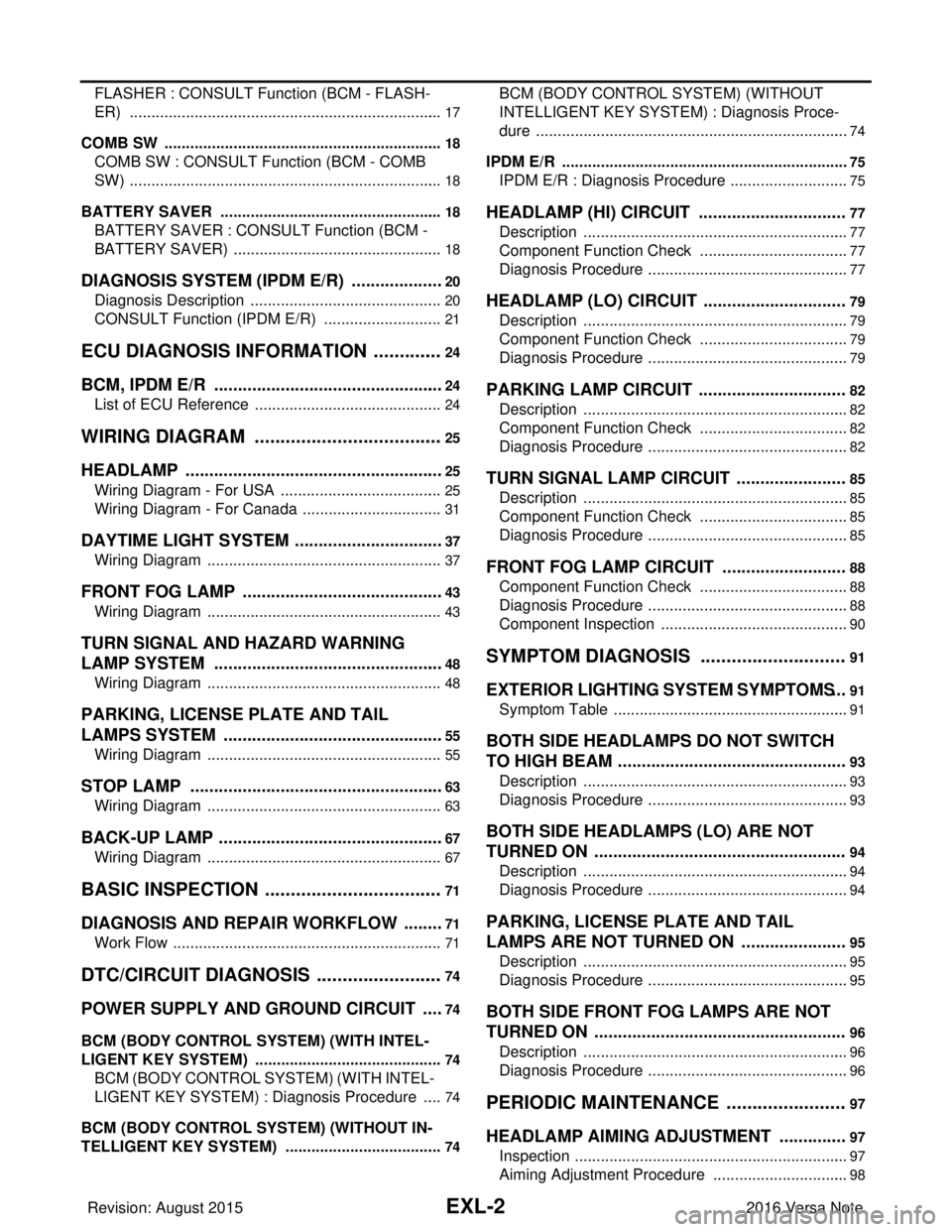

DAYTIME RUNNING LIGHT SYSTEM

DAYTIME RUNNING LIGHT SYSTEM : System DiagramINFOID:0000000012432771

DAYTIME RUNNING LIGHT SYST EM : System DescriptionINFOID:0000000012432772

The headlamp system is equipped with a daytime running light control that activates the high beam head-

lamps at approximately half illumination whenever the e ngine is operating. If the parking brake is applied

before the engine is started the daytime running lights will not be illuminated. The daytime running lights will

illuminate once the parking brake is released. Thereaf ter, the daytime running lights will continue to operate

when the parking brake is applied.

OPERATION

The BCM monitors inputs from the parking brake swit ch and the combination switch (lighting and turn signal

switch) to determine when to activate the daytime running light system. The BCM sends a daytime running

light request to the IPDM E/R via the CAN communication lines. The IPDM E/R grounds the daytime running

light relay 1 which in turn, provides power to the LH high beam lamp. Power flows through the LH high beam

lamp to the RH high beam lamp. The high beam lamps are wired in series which causes them to illuminate at

a reduced intensity. When daytime light relay 2 is open, it prevents headlamp low beam from turning on while

daytime running lights are operating.

FRONT FOG LAMP SYSTEM

FRONT FOG LAMP SYSTEM : System DiagramINFOID:0000000012432773

ALLIA1577GB

ALLIA1578GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1662 of 3641

EXL-10

< SYSTEM DESCRIPTION >

SYSTEM

FRONT FOG LAMP SYSTEM : System Description

INFOID:0000000012432774

FRONT FOG LAMP OPERATION

When the combination switch (lighting and turn signal switch) is in front fog lamp ON position and also in 1ST

or 2ND position (headlamp is ON), the BCM detects FR FOG ON and the HEAD LAMP 1 or 2 ON. The BCM

sends a front fog lamp request ON signal through the CAN communication lines to the IPDM E/R. The IPDM

E/R then turns ON the front fog lamp relay sending power to the front fog lamps.

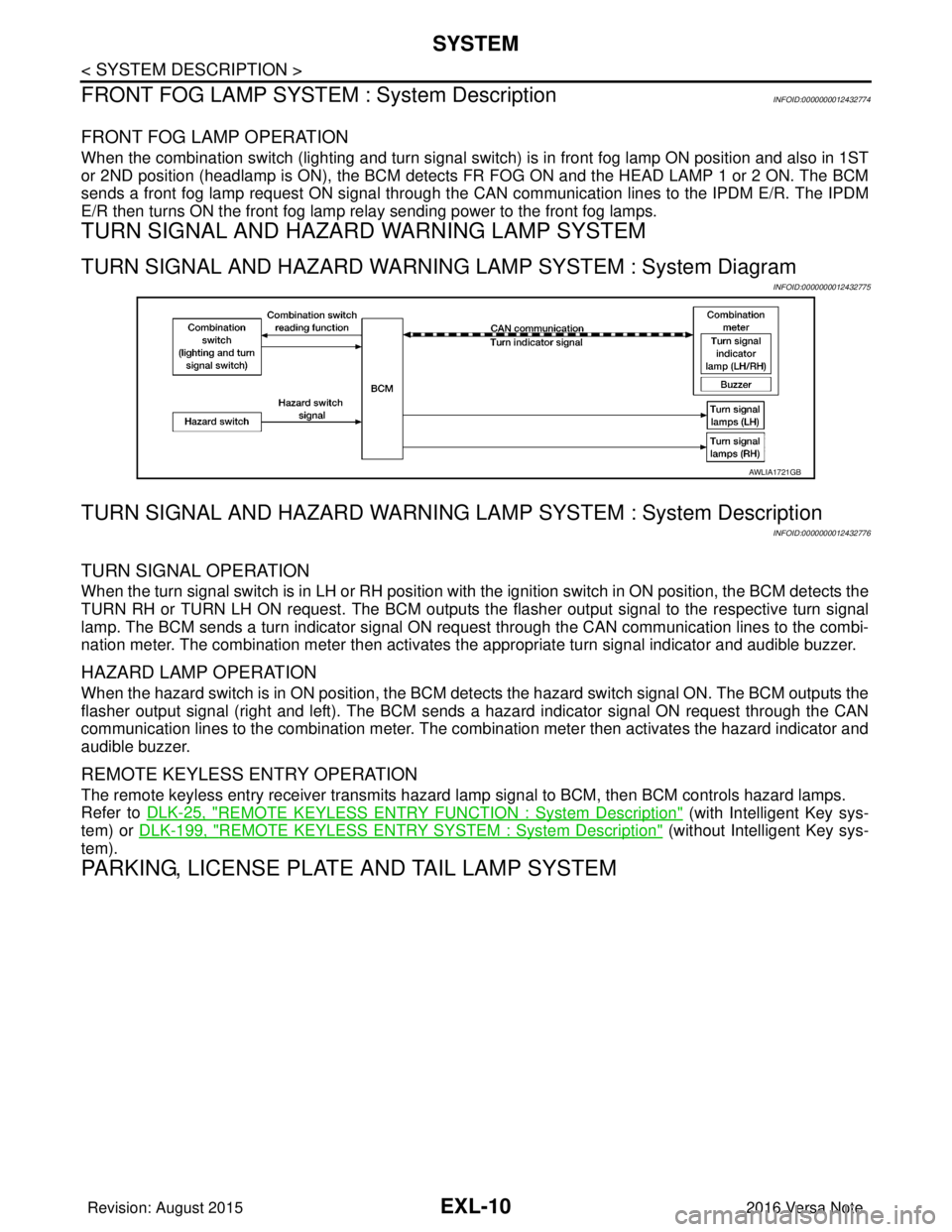

TURN SIGNAL AND HAZARD WARNING LAMP SYSTEM

TURN SIGNAL AND HAZARD WARNING LAMP SYSTEM : System Diagram

INFOID:0000000012432775

TURN SIGNAL AND HAZARD WARNING LA MP SYSTEM : System Description

INFOID:0000000012432776

TURN SIGNAL OPERATION

When the turn signal switch is in LH or RH position with the ignition switch in ON position, the BCM detects the

TURN RH or TURN LH ON request. The BCM outputs the flasher output signal to the respective turn signal

lamp. The BCM sends a turn indicator signal ON request through the CAN communication lines to the combi-

nation meter. The combination meter then activates the appropriate turn signal indicator and audible buzzer.

HAZARD LAMP OPERATION

When the hazard switch is in ON position, the BCM det ects the hazard switch signal ON. The BCM outputs the

flasher output signal (right and left). The BCM sends a hazard indicator signal ON request through the CAN

communication lines to the combination meter. The combination meter then activates the hazard indicator and

audible buzzer.

REMOTE KEYLESS ENTRY OPERATION

The remote keyless entry receiver transmits hazard lamp signal to BCM, then BCM controls hazard lamps.

Refer to DLK-25, "

REMOTE KEYLESS ENTRY FUNCTION : System Description" (with Intelligent Key sys-

tem) or DLK-199, "

REMOTE KEYLESS ENTRY SYSTEM : System Description" (without Intelligent Key sys-

tem).

PARKING, LICENSE PLATE AND TAIL LAMP SYSTEM

AWLIA1721GB

Revision: August 2015 2016 Versa Note

cardiagn.com