heater NISSAN NOTE 2016 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2059 of 3641

HA-34

< REMOVAL AND INSTALLATION >

HEATING AND COOLING UNIT ASSEMBLY

HEATING AND COOLING UNIT ASSEMBLY

HEATING AND COOLING UNIT ASSEMBLY : Removal and InstallationINFOID:0000000012432019

CAUTION:

Perform oil return operation before each refrigeration system disassembly. However, if a large

amountof refrigerant or oil is detected, do not perform oil return operation. Refer to HA-22, "

Perform

Oil Return Operation".

REMOVAL

1. Discharge the refrigerant (if equipped). Refer to HA-20, "Recycle Refrigerant".

2. Drain engine coolant. Refer to CO-8, "

Draining Engine Coolant".

3. Disconnect low-pressure flexible hose from expansion valve (if equipped). Refer to HA-28, "

LOW-PRES-

SURE FLEXIBLE HOSE : Removal and Installation".

CAUTION:

Cap or wrap the joint of the A/C hose and expansion valve with suitable material such as vinyl tape

to avoid the entry of air.

4. Disconnect high-pressure pipe from expansion valve (if equipped). Refer to HA-29, "

HIGH-PRESSURE

PIPE : Removal and Installation".

CAUTION:

Cap or wrap the joint of the A/C piping and expans ion valve with suitable material such as vinyl

tape to avoid the entry of air.

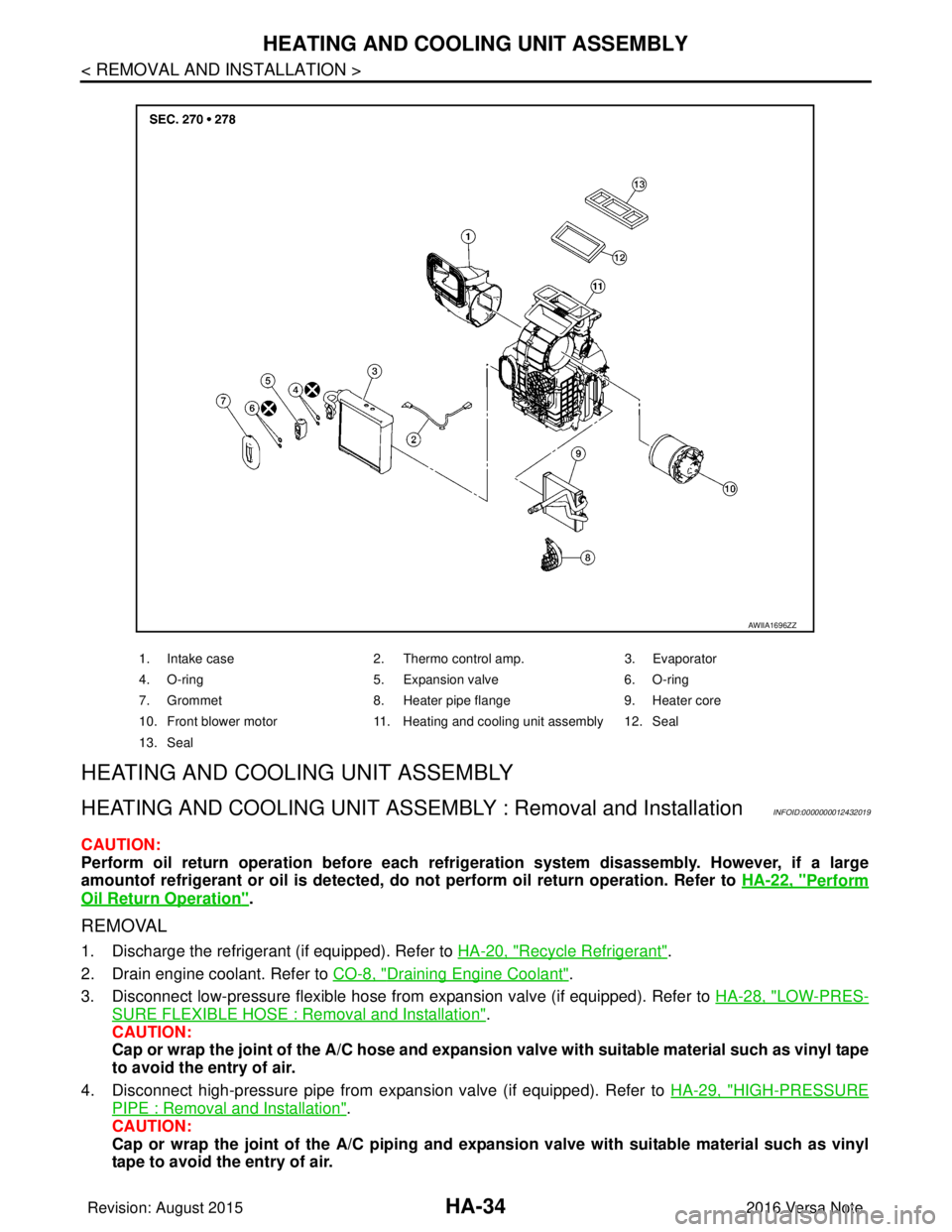

1. Intake case 2. Thermo control amp. 3. Evaporator

4. O-ring 5. Expansion valve 6. O-ring

7. Grommet 8. Heater pipe flange 9. Heater core

10. Front blower motor 11. Heating and cooling unit assembly 12. Seal

13. Seal

AWIIA1696ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2060 of 3641

HEATING AND COOLING UNIT ASSEMBLYHA-35

< REMOVAL AND INSTALLATION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

5. Disconnect heater hoses from heater core.

6. Remove instrument panel assembly. Refer to IP-15, "

Removal and Installation".

7. Disconnect evaporator drain hose from heating and cooling unit assembly.

8. Disconnect harness connectors, grounds, retainers, etc. , and remove bolts required to remove steering

member.

9. Remove steering member and heating and cooling unit assembly.

10. Remove heating and cooling unit assembly from steering member. Refer to HA-33, "

Exploded View".

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-rings.

• Apply compressor oil to new O-rings of the low-pressure flexible hose and high-pressure pipe for

installation.

• After charging refrigerant, check for leaks. Refer to HA-18, "

Leak Test".

NOTE:

When refilling engine coolant, refer to CO-9, "

Refilling".

HEATER CORE

HEATER CORE : Removal and InstallationINFOID:0000000012432020

REMOVAL

1. Remove the heating and cooling unit assembly. Refer to HA-34, "HEATING AND COOLING UNIT

ASSEMBLY : Removal and Installation".

2. Remove foot duct (LH). Refer to VTL-7, "

FOOT DUCT : Removal and Installation".

3. Remove heater packing.

4. Remove heater pipe flange.

5. Remove heater core.

INSTALLATION

Installation is in the reverse order of removal.

NOTE:

When refilling engine coolant, refer to CO-9, "

Refilling".

EVAPORATOR

EVAPORATOR : Removal and InstallationINFOID:0000000012432021

REMOVAL

1. Remove heating and cooling unit assembly. Refer to HA-34, "HEATING AND COOLING UNIT ASSEM-

BLY : Removal and Installation".

2. Remove foot duct (RH). Refer to VTL-7, "

FOOT DUCT : Removal and Installation".

3. Remove intake case. Refer to HA-33, "

Exploded View".

4. Remove expansion valve. Refer to HA-36, "

EXPANSION VALVE : Removal and Installation".

5. Remove evaporator cover and evaporator assembly.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-rings.

• Apply compressor oil to ne w O-rings for installation.

• Perform oil adjusting procedure afte r installing new evaporator. Refer to HA-22, "

Oil Adjusting Pro-

cedure for Components Replacement Except Compressor".

• After charging refrigerant, check for leaks. Refer to HA-18, "

Leak Test".

EXPANSION VALVE

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2320 of 3641

GENERAL MAINTENANCEMA-5

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

PERIODIC MAINTENANCE

GENERAL MAINTENANCE

Explanation of Gene

ral MaintenanceINFOID:0000000012432243

General maintenance includes those items which shoul d be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operati ng properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers do them.

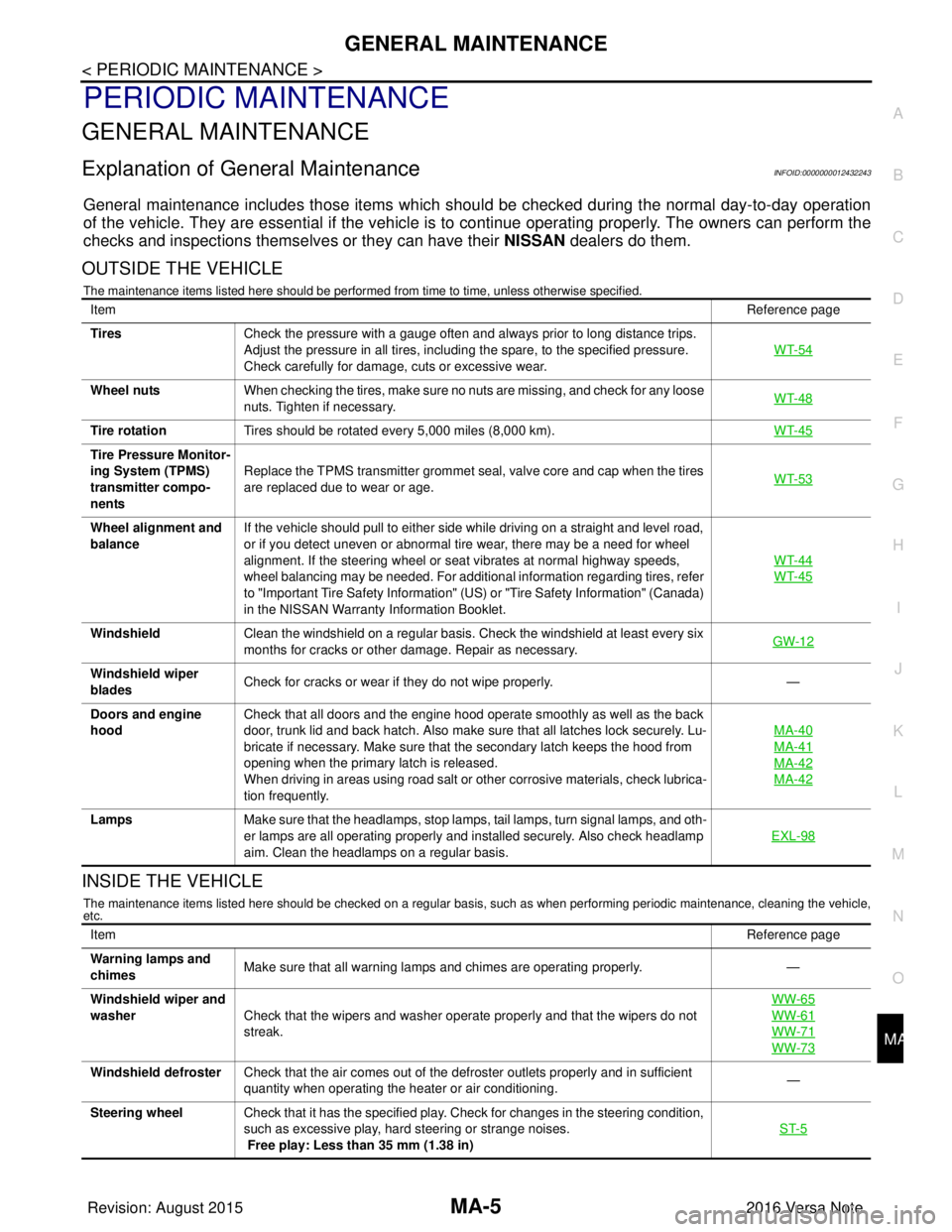

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Tires Check the pressure with a gauge often and always prior to long distance trips.

Adjust the pressure in all tires, including the spare, to the specified pressure.

Check carefully for damage, cuts or excessive wear. WT-54

Wheel nuts

When checking the tires, make sure no nuts are missing, and check for any loose

nuts. Tighten if necessary. WT-48

Tire rotation

Tires should be rotated every 5,000 miles (8,000 km). WT-45

Tire Pressure Monitor-

ing System (TPMS)

transmitter compo-

nentsReplace the TPMS transmitter grommet seal, valve core and cap when the tires

are replaced due to wear or age.

WT-53

Wheel alignment and

balanceIf the vehicle should pull to either side while driving on a straight and level road,

or if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed. For additional information regarding tires, refer

to "Important Tire Safety Information" (US) or "Tire Safety Information" (Canada)

in the NISSAN Warranty

Information Booklet. WT-44

WT-45

Windshield

Clean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary. GW-12

Windshield wiper

bladesCheck for cracks or wear if they do not wipe properly.

—

Doors and engine

hood Check that all doors and the engine hood operate smoothly as well as the back

door, trunk lid and back hatch. Also make sure that all latches lock securely. Lu-

bricate if necessary. Make sure that the secondary latch keeps the hood from

opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check lubrica-

tion frequently. MA-40

MA-41

MA-42

MA-42

Lamps

Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and oth-

er lamps are all operating properly and installed securely. Also check headlamp

aim. Clean the headlamps on a regular basis. EXL-98

Item

Reference page

Warning lamps and

chimes Make sure that all warning lamps and chimes are operating properly.

—

Windshield wiper and

washer Check that the wipers and washer operate properly and that the wipers do not

streak. WW-65

WW-61

WW-71

WW-73

Windshield defroster

Check that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioning. —

Steering wheel Check that it has the specified play. Check for changes in the steering condition,

such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in) ST-5

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2331 of 3641

MA-16

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE

ENGINE COOLANT : Draining Engine Coolant

INFOID:0000000012432253

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high-pressure

engine coolant escaping from the radiator. Wrap a th ick cloth around the cap. Slowly push down and

turn it a quarter turn to allow built-up pressure to escape. Carefully remove the cap by pushing it down

and turning it all the way.

1. Remove front under cover. Refer to EXT-39, "

FRONT UNDER COVER : Removal and Installation".

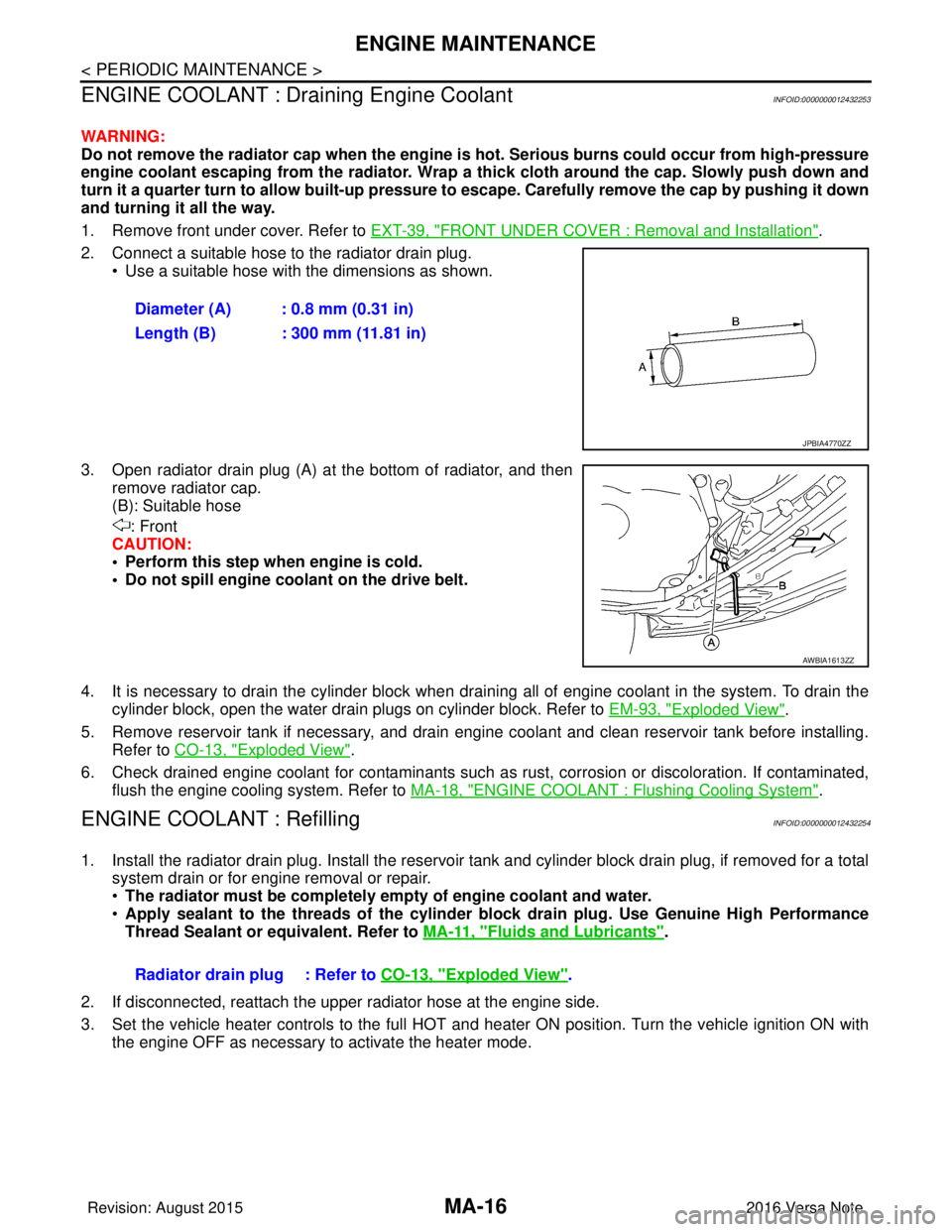

2. Connect a suitable hose to the radiator drain plug. • Use a suitable hose with the dimensions as shown.

3. Open radiator drain plug (A) at the bottom of radiator, and then remove radiator cap.

(B): Suitable hose

: Front

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on the drive belt.

4. It is necessary to drain the cylinder block when drai ning all of engine coolant in the system. To drain the

cylinder block, open the water drain plugs on cylinder block. Refer to EM-93, "

Exploded View".

5. Remove reservoir tank if necessary, and drain engine coolant and clean reservoir tank before installing. Refer to CO-13, "

Exploded View".

6. Check drained engine coolant for contaminants such as rust, corrosion or discoloration. If contaminated, flush the engine cooling system. Refer to MA-18, "

ENGINE COOLANT : Flushing Cooling System".

ENGINE COOLANT : RefillingINFOID:0000000012432254

1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

system drain or for engine removal or repair.

• The radiator must be completely empty of engine coolant and water.

• Apply sealant to the threads of the cylinder block drain plug. Use Genuine High Performance

Thread Sealant or equivalent. Refer to MA-11, "

Fluids and Lubricants".

2. If disconnected, reattach the upper radiator hose at the engine side.

3. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode. Diameter (A) : 0.8 mm (0.31 in)

Length (B) : 300 mm (11.81 in)

JPBIA4770ZZ

AWBIA1613ZZ

Radiator drain plug : Refer to

CO-13, "Exploded View".

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2333 of 3641

MA-18

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE

ENGINE COOLANT : Flushing Cooling System

INFOID:0000000012432255

1. Install radiator drain plug and reservoir tank, if removed.

CAUTION:

Be sure to clean drain plug and install with new O-ring.

2. If water drain plugs on cylinder block were removed, close and tighten them. Refer to EM-93, "

Exploded

View".

3. Remove air duct from between air cleaner case and electric throttle control actuator. Refer to EM-26,

"Removal and Installation".

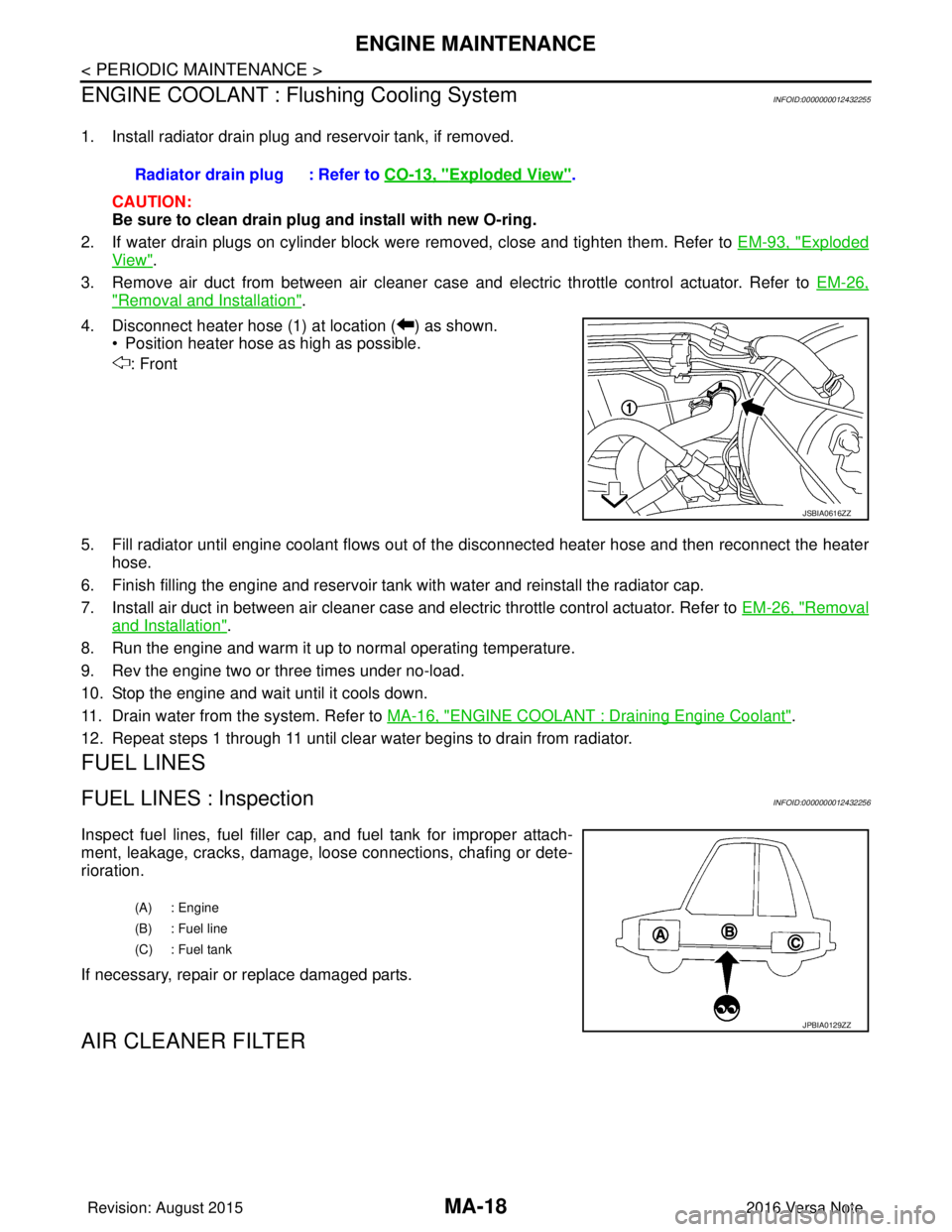

4. Disconnect heater hose (1) at location ( ) as shown. • Position heater hose as high as possible.

: Front

5. Fill radiator until engine coolant flows out of the disconnected heater hose and then reconnect the heater

hose.

6. Finish filling the engine and reservoir tank with water and reinstall the radiator cap.

7. Install air duct in between air cleaner case and electric throttle control actuator. Refer to EM-26, "

Removal

and Installation".

8. Run the engine and warm it up to normal operating temperature.

9. Rev the engine two or three times under no-load.

10. Stop the engine and wait until it cools down.

11. Drain water from the system. Refer to MA-16, "

ENGINE COOLANT : Draining Engine Coolant".

12. Repeat steps 1 through 11 until clear water begins to drain from radiator.

FUEL LINES

FUEL LINES : InspectionINFOID:0000000012432256

Inspect fuel lines, fuel filler cap, and fuel tank for improper attach-

ment, leakage, cracks, damage, l oose connections, chafing or dete-

rioration.

If necessary, repair or replace damaged parts.

AIR CLEANER FILTER

Radiator drain plug : Refer to CO-13, "Exploded View".

JSBIA0616ZZ

(A) : Engine

(B) : Fuel line

(C) : Fuel tank

JPBIA0129ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2638 of 3641

PG

HARNESSPG-51

< WIRING DIAGRAM >

C

DE

F

G H

I

J

K L

B A

O P

N

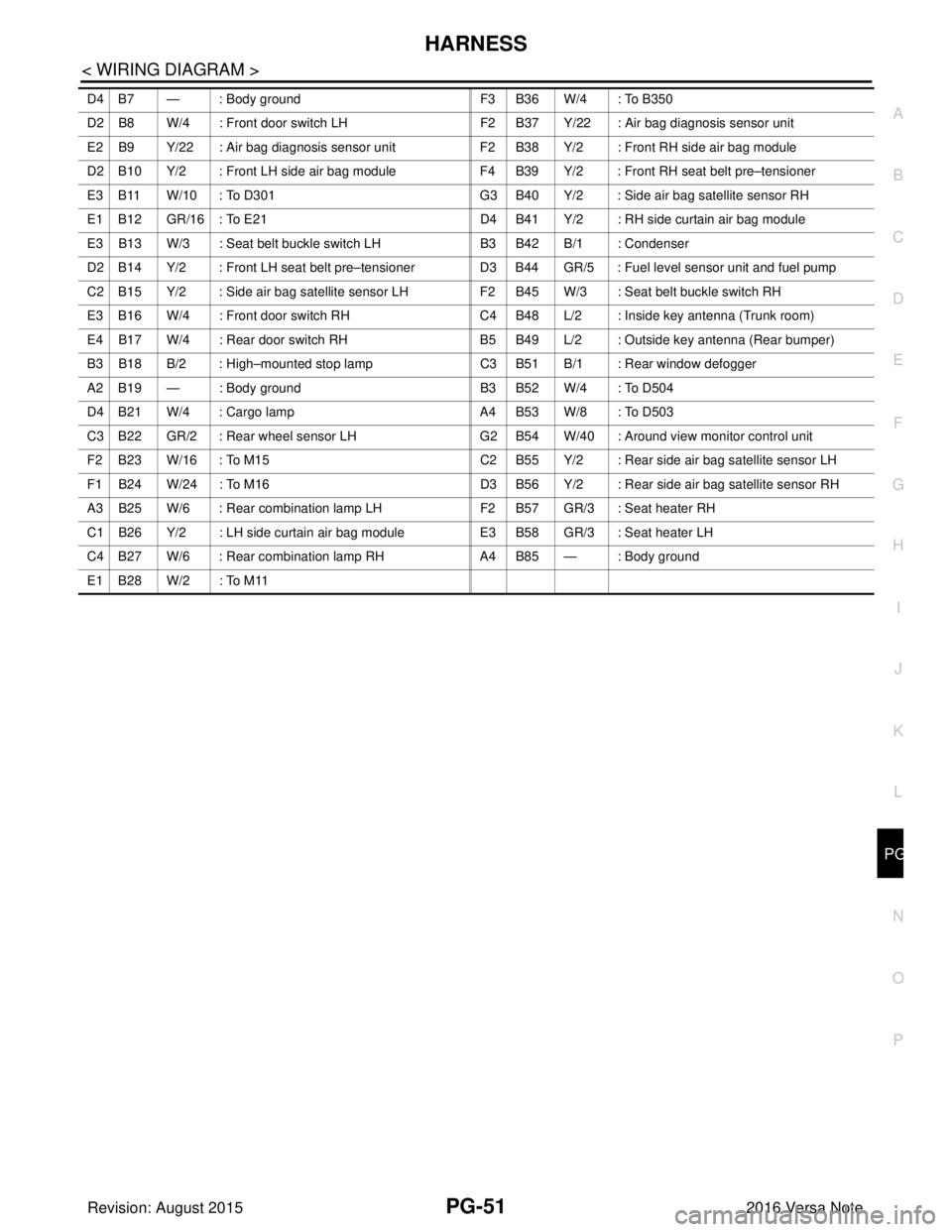

D4 B7 — : Body ground

F3 B36 W/4 : To B350

D2 B8 W/4 : Front door switch LH F2 B37 Y/22 : Air bag diagnosis sensor unit

E2 B9 Y/22 : Air bag diagnosis sensor unit F2 B38 Y/2 : Front RH side air bag module

D2 B10 Y/2 : Front LH side air bag module F4 B39 Y/2 : Front RH seat belt pre–tensioner

E3 B11 W/10 : To D301 G3 B40 Y/2 : Side air bag satellite sensor RH

E1 B12 GR/16 : To E21 D4 B41 Y/2 : RH side curtain air bag module

E3 B13 W/3 : Seat belt buckle switch LH B3 B42 B/1 : Condenser

D2 B14 Y/2 : Front LH seat belt pre–tensioner D3 B44 GR/5 : Fuel level sensor unit and fuel pump

C2 B15 Y/2 : Side air bag satellite sensor LH F2 B45 W/3 : Seat belt buckle switch RH

E3 B16 W/4 : Front door switch RH C4 B48 L/2 : Inside key antenna (Trunk room)

E4 B17 W/4 : Rear door switch RH B5 B49 L/2 : Outside key antenna (Rear bumper)

B3 B18 B/2 : High–mounted stop lamp C3 B51 B/1 : Rear window defogger

A2 B19 — : Body ground B3 B52 W/4 : To D504

D 4 B 2 1 W / 4 : C a r g o l a m p A 4 B 5 3 W / 8 : To D 5 0 3

C3 B22 GR/2 : Rear wheel sensor LH G2 B54 W/40 : Around view monitor control unit

F2 B23 W/16 : To M15 C2 B55 Y/2 : Rear side air bag satellite sensor LH

F1 B24 W/24 : To M16 D3 B56 Y/2 : Rear side air bag satellite sensor RH

A3 B25 W/6 : Rear combination lamp LH F2 B57 GR/3 : Seat heater RH

C1 B26 Y/2 : LH side curtain air bag module E3 B58 GR/3 : Seat heater LH

C4 B27 W/6 : Rear combination lamp RH A4 B85 — : Body ground

E 1 B 2 8 W / 2 : To M 1 1

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3492 of 3641

![NISSAN NOTE 2016 Service Service Manual WATER HOSETM-251

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

WATER HOSE

Exploded ViewINFOID:0000000012431207

Removal and InstallationINFOID:0000000012431208

REMOVAL

WAR NISSAN NOTE 2016 Service Service Manual WATER HOSETM-251

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

WATER HOSE

Exploded ViewINFOID:0000000012431207

Removal and InstallationINFOID:0000000012431208

REMOVAL

WAR](/img/5/57363/w960_57363-3491.png)

WATER HOSETM-251

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

WATER HOSE

Exploded ViewINFOID:0000000012431207

Removal and InstallationINFOID:0000000012431208

REMOVAL

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high-pressure

engine coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly push down and

turn it a quarter turn to allow built-up pressure to escape. Carefully remove the cap by pushing it down

and turning it all the way.

CAUTION:

Perform these steps after the engine cool ant temperature has cooled sufficiently.

NOTE:

When removing components such as hoses, tubes/lines, etc. , cap or plug openings to prevent fluid from spill-

ing.

1. Remove the hose clamp and pull out the water hose A.

2. Remove the hose clamp and pull out the water hose B.

3. Remove the hose clamp and pull out the water hose C.

4. Pull out the heater hose and remove the water bypass pipe.

5. Remove the heater thermostat assembly.

1. Hose clamp 2. Water hose A3. Clip

4. Bracket A 5. Bracket B6. CVT oil warner

7. Water hose B 8. Water bypass pipe9. Hose clamp

10. Water hose C 11. Water outlet

A. To heater core : Always replace after every disassembly.

: N·m (kg-m, in-lb)

JSDIA4111GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3507 of 3641

VTL-1

VENTILATION, HEATER & AIR CONDITIONER

C

DE

F

G H

J

K L

M

SECTION VTL

A

B

VTL

N

O P

CONTENTS

VENTILATION SYSTEM

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution for Work ..................................................2

PREPARATION ............................................3

PREPARATION .............................................. .....3

Special Service Tool ........................................... ......3

Commercial Service Tool ..........................................3

SYSTEM DESCRIPTION ..............................4

VENTILATION SYSTEM ................................ .....4

System Description ............................................. ......4

REMOVAL AND INSTALLATION ................5

DUCT AND GRILLE ....................................... .....5

Exploded View .................................................... ......5

CENTER VENTILATOR GRILLE .......................... ......6

CENTER VENTILATOR GRILLE : Removal and

Installation .................................................................

6

SIDE VENTILATOR GRILLE ................................. .....6

SIDE VENTILATOR GRILLE : Removal and In-

stallation ...................................................................

6

SIDE DEFROSTER GRILLE .................................. .....6

SIDE DEFROSTER GRILLE : Removal and In-

stallation ...................................................................

6

CENTER VENTILATOR DUCT .............................. .....7

CENTER VENTILATOR DUCT : Removal and In-

stallation ...................................................................

7

CENTER DEFROSTER DUCT ............................... .....7

CENTER DEFROSTER DUCT : Removal and In-

stallation ...................................................................

7

SIDE DEFROSTER DUCT ..................................... .....7

SIDE DEFROSTER DUCT : Removal and Instal-

lation .........................................................................

7

FOOT DUCT ........................................................... .....7

FOOT DUCT : Removal and Installation ..................7

REAR FLOOR DUCT ............................................. .....8

REAR FLOOR DUCT : Removal and Installation .....8

FRONT BLOWER MOTOR ................................9

Exploded View ..........................................................9

Removal and Installation ..........................................9

Revision: August 2015 2016 Versa Note

cardiagn.com