height NISSAN NOTE 2016 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1866 of 3641

SERVICE DATA AND SPECIFICATIONS (SDS)FSU-21

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

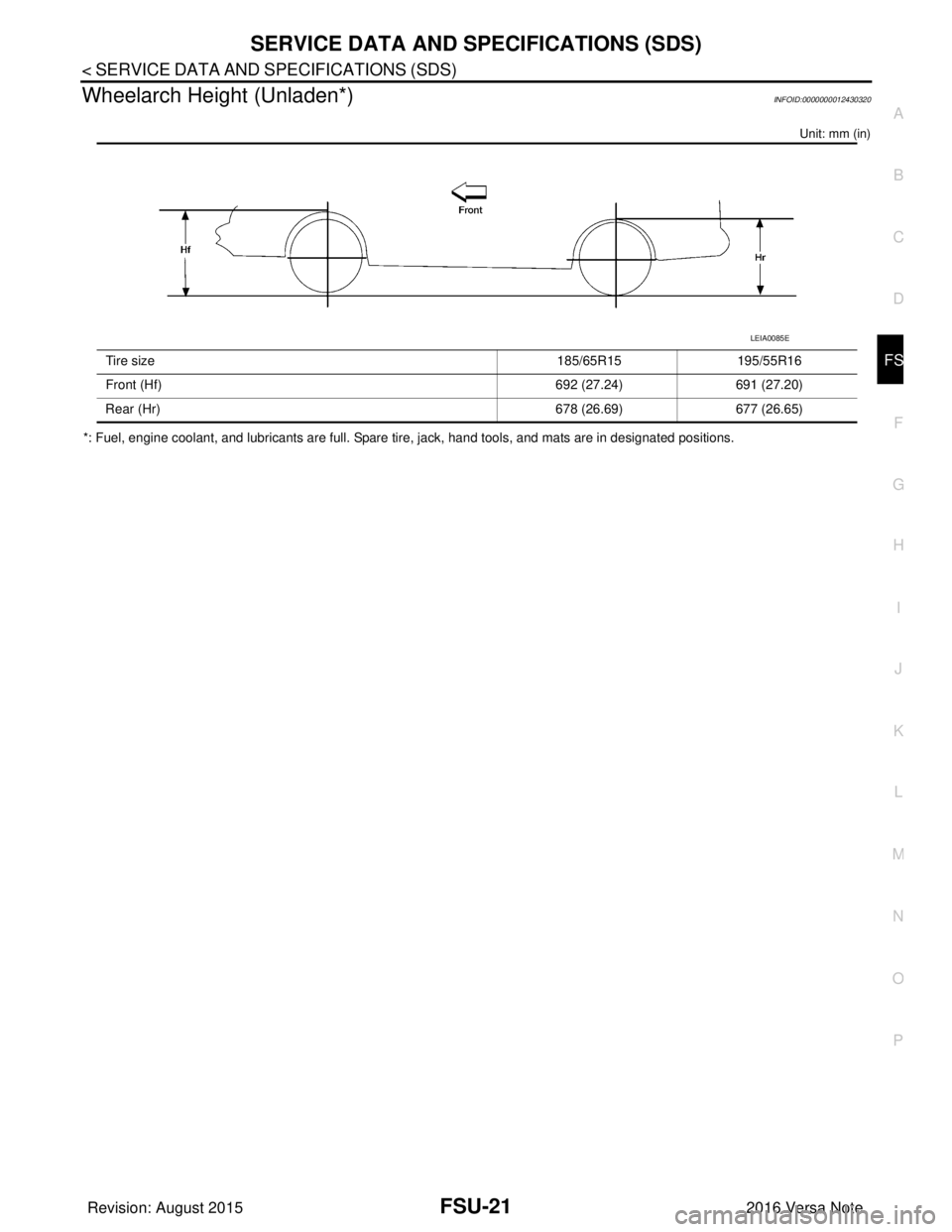

Wheelarch Height (Unladen*)INFOID:0000000012430320

Unit: mm (in)

*: Fuel, engine coolant, and lubricants are full. Spare tire, jack, hand tools, and mats are in designated positions. Tire size

185/65R15195/55R16

Front (Hf) 692 (27.24)691 (27.20)

Rear (Hr) 678 (26.69)677 (26.65)

LEIA0085E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1924 of 3641

GI-36

< VEHICLE INFORMATION >

IDENTIFICATION INFORMATION

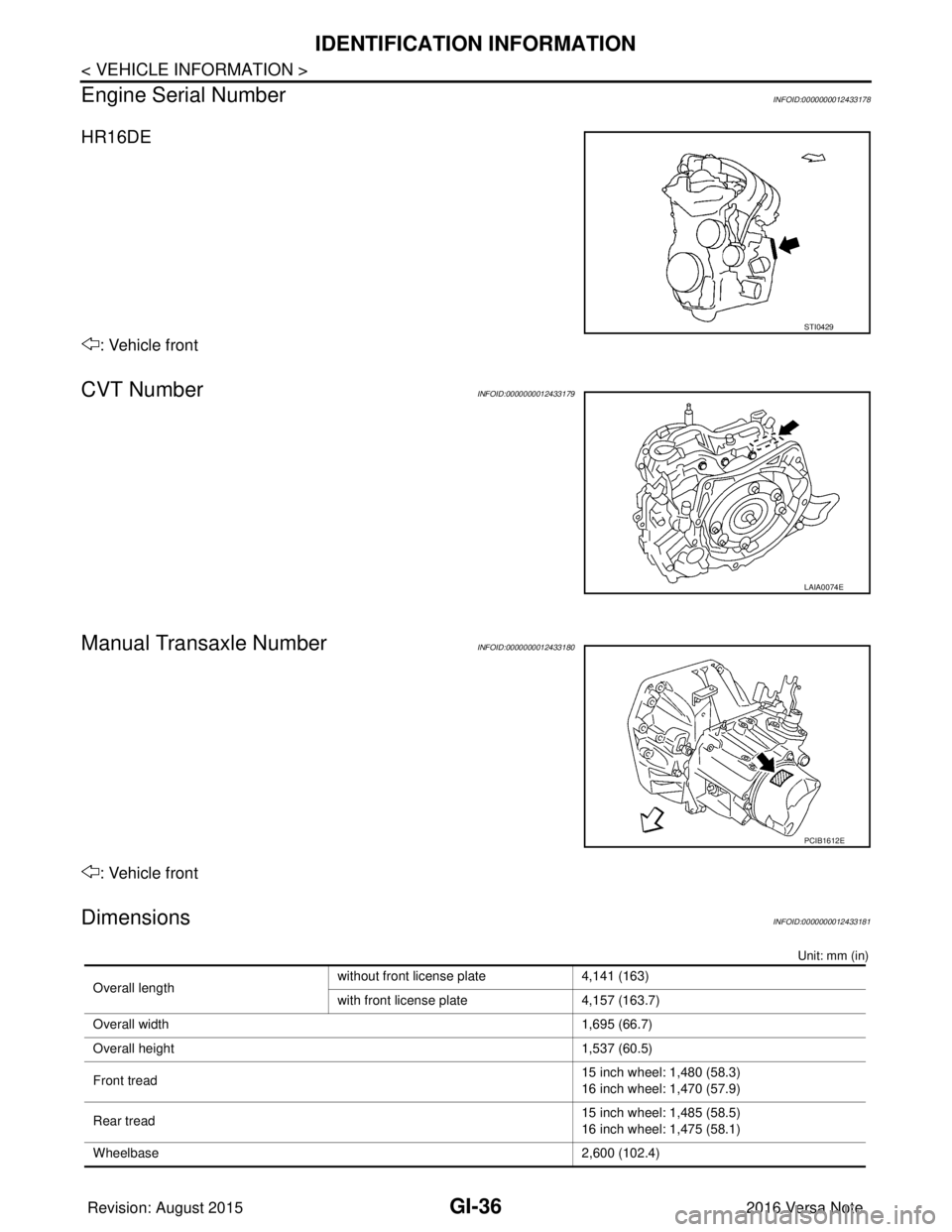

Engine Serial Number

INFOID:0000000012433178

HR16DE

: Vehicle front

CVT NumberINFOID:0000000012433179

Manual Transaxle NumberINFOID:0000000012433180

: Vehicle front

DimensionsINFOID:0000000012433181

Unit: mm (in)

STI0429

LAIA0074E

PCIB1612E

Overall length without front license plate 4,141 (163)

with front license plate

4,157 (163.7)

Overall width 1,695 (66.7)

Overall height 1,537 (60.5)

Front tread 15 inch wheel: 1,480 (58.3)

16 inch wheel: 1,470 (57.9)

Rear tread 15 inch wheel: 1,485 (58.5)

16 inch wheel: 1,475 (58.1)

Wheelbase 2,600 (102.4)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2176 of 3641

BODY SIDE TRIMINT-25

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

Installation

Installation is in the reverse order of removal.

CENTER PILLAR LOWER FINISHER

CENTER PILLAR LOWER FINISHER

: Removal and InstallationINFOID:0000000012431869

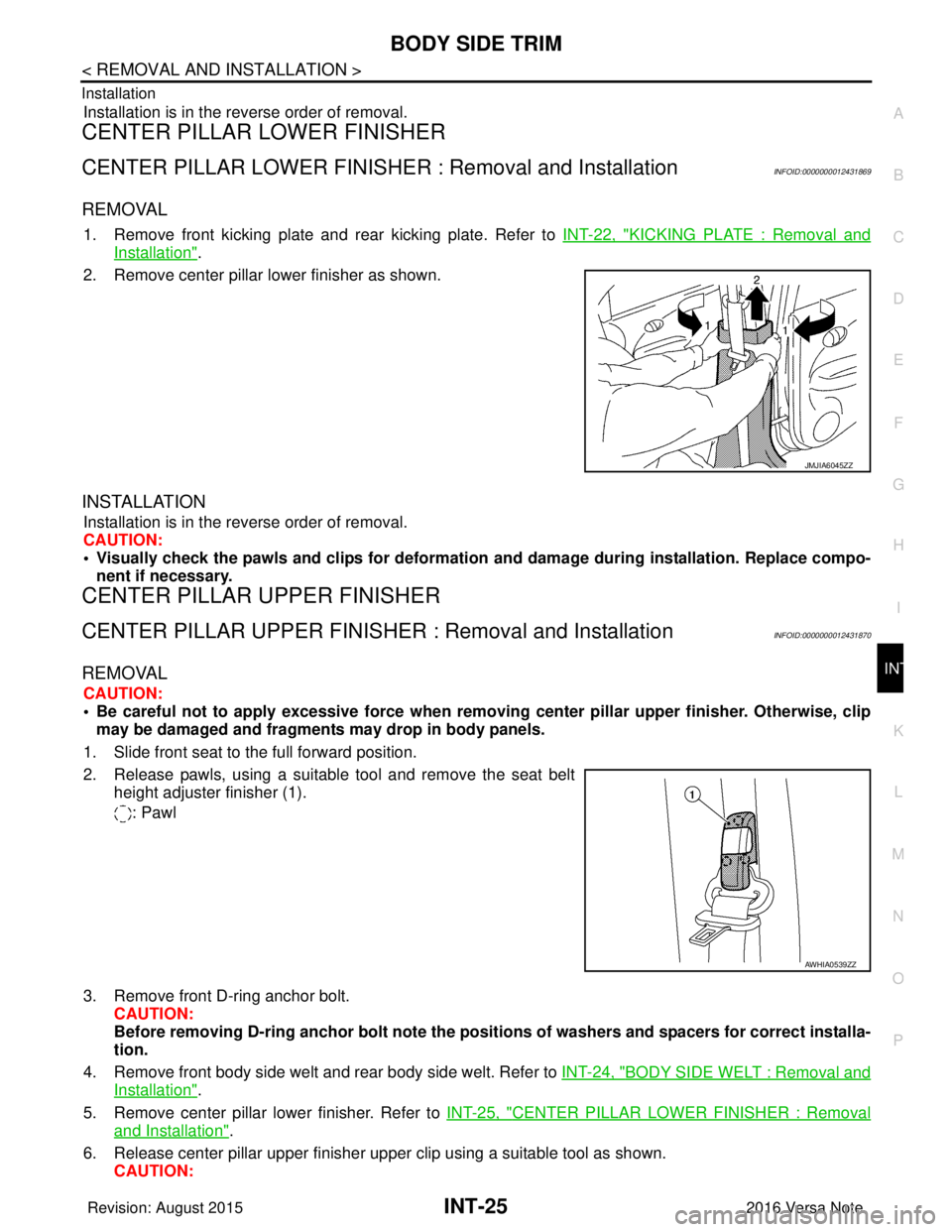

REMOVAL

1. Remove front kicking plate and rear kicking plate. Refer to INT-22, "KICKING PLATE : Removal and

Installation".

2. Remove center pillar lower finisher as shown.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Visually check the pawls and clips for deformation and damage during installation. Replace compo-

nent if necessary.

CENTER PILLAR UPPER FINISHER

CENTER PILLAR UPPER FINISHER : Removal and InstallationINFOID:0000000012431870

REMOVAL

CAUTION:

• Be careful not to apply excessive for ce when removing center pillar upper finisher. Otherwise, clip

may be damaged and fragments may drop in body panels.

1. Slide front seat to the full forward position.

2. Release pawls, using a suitable tool and remove the seat belt height adjuster finisher (1).

: Pawl

3. Remove front D-ring anchor bolt. CAUTION:

Before removing D-ring anchor bolt note the positions of washers and spacers for correct installa-

tion.

4. Remove front body side welt and rear body side welt. Refer to INT-24, "

BODY SIDE WELT : Removal and

Installation".

5. Remove center pillar lower finisher. Refer to INT-25, "

CENTER PILLAR LOWER FINISHER : Removal

and Installation".

6. Release center pillar upper finisher upper clip using a suitable tool as shown. CAUTION:

JMJIA6045ZZ

AWHIA0539ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2351 of 3641

MA-36

< PERIODIC MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

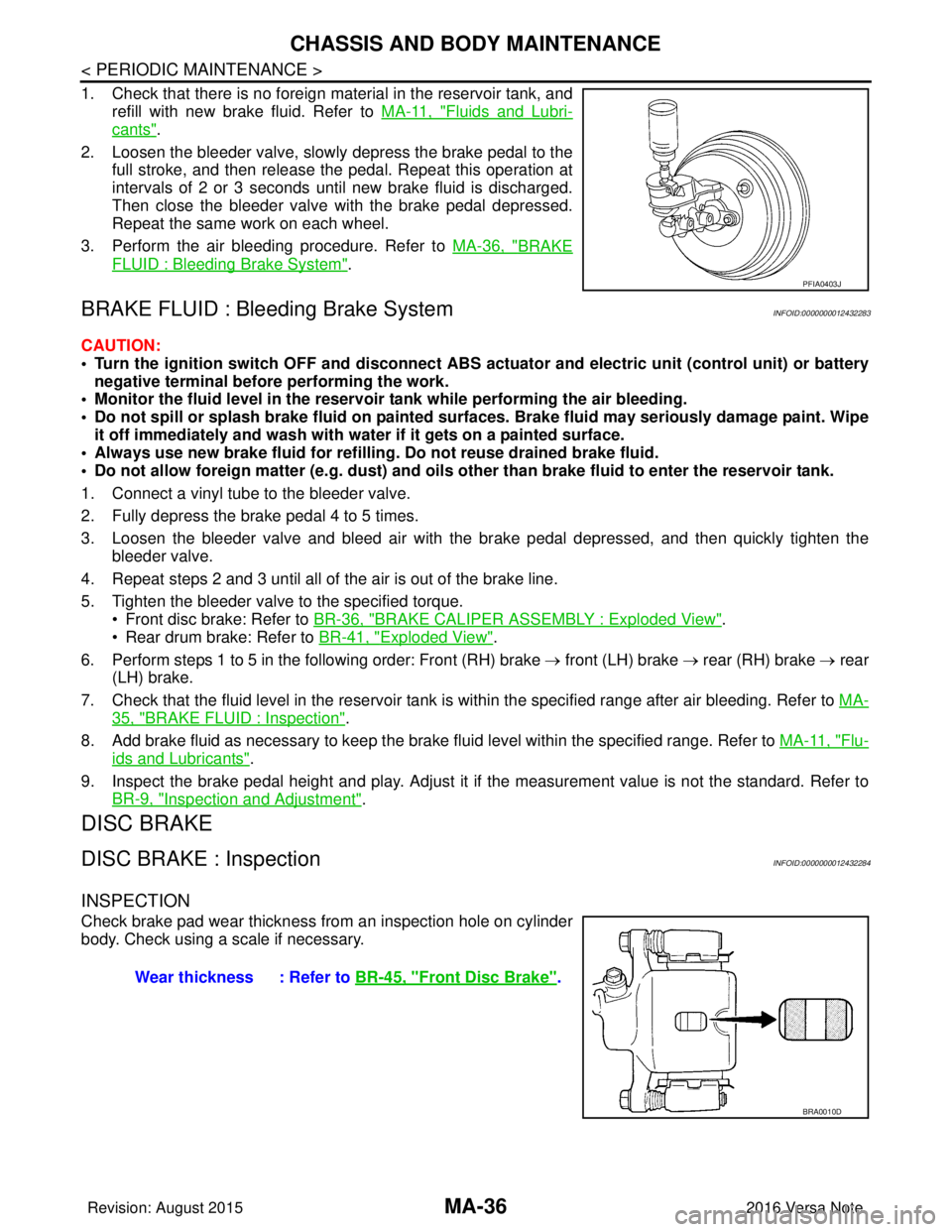

1. Check that there is no foreign material in the reservoir tank, andrefill with new brake fluid. Refer to MA-11, "

Fluids and Lubri-

cants".

2. Loosen the bleeder valve, slowly depress the brake pedal to the full stroke, and then release the pedal. Repeat this operation at

intervals of 2 or 3 seconds until new brake fluid is discharged.

Then close the bleeder valve with the brake pedal depressed.

Repeat the same work on each wheel.

3. Perform the air bleeding procedure. Refer to MA-36, "

BRAKE

FLUID : Bleeding Brake System".

BRAKE FLUID : Bleeding Brake SystemINFOID:0000000012432283

CAUTION:

• Turn the ignition switch OFF and disconnect ABS act uator and electric unit (control unit) or battery

negative terminal before performing the work.

• Monitor the fluid level in the reservoir tank while performing the air bleeding.

• Do not spill or splash brake fluid on painted su rfaces. Brake fluid may seriously damage paint. Wipe

it off immediately and wash with wa ter if it gets on a painted surface.

• Always use new brake fluid for refilling. Do not reuse drained brake fluid.

• Do not allow foreign matter (e.g. dust) and oils other than brake fluid to enter the reservoir tank.

1. Connect a vinyl tube to the bleeder valve.

2. Fully depress the brake pedal 4 to 5 times.

3. Loosen the bleeder valve and bleed air with the br ake pedal depressed, and then quickly tighten the

bleeder valve.

4. Repeat steps 2 and 3 until all of the air is out of the brake line.

5. Tighten the bleeder valve to the specified torque. • Front disc brake: Refer to BR-36, "

BRAKE CALIPER ASSEMBLY : Exploded View".

• Rear drum brake: Refer to BR-41, "

Exploded View".

6. Perform steps 1 to 5 in the following order: Front (RH) brake → front (LH) brake → rear (RH) brake → rear

(LH) brake.

7. Check that the fluid level in the reservoir tank is within the specified range after air bleeding. Refer to MA-

35, "BRAKE FLUID : Inspection".

8. Add brake fluid as necessary to keep the brake fluid level within the specified range. Refer to MA-11, "

Flu-

ids and Lubricants".

9. Inspect the brake pedal height and play. Adjust it if the measurement value is not the standard. Refer to

BR-9, "

Inspection and Adjustment".

DISC BRAKE

DISC BRAKE : InspectionINFOID:0000000012432284

INSPECTION

Check brake pad wear thickness from an inspection hole on cylinder

body. Check using a scale if necessary.

PFIA0403J

Wear thickness : Refer to BR-45, "Front Disc Brake".

BRA0010D

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2404 of 3641

![NISSAN NOTE 2016 Service Workshop Manual MWI-46

< DTC/CIRCUIT DIAGNOSIS >[TYPE A]

FUEL LEVEL SENSOR SIGNAL CIRCUIT

3.CHECK FUEL LEVEL SENSOR GROUND CIRCUIT

1. Disconnect ECM connector F11.

2. Check continuity between combination meter har ne NISSAN NOTE 2016 Service Workshop Manual MWI-46

< DTC/CIRCUIT DIAGNOSIS >[TYPE A]

FUEL LEVEL SENSOR SIGNAL CIRCUIT

3.CHECK FUEL LEVEL SENSOR GROUND CIRCUIT

1. Disconnect ECM connector F11.

2. Check continuity between combination meter har ne](/img/5/57363/w960_57363-2403.png)

MWI-46

< DTC/CIRCUIT DIAGNOSIS >[TYPE A]

FUEL LEVEL SENSOR SIGNAL CIRCUIT

3.CHECK FUEL LEVEL SENSOR GROUND CIRCUIT

1. Disconnect ECM connector F11.

2. Check continuity between combination meter har ness connector M82 terminal 24 and fuel level sensor

unit and fuel pump harness connector B44 terminal 5.

3. Check continuity between fuel level sensor unit and fuel pump harness connector B44 terminal 5 and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair harness or connector.

4.CHECK INSTALLATION CONDITION

Check fuel level sensor unit installation, and verify t he float arm does not interfere or bind with the internal

components in the fuel tank.

Is the inspection result normal?

YES >> Inspection End.

NO >> Install the fuel level sensor unit properly.

Component InspectionINFOID:0000000012432579

1.REMOVE FUEL LEVEL SENSOR UNIT

Remove the fuel level sensor unit. Refer to FL-6, "

Removal and Installation".

>> GO TO 2.

2.CHECK FUEL LEVEL SENSOR UNIT

Check the resistance between fuel level sensor unit and fuel pump.

*: When float rod is in contact with stopper.

Is inspection result OK?

YES >> Inspection End.

NO >> Replace fuel level sensor unit and fuel pump. Refer to

FL-6, "

Removal and Installation".

Connector TerminalConnector Terminal Continuity

M82 24B44 5Yes

Connector Terminal

GroundContinuity

B44 5 No

Te r m i n a l s

ConditionResistance (Ω

)

(Approx.) Height [mm (in)]

Fuel level sensor unit

25 Full

* (A)

51 171.4 (6.75)

Empty

* (B) 283 18.5 (0.73)

JPNIA0841ZZ

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2460 of 3641

![NISSAN NOTE 2016 Service Workshop Manual MWI-102

< DTC/CIRCUIT DIAGNOSIS >[TYPE B]

FUEL LEVEL SENSOR SIGNAL CIRCUIT

3.CHECK FUEL LEVEL SENSOR GROUND CIRCUIT

1. Disconnect ECM connector F11

2. Check continuity between combination meter har ne NISSAN NOTE 2016 Service Workshop Manual MWI-102

< DTC/CIRCUIT DIAGNOSIS >[TYPE B]

FUEL LEVEL SENSOR SIGNAL CIRCUIT

3.CHECK FUEL LEVEL SENSOR GROUND CIRCUIT

1. Disconnect ECM connector F11

2. Check continuity between combination meter har ne](/img/5/57363/w960_57363-2459.png)

MWI-102

< DTC/CIRCUIT DIAGNOSIS >[TYPE B]

FUEL LEVEL SENSOR SIGNAL CIRCUIT

3.CHECK FUEL LEVEL SENSOR GROUND CIRCUIT

1. Disconnect ECM connector F11

2. Check continuity between combination meter har ness connector M24 terminal 24 and fuel level sensor

unit and fuel pump harness connector B44 terminal 5.

3. Check continuity between fuel level sensor unit and fuel pump harness connector B44 terminal 5 and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair harness or connector.

4.CHECK INSTALLATION CONDITION

Check fuel level sensor unit installation, and verify t he float arm does not interfere or bind with the internal

components in the fuel tank.

Is the inspection result normal?

YES >> Inspection End.

NO >> Install the fuel level sensor unit properly.

Component InspectionINFOID:0000000012432639

1.REMOVE FUEL LEVEL SENSOR UNIT

Remove the fuel level sensor unit. Refer to FL-6, "

Removal and Installation".

>> GO TO 2.

2.CHECK FUEL LEVEL SENSOR UNIT

Check the resistance between fuel level sensor unit and fuel pump.

*: When float rod is in contact with stopper.

Is inspection result OK?

YES >> Inspection End.

NO >> Replace fuel level sensor unit and fuel pump. Refer to

FL-6, "

Removal and Installation".

Connector TerminalConnector Terminal Continuity

M24 24B44 5Yes

Connector Terminal

GroundContinuity

B44 5 No

Te r m i n a l s

ConditionResistance (Ω

)

(Approx.) Height [mm (in)]

Fuel level sensor unit

25 Full

* (A)

51 168.2 (6.62)

Empty

* (B) 283 17.5 (0.69)

JPNIA0841ZZ

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2729 of 3641

RSU-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION RSU

A

B

RSU

N

O PCONTENTS

REAR SUSPENSION

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution for Suspension ........................................2

PREPARATION ............................................3

PREPARATION .............................................. .....3

Special Service Tool ........................................... ......3

Commercial Service Tools ........................................3

SYMPTOM DIAGNOSIS ...............................4

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

4

NVH Troubleshooting Chart ................................ ......4

PERIODIC MAINTENANCE ..........................5

REAR SUSPENSION ASSEMBLY ................ .....5

Inspection ............................................................ ......5

WHEEL ALIGNMENT ..........................................6

Inspection ............................................................ ......6

REMOVAL AND INSTALLATION ................8

REAR SHOCK ABSORBER ..............................8

Exploded View ..................................................... .....8

Removal and Installation ..........................................8

Inspection .................................................................9

Disposal ...................................................................10

COIL SPRING ...................................................11

Exploded View .........................................................11

Removal and Installation .........................................11

Inspection ................................................................12

REAR SUSPENSION BEAM ............................13

Exploded View ..................................................... ....13

Removal and Installation .........................................13

Inspection ................................................................14

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

15

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

15

Wheel Alignment (Unladen*1) ..................................15

Wheelarch Height (Unladen*) .............................. ....15

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2734 of 3641

RSU-6

< PERIODIC MAINTENANCE >

WHEEL ALIGNMENT

WHEEL ALIGNMENT

InspectionINFOID:0000000012431922

DESCRIPTION

Measure the wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricants are full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY

Check the following:

1. Tires for improper air pressure and wear.

2. Road wheels for runout. Refer to WT-44, "

Inspection".

3. Wheel bearing axial end play. Refer to RAX-10, "

Wheel Bearing".

4. Shock absorber operation.

5. Each mounting part of suspension for looseness and deformation.

6. Rear suspension beam for cracks, deformation, and other damage.

7. Vehicle height (posture).

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed. • This type of alignment is recommended for any NISSAN/INFINITI vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be capabl e of accepting any NISSAN/INFINITI vehicle.

• The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated. • Your alignment machine should be regularly calibrated in order to give correct information.

• Check with the manufacturer of your specific al ignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to RSU-15, "Wheel

Alignment (Unladen*1)".

1. When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or minus, Go/No Go). Do NOT use these indicators.

• The alignment specifications programmed into your alignment machine that operate these indicators may not be correct.

• This may result in an ERROR.

2. Most camera-type alignment machines are equipped with both "Rolling Compensation" method and optional "Jacking Compensation" method to "com pensate" the alignment targets or head units.

"Rolling Compensation" is the preferred method.

• If using the "Rolling Compensation" method, after installing the alignment targets or head units, push or pull on the rear wheel to move the vehicle. Do not push or pull the vehicle body.

• If using the "Jacking Compensation" method, after in stalling the alignment targets or head units, raise

the vehicle and rotate the wheels 1/2 turn both ways.

NOTE:

Do not use the "rolling compensation" if you are using sensor-type alignment equipment.

• Follow all instructions for the alignment machine you're using for more information.

CAMBER INSPECTION

• Measure camber of both right and left wheels with a suitable alignment gauge.

• If it is out of the specificati on value, inspect and replace any damaged or worn rear suspension parts.

Camber : Refer to RSU-15, "

Wheel Alignment

(Unladen*1)".

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2735 of 3641

WHEEL ALIGNMENTRSU-7

< PERIODIC MAINTENANCE >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

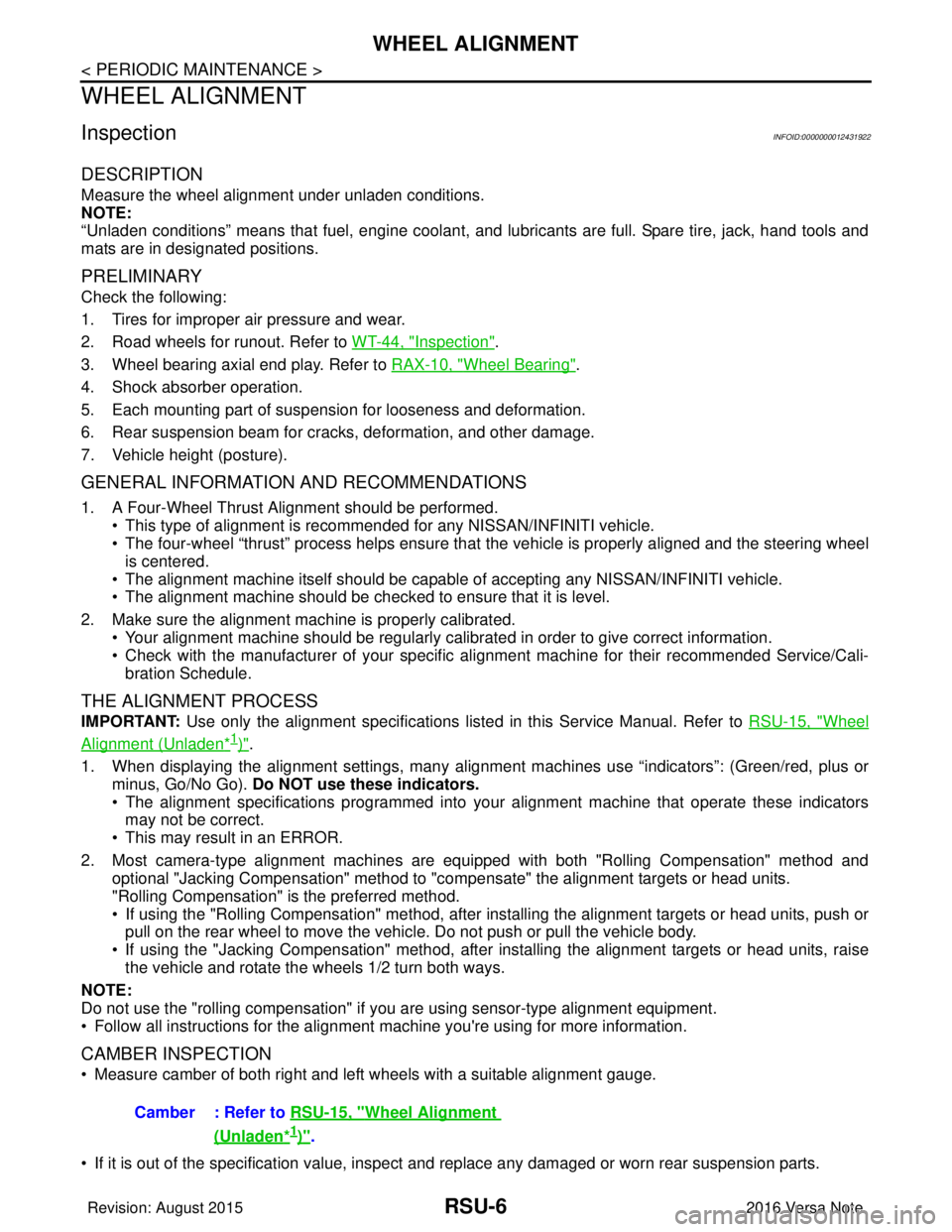

TOTAL TOE-IN INSPECTION

Measure the total toe-in using following procedure. If it is out of the specification, inspect and replace any

damaged or worn rear suspension parts.

WARNING:

• Always perform the following procedure on a flat surface.

• Make sure that no person is in front of the vehicle before pushing it.

1. Bounce the rear of the vehicle up and down to stabilize the vehicle height (posture).

2. Push the rear wheel to move the vehicle straight ahead about 5 m (16 ft).

3. Put a mark on the base line of the tread (rear side) of both tires at the same height of hub center. These are measuring points.

4. Measure the distance (A) from the rear side.

5. Push the rear wheel to move the vehicle slowly ahead and to rotate the wheels 180 degrees (1/2 turn).

CAUTION:

If the wheels have rotated more than 180 degrees (1/2 turn),

try the above procedure again from the beginning. Do not

push the vehicle backward.

6. Measure the distance (B) from the front side.

SEIA0362E

Total toe-in : Refer to RSU-15, "Wheel Alignment

(Unladen*1)".SFA234AC

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2743 of 3641

SERVICE DATA AND SPECIFICATIONS (SDS)RSU-15

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

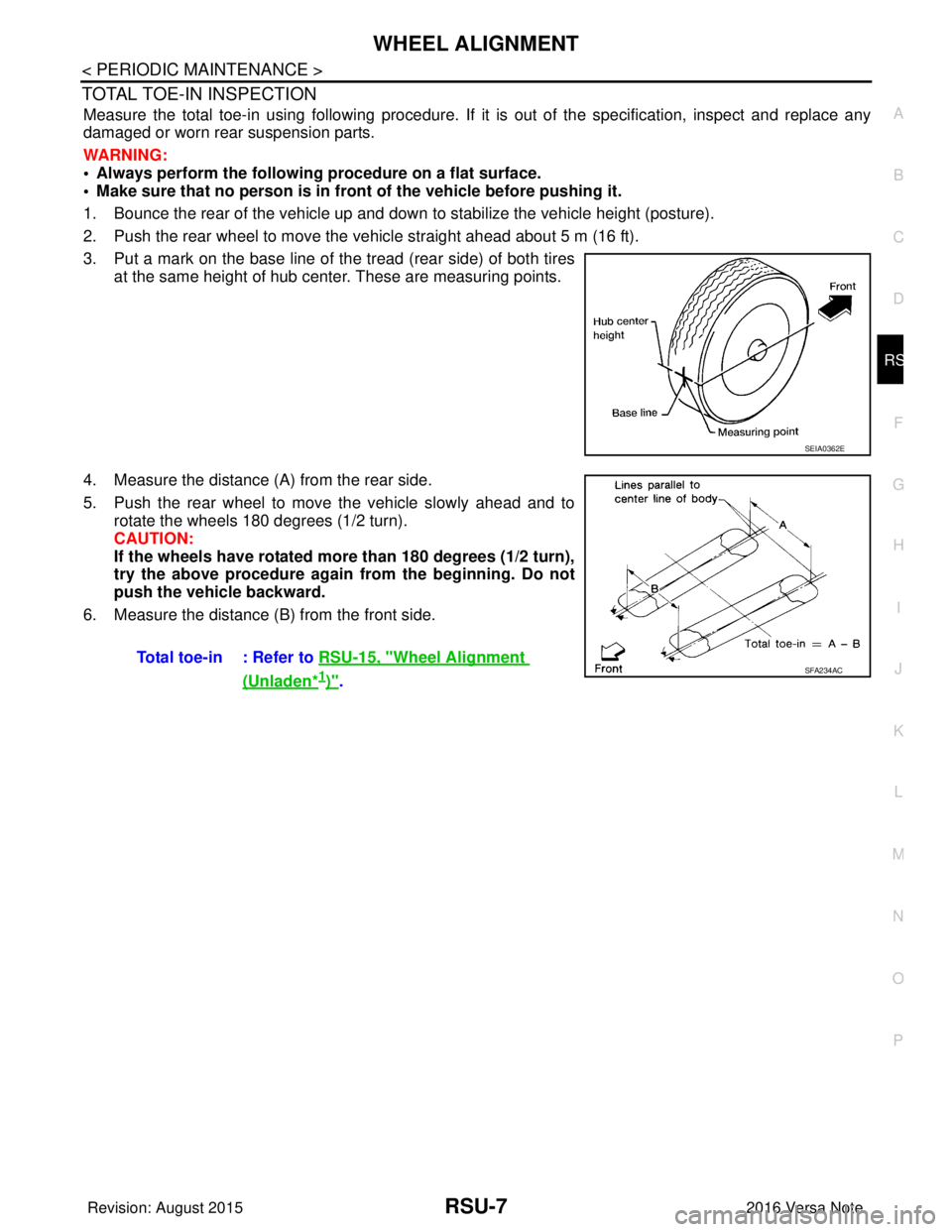

Wheel Alignment (Unladen*1)INFOID:0000000012431933

*1: Fuel, engine coolant, and lubricants are full. Spare tire, jack, hand tools, and mats are in designated positions.

*2: Since an adjustment mechanism is not included, the value of the left and right wheels must be used as the standard value.

Wheelarch Height (Unladen*)INFOID:0000000012431934

Unit: mm (in)

*: Fuel, engine coolant, and lubricants are full. Spare tire, jack, hand tools, and mats are in designated positions. Camber

Degree minute (Decimal degree)

Minimum

−1° 55 ′ ( −1.92 °)

Nominal −1° 25 ′ ( −1.42 °)

Maximum −0° 55 ′ ( −0.92 °)

Total toe-in Distance (A - B)

Minimum

Out 2.0 mm (Out 0.079 in)

Nominal In 2.0 mm (In 0.079 in)

Maximum In 6.0 mm (In 0.236 in)

Angle (LH and RH)

*2

Degree minute (Decimal degree) Minimum Out 0

° 15 ′ (Out 0.25 °)

Nominal In 0° 10 ′ (In 0.17 °)

Maximum In 0° 35 ′ (In 0.58 °)

SFA234AC

Tire size 185/65R15195/55R16

Front (Hf) 692 (27.24)691 (27.20)

Rear (Hr) 678 (26.69)677 (26.65)

LEIA0085E

Revision: August 2015 2016 Versa Note

cardiagn.com