height NISSAN NOTE 2016 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2798 of 3641

SB-1

RESTRAINTS

C

DE

F

G

I

J

K L

M

SECTION SB

A

B

SB

N

O P

CONTENTS

SEAT BELT

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution for Seat Belt Service ...............................2

Precaution for Work ..................................................2

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tools .......................................... ......4

BASIC INSPECTION ....................................5

COMPONENT INSPEC TION ...............................5

Inspection ............................................................ ......5

REMOVAL AND INSTALLATION ................8

FRONT SEAT BELT ............................................8

Exploded View .................................................... ......8

FRONT SEAT BELT BUCKLE .............................. ......8

FRONT SEAT BELT BUCKLE : Removal and In-

stallation ....................................................................

8

SEAT BELT RETRACTOR .................................... .....9

SEAT BELT RETRACTOR : Removal and Instal-

lation .........................................................................

9

SEAT BELT HEIGHT ADJUSTER ......................... ....10

SEAT BELT HEIGHT ADJUSTER : Removal and

Installation ...............................................................

10

REAR SEAT BELT ............................................12

Exploded View .........................................................12

REAR SEAT BELT BUCKLE ................................ ....12

REAR SEAT BELT BUCKLE : Removal and In-

stallation ..................................................................

12

SEAT BELT RETRACTOR .................................... ....13

SEAT BELT RETRACTOR : Removal and Instal-

lation ........................................................................

13

LATCH (LOWER ANCHORS AND TETHER

FOR CHILDREN) SYSTEM ...............................

15

Removal and Installation .........................................15

TOP TETHER STRAP CHILD RESTRAINT .....16

Removal and Installation .........................................16

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2802 of 3641

COMPONENT INSPECTIONSB-5

< BASIC INSPECTION >

C

DE

F

G

I

J

K L

M A

B

SB

N

O P

BASIC INSPECTION

COMPONENT INSPECTION

InspectionINFOID:0000000012430699

AFTER A COLLISION

WARNING:

Inspect all seat belt assemblies in cluding retractors and attaching hardware after any collision.

NISSAN/INFINITI recommends that all seat belt assemblies in use during a collision be replaced

unless the collision was minor and th e belts show no damage and continue to operate properly. Fail-

ure to do so could result in serious personal inju ry in an accident. Seat belt assemblies not in use dur-

ing a collision should also be replaced if either damage or improper operation is noted. Seat belt pre-

tensioners should be replaced even if the seat belts are not in use during a frontal collision in which

the air bags are deployed.

Replace any seat belt assembly (including anchor bolts) if:

• The seat belt was in use at the time of a collision (except for minor collisions and the belts, retractors and buckles show no damage and continue to operate properly).

• The seat belt was damaged in an accident (i.e. torn webbing, bent retractor or guide, etc.).

• The seat belt attaching point is damaged in an accident. Inspect the seat belt attaching area for damage or

distortion and repair if necessary before installing a new seat belt assembly.

• Anchor bolts are deformed or worn out.

• The seat belt pre-tensioner should be replaced even if t he seat belts are not in use during the collision in

which the air bags are deployed.

PRELIMINARY CHECKS

1. Check the seat belt warning lamp for proper operation per the following:

a. Turn ignition switch ON. The seat belt warning lamp should illuminate.

b. Fasten driver seat belt. The seat belt warning lamp should turn OFF.

2. If the air bag warning lamp is blinking, perform self-diagnosis with CONSULT and air bag warning lamp. Refer to SRC-14, "

Description".

3. Check that the seat belt retractor, seat belt anchor and buckle bolts are tightened firmly.

4. Check the shoulder seat belt guide and shoulder belt height adjuster for front seats. Check that guide

swivels freely and that webbing lays flat and does not bind in guide. Check that height adjuster operates

properly and holds securely.

5. Check retractor operation:

a. Fully extend the seat belt webbing and check for twists, tears or other damage.

b. Allow the seat belt to retract. Check that webbing retu rns smoothly and completely into the retractor. If the

seat belt does not return smoothly, wipe the inside of the loops with a clean paper cloth. Dirt build-up in the

loops of the upper anchors can cause the seat belts to retract slowly.

c. Fasten the seat belt. Check that seat belt returns smoothly and completely to the retractor. If the webbing does not return smoothly, the cause may be an accu mulation of dust or dirt. Use the “SEAT BELT TAPE

SET” and perform the following steps.

d. Inspect the front seat belt D-ring anchor 1. Pull the seat belt out to a length of 500 mm (19.69 in) or more.

2. Hold the seat belt at the center pillar webbing opening with a clip or other device.

3. Pass a thin wire through the D-ring anchor webbing opening. Hold both ends of the wire and pull it tightly while moving it up and down several times along the webbing opening surface to remove dirt

stuck there.

4. Any dirt that cannot be removed with the wire can be removed by cleaning the opening with a clean

cloth.

5. Apply tape at the point where the webbing contacts the D-ring anchor webbing opening. NOTE:

Apply the tape so that there is no slack or wrinkling.

6. Remove the clip holding the seat belt and check that the webbing returns smoothly.

6. Repeat steps above if necessary to check the other seat belts.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2805 of 3641

SB-8

< REMOVAL AND INSTALLATION >

FRONT SEAT BELT

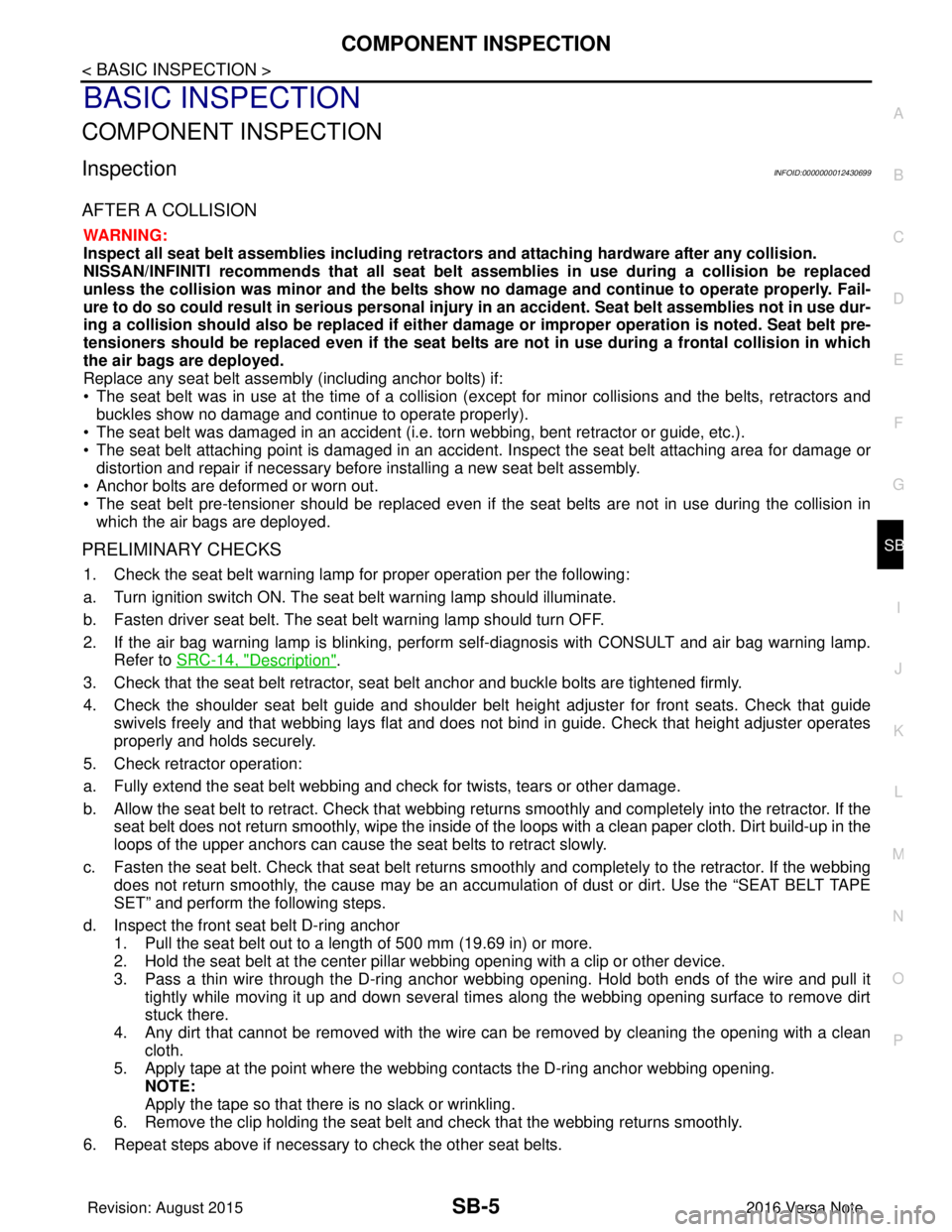

REMOVAL AND INSTALLATION

FRONT SEAT BELT

Exploded ViewINFOID:0000000012430700

FRONT SEAT BELT BUCKLE

FRONT SEAT BELT BUCKLE : Removal and InstallationINFOID:0000000012430701

REMOVAL

1. Remove front seat. Refer to SE-20, "DRIVER SIDE : Removal and Installation" (Driver Side) or SE-22,

"PASSENGER SIDE : Removal and Installation" (Passenger Side).

2. Unclip seat belt buckle harness from the seat frame.

1. Seat belt height adjuster (LH/RH) 2. Seat belt height adjuster finisher (LH/RH) 3. Seat belt retractor (RH)

4. Seat belt buckle (RH) 5. Seat belt buckle (LH) 6. Seat belt retractor (LH)

AWHIA0550ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2807 of 3641

SB-10

< REMOVAL AND INSTALLATION >

FRONT SEAT BELT

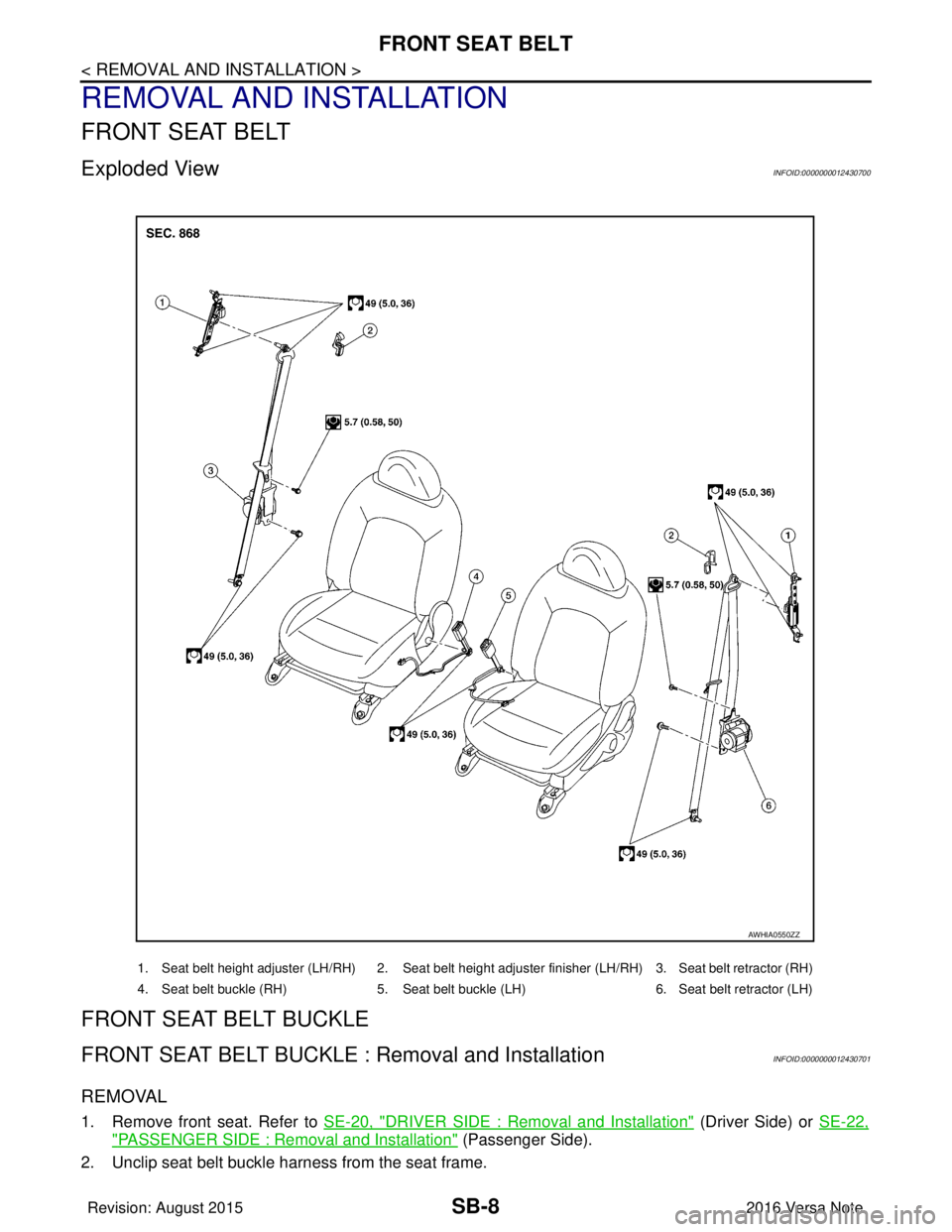

6. Release pawls, using a suitable tool and remove the seat beltheight adjuster finisher (1).

: Pawl

7. Remove D-ring anchor bolt. CAUTION:

Before removing the D-ring anchor bolt, note the positions of washers and spacers for correct

installation.

8. Remove bolts (A) and the seat belt retractor (1).

INSTALLATION

Installation is in the reverse order of removal.

• Make sure the seat belt height adjuster is lo cked in the lowest position during installation.

• Install the seat belt retractor upper bolt first.

• Tighten the D-ring anchor bolt, seat belt lower anchor bolt, and the seat belt retractor bolts to specification. Refer to SB-8, "

Exploded View".

• Make sure both the D-ring anchors and seat belt height adjuster operate freely.

• Always perform an inspection after repair to make sure the system is functioning within specifications. Refer to SB-5, "

Inspection".

SEAT BELT HEIGHT ADJUSTER

SEAT BELT HEIGHT ADJUSTER : Removal and InstallationINFOID:0000000012430703

REMOVAL

1. Slide front seat to the full forward position.

2. Release pawls, using a suitable tool and remove the seat belt

height adjuster finisher (1).

: Pawl

3. Remove D-ring anchor bolt. CAUTION:

AWHIA0539ZZ

ALHIA0317ZZ

AWHIA0539ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2808 of 3641

FRONT SEAT BELTSB-11

< REMOVAL AND INSTALLATION >

C

DE

F

G

I

J

K L

M A

B

SB

N

O P

Before removing the D-ring anch or bolt, note the positions of washers and spacers for correct

installation.

4. Remove center pillar upper finisher. Refer to INT-25, "

CENTER PILLAR UPPER FINISHER : Removal

and Installation".

5. Remove seat belt height adjuster bolts and the seat belt height adjuster. CAUTION:

Before removing the seat belt height adjuster bo lts, note the positions of washers and spacers for

correct installation.

INSTALLATION

Installation is in the reverse order of removal.

• Make sure that the seat belt height adjuster is locked in the lowest position during installation.

• Make sure both the D-ring anchor and seat belt height adjuster operate freely.

• Tighten the D-ring anchor bolt and seat belt height adjuster bolts to specification. Refer to SB-8, "

Exploded

View".

• Always perform an inspection after repair to make sure the system is functioning within specifications. Refer

to SB-5, "

Inspection".

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3490 of 3641

![NISSAN NOTE 2016 Service Manual PDF DIFFERENTIAL SIDE OIL SEALTM-249

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

DIFFERENTIAL SIDE OIL SEAL

Exploded ViewINFOID:0000000012431204

Removal and InstallationINF NISSAN NOTE 2016 Service Manual PDF DIFFERENTIAL SIDE OIL SEALTM-249

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

DIFFERENTIAL SIDE OIL SEAL

Exploded ViewINFOID:0000000012431204

Removal and InstallationINF](/img/5/57363/w960_57363-3489.png)

DIFFERENTIAL SIDE OIL SEALTM-249

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

DIFFERENTIAL SIDE OIL SEAL

Exploded ViewINFOID:0000000012431204

Removal and InstallationINFOID:0000000012431205

NOTE:

When removing components such as hoses, tubes/lines, etc. , cap or plug openings to prevent fluid from spill-

ing.

REMOVAL

1. Remove the front drive shaft from the transaxle assembly. Refer to FAX-19, "Removal and Installation"

2. Remove the differential side oil seal using suitable tool.

CAUTION:

When removing the differential side oil seal, be careful not to scratch the oil seal mating surfaces

of the transaxle case and converter housing.

INSTALLATION

CAUTION:

When inserting the drive shaf t, be sure to use Tool.

1. Measure height (A) of seal lip. Calculate protrusion (C) of seal

lip according to measured height (A) of seal lip and reference

value (B) of side oil seal insertion.

CAUTION:

• Do not reuse differential side oil seal.

• Put a mark on the measurement area and measure height of seal lip at four points diagonally

using suitable tool.

NOTICE:

1. Transaxle assembly 2. Differential side oil seal (left side) 3. Differential side oil seal (right side)

Front Genuine NISSAN CVT Fluid NS-3

JSDIA1888ZZ

Tool number : KV38107900 ( — )

(1) : Differential side oil seal

(2) : Converter housing or transaxle case

Lip protrusion (C): C=A–B

Differential side oil seal insertion

reference value (B) : 1.8 mm (0.071 in)

JSDIA4816ZZ

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 3491 of 3641

![NISSAN NOTE 2016 Service Manual PDF TM-250

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

DIFFERENTIAL SIDE OIL SEAL

Since seal lips have a tolerance of

± 0.3 mm ( ± 0.012 in) at maximum due to manufacturing tolerances or

packing conditi NISSAN NOTE 2016 Service Manual PDF TM-250

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

DIFFERENTIAL SIDE OIL SEAL

Since seal lips have a tolerance of

± 0.3 mm ( ± 0.012 in) at maximum due to manufacturing tolerances or

packing conditi](/img/5/57363/w960_57363-3490.png)

TM-250

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

DIFFERENTIAL SIDE OIL SEAL

Since seal lips have a tolerance of

± 0.3 mm ( ± 0.012 in) at maximum due to manufacturing tolerances or

packing conditions, it is necessary to measure t he seal lip height beforehand to clarify the tolerance.

2. As an indicator of the parallelism and insertion depth, cut a masking tape (1) to specified width [add 1 mm (0.04 in) to the

value calculated from the tip of differential side oil seal lip] and

affix to the differential side oil seal.

3. Install the differential side oil seal using a suitable tool according to the guide of the masking tape (1).

CAUTION:

• If differential side oil seal is inserted deeper than the ref-erence value, use a new differe ntial side oil seal and per-

form the steps again.

• Apply ATF to the differential side oil seal lip and around

the oil seal.

NOTE:

A hub cap (Part No. 43234 1HA0A) can be used as substitute for drift. To use a hub cap, be sure to pre-

pare a new one specifically for patting seal.

4. Remove masking tape.

5. Adjust as instructed below to optimize the protrusion size and parallelism. CAUTION:

If differential side oil seal is inserted deeper th an the reference value, use a new differential side

oil seal and perform the steps again.

• Protrusion size (A) CAUTION:

Protrusion must fall within ± 0.5mm (0.020 in) of calculated

size.

• Parallelism at four diagonal points ( ) CAUTION:

The difference among four diagona l points must be within 0.3

mm (0.012 in).

NOTE:

If differential side oil seal is uneven while installing, tilt suitable tool.

6. Check that the protrusion size and parallelism are adequate.

Inspection and AdjustmentINFOID:0000000012431206

INSPECTION AFTER INSTALLATION

Check for CVT fluid leakage. Refer to TM-228, "Inspection".

ADJUSTMENT AFTER INSTALLATION

Adjust the CVT fluid level. Refer to TM-229, "Adjustment".

JSDIA4817ZZ

JSDIA4815ZZ

JSDIA4814ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com