height NISSAN NOTE 2016 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1527 of 3641

![NISSAN NOTE 2016 Service Service Manual EC-400

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P2096, P2097 A/F SENSOR 1

4. Check the continuity between ECM harness connec

tor or A/F sensor 1 harness connector and ground.

5. Also check harness for short NISSAN NOTE 2016 Service Service Manual EC-400

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P2096, P2097 A/F SENSOR 1

4. Check the continuity between ECM harness connec

tor or A/F sensor 1 harness connector and ground.

5. Also check harness for short](/img/5/57363/w960_57363-1526.png)

EC-400

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P2096, P2097 A/F SENSOR 1

4. Check the continuity between ECM harness connec

tor or A/F sensor 1 harness connector and ground.

5. Also check harness for short to power.

Is the inspection result normal?

YES >> GO TO 10.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

10.CHECK A/F SENSOR 1 HEATER

Refer to EC-175, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 11.

NO >> GO TO 13.

11 .CHECK HEATED OXYGEN SENSOR 2

Refer to EC-226, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 12.

NO >> Replace heated oxygen sensor 2. Refer to EX-5, "

Exploded View".

12.CHECK INTERMITTENT INCIDENT

Perform GI-42, "

Intermittent Incident".

Is the inspection result normal?

YES >> GO TO 13.

NO >> Repair or replace.

13.REPLACE AIR FUEL RATIO (A/F) SENSOR 1

Replace air fuel ratio (A/F) sensor 1. Refer to EM-31, "

Removal and Installation".

CAUTION:

• Discard any sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a hard

surface such as a concrete floor; use a new one.

• Before installing new sensor, cl ean exhaust system threads using oxygen sensor thread cleaner tool

[commercial service tool: (J-43897-18) or (J-43897-12)] and approved anti-seize lubricant (commer-

cial service tool).

Do you have CONSULT?

YES >> GO TO 14.

NO >> GO TO 15.

14.CONFIRM A/F ADJUSTMENT DATA

With CONSULT

1. Turn ignition switch ON.

2. Select “A/F ADJ-B1” in “D ATA MONITOR” mode with CONSULT.

3. Make sure that “0.000” is displayed on CONSULT screen.

Is

“0.000” displayed?

YES >> INSPECTION END

NO >> GO TO 15.

A/F sensor 1 ECM

Continuity

Connector Terminal Connector Terminal

F12 1

F11 49

Existed

25 3

A/F sensor 1 ECM

Ground Continuity

Connector Terminal Connector Terminal

F12 1

F11 49

Ground Not existed

25 3

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1651 of 3641

EX-6

< REMOVAL AND INSTALLATION >

EXHAUST SYSTEM

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse gasket.

• Do not reuse seal bearing.

• Discard any heated oxygen sensor 2 which has been dropped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a concrete floor. Use a new one.

• Before installing a new heated o xygen sensor 2, clean exhaust system threads using a suitable tool

and apply anti-seize lubricant.

• Do not over tighten heated oxygen sensor 2. Doin g so may cause damage to the heated oxygen sen-

sor 2, resulting in the “MIL” coming on.

• Prevent rust preventives from adhering to the sensor body.

• If heat insulator is badly deformed, repair or re place it. If deposits such as mud pile up on the heat

insulator, remove them.

• When installing heat insulator avoid large gaps or interference between heat insulator and each

exhaust pipe.

• Remove deposits from the sealing surface of each connection. Connect them securely to avoid

exhaust gas leaks.

• When installing each mounting rubber, use silicon oil to avoid twisting.

• Temporarily tighten nuts and bolts. Check each part for unusual interference and mounting rubber interference, and then tighten them to the specified torque.

• When installing each mounting rubber, avoid twisting or unus ual extension in up/down, front/rear

and right/left directions.

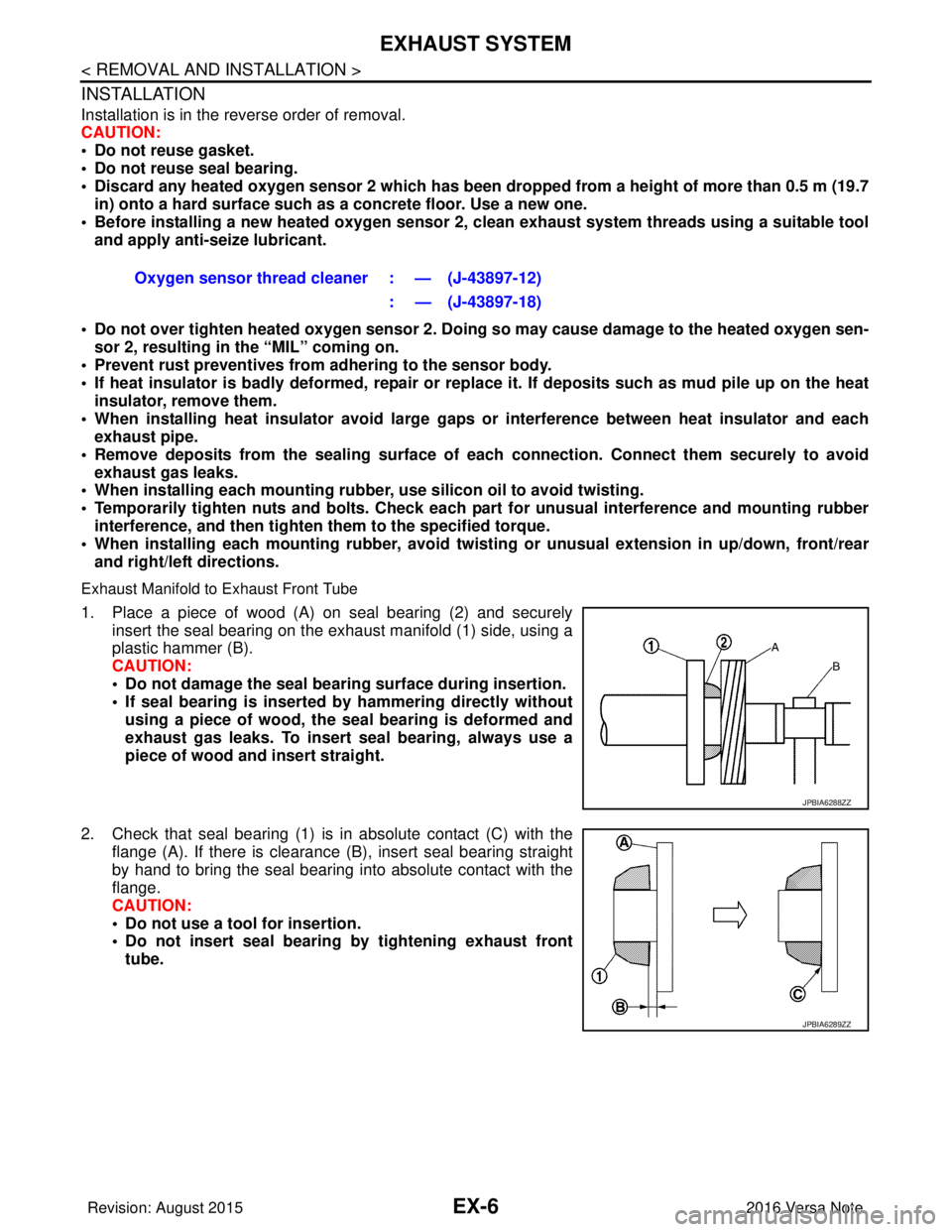

Exhaust Manifold to Exhaust Front Tube

1. Place a piece of wood (A) on seal bearing (2) and securely insert the seal bearing on the exhaust manifold (1) side, using a

plastic hammer (B).

CAUTION:

• Do not damage the seal bearing surface during insertion.

• If seal bearing is inserted by hammering directly without

using a piece of wood, the seal bearing is deformed and

exhaust gas leaks. To insert seal bearing, always use a

piece of wood and insert straight.

2. Check that seal bearing (1) is in absolute contact (C) with the flange (A). If there is clearance (B), insert seal bearing straight

by hand to bring the seal bearing into absolute contact with the

flange.

CAUTION:

• Do not use a tool for insertion.

• Do not insert seal bearing by tightening exhaust front

tube. Oxygen sensor thread cleaner : — (J-43897-12)

: — (J-43897-18)

JPBIA6288ZZ

JPBIA6289ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1751 of 3641

HEADLAMP AIMING ADJUSTMENTEXL-99

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

7. Measure the projected beam within t he aim evaluation segment on the screen.

8. Adjust the beam pattern of each headlamp until the ai m evaluation segment (the area relative to both the

highest and lowest cutoff line height) is positioned within the vertical aim range dimensions shown on the

aiming chart.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1753 of 3641

FRONT FOG LAMP AIMING ADJUSTMENTEXL-101

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

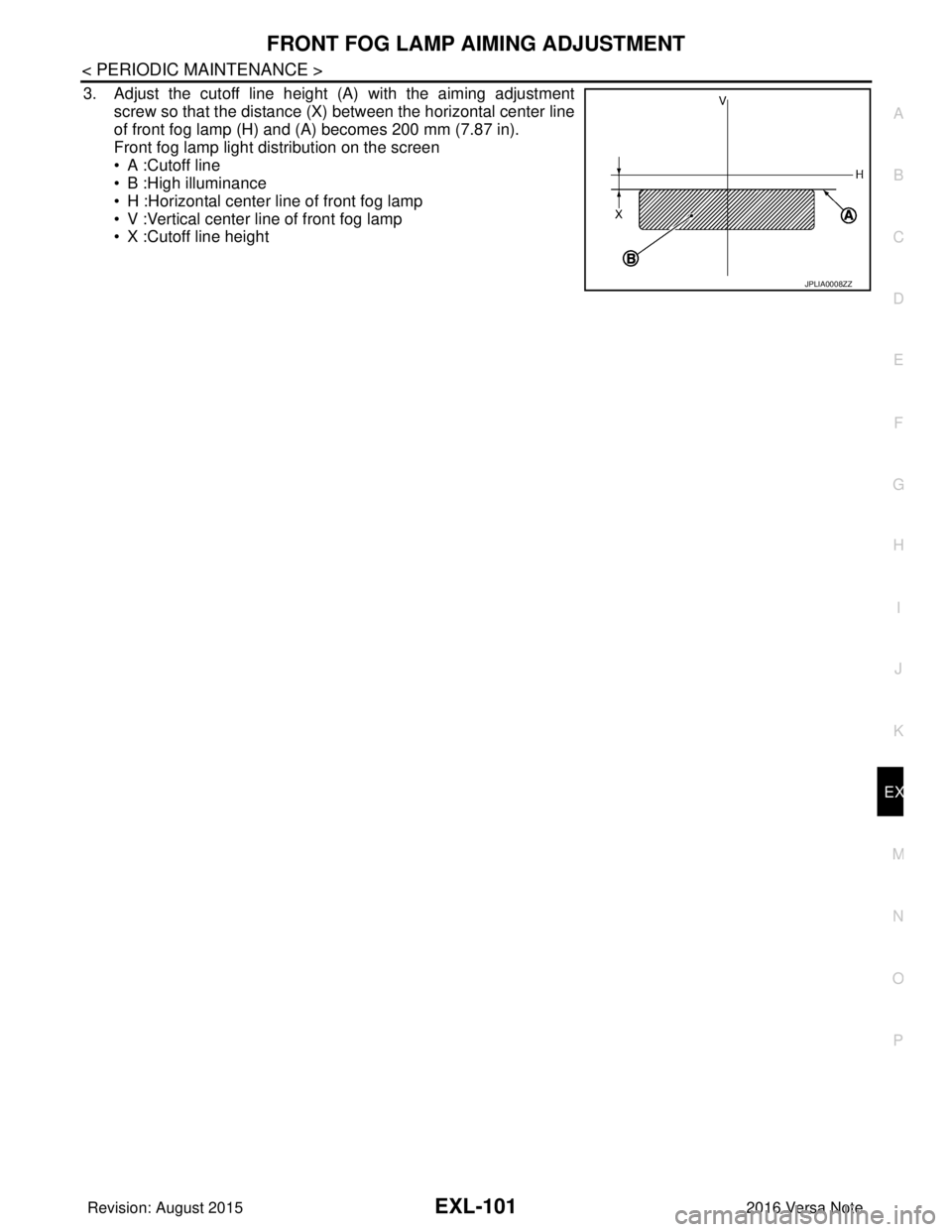

3. Adjust the cutoff line height (A) with the aiming adjustment screw so that the distance (X) between the horizontal center line

of front fog lamp (H) and (A) becomes 200 mm (7.87 in).

Front fog lamp light distribution on the screen

• A :Cutoff line

• B :High illuminance

• H :Horizontal center line of front fog lamp

• V :Vertical center line of front fog lamp

• X :Cutoff line height

JPLIA0008ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1793 of 3641

EXT-26

< REMOVAL AND INSTALLATION >

FRONT BUMPER

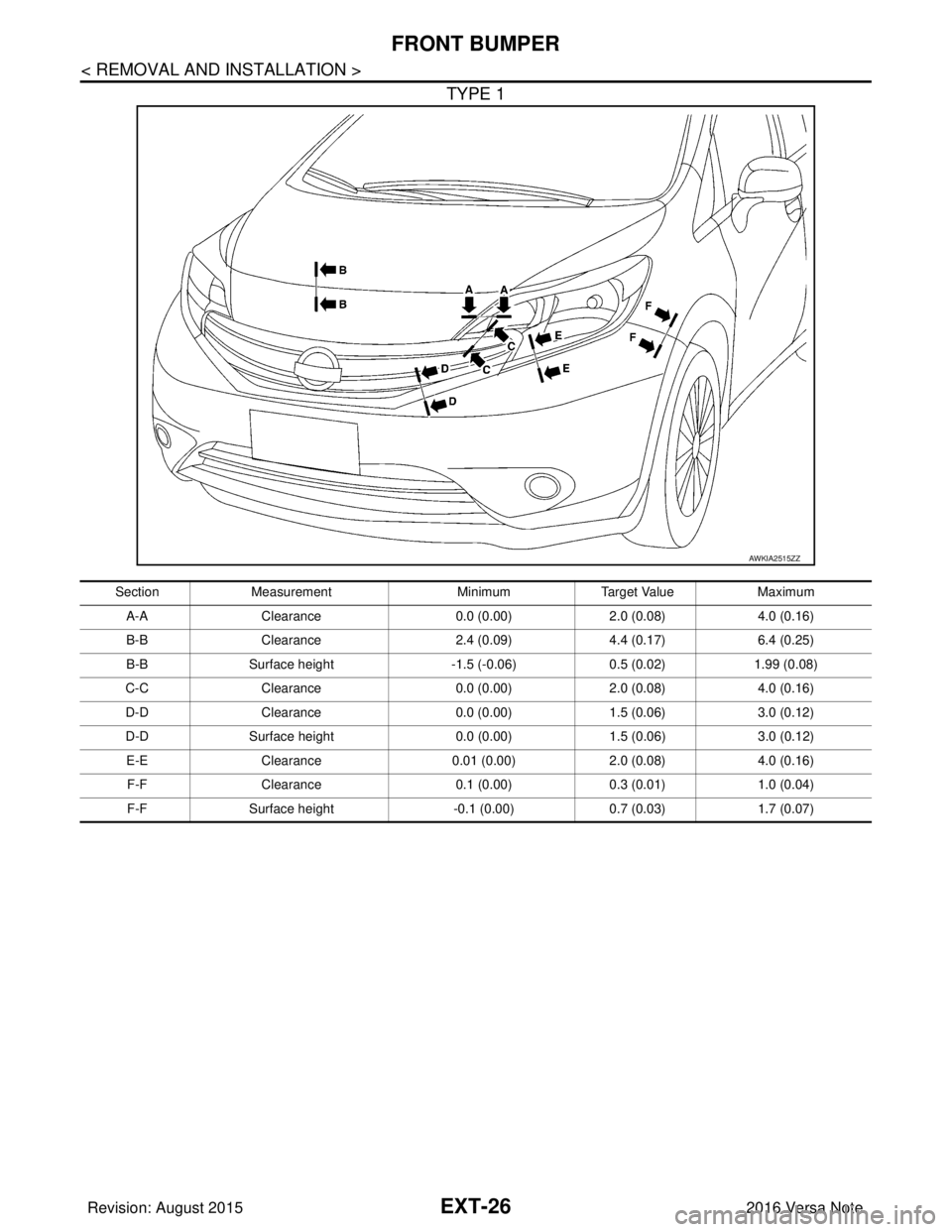

TYPE 1

AWKIA2515ZZ

SectionMeasurement MinimumTarget Value Maximum

A-A Clearance 0.0 (0.00)2.0 (0.08)4.0 (0.16)

B-B Clearance 2.4 (0.09)4.4 (0.17)6.4 (0.25)

B-B Surface height -1.5 (-0.06)0.5 (0.02)1.99 (0.08)

C-C Clearance 0.0 (0.00)2.0 (0.08)4.0 (0.16)

D-D Clearance 0.0 (0.00)1.5 (0.06)3.0 (0.12)

D-D Surface height 0.0 (0.00)1.5 (0.06)3.0 (0.12)

E-E Clearance 0.01 (0.00)2.0 (0.08)4.0 (0.16)

F-F Clearance 0.1 (0.00)0.3 (0.01)1.0 (0.04)

F-F Surface height -0.1 (0.00)0.7 (0.03)1.7 (0.07)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1794 of 3641

FRONT BUMPEREXT-27

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

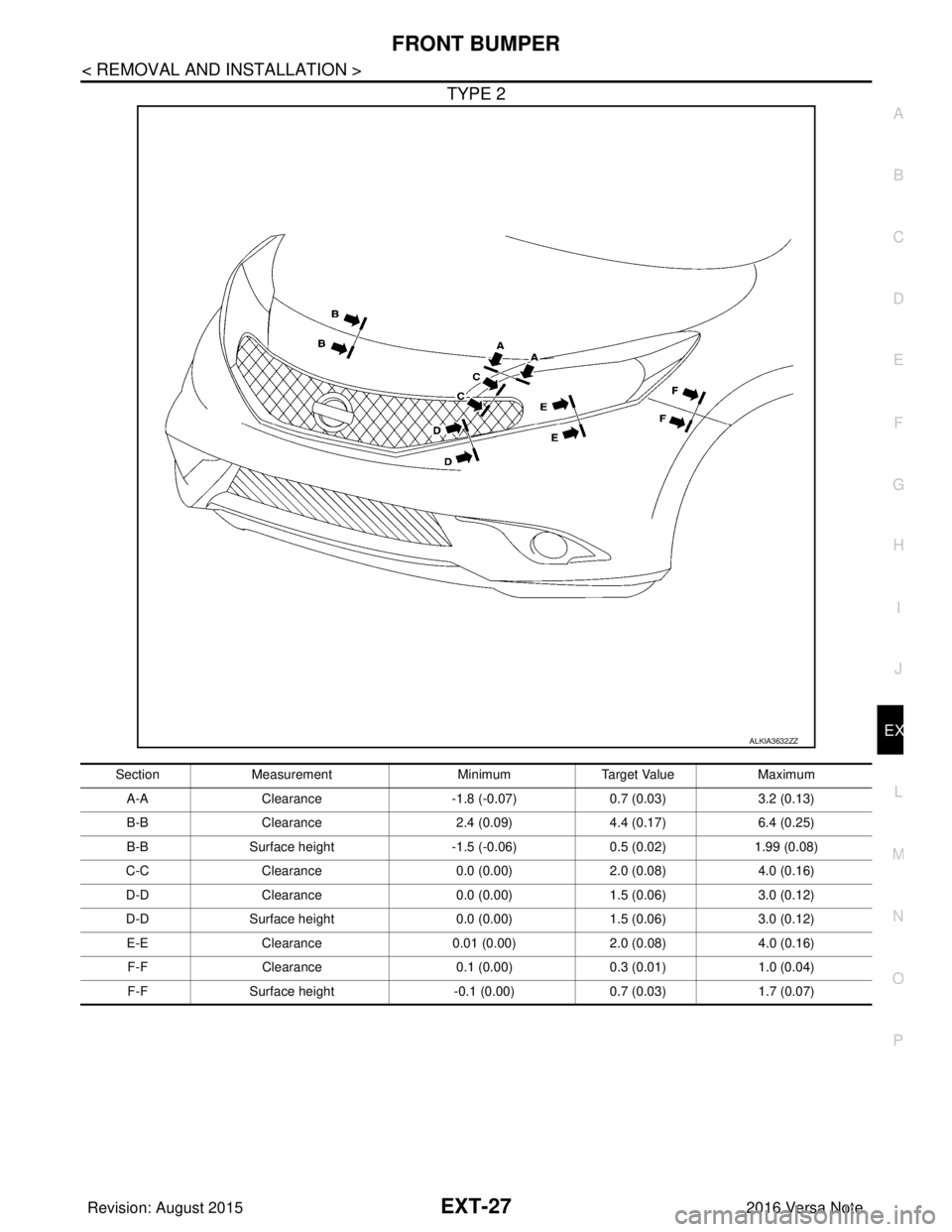

TYPE 2

ALKIA3632ZZ

Section Measurement MinimumTarget Value Maximum

A-A Clearance -1.8 (-0.07)0.7 (0.03)3.2 (0.13)

B-B Clearance 2.4 (0.09)4.4 (0.17)6.4 (0.25)

B-B Surface height -1.5 (-0.06)0.5 (0.02)1.99 (0.08)

C-C Clearance 0.0 (0.00)2.0 (0.08)4.0 (0.16)

D-D Clearance 0.0 (0.00)1.5 (0.06)3.0 (0.12)

D-D Surface height 0.0 (0.00)1.5 (0.06)3.0 (0.12)

E-E Clearance 0.01 (0.00)2.0 (0.08)4.0 (0.16)

F-F Clearance 0.1 (0.00)0.3 (0.01)1.0 (0.04)

F-F Surface height -0.1 (0.00)0.7 (0.03)1.7 (0.07)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1798 of 3641

REAR BUMPEREXT-31

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

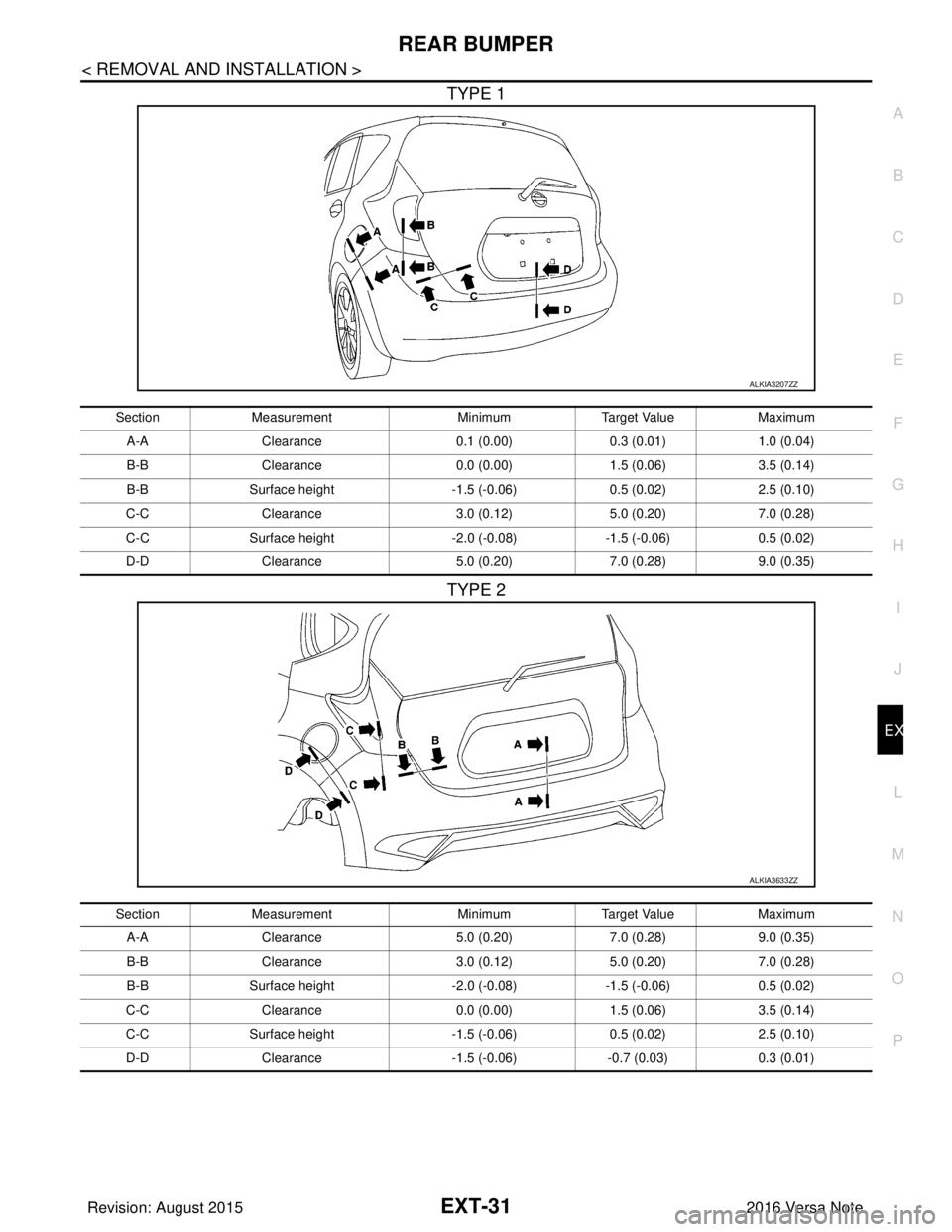

TYPE 1

TYPE 2

ALKIA3207ZZ

Section Measurement MinimumTarget Value Maximum

A-A Clearance 0.1 (0.00)0.3 (0.01)1.0 (0.04)

B-B Clearance 0.0 (0.00)1.5 (0.06)3.5 (0.14)

B-B Surface height -1.5 (-0.06)0.5 (0.02)2.5 (0.10)

C-C Clearance 3.0 (0.12)5.0 (0.20)7.0 (0.28)

C-C Surface height -2.0 (-0.08) -1.5 (-0.06) 0.5 (0.02)

D-D Clearance 5.0 (0.20)7.0 (0.28)9.0 (0.35)

ALKIA3633ZZ

SectionMeasurement MinimumTarget Value Maximum

A-A Clearance 5.0 (0.20)7.0 (0.28)9.0 (0.35)

B-B Clearance 3.0 (0.12)5.0 (0.20)7.0 (0.28)

B-B Surface height -2.0 (-0.08) -1.5 (-0.06) 0.5 (0.02)

C-C Clearance 0.0 (0.00)1.5 (0.06)3.5 (0.14)

C-C Surface height -1.5 (-0.06)0.5 (0.02)2.5 (0.10)

D-D Clearance -1.5 (-0.06)-0.7 (0.03) 0.3 (0.01)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1846 of 3641

FSU-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION FSU

A

B

FSU

N

O PCONTENTS

FRONT SUSPENSION

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution for Procedure without Cowl Top Cover ......2

Precaution for Suspension ........................................2

PREPARATION ............................................3

PREPARATION .............................................. .....3

Special Service Tools .......................................... ......3

Commercial Service Tools ........................................3

SYMPTOM DIAGNOSIS ...............................5

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

5

NVH Troubleshooting Chart ................................ ......5

PERIODIC MAINTENANCE ..........................6

FRONT SUSPENSION ASSEMBLY .............. .....6

Inspection ............................................................ ......6

WHEEL ALIGNMENT ..........................................7

Inspection ............................................................ ......7

Adjustment ................................................................8

REMOVAL AND INSTALLATION ................9

FRONT COIL SPRING AND STRUT ............. .....9

Exploded View .................................................... ......9

Removal and Installation ...........................................9

TRANSVERSE LINK .........................................10

Exploded View ..................................................... ....10

Removal and Installation .........................................10

Inspection ................................................................10

FRONT STABILIZER ........................................12

Exploded View .........................................................12

Removal and Installation .........................................12

Inspection ................................................................13

UNIT REMOVAL AND INSTALLATION ......14

FRONT SUSPENSION MEMBER .....................14

Exploded View ..................................................... ....14

Removal and Installation .........................................14

Inspection ................................................................15

UNIT DISASSEMBLY AND ASSEMBLY ....16

FRONT COIL SPRING AND STRUT ................16

Exploded View ..................................................... ....16

Disassembly and Assembly .....................................16

Inspection ................................................................19

Disposal ...................................................................19

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

20

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

20

Wheel Alignment (Unladen*1) ..................................20

Ball Joint .............................................................. ....20

Wheelarch Height (Unladen*) ..................................21

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1852 of 3641

WHEEL ALIGNMENTFSU-7

< PERIODIC MAINTENANCE >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

WHEEL ALIGNMENT

InspectionINFOID:0000000012430301

PRELIMINARY INSPECTION

WARNING:

Always adjust the wheel alignment with the vehicle on a flat surface.

NOTE:

If the wheel alignment is out of s pecification, inspect and replace any damaged or worn rear suspension parts

before making any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, engine coolant, and lubricants are full; the spare tire, jack, hand tools and mats are in

designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for run out and damage. Refer to WT-54, "

Wheel".

4. Check the wheel bearing axial end play. Refer to FAX-27, "

Wheel Bearing".

5. Check the shock absorbers for leaks or damage.

6. Check each mount point of the suspension co mponents for any excessive looseness or damage.

7. Check each link, arm, and the suspension member for any damage.

8. Check the vehicle height. Refer to FSU-21, "

Wheelarch Height (Unladen*)".

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed.

• This type of alignment is recomm ended for any NISSAN/INFINITI vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be capabl e of accepting any NISSAN/INFINITI vehicle.

• The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated. • Your alignment machine should be regularly calibrated in order to give correct information.

• Check with the manufacturer of your specific a lignment machine for their recommended Service/Cali-

bration Schedule.

ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to FSU-20, "Wheel

Alignment (Unladen*1)".

• When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators.

- The alignment specifications programmed into your alignment machine that operate these indicators may

not be correct.

- This may result in an ERROR.

• Most camera-type alignment machines are equipped with "Rolling Compensation" method and optional

"Jacking Compensation" method to "compensate" the alignment targets or head units.

"Rolling Compensation" is the preferred method.

- If using the "Rolling Compensation" method, after inst alling the alignment targets or head units, push or pull

on the rear wheel to move the vehicle. Do not push or pull on the vehicle body.

- If using the "Jacking Compensation" method, after inst alling the alignment targets or head units, raise the

vehicle and rotate the wheels 1/2 turn in either direction.

NOTE:

Do not use the "Rolling Compensation" method if you are using sensor-type alignment equipment.

• Follow all instructions for the alignment machine you're using for more information.

CAMBER, CASTER AND KINGPIN INCLINATION ANGLES INSPECTION

• Camber, caster, kingpin inclination angles cannot be adjusted.

• Before inspection, set the front wheels onto a turning radius gauge. Set the rear wheels onto a pad that has

the same height so the vehicle will remain horizontal.

TOTAL TOE-IN INSPECTION

Measure the total toe-in using the following procedure.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1853 of 3641

FSU-8

< PERIODIC MAINTENANCE >

WHEEL ALIGNMENT

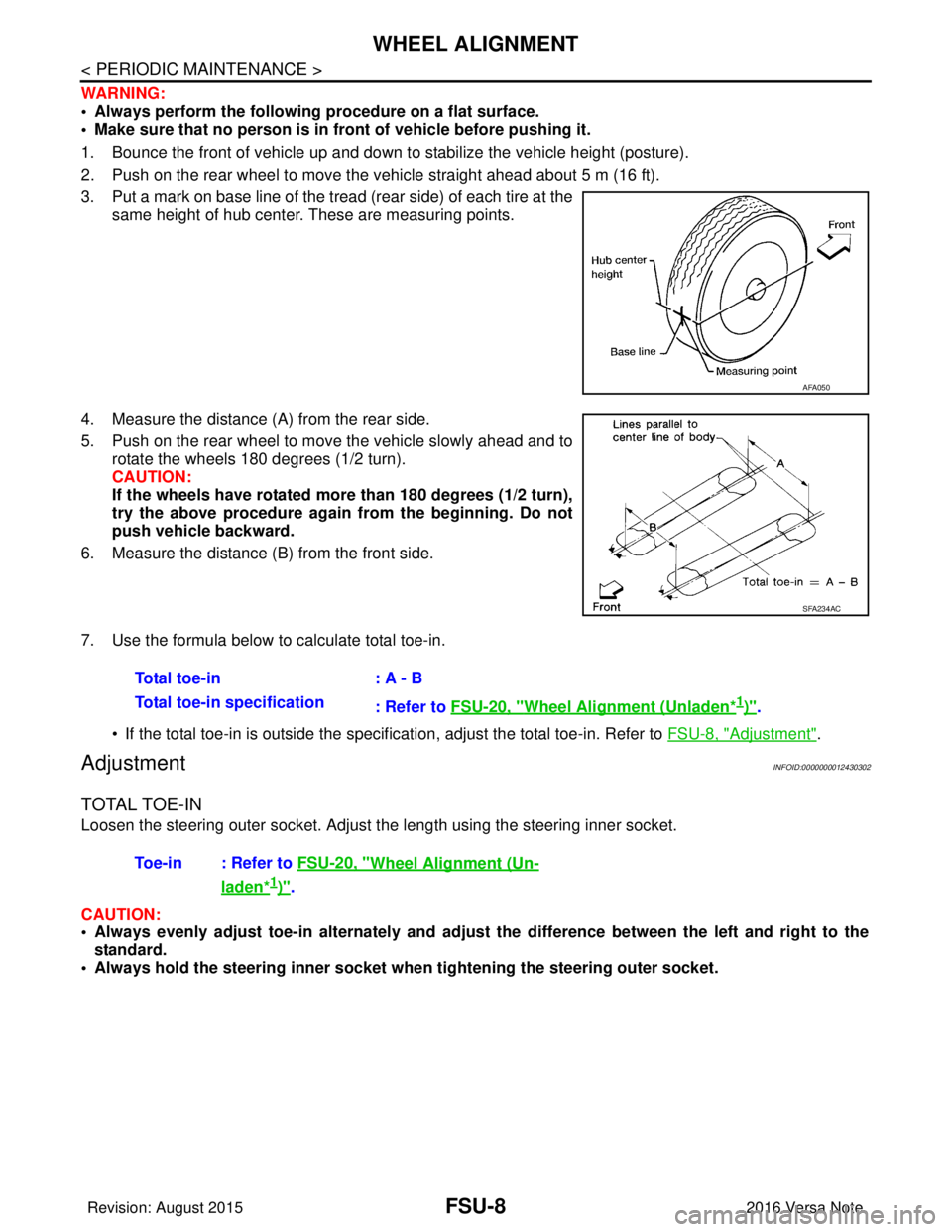

WARNING:

• Always perform the following procedure on a flat surface.

• Make sure that no person is in fr ont of vehicle before pushing it.

1. Bounce the front of vehicle up and down to stabilize the vehicle height (posture).

2. Push on the rear wheel to move the vehicle straight ahead about 5 m (16 ft).

3. Put a mark on base line of the tread (rear side) of each tire at the same height of hub center. These are measuring points.

4. Measure the distance (A) from the rear side.

5. Push on the rear wheel to move the vehicle slowly ahead and to rotate the wheels 180 degrees (1/2 turn).

CAUTION:

If the wheels have rotated more than 180 degrees (1/2 turn),

try the above procedure again from the beginning. Do not

push vehicle backward.

6. Measure the distance (B) from the front side.

7. Use the formula below to calculate total toe-in.

• If the total toe-in is outside the specification, adjust the total toe-in. Refer to FSU-8, "

Adjustment".

AdjustmentINFOID:0000000012430302

TOTAL TOE-IN

Loosen the steering outer socket. Adjust the length using the steering inner socket.

CAUTION:

• Always evenly adjust toe-in alternately and adjust the difference be tween the left and right to the

standard.

• Always hold the steering inner socket wh en tightening the steering outer socket.

AFA050

SFA234AC

Total toe-in: A - B

Total toe-in specification : Refer to FSU-20, "

Wheel Alignment (Unladen*1)".

Toe-in : Refer to FSU-20, "

Wheel Alignment (Un-

laden*1)".

Revision: August 2015 2016 Versa Note

cardiagn.com