battery NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 3003 of 3641

![NISSAN NOTE 2016 Service Repair Manual SEC-146

< DTC/CIRCUIT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

B2190, P1614 NATS ANTENNA AMP.

Is the inspection result normal?

YES >> NATS antenna amp. is malfunctioning. Replace NATS antenna amp. NISSAN NOTE 2016 Service Repair Manual SEC-146

< DTC/CIRCUIT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

B2190, P1614 NATS ANTENNA AMP.

Is the inspection result normal?

YES >> NATS antenna amp. is malfunctioning. Replace NATS antenna amp.](/img/5/57363/w960_57363-3002.png)

SEC-146

< DTC/CIRCUIT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

B2190, P1614 NATS ANTENNA AMP.

Is the inspection result normal?

YES >> NATS antenna amp. is malfunctioning. Replace NATS antenna amp. Refer to

SEC-159, "Removal

and Installation".

NO >> • Repair or replace harness.

NOTE:

If harness is OK, replace BCM, refer to BCS-137, "

Removal and Installation". Perform initializa-

tion with CONSULT. For initialization, refer to CONSULT Immobilizer mode and follow the on-

screen instructions.

Te r m i n a l s Position of ignition key cylinder Voltage (V)

(Approx.)

( + ) ( - )

4G ro un d Before inserting ignition key

Battery voltage

After inserting ignition key Pointer of tester should move for approx. 30 seconds,

then return to battery voltage

Just after turning ignition switch ON Pointer of tester should move for approx. 1 second, then

return to battery voltage

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3011 of 3641

![NISSAN NOTE 2016 Service Repair Manual SEC-154

< DTC/CIRCUIT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:0000000012542538

Regarding Wiring NISSAN NOTE 2016 Service Repair Manual SEC-154

< DTC/CIRCUIT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:0000000012542538

Regarding Wiring](/img/5/57363/w960_57363-3010.png)

SEC-154

< DTC/CIRCUIT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:0000000012542538

Regarding Wiring Diagram information, refer to

BCS-117, "Wiring Diagram".

1.CHECK FUSES AND FUSIBLE LINK

Check that the following fuses and fusible link are not blown.

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2.

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connectors.

3. Check voltage between BCM connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

Check continuity between BCM connector and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair harness or connector.

Terminal No. Signal nameFuses and fusible link No.

37 Battery power supply 8 (10A)

42 12 (10A)

50 G (40A)

11 Ignition switch ACC or ON 18 (10A)

38 Ignition switch ON or START 2 (10A)

BCMGround Ignition switch position

Connector Terminal

—OFF

ACC ON

M18 11

0 V

Battery voltage

Battery voltage

37

Battery voltage

38 0 V0 V

M19 42

Battery voltage Battery voltage

50

BCM GroundContinuity

Connector Terminal

M19 55—Yes

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3012 of 3641

![NISSAN NOTE 2016 Service Repair Manual VEHICLE SECURITY INDICATORSEC-155

< DTC/CIRCUIT DIAGNOSIS > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

VEHICLE SECURITY INDICATOR

DescriptionINFOID:0000000012430486

• Vehicle NISSAN NOTE 2016 Service Repair Manual VEHICLE SECURITY INDICATORSEC-155

< DTC/CIRCUIT DIAGNOSIS > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

VEHICLE SECURITY INDICATOR

DescriptionINFOID:0000000012430486

• Vehicle](/img/5/57363/w960_57363-3011.png)

VEHICLE SECURITY INDICATORSEC-155

< DTC/CIRCUIT DIAGNOSIS > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

VEHICLE SECURITY INDICATOR

DescriptionINFOID:0000000012430486

• Vehicle security indicator is built in combination meter.

• NATS (Nissan Anti-Theft System) condition is indicated by blink or illumination of vehicle security indicator.

Component Function CheckINFOID:0000000012430487

1.CHECK FUNCTION

1. Perform “Active Test” of “THEFT I ND” in the “IMMU” using CONSULT.

2. Check vehicle security indicator operation.

Is the inspection result normal?

YES >> Inspection End.

NO >> Refer to SEC-155, "

Diagnosis Procedure (Type B)" or SEC-156, "Diagnosis Procedure (Type A)".

Diagnosis Procedu re (Type B)INFOID:0000000012430488

Regarding Wiring Diagram information, refer to SEC-132, "Wiring Diagram".

1.SECURITY INDICATOR LAMP ACTIVE TEST

With CONSULT

Check “THEFT IND”” in “Active Test” of “IMMU”.

Without CONSULT

1. Disconnect BCM.

2. Check voltage between BCM harness connector M18 terminal 23 and ground.

Is the inspection result normal?

YES >> Security indicator lamp is OK.

NO >> GO TO 2.

2.SECURITY INDICATOR LAMP CHECK

Check security indicator lamp condition.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Replace combination meter. Refer to MWI-115, "

Removal and Installation".

3.CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect BCM and security indicator lamp connector.

3. Check continuity between BCM connector M18 terminal 23 and combination meter connector M24 termi- nal 18.

Te s t i t e m D e s c r i p t i o n

THEFT IND ON

Vehicle security indicator ON

OFF OFF

ConnectorTe r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

M18 23Ground ON

0

OFF Battery voltage

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3013 of 3641

![NISSAN NOTE 2016 Service Repair Manual SEC-156

< DTC/CIRCUIT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

VEHICLE SECURITY INDICATOR

4. Check continuity between BCM connector M18 terminal 23 and ground.

Is the inspection result normal?

YES NISSAN NOTE 2016 Service Repair Manual SEC-156

< DTC/CIRCUIT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

VEHICLE SECURITY INDICATOR

4. Check continuity between BCM connector M18 terminal 23 and ground.

Is the inspection result normal?

YES](/img/5/57363/w960_57363-3012.png)

SEC-156

< DTC/CIRCUIT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

VEHICLE SECURITY INDICATOR

4. Check continuity between BCM connector M18 terminal 23 and ground.

Is the inspection result normal?

YES >> Check the following:

• 10A fuse No. 8, located in fuse block (J/B)

• Harness for open or short between security indicator lamp and fuse.

NO >> Repair or replace harness.

Diagnosis Procedure (Type A)INFOID:0000000012430489

Regarding Wiring Diagram information, refer to SEC-132, "Wiring Diagram".

1.SECURITY INDICATOR LAMP ACTIVE TEST

With CONSULT

Check “THEFT IND”” in “Active Test” of “IMMU”.

Without CONSULT

1. Disconnect BCM.

2. Check voltage between BCM harness connector M18 terminal 23 and ground.

Is the inspection result normal?

YES >> Security indicator lamp is OK.

NO >> GO TO 2.

2.SECURITY INDICATOR LAMP CHECK

Check security indicator lamp condition.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Replace combination meter. Refer to MWI-54, "

Removal and Installation".

3.CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect BCM and security indicator lamp connector.

3. Check continuity between BCM connector M18 term inal 23 and combination meter connector M82 termi-

nal 18.

4. Check continuity between BCM connector M18 terminal 23 and ground.

BCM Combination meter

Continuity

Connector TerminalConnector Terminal

M 182 3M 241 8 Y es

BCM GroundContinuity

Connector Terminal

M18 23 No

ConnectorTe r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

M18 23Ground ON

0

OFF Battery voltage

BCM Combination meter

Continuity

Connector TerminalConnector Terminal

M 182 3M 821 8 Y es

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3021 of 3641

SRC-4

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012430587

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

ServiceINFOID:0000000012430588

• Never use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

• Before servicing the SRS, turn ignition switch OF F, disconnect battery negative terminal and wait 3 minutes

or more.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt pre-

tensioner to deploy. Therefore, never work on any SR S connectors or wires until at least 3 minutes have

passed.

• Diagnosis sensor unit must always be installed with their arrow marks “ ⇐” pointing towards the front of the

vehicle for proper operation. Also chec k diagnosis sensor unit for cracks, deformities or rust before installa-

tion and replace as required.

• The spiral cable must be aligned with the neutral position since its rotations are limited. Never turn steering wheel and column after removal of steering gear.

• Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad side facing upward and seat mounted front side air bag module standing with the stud bolt side facing down.

• Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

• After air bag inflates, the front instrument panel assembly should be replaced if damaged.

• Always replace instrument panel pad following front passenger air bag deployment.

• Never solder the harness when making repairs. Check that harness is not pinched and that there is no con-

tact with other components.

• Never allow harness to come in contact with oil, grease, waste oil, or water.

• Never insert foreign materials, such as a screwdriver, into the harness connector. (This is to prevent acci- dental activation caused by static electricity.)

• Always use CONSULT or SRS air bag warning lamp to perform the circuit diagnosis. (Never use an electric tester such as a circuit tester.)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3060 of 3641

B0001, B0002 DRIVER AIRBAG MODULE

SRC-43

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G

I

J

K L

M A

B

SRC

N

O P

Is the DTC detected?

YES >> Refer to SRC-43, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000012430618

WARNING:

• Before servicing, turn ignition sw itch OFF, disconnect battery negative terminal, and wait 3 minutes

or more. (To discharge backup capacitor.)

• Never use unspecified tester or other measuring device.

1.HARNESS CONNECTOR

Visually inspect all applicable harness connectors for the following:

• Visible damage to connector or terminal

• Loose terminal

• Poor connection NOTE:

All harness connectors should be inspected from t he air bag diagnosis sensor unit to the end component

(including any in-line connectors).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Perform one of the following repairs: • Visible damage: Replace the harness.

• Loose terminal: Secure the terminal.

• Poor connection: Secure the connection.

2.CONFIRM DTC

1. Reconnect all harness connectors.

2. Turn ignition switch ON.

3. Check for DTC using CONSULT.

Is DTC still current?

YES >> GO TO 3.

NO >> Refer to GI-42, "

Intermittent Incident".

3.WIRING HARNESS

Check the wiring harness for visible damage.

NOTE:

The entire wiring harness should be inspected from the air bag diagnosis sensor unit to the end component

(including any in-line connectors).

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace the harness.

4.CHECK SPIRAL CABLE CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect driver air bag module harness connector and combination switch (spiral cable) harness con- nector.

3. Check continuity between driver air bag module har ness connector and combination switch (spiral cable)

harness connector.

4. Check continuity between driver air bag module harness connector and ground.

Driver air bag module Combination switch (spiral cable)

Continuity

Connector TerminalConnector Terminal

M86 9

M30 30

Ye s

12

29

M87 10

28

11 3 0

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3118 of 3641

SR-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012430560

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

ServiceINFOID:0000000012430561

• Do not use electrical test equipment to check SRS ci rcuits unless instructed to in this Service Manual.

• Before servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at least three

minutes.

For approximately three minutes after the cables are remo ved, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least three minutes

have passed.

• Diagnosis sensor unit must always be installed with their arrow marks “ ⇐” pointing towards the front of the

vehicle for proper operation. Also chec k diagnosis sensor unit for cracks, deformities or rust before installa-

tion and replace as required.

• The spiral cable must be aligned with the neutral position since its rotations are limited. Do not turn steering wheel and column after removal of steering gear.

• Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad side facing upward and seat mounted front side air bag module standing with the stud bolt side facing down.

• Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

• After air bag inflates, the instrument panel assembly should be replaced if damaged.

• Always replace instrument panel pad following front passenger air bag deployment.

Precaution for WorkINFOID:0000000012430562

• When removing or disassembling each component, be careful not to damage or deform it. If a component may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3128 of 3641

SR-12

< REMOVAL AND INSTALLATION >

DRIVER AIR BAG MODULE

REMOVAL AND INSTALLATION

DRIVER AIR BAG MODULE

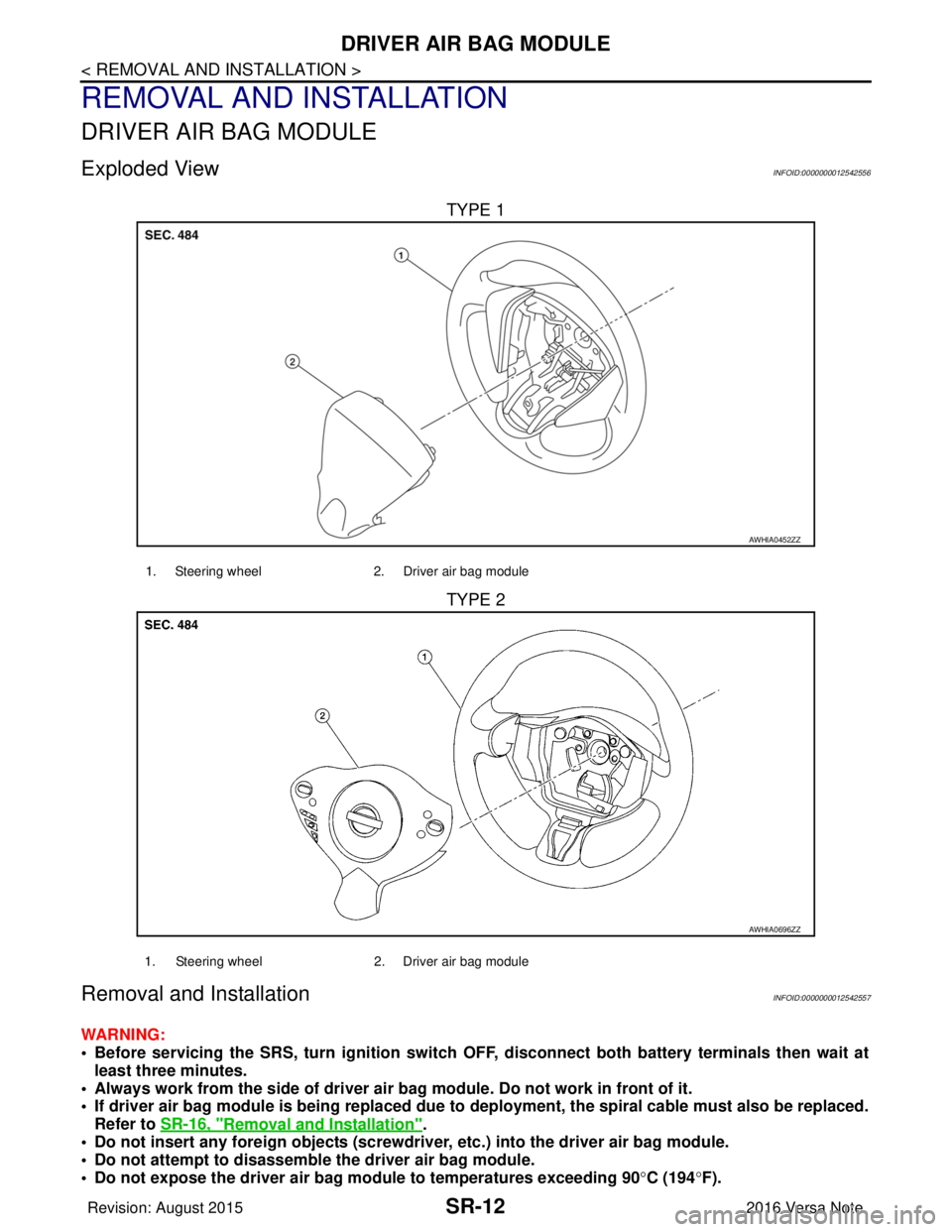

Exploded ViewINFOID:0000000012542556

TYPE 1

TYPE 2

Removal and InstallationINFOID:0000000012542557

WARNING:

• Before servicing the SRS, turn ignition switch OFF, disconnect bot h battery terminals then wait at

least three minutes.

• Always work from the side of driver air bag module. Do not work in front of it.

• If driver air bag module is being replaced due to deployment, the spiral cable must also be replaced.

Refer to SR-16, "

Removal and Installation".

• Do not insert any foreign objects (screwdriver, etc.) into the driver air bag module.

• Do not attempt to disassemble the driver air bag module.

• Do not expose the driver air bag module to temperatures exceeding 90° C (194°F).

AWHIA0452ZZ

1. Steering wheel 2. Driver air bag module

AWHIA0696ZZ

1. Steering wheel 2. Driver air bag module

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3129 of 3641

DRIVER AIR BAG MODULESR-13

< REMOVAL AND INSTALLATION >

C

DE

F

G

I

J

K L

M A

B

SR

N

O P

• Do not use air tools or electric tools for servicing.

CAUTION:

• Do not allow oil, grease, detergent or water to come in contact with the driver air bag module.

REMOVAL

1. Disconnect negative and positive battery terminals, then wait at least three minutes. Refer to PG-70,

"Removal and Installation (Battery)".

2. Remove driver air bag module type 1:

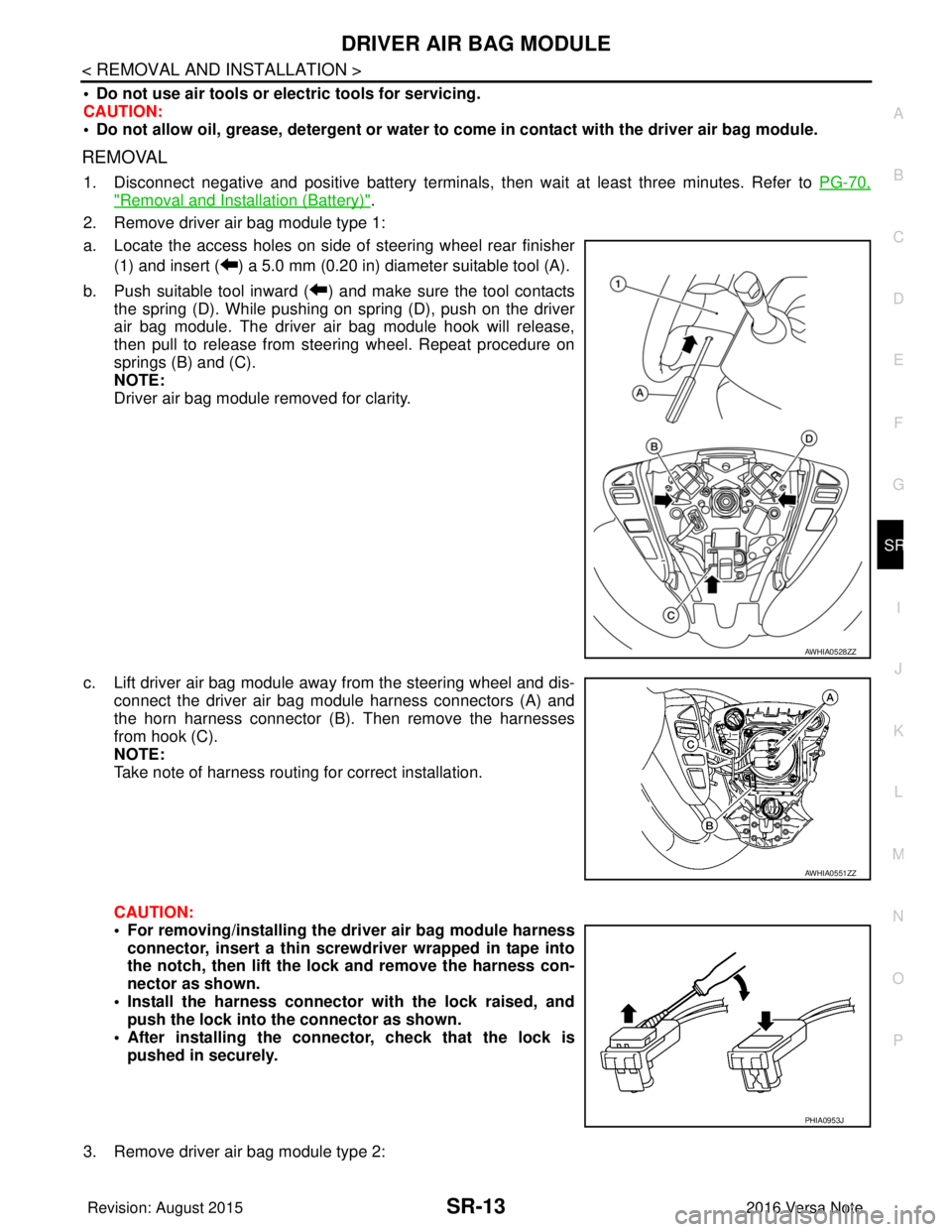

a. Locate the access holes on side of steering wheel rear finisher (1) and insert ( ) a 5.0 mm (0.20 in) diameter suitable tool (A).

b. Push suitable tool inward ( ) and make sure the tool contacts the spring (D). While pushing on spring (D), push on the driver

air bag module. The driver air bag module hook will release,

then pull to release from steering wheel. Repeat procedure on

springs (B) and (C).

NOTE:

Driver air bag module removed for clarity.

c. Lift driver air bag module away from the steering wheel and dis- connect the driver air bag module harness connectors (A) and

the horn harness connector (B). Then remove the harnesses

from hook (C).

NOTE:

Take note of harness routing for correct installation.

CAUTION:

• For removing/installing the driver air bag module harness

connector, insert a thin screwdriver wrapped in tape into

the notch, then lift the lock and remove the harness con-

nector as shown.

• Install the harness connector with the lock raised, and push the lock into the connector as shown.

• After installing the connector, check that the lock is pushed in securely.

3. Remove driver air bag module type 2:

AWHIA0528ZZ

AWHIA0551ZZ

PHIA0953J

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3132 of 3641

SR-16

< REMOVAL AND INSTALLATION >

SPIRAL CABLE

SPIRAL CABLE

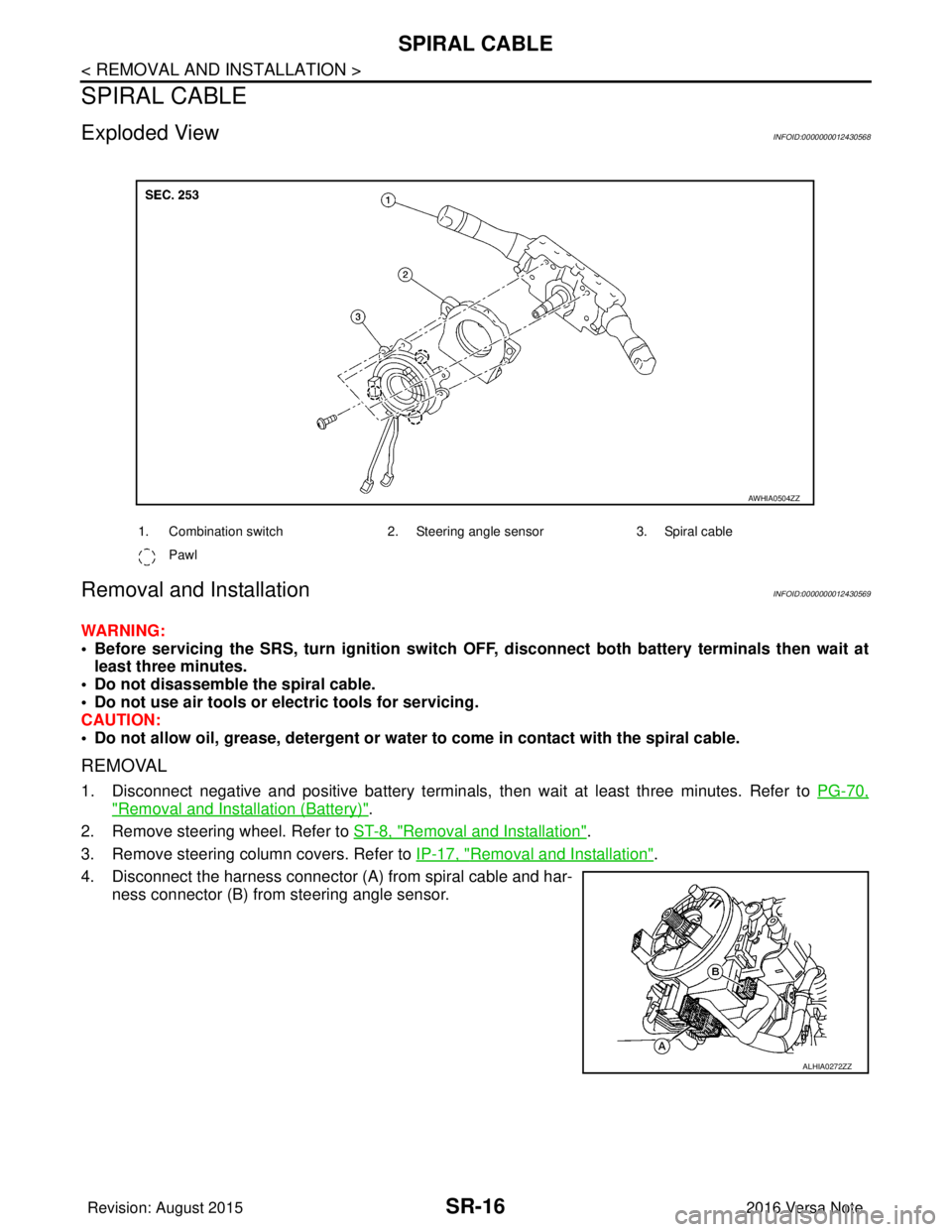

Exploded ViewINFOID:0000000012430568

Removal and InstallationINFOID:0000000012430569

WARNING:

• Before servicing the SRS, turn ignition switch OFF, disconnect bot h battery terminals then wait at

least three minutes.

• Do not disassemble the spiral cable.

• Do not use air tools or el ectric tools for servicing.

CAUTION:

• Do not allow oil, grease, detergent or water to come in contact with the spiral cable.

REMOVAL

1. Disconnect negative and positive battery terminals, then wait at least three minutes. Refer to PG-70,

"Removal and Installation (Battery)".

2. Remove steering wheel. Refer to ST-8, "

Removal and Installation".

3. Remove steering column covers. Refer to IP-17, "

Removal and Installation".

4. Disconnect the harness connector (A) from spiral cable and har- ness connector (B) from steering angle sensor.

1. Combination switch 2. Steering angle sensor3. Spiral cable

Pawl

AWHIA0504ZZ

ALHIA0272ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com