battery NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 3204 of 3641

STC-20

< DTC/CIRCUIT DIAGNOSIS >

C1601 BATTERY POWER SUPPLY

NO >> Repair or replace malfunctioning component.

6.CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect torque sensor harness connector.

3. Check terminal for deformation, disconnection, looseness, and so on. If any malfunction is found, repair or replace terminal.

Is the inspection result normal?

YES >> Replace EPS control unit. Refer to STC-37, "Removal and Installation".

NO >> Repair or replace malfunctioning component.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3205 of 3641

C1604 TORQUE SENSORSTC-21

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

H I

J

K L

M A

B

STC

N

O P

C1604 TORQUE SENSOR

DTC LogicINFOID:0000000012431955

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With CONSULT

1. Turn the ignition switch OFF to ON.

2. Perform “Self Diagnostic Result” of “EPS”.

Is DTC

“C1604” detected?

YES >> Proceed to diagnosis procedure. Refer to STC-21, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000012431956

Regarding Wiring Diagram information, refer to STC-11, "Wiring Diagram".

1.CHECK TORQUE SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF to ON. CAUTION:

Never start the engine.

2. Check voltage between EPS control unit harness connector terminal and ground.

CAUTION:

Steering wheel in neutral position . (There is no steering force.)

Is the inspection result normal?

YES >> GO TO 2.

NO >> Perform the trouble diagnosis for battery power supply circuit. Refer to STC-18, "

Diagnosis Proce-

dure".

2.CHECK TORQUE SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between EPS control unit harness connector terminal and ground. CAUTION:

Steering wheel in neutral position . (There is no steering force.)

DTCDisplay item Malfunction detected condition Possible cause

C1604 TORQUE SENSOR When torque sensor output signal is malfunctioning. • Harness or connector

• Torque sensor

• EPS control unit

EPS control unit

—Vo l ta g e

(Approx.)

Connector Terminal

M54 13Ground 5 V

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3216 of 3641

STC-32

< SYMPTOM DIAGNOSIS >

STEERING WHEEL TURNING FORCE IS HEAVY OR LIGHT

STEERING WHEEL TURNING FORCE IS HEAVY OR LIGHT

DescriptionINFOID:0000000012431977

Steering wheel turning force is heavy or light.

Diagnosis ProcedureINFOID:0000000012431978

1.PERFORM SELF DIAGNOSTIC RESULT

With CONSULT

1. Turn the ignition switch OFF to ON.

2. Perform “Self Diagnostic Result” of “EPS”.

Is any DTC detected?

YES >> Check the DTC. Refer to STC-10, "DTC Index".

NO >> GO TO 2.

2.CHECK THE ILLUMINATION OF THE EPS WARNING LAMP

Check that the EPS warning lamp turns ON when igni tion switch turns ON. Then, EPS warning lamp turns

OFF after the engine is started.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Perform trouble diagnosis of EPS warning lamp. Refer to STC-29, "

Diagnosis Procedure".

3.CHECK EPS CONTROL UNIT SIGNAL (1)

With CONSULT

1. Start the engine. CAUTION:

Never drive the vehicle.

2. Select “ASSIST LEVEL” in “Data Monitor” of “EPS”.

Does the item in

“Data Monitor” indicate 100%?

YES >> GO TO 6.

NO >> GO TO 4.

4.CHECK EPS CONTROL UNIT SIGNAL (2)

With CONSULT

Select “BATTERY VOLT” in “Data Monitor” of “EPS”.

Does the item in

“Data Monitor” indicate 10 V or more?

YES >> GO TO 5.

NO >> Perform trouble diagnosis of EPS control unit power supply and ground. Refer to STC-18, "

Diag-

nosis Procedure".

5.CHECK EPS CONTROL UNIT SIGNAL (3)

With CONSULT

1. Select “ASSIST LEVEL” in “Data Monitor” of “EPS”.

2. Stop the EPS system until the item in “Data Monitor” becomes “100%”.

NOTE:

While stopping the EPS system, do not turn steering wheel.

3. Check that the symptom continues.

Does the symptom continue?

YES >> GO TO 6.

NO >> The assist torque decreases because of protection function. This is not malfunction. Inspection End.

6.CHECK EPS CONTROL UNIT SIGNAL (4)

With CONSULT

1. Start the engine. CAUTION:

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3219 of 3641

UNBALANCE STEERING WHEEL TURNING FORCE (TORQUE VARIATION)

STC-35

< SYMPTOM DIAGNOSIS >

C

D E

F

H I

J

K L

M A

B

STC

N

O P

UNBALANCE STEERING WHEEL TU RNING FORCE (TORQUE VARIA-

TION)

DescriptionINFOID:0000000012431981

Unbalance steering wheel turning force (torque variation).

Diagnosis ProcedureINFOID:0000000012431982

1.PERFORM SELF DIAGNOSTIC RESULT

With CONSULT

1. Turn the ignition switch OFF to ON.

2. Perform “Self Diagnostic Result” of “EPS”.

Is any DTC detected?

YES >> Check the DTC. Refer to STC-10, "DTC Index".

NO >> GO TO 2.

2.CHECK THE ILLUMINATION OF THE EPS WARNING LAMP

Check the EPS warning lamp while the engine is started.

Does the EPS warning lamp turn OFF?

YES >> GO TO 3.

NO >> Refer to STC-29, "

Diagnosis Procedure".

3.CHECK STEERING COLU MN AND STEERING GEAR

Check the steering column assembly and steering gear assembly.

• Steering column assembly. Refer to ST-9, "

Exploded View".

• Steering gear assembly. Refer to ST-14, "

Exploded View".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace the specific malfunctioning part.

4.CHECK EPS CONTROL UNIT SIGNAL (1)

With CONSULT

1. Start the engine. CAUTION:

Never drive the vehicle.

2. Turn steering wheel from full left stop to full right stop.

3. Select “ASSIST LEVEL” in “Data Monitor” of “EPS”.

Does the item in

“Data Monitor” maintain “100%”?

YES >> GO TO 7.

NO >> GO TO 5.

5.CHECK EPS CONTROL UNIT SIGNAL (2)

With CONSULT

Select “BATTERY VOLT” in “Data Monitor” of “EPS”.

Does the item in

“Data Monitor” indicate 10 V or more?

YES >> GO TO 6.

NO >> Perform trouble diagnosis of EPS control unit power supply and ground. Refer to STC-18, "

Diag-

nosis Procedure".

6.CHECK EPS CONTROL UNIT SIGNAL (3)

With CONSULT

1. Select “ASSIST LEVEL” in “Data Monitor” of “EPS”.

2. Stop the EPS system until the item in “Data Monitor” becomes “100%”. NOTE:

While stopping the EPS system, do not turn steering wheel.

3. Check that the symptom continues.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3221 of 3641

EPS CONTROL UNITSTC-37

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

STC

N

O P

REMOVAL AND INSTALLATION

EPS CONTROL UNIT

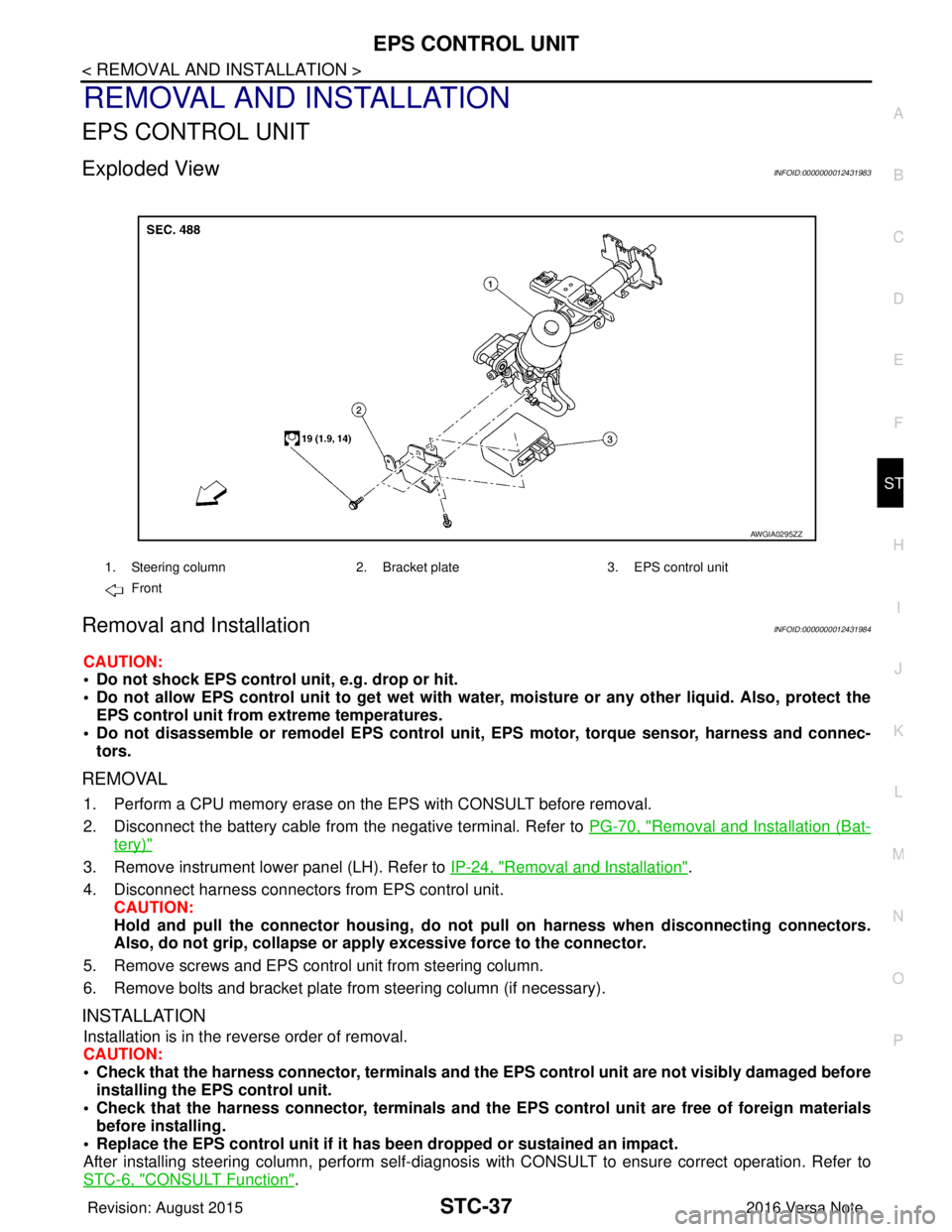

Exploded ViewINFOID:0000000012431983

Removal and InstallationINFOID:0000000012431984

CAUTION:

• Do not shock EPS control unit, e.g. drop or hit.

• Do not allow EPS control unit to get wet with wate r, moisture or any other liquid. Also, protect the

EPS control unit from extreme temperatures.

• Do not disassemble or remodel EPS control unit, EPS motor, torque sensor, harness and connec-

tors.

REMOVAL

1. Perform a CPU memory erase on t he EPS with CONSULT before removal.

2. Disconnect the battery cable from the negative terminal. Refer to PG-70, "

Removal and Installation (Bat-

tery)"

3. Remove instrument lower panel (LH). Refer to IP-24, "Removal and Installation".

4. Disconnect harness connectors from EPS control unit. CAUTION:

Hold and pull the connector housing, do not pull on harness when disconnecting connectors.

Also, do not grip, collapse or ap ply excessive force to the connector.

5. Remove screws and EPS control unit from steering column.

6. Remove bolts and bracket plate from steering column (if necessary).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Check that the harness connector, terminals and the EPS control unit are not visibly damaged before

installing the EPS control unit.

• Check that the harness connector, te rminals and the EPS control unit are free of foreign materials

before installing.

• Replace the EPS control unit if it has been dropped or sustained an impact.

After installing steering column, perform self-diagnosis with CONSULT to ensure correct operation. Refer to

STC-6, "

CONSULT Function".

1. Steering column 2. Bracket plate3. EPS control unit

Front

AWGIA0295ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3223 of 3641

ST-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012430493

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Service Notice or Precautions for Steering SystemINFOID:0000000012430494

• In case of removing the steering gear, make the final tightening with grounded and unloaded vehicle condi- tion, and then check wheel alignment.

• Observe the following precautions when disassembling.

- Before disassembly, thoroughly clean the outside of the unit.

- Disassembly should be done in a clean work area. It is im portant to prevent the internal parts from becoming

contaminated by dirt or other foreign matter.

- For easier and proper assembly, place disassembled parts in order on a parts rack.

- Use nylon cloth or paper towels to clean the parts; co mmon shop rags can leave lint that might interfere with

their operation.

- Do not reuse non-reusable parts.

- Before assembling, apply the specified grease to the directed parts.

FOR ELECTRIC POWER STEERING (EPS)

• During quick steering, rasping noise may be heard from around the steering wheel. This is not a malfunction.

The noise is an operating noise of the EPS system under normal conditions. If the rasping noise occurs dur-

ing slow steering, this may not be an operating noise of the system. In this case, it is necessary to find out

the location of the noise and repair, if necessary.

• Do not repeat static steering. (Mot or and EPS control unit could be heated.)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3248 of 3641

![NISSAN NOTE 2016 Service Repair Manual PRECAUTIONSTM-7

< PRECAUTION > [5MT: RS5F91R]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID NISSAN NOTE 2016 Service Repair Manual PRECAUTIONSTM-7

< PRECAUTION > [5MT: RS5F91R]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID](/img/5/57363/w960_57363-3247.png)

PRECAUTIONSTM-7

< PRECAUTION > [5MT: RS5F91R]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012430936

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

General PrecautionsINFOID:0000000012430937

CAUTION:

• Do not reuse CSC (Concentric Sl ave Cylinder). CSC slides back to th e original position every time

when removing transaxle assembly. At this time, du st on the sliding parts may damage the seal of

CSC and may cause clutch fluid leakage. Refer to CL-17, "

Removal and Installation".

• Do not reuse transaxle gear oi l, once it has been drained.

• Check oil level or replace gear oil with vehicle on level surface.

• During removal or installation, keep insi de of transaxle clear of dust or dirt.

• Check for the correct installation alignment prior to removal or disassembly. If matching marks are

required, be certain they do not interfer e with the function of the parts marked.

• In principle, tighten bolts or nu ts gradually in several steps workin g diagonally from inside to out-

side. If tightening sequence is specified, use it.

• Do not damage sliding surfaces and mating surfaces.

Precaution for WorkINFOID:0000000012430938

• When removing or disassembling each component, be ca reful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusabl e part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3261 of 3641

![NISSAN NOTE 2016 Service Repair Manual TM-20

< REMOVAL AND INSTALLATION >[5MT: RS5F91R]

CONTROL LINKAGE

CONTROL LINKAGE

Exploded ViewINFOID:0000000012430954

Removal and InstallationINFOID:0000000012430955

REMOVAL

1. Move the shift selecto NISSAN NOTE 2016 Service Repair Manual TM-20

< REMOVAL AND INSTALLATION >[5MT: RS5F91R]

CONTROL LINKAGE

CONTROL LINKAGE

Exploded ViewINFOID:0000000012430954

Removal and InstallationINFOID:0000000012430955

REMOVAL

1. Move the shift selecto](/img/5/57363/w960_57363-3260.png)

TM-20

< REMOVAL AND INSTALLATION >[5MT: RS5F91R]

CONTROL LINKAGE

CONTROL LINKAGE

Exploded ViewINFOID:0000000012430954

Removal and InstallationINFOID:0000000012430955

REMOVAL

1. Move the shift selector to the neutral position.

2. Remove the battery tray. Refer to

PG-71, "

Removal and Installation (Battery Tray)".

3. Pull out and disconnect cables from shifter lever A and selector lever, using a suitable tool.

4. While pressing the lock of the selector cable in the direction of the arrows shown, remove the selector cable from the cable

mounting bracket.

5. While pressing the lock of the shifter cable in the direction of the arrows shown, remove the shifter cable from the cable mounting

bracket.

6. Remove cable mounting bracket from clutch housing.

7. Pull the shift selector handle upward to remove.

8. Remove center console assembly. Refer to IP-18, "

Removal and

Installation".

9. Pull out and disconnect each cable from the shift selector assembly, using a suitable tool.

1. Shifter lever A 2. Selector lever 3. Selector cable

4. Shifter cable 5. Cable mounting bracket6. Tapping bolt

7. Bracket 8. Grommet9. Shift selector assembly

10. Shift selector 11. Shift selector handle

JPDIC0789GB

JPDIC0793ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3296 of 3641

![NISSAN NOTE 2016 Service Repair Manual PRECAUTIONSTM-55

< PRECAUTION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOI NISSAN NOTE 2016 Service Repair Manual PRECAUTIONSTM-55

< PRECAUTION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOI](/img/5/57363/w960_57363-3295.png)

PRECAUTIONSTM-55

< PRECAUTION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012430981

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Precaution for Procedure without Cowl Top CoverINFOID:0000000012430982

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc to prevent damage to

windshield.

Precaution for TCM, Transaxle Asse mbly or Control Valve ReplacementINFOID:0000000012430983

CAUTION:

• To replace TCM, refer to TM-125, "

Description".

• To replace transaxle assembly or control valve, refer to TM-127, "

Description".

Precaution for G Sensor Removal/Installation or ReplacementINFOID:0000000012430984

CAUTION:

To remove/install or replace G sensor, refer to TM-130, "

Description".

PIIB3706J

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3297 of 3641

![NISSAN NOTE 2016 Service Repair Manual TM-56

< PRECAUTION >[CVT: RE0F11A]

PRECAUTIONS

General Precautions

INFOID:0000000012430985

• Turn ignition switch OFF an d disconnect the battery cable

from the negative terminal before connecting o NISSAN NOTE 2016 Service Repair Manual TM-56

< PRECAUTION >[CVT: RE0F11A]

PRECAUTIONS

General Precautions

INFOID:0000000012430985

• Turn ignition switch OFF an d disconnect the battery cable

from the negative terminal before connecting o](/img/5/57363/w960_57363-3296.png)

TM-56

< PRECAUTION >[CVT: RE0F11A]

PRECAUTIONS

General Precautions

INFOID:0000000012430985

• Turn ignition switch OFF an d disconnect the battery cable

from the negative terminal before connecting or disconnect-

ing the CVT assembly harness connector. Because battery

voltage is applied to TCM even if ignition switch is turned

OFF.

• When connecting or disconnect ing pin connectors into or

from TCM, do not damage pin terminals (bend or break).

Check that there are not any bends or breaks on TCM pin ter-

minal, when connect ing pin connectors.

• Perform TCM input/output si gnal inspection and check

whether TCM functions normally or not before replacing TCM.

Refer to TM-99, "

Reference Value".

• Perform “DTC (Diagnostic Trouble Code) CONFIRMATION

PROCEDURE”.

If the repair is completed DTC should not be displayed in the

“DTC CONFIRMATION PROCEDURE”.

• Always use the specified brand of CVT fluid. Refer to MA-11, "

Fluids and Lubricants".

• Use lint-free paper not cloth rags during work.

• Dispose of the waste oil using the methods prescribed by law, ordinance, etc. after replacing the CVT fluid.

• Before proceeding with disassembly, thoroughly clean the outside of the transaxle. It is important to prevent the internal parts from becoming contami nated by dirt or other foreign matter.

• Disassembly should be done in a clean work area.

SEF289H

AAT470A

MEF040DA

JSBIA1315ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com