maintenance NISSAN NOTE 2016 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1656 of 3641

EXL-4

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432764

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for WorkINFOID:0000000012432765

• When removing or disassembling each component, be careful not to damage or deform it. If a component may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

- Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1749 of 3641

HEADLAMP AIMING ADJUSTMENTEXL-97

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

PERIODIC MAINTENANCE

HEADLAMP AIMING ADJUSTMENT

InspectionINFOID:0000000012432828

PREPARATION BEFORE ADJUSTING

Before performing aiming adjustment, check the following:

• Ensure all tires are inflated to correct pressure.

• Place vehicle and screen on level surface.

• Ensure there is no load in vehicle other than the driver (or equivalent weight placed in driver's position).

• Coolant and engine oil filled to correct level, and fuel tank full.

• Remove cargo and/or luggage to maintain an unloaded vehicle condition.

• Confirm spare tire, jack and tools are properly stowed.

• Carefully wipe off any dirt from headlamp lens. CAUTION:

Do not use organic solvent (thinner, gasoline etc.)

• Place a driver or equivalent weight of 68.5 kg (150 lb) on the driver seat.

• By hand, bounce the front and rear of the vehicle to settle the suspension and eliminate any static load.

• Place the front tires in the straight ahead position.

• Confirm headlamp aiming switch is set to "0" (zero) position.

• Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

NOTE:

• For headlamp aiming details, refer to regulations in your area.

• By regulation, no means for horizontal aim adjustment is provided from the factory; only vertical aim is

adjustable.

• Use adjusting screw to perform aiming adjustment.

• Perform headlamp aiming if:

- The vehicle front body has been repaired.

- The front combination lamp has been removed or replaced.

- Any outfitting has been installed.

- The vehicle’s standard load condition has been substantially increased.

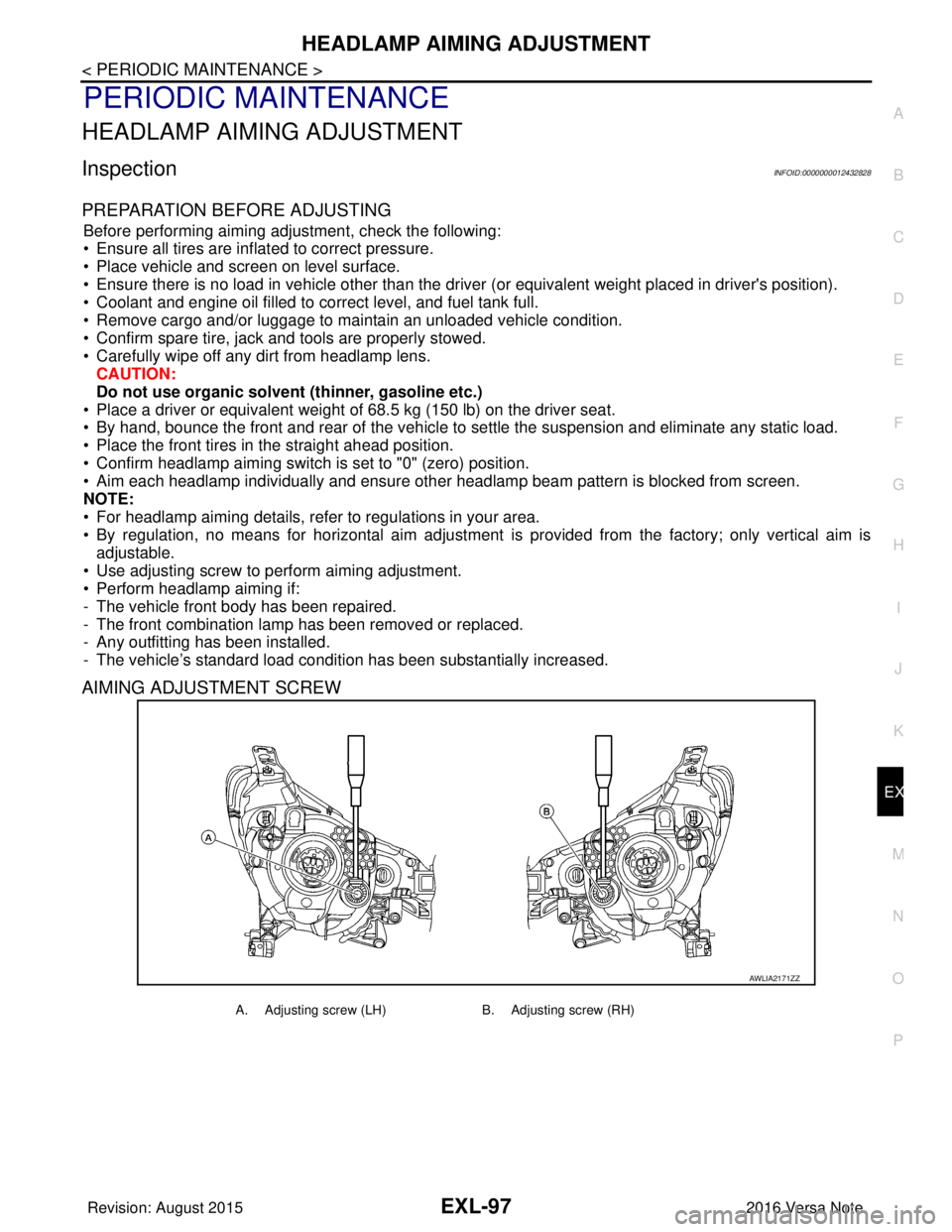

AIMING ADJUSTMENT SCREW

AWLIA2171ZZ

A. Adjusting screw (LH) B. Adjusting screw (RH)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1750 of 3641

EXL-98

< PERIODIC MAINTENANCE >

HEADLAMP AIMING ADJUSTMENT

Aiming Adjustment Procedure

INFOID:0000000012432829

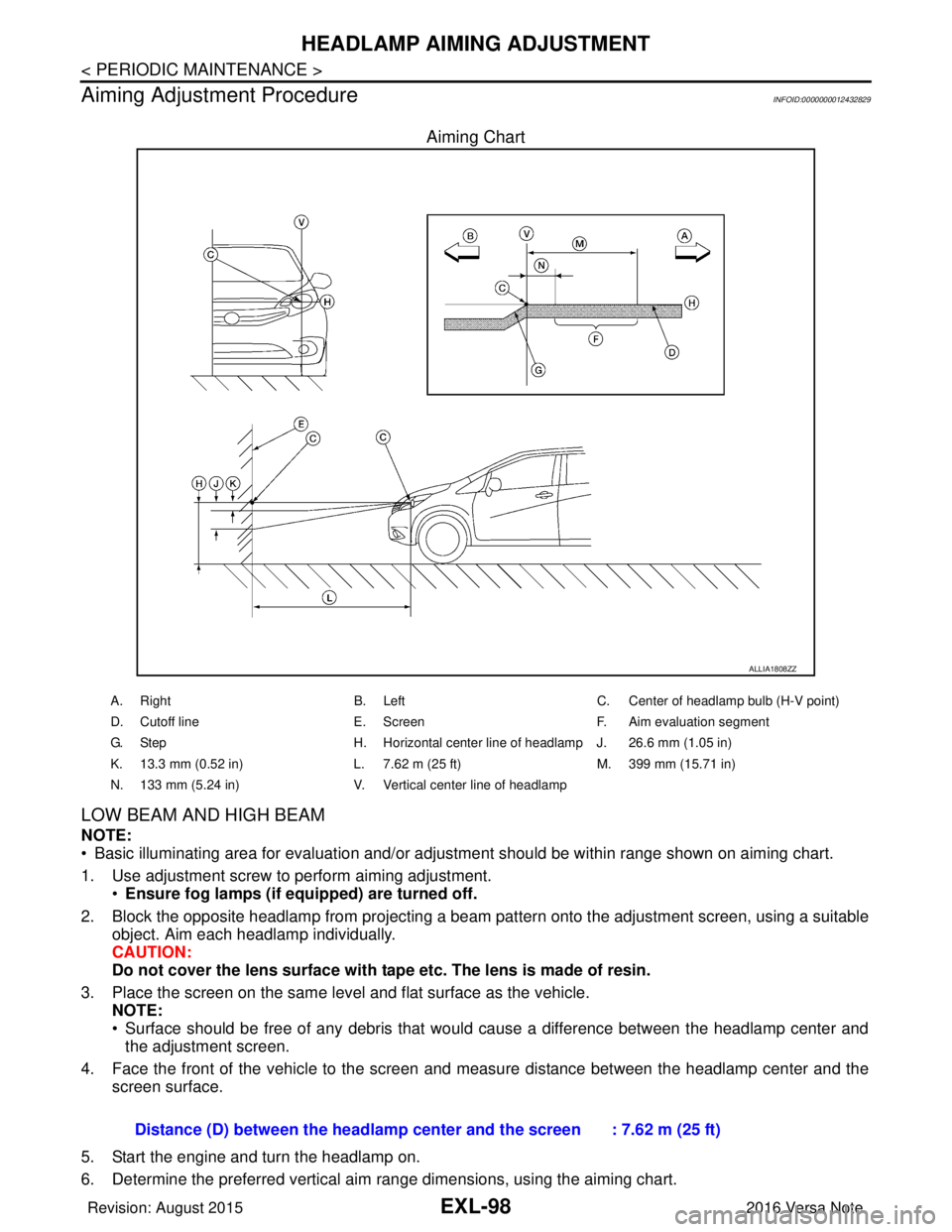

Aiming Chart

LOW BEAM AND HIGH BEAM

NOTE:

• Basic illuminating area for evaluation and/or adjus tment should be within range shown on aiming chart.

1. Use adjustment screw to perform aiming adjustment. •Ensure fog lamps (if eq uipped) are turned off.

2. Block the opposite headlamp from projecting a beam pa ttern onto the adjustment screen, using a suitable

object. Aim each headlamp individually.

CAUTION:

Do not cover the lens surface with tape etc. The lens is made of resin.

3. Place the screen on the same level and flat surface as the vehicle. NOTE:

• Surface should be free of any debris that would cause a difference between the headlamp center and

the adjustment screen.

4. Face the front of the vehicle to the screen and measure distance between the headlamp center and the screen surface.

5. Start the engine and turn the headlamp on.

6. Determine the preferred vertical aim range dimensions, using the aiming chart.

ALLIA1808ZZ

A. Right B. LeftC. Center of headlamp bulb (H-V point)

D. Cutoff line E. ScreenF. Aim evaluation segment

G. Step H. Horizontal center line of headlamp J. 26.6 mm (1.05 in)

K. 13.3 mm (0.52 in) L. 7.62 m (25 ft)M. 399 mm (15.71 in)

N. 133 mm (5.24 in) V. Vertical center line of headlamp

Distance (D) between the headlamp center and the screen : 7.62 m (25 ft)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1751 of 3641

HEADLAMP AIMING ADJUSTMENTEXL-99

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

7. Measure the projected beam within t he aim evaluation segment on the screen.

8. Adjust the beam pattern of each headlamp until the ai m evaluation segment (the area relative to both the

highest and lowest cutoff line height) is positioned within the vertical aim range dimensions shown on the

aiming chart.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1752 of 3641

EXL-100

< PERIODIC MAINTENANCE >

FRONT FOG LAMP AIMING ADJUSTMENT

FRONT FOG LAMP AIMING ADJUSTMENT

InspectionINFOID:0000000012432830

PREPARATION BEFORE ADJUSTING

Before performing aiming adjustment procedure, check the following:

• Ensure all tires are inflated to correct pressure.

• Place vehicle and screen on level surface.

• Ensure there is no load in vehicle other than the driver (or equivalent weight placed in driver's position).

• Coolant and engine oil filled to correct level, and fuel tank full.

• Remove cargo and/or luggage to maintain an unloaded vehicle condition.

• Confirm spare tire, jack and tools are properly stowed.

• Carefully wipe off any dirt from fog lamp lens. CAUTION:

Do not use organic solvent (thinner, gasoline etc.)

• Place a driver or equivalent weight of 68.5 kg (150 lb) on the driver seat.

• By hand, bounce the front and rear of the vehicle to settle the suspension and eliminate any static load.

• Place the front tires in the straight ahead position.

• Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

NOTE:

• For headlamp aiming details, refer to regulations in your area.

• By regulation, no means for horizontal aim adjustment is provided from the factory; only vertical aim is

adjustable.

• Use adjusting screw to perform aiming adjustment.

• Perform headlamp aiming if:

- The vehicle front body has been repaired.

- The front combination lamp has been removed or replaced.

- Any outfitting has been installed.

- The vehicle’s standard load condition has been substantially increased.

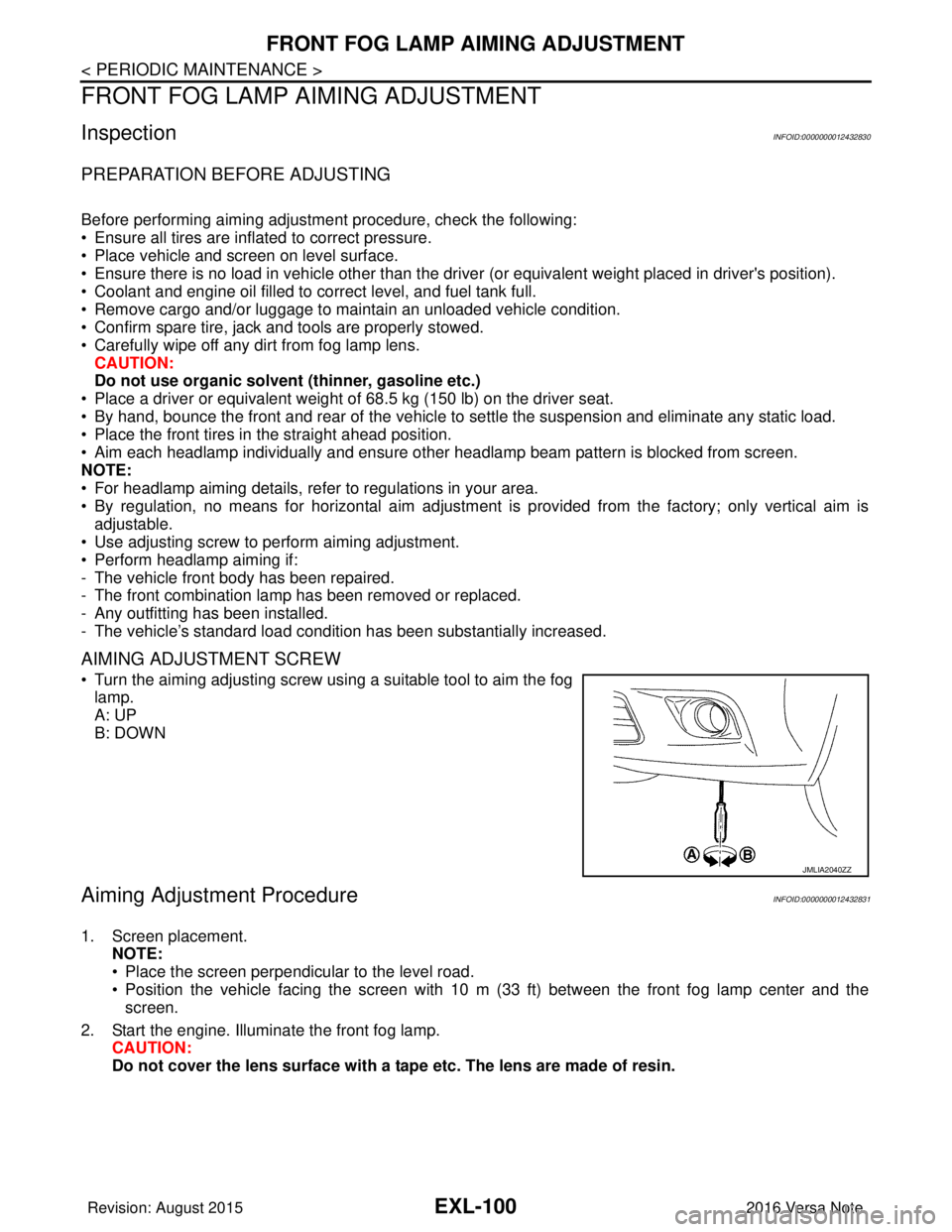

AIMING ADJUSTMENT SCREW

• Turn the aiming adjusting screw using a suitable tool to aim the fog

lamp.

A: UP

B: DOWN

Aiming Adjustment ProcedureINFOID:0000000012432831

1. Screen placement. NOTE:

• Place the screen perpendicular to the level road.

• Position the vehicle facing the screen with 10 m (33 ft) between the front fog lamp center and thescreen.

2. Start the engine. Illuminate the front fog lamp. CAUTION:

Do not cover the lens surface with a tape etc. The lens are made of resin.

JMLIA2040ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1753 of 3641

FRONT FOG LAMP AIMING ADJUSTMENTEXL-101

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

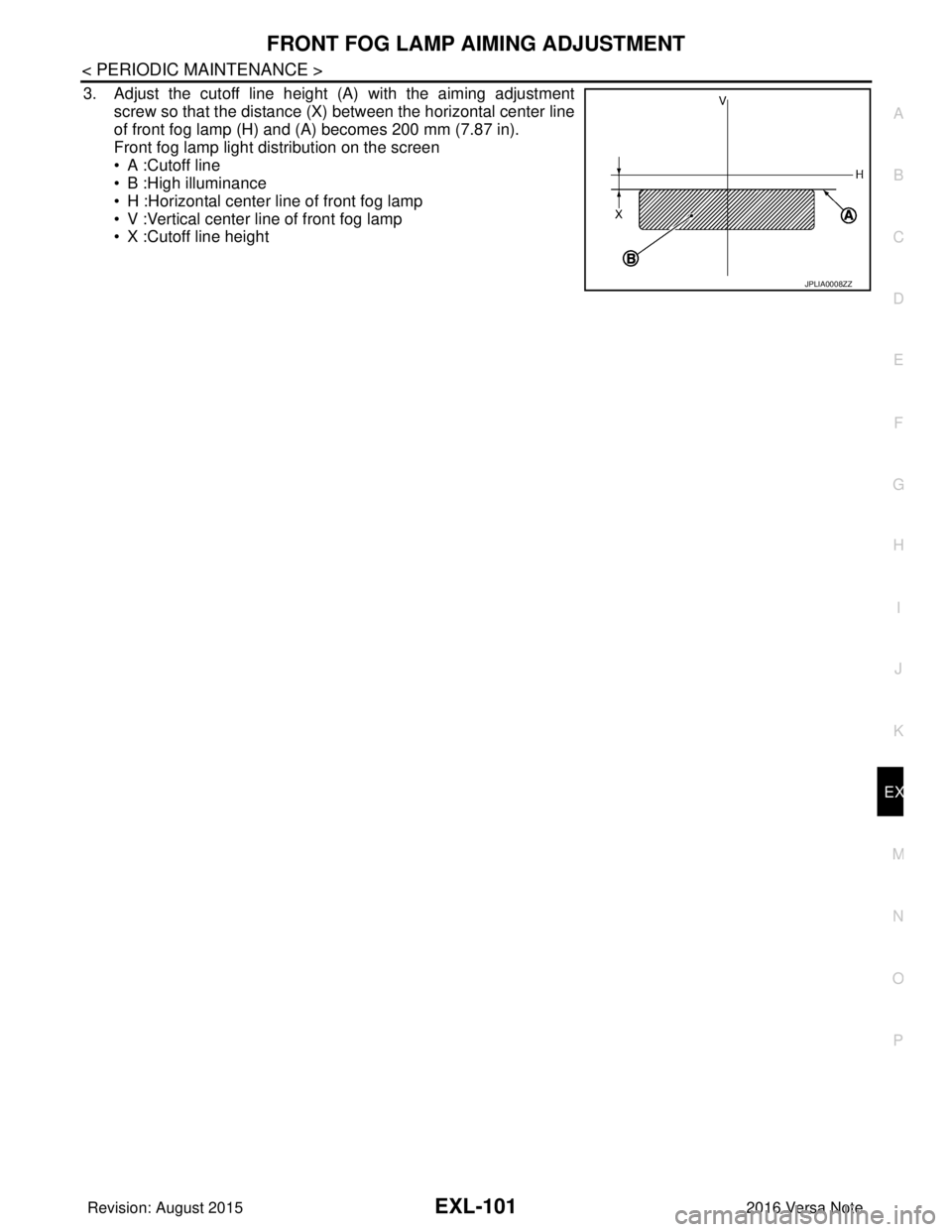

3. Adjust the cutoff line height (A) with the aiming adjustment screw so that the distance (X) between the horizontal center line

of front fog lamp (H) and (A) becomes 200 mm (7.87 in).

Front fog lamp light distribution on the screen

• A :Cutoff line

• B :High illuminance

• H :Horizontal center line of front fog lamp

• V :Vertical center line of front fog lamp

• X :Cutoff line height

JPLIA0008ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1770 of 3641

PRECAUTIONSEXT-3

< PRECAUTION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432151

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

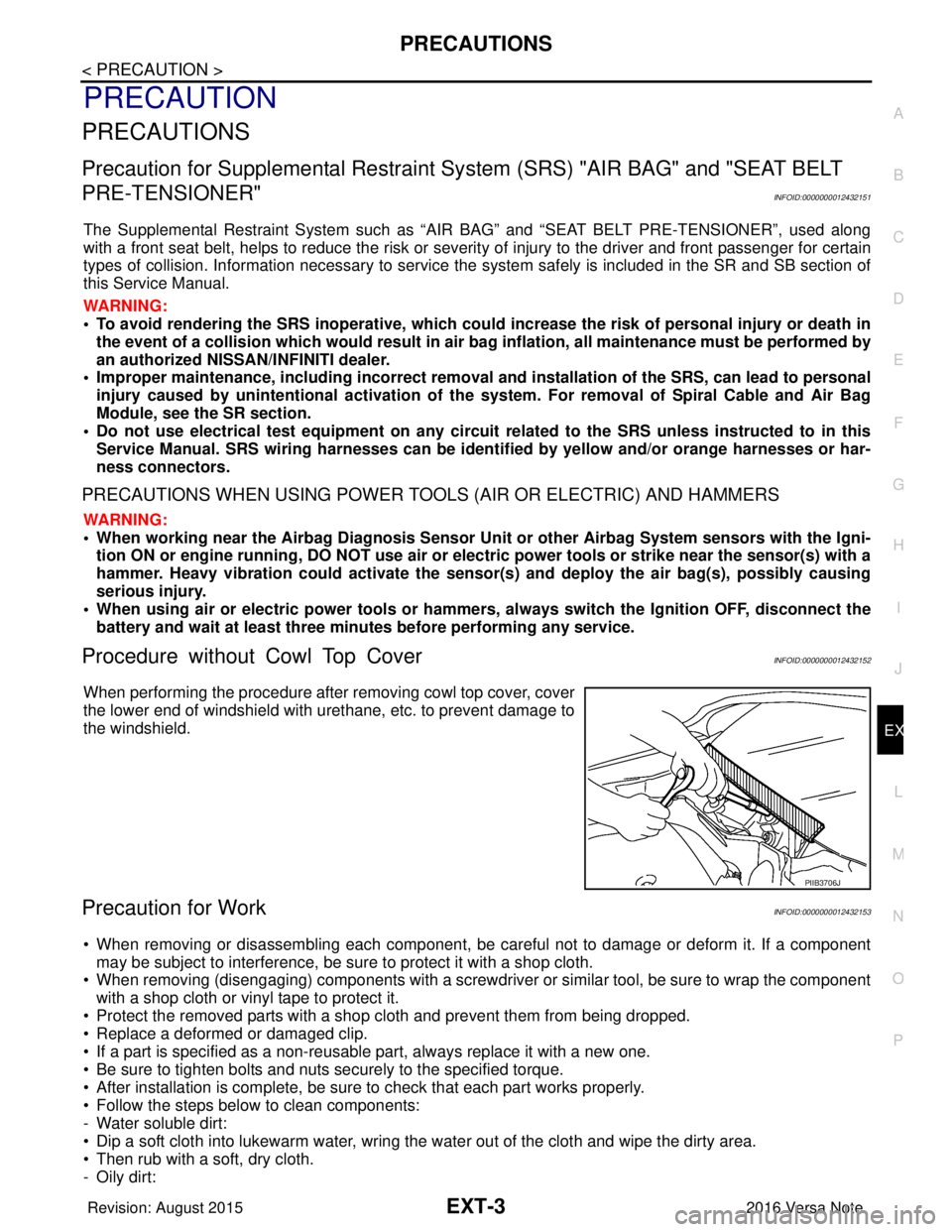

Procedure without Cowl Top CoverINFOID:0000000012432152

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc. to prevent damage to

the windshield.

Precaution for WorkINFOID:0000000012432153

• When removing or disassembling each component, be ca reful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusabl e part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

-Oily dirt:

PIIB3706J

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1818 of 3641

FAX-1

TRANSMISSION & DRIVELINE

CEF

G H

I

J

K L

M

SECTION FA X

A

B

FA X

N

O P

CONTENTS

FRONT AXLE

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution for Drive Shaft .........................................2

Precautions for Wheel Hub and Knuckle ..................2

PREPARATION ............................................3

PREPARATION .............................................. .....3

Special Service Tools .......................................... ......3

Commercial Service Tools ........................................4

SYMPTOM DIAGNOSIS ...............................6

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

6

NVH Troubleshooting Chart ................................ ......6

PERIODIC MAINTENANCE ..........................7

FRONT WHEEL HUB AND KNUCKLE ......... .....7

Inspection ............................................................ ......7

FRONT DRIVE SHAFT ........................................8

Inspection ............................................................ ......8

REMOVAL AND INSTALLATION ................9

FRONT WHEEL HUB AND KNUCKLE ......... .....9

Exploded View ..................................................... .....9

Removal and Installation ..........................................9

Disassembly and Assembly .....................................11

Inspection ................................................................13

FRONT DRIVE SHAFT BOOT ..........................14

Exploded View .........................................................14

WHEEL SIDE ......................................................... ....14

WHEEL SIDE : Removal and Installation ................15

TRANSAXLE SIDE ................................................ ....18

TRANSAXLE SIDE : Removal and Installation .......18

Inspection ............................................................ ....18

FRONT DRIVE SHAFT .....................................19

Exploded View .........................................................19

Removal and Installation .........................................19

UNIT DISASSEMBLY AND ASSEMBLY ....21

FRONT DRIVE SHAFT .....................................21

Exploded View ..................................................... ....21

Disassembly and Assembly .....................................22

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

27

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

27

Wheel Bearing ..................................................... ....27

Drive Shaft ...............................................................27

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1819 of 3641

FAX-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431882

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for Drive ShaftINFOID:0000000012431883

Observe the following precautions when disassembling and assembling drive shaft.

• Do not disassemble joint sub-assembly because it is non-overhaul parts.

• Perform work in a location which is as dust-free as possible.

• Clean the parts, before disassembling and assembling.

• Prevent the entry of foreign objects dur ing disassembly of the service location.

• Reassemble disassembled parts carefully in the correct order. If work is interrupted, a clean cover must be placed over parts.

• Use paper waste. Fabric shop cloths must not be used because of the danger of lint adhering to parts.

• Clean disassembled parts (except for rubber parts) with kerosene which shall be removed by blowing with air or wiping with paper waste.

Precautions for Wheel Hub and KnuckleINFOID:0000000012431884

Observe the following precautions when assembling wheel hub and knuckle.

• Perform work in a location which is as dust-free as possible.

• Use paper waste. Fabric shop cloths must not be used because of the danger of lint adhering to parts.

• If any of wheel hub, steering knuckle, wheel bearing, and wheel hub lock nut is dropped, it must not be used.

• Always check that the tools used for press-fit work of wheel hub and wheel bearing have no wear and defor- mation so that a pressure can be applied vertically.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1824 of 3641

FRONT WHEEL HUB AND KNUCKLEFAX-7

< PERIODIC MAINTENANCE >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

PERIODIC MAINTENANCE

FRONT WHEEL HUB AND KNUCKLE

InspectionINFOID:0000000012431888

COMPONENT PART

• Check that the mounting conditions (looseness, ba cklash) of each component and component conditions

(wear, damage) are normal.

• Check the axle and suspension parts for excessive play, weary or damage.

• Shake each front wheel to check for excessive play.

FRONT WHEEL BEARING INSPECTION

Check the following items, and replace the part if necessary.

• Move the wheel bearing in the axial direction by hand. Make sure there is no looseness in the wheel bearing.

• Rotate the wheel bearing and make sure there is no unusual noise or other irregular conditions. If there are any irregular conditions, replace wheel bearing.

SMA525A

Axial end play : Refer to FA X - 2 7.

Revision: August 2015 2016 Versa Note

cardiagn.com