maintenance NISSAN NOTE 2016 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1825 of 3641

FAX-8

< PERIODIC MAINTENANCE >

FRONT DRIVE SHAFT

FRONT DRIVE SHAFT

InspectionINFOID:0000000012431889

Check the following items, and replace the part if necessary.

• Check drive shaft mounting point and joint for looseness and other damage.CAUTION:

Replace entire drive shaft when noise or vibration occurs from drive shaft.

• Check boot for cracks and other damage.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1846 of 3641

FSU-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION FSU

A

B

FSU

N

O PCONTENTS

FRONT SUSPENSION

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution for Procedure without Cowl Top Cover ......2

Precaution for Suspension ........................................2

PREPARATION ............................................3

PREPARATION .............................................. .....3

Special Service Tools .......................................... ......3

Commercial Service Tools ........................................3

SYMPTOM DIAGNOSIS ...............................5

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

5

NVH Troubleshooting Chart ................................ ......5

PERIODIC MAINTENANCE ..........................6

FRONT SUSPENSION ASSEMBLY .............. .....6

Inspection ............................................................ ......6

WHEEL ALIGNMENT ..........................................7

Inspection ............................................................ ......7

Adjustment ................................................................8

REMOVAL AND INSTALLATION ................9

FRONT COIL SPRING AND STRUT ............. .....9

Exploded View .................................................... ......9

Removal and Installation ...........................................9

TRANSVERSE LINK .........................................10

Exploded View ..................................................... ....10

Removal and Installation .........................................10

Inspection ................................................................10

FRONT STABILIZER ........................................12

Exploded View .........................................................12

Removal and Installation .........................................12

Inspection ................................................................13

UNIT REMOVAL AND INSTALLATION ......14

FRONT SUSPENSION MEMBER .....................14

Exploded View ..................................................... ....14

Removal and Installation .........................................14

Inspection ................................................................15

UNIT DISASSEMBLY AND ASSEMBLY ....16

FRONT COIL SPRING AND STRUT ................16

Exploded View ..................................................... ....16

Disassembly and Assembly .....................................16

Inspection ................................................................19

Disposal ...................................................................19

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

20

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

20

Wheel Alignment (Unladen*1) ..................................20

Ball Joint .............................................................. ....20

Wheelarch Height (Unladen*) ..................................21

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1847 of 3641

FSU-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012430294

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

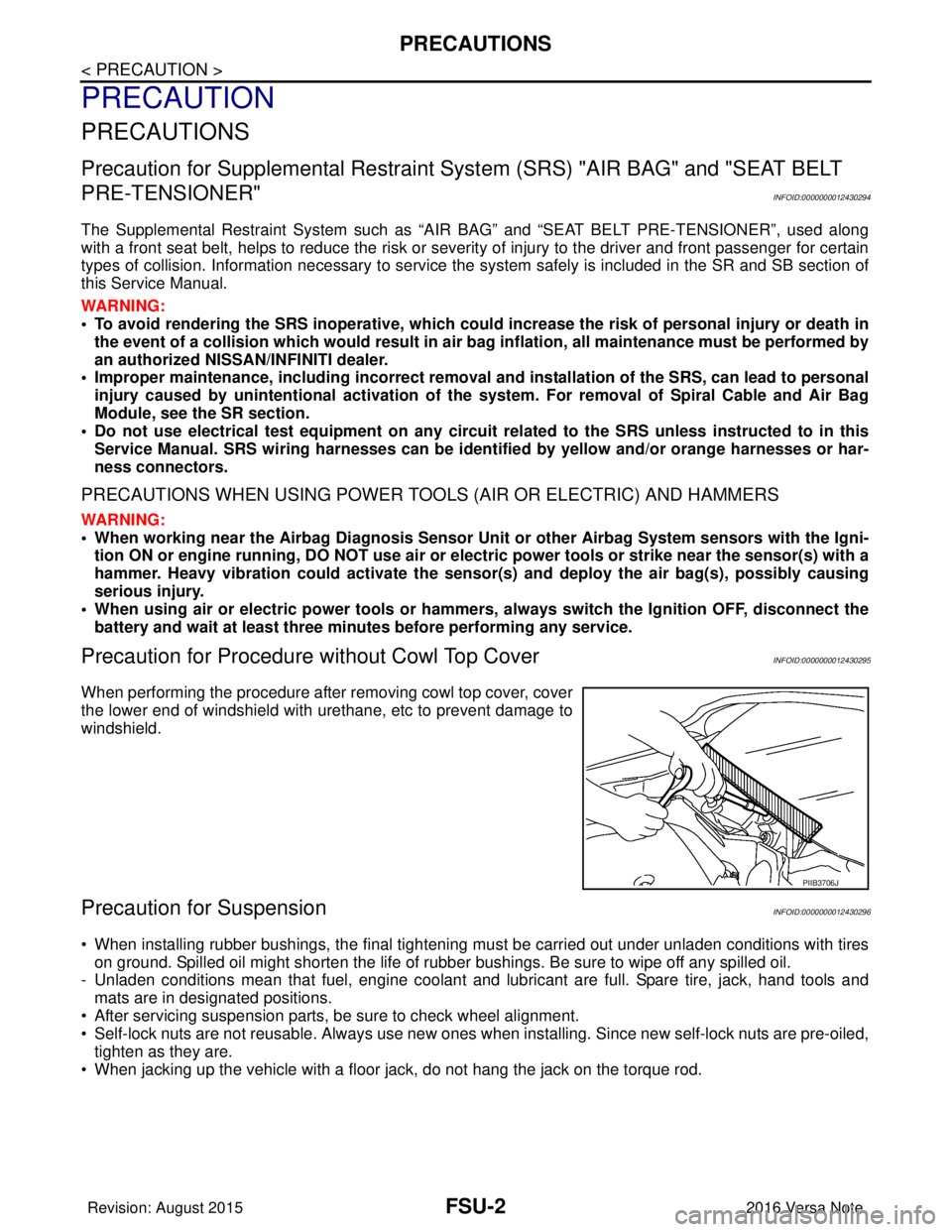

Precaution for Procedure without Cowl Top CoverINFOID:0000000012430295

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc to prevent damage to

windshield.

Precaution for SuspensionINFOID:0000000012430296

• When installing rubber bushings, the final tightening mu st be carried out under unladen conditions with tires

on ground. Spilled oil might shorten the life of rubber bushings. Be sure to wipe off any spilled oil.

- Unladen conditions mean that fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and mats are in designated positions.

• After servicing suspension parts, be sure to check wheel alignment.

• Self-lock nuts are not reusable. Always use new ones when installing. Since new self-lock nuts are pre-oiled,

tighten as they are.

• When jacking up the vehicle with a floor jack, do not hang the jack on the torque rod.

PIIB3706J

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1851 of 3641

FSU-6

< PERIODIC MAINTENANCE >

FRONT SUSPENSION ASSEMBLY

PERIODIC MAINTENANCE

FRONT SUSPENSION ASSEMBLY

InspectionINFOID:0000000012430300

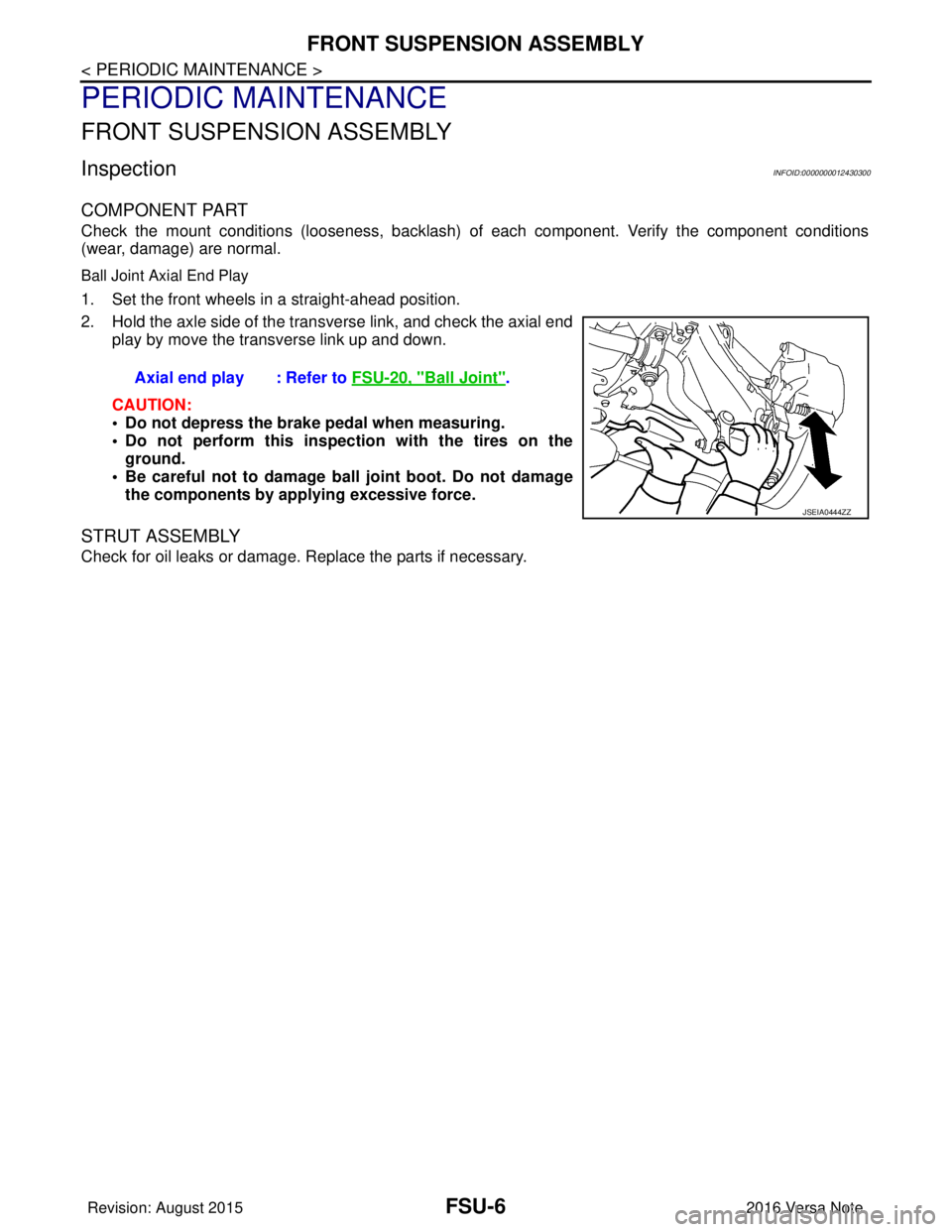

COMPONENT PART

Check the mount conditions (looseness, backlash) of each component. Verify the component conditions

(wear, damage) are normal.

Ball Joint Axial End Play

1. Set the front wheels in a straight-ahead position.

2. Hold the axle side of the tran sverse link, and check the axial end

play by move the transverse link up and down.

CAUTION:

• Do not depress the brake pedal when measuring.

• Do not perform this inspect ion with the tires on the

ground.

• Be careful not to damage ball joint boot. Do not damage the components by applying excessive force.

STRUT ASSEMBLY

Check for oil leaks or damage. Replace the parts if necessary.Axial end play : Refer to

FSU-20, "

Ball Joint".

JSEIA0444ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1852 of 3641

WHEEL ALIGNMENTFSU-7

< PERIODIC MAINTENANCE >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

WHEEL ALIGNMENT

InspectionINFOID:0000000012430301

PRELIMINARY INSPECTION

WARNING:

Always adjust the wheel alignment with the vehicle on a flat surface.

NOTE:

If the wheel alignment is out of s pecification, inspect and replace any damaged or worn rear suspension parts

before making any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, engine coolant, and lubricants are full; the spare tire, jack, hand tools and mats are in

designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for run out and damage. Refer to WT-54, "

Wheel".

4. Check the wheel bearing axial end play. Refer to FAX-27, "

Wheel Bearing".

5. Check the shock absorbers for leaks or damage.

6. Check each mount point of the suspension co mponents for any excessive looseness or damage.

7. Check each link, arm, and the suspension member for any damage.

8. Check the vehicle height. Refer to FSU-21, "

Wheelarch Height (Unladen*)".

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed.

• This type of alignment is recomm ended for any NISSAN/INFINITI vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be capabl e of accepting any NISSAN/INFINITI vehicle.

• The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated. • Your alignment machine should be regularly calibrated in order to give correct information.

• Check with the manufacturer of your specific a lignment machine for their recommended Service/Cali-

bration Schedule.

ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to FSU-20, "Wheel

Alignment (Unladen*1)".

• When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators.

- The alignment specifications programmed into your alignment machine that operate these indicators may

not be correct.

- This may result in an ERROR.

• Most camera-type alignment machines are equipped with "Rolling Compensation" method and optional

"Jacking Compensation" method to "compensate" the alignment targets or head units.

"Rolling Compensation" is the preferred method.

- If using the "Rolling Compensation" method, after inst alling the alignment targets or head units, push or pull

on the rear wheel to move the vehicle. Do not push or pull on the vehicle body.

- If using the "Jacking Compensation" method, after inst alling the alignment targets or head units, raise the

vehicle and rotate the wheels 1/2 turn in either direction.

NOTE:

Do not use the "Rolling Compensation" method if you are using sensor-type alignment equipment.

• Follow all instructions for the alignment machine you're using for more information.

CAMBER, CASTER AND KINGPIN INCLINATION ANGLES INSPECTION

• Camber, caster, kingpin inclination angles cannot be adjusted.

• Before inspection, set the front wheels onto a turning radius gauge. Set the rear wheels onto a pad that has

the same height so the vehicle will remain horizontal.

TOTAL TOE-IN INSPECTION

Measure the total toe-in using the following procedure.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1853 of 3641

FSU-8

< PERIODIC MAINTENANCE >

WHEEL ALIGNMENT

WARNING:

• Always perform the following procedure on a flat surface.

• Make sure that no person is in fr ont of vehicle before pushing it.

1. Bounce the front of vehicle up and down to stabilize the vehicle height (posture).

2. Push on the rear wheel to move the vehicle straight ahead about 5 m (16 ft).

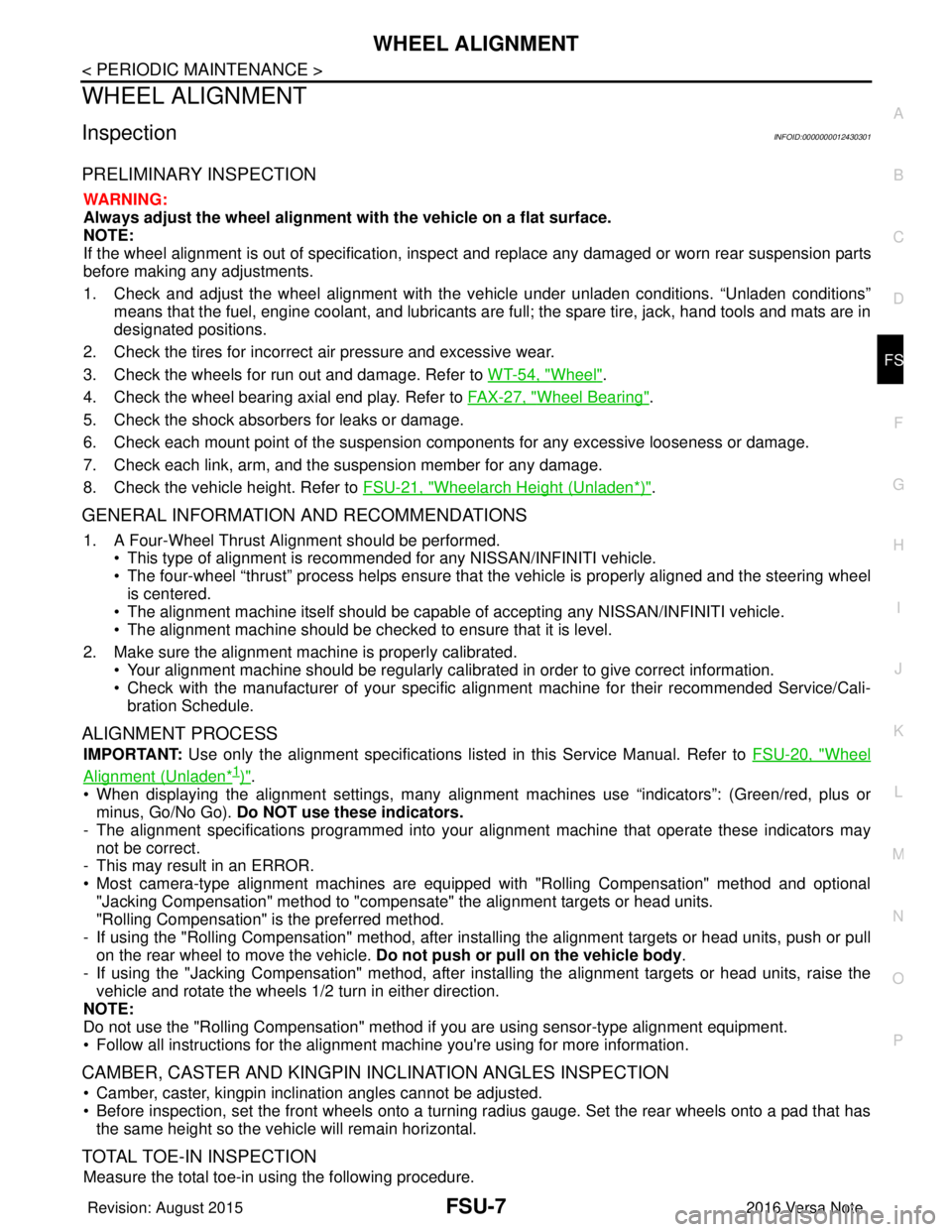

3. Put a mark on base line of the tread (rear side) of each tire at the same height of hub center. These are measuring points.

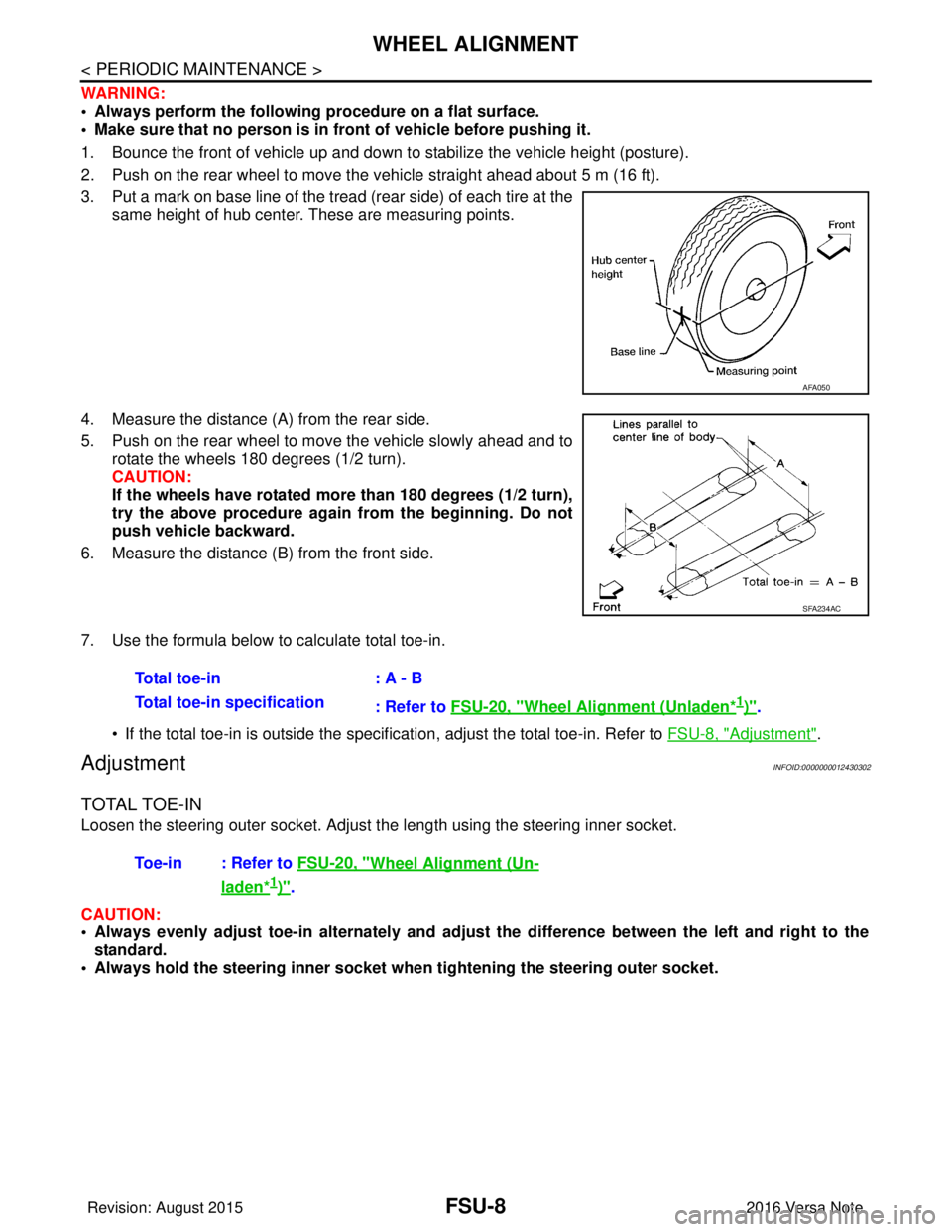

4. Measure the distance (A) from the rear side.

5. Push on the rear wheel to move the vehicle slowly ahead and to rotate the wheels 180 degrees (1/2 turn).

CAUTION:

If the wheels have rotated more than 180 degrees (1/2 turn),

try the above procedure again from the beginning. Do not

push vehicle backward.

6. Measure the distance (B) from the front side.

7. Use the formula below to calculate total toe-in.

• If the total toe-in is outside the specification, adjust the total toe-in. Refer to FSU-8, "

Adjustment".

AdjustmentINFOID:0000000012430302

TOTAL TOE-IN

Loosen the steering outer socket. Adjust the length using the steering inner socket.

CAUTION:

• Always evenly adjust toe-in alternately and adjust the difference be tween the left and right to the

standard.

• Always hold the steering inner socket wh en tightening the steering outer socket.

AFA050

SFA234AC

Total toe-in: A - B

Total toe-in specification : Refer to FSU-20, "

Wheel Alignment (Unladen*1)".

Toe-in : Refer to FSU-20, "

Wheel Alignment (Un-

laden*1)".

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1867 of 3641

FL-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION FL

A

FL

N

O P

CONTENTS

FUEL SYSTEM

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

General Precaution ...................................................2

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tools ........................................4

PERIODIC MAINTENANCE ..........................5

FUEL SYSTEM ............................................... .....5

Inspection ............................................................ ......5

Quick Connector .......................................................5

REMOVAL AND INSTALLATION ................6

FUEL LEVEL SENSOR UNIT, FUEL FILTER

AND FUEL PUMP ASSEMBLY ..................... .....

6

Exploded View .................................................... ......6

Removal and Installation ...........................................6

Inspection ............................................................ ......9

FUEL TANK ........................................................10

Exploded View .................................................... ....10

Removal and Installation .........................................10

Inspection ............................................................ ....13

EVAP CANISTER ..............................................14

Exploded View ..................................................... ....14

Removal and Installation .........................................14

Inspection ................................................................15

EVAP CANISTER FILTER ................................16

Exploded View .........................................................16

Removal and Installation .........................................16

EVAP CANISTER VENT CONTROL VALVE ...17

Exploded View .........................................................17

Removal and Installation .........................................17

EVAP CONTROL SYSTEM PRESSURE SEN-

SOR ...................................................................

19

Exploded View .........................................................19

Removal and Installation .........................................19

DISASSEMBLY AND ASSEMBLY ..............20

FUEL LEVEL SENSOR UNIT ...........................20

Exploded View ..................................................... ....20

Disassembly and Assembly .....................................20

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

22

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

22

Fuel Tank ............................................................. ....22

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1868 of 3641

FL-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432103

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

General PrecautionINFOID:0000000012432104

WARNING:

When replacing fuel line parts, be sure to observe the following.

• Put a “CAUTION: FLAMMABLE” sign in the work area.

• Be sure to work in a well ventilated area and have a CO

2 fire extinguisher.

• Do not smoke while working on the fuel system. Keep open flames and sparks away from the work

area.

CAUTION:

• Before removing fuel line parts, carry out the following procedures:

- Put drained fuel in an explosi on-proof container and put the lid on securely. Keep the container in

safe area.

- Release fuel pressure from the fuel lines. Refer to EC-1

37, "Work Procedure" .

- Disconnect the battery ground

cable.

• Always replace O-rings and clamps with new ones.

• Do not kink or twist tubes when they are being installed.

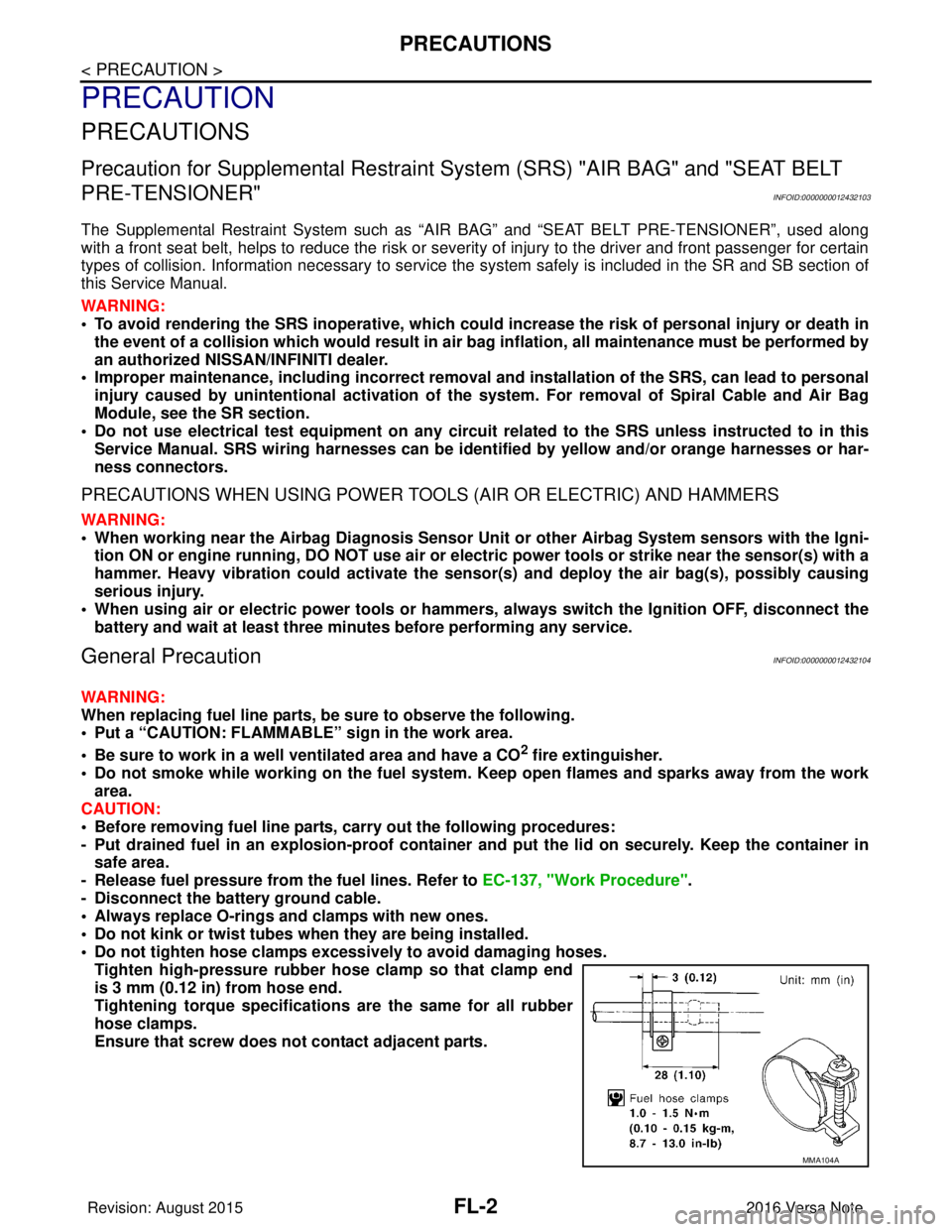

• Do not tighten hose clamps excessi vely to avoid damaging hoses.

Tighten high-pressure rubber hose clamp so that clamp end

is 3 mm (0.12 in) from hose end.

Tightening torque specificati ons are the same for all rubber

hose clamps.

Ensure that screw does not contact adjacent parts.

MMA104A

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1871 of 3641

FUEL SYSTEMFL-5

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M A

FL

NP

O

PERIODIC MAINTENANCE

FUEL SYSTEM

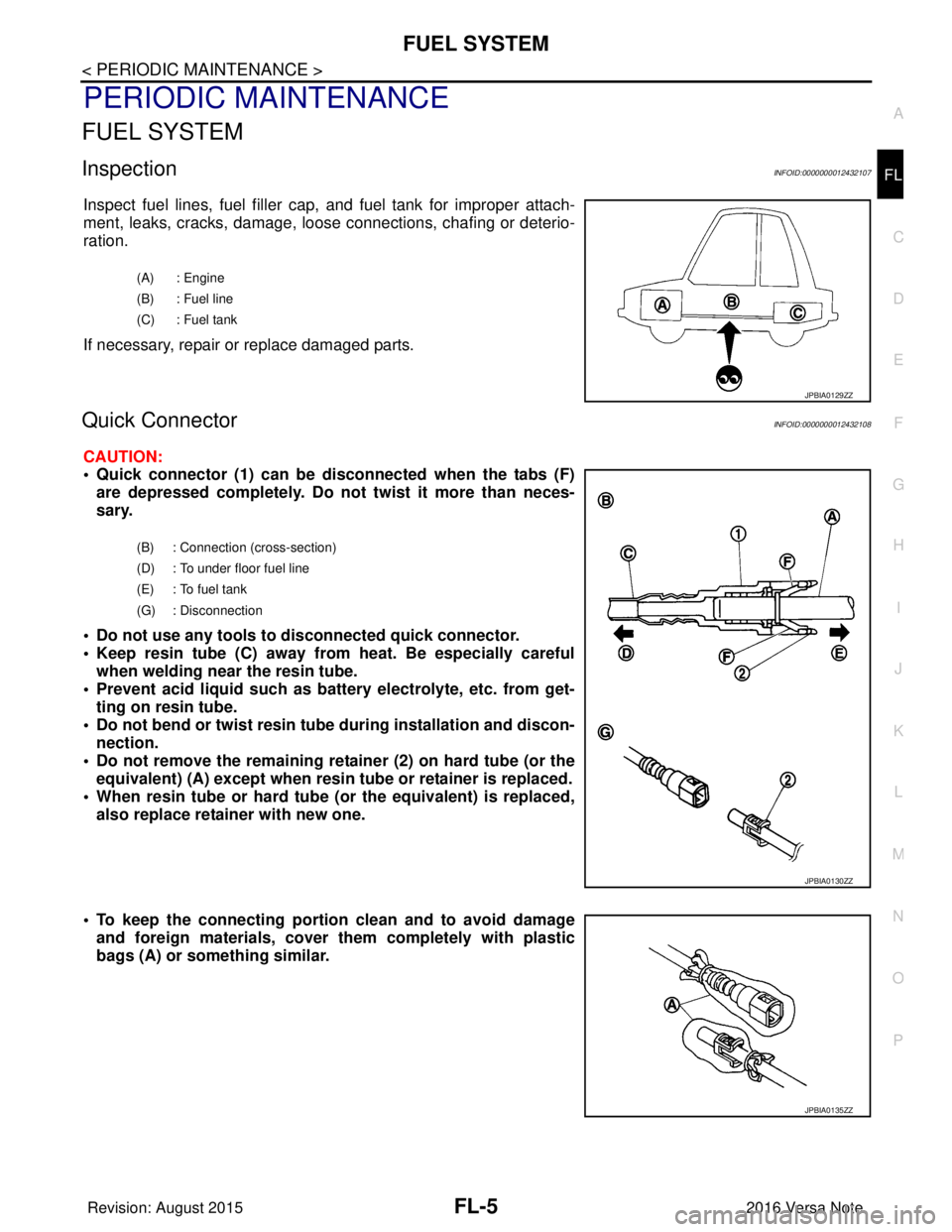

InspectionINFOID:0000000012432107

Inspect fuel lines, fuel filler cap,

and fuel tank for improper attach-

ment, leaks, cracks, damage, loos e connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

Quick ConnectorINFOID:0000000012432108

CAUTION:

• Quick connector (1) can be di sconnected when the tabs (F)

are depressed completely. Do not twist it more than neces-

sary.

• Do not use any tools to di sconnected quick connector.

• Keep resin tube (C) away from heat. Be especially careful when welding near the resin tube.

• Prevent acid liquid such as battery electrolyte, etc. from get- ting on resin tube.

• Do not bend or twist resin tube during installation and discon-

nection.

• Do not remove the remaining retainer (2) on hard tube (or the equivalent) (A) except when resin tu be or retainer is replaced.

• When resin tube or hard tube (or the equivalent) is replaced, also replace retainer with new one.

• To keep the connecting portion clean and to avoid damage and foreign materials, cover them completely with plastic

bags (A) or something similar.

(A) : Engine

(B) : Fuel line

(C) : Fuel tank

JPBIA0129ZZ

(B) : Connection (cross-section)

(D) : To under floor fuel line

(E) : To fuel tank

(G) : Disconnection

JPBIA0130ZZ

JPBIA0135ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1904 of 3641

GI-16

< HOW TO USE THIS MANUAL >

ABBREVIATIONS

I

K

L

M

N

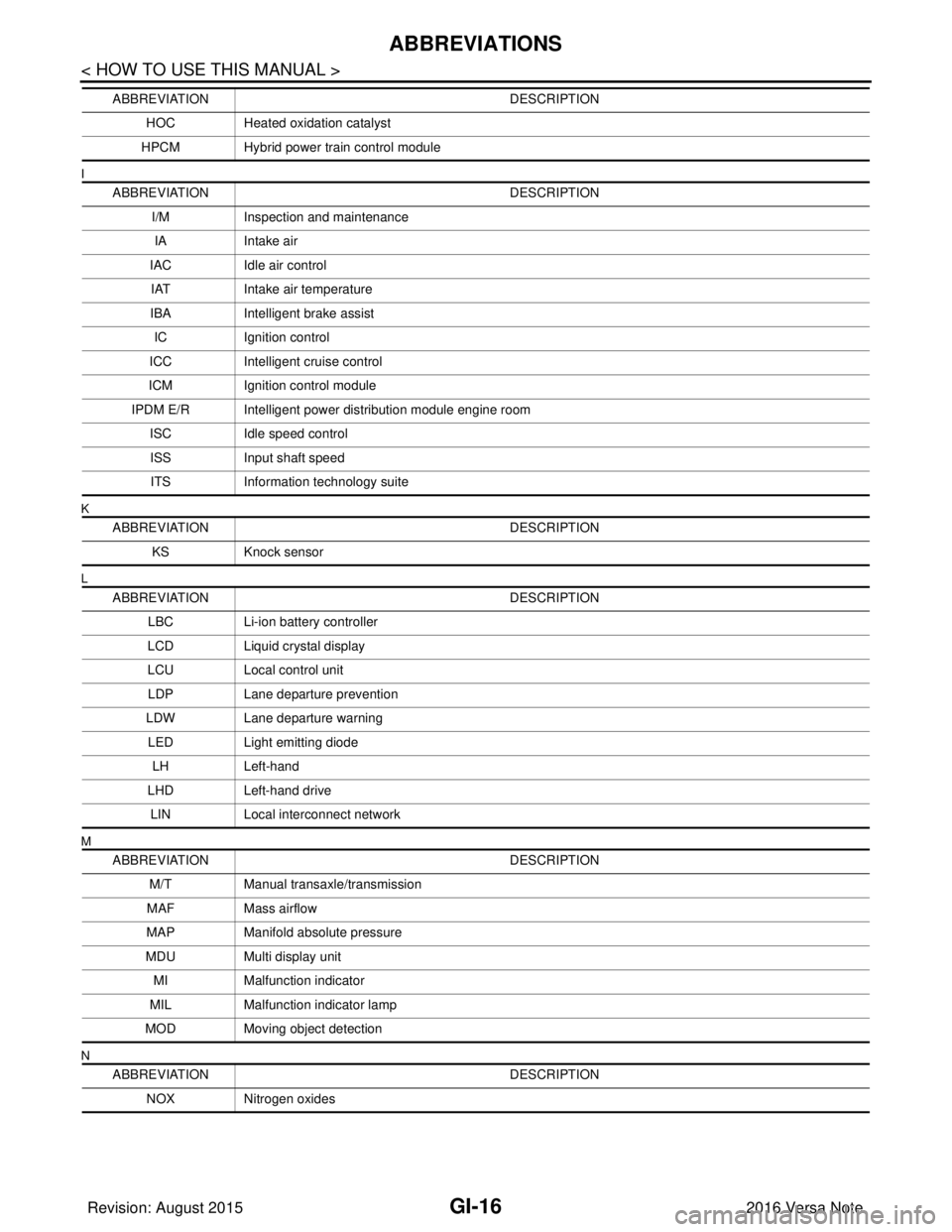

HOCHeated oxidation catalyst

HPCM Hybrid power train control module

ABBREVIATION DESCRIPTION

I/M Inspection and maintenance

IA Intake air

IAC Idle air control

IAT Intake air temperature

IBA Intelligent brake assist

IC Ignition control

ICC Intelligent cruise control

ICM Ignition control module

IPDM E/R Intelligent power distribution module engine room ISC Idle speed control

ISS Input shaft speed

ITS Information technology suite

ABBREVIATION DESCRIPTION

KS Knock sensor

ABBREVIATION DESCRIPTION

LBC Li-ion battery controller

LCD Liquid crystal display

LCU Local control unit

LDP Lane departure prevention

LDW Lane departure warning

LED Light emitting diode

LH Left-hand

LHD Left-hand drive

LIN Local interconnect network

ABBREVIATION DESCRIPTION

M/T Manual transaxle/transmission

MAF Mass airflow

MAP Manifold absolute pressure

MDU Multi display unit

MI Malfunction indicator

MIL Malfunction indicator lamp

MOD Moving object detection

ABBREVIATION DESCRIPTION

NOX Nitrogen oxides

ABBREVIATION

DESCRIPTION

Revision: August 2015 2016 Versa Note

cardiagn.com