relay NISSAN NOTE 2016 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1531 of 3641

![NISSAN NOTE 2016 Service Manual PDF EC-404

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P2100, P2103 THROTTLE

CONTROL MOTOR RELAY

7.DETECT MALFUNCTIONING PART

Check the following.

• IPDM E/R connector F42

• Harness for open or short between I NISSAN NOTE 2016 Service Manual PDF EC-404

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P2100, P2103 THROTTLE

CONTROL MOTOR RELAY

7.DETECT MALFUNCTIONING PART

Check the following.

• IPDM E/R connector F42

• Harness for open or short between I](/img/5/57363/w960_57363-1530.png)

EC-404

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P2100, P2103 THROTTLE

CONTROL MOTOR RELAY

7.DETECT MALFUNCTIONING PART

Check the following.

• IPDM E/R connector F42

• Harness for open or short between IPDM E/R and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

8.CHECK FUSE

1. Disconnect 15 A fuse (No. 52) from IPDM E/R.

2. Check 15 A fuse for blown.

Is the inspection result normal?

YES >> GO TO 9.

NO >> Replace 15 A fuse.

9.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "

Intermittent Incident".

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-30, "Removal and Installation".

NO >> Repair or replace harness or connectors.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1532 of 3641

![NISSAN NOTE 2016 Service Manual PDF P2101 ELECTRIC THROTTLE CONTROL FUNCTIONEC-405

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P2101 ELECTRIC THROTTLE CONTROL FUNCTION

DTC LogicINFOID:0000000012431615

DTC DETECTIO NISSAN NOTE 2016 Service Manual PDF P2101 ELECTRIC THROTTLE CONTROL FUNCTIONEC-405

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P2101 ELECTRIC THROTTLE CONTROL FUNCTION

DTC LogicINFOID:0000000012431615

DTC DETECTIO](/img/5/57363/w960_57363-1531.png)

P2101 ELECTRIC THROTTLE CONTROL FUNCTIONEC-405

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P2101 ELECTRIC THROTTLE CONTROL FUNCTION

DTC LogicINFOID:0000000012431615

DTC DETECTION LOGIC

NOTE:

•

If DTC P2101 is displayed with DT C P2100, first perform the trouble diagnosis for DTC P2100. Refer

to EC-402, "

DTC Logic".

• If DTC P2101 is displayed with DTC P2119, first pe rform the trouble diagnosis for DTC P2119. Refer

to EC-411, "

DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following before conduct-

ing the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11 V when

engine is running.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON and wait at least 2 seconds.

2. Start engine and let it idle for 5 seconds.

3. Check DTC.

Is DTC detected?

YES >> Go to EC-405, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000012431616

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E15. Refer to Ground Inspection in GI-44, "

Circuit Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace ground connection.

2.CHECK THROTTLE CONTROL MOTO R RELAY INPUT SIGNAL CIRCUIT

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector and ground.

DTC No. Trouble diagnosis content DTC detecting conditionPossible cause

P2101 Electric throttle control per-

formance Electric throttle control function does

not operate properly. • Harness or connectors

(Throttle control motor circuit is open or

shorted)

• Electric throttle control actuator

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1533 of 3641

![NISSAN NOTE 2016 Service Manual PDF EC-406

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P2101 ELECTRIC THROTTLE CONTROL FUNCTION

Is the inspection result normal?

YES >> GO TO 11.

NO >> GO TO 3.

3.CHECK THROTTLE CONTROL MOTOR

RELAY POWER SUPPLY CI NISSAN NOTE 2016 Service Manual PDF EC-406

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P2101 ELECTRIC THROTTLE CONTROL FUNCTION

Is the inspection result normal?

YES >> GO TO 11.

NO >> GO TO 3.

3.CHECK THROTTLE CONTROL MOTOR

RELAY POWER SUPPLY CI](/img/5/57363/w960_57363-1532.png)

EC-406

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P2101 ELECTRIC THROTTLE CONTROL FUNCTION

Is the inspection result normal?

YES >> GO TO 11.

NO >> GO TO 3.

3.CHECK THROTTLE CONTROL MOTOR

RELAY POWER SUPPLY CIRCUIT-I

1. Turn ignition switch OFF.

2. Check voltage between ECM harness connector and ground.

Is the inspection result normal?

YES >> GO TO 7.

NO >> GO TO 4.

4.CHECK THROTTLE CONTROL MOTOR RELAY POWER SUPPLY CIRCUIT-II

1. Disconnect ECM harness connector.

2. Disconnect IPDM E/R harness connector F42.

3. Check the continuity between ECM harnes s connector and IPDM E/R harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 6.

NO >> GO TO 5.

5.DETECT MALFUNCTIONING PART

Check the following.

• IPDM E/R connector F42

• Harness for open or short between IPDM E/R and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK FUSE

1. Disconnect 20 A fuse (No. 53) from IPDM E/R.

2. Check 20 A fuse for blown.

Is the inspection result normal?

YES >> GO TO 10.

NO >> Replace 20 A fuse.

7.CHECK THROTTLE CONTROL MOTOR RELAY POWER SUPPLY CIRCUIT-III

1. Disconnect ECM harness connector.

2. Disconnect IPDM E/R harness connector F42.

3. Check the continuity between ECM harnes s connector and IPDM E/R harness connector.

ECM

ConditionVoltage

+ −

Connector Terminal Connector Terminal

F10 2 E16 108 Ignition switch OFF Approx. 0 V

Ignition switch ON Battery voltage

ECM

Voltag e

+ −

Connector Terminal Connector Terminal F10 15 E16 108 Battery voltage

IPDM E/R ECM

Continuity

Connector Terminal Connector Terminal

F423 2F 101 5Exis te d

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1568 of 3641

![NISSAN NOTE 2016 Service Manual PDF COOLING FANEC-441

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

COOLING FAN

Component Function CheckINFOID:0000000012431641

1.CHECK COOLING FAN FUNCTION

With CONSULT

1. Turn ignit NISSAN NOTE 2016 Service Manual PDF COOLING FANEC-441

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

COOLING FAN

Component Function CheckINFOID:0000000012431641

1.CHECK COOLING FAN FUNCTION

With CONSULT

1. Turn ignit](/img/5/57363/w960_57363-1567.png)

COOLING FANEC-441

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

COOLING FAN

Component Function CheckINFOID:0000000012431641

1.CHECK COOLING FAN FUNCTION

With CONSULT

1. Turn ignition switch ON.

2. Perform “COOLING FAN” in “A CTIVE TEST” mode with CONSULT.

3. Touch “LOW” and “Hi” on the CONSULT screen.

4. Check that cooling fan operates.

NOTE:

The cooling fan operates at high speeds even when “LOW” is selected in CONSULT “ACTIVE TEST”. (For sin-

gle connector cooling fan with M/T models)

Without CONSULT

1. Perform IPDM E/R auto active test and check cooling fan motor operation. Refer to PCS-9, "

Diagnosis

Description".

2. Check that cooling fan operates.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Refer to EC-441, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000012431642

1.CHECK COOLING FAN MOTOR CIRCUIT

1. Disconnect cooling fan motor harness connector.

2. Check the continuity between IPDM E/R harne ss connector and cooling fan motor harness connector.

CVT models

M/T models

3. Check the continuity between cooling fan relay harness connector and cooling fan motor harness connec-

tor.

CVT models

M/T models

4. Check the continuity between cooling fan motor harness connector and ground.

IPDM E/R Cooling fan motor

Continuity

Connector Terminal Connector Terminal

E43 7E

51

Existed

5E 323

IPDM E/R Cooling fan motor

Continuity

Connector Terminal Connector Terminal

E43 7

E31 2

Existed

51

Cooling fan relay Cooling fan motor

Continuity

Connector Terminal Connector Terminal

E62 5E32 4 Existed

Cooling fan relay Cooling fan motor

Continuity

Connector Terminal Connector Terminal

E62 5E31 4 Existed

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1569 of 3641

![NISSAN NOTE 2016 Service Manual PDF EC-442

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

COOLING FAN

CVT models

M/T models

5. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair o NISSAN NOTE 2016 Service Manual PDF EC-442

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

COOLING FAN

CVT models

M/T models

5. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair o](/img/5/57363/w960_57363-1568.png)

EC-442

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

COOLING FAN

CVT models

M/T models

5. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

2.CHECK COOLING FAN RELAY CIRCUIT

1. Disconnect cooling fan relay harness connector.

2. Disconnect IPDM E/R harness connector.

3. Check the continuity between IPDM E/R harnes s connector and cooling fan relay harness connector.

4. Check the continuity between cooling fan relay harness connector and ground.

5. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

3.CHECK COOLING FAN RELAY

Refer to EC-443, "

Component Inspection (Cooling Fan Relay)".

YES or NO

YES >> GO TO 4.

NO >> Replace cooling fan relay.

4.CHECK COOLING FAN MOTOR

Refer to EC-443, "

Component Inspection (Cooling Fan Motor)".

YES or NO

YES >> GO TO 5.

NO >> Replace cooling fan motor. Refer to CO-16, "

Exploded View".

5.CHECK INTERMITTENT INCIDENT

Perform GI-42, "

Intermittent Incident".

YES or NO

YES >> Replace IPDM E/R. Refer to PCS-30, "Removal and Installation".

NO >> Repair or replace harness or connector.

Cooling fan motor Ground Continuity

Connector Terminal

E5 2Ground Existed

Cooling fan motor Ground Continuity

Connector Terminal

E31 3Ground Existed

IPDM E/R Cooling fan relay

Continuity

Connector Terminal Connector Terminal

E46 65

E62 1

Existed

59 2

Cooling fan relay Ground Continuity

Connector Terminal

E62 3Ground Existed

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1570 of 3641

![NISSAN NOTE 2016 Service Manual PDF COOLING FANEC-443

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Component Inspection (Cooling Fan Motor)INFOID:0000000012431643

1.CHECK COOLING FAN MOTOR

1. Turn ignition switch O NISSAN NOTE 2016 Service Manual PDF COOLING FANEC-443

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Component Inspection (Cooling Fan Motor)INFOID:0000000012431643

1.CHECK COOLING FAN MOTOR

1. Turn ignition switch O](/img/5/57363/w960_57363-1569.png)

COOLING FANEC-443

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Component Inspection (Cooling Fan Motor)INFOID:0000000012431643

1.CHECK COOLING FAN MOTOR

1. Turn ignition switch OFF.

2. Disconnect cooling fan motor harness connector.

3. Supply cooling fan motor terminals with battery voltage and check operation.

CVT models

M/T models

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace cooling fan motor. Refer to CO-16, "

Exploded View".

Component Inspection (Cooling Fan Relay)INFOID:0000000012431644

1.CHECK COOLING FAN RELAY

1. Turn ignition switch OFF.

2. Remove cooling fan relay.

3. Check continuity between cooling fan relay terminals under the following conditions.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace cooling fan relay.

Cooling fan motor Operation

Connector +

−

terminals

E5 1 2 Cooling fan motor operates

E32 3 4

Cooling fan motor Operation

Connector +

−

terminals

E31 23

Cooling fan motor operates

14

Cooling fan relay ConditionsContinuity

terminals

35 12 V direct current supply between

terminals 1 and 2

Existed

No current supply Not existed

JSBIA0671ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1586 of 3641

![NISSAN NOTE 2016 Service Manual PDF ON BOARD REFUELING VAPOR RECOVERY (ORVR)EC-459

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Check recirculation line for clogging, dents and cracks.

Is the inspection result nor NISSAN NOTE 2016 Service Manual PDF ON BOARD REFUELING VAPOR RECOVERY (ORVR)EC-459

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Check recirculation line for clogging, dents and cracks.

Is the inspection result nor](/img/5/57363/w960_57363-1585.png)

ON BOARD REFUELING VAPOR RECOVERY (ORVR)EC-459

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Check recirculation line for clogging, dents and cracks.

Is the inspection result normal?

YES >> GO TO 15.

NO >> Replace fuel filler tube.

15.CHECK REFUELING EVAP VAPOR CUT VALVE

Refer to EC-459, "

Component Inspection (Refueling EVAP vapor cut valve)".

Is the inspection result normal?

YES >> GO TO 16.

NO >> Replace refueling EVAP vapor cut valve with fuel tank.

16.CHECK FUEL FILLER TUBE

Check fuel filler tube and hose connected to the fuel tank for clogging, dents and cracks.

Is the inspection result normal?

YES >> GO TO 17.

NO >> Replace fuel filler tube.

17.CHECK ONE-WAY FUEL VALVE-I

Check one-way valve for clogging.

Is the inspection result normal?

YES >> GO TO 18.

NO >> Repair or replace one-way fuel valve with fuel tank.

18.CHECK ONE-WAY FUEL VALVE-II

1. Make sure that fuel is drained from the tank.

2. Remove fuel filler tube and hose.

3. Check one-way fuel valve for operation as per the following. When a stick is inserted, the valve should open, when removing

stick it should close.

Do not drop any material into the tank.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace fuel filler tube or replace one-way fuel valve with fuel tank.

Component Inspection (Refuel ing EVAP vapor cut valve)INFOID:0000000012431662

1.INSPECTION START

Do you have CONSULT?

Do you have CONSULT?

YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK REFUELING EVAP VAPOR CUT VALVE

With CONSULT

1. Remove fuel tank. Refer to FL-10, "

Removal and Installation".

2. Drain fuel from the tank as per the following:

- Remove fuel feed hose located on the fuel gauge retainer.

- Connect a spare fuel hose, one side to fuel gauge retainer where the hose was removed and the other side to a fuel container.

- Drain fuel using “FUEL PUMP RELAY” in “ACTIVE TEST” mode of “ENGINE” using CONSULT.

3. Check refueling EVAP vapor cut valve for being stuck to close as per the following. Blow air into the refueling EVAP vapor cut valv e (from the end of EVAP/ORVR line hose), and check that

the air flows freely into the tank.

4. Check refueling EVAP vapor cut valve for being stuck to open as per the following.

SEF665U

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1658 of 3641

EXL-6

< SYSTEM DESCRIPTION >

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

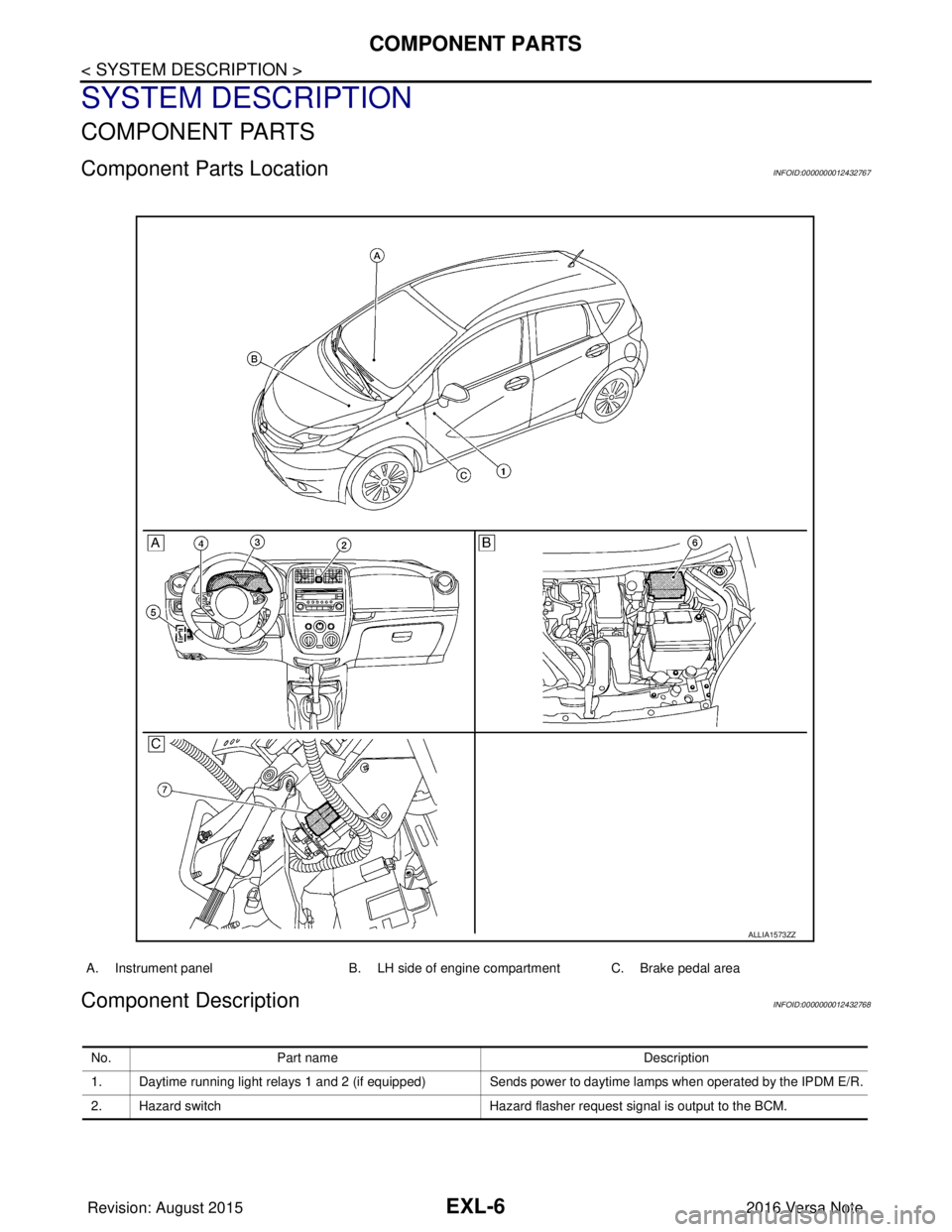

Component Parts LocationINFOID:0000000012432767

Component DescriptionINFOID:0000000012432768

A. Instrument panelB. LH side of engine compartment C. Brake pedal area

ALLIA1573ZZ

No.Part name Description

1. Daytime running light relays 1 and 2 (if equipped) Sends power to daytime lamps when operated by the IPDM E/R.

2. Hazard switch Hazard flasher request signal is output to the BCM.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1659 of 3641

COMPONENT PARTSEXL-7

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

3. Combination meter • Blinks the turn signal indicator lamp and outputs the turn signal

operating sound with integrated buzzer according to the re-

quest from BCM (via CAN communication).

• Turns the tail lamp indicator lamp and high beam indicator lamp ON according to the request from BCM (via CAN commu-

nication).

4. Combination switch (lighting and turn signal switch) Refer to BCS-9, "

COMBINATION SWITCH READING SYSTEM

: System Description" (with Intelligent Key system) or

BCS-79,

"COMBINATION SWITCH READING SYSTEM : System De-

scription" (without Intelligent Key system).

5. BCM Controls the exterior lighting system.

6. IPDM E/R Controls the integrated relay, and supplies voltage to the load ac-

cording to the request from BCM (via CAN communication).

7. Stop lamp switch Stop lamp signal is output to the rear combination lamps and

high-mounted stop lamp.

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1660 of 3641

EXL-8

< SYSTEM DESCRIPTION >

SYSTEM

SYSTEM

HEADLAMP SYSTEM

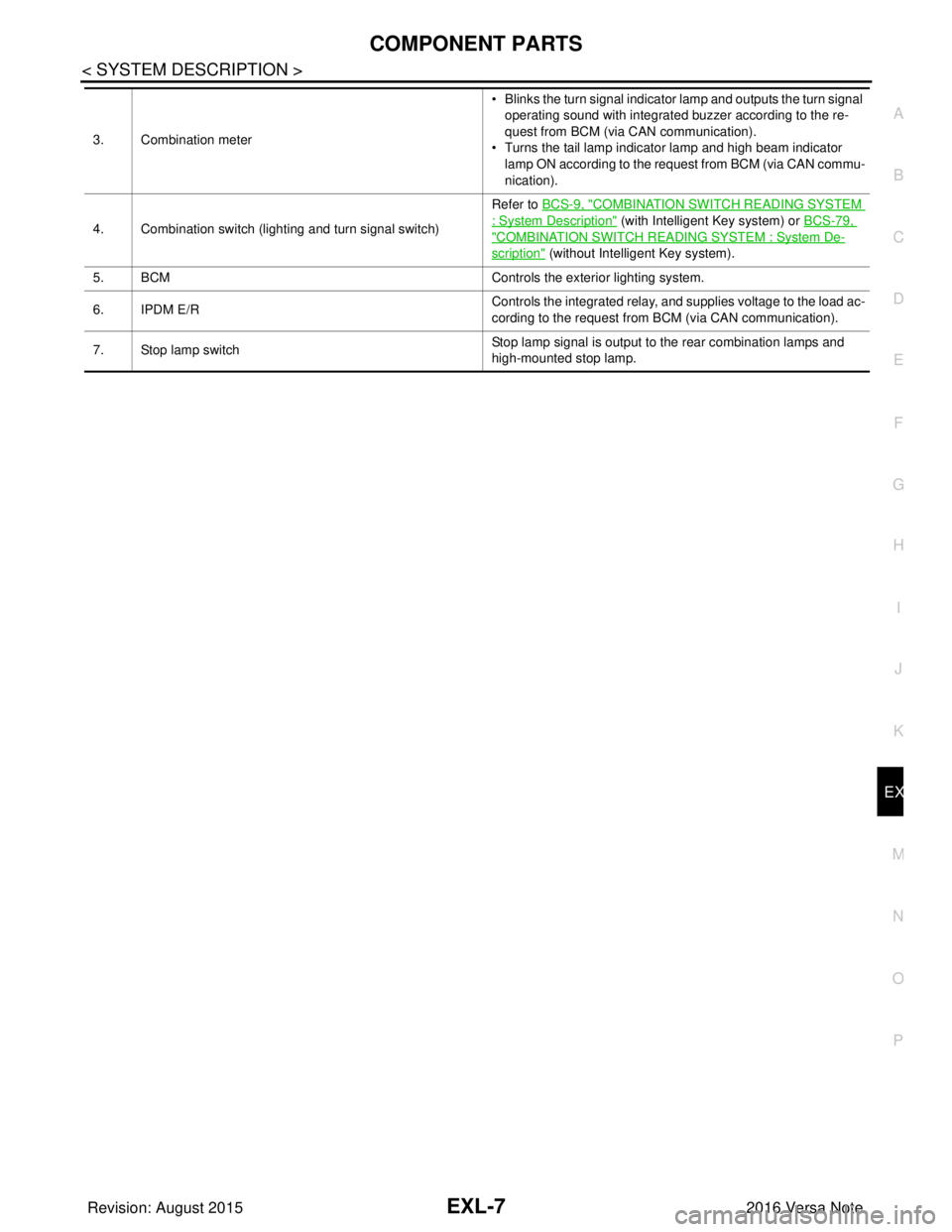

HEADLAMP SYSTEM : System Diagram INFOID:0000000012432769

System Diagram - For USA

System Diagram - For Canada

HEADLAMP SYSTEM : System DescriptionINFOID:0000000012432770

LOW BEAM OPERATION

When the lighting switch is in 2nd position, the BCM receives input requesting the headlamps to illuminate.

This input is communicated to the IPDM E/R across the CAN communication lines. The CPU of the IPDM E/R

controls the headlamp low relay coil which supplies power to the low beam headlamps.

HIGH BEAM OPERATION/FLASH-TO-PASS OPERATION

With the lighting switch in the 2nd position and placed in HIGH position, the BCM receives input requesting the

headlamp high beams to illuminate. The flash to pass f eature can be used any time and also sends a signal to

the BCM. This input is communicated to the IPDM E/R across the CAN communication lines. The CPU of the

combination meter controls the ON/OFF status off the HIGH BEAM indicator. The CPU of the IPDM E/R con-

trols the headlamp high relay coil which supplies power to the high beam headlamps.

The combination meter receives a high beam request signal (ON) through the CAN communication lines and

turns the high beam indicator lamp ON.

EXTERIOR LAMP BATTERY SAVER CONTROL

With the combination switch (lighting and turn signal switch) in the 2nd position and the ignition switch is

turned from ON or ACC to OFF, the battery saver feature is activated.

ALLIA1579GB

ALLIA1580GB

Revision: August 2015 2016 Versa Note

cardiagn.com