relay NISSAN NOTE 2016 Service Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1661 of 3641

SYSTEMEXL-9

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

Under this condition, the headlamps remain illuminated for 45 seconds unless the lighting switch position is

changed. If the lighting switch position is changed, then the headlamps are turned off.

This setting can be changed by CONSULT. Refer to BCS-20, "

HEADLAMP : CONSULT Function (BCM -

HEAD LAMP)" (with Intelligent Key system) or BCS-93, "HEADLAMP : CONSULT Function (BCM - HEAD

LAMP)" (without Intelligent Key system).

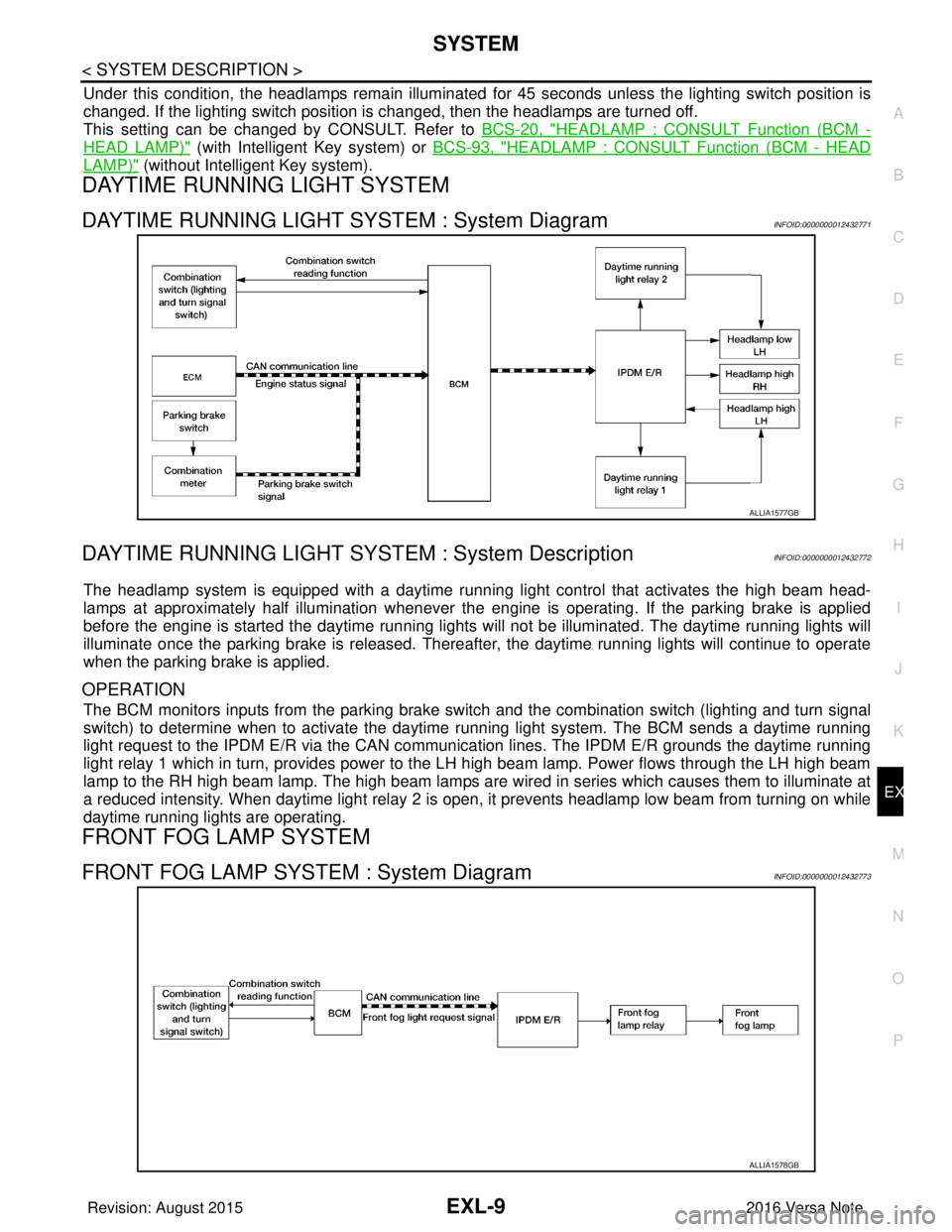

DAYTIME RUNNING LIGHT SYSTEM

DAYTIME RUNNING LIGHT SYSTEM : System DiagramINFOID:0000000012432771

DAYTIME RUNNING LIGHT SYST EM : System DescriptionINFOID:0000000012432772

The headlamp system is equipped with a daytime running light control that activates the high beam head-

lamps at approximately half illumination whenever the e ngine is operating. If the parking brake is applied

before the engine is started the daytime running lights will not be illuminated. The daytime running lights will

illuminate once the parking brake is released. Thereaf ter, the daytime running lights will continue to operate

when the parking brake is applied.

OPERATION

The BCM monitors inputs from the parking brake swit ch and the combination switch (lighting and turn signal

switch) to determine when to activate the daytime running light system. The BCM sends a daytime running

light request to the IPDM E/R via the CAN communication lines. The IPDM E/R grounds the daytime running

light relay 1 which in turn, provides power to the LH high beam lamp. Power flows through the LH high beam

lamp to the RH high beam lamp. The high beam lamps are wired in series which causes them to illuminate at

a reduced intensity. When daytime light relay 2 is open, it prevents headlamp low beam from turning on while

daytime running lights are operating.

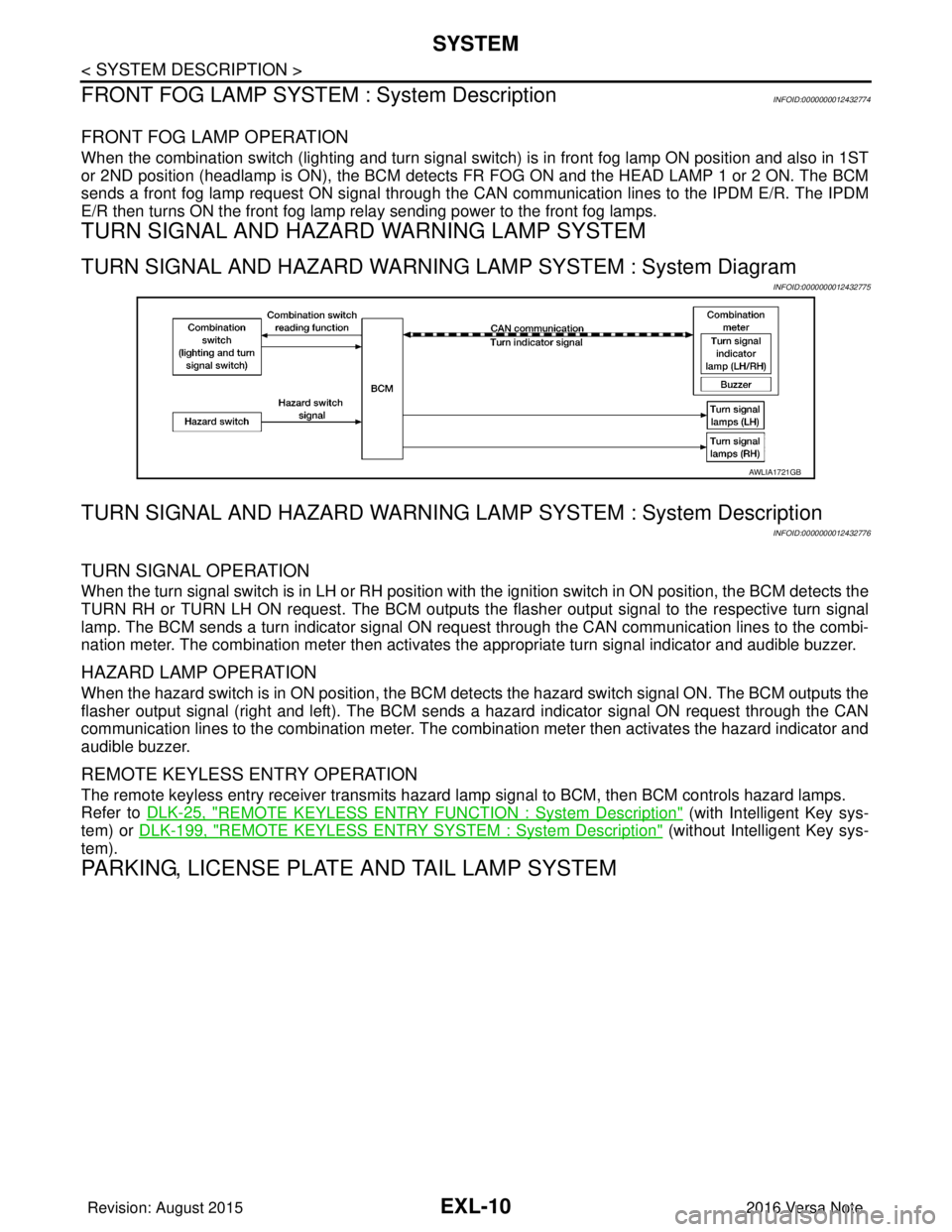

FRONT FOG LAMP SYSTEM

FRONT FOG LAMP SYSTEM : System DiagramINFOID:0000000012432773

ALLIA1577GB

ALLIA1578GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1662 of 3641

EXL-10

< SYSTEM DESCRIPTION >

SYSTEM

FRONT FOG LAMP SYSTEM : System Description

INFOID:0000000012432774

FRONT FOG LAMP OPERATION

When the combination switch (lighting and turn signal switch) is in front fog lamp ON position and also in 1ST

or 2ND position (headlamp is ON), the BCM detects FR FOG ON and the HEAD LAMP 1 or 2 ON. The BCM

sends a front fog lamp request ON signal through the CAN communication lines to the IPDM E/R. The IPDM

E/R then turns ON the front fog lamp relay sending power to the front fog lamps.

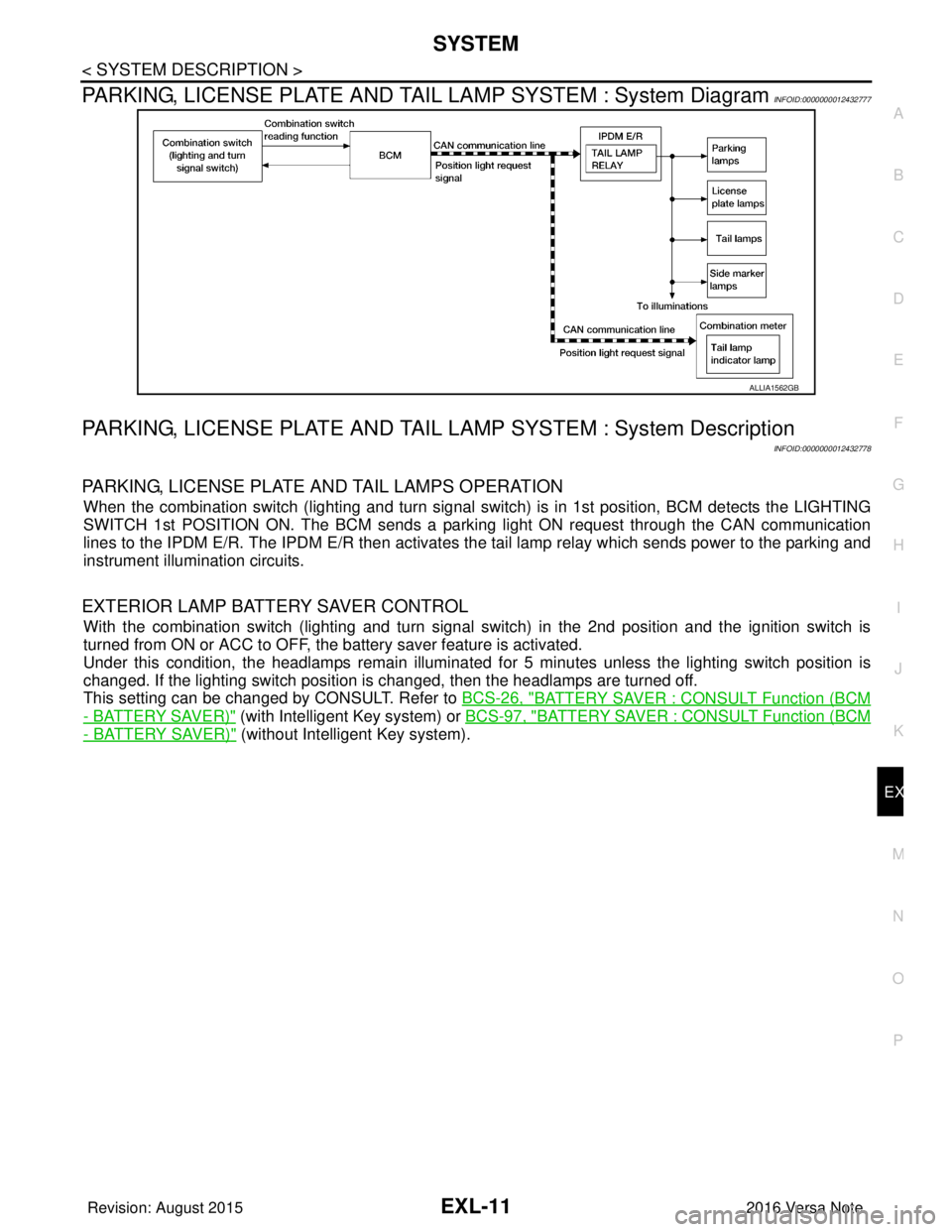

TURN SIGNAL AND HAZARD WARNING LAMP SYSTEM

TURN SIGNAL AND HAZARD WARNING LAMP SYSTEM : System Diagram

INFOID:0000000012432775

TURN SIGNAL AND HAZARD WARNING LA MP SYSTEM : System Description

INFOID:0000000012432776

TURN SIGNAL OPERATION

When the turn signal switch is in LH or RH position with the ignition switch in ON position, the BCM detects the

TURN RH or TURN LH ON request. The BCM outputs the flasher output signal to the respective turn signal

lamp. The BCM sends a turn indicator signal ON request through the CAN communication lines to the combi-

nation meter. The combination meter then activates the appropriate turn signal indicator and audible buzzer.

HAZARD LAMP OPERATION

When the hazard switch is in ON position, the BCM det ects the hazard switch signal ON. The BCM outputs the

flasher output signal (right and left). The BCM sends a hazard indicator signal ON request through the CAN

communication lines to the combination meter. The combination meter then activates the hazard indicator and

audible buzzer.

REMOTE KEYLESS ENTRY OPERATION

The remote keyless entry receiver transmits hazard lamp signal to BCM, then BCM controls hazard lamps.

Refer to DLK-25, "

REMOTE KEYLESS ENTRY FUNCTION : System Description" (with Intelligent Key sys-

tem) or DLK-199, "

REMOTE KEYLESS ENTRY SYSTEM : System Description" (without Intelligent Key sys-

tem).

PARKING, LICENSE PLATE AND TAIL LAMP SYSTEM

AWLIA1721GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1663 of 3641

SYSTEMEXL-11

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

PARKING, LICENSE PLATE AND TAIL LAMP SYSTEM : System DiagramINFOID:0000000012432777

PARKING, LICENSE PLATE AND TAIL LA MP SYSTEM : System Description

INFOID:0000000012432778

PARKING, LICENSE PLATE AND TAIL LAMPS OPERATION

When the combination switch (lighting and turn signal s witch) is in 1st position, BCM detects the LIGHTING

SWITCH 1st POSITION ON. The BCM sends a parking light ON request through the CAN communication

lines to the IPDM E/R. The IPDM E/R then activates the tail lamp relay which sends power to the parking and

instrument illumination circuits.

EXTERIOR LAMP BATTERY SAVER CONTROL

With the combination switch (lighting and turn signal switch) in the 2nd position and the ignition switch is

turned from ON or ACC to OFF, the battery saver feature is activated.

Under this condition, the headlamps remain illuminated for 5 minutes unless the lighting switch position is

changed. If the lighting switch position is changed, then the headlamps are turned off.

This setting can be changed by CONSULT. Refer to BCS-26, "

BATTERY SAVER : CONSULT Function (BCM

- BATTERY SAVER)" (with Intelligent Key system) or BCS-97, "BATTERY SAVER : CONSULT Function (BCM

- BATTERY SAVER)" (without Intelligent Key system).

ALLIA1562GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1674 of 3641

EXL-22

< SYSTEM DESCRIPTION >

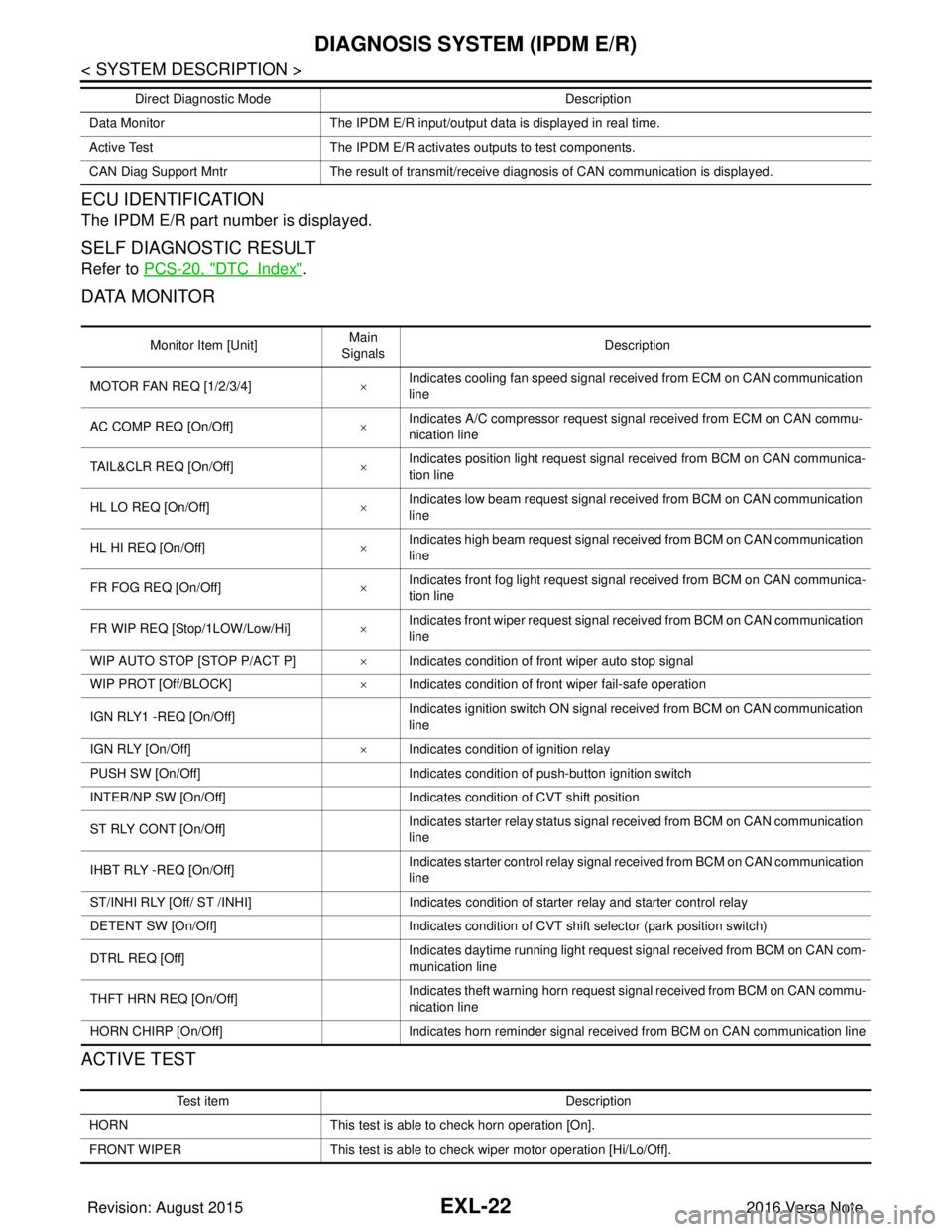

DIAGNOSIS SYSTEM (IPDM E/R)

ECU IDENTIFICATION

The IPDM E/R part number is displayed.

SELF DIAGNOSTIC RESULT

Refer to PCS-20, "DTCIndex".

DATA MONITOR

ACTIVE TEST

Data Monitor The IPDM E/R input/output data is displayed in real time.

Active Test The IPDM E/R activates outputs to test components.

CAN Diag Support Mntr The result of transmit/receive diagnosis of CAN communication is displayed.

Direct Diagnostic Mode

Description

Monitor Item [Unit]Main

Signals Description

MOTOR FAN REQ [1/2/3/4] ×Indicates cooling fan speed signal received from ECM on CAN communication

line

AC COMP REQ [On/Off] ×Indicates A/C compressor request signal received from ECM on CAN commu-

nication line

TAIL&CLR REQ [On/Off] ×Indicates position light request signal received from BCM on CAN communica-

tion line

HL LO REQ [On/Off] ×Indicates low beam request signal received from BCM on CAN communication

line

HL HI REQ [On/Off] ×Indicates high beam request signal received from BCM on CAN communication

line

FR FOG REQ [On/Off] ×Indicates front fog light request signal received from BCM on CAN communica-

tion line

FR WIP REQ [Stop/1LOW/Low/Hi] ×Indicates front wiper request signal received from BCM on CAN communication

line

WIP AUTO STOP [STOP P/ACT P] ×Indicates condition of front wiper auto stop signal

WIP PROT [Off/BLOCK] ×Indicates condition of front wiper fail-safe operation

IGN RLY1 -REQ [On/Off] Indicates ignition switch ON signal received from BCM on CAN communication

line

IGN RLY [On/Off] ×Indicates condition of ignition relay

PUSH SW [On/Off] Indicates condition of push-button ignition switch

INTER/NP SW [On/Off] Indicates condition of CVT shift position

ST RLY CONT [On/Off] Indicates starter relay status signal received from BCM on CAN communication

line

IHBT RLY -REQ [On/Off] Indicates starter control relay signal received from BCM on CAN communication

line

ST/INHI RLY [Off/ ST /INHI] Indicates condition of starter relay and starter control relay

DETENT SW [On/Off] Indicates condition of CVT shift selector (park position switch)

DTRL REQ [Off] Indicates daytime running light request signal received from BCM on CAN com-

munication line

THFT HRN REQ [On/Off] Indicates theft warning horn request signal received from BCM on CAN commu-

nication line

HORN CHIRP [On/Off] Indicates horn reminder signal received from BCM on CAN communication line

Te s t i t e m D e s c r i p t i o n

HORN This test is able to check horn operation [On].

FRONT WIPER This test is able to check wiper motor operation [Hi/Lo/Off].

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1729 of 3641

HEADLAMP (HI) CIRCUITEXL-77

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

HEADLAMP (HI) CIRCUIT

DescriptionINFOID:0000000012432804

The IPDM E/R (intelligent power distribution modul e engine room) controls the headlamp high relay based on

inputs from the BCM via the CAN communication lines. When the headlamp high relay is energized, power

flows through fuses 34 and 35, located in the IPDM E/R. Power then flows to the front combination lamp LH

and RH high beams.

Component Function CheckINFOID:0000000012432805

1.CHECK HEADLAMP (HI) OPERATION

WITHOUT CONSULT

1. Start IPDM E/R auto active test. Refer to PCS-9, "

Diagnosis Description".

2. Check that the headlamp switches to the high beam.

CONSULT

1. Select EXTERNAL LAMPS of IP DM E/R active test item.

2. While operating the test items, check that the headlamp switches to the high beam.

Does the headlamp switch to high beam?

YES >> Headlamp (HI) circuit is normal.

NO >> Refer to EXL-77, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000012432806

Regarding Wiring Diagram information, refer to EXL-25, "Wiring Diagram - For USA" or EXL-31, "Wiring Dia-

gram - For Canada".

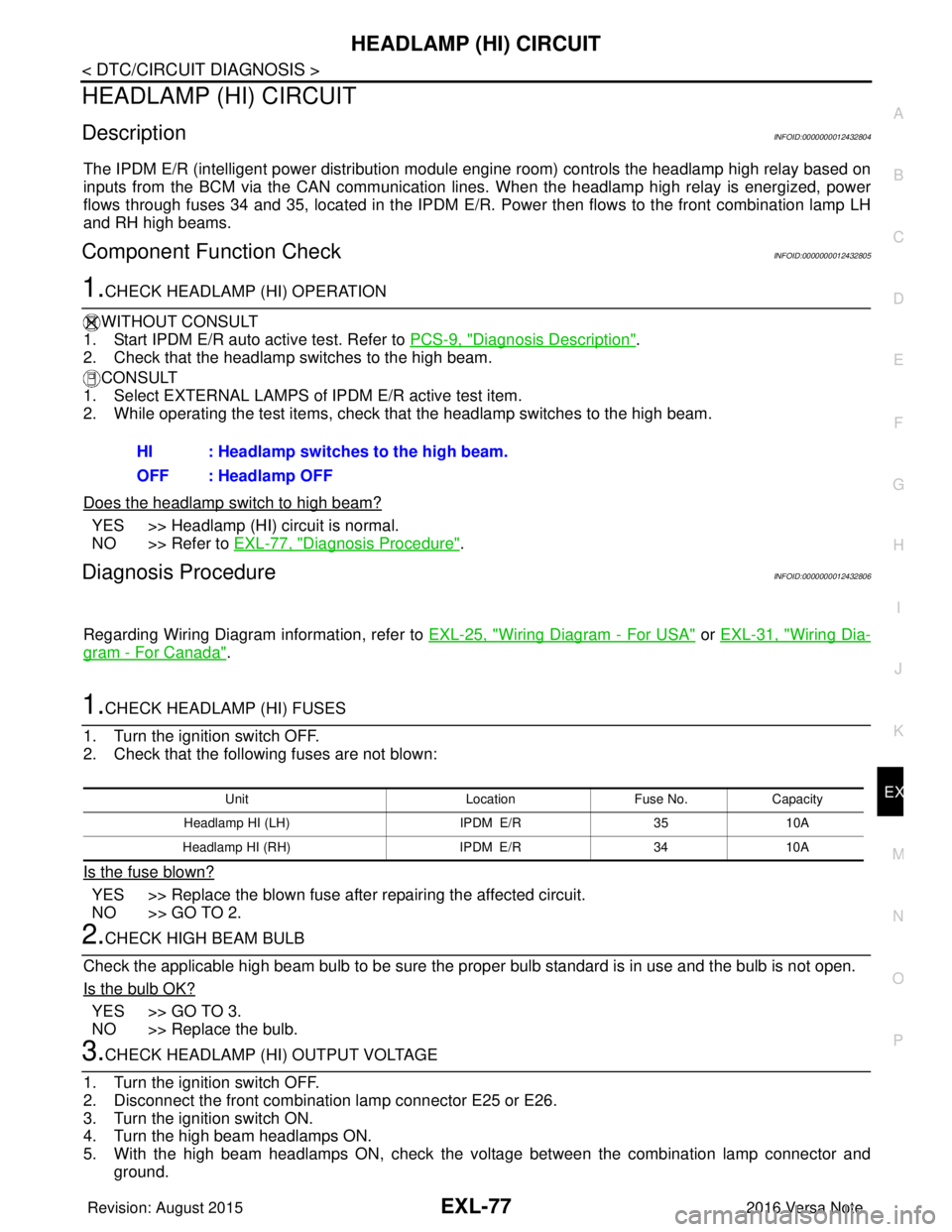

1.CHECK HEADLAMP (HI) FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not blown:

Is the fuse blown?

YES >> Replace the blown fuse after repairing the affected circuit.

NO >> GO TO 2.

2.CHECK HIGH BEAM BULB

Check the applicable high beam bulb to be sure the proper bulb standard is in use and the bulb is not open.

Is the bulb OK?

YES >> GO TO 3.

NO >> Replace the bulb.

3.CHECK HEADLAMP (HI) OUTPUT VOLTAGE

1. Turn the ignition switch OFF.

2. Disconnect the front combination lamp connector E25 or E26.

3. Turn the ignition switch ON.

4. Turn the high beam headlamps ON.

5. With the high beam headlamps ON, check the vo ltage between the combination lamp connector and

ground. HI : Headlamp switches to the high beam.

OFF : Headlamp OFF

Unit

LocationFuse No.Capacity

Headlamp HI (LH) IPDM E/R3510A

Headlamp HI (RH) IPDM E/R3410A

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1730 of 3641

EXL-78

< DTC/CIRCUIT DIAGNOSIS >

HEADLAMP (HI) CIRCUIT

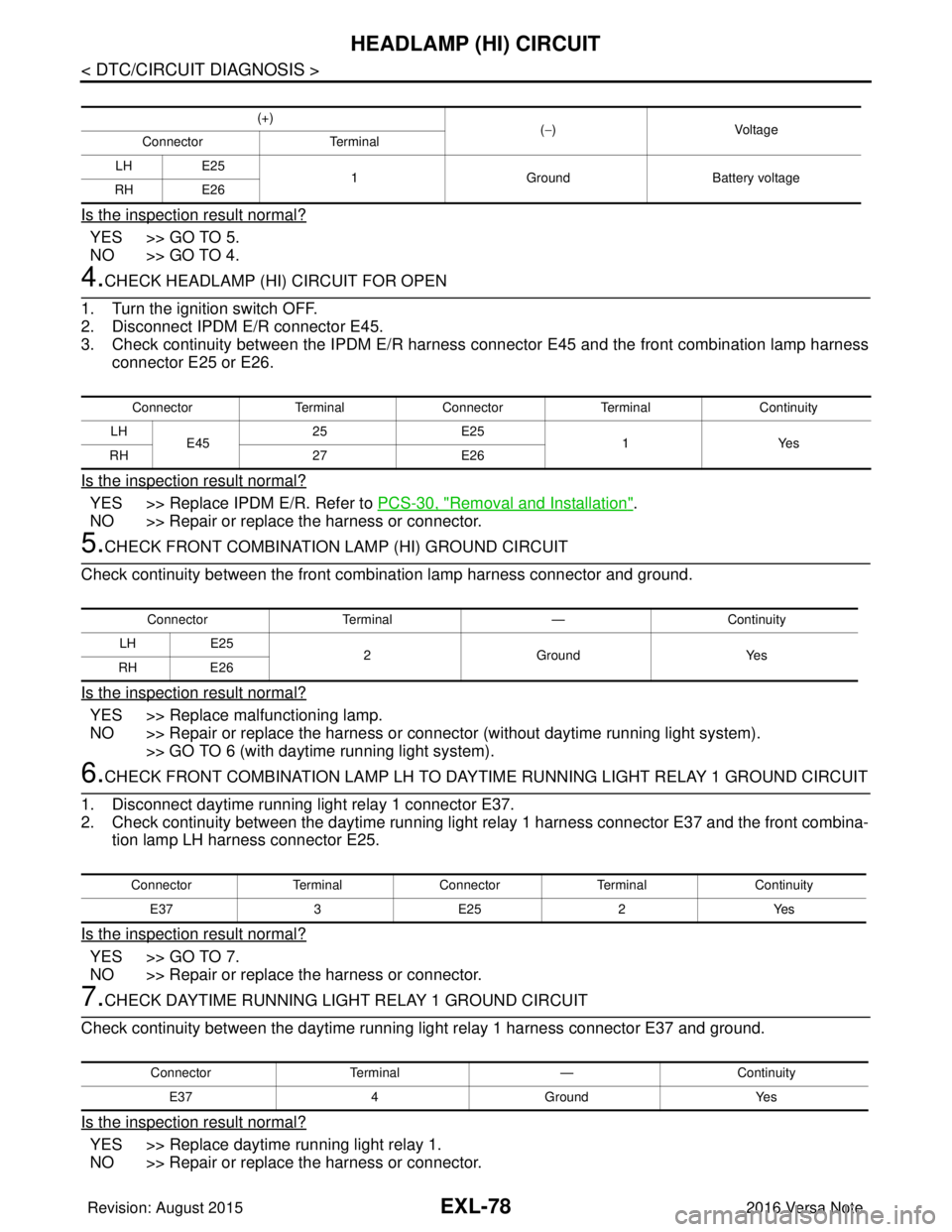

Is the inspection result normal?

YES >> GO TO 5.

NO >> GO TO 4.

4.CHECK HEADLAMP (HI) CIRCUIT FOR OPEN

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector E45.

3. Check continuity between the IPDM E/R harness connector E45 and the front combination lamp harness connector E25 or E26.

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-30, "Removal and Installation".

NO >> Repair or replace the harness or connector.

5.CHECK FRONT COMBINATION LAMP (HI) GROUND CIRCUIT

Check continuity between the front combination lamp harness connector and ground.

Is the inspection result normal?

YES >> Replace malfunctioning lamp.

NO >> Repair or replace the harness or c onnector (without daytime running light system).

>> GO TO 6 (with daytime running light system).

6.CHECK FRONT COMBINATION LAMP LH TO DA YTIME RUNNING LIGHT RELAY 1 GROUND CIRCUIT

1. Disconnect daytime running light relay 1 connector E37.

2. Check continuity between the daytime running light relay 1 harness connector E37 and the front combina- tion lamp LH harness connector E25.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair or replace the harness or connector.

7.CHECK DAYTIME RUNNING LIGHT RELAY 1 GROUND CIRCUIT

Check continuity between the daytime running light relay 1 harness connector E37 and ground.

Is the inspection result normal?

YES >> Replace daytime running light relay 1.

NO >> Repair or replace the harness or connector.

(+) (−)Voltage

Connector Terminal

LH E25

1 Ground Battery voltage

RH E26

Connector TerminalConnector Terminal Continuity

LH E45 25

E25

1Y es

RH 27E26

Connector Terminal —Continuity

LH E25

2G ro un dY es

RH E26

Connector TerminalConnector Terminal Continuity

E37 3E25 2Yes

Connector Terminal —Continuity

E37 4Ground Yes

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1731 of 3641

HEADLAMP (LO) CIRCUITEXL-79

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

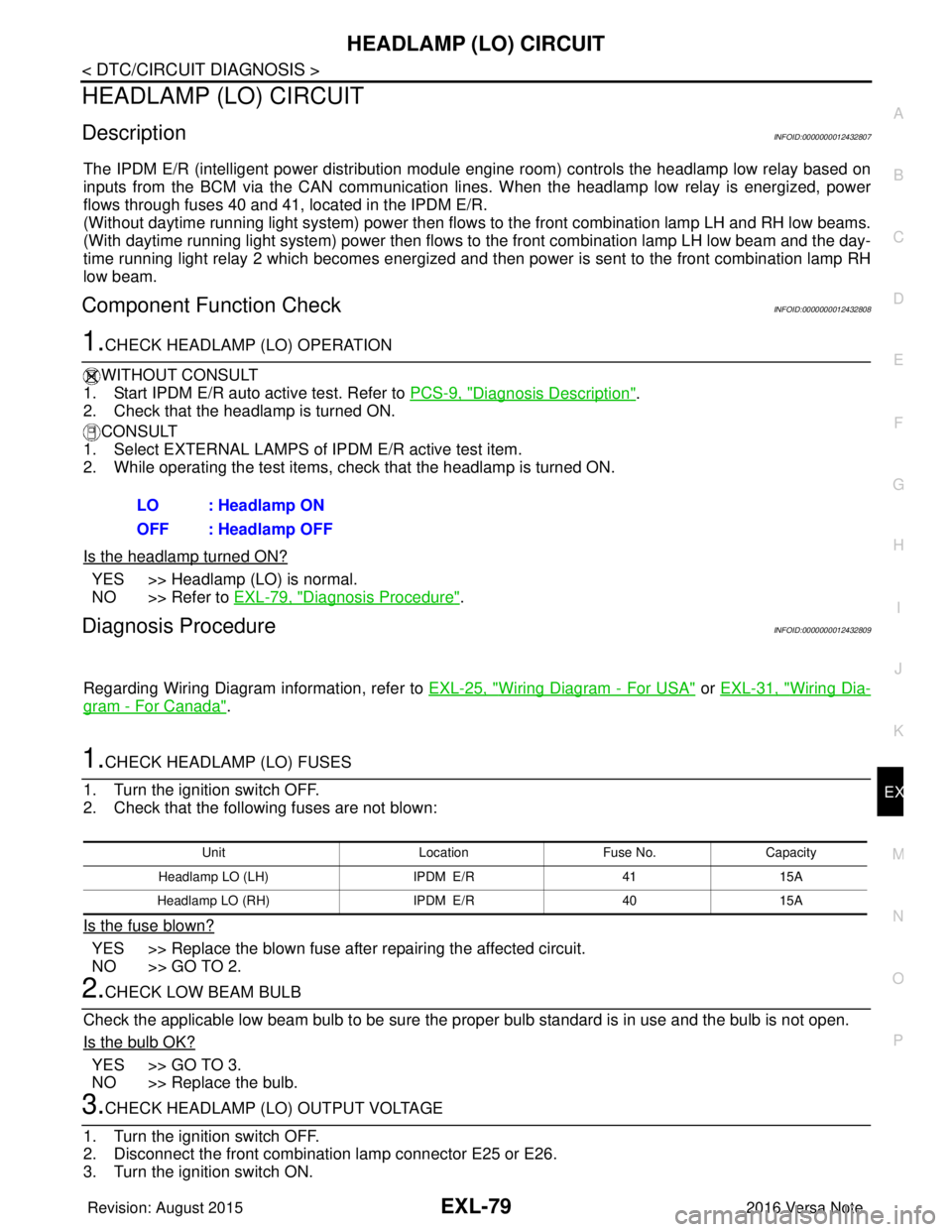

HEADLAMP (LO) CIRCUIT

DescriptionINFOID:0000000012432807

The IPDM E/R (intelligent power distribution modul e engine room) controls the headlamp low relay based on

inputs from the BCM via the CAN communication li nes. When the headlamp low relay is energized, power

flows through fuses 40 and 41, located in the IPDM E/R.

(Without daytime running light system) power then flow s to the front combination lamp LH and RH low beams.

(With daytime running light system) power then flows to the front combination lamp LH low beam and the day-

time running light relay 2 which becomes energized and t hen power is sent to the front combination lamp RH

low beam.

Component Function CheckINFOID:0000000012432808

1.CHECK HEADLAMP (LO) OPERATION

WITHOUT CONSULT

1. Start IPDM E/R auto active test. Refer to PCS-9, "

Diagnosis Description".

2. Check that the headlamp is turned ON.

CONSULT

1. Select EXTERNAL LAMPS of IP DM E/R active test item.

2. While operating the test items, check that the headlamp is turned ON.

Is the headlamp turned ON?

YES >> Headlamp (LO) is normal.

NO >> Refer to EXL-79, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000012432809

Regarding Wiring Diagram information, refer to EXL-25, "Wiring Diagram - For USA" or EXL-31, "Wiring Dia-

gram - For Canada".

1.CHECK HEADLAMP (LO) FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not blown:

Is the fuse blown?

YES >> Replace the blown fuse after repairing the affected circuit.

NO >> GO TO 2.

2.CHECK LOW BEAM BULB

Check the applicable low beam bulb to be sure the proper bulb standard is in use and the bulb is not open.

Is the bulb OK?

YES >> GO TO 3.

NO >> Replace the bulb.

3.CHECK HEADLAMP (LO) OUTPUT VOLTAGE

1. Turn the ignition switch OFF.

2. Disconnect the front combination lamp connector E25 or E26.

3. Turn the ignition switch ON. LO : Headlamp ON

OFF : Headlamp OFF

Unit

LocationFuse No.Capacity

Headlamp LO (L H) IPDM E/R 4115A

Headlamp LO (RH) IPDM E/R4015A

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1732 of 3641

EXL-80

< DTC/CIRCUIT DIAGNOSIS >

HEADLAMP (LO) CIRCUIT

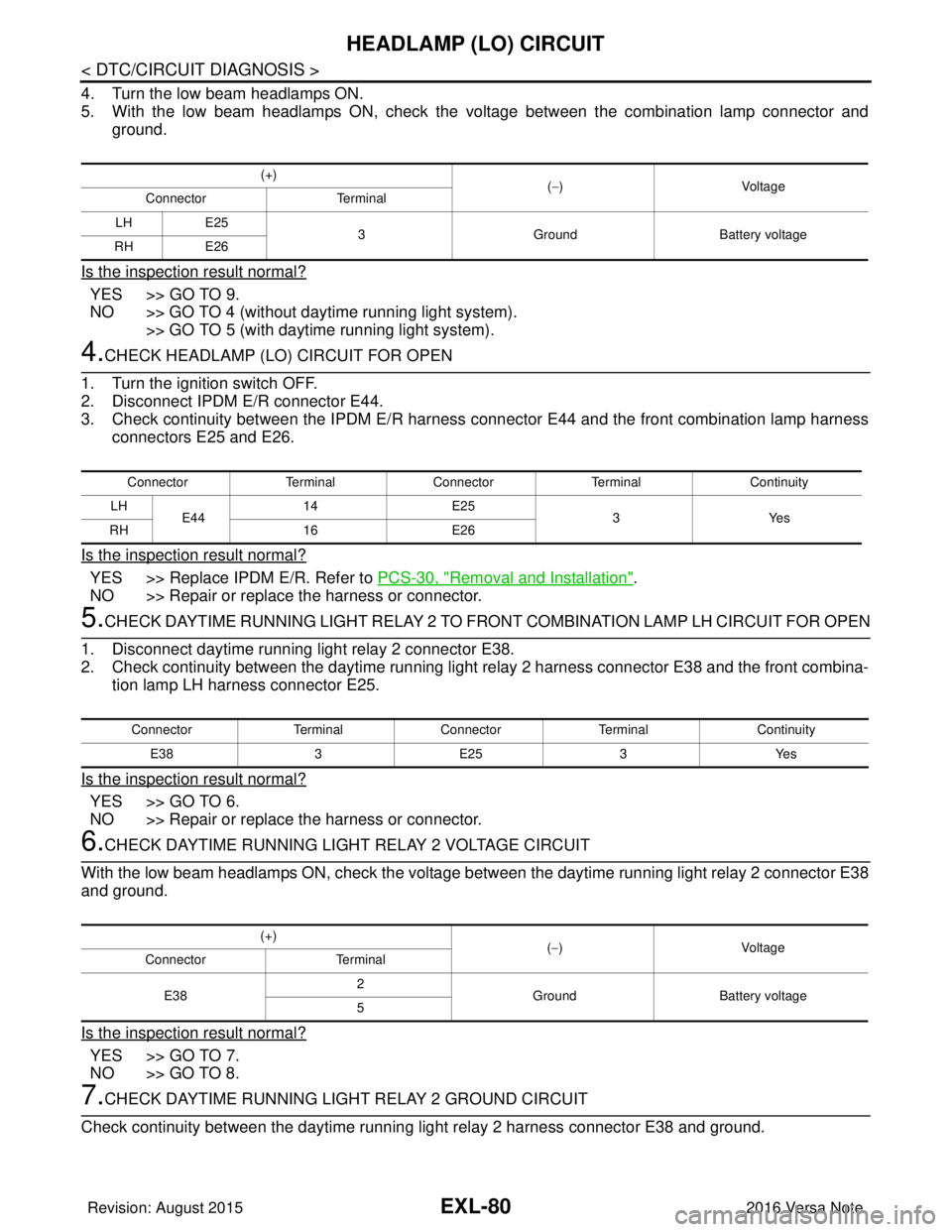

4. Turn the low beam headlamps ON.

5. With the low beam headlamps ON, check the voltage between the combination lamp connector andground.

Is the inspection result normal?

YES >> GO TO 9.

NO >> GO TO 4 (without daytime running light system). >> GO TO 5 (with daytime running light system).

4.CHECK HEADLAMP (LO) CIRCUIT FOR OPEN

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector E44.

3. Check continuity between the IPDM E/R harness connector E44 and the front combination lamp harness connectors E25 and E26.

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-30, "Removal and Installation".

NO >> Repair or replace the harness or connector.

5.CHECK DAYTIME RUNNING LIGHT RELAY 2 TO FR ONT COMBINATION LAMP LH CIRCUIT FOR OPEN

1. Disconnect daytime running light relay 2 connector E38.

2. Check continuity between the daytime running light relay 2 harness connector E38 and the front combina- tion lamp LH harness connector E25.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Repair or replace the harness or connector.

6.CHECK DAYTIME RUNNING LIGHT RELAY 2 VOLTAGE CIRCUIT

With the low beam headlamps ON, check the voltage bet ween the daytime running light relay 2 connector E38

and ground.

Is the inspection result normal?

YES >> GO TO 7.

NO >> GO TO 8.

7.CHECK DAYTIME RUNNING LIGHT RELAY 2 GROUND CIRCUIT

Check continuity between the daytime running light relay 2 harness connector E38 and ground.

(+) (−)Voltage

Connector Terminal

LH E25 3 Ground Battery voltage

RH E26

Connector TerminalConnector Terminal Continuity

LH E44 14

E25

3Y es

RH 16E26

Connector TerminalConnector Terminal Continuity

E38 3E25 3Yes

(+)

(−)Voltage

Connector Terminal

E38 2

Ground Battery voltage

5

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1733 of 3641

HEADLAMP (LO) CIRCUITEXL-81

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

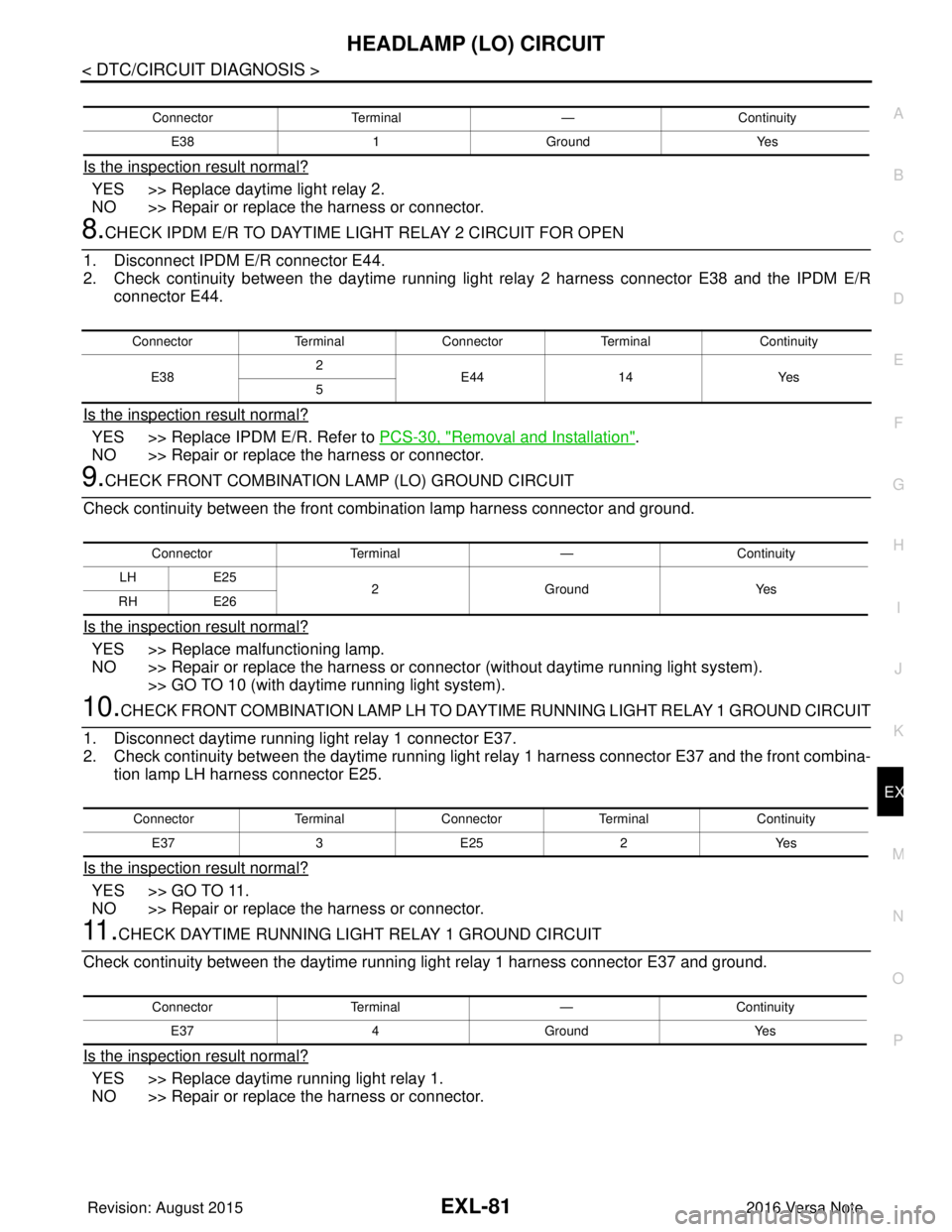

Is the inspection result normal?

YES >> Replace daytime light relay 2.

NO >> Repair or replace the harness or connector.

8.CHECK IPDM E/R TO DAYTIME LIGHT RELAY 2 CIRCUIT FOR OPEN

1. Disconnect IPDM E/R connector E44.

2. Check continuity between the daytime running li ght relay 2 harness connector E38 and the IPDM E/R

connector E44.

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-30, "Removal and Installation".

NO >> Repair or replace the harness or connector.

9.CHECK FRONT COMBINATION LAMP (LO) GROUND CIRCUIT

Check continuity between the front combination lamp harness connector and ground.

Is the inspection result normal?

YES >> Replace malfunctioning lamp.

NO >> Repair or replace the harness or connec tor (without daytime running light system).

>> GO TO 10 (with daytime running light system).

10.CHECK FRONT COMBINATION LAMP LH TO DA YTIME RUNNING LIGHT RELAY 1 GROUND CIRCUIT

1. Disconnect daytime running light relay 1 connector E37.

2. Check continuity between the daytime running light relay 1 harness connector E37 and the front combina-

tion lamp LH harness connector E25.

Is the inspection result normal?

YES >> GO TO 11.

NO >> Repair or replace the harness or connector.

11 .CHECK DAYTIME RUNNING LIGHT RELAY 1 GROUND CIRCUIT

Check continuity between the daytime running light relay 1 harness connector E37 and ground.

Is the inspection result normal?

YES >> Replace daytime running light relay 1.

NO >> Repair or replace the harness or connector.

Connector Terminal —Continuity

E38 1Ground Yes

ConnectorTerminalConnector Terminal Continuity

E38 2

E44 14 Yes

5

Connector Terminal —Continuity

LH E25

2 Ground Yes

RH E26

Connector TerminalConnector Terminal Continuity

E37 3E25 2Yes

Connector Terminal —Continuity

E37 4Ground Yes

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1734 of 3641

EXL-82

< DTC/CIRCUIT DIAGNOSIS >

PARKING LAMP CIRCUIT

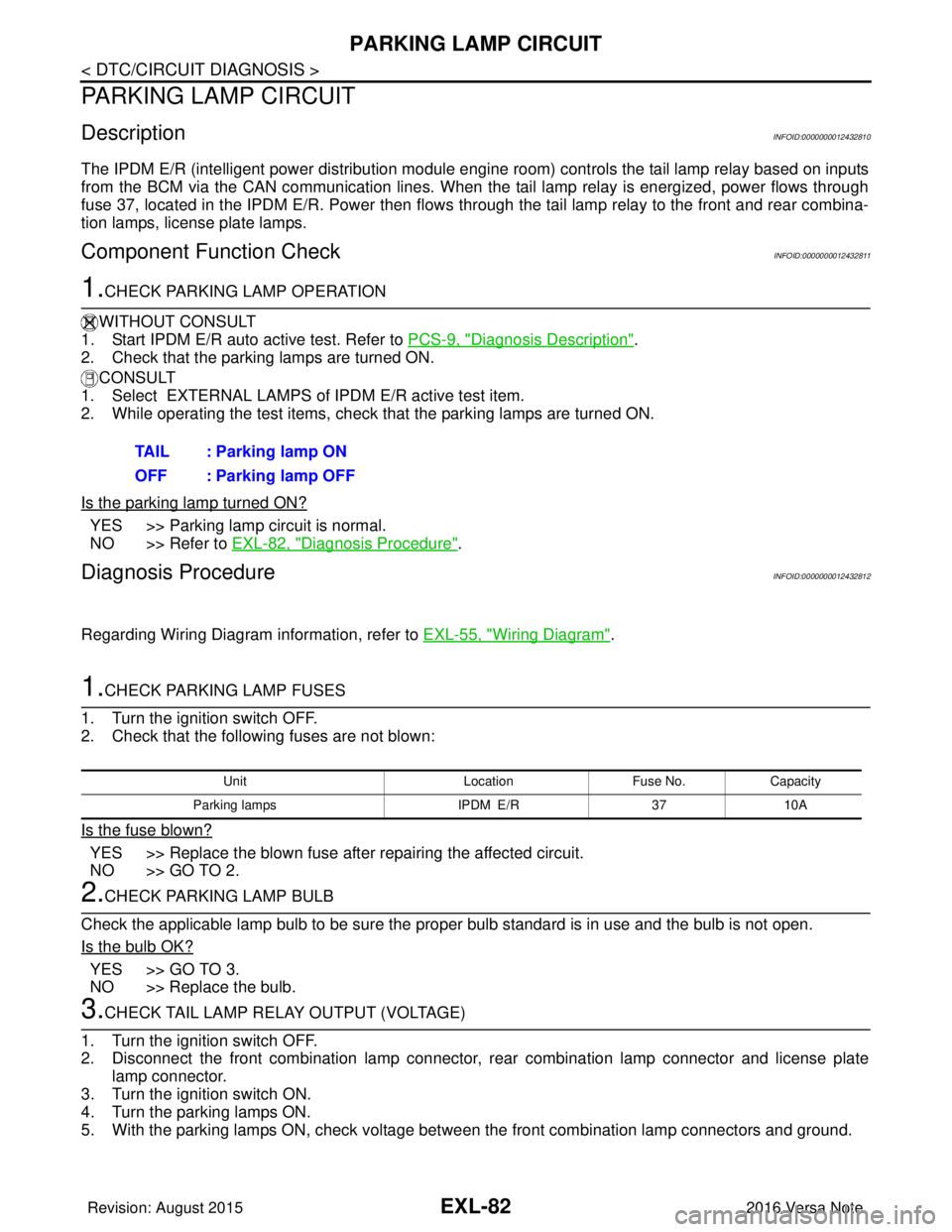

PARKING LAMP CIRCUIT

DescriptionINFOID:0000000012432810

The IPDM E/R (intelligent power distribution module engine room) controls the tail lamp relay based on inputs

from the BCM via the CAN communication lines. When the tail lamp relay is energized, power flows through

fuse 37, located in the IPDM E/R. Power then flows through the tail lamp relay to the front and rear combina-

tion lamps, license plate lamps.

Component Function CheckINFOID:0000000012432811

1.CHECK PARKING LAMP OPERATION

WITHOUT CONSULT

1. Start IPDM E/R auto active test. Refer to PCS-9, "

Diagnosis Description".

2. Check that the parking lamps are turned ON.

CONSULT

1. Select EXTERNAL LAMPS of IPDM E/R active test item.

2. While operating the test items, check that the parking lamps are turned ON.

Is the parking lamp turned ON?

YES >> Parking lamp circuit is normal.

NO >> Refer to EXL-82, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000012432812

Regarding Wiring Diagram information, refer to EXL-55, "Wiring Diagram".

1.CHECK PARKING LAMP FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not blown:

Is the fuse blown?

YES >> Replace the blown fuse after repairing the affected circuit.

NO >> GO TO 2.

2.CHECK PARKING LAMP BULB

Check the applicable lamp bulb to be sure the proper bulb standard is in use and the bulb is not open.

Is the bulb OK?

YES >> GO TO 3.

NO >> Replace the bulb.

3.CHECK TAIL LAMP RELAY OUTPUT (VOLTAGE)

1. Turn the ignition switch OFF.

2. Disconnect the front combination lamp connector, rear combination lamp connector and license plate

lamp connector.

3. Turn the ignition switch ON.

4. Turn the parking lamps ON.

5. With the parking lamps ON, check voltage between the front combination lamp connectors and ground. TAIL : Parking lamp ON

OFF : Parking lamp OFF

Unit

LocationFuse No.Capacity

Parking lamps IPDM E/R3710A

Revision: August 2015 2016 Versa Note

cardiagn.com