relay NISSAN NOTE 2016 Service Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1741 of 3641

FRONT FOG LAMP CIRCUITEXL-89

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

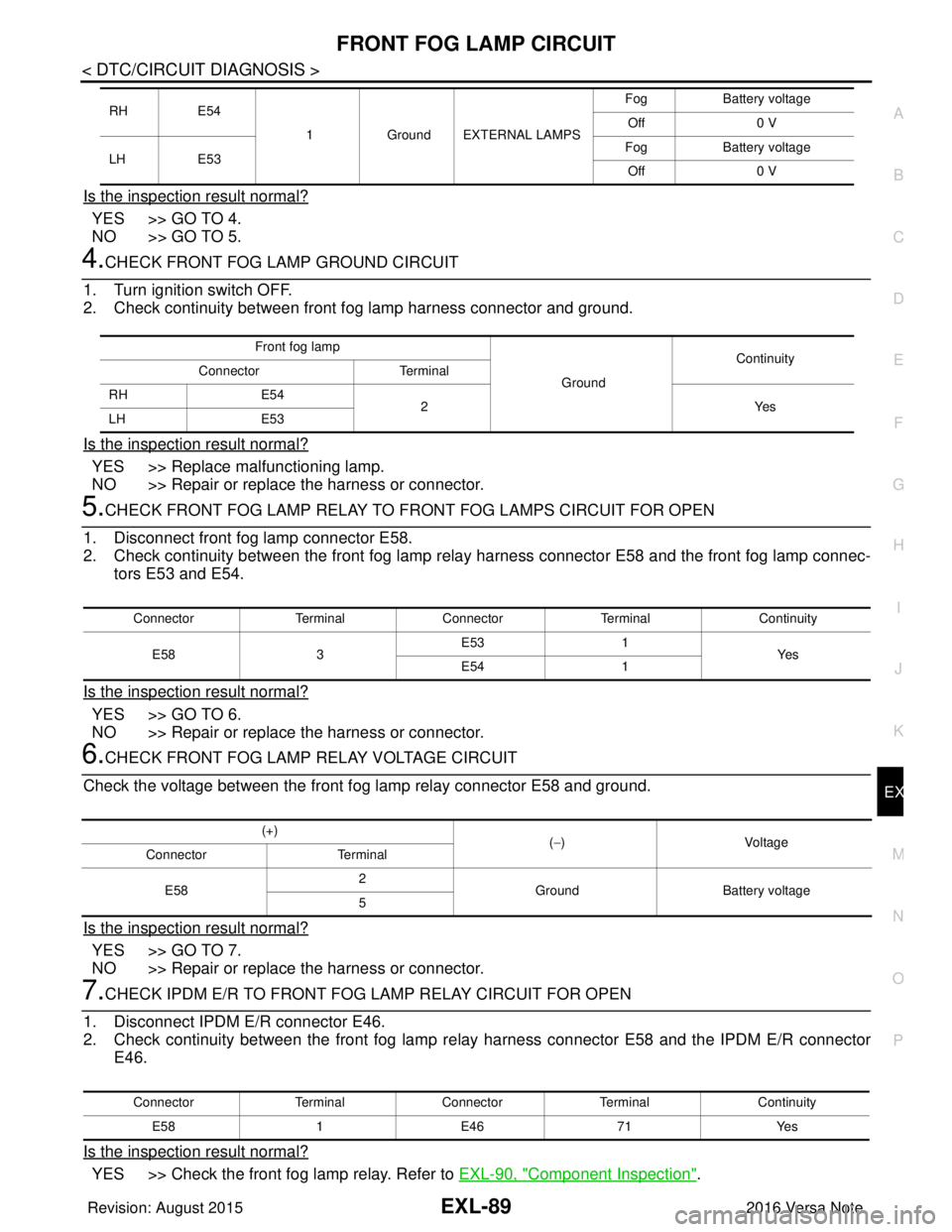

Is the inspection result normal?

YES >> GO TO 4.

NO >> GO TO 5.

4.CHECK FRONT FOG LAMP GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between front fog lamp harness connector and ground.

Is the inspection result normal?

YES >> Replace malfunctioning lamp.

NO >> Repair or replace the harness or connector.

5.CHECK FRONT FOG LAMP RELAY TO FRONT FOG LAMPS CIRCUIT FOR OPEN

1. Disconnect front fog lamp connector E58.

2. Check continuity between the front fog lamp relay harness connector E58 and the front fog lamp connec- tors E53 and E54.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Repair or replace the harness or connector.

6.CHECK FRONT FOG LAMP RELAY VOLTAGE CIRCUIT

Check the voltage between the front fog lamp relay connector E58 and ground.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair or replace the harness or connector.

7.CHECK IPDM E/R TO FRONT FO G LAMP RELAY CIRCUIT FOR OPEN

1. Disconnect IPDM E/R connector E46.

2. Check continuity between the front fog lamp re lay harness connector E58 and the IPDM E/R connector

E46.

Is the inspection result normal?

YES >> Check the front fog lamp relay. Refer to EXL-90, "Component Inspection".

RH E54

1Ground EXTERNAL LAMPS Fog

Battery voltage

Off 0 V

LH E53 Fog

Battery voltage

Off 0 V

Front fog lamp

GroundContinuity

Connector Terminal

RH E54

2Y es

LH E53

Connector TerminalConnector Terminal Continuity

E58 3E53

1

Ye s

E54 1

(+)

(−)Voltage

Connector Terminal

E58 2

Ground Battery voltage

5

Connector TerminalConnector Terminal Continuity

E58 1E46 71 Yes

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1742 of 3641

EXL-90

< DTC/CIRCUIT DIAGNOSIS >

FRONT FOG LAMP CIRCUIT

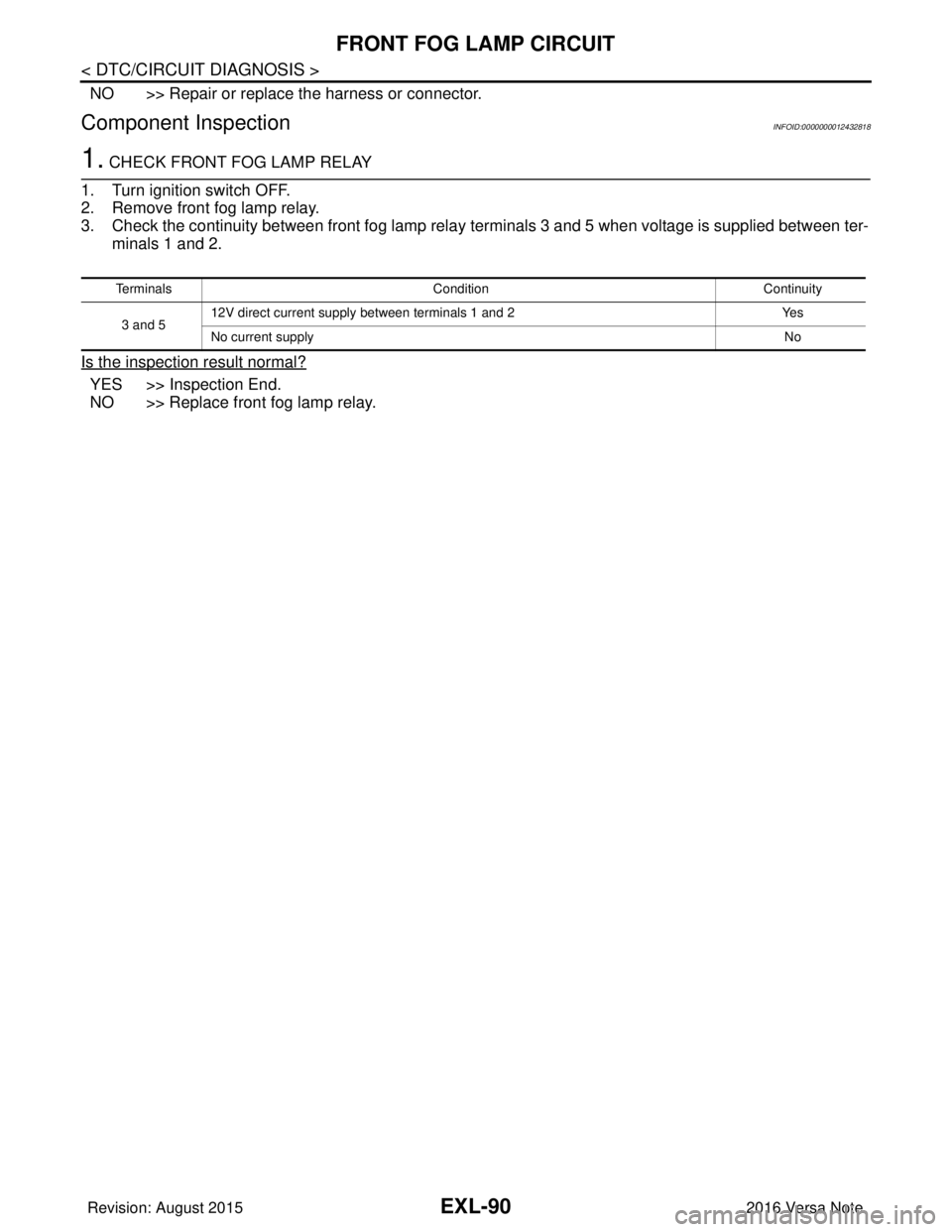

NO >> Repair or replace the harness or connector.

Component InspectionINFOID:0000000012432818

1. CHECK FRONT FOG LAMP RELAY

1. Turn ignition switch OFF.

2. Remove front fog lamp relay.

3. Check the continuity between front fog lamp rela y terminals 3 and 5 when voltage is supplied between ter-

minals 1 and 2.

Is the inspection result normal?

YES >> Inspection End.

NO >> Replace front fog lamp relay.

Terminals Condition Continuity

3 and 5 12V direct current supply between terminals 1 and 2

Yes

No current supply No

Revision: August 20152016 Versa Note

cardiagn.com

Page 1743 of 3641

EXTERIOR LIGHTING SYSTEM SYMPTOMSEXL-91

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

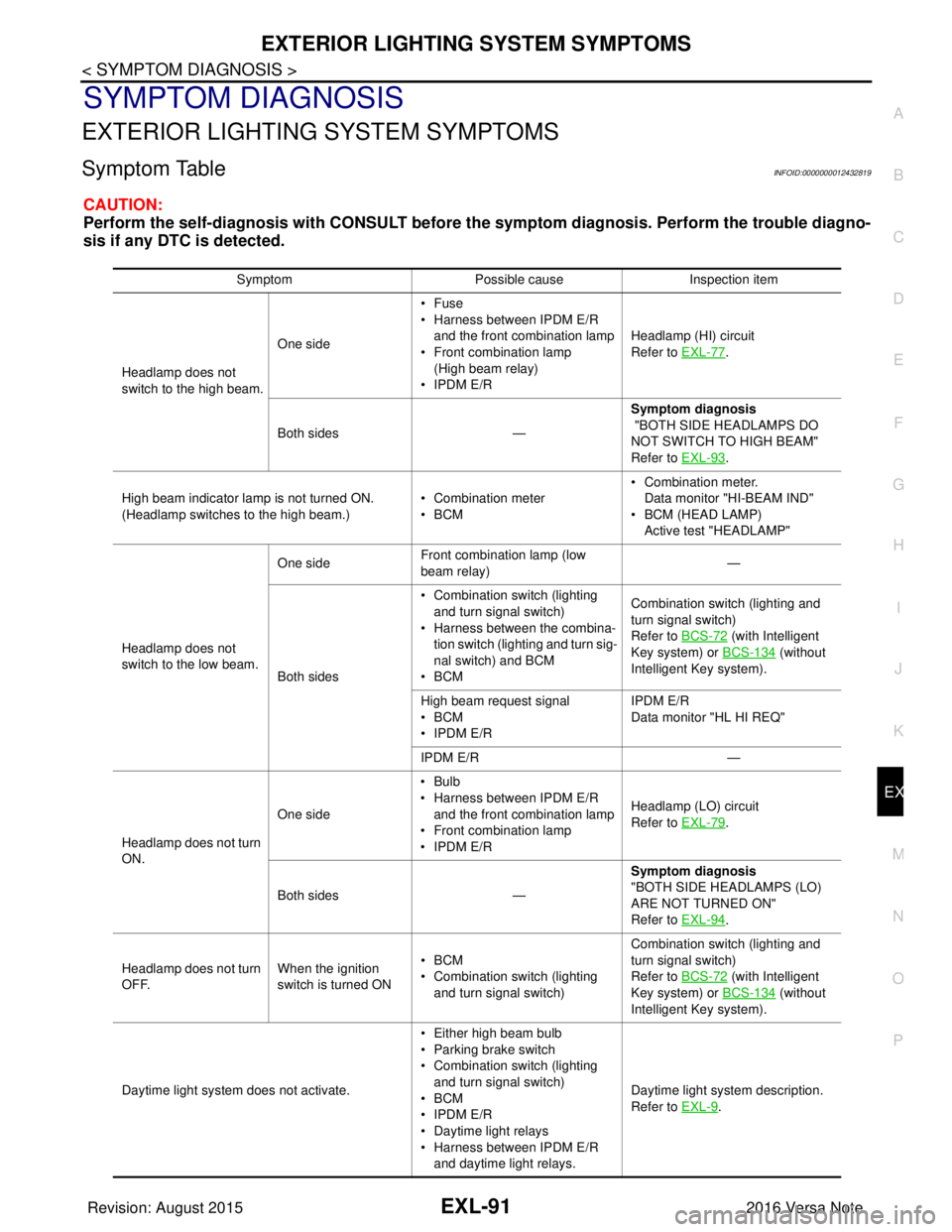

SYMPTOM DIAGNOSIS

EXTERIOR LIGHTING SYSTEM SYMPTOMS

Symptom TableINFOID:0000000012432819

CAUTION:

Perform the self-diagnosis with CONSULT before th e symptom diagnosis. Perform the trouble diagno-

sis if any DTC is detected.

Symptom Possible causeInspection item

Headlamp does not

switch to the high beam. One side

•Fuse

• Harness between IPDM E/R

and the front combination lamp

• Front combination lamp

(High beam relay)

• IPDM E/R Headlamp (HI) circuit

Refer to EXL-77

.

Both sides — Symptom diagnosis

"BOTH SIDE HEADLAMPS DO

NOT SWITCH TO HIGH BEAM"

Refer to EXL-93

.

High beam indicator lamp is not turned ON.

(Headlamp switches to the high beam.) • Combination meter

•BCM• Combination meter.

Data monitor "HI-BEAM IND"

• BCM (HEAD LAMP)

Active test "HEADLAMP"

Headlamp does not

switch to the low beam. One side

Front combination lamp (low

beam relay) —

Both sides • Combination switch (lighting

and turn signal switch)

• Harness between the combina- tion switch (lighting and turn sig-

nal switch) and BCM

•BCM Combination switch (lighting and

turn signal switch)

Refer to BCS-72

(with Intelligent

Key system) or BCS-134

(without

Intelligent Key system).

High beam request signal

•BCM

• IPDM E/R IPDM E/R

Data monitor "HL HI REQ"

IPDM E/R —

Headlamp does not turn

ON. One side

•Bulb

• Harness between IPDM E/R

and the front combination lamp

• Front combination lamp

• IPDM E/R Headlamp (LO) circuit

Refer to EXL-79

.

Both sides — Symptom diagnosis

"BOTH SIDE HEADLAMPS (LO)

ARE NOT TURNED ON"

Refer to EXL-94

.

Headlamp does not turn

OFF. When the ignition

switch is turned ON•BCM

• Combination switch (lighting

and turn signal switch) Combination switch (lighting and

turn signal switch)

Refer to BCS-72

(with Intelligent

Key system) or BCS-134

(without

Intelligent Key system).

Daytime light system does not activate. • Either high beam bulb

• Parking brake switch

• Combination switch (lighting

and turn signal switch)

•BCM

• IPDM E/R

• Daytime light relays

• Harness between IPDM E/R

and daytime light relays. Daytime light system description.

Refer to EXL-9

.

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1747 of 3641

PARKING, LICENSE PLATE AND TAIL LAMPS ARE NOT TURNED ON

EXL-95

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

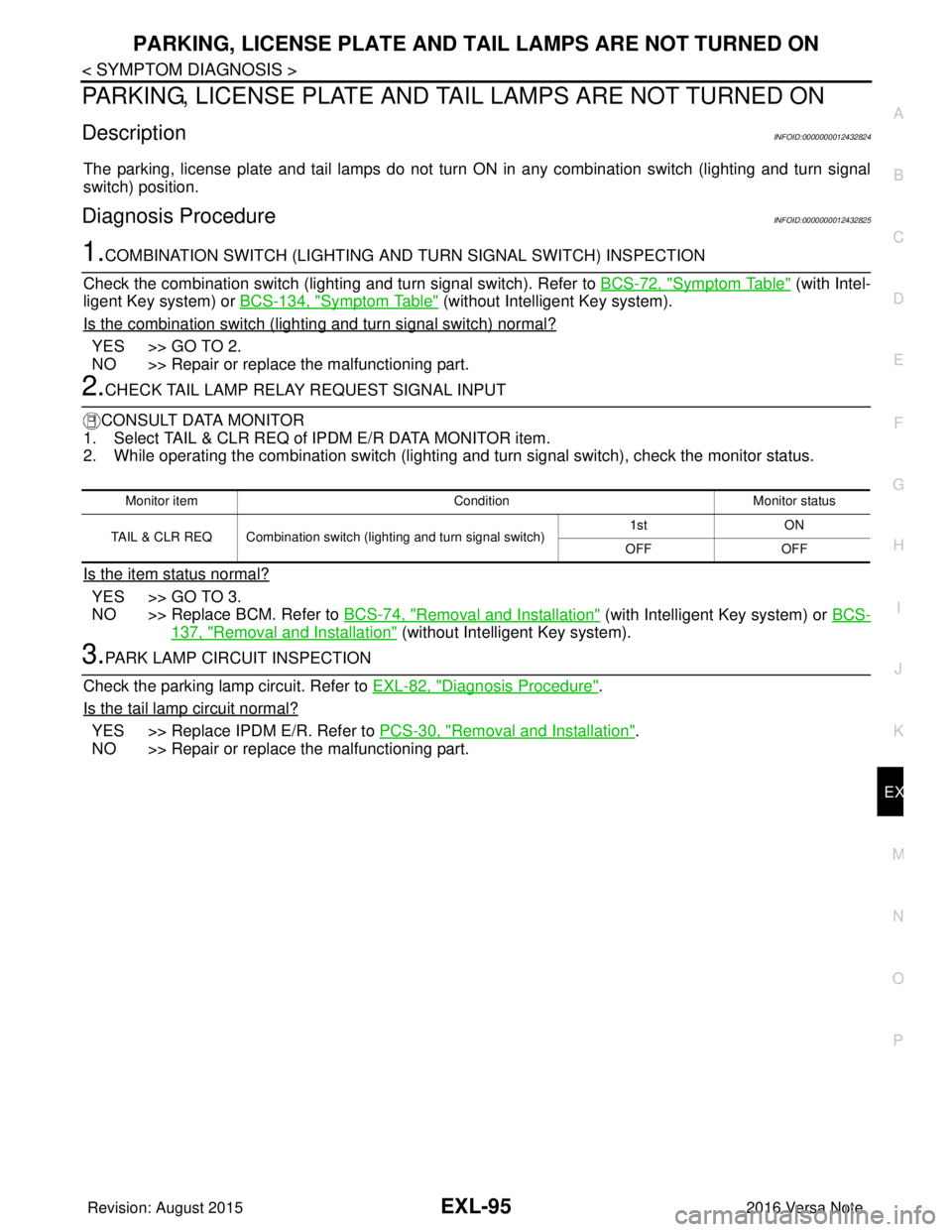

PARKING, LICENSE PLATE AND TA IL LAMPS ARE NOT TURNED ON

DescriptionINFOID:0000000012432824

The parking, license plate and tail lamps do not turn ON in any combination switch (lighting and turn signal

switch) position.

Diagnosis ProcedureINFOID:0000000012432825

1.COMBINATION SWITCH (LIGHTING AND TURN SIGNAL SWITCH) INSPECTION

Check the combination switch (lighti ng and turn signal switch). Refer to BCS-72, "

Symptom Table" (with Intel-

ligent Key system) or BCS-134, "

Symptom Table" (without Intelligent Key system).

Is the combination switch (lighting and turn signal switch) normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning part.

2.CHECK TAIL LAMP RELAY REQUEST SIGNAL INPUT

CONSULT DATA MONITOR

1. Select TAIL & CLR REQ of IPDM E/R DATA MONITOR item.

2. While operating the combination switch (lighting and turn signal switch), check the monitor status.

Is the item status normal?

YES >> GO TO 3.

NO >> Replace BCM. Refer to BCS-74, "

Removal and Installation" (with Intelligent Key system) or BCS-

137, "Removal and Installation" (without Intelligent Key system).

3.PARK LAMP CIRCUIT INSPECTION

Check the parking lamp circuit. Refer to EXL-82, "

Diagnosis Procedure".

Is the tail lamp circuit normal?

YES >> Replace IPDM E/R. Refer to PCS-30, "Removal and Installation".

NO >> Repair or replace the malfunctioning part.

Monitor item ConditionMonitor status

TAIL & CLR REQ Combination switch (lighting and turn signal switch) 1st

ON

OFF OFF

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1899 of 3641

HOW TO READ WIRING DIAGRAMSGI-11

< HOW TO USE THIS MANUAL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

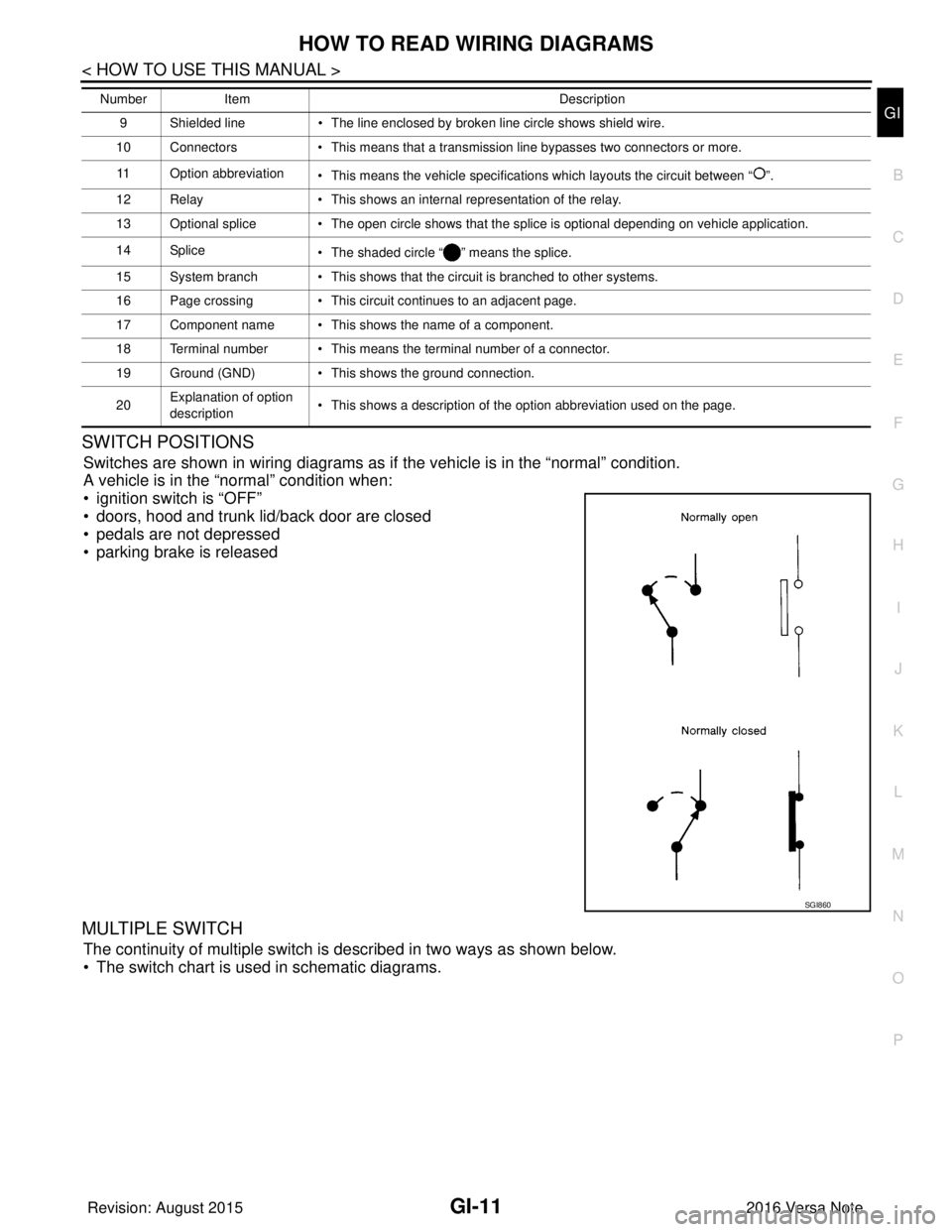

SWITCH POSITIONS

Switches are shown in wiring diagrams as if the vehicle is in the “normal” condition.

A vehicle is in the “normal” condition when:

• ignition switch is “OFF”

• doors, hood and trunk lid/back door are closed

• pedals are not depressed

• parking brake is released

MULTIPLE SWITCH

The continuity of multiple switch is described in two ways as shown below.

• The switch chart is used in schematic diagrams.

9 Shielded line • The line enclosed by broken line circle shows shield wire.

10 Connectors • This means that a transmission line bypasses two connectors or more.

11 Option abbreviation • This means the vehicle specifications which layouts the circuit between “ ”.

12 Relay • This shows an internal representation of the relay.

13 Optional splice • The open circle shows that the splice is optional depending on vehicle application.

14 Splice • The shaded circle “ ” means the splice.

15 System branch • This shows that the circuit is branched to other systems.

16 Page crossing • This circuit continues to an adjacent page.

17 Component name • This shows the name of a component.

18 Terminal number • This means the terminal number of a connector.

19 Ground (GND) • This shows the ground connection.

20 Explanation of option

description • This shows a description of the option abbreviation used on the page.

Number

Item Description

SGI860

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1930 of 3641

GI-42

< BASIC INSPECTION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

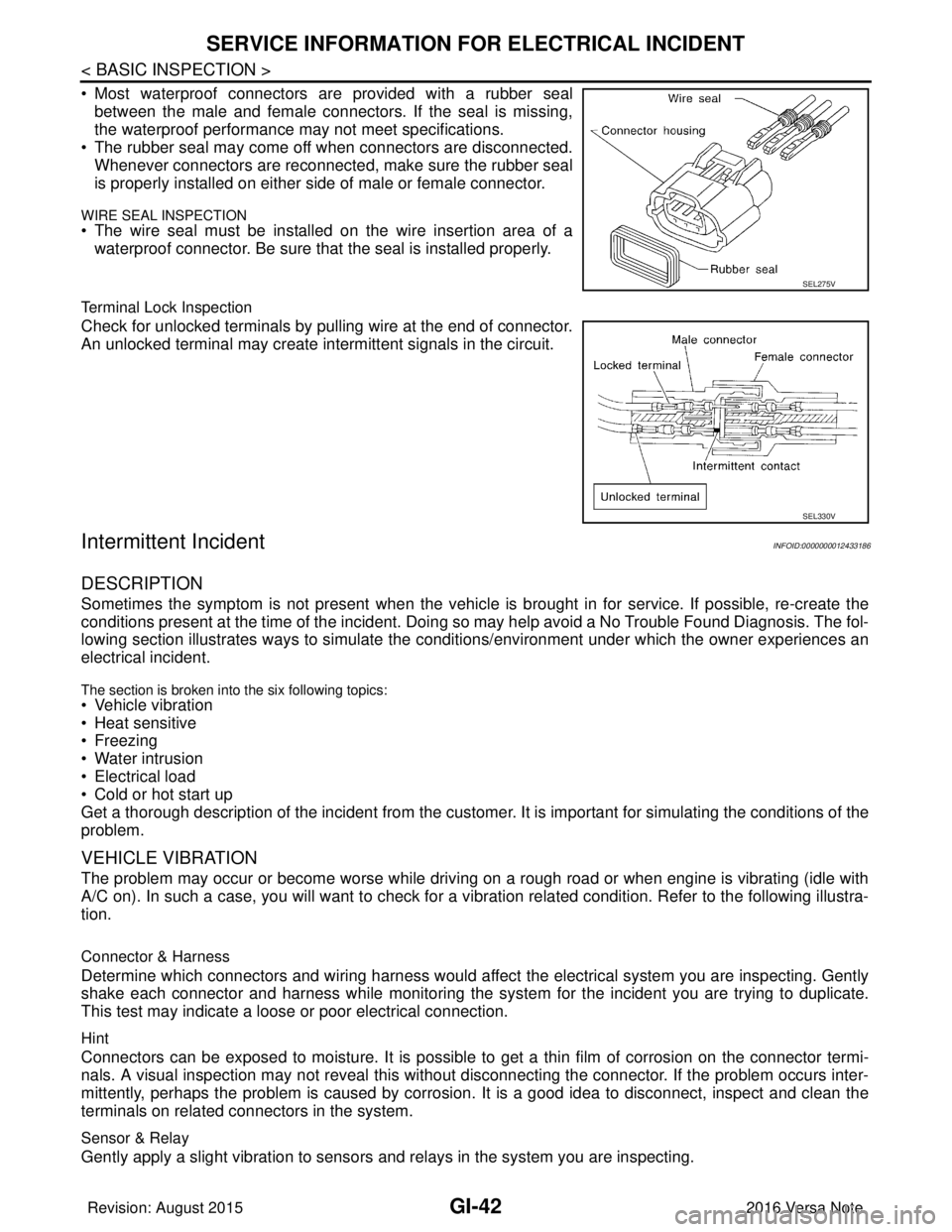

• Most waterproof connectors are provided with a rubber sealbetween the male and female connectors. If the seal is missing,

the waterproof performance may not meet specifications.

• The rubber seal may come off when connectors are disconnected. Whenever connectors are reconnected, make sure the rubber seal

is properly installed on either side of male or female connector.

WIRE SEAL INSPECTION

• The wire seal must be installed on the wire insertion area of awaterproof connector. Be sure that the seal is installed properly.

Terminal Lock Inspection

Check for unlocked terminals by pulling wire at the end of connector.

An unlocked terminal may create intermittent signals in the circuit.

Intermittent IncidentINFOID:0000000012433186

DESCRIPTION

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doi ng so may help avoid a No Trouble Found Diagnosis. The fol-

lowing section illustrates ways to simulate the condi tions/environment under which the owner experiences an

electrical incident.

The section is broken into the six following topics:

• Vehicle vibration

• Heat sensitive

• Freezing

• Water intrusion

• Electrical load

• Cold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of the

problem.

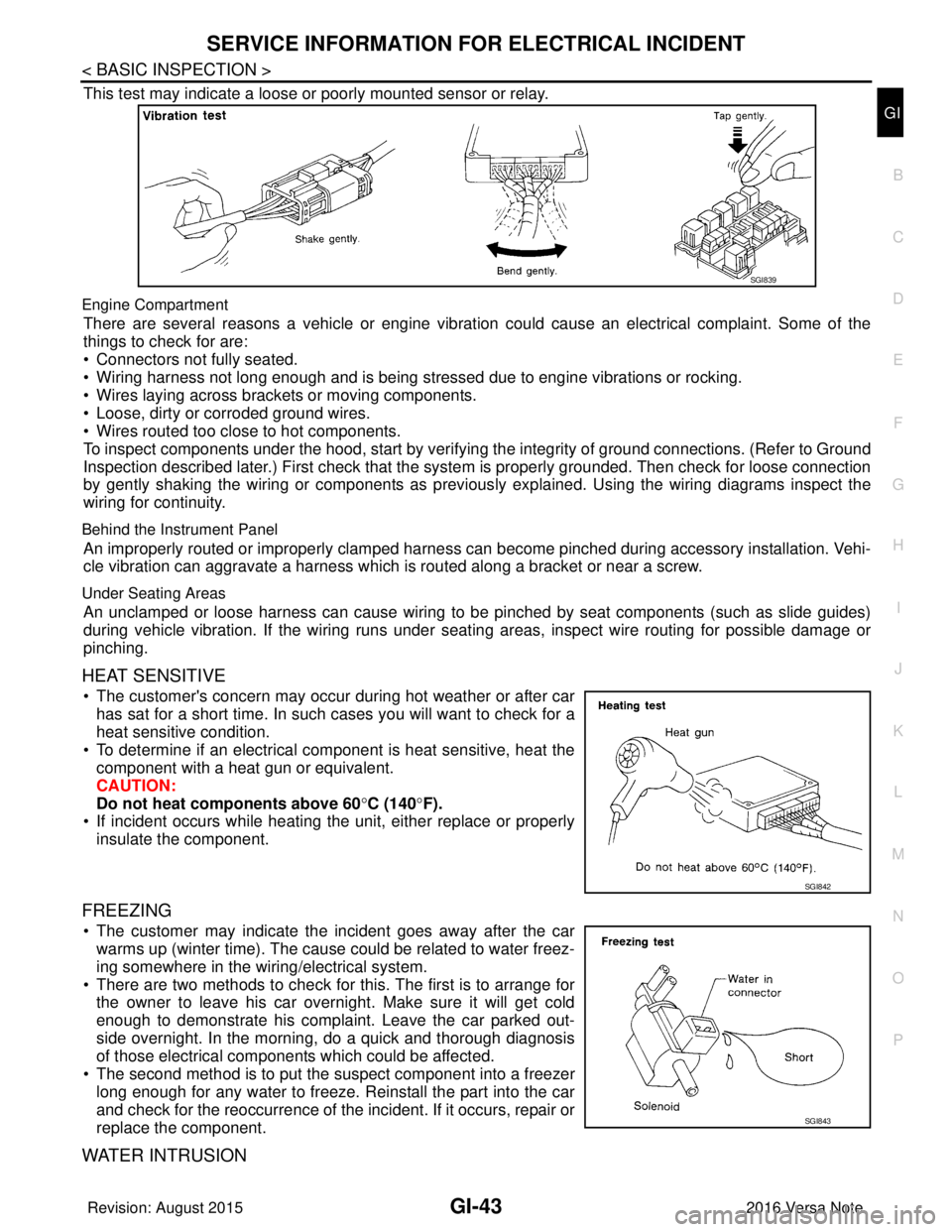

VEHICLE VIBRATION

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vi bration related condition. Refer to the following illustra-

tion.

Connector & Harness

Determine which connectors and wiring harness would affect the electrical system you are inspecting. Gently

shake each connector and harness while monitoring the sy stem for the incident you are trying to duplicate.

This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs inter-

mittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean the

terminals on related connectors in the system.

Sensor & Relay

Gently apply a slight vibration to sensors and relays in the system you are inspecting.

SEL275V

SEL330V

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1931 of 3641

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-43

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

This test may indicate a loose or poorly mounted sensor or relay.

Engine Compartment

There are several reasons a vehicle or engine vibration could cause an electrical complaint. Some of the

things to check for are:

• Connectors not fully seated.

• Wiring harness not long enough and is being stressed due to engine vibrations or rocking.

• Wires laying across brackets or moving components.

• Loose, dirty or corroded ground wires.

• Wires routed too close to hot components.

To inspect components under the hood, start by verifyi ng the integrity of ground connections. (Refer to Ground

Inspection described later.) First check that the system is properly grounded. Then check for loose connection

by gently shaking the wiring or components as previous ly explained. Using the wiring diagrams inspect the

wiring for continuity.

Behind the Instrument Panel

An improperly routed or improperly clamped harness can become pinched during accessory installation. Vehi-

cle vibration can aggravate a harness which is routed along a bracket or near a screw.

Under Seating Areas

An unclamped or loose harness can cause wiring to be pinched by seat components (such as slide guides)

during vehicle vibration. If the wiring runs under s eating areas, inspect wire routing for possible damage or

pinching.

HEAT SENSITIVE

• The customer's concern may occur during hot weather or after car has sat for a short time. In such cases you will want to check for a

heat sensitive condition.

• To determine if an electrical component is heat sensitive, heat the component with a heat gun or equivalent.

CAUTION:

Do not heat components above 60 °C (140° F).

• If incident occurs while heating t he unit, either replace or properly

insulate the component.

FREEZING

• The customer may indicate the incident goes away after the car warms up (winter time). The cause could be related to water freez-

ing somewhere in the wiring/electrical system.

• There are two methods to check for this. The first is to arrange for the owner to leave his car overnight. Make sure it will get cold

enough to demonstrate his complaint. Leave the car parked out-

side overnight. In the morning, do a quick and thorough diagnosis

of those electrical components which could be affected.

• The second method is to put the suspect component into a freezer long enough for any water to freeze. Reinstall the part into the car

and check for the reoccurrence of the incident. If it occurs, repair or

replace the component.

WATER INTRUSION

SGI839

SGI842

SGI843

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1933 of 3641

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-45

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

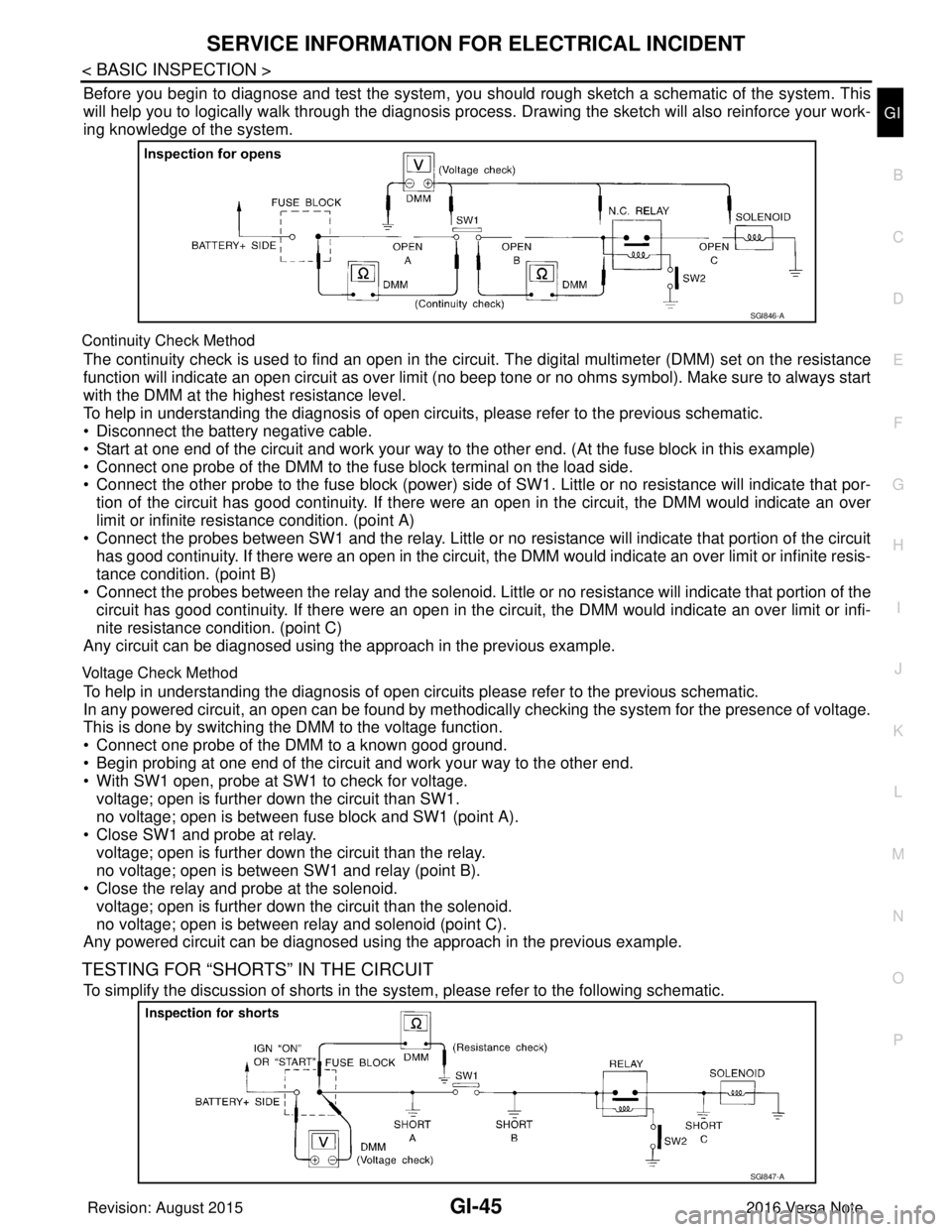

Before you begin to diagnose and test the system, you should rough sketch a schematic of the system. This

will help you to logically walk through the diagnosis process. Drawing the sketch will also reinforce your work-

ing knowledge of the system.

Continuity Check Method

The continuity check is used to find an open in the circui t. The digital multimeter (DMM) set on the resistance

function will indicate an open circuit as over limit (no beep tone or no ohms symbol). Make sure to always start

with the DMM at the highest resistance level.

To help in understanding the diagnosis of open circui ts, please refer to the previous schematic.

• Disconnect the battery negative cable.

• Start at one end of the circuit and work your way to the other end. (At the fuse block in this example)

• Connect one probe of the DMM to the fuse block terminal on the load side.

• Connect the other probe to the fuse block (power) side of SW1. Little or no resistance will indicate that por-

tion of the circuit has good continuity. If there were an open in the circuit, the DMM would indicate an over

limit or infinite resistance condition. (point A)

• Connect the probes between SW1 and the relay. Little or no resistance will indicate that portion of the circuit

has good continuity. If there were an open in the circuit, t he DMM would indicate an over limit or infinite resis-

tance condition. (point B)

• Connect the probes between the relay and the solenoid. Little or no resistance will indicate that portion of the

circuit has good continuity. If there were an open in the ci rcuit, the DMM would indicate an over limit or infi-

nite resistance condition. (point C)

Any circuit can be diagnosed using the approach in the previous example.

Voltage Check Method

To help in understanding the diagnosis of open circuits please refer to the previous schematic.

In any powered circuit, an open can be found by methodica lly checking the system for the presence of voltage.

This is done by switching the DMM to the voltage function.

• Connect one probe of the DMM to a known good ground.

• Begin probing at one end of the circuit and work your way to the other end.

• With SW1 open, probe at SW1 to check for voltage.

voltage; open is further down the circuit than SW1.

no voltage; open is between fuse block and SW1 (point A).

• Close SW1 and probe at relay.

voltage; open is further down the circuit than the relay.

no voltage; open is between SW1 and relay (point B).

• Close the relay and probe at the solenoid.

voltage; open is further down the circuit than the solenoid.

no voltage; open is between relay and solenoid (point C).

Any powered circuit can be diagnosed using the approach in the previous example.

TESTING FOR “SHORTS” IN THE CIRCUIT

To simplify the discussion of shorts in the system, please refer to the following schematic.

SGI846-A

SGI847-A

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1934 of 3641

GI-46

< BASIC INSPECTION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Resistance Check Method

• Disconnect the battery negative cable and remove the blown fuse.

• Disconnect all loads (SW1 open, relay disconnected and solenoid disconnected) powered through the fuse.

• Connect one probe of the DMM to the load side of the fuse terminal. Connect the other probe to a knowngood ground.

• With SW1 open, check for continuity. continuity; short is between fuse terminal and SW1 (point A).

no continuity; short is further down the circuit than SW1.

• Close SW1 and disconnect the relay. Put probes at the load side of fuse terminal and a known good ground. Then, check for continuity.

continuity; short is between SW1 and the relay (point B).

no continuity; short is further down the circuit than the relay.

• Close SW1 and jump the relay contacts with jumper wire. Put probes at the load side of fuse terminal and a known good ground. Then, check for continuity.

continuity; short is between relay and solenoid (point C).

no continuity; check solenoid, retrace steps.

Voltage Check Method

• Remove the blown fuse and disconnect all loads (i.e. SW1 open, relay disconnected and solenoid discon-

nected) powered through the fuse.

• Turn the ignition key to the ON or START position. Verify battery voltage at the battery + side of the fuse ter- minal (one lead on the battery + terminal side of the fuse block and one lead on a known good ground).

• With SW1 open and the DMM leads across both fuse terminals, check for voltage. voltage; short is between fuse block and SW1 (point A).

no voltage; short is further down the circuit than SW1.

• With SW1 closed, relay and solenoid disconnected and the DMM leads across both fuse terminals, check for voltage.

voltage; short is between SW1 and the relay (point B).

no voltage; short is further down the circuit than the relay.

• With SW1 closed, relay contacts jumped with fused jumper wire check for voltage. voltage; short is down the circuit of the relay or between the relay and the disconnected solenoid (point C).

no voltage; retrace steps and check power to fuse block.

GROUND INSPECTION

• Ground connections are very important to the proper operation of electrical and electronic circuits. Ground

connections are often exposed to moisture, dirt and other corrosive elements. The corrosion (rust) can

become an unwanted resistance. This unwanted resistance can change the way a circuit works.

• Electronically controlled circuits are very sens itive to proper grounding. A loose or corroded ground can

drastically affect an electronically controlled circuit. A poor or corroded ground can easily affect the circuit.

Even when the ground connection looks clean, there c an be a thin film of rust on the surface.

• When inspecting a ground connection follow these rules:

- Remove the ground bolt or screw.

- Inspect all mating surfaces for tarnish, dirt, rust, etc.

- Clean as required to assure good contact.

- Reinstall bolt or screw securely.

- Inspect for “add-on” accessories which may be interfering with the ground circuit.

- If several wires are crimped into one ground eyelet terminal, check for proper crimps. Make sure all of the

wires are clean, securely fastened and providing a good ground path. If multiple wires are cased in one eye-

let make sure no ground wires have excess wire insulation.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1970 of 3641

HAC-2

Diagnosis Procedure ..............................................37

A/C INDICATOR ................................................39

Diagnosis Procedure ........................................... ...39

FRONT BLOWER MOTOR ................................41

Description ........................................................... ...41

Diagnosis Procedure ..............................................41

Component Inspection (Front Blower Motor) ..........43

Component Inspection (B lower Relay) ...................43

Component Inspection (Front Blower Motor Re-

sistor) ................................................................... ...

43

Component Inspection (Fan Switch) ......................43

MAGNET CLUTCH ............................................45

Description ........................................................... ...45

Component Function Check ...................................45

Diagnosis Procedure ..............................................45

SYMPTOM DIAGNOSIS .............................47

MANUAL AIR CONDITIONING SYSTEM ...... ...47

Symptom Table ................................................... ...47

INSUFFICIENT COOLING .................................48

Description ........................................................... ...48

Diagnosis Procedure ..............................................48

INSUFFICIENT HEATING .................................49

Description ........................................................... ...49

Diagnosis Procedure ..............................................49

COMPRESSOR DOES NOT OPERATE ...........50

Description ........................................................... ...50

Diagnosis Procedure ............................................ ...50

REMOVAL AND INSTALLATION ..............52

FRONT AIR CONTROL .................................. ...52

Exploded View ..................................................... ...52

Removal and Installation .........................................52

THERMO CONTROL AMPLIFIER ................. ...53

Removal and Installation .........................................53

REFRIGERANT PRESSURE SENSOR ......... ...54

Removal and Installation .........................................54

FRONT BLOWER MOTOR RESISTOR ......... ...55

Exploded View ..................................................... ...55

Removal and Installation .........................................55

DOOR CABLE ................................................ ...56

Exploded View ..................................................... ...56

INTAKE DOOR CABLE ......................................... ...56

INTAKE DOOR CABLE : Removal and Installation

...

56

INTAKE DOOR CABLE : Adjustment .................. ...56

MODE DOOR CABLE ............................................ ...57

MODE DOOR CABLE : Removal and Installation ...57

MODE DOOR CABLE : Adjustment ........................57

AIR MIX DOOR CABLE ......................................... ...57

AIR MIX DOOR CABLE : Removal and Installation

...

57

AIR MIX DOOR CABLE : Adjustment .................. ...57

Revision: August 2015 2016 Versa Note

cardiagn.com