Ignition system NISSAN PATROL 1998 Y61 / 5.G Electrical System User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 326, PDF Size: 11.36 MB

Page 139 of 326

System Description

The warning chime is combined with the smart entrance control unit.

Both the ignition key and light warning chime will not sound, when ignition switch in the ON or START posi-

tion. (When power supply exists at smart entrance control unit terminalj

12.)

IGNITION KEY WARNING CHIME

With the key in the ignition key cylinder, the ignition switch in the OFF or ACC position, and the driver's door

open, the warning chime will sound. A battery positive voltage is supplied

+from key switch terminalj

1

+to smart entrance control unit terminalj1.

Ground is supplied

+through driver side door switch

+to smart entrance control unit terminalj

7.

LIGHT WARNING CHIME

With ignition switch in the OFF or ACC position, driver's door open, and lighting switch in 1ST or 2ND position,

warning chime will sound. A battery positive voltage is supplied

+from lighting switch terminalj

12or daytime light control unit

+to smart entrance control unit terminalj

14.

Ground is supplied

+through driver side door switch

+to smart entrance control unit terminalj

7.

WARNING CHIME

EL-135

Page 145 of 326

System Description

WIPER OPERATION

The wiper switch is controlled by a lever built into the combination switch.

There are three wiper switch positions:

+LO speed

+HI speed

+INT (Intermittent)

With the ignition switch in the ACC or ON position, power is supplied

+through 20A fuse [No.

, located in the fuse block (J/B)]

+to wiper motor terminalj

4.

Low and high speed wiper operation

Ground is supplied to wiper switch terminalj

17through body grounds.

When the wiper switch is placed in the LO position, ground is supplied

+through terminalj

14of the wiper switch

+to wiper motor terminalj

2.

With power and ground supplied, the wiper motor operates at low speed.

When the wiper switch is placed in the HI position, ground is supplied

+through terminalj

16of the wiper switch

+to wiper motor terminalj

3.

With power and ground supplied, the wiper motor operates at high speed.

Auto stop operation

With wiper switch turned OFF, wiper motor will continue to operate until wiper arms reach windshield base.

When wiper arms are not located at base of windshield with wiper switch OFF, ground is provided

+from terminalj

14of the wiper switch

+to wiper motor terminalj

2, in order to continue wiper motor operation at low speed.

+through wiper ampli®er (OUTPUT) combined with wiper switch and (with intermittent wiper)

+through terminalj

13of wiper switch

+to wiper motor terminalj

5

+through terminalj6of the wiper motor, and

+through body grounds.

When wiper arms reach base of windshield, wiper motor terminalsj

4andj5are connected instead of ter-

minalsj

5andj6. Wiper motor will then stop wiper arms at the PARK position.

Intermittent operation

The wiper motor operates the wiper arms one time at low speed at a set interval of approximately 3 to 13

seconds. This feature is controlled by the wiper ampli®er (INT SW) combined with wiper switch.

When the wiper switch is placed in the INT position, ground is supplied to wiper ampli®er.

The desired interval time is input to wiper ampli®er (INT VR) from wiper volume switch combined with wiper

switch.

Then intermittent ground is supplied

+to wiper motor terminalj

2

+from terminalj14of wiper switch

+through wiper ampli®er (OUTPUT).

The wiper motor operates at low speed at the desired interval.

WASHER OPERATION

With the ignition switch in the ACC or ON position, power is supplied

+through 20A fuse [No.

, located in the fuse block (J/B)]

+to washer motor terminalj

2.

When the lever is pulled to the WASH position, ground is supplied through wiper switch

+to washer motor terminalj

1, and

+to wiper ampli®er (WASH SW) combined with wiper switch.

With power and ground supplied, the washer motor operates.

When the lever is pulled to the WASH position for one second or more, the wiper motor operates at low speed

for approximately 3 seconds to clean windshield. This feature is controlled by the wiper ampli®er in the same

manner as the intermittent operation.

FRONT WIPER AND WASHER

EL-141

Page 149 of 326

System Description

WIPER OPERATION

The rear wiper switch is controlled by a ring built into the combination switch.

There are two wiper switch positions:

+ON (LO speed)

+INT (Intermittent)

With the ignition switch in the ON position, power is supplied

+through 10A fuse (No.

18, located in the fuse block)

+to rear wiper motor terminalj

4, and

+to rear wiper ampli®er terminalj

5.

Low speed wiper operation

Ground is supplied to rear wiper switch terminalj24through body grounds.

When the rear wiper is placed in the ON position, ground is supplied

+through rear wiper switch terminalj

22

+to rear wiper relay terminalj6.

Then ground is supplied

+to rear wiper motor terminalj

1

+through rear wiper ampli®er terminalsj2andj3.

With power and ground supplied, the wiper motor operates.

Auto stop operation

With the rear wiper switch turned OFF, rear wiper motor will continue to operate until wiper arm reaches rear

window base.

When wiper arm is not located at base of rear window with rear wiper switch OFF, ground is supplied

+to rear wiper motor terminalj

1

+through rear wiper ampli®er terminalsj2,j7and

+through rear wiper motor terminalj

3, in order to continue rear wiper motor operation at low speed.

Ground is also supplied

+to rear wiper motor terminalj

2

+through body grounds.

When wiper arm reaches base of rear window, rear wiper motor terminalsj

3andj4are connected instead

of terminalsj

2andj3. Rear wiper motor will then stop wiper arm at the PARK position.

Intermittent operation

The rear wiper motor operates the wiper arm one time at low speed at an interval of approximately 7 sec-

onds.

When the rear wiper switch is placed in the INT position, ground is supplied

+to rear wiper ampli®er terminalj

1

+through rear wiper switch terminalj21.

Then the rear wiper motor operates intermittently in the same manner as the low speed wiper operation.

WASHER OPERATION

With the ignition switch in the ACC or ON position, power is supplied

+through 10A fuse (No.

18, located in the fuse block)

+to rear washer motor terminalj

2.

When the ring is turned WASH position, ground is supplied

+to rear washer motor terminalj

1, and

+to rear wiper ampli®er terminalj

4

+through terminalj23of rear wiper switch.

With power and ground is supplied, the rear washer motor operates.

The rear wiper motor operates when the ring is turned to WASH position for one second or more and for

approximately 3 seconds after the ring is released. This feature is controlled by the rear wiper ampli®er in the

same manner as the low speed wiper operation.

REAR WIPER AND WASHER

EL-145

Page 162 of 326

System Description

The rear window defogger system is controlled by the smart entrance control unit. The rear window defogger

operates only for approximately 15 minutes.

Power is supplied at all times

+to rear window defogger relay terminalj

3

+through 15A fuse (No.43, located in the fuse and fusible link box) and

+to rear window defogger relay terminalj

6

+through 20A fuse (No.44, located in the fuse and fusible link box).

With the ignition switch in the ON or START position, power is supplied

+to the rear window defogger relay terminalj

1and

+to smart entrance control unit terminalj

12

+through 7.5A fuse [No.8, located in the fuse block (J/B)].

Ground is supplied to terminalj

2of the rear window defogger switch through body grounds.

When the rear window defogger switch is turned ON, ground is supplied

+through terminalj

1of the rear window defogger switch

+to smart entrance control unit terminalj

8.

Terminalj

9of the smart entrance control unit then supplies ground to the rear window defogger relay termi-

nalj

2.

With power and ground supplied, the rear window defogger relay is energized.

Power is supplied

+through terminalsj

5andj7of the rear window defogger relay

+to the rear window defogger.

The rear window defogger has an independent ground.

With power and ground supplied, the rear window defogger ®laments heat and defog the rear window.

When the system is activated, the rear window defogger indicator illuminates in the rear window defogger

switch.

Power is supplied

+to terminalj

3of the rear window defogger switch

+from terminalj

5of the rear window defogger relay.

Terminalj

4of the rear window defogger switch is grounded through body grounds.

REAR WINDOW DEFOGGER

EL-158

Page 170 of 326

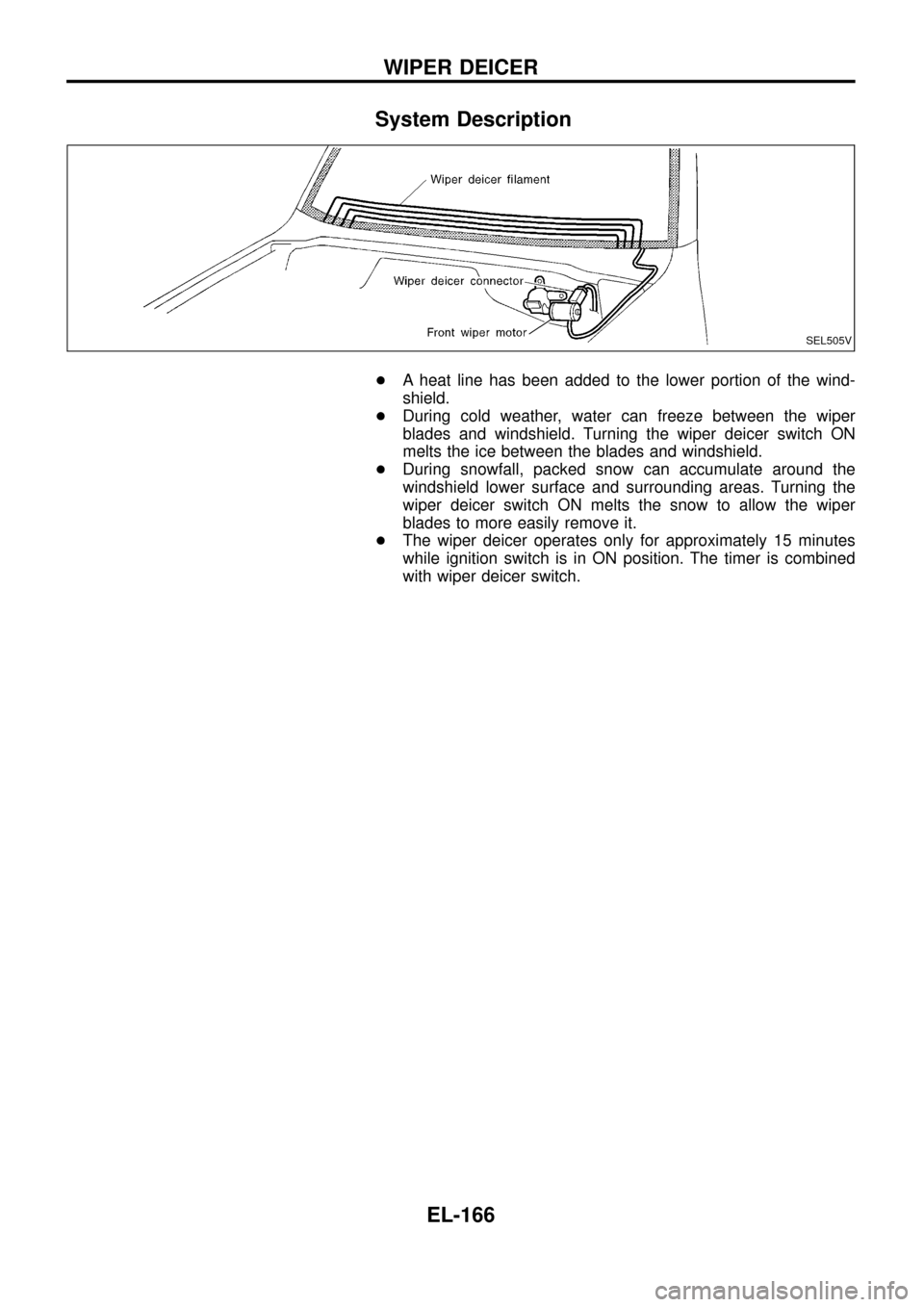

System Description

+A heat line has been added to the lower portion of the wind-

shield.

+During cold weather, water can freeze between the wiper

blades and windshield. Turning the wiper deicer switch ON

melts the ice between the blades and windshield.

+During snowfall, packed snow can accumulate around the

windshield lower surface and surrounding areas. Turning the

wiper deicer switch ON melts the snow to allow the wiper

blades to more easily remove it.

+The wiper deicer operates only for approximately 15 minutes

while ignition switch is in ON position. The timer is combined

with wiper deicer switch.

SEL505V

WIPER DEICER

EL-166

Page 200 of 326

![NISSAN PATROL 1998 Y61 / 5.G Electrical System User Guide System Description

With ignition switch in ON or START position, power is supplied

+through 7.5A fuse [No.

8, located in the fuse block (J/B)]

+to power window relay terminalj

1.

The power window rela NISSAN PATROL 1998 Y61 / 5.G Electrical System User Guide System Description

With ignition switch in ON or START position, power is supplied

+through 7.5A fuse [No.

8, located in the fuse block (J/B)]

+to power window relay terminalj

1.

The power window rela](/img/5/616/w960_616-199.png)

System Description

With ignition switch in ON or START position, power is supplied

+through 7.5A fuse [No.

8, located in the fuse block (J/B)]

+to power window relay terminalj

1.

The power window relay is energized and power is supplied

+through power window relay terminalj

5

+to power window main switch terminalj1,

+to power window sub switch terminalj

5.

MANUAL OPERATION

NOTE:

Numbers in parentheses are terminal numbers, when power window switch is pressed in the UP and DOWN

positions respectively.

Driver side

When the driver side switch in the power window main switch is pressed in the up position, power is supplied

+to driver side power window regulator terminal (j

2,j1)

+through power window main switch terminal (j

9,j8).

Ground is supplied

+to driver side power window regulator terminal (j

1,j2)

+through power window main switch terminal (j

8,j9).

Then, the motor raises or lowers the window until the switch is released.

Passenger side

MAIN SWITCH OPERATION

Power is supplied

+through power window main switch (j

5,j6)

+to front power window sub-switch (j

3,j4).

The subsequent operation is the same as the sub-switch operation.

SUB-SWITCH OPERATION

Power is supplied

+through front power window sub-switch (j

1,j2)

+to passenger side power window regulator (j

2,j1).

Ground is supplied

+to passenger side power window regulator (j

1,j2)

+through front power window sub-switch (j

2,j1)

+to front power window sub-switch (j

4,j3)

+through power window main switch (j

6,j5).

Then, the motor raises or lowers the window until the switch is released.

Rear door

Rear door windows will raise and lower in the same manner as passenger side door window.

AUTO OPERATION

The power window AUTO feature enables the driver to open or close the driver's window without holding the

window switch in the respective position.

When the AUTO switch in the main switch is pressed and released, the driver's window will travel to the fully

open or closed position.

POWER WINDOW LOCK

The power window lock is designed to lock operation of all windows except for driver's door window.

When the lock switch is pressed to lock position, ground of the sub-switches in the power window main switch

is disconnected. This prevents the power window motors from operating.

POWER WINDOW

EL-196

Page 211 of 326

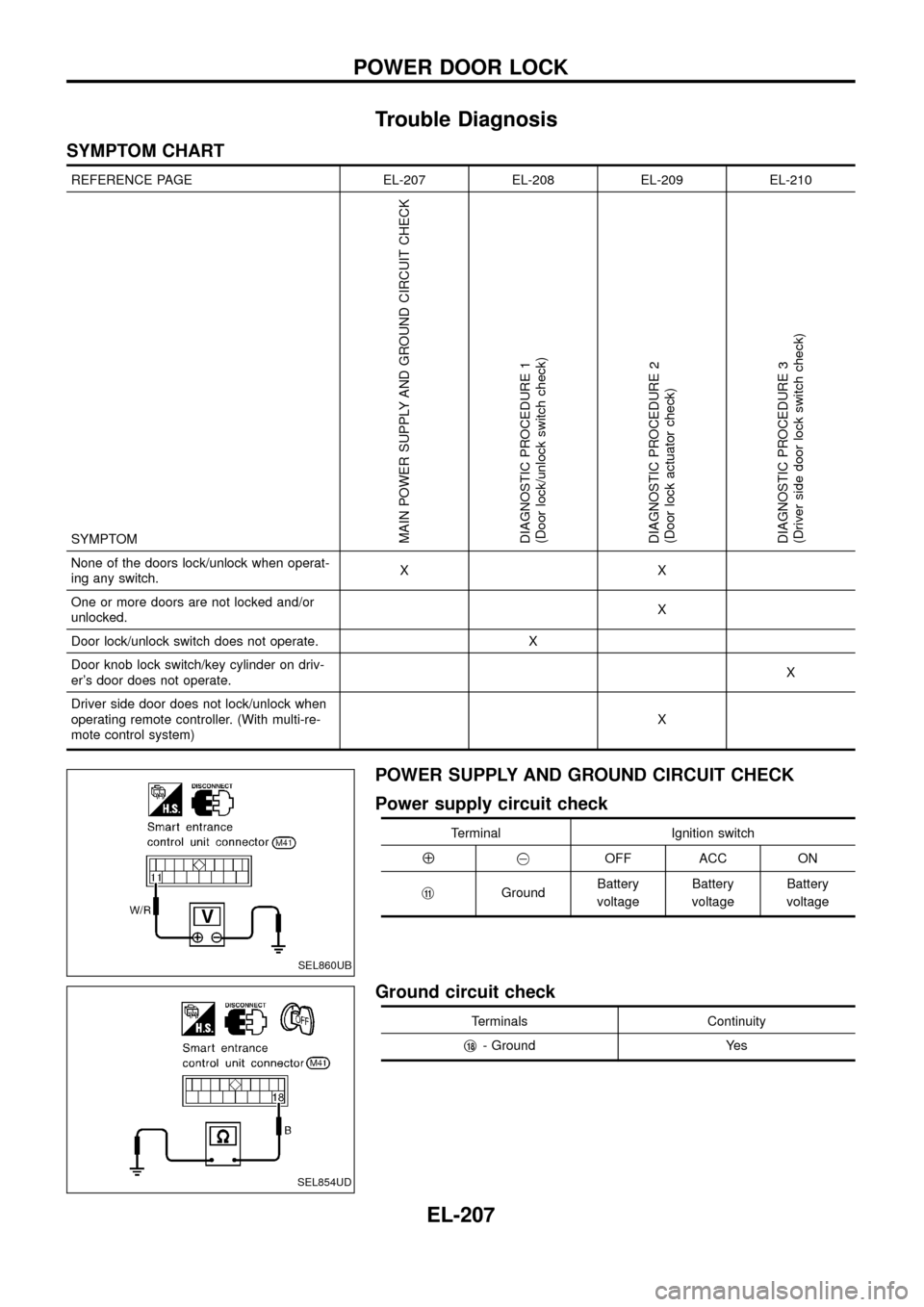

Trouble Diagnosis

SYMPTOM CHART

REFERENCE PAGE EL-207 EL-208 EL-209 EL-210

SYMPTOM

MAIN POWER SUPPLY AND GROUND CIRCUIT CHECK

DIAGNOSTIC PROCEDURE 1

(Door lock/unlock switch check)

DIAGNOSTIC PROCEDURE 2

(Door lock actuator check)

DIAGNOSTIC PROCEDURE 3

(Driver side door lock switch check)

None of the doors lock/unlock when operat-

ing any switch.XX

One or more doors are not locked and/or

unlocked.X

Door lock/unlock switch does not operate. X

Door knob lock switch/key cylinder on driv-

er's door does not operate.X

Driver side door does not lock/unlock when

operating remote controller. (With multi-re-

mote control system)X

POWER SUPPLY AND GROUND CIRCUIT CHECK

Power supply circuit check

Terminal Ignition switch

Å@OFF ACC ON

j

11GroundBattery

voltageBattery

voltageBattery

voltage

Ground circuit check

Terminals Continuity

j

18- Ground Yes

SEL860UB

SEL854UD

POWER DOOR LOCK

EL-207

Page 216 of 326

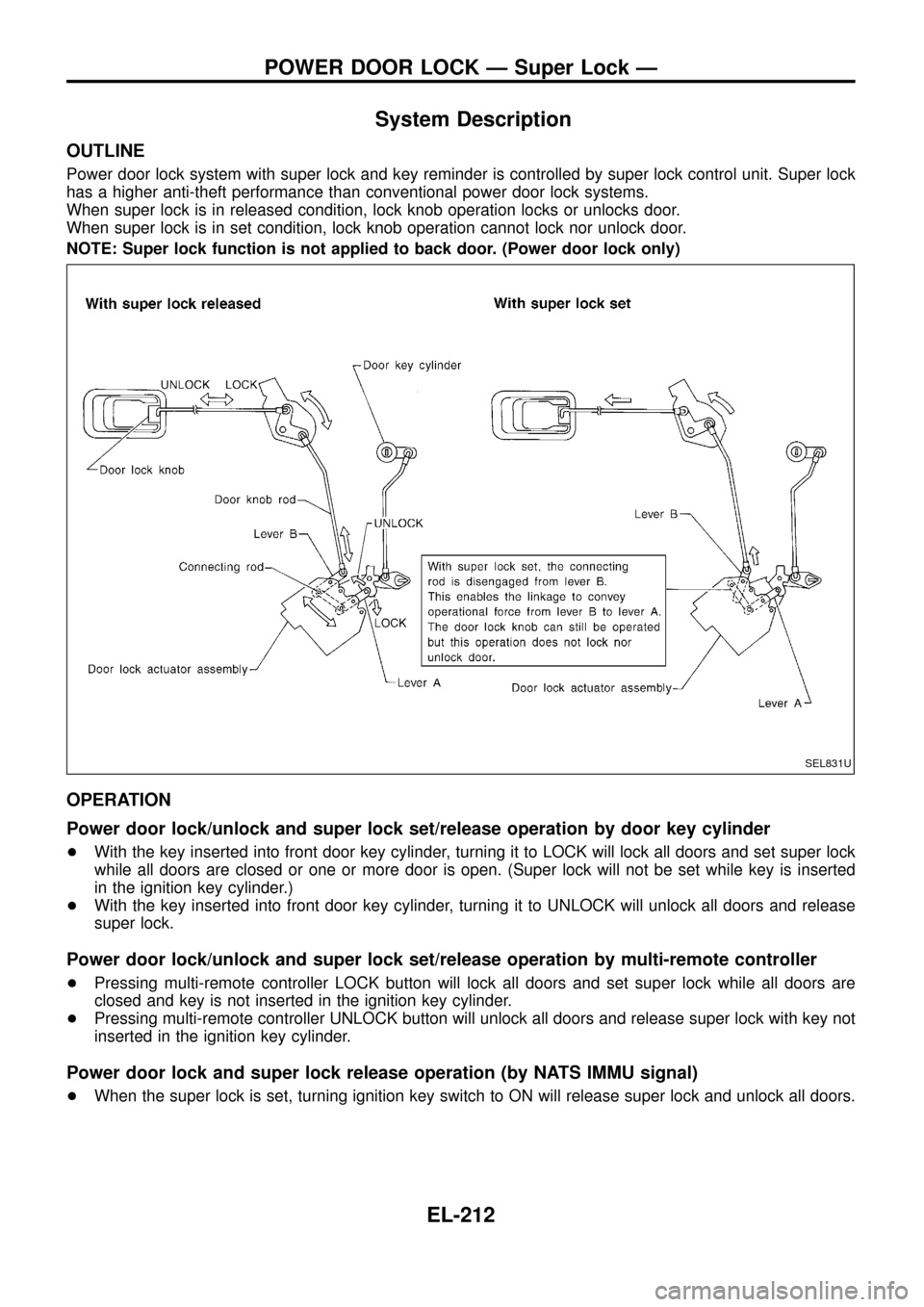

System Description

OUTLINE

Power door lock system with super lock and key reminder is controlled by super lock control unit. Super lock

has a higher anti-theft performance than conventional power door lock systems.

When super lock is in released condition, lock knob operation locks or unlocks door.

When super lock is in set condition, lock knob operation cannot lock nor unlock door.

NOTE: Super lock function is not applied to back door. (Power door lock only)

OPERATION

Power door lock/unlock and super lock set/release operation by door key cylinder

+With the key inserted into front door key cylinder, turning it to LOCK will lock all doors and set super lock

while all doors are closed or one or more door is open. (Super lock will not be set while key is inserted

in the ignition key cylinder.)

+With the key inserted into front door key cylinder, turning it to UNLOCK will unlock all doors and release

super lock.

Power door lock/unlock and super lock set/release operation by multi-remote controller

+Pressing multi-remote controller LOCK button will lock all doors and set super lock while all doors are

closed and key is not inserted in the ignition key cylinder.

+Pressing multi-remote controller UNLOCK button will unlock all doors and release super lock with key not

inserted in the ignition key cylinder.

Power door lock and super lock release operation (by NATS IMMU signal)

+When the super lock is set, turning ignition key switch to ON will release super lock and unlock all doors.

SEL831U

POWER DOOR LOCK Ð Super Lock Ð

EL-212

Page 217 of 326

Power door lock/unlock operation by lock knob

+With lock knob on driver or passenger door setting to LOCK while all doors are closed will lock all doors.

When one or more door is opened, with lock knob on passenger door setting to LOCK will lock

passenger door only. (Power door lock system will not operate.)

+With lock knob on driver or passenger door setting to UNLOCK while all doors are closed will unlock all

doors.

Lock knob operation cannot control super lock.

Key reminder system

+If the ignition key is in the ignition key cylinder and any door is open, setting lock/unlock switch or lock

knob on driver or passenger door to ``LOCK'' locks the door once but then immediately unlocks all doors.

System initialisation

+System initialisation is required when battery cables are reconnected. Conduct one of the followings to

release super lock once;

Ð insert the key into ignition key cylinder and turn it to ON.

Ð LOCK/UNLOCK operation using door key cylinder.

POWER DOOR LOCK Ð Super Lock Ð

System Description (Cont'd)

EL-213

Page 227 of 326

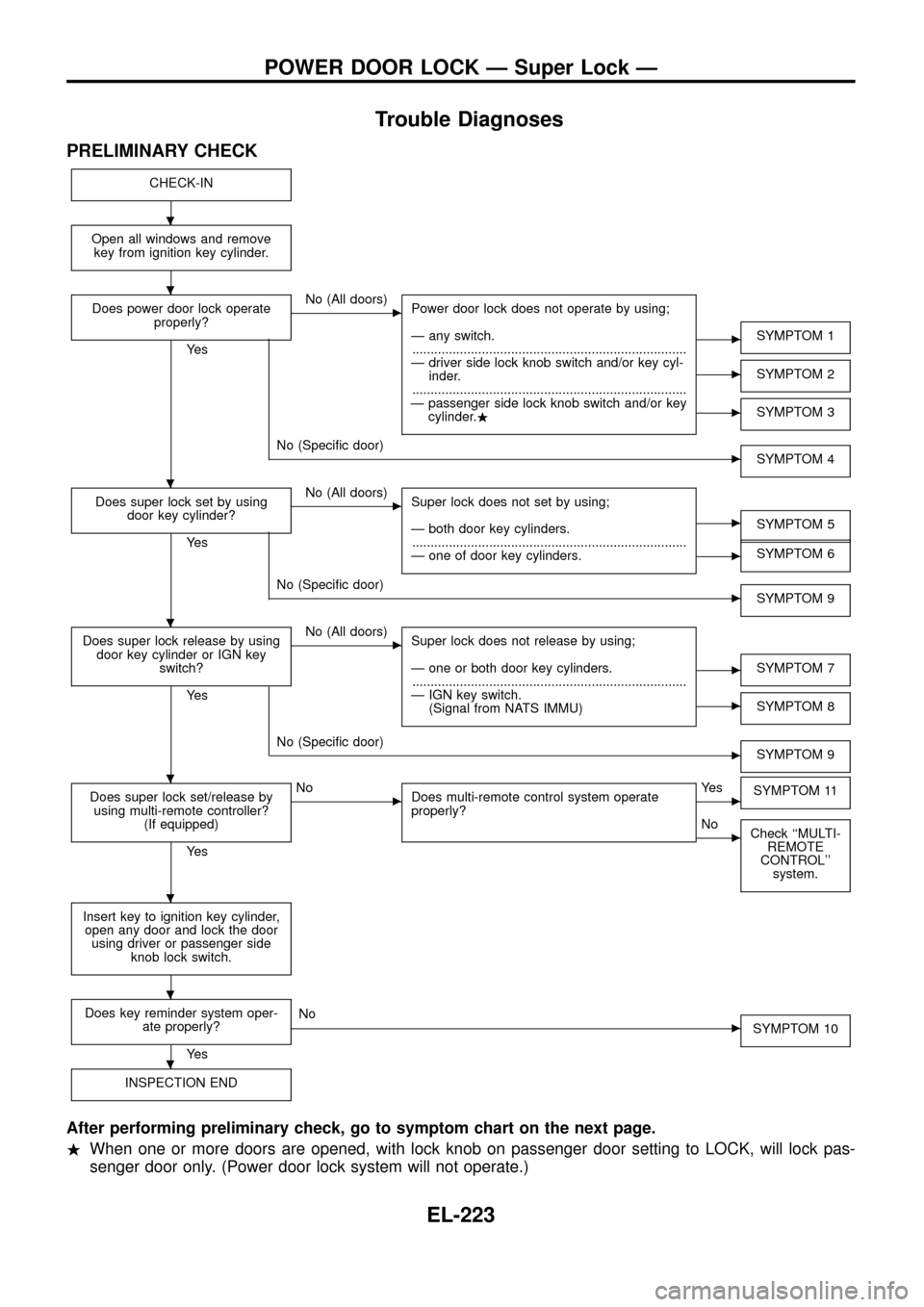

Trouble Diagnoses

PRELIMINARY CHECK

CHECK-IN

Open all windows and remove

key from ignition key cylinder.

Does power door lock operate

properly?

Ye s

cNo (All doors)

Power door lock does not operate by using;

Ð any switch.

...........................................................................

Ð driver side lock knob switch and/or key cyl-

inder.

...........................................................................

Ð passenger side lock knob switch and/or key

cylinder..

cSYMPTOM 1

cSYMPTOM 2

cSYMPTOM 3

cNo (Speci®c door)

SYMPTOM 4

Does super lock set by using

door key cylinder?

Ye s

cNo (All doors)

Super lock does not set by using;

Ð both door key cylinders.

...........................................................................

Ð one of door key cylinders.

cSYMPTOM 5

cSYMPTOM 6

cNo (Speci®c door)

SYMPTOM 9

Does super lock release by using

door key cylinder or IGN key

switch?

Ye s

cNo (All doors)

Super lock does not release by using;

Ð one or both door key cylinders.

...........................................................................

Ð IGN key switch.

(Signal from NATS IMMU)

cSYMPTOM 7

cSYMPTOM 8

cNo (Speci®c door)

SYMPTOM 9

Does super lock set/release by

using multi-remote controller?

(If equipped)

Ye s

cNo

Does multi-remote control system operate

properly?cYe s

SYMPTOM 11

cNo

Check ``MULTI-

REMOTE

CONTROL''

system.

Insert key to ignition key cylinder,

open any door and lock the door

using driver or passenger side

knob lock switch.

Does key reminder system oper-

ate properly?

Ye s

cNo

SYMPTOM 10

INSPECTION END

After performing preliminary check, go to symptom chart on the next page.

.When one or more doors are opened, with lock knob on passenger door setting to LOCK, will lock pas-

senger door only. (Power door lock system will not operate.)

.

.

.

.

.

.

.

.

POWER DOOR LOCK Ð Super Lock Ð

EL-223