NISSAN PATROL 1998 Y61 / 5.G Engine Control Workshop Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 192, PDF Size: 4.28 MB

Page 181 of 192

TEC439

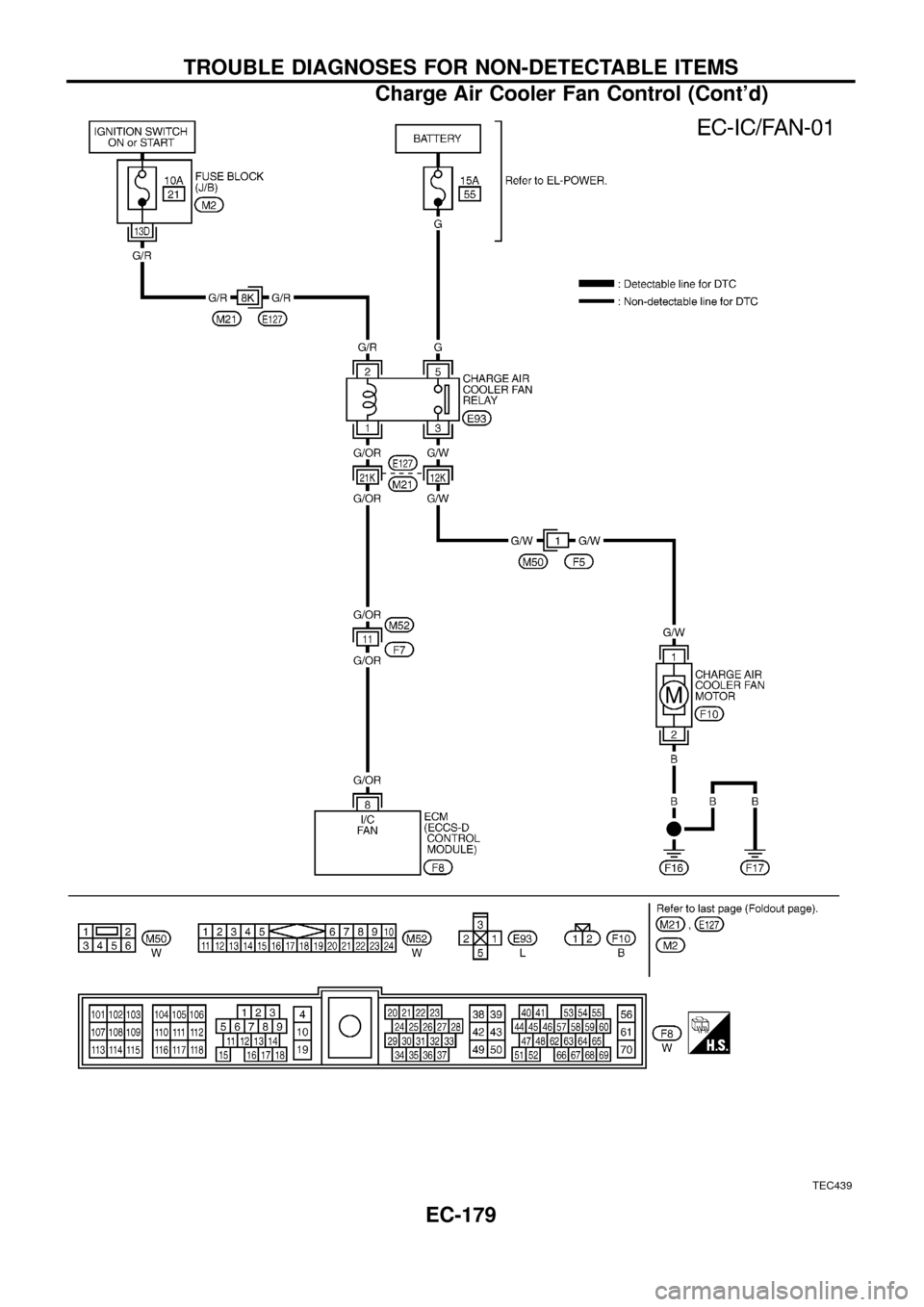

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Charge Air Cooler Fan Control (Cont'd)

EC-179

Page 182 of 192

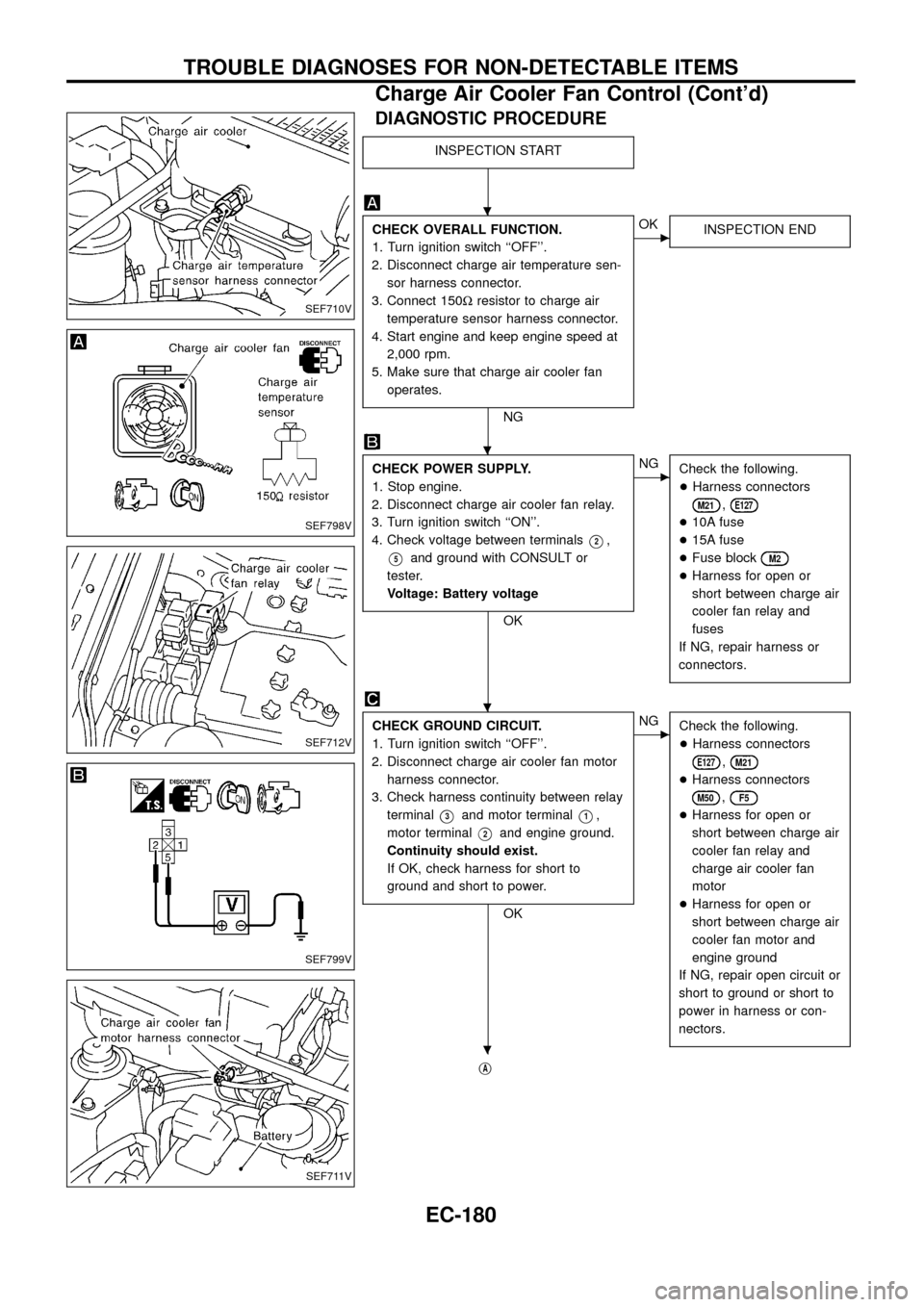

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK OVERALL FUNCTION.

1. Turn ignition switch ``OFF''.

2. Disconnect charge air temperature sen-

sor harness connector.

3. Connect 150Wresistor to charge air

temperature sensor harness connector.

4. Start engine and keep engine speed at

2,000 rpm.

5. Make sure that charge air cooler fan

operates.

NG

cOK

INSPECTION END

CHECK POWER SUPPLY.

1. Stop engine.

2. Disconnect charge air cooler fan relay.

3. Turn ignition switch ``ON''.

4. Check voltage between terminals

V2,

V5and ground with CONSULT or

tester.

Voltage: Battery voltage

OK

cNG

Check the following.

+Harness connectors

M21,E127

+10A fuse

+15A fuse

+Fuse block

M2

+Harness for open or

short between charge air

cooler fan relay and

fuses

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect charge air cooler fan motor

harness connector.

3. Check harness continuity between relay

terminal

V3and motor terminalV1,

motor terminal

V2and engine ground.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Harness connectors

E127,M21

+Harness connectors

M50,F5

+Harness for open or

short between charge air

cooler fan relay and

charge air cooler fan

motor

+Harness for open or

short between charge air

cooler fan motor and

engine ground

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

jA

SEF710V

SEF798V

SEF712V

SEF799V

SEF711V

.

.

.

.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Charge Air Cooler Fan Control (Cont'd)

EC-180

Page 183 of 192

jA

CHECK OUTPUT SIGNAL CIRCUIT.

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM

terminal

V8and relay terminalV1.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Harness connectors

E127,M21

+Harness connectors

M52,F7

+Harness for open or

short between ECM and

charge air cooler fan

relay

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK COMPONENT

(Charge air cooler fan relay).

Refer to ``COMPONENT INSPECTION''

on next page.

OK

cNG

Replace charge air cooler

fan relay.

CHECK COMPONENT

(Charge air cooler fan motor).

Refer to ``COMPONENT INSPECTION''

on next page.

OK

cNG

Replace charge air cooler

fan motor.

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not ®xed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

SEF800V

SEF801V

.

.

.

.

.

.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Charge Air Cooler Fan Control (Cont'd)

EC-181

Page 184 of 192

COMPONENT INSPECTION

Charge air cooler fan relay

Check continuity between terminalsV3andV5.

Conditions Continuity

12V direct current supply between

terminals

V1andV2Ye s

No current supply No

If NG, replace relay.

Charge air cooler fan motor

1. Disconnect charge air cooler fan motor harness connector.

2. Supply charge air cooler fan motor terminals with battery volt-

age and check operation.

Charge air cooler fan motor should operate.

If NG, replace charge air cooler fan motor.

SEF511P

SEF802V

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Charge Air Cooler Fan Control (Cont'd)

EC-182

Page 185 of 192

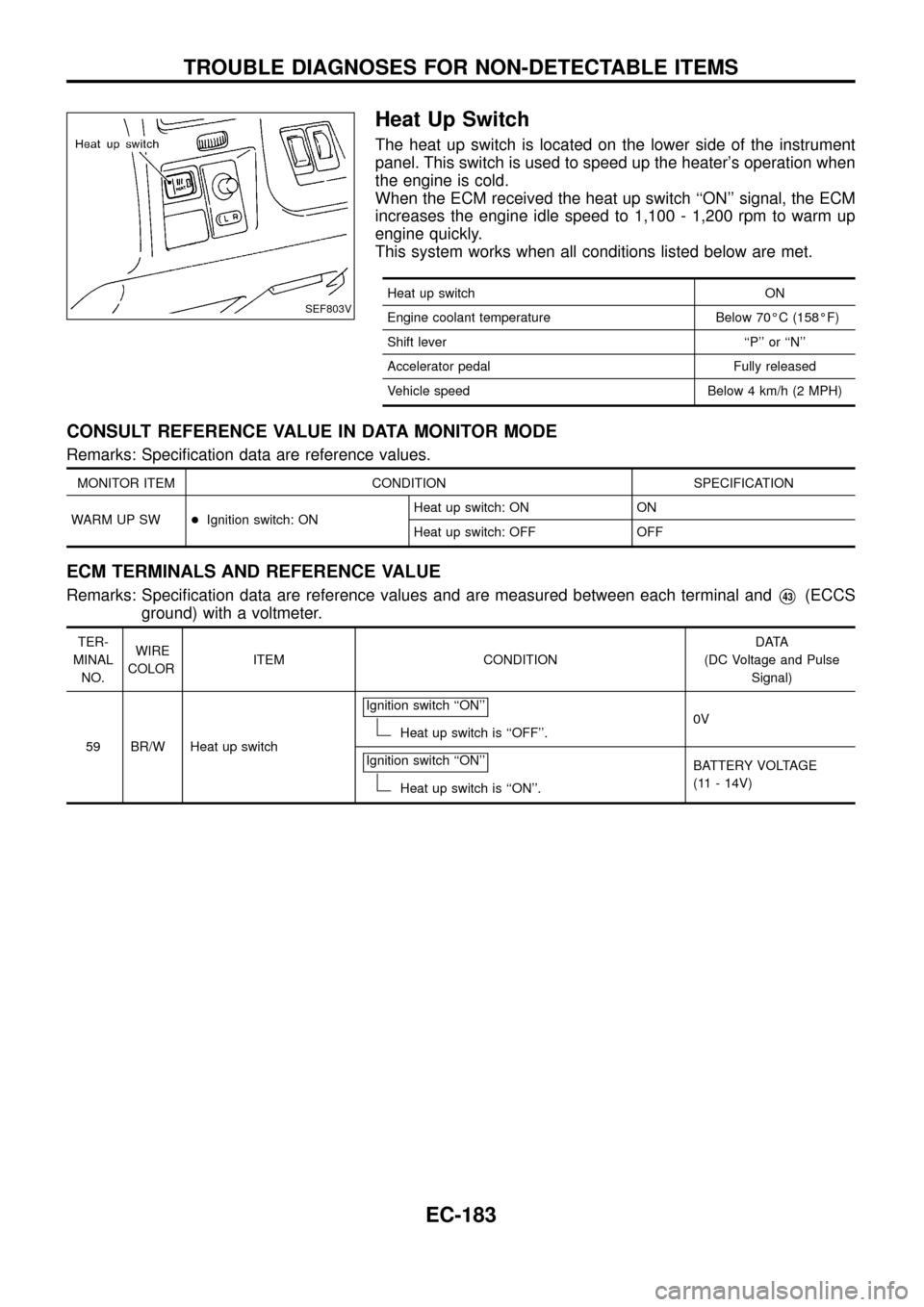

Heat Up Switch

The heat up switch is located on the lower side of the instrument

panel. This switch is used to speed up the heater's operation when

the engine is cold.

When the ECM received the heat up switch ``ON'' signal, the ECM

increases the engine idle speed to 1,100 - 1,200 rpm to warm up

engine quickly.

This system works when all conditions listed below are met.

Heat up switch ON

Engine coolant temperature Below 70ÉC (158ÉF)

Shift lever ``P'' or ``N''

Accelerator pedal Fully released

Vehicle speed Below 4 km/h (2 MPH)

CONSULT REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Speci®cation data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

WARM UP SW+Ignition switch: ONHeat up switch: ON ON

Heat up switch: OFF OFF

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

59 BR/W Heat up switchIgnition switch ``ON''

Heat up switch is ``OFF''.0V

Ignition switch ``ON''

Heat up switch is ``ON''.BATTERY VOLTAGE

(11 - 14V)

SEF803V

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

EC-183

Page 186 of 192

TEC447

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Heat Up Switch (Cont'd)

EC-184

Page 187 of 192

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK OVERALL FUNCTION.

1. Turn ignition switch ``ON''.

2. Check ``WARM UP SW'' signal

in ``DATA MONITOR'' mode with

CONSULT.

Heat up switch is ``ON'': ON

Heat up switch is ``OFF'': OFF

--------------------------------------------------------------------------------------------------------------------------------------OR--------------------------------------------------------------------------------------------------------------------------------------

2. Check voltage between ECM

terminal

V59and ground under

the following condition.

Voltage:

Heat up switch is ``ON''

Battery voltage

Heat up switch is ``OFF''

Approximately 0V

NG

cOK

INSPECTION END

CHECK POWER SUPPLY.

1. Turn heat up switch ``OFF''.

2. Turn ignition switch ``OFF''.

3. Disconnect heat up switch harness con-

nector.

4. Turn ignition switch ``ON''.

5. Check voltage between terminal

V6

and ground with CONSULT or tester.

Voltage: Battery voltage

OK

cNG

Check the following.

+Fuse block

M3

+10A fuse

+Harness for open or

short between heat up

switch and fuse

If NG, repair harness or

connectors.

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM

terminal

V59and terminalV5.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Harness connectors

M51,F6

+Harness for open or

short between heat up

switch and ECM

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

jA

SEF804V

SEF805V

SEF806V

SEF807V

.

.

.

.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Heat Up Switch (Cont'd)

EC-185

Page 188 of 192

jA

CHECK COMPONENT

(Heat up switch).

Refer to ``COMPONENT INSPECTION''

below.

OK

cNG

Replace heat up switch.

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not ®xed.

Check ECM pin terminals for damage or

the connection of ECM harness connector.

Reconnect ECM harness connector and

retest.

INSPECTION END

COMPONENT INSPECTION

Heat up switch

1. Disconnect heat up switch harness connector.

2. Check continuity between terminals

V5andV6.

Condition Continuity

Heat up switch ``ON'' Yes

Heat up switch ``OFF'' No

If NG, replace heat up switch.SEF808V

.

.

.

.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Heat Up Switch (Cont'd)

EC-186

Page 189 of 192

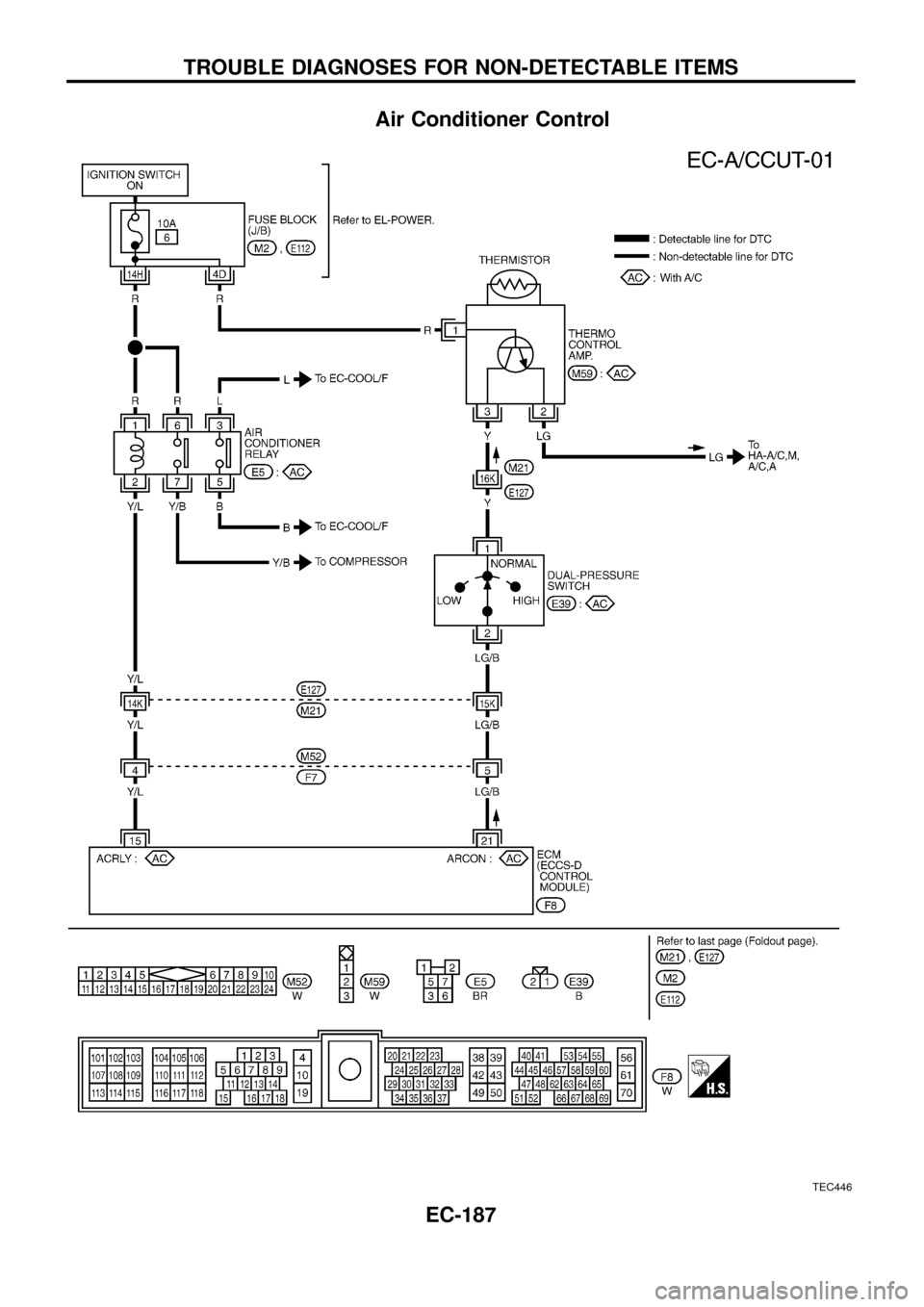

Air Conditioner Control

TEC446

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

EC-187

Page 190 of 192

MIL & Data Link Connectors

TEC448

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

EC-188