NISSAN PATROL 1998 Y61 / 5.G Engine Control Workshop Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 192, PDF Size: 4.28 MB

Page 171 of 192

COMPONENT INSPECTION

Accelerator position switch

1. Disconnect accelerator position switch harness connector.

2. Check continuity between terminals

V5andV6.

Conditions Continuity

Accelerator pedal released Yes

Accelerator pedal depressed No

3. Check continuity between terminalsV4andV5.

Conditions Continuity

Accelerator pedal released No

Accelerator pedal fully depressed Yes

If NG, replace accelerator pedal assembly.

CAUTION:

If accelerator position sensor or ECM connector is

disconnected, perform the following procedures:

Select ``OFF ACCEL PO SIG'' in ``ACTIVE TEST'' mode.

Touch CLEAR.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Start and warm up engine. After engine has warmed up,

idle for 10 minutes.

SEF709V

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Accelerator Position Switch (Cont'd)

EC-169

Page 172 of 192

Park/Neutral Position Switch

TEC445

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

EC-170

Page 173 of 192

When the gear position is in ``N'', neutral position switch is ``ON''.

The ECM detects the position because the continuity of the line (the

``ON'' signal) exists.

CONSULT REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Speci®cation data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

P/N POSI SW+Ignition switch: ONShift lever: Neutral/Park ON

Except above OFF

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

22 P/BInhibitor switch/

Neutral position switchIgnition switch ``ON''

Gear position is ``N'' or ``P'' (A/T models).Gear position is ``Neutral'' (M/T models).Approximately 0V

Ignition switch ``ON''

Except the above gear positionBATTERY VOLTAGE

(11 - 14V)

DIAGNOSTIC PROCEDURE

M/T models

INSPECTION START

CHECK OVERALL FUNCTION.

1. Turn ignition switch ``ON''.

2. Select ``P/N POSI SW'' in

``DATA MONITOR'' mode with

CONSULT.

3. Check ``P/N POSI SW'' signal

under the following conditions.

Neutral position: ON

Except neutral position: OFF

--------------------------------------------------------------------------------------------------------------------------------------OR--------------------------------------------------------------------------------------------------------------------------------------

2. Check voltage between ECM

terminal

V22and ground under

the following conditions.

Voltage:

Neutral position

Approximately 0V

Except neutral position

Battery voltage

NG

cOK

INSPECTION END

jA

SEF963N

SEF622S

SEF789V

.

.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Park/Neutral Position Switch (Cont'd)

EC-171

Page 174 of 192

jA

CHECK GROUND CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect neutral position switch har-

ness connector.

3. Check harness continuity between termi-

nal

V2and body ground.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Harness connectors

E202,E69

+Harness for open or short

between neutral position

switch and body ground

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK INPUT SIGNAL CIRCUIT.

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM

terminal

V22and terminalV1.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Harness connectors

F7,M52

+Harness connectors

M21,E127

+Harness connectors

E70,E201

+Harness for open or short

between ECM and neu-

tral position switch

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK COMPONENT

(Neutral position switch).

Refer to MT section.

OK

cNG

Replace neutral position

switch.

Disconnect and reconnect harness connec-

tors in the circuit. Then retest.

Trouble is not ®xed.

Check ECM pin terminals for damage and

check the connection of ECM harness con-

nector. Reconnect ECM harness connector

and retest.

INSPECTION END

AEC750

SEF624S

.

.

.

.

.

.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Park/Neutral Position Switch (Cont'd)

EC-172

Page 175 of 192

A/T models

INSPECTION START

CHECK OVERALL FUNCTION.

1. Turn ignition switch ``ON''.

2. Select ``P/N POSI SW'' in

``DATA MONITOR'' mode with

CONSULT.

3. Check ``P/N POSI SW'' signal

under the following conditions.

``P'' or ``N'' position: ON

Except above positions: OFF

--------------------------------------------------------------------------------------------------------------------------------------OR--------------------------------------------------------------------------------------------------------------------------------------

2. Check voltage between ECM

terminal

V22and ground under

the following conditions.

Voltage:

``P'' or ``N'' position

Approximately 0V

Except above positions

Battery voltage

NG

cOK

INSPECTION END

CHECK POWER SUPPLY.

1. Turn ignition switch ``OFF''.

2. Disconnect inhibitor switch harness con-

nector.

3. Turn ignition switch ``ON''.

4. Check voltage between terminal

V3and

ground with CONSULT or tester.

Voltage: Battery voltage

OK

cNG

Check the following.

+7.5A fuse

+Harness for open or short

between inhibitor switch

and fuse

If NG, repair harness or

connectors.

jA

SEF963N

SEF622S

SEF790V

SEF791V

SEF792V

.

.

.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Park/Neutral Position Switch (Cont'd)

EC-173

Page 176 of 192

jA

CHECK INPUT SIGNAL CIRCUIT-I.

1. Turn ignition switch ``OFF''.

2. Disconnect TCM harness connector.

3. Check harness continuity between TCM

terminal

V36and terminalsV7,V9.

Continuity should exist.

If OK, check harness for short to ground

and short to power.

OK

cNG

Check the following.

+Diode

E103

+Harness continuity

between inhibitor switch

and TCM

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK INPUT SIGNAL CIRCUIT-II.

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM

terminal

V22and TCM terminalV14.

Continuity should exist.

If OK, check harness for short to ground

and short to power.

OK

cNG

Check the following.

+Harness connectors

F7,M52

+Harness connectors

M21,E127

+Harness for open or short

between ECM and TCM

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK COMPONENT

(Inhibitor switch).

Refer to AT section.

OK

cNG

Replace inhibitor switch.

Disconnect and reconnect harness connec-

tors in the circuit. Then retest.

Trouble is not ®xed.

Check ECM pin terminals for damage or

the connection of ECM harness connector.

Reconnect ECM harness connector and

retest.

INSPECTION END

SEF793V

SEF794V

.

.

.

.

.

.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Park/Neutral Position Switch (Cont'd)

EC-174

Page 177 of 192

A/T Control

These circuit lines are used to control the smooth shifting up and

down of A/T during the hard acceleration/deceleration.

Voltage signals are exchanged between ECM and TCM.

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

24 PU/W A/T signal No. 1Engine is running.

Idle speed6-8V

30 P A/T signal No. 3Engine is running.

Idle speedApproximately 0V

37 P/B A/T signal No. 2Engine is running.

Idle speed6-8V

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

EC-175

Page 178 of 192

TEC440

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

A/T Control (Cont'd)

EC-176

Page 179 of 192

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK OVERALL FUNCTION.

1. Start engine and let it idle.

2. Check voltage between ECM terminals

V24,V30,V37and ground with CON-

SULT or tester.

NG

cOK

INSPECTION END

CHECK INPUT SIGNAL CIRCUIT-I.

1. Turn ignition switch ``OFF''.

2. Disconnect ECM harness connector

and TCM harness connector.

3. Check harness continuity between

ECM terminal

V24and terminalV5,

ECM terminal

V30and terminalV7,

ECM terminal

V37and terminalV6.

Continuity should exist.

OK

cNG

Check the following.

+Harness connectors

M51,F6

+Harness connectors

E106,M88

+Harness continuity

between ECM and TCM

If NG, repair harness or

connectors.

CHECK INPUT SIGNAL CIRCUIT-II.

Check harness continuity between ECM

terminal

V24and ground, ECM terminal

V30and ground, ECM terminalV37and

ground.

Continuity should not exist.

If OK, check harness for short to power.

OK

cNG

Check the following.

+Harness connectors

E106,M88

+Harness connectors

M51,F6

+Harness for short

between ECM and TCM

If NG, repair short to

ground or short to power in

harness or connectors.

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not ®xed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

Terminal Voltage

V24and ground 6 - 8V

V30and ground Approximately 0V

V37and ground 6 - 8V

SEF792V

SEF795V

SEF796V

SEF797V

.

.

.

.

.

.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

A/T Control (Cont'd)

EC-177

Page 180 of 192

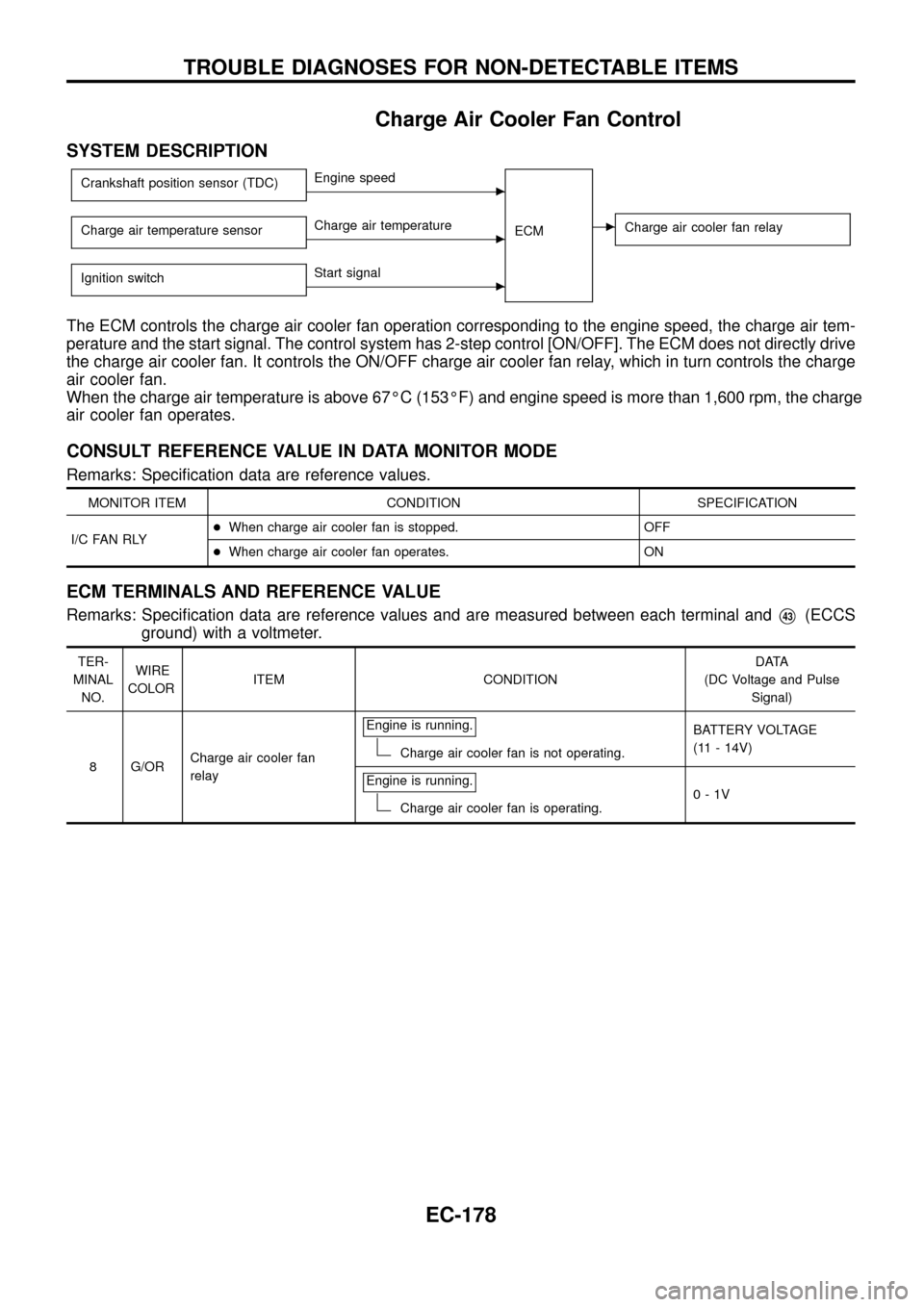

Charge Air Cooler Fan Control

SYSTEM DESCRIPTION

Crankshaft position sensor (TDC)cEngine speed

ECM

cCharge air cooler fan relayCharge air temperature sensorcCharge air temperature

Ignition switch

cStart signal

The ECM controls the charge air cooler fan operation corresponding to the engine speed, the charge air tem-

perature and the start signal. The control system has 2-step control [ON/OFF]. The ECM does not directly drive

the charge air cooler fan. It controls the ON/OFF charge air cooler fan relay, which in turn controls the charge

air cooler fan.

When the charge air temperature is above 67ÉC (153ÉF) and engine speed is more than 1,600 rpm, the charge

air cooler fan operates.

CONSULT REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Speci®cation data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

I/C FAN RLY+When charge air cooler fan is stopped. OFF

+When charge air cooler fan operates. ON

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

8 G/ORCharge air cooler fan

relayEngine is running.

Charge air cooler fan is not operating.BATTERY VOLTAGE

(11 - 14V)

Engine is running.

Charge air cooler fan is operating.0-1V

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

EC-178