Fuel NISSAN PATROL 1998 Y61 / 5.G Engine Control Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 192, PDF Size: 4.28 MB

Page 151 of 192

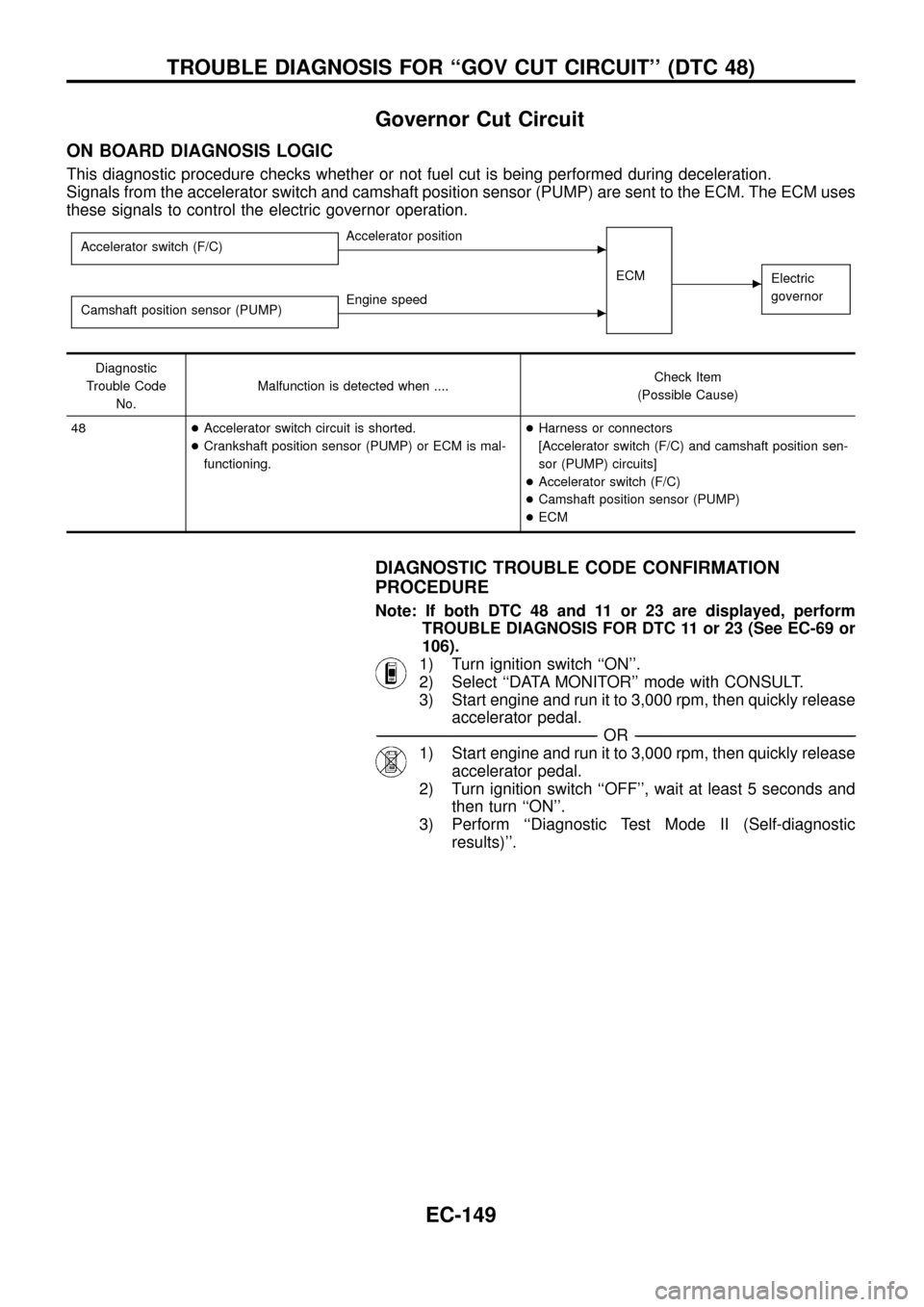

Governor Cut Circuit

ON BOARD DIAGNOSIS LOGIC

This diagnostic procedure checks whether or not fuel cut is being performed during deceleration.

Signals from the accelerator switch and camshaft position sensor (PUMP) are sent to the ECM. The ECM uses

these signals to control the electric governor operation.

Accelerator switch (F/C)cAccelerator position

ECM

cElectric

governor

Camshaft position sensor (PUMP)cEngine speed

Diagnostic

Trouble Code

No.Malfunction is detected when ....Check Item

(Possible Cause)

48+Accelerator switch circuit is shorted.

+Crankshaft position sensor (PUMP) or ECM is mal-

functioning.+Harness or connectors

[Accelerator switch (F/C) and camshaft position sen-

sor (PUMP) circuits]

+Accelerator switch (F/C)

+Camshaft position sensor (PUMP)

+ECM

DIAGNOSTIC TROUBLE CODE CONFIRMATION

PROCEDURE

Note: If both DTC 48 and 11 or 23 are displayed, perform

TROUBLE DIAGNOSIS FOR DTC 11 or 23 (See EC-69 or

106).

1) Turn ignition switch ``ON''.

2) Select ``DATA MONITOR'' mode with CONSULT.

3) Start engine and run it to 3,000 rpm, then quickly release

accelerator pedal.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Start engine and run it to 3,000 rpm, then quickly release

accelerator pedal.

2) Turn ignition switch ``OFF'', wait at least 5 seconds and

then turn ``ON''.

3) Perform ``Diagnostic Test Mode II (Self-diagnostic

results)''.

TROUBLE DIAGNOSIS FOR ``GOV CUT CIRCUIT'' (DTC 48)

EC-149

Page 155 of 192

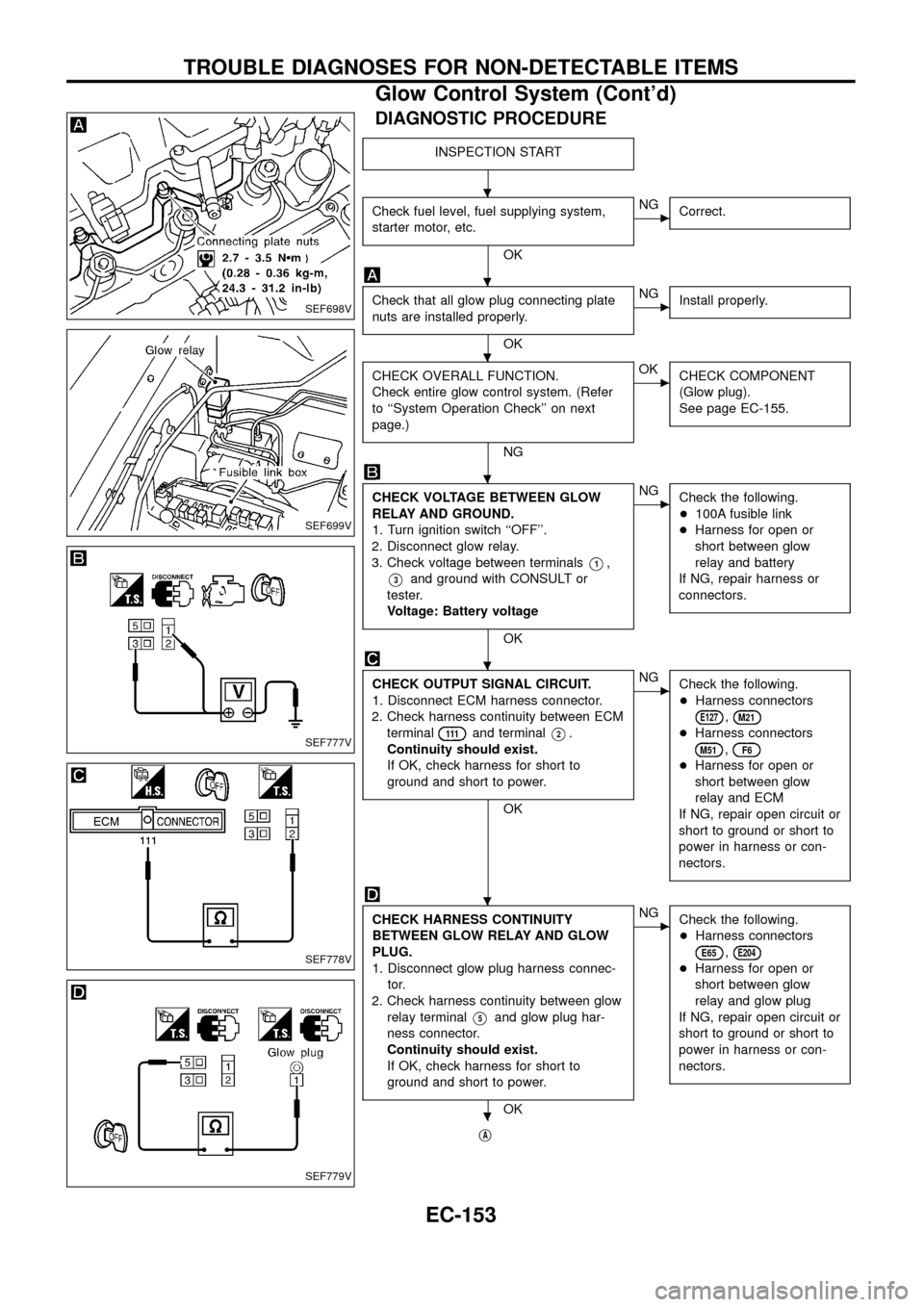

DIAGNOSTIC PROCEDURE

INSPECTION START

Check fuel level, fuel supplying system,

starter motor, etc.

OK

cNG

Correct.

Check that all glow plug connecting plate

nuts are installed properly.

OK

cNG

Install properly.

CHECK OVERALL FUNCTION.

Check entire glow control system. (Refer

to ``System Operation Check'' on next

page.)

NG

cOK

CHECK COMPONENT

(Glow plug).

See page EC-155.

CHECK VOLTAGE BETWEEN GLOW

RELAY AND GROUND.

1. Turn ignition switch ``OFF''.

2. Disconnect glow relay.

3. Check voltage between terminals

V1,

V3and ground with CONSULT or

tester.

Voltage: Battery voltage

OK

cNG

Check the following.

+100A fusible link

+Harness for open or

short between glow

relay and battery

If NG, repair harness or

connectors.

CHECK OUTPUT SIGNAL CIRCUIT.

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM

terminal

111and terminalV2.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Harness connectors

E127,M21

+Harness connectors

M51,F6

+Harness for open or

short between glow

relay and ECM

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK HARNESS CONTINUITY

BETWEEN GLOW RELAY AND GLOW

PLUG.

1. Disconnect glow plug harness connec-

tor.

2. Check harness continuity between glow

relay terminal

V5and glow plug har-

ness connector.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Harness connectors

E65,E204

+Harness for open or

short between glow

relay and glow plug

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

jA

SEF698V

SEF699V

SEF777V

SEF778V

SEF779V

.

.

.

.

.

.

.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Glow Control System (Cont'd)

EC-153

Page 192 of 192

![NISSAN PATROL 1998 Y61 / 5.G Engine Control Repair Manual ADJUSTMENT RESISTOR

Resistance [at 25ÉC (77ÉF)] kW0.2 - 15.0

INJECTION TIMING CONTROL VALVE

Resistance [at 20ÉC (68ÉF)]WApproximately 11

ELECTRIC GOVERNOR

Resistance [at 23ÉC (73ÉF)]W0.68

CRANKS NISSAN PATROL 1998 Y61 / 5.G Engine Control Repair Manual ADJUSTMENT RESISTOR

Resistance [at 25ÉC (77ÉF)] kW0.2 - 15.0

INJECTION TIMING CONTROL VALVE

Resistance [at 20ÉC (68ÉF)]WApproximately 11

ELECTRIC GOVERNOR

Resistance [at 23ÉC (73ÉF)]W0.68

CRANKS](/img/5/617/w960_617-191.png)

ADJUSTMENT RESISTOR

Resistance [at 25ÉC (77ÉF)] kW0.2 - 15.0

INJECTION TIMING CONTROL VALVE

Resistance [at 20ÉC (68ÉF)]WApproximately 11

ELECTRIC GOVERNOR

Resistance [at 23ÉC (73ÉF)]W0.68

CRANKSHAFT POSITION SENSOR (TDC)

Resistance [at 25ÉC (77ÉF)] kWApproximately 0.8 - 1.2

GLOW PLUG

Resistance [at 25ÉC (77ÉF)]W0.8

ACCELERATOR POSITION SENSOR

Throttle valve conditionsResistance kW

[at 25ÉC (77ÉF)]

Completely closed Approximately 0.5

Partially open 0.5 - 4

Completely open Approximately 4

FUEL TEMPERATURE SENSOR

Temperature ÉC (ÉF) Resistance kW

þ20 (þ4) 13.67 - 16.37

20 (68) 2.306 - 2.568

60 (140) 0.538 - 0.624

80 (176) 0.289 - 0.344

SERVICE DATA AND SPECIFICATIONS (SDS)

Inspection and Adjustment (Cont'd)

EC-190