sensor NISSAN PATROL 1998 Y61 / 5.G Engine Control Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 192, PDF Size: 4.28 MB

Page 140 of 192

COMPONENT INSPECTION

Fuel temperature sensor

Wait until fuel temperature sensor reaches room temperature.

Check resistance as shown in the ®gure.

Temperature ÉC (ÉF) Resistance kW

20 (68) 2.306 - 2.568

60 (140) 0.538 - 0.624

80 (176) 0.289 - 0.344

If NG, take proper action.SEF693V

SEF012P

TROUBLE DIAGNOSIS FOR ``FUEL TEMP SENSOR'' (DTC 42)

Fuel Temperature Sensor (FTS) (Cont'd)

EC-138

Page 141 of 192

Accelerator Position Sensor

The accelerator position sensor is installed on the upper end of the

accelerator pedal assembly. The sensor detects the accelerator

position and sends a signal to the ECM. The ECM uses the signal

to determine the amount of fuel to be injected.

CONSULT REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Speci®cation data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

ACCEL POS SEN+Ignition switch: ON

(Engine stopped)Accelerator pedal: released 0.40 - 0.60V

Accelerator pedal: depressed Approx. 4.0V

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

23 WAccelerator position sen-

sorIgnition switch ``ON''

Accelerator pedal fully released0.4 - 0.6V

Ignition switch ``ON''

Accelerator pedal fully depressedApproximately 4.3V

48 G/RAccelerator position sen-

sor power supplyIgnition switch ``ON''

Approximately 5V

51 L/WAccelerator position sen-

sor groundEngine is running.

(Warm-up condition)

Idle speedApproximately 0V

SEF861SA

TROUBLE DIAGNOSIS FOR ``ACCEL POS SENSOR'' (DTC 43)

EC-139

Page 142 of 192

ON BOARD DIAGNOSIS LOGIC

Diagnostic

Trouble

Code No.Malfunction is detected when ...Check Items

(Possible Cause)

43+An excessively low or high voltage from the sensor is

detected by the ECM.+Harness or connectors

(The sensor circuit is open or shorted.)

+Accelerator position sensor

+Accelerator position switch

+Accelerator switch (F/C)

DIAGNOSTIC TROUBLE CODE CONFIRMATION

PROCEDURE

1) Turn ignition switch ``ON''.

2) Select ``DATA MONITOR'' mode with CONSULT.

3) Wait at least 2 seconds.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Turn ignition switch ``ON'' and wait at least 2 seconds.

2) Turn ignition switch ``OFF'', wait at least 5 seconds and

then turn ``ON''.

3) Perform ``Diagnostic Test Mode II (Self-diagnostic

results)'' with ECM.

SEF748V

TROUBLE DIAGNOSIS FOR ``ACCEL POS SENSOR'' (DTC 43)

Accelerator Position Sensor (Cont'd)

EC-140

Page 143 of 192

TEC436

TROUBLE DIAGNOSIS FOR ``ACCEL POS SENSOR'' (DTC 43)

Accelerator Position Sensor (Cont'd)

EC-141

Page 144 of 192

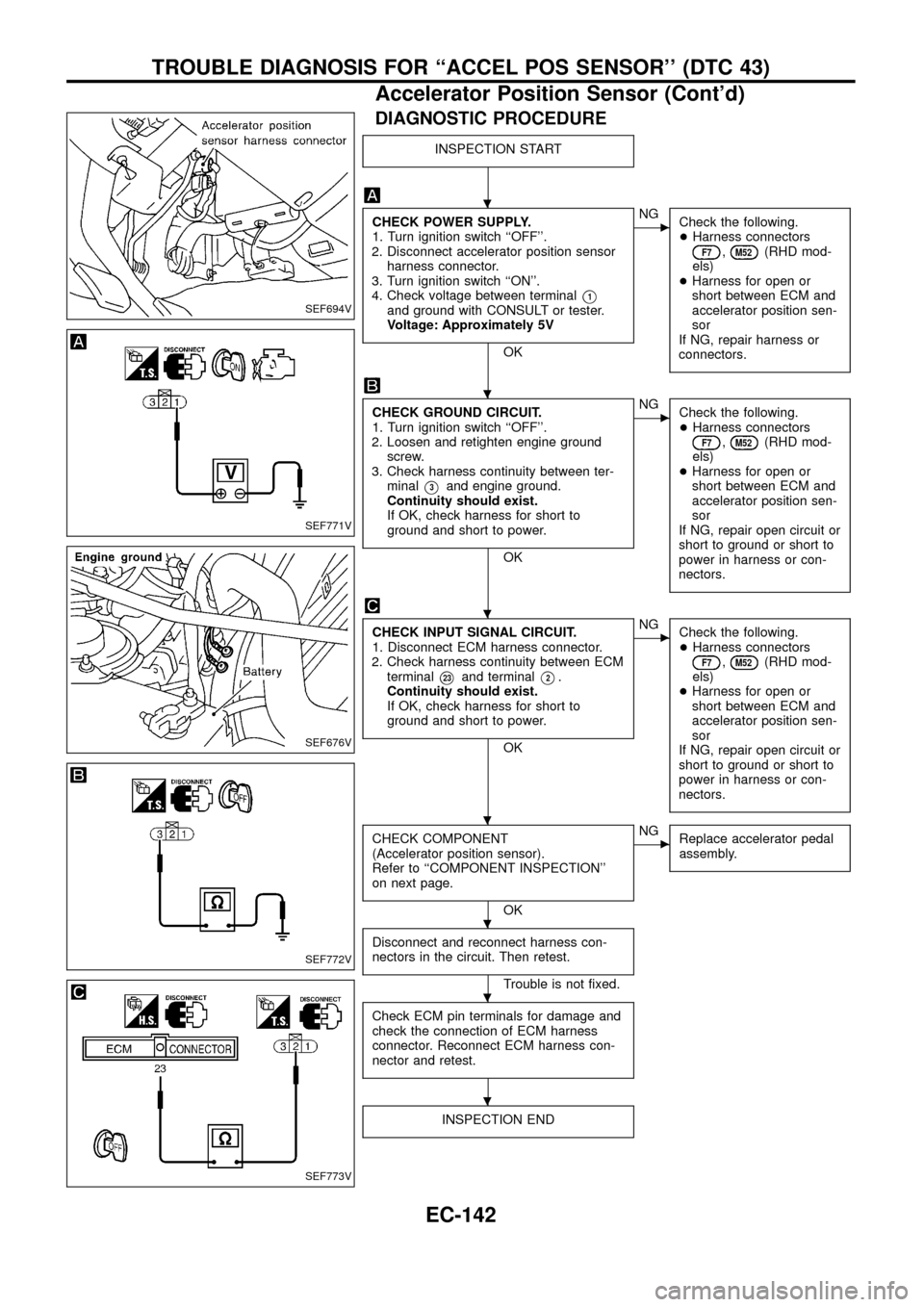

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK POWER SUPPLY.

1. Turn ignition switch ``OFF''.

2. Disconnect accelerator position sensor

harness connector.

3. Turn ignition switch ``ON''.

4. Check voltage between terminal

V1and ground with CONSULT or tester.

Voltage: Approximately 5V

OK

cNG

Check the following.

+Harness connectors

F7,M52(RHD mod-

els)

+Harness for open or

short between ECM and

accelerator position sen-

sor

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Loosen and retighten engine ground

screw.

3. Check harness continuity between ter-

minal

V3and engine ground.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Harness connectors

F7,M52(RHD mod-

els)

+Harness for open or

short between ECM and

accelerator position sen-

sor

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK INPUT SIGNAL CIRCUIT.

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM

terminal

V23and terminalV2.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Harness connectors

F7,M52(RHD mod-

els)

+Harness for open or

short between ECM and

accelerator position sen-

sor

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK COMPONENT

(Accelerator position sensor).

Refer to ``COMPONENT INSPECTION''

on next page.

OK

cNG

Replace accelerator pedal

assembly.

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not ®xed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

SEF694V

SEF771V

SEF676V

SEF772V

SEF773V

.

.

.

.

.

.

.

TROUBLE DIAGNOSIS FOR ``ACCEL POS SENSOR'' (DTC 43)

Accelerator Position Sensor (Cont'd)

EC-142

Page 145 of 192

COMPONENT INSPECTION

Accelerator position sensor

1. Disconnect accelerator position sensor harness connector.

2. Make sure that resistance between terminals

V2andV3

changes when depressing accelerator pedal manually.

Accelerator pedal conditions Resistance [at 25ÉC (77ÉF)]

Completely released Approximately 0.5 kW

Partially depressed 0.5-4kW

Completely depressed Approximately 4 kW

If NG, replace accelerator pedal assembly.

CAUTION:

If accelerator position sensor or ECM connector is

disconnected, perform the following procedures:

Select ``OFF ACCEL PO SIG'' in ``ACTIVE TEST'' mode.

Touch CLEAR.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Start and warm up engine. After engine has warmed up,

idle for 10 minutes.

SEF695V

TROUBLE DIAGNOSIS FOR ``ACCEL POS SENSOR'' (DTC 43)

Accelerator Position Sensor (Cont'd)

EC-143

Page 146 of 192

Crankshaft Position Sensor (TDC)

The crankshaft position sensor (TDC) monitors engine speed by

means of signals from the sensing plate (with two protrusions)

installed to the crankshaft pulley. The datum signal output is

detected at ATDC 70É and sent to the ECM. The sensor signal is

used for fuel injection control and fuel injection timing control.

CONSULT REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Speci®cation data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

CKPSzRPM (TDC)+Tachometer: Connect

+Run engine and compare tachometer indication with the CONSULT

value.Almost the same speed as the

CONSULT value.

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

40

44LCrankshaft position sensor

(TDC)Engine is running.

(Warm-up condition)

Idle speedApproximately 0V

SEF720V

Engine is running.(Warm-up condition)

Engine speed is 2,000 rpm.Approximately 0V

SEF721V

47

52B/WCrankshaft position sensor

(TDC) groundEngine is running.(Warm-up condition)

Idle speedApproximately 0V

ON BOARD DIAGNOSIS LOGIC

Diagnostic

Trouble Code

No.Malfunction is detected when ....Check Items

(Possible Cause)

47+An improper signal from the sensor is detected by

ECM during engine running and cranking.+Harness or connectors

(The sensor circuit is open.)

+Crankshaft position sensor (TDC)

SEF615S

TROUBLE DIAGNOSIS FOR ``CRANK POS SEN (TDC)'' (DTC 47)

EC-144

Page 147 of 192

DIAGNOSTIC TROUBLE CODE CONFIRMATION

PROCEDURE

Before performing the following procedure, con®rm that bat-

tery voltage is more than 10V.

1) Turn ignition switch ``ON'' and select ``DATA MONITOR''

mode with CONSULT.

2) Crank engine for at least 1 second.

3) Start engine and run it for at least 2 seconds at idle

speed.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Crank engine for at least 1 second.

2) Start engine and run it for at least 2 seconds at idle

speed.

3) Turn ignition switch ``OFF'', wait at least 5 seconds and

then turn ``ON''.

4) Perform ``Diagnostic Test Mode II (Self-diagnostic

results)'' with ECM.SEF714V

TROUBLE DIAGNOSIS FOR ``CRANK POS SEN (TDC)'' (DTC 47)

Crankshaft Position Sensor (TDC) (Cont'd)

EC-145

Page 148 of 192

TEC437

TROUBLE DIAGNOSIS FOR ``CRANK POS SEN (TDC)'' (DTC 47)

Crankshaft Position Sensor (TDC) (Cont'd)

EC-146

Page 149 of 192

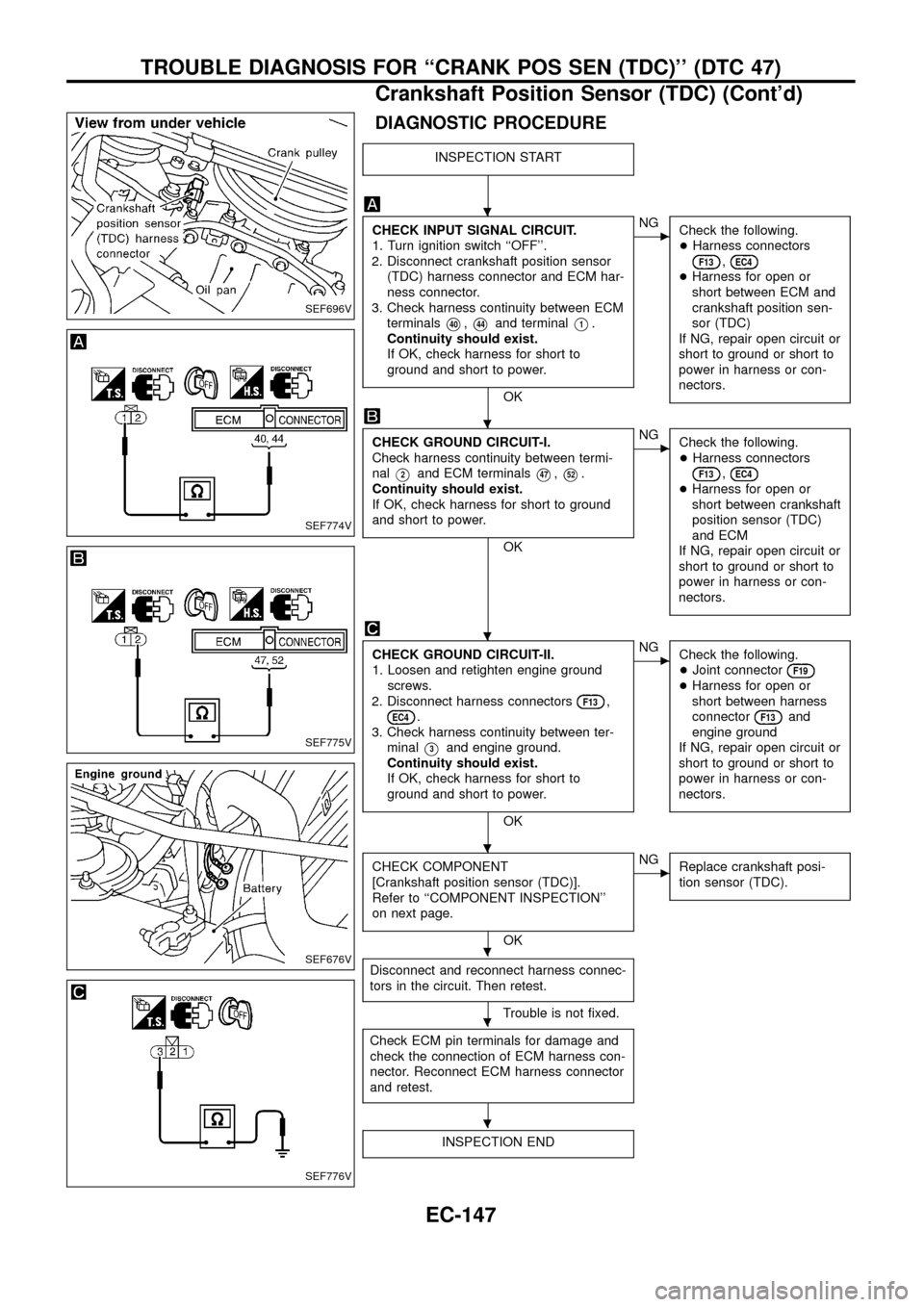

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect crankshaft position sensor

(TDC) harness connector and ECM har-

ness connector.

3. Check harness continuity between ECM

terminals

V40,V44and terminalV1.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Harness connectors

F13,EC4+Harness for open or

short between ECM and

crankshaft position sen-

sor (TDC)

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK GROUND CIRCUIT-I.

Check harness continuity between termi-

nal

V2and ECM terminalsV47,V52.

Continuity should exist.

If OK, check harness for short to ground

and short to power.

OK

cNG

Check the following.

+Harness connectors

F13,EC4+Harness for open or

short between crankshaft

position sensor (TDC)

and ECM

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK GROUND CIRCUIT-II.

1. Loosen and retighten engine ground

screws.

2. Disconnect harness connectors

F13,EC4.

3. Check harness continuity between ter-

minal

V3and engine ground.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Joint connector

F19+Harness for open or

short between harness

connector

F13and

engine ground

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK COMPONENT

[Crankshaft position sensor (TDC)].

Refer to ``COMPONENT INSPECTION''

on next page.

OK

cNG

Replace crankshaft posi-

tion sensor (TDC).

Disconnect and reconnect harness connec-

tors in the circuit. Then retest.

Trouble is not ®xed.

Check ECM pin terminals for damage and

check the connection of ECM harness con-

nector. Reconnect ECM harness connector

and retest.

INSPECTION END

SEF696V

SEF774V

SEF775V

SEF676V

SEF776V

.

.

.

.

.

.

.

TROUBLE DIAGNOSIS FOR ``CRANK POS SEN (TDC)'' (DTC 47)

Crankshaft Position Sensor (TDC) (Cont'd)

EC-147