lock NISSAN PATROL 2006 Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 612 of 1226

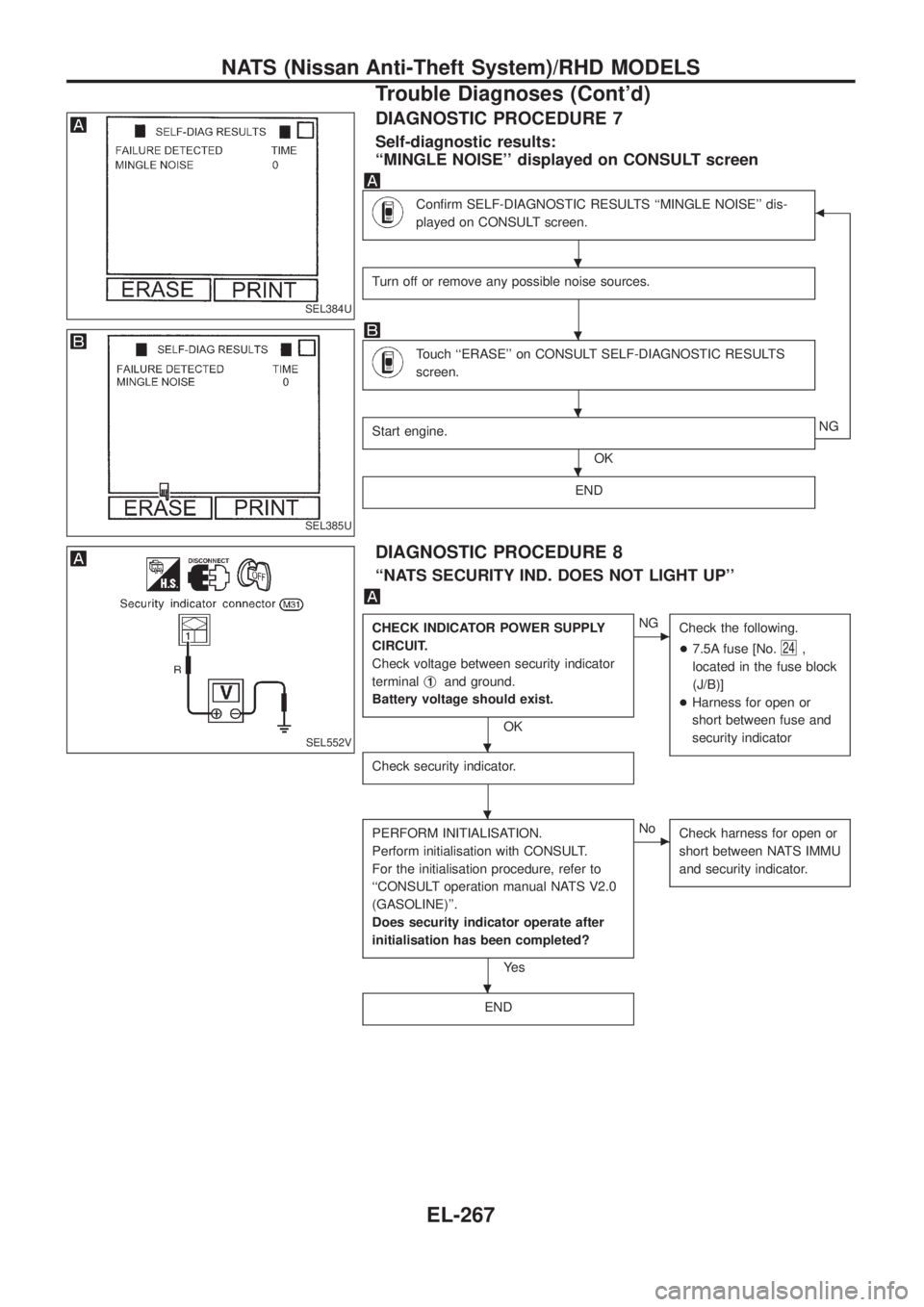

DIAGNOSTIC PROCEDURE 7

Self-diagnostic results:

``MINGLE NOISE'' displayed on CONSULT screen

Con®rm SELF-DIAGNOSTIC RESULTS ``MINGLE NOISE'' dis-

played on CONSULT screen.b

Turn off or remove any possible noise sources.

Touch ``ERASE'' on CONSULT SELF-DIAGNOSTIC RESULTS

screen.

Start engine.

OKNG

END

DIAGNOSTIC PROCEDURE 8

``NATS SECURITY IND. DOES NOT LIGHT UP''

CHECK INDICATOR POWER SUPPLY

CIRCUIT.

Check voltage between security indicator

terminalj

1and ground.

Battery voltage should exist.

OK

cNG

Check the following.

+7.5A fuse [No.

24,

located in the fuse block

(J/B)]

+Harness for open or

short between fuse and

security indicator

Check security indicator.

PERFORM INITIALISATION.

Perform initialisation with CONSULT.

For the initialisation procedure, refer to

``CONSULT operation manual NATS V2.0

(GASOLINE)''.

Does security indicator operate after

initialisation has been completed?

Ye s

cNo

Check harness for open or

short between NATS IMMU

and security indicator.

END

SEL384U

SEL385U

SEL552V

.

.

.

.

.

.

.

NATS (Nissan Anti-Theft System)/RHD MODELS

Trouble Diagnoses (Cont'd)

EL-267

Page 613 of 1226

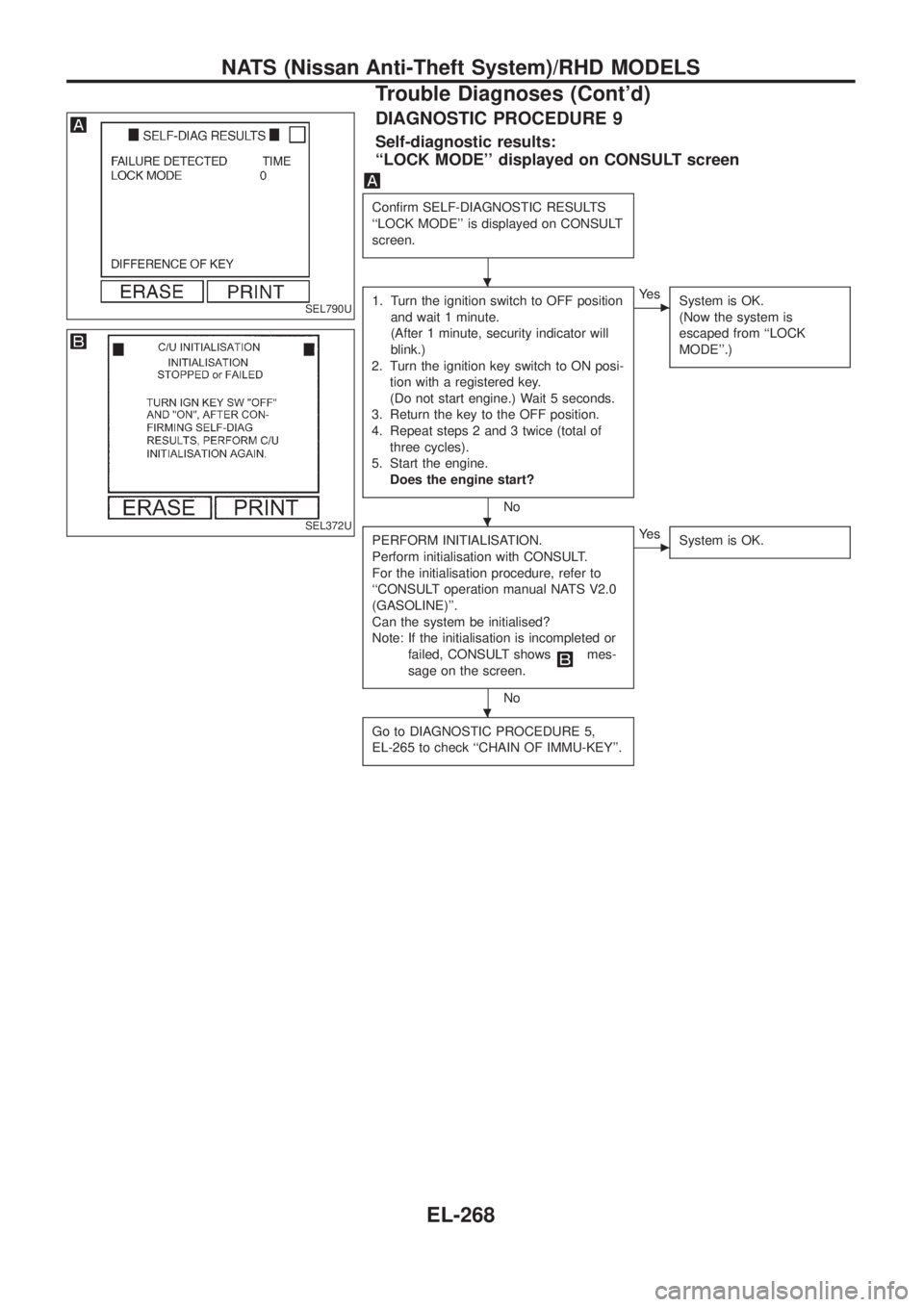

DIAGNOSTIC PROCEDURE 9

Self-diagnostic results:

``LOCK MODE'' displayed on CONSULT screen

Con®rm SELF-DIAGNOSTIC RESULTS

``LOCK MODE'' is displayed on CONSULT

screen.

1. Turn the ignition switch to OFF position

and wait 1 minute.

(After 1 minute, security indicator will

blink.)

2. Turn the ignition key switch to ON posi-

tion with a registered key.

(Do not start engine.) Wait 5 seconds.

3. Return the key to the OFF position.

4. Repeat steps 2 and 3 twice (total of

three cycles).

5. Start the engine.

Does the engine start?

No

cYe s

System is OK.

(Now the system is

escaped from ``LOCK

MODE''.)

PERFORM INITIALISATION.

Perform initialisation with CONSULT.

For the initialisation procedure, refer to

``CONSULT operation manual NATS V2.0

(GASOLINE)''.

Can the system be initialised?

Note: If the initialisation is incompleted or

failed, CONSULT shows

mes-

sage on the screen.

No

cYe s

System is OK.

Go to DIAGNOSTIC PROCEDURE 5,

EL-265 to check ``CHAIN OF IMMU-KEY''.

SEL790U

SEL372U

.

.

.

NATS (Nissan Anti-Theft System)/RHD MODELS

Trouble Diagnoses (Cont'd)

EL-268

Page 660 of 1226

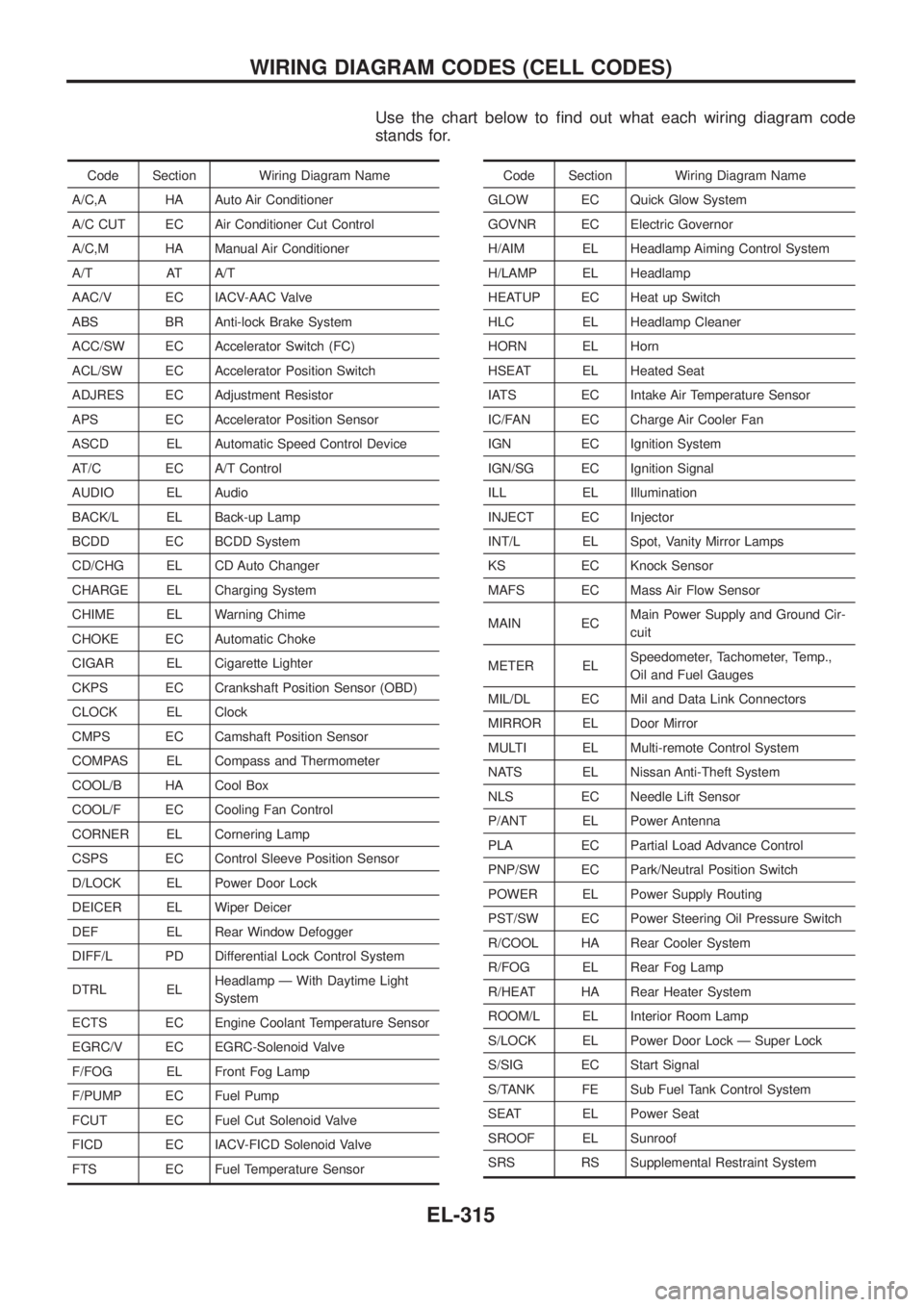

Use the chart below to ®nd out what each wiring diagram code

stands for.

Code Section Wiring Diagram Name

A/C,A HA Auto Air Conditioner

A/C CUT EC Air Conditioner Cut Control

A/C,M HA Manual Air Conditioner

A/T AT A/T

AAC/V EC IACV-AAC Valve

ABS BR Anti-lock Brake System

ACC/SW EC Accelerator Switch (FC)

ACL/SW EC Accelerator Position Switch

ADJRES EC Adjustment Resistor

APS EC Accelerator Position Sensor

ASCD EL Automatic Speed Control Device

AT/C EC A/T Control

AUDIO EL Audio

BACK/L EL Back-up Lamp

BCDD EC BCDD System

CD/CHG EL CD Auto Changer

CHARGE EL Charging System

CHIME EL Warning Chime

CHOKE EC Automatic Choke

CIGAR EL Cigarette Lighter

CKPS EC Crankshaft Position Sensor (OBD)

CLOCK EL Clock

CMPS EC Camshaft Position Sensor

COMPAS EL Compass and Thermometer

COOL/B HA Cool Box

COOL/F EC Cooling Fan Control

CORNER EL Cornering Lamp

CSPS EC Control Sleeve Position Sensor

D/LOCK EL Power Door Lock

DEICER EL Wiper Deicer

DEF EL Rear Window Defogger

DIFF/L PD Differential Lock Control System

DTRL ELHeadlamp Ð With Daytime Light

System

ECTS EC Engine Coolant Temperature Sensor

EGRC/V EC EGRC-Solenoid Valve

F/FOG EL Front Fog Lamp

F/PUMP EC Fuel Pump

FCUT EC Fuel Cut Solenoid Valve

FICD EC IACV-FICD Solenoid Valve

FTS EC Fuel Temperature SensorCode Section Wiring Diagram Name

GLOW EC Quick Glow System

GOVNR EC Electric Governor

H/AIM EL Headlamp Aiming Control System

H/LAMP EL Headlamp

HEATUP EC Heat up Switch

HLC EL Headlamp Cleaner

HORN EL Horn

HSEAT EL Heated Seat

IATS EC Intake Air Temperature Sensor

IC/FAN EC Charge Air Cooler Fan

IGN EC Ignition System

IGN/SG EC Ignition Signal

ILL EL Illumination

INJECT EC Injector

INT/L EL Spot, Vanity Mirror Lamps

KS EC Knock Sensor

MAFS EC Mass Air Flow Sensor

MAIN ECMain Power Supply and Ground Cir-

cuit

METER ELSpeedometer, Tachometer, Temp.,

Oil and Fuel Gauges

MIL/DL EC Mil and Data Link Connectors

MIRROR EL Door Mirror

MULTI EL Multi-remote Control System

NATS EL Nissan Anti-Theft System

NLS EC Needle Lift Sensor

P/ANT EL Power Antenna

PLA EC Partial Load Advance Control

PNP/SW EC Park/Neutral Position Switch

POWER EL Power Supply Routing

PST/SW EC Power Steering Oil Pressure Switch

R/COOL HA Rear Cooler System

R/FOG EL Rear Fog Lamp

R/HEAT HA Rear Heater System

ROOM/L EL Interior Room Lamp

S/LOCK EL Power Door Lock Ð Super Lock

S/SIG EC Start Signal

S/TANK FE Sub Fuel Tank Control System

SEAT EL Power Seat

SROOF EL Sunroof

SRS RS Supplemental Restraint System

WIRING DIAGRAM CODES (CELL CODES)

EL-315

Page 664 of 1226

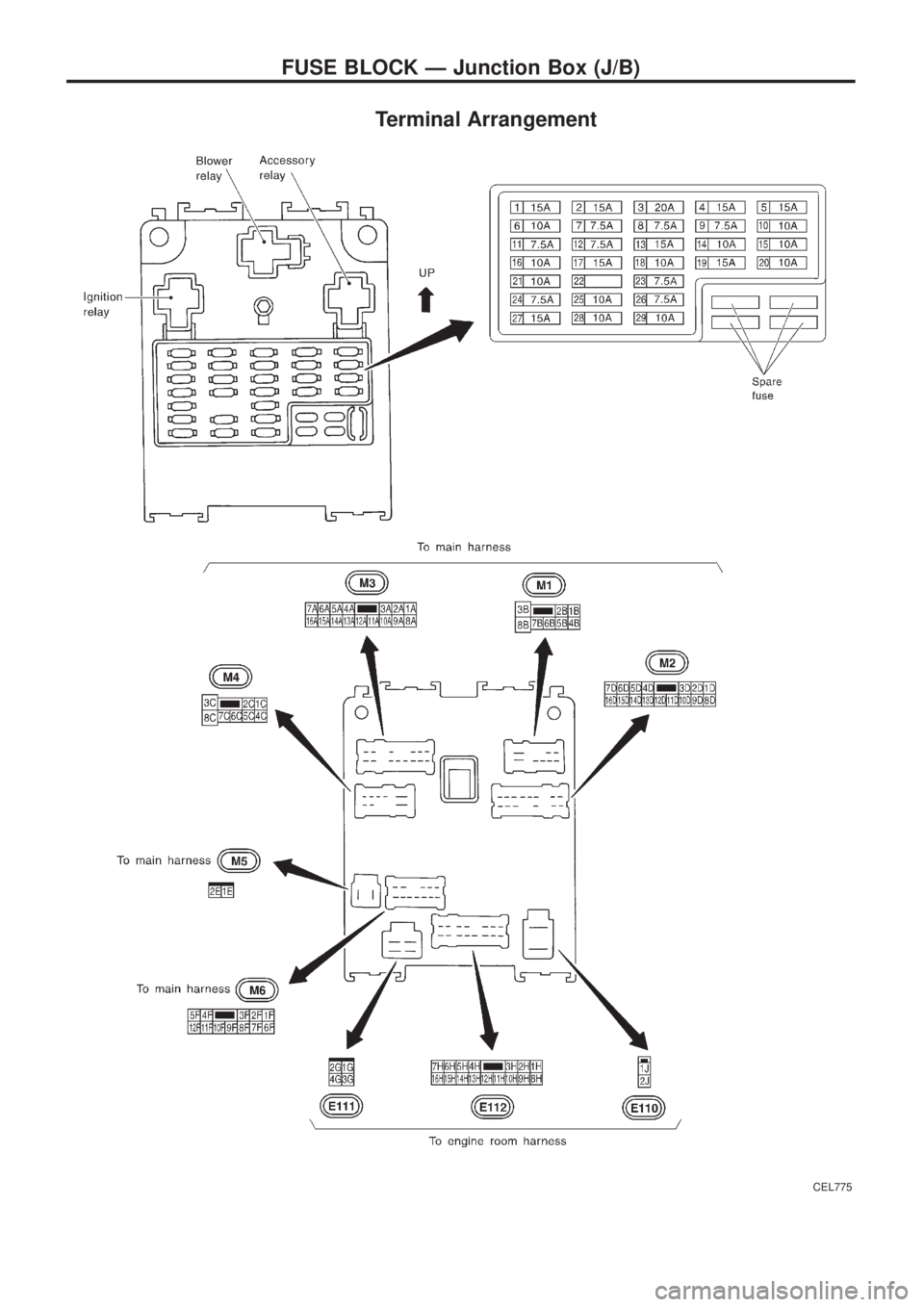

Terminal Arrangement

CEL775

FUSE BLOCK Ð Junction Box (J/B)

Page 668 of 1226

ENGINE MECHANICAL

SECTION

EM

CONTENTS

PRECAUTIONS...............................................................1

Parts Requiring Angular Tightening .............................1

Liquid Gasket Application Procedure ..........................1

PREPARATION................................................................2

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................6

NVH Troubleshooting Chart Ð Engine Noise .............7

OUTER COMPONENT PARTS.......................................8

COMPRESSION PRESSURE........................................10

Measurement of Compression Pressure ...................10

OIL PAN.........................................................................13

Removal .....................................................................13

Installation ..................................................................14

TIMING BELT.................................................................15

Removal .....................................................................15

Inspection...................................................................17

Installation ..................................................................18

OIL SEAL REPLACEMENT..........................................20

TURBOCHARGER.........................................................23

Removal and Installation ...........................................23

Inspection...................................................................24CHARGE AIR COOLERS..............................................27

CYLINDER HEAD..........................................................28

Removal .....................................................................29

Disassembly...............................................................30

Inspection...................................................................31

Assembly ...................................................................37

Installation ..................................................................37

VALVE CLEARANCE....................................................40

Checking ....................................................................40

Adjusting ....................................................................41

ENGINE REMOVAL.......................................................43

Removal .....................................................................44

Installation ..................................................................44

CYLINDER BLOCK.......................................................45

Disassembly...............................................................46

Inspection...................................................................46

Assembly ...................................................................53

SERVICE DATA AND SPECIFICATIONS (SDS)..........56

General Speci®cations ...............................................56

Inspection and Adjustment ........................................56

EM

Page 676 of 1226

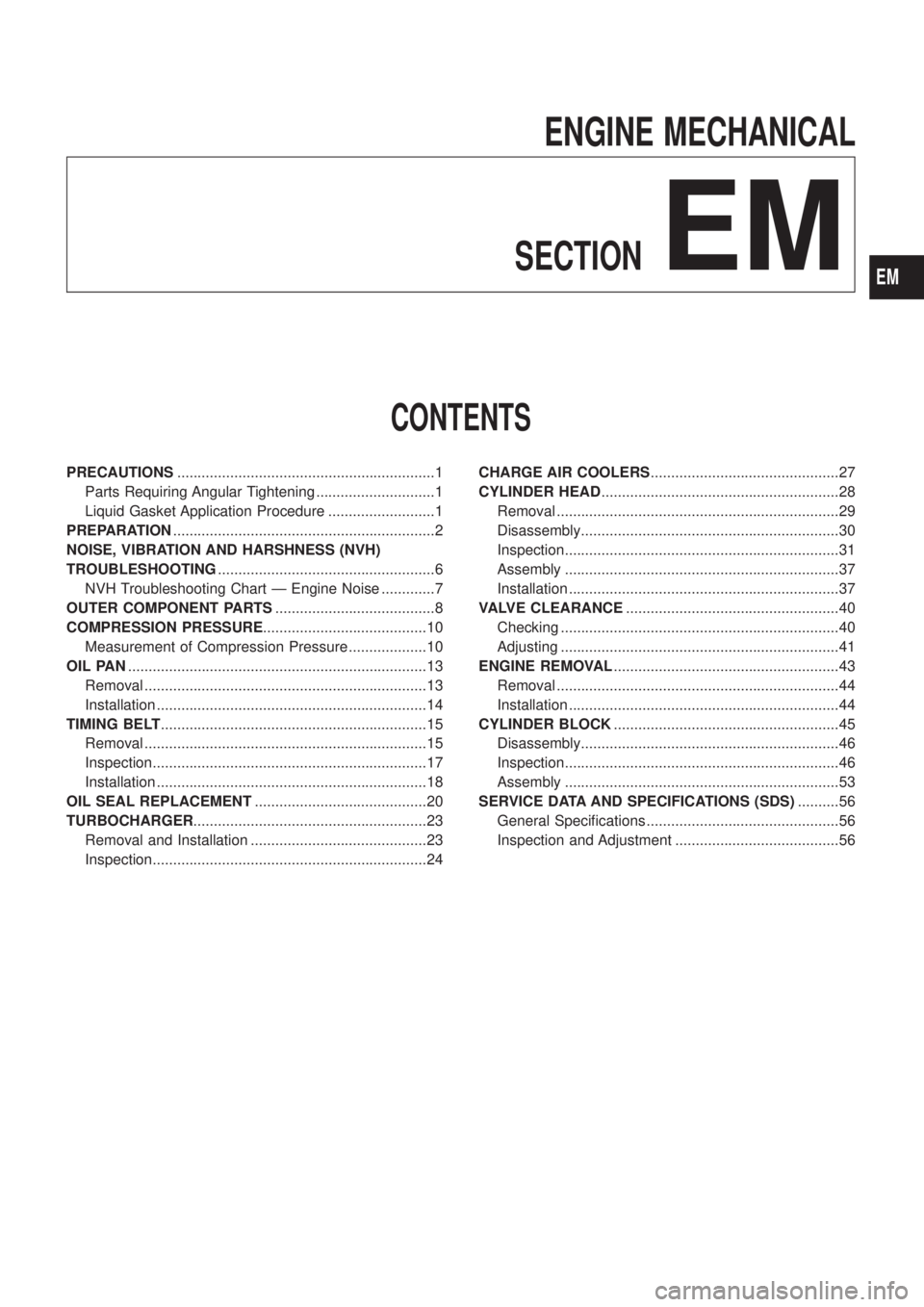

NVH Troubleshooting Chart Ð Engine Noise

Use the chart below to help you ®nd the cause of the problem.

1. Locate the area where noise occurs.

2. Con®rm the type of noise.

3. Specify the operating condition of engine.

4. Check speci®ed noise source.

If necessary, repair or replace these parts.

Location of

noiseType of

noiseOperating condition of engine

Source of

noiseCheck itemReference

page Before

warm-upAfter

warm-upWhen

startingWhen

idlingWhen

racingWhile

driving

To p o f

engine

Rocker

cover

Cylinder

headTicking or

clickingCAÐABÐTappet

noiseValve clearance EM-41

Rattle C A Ð A B CCamshaft

bearing

noiseCamshaft journal clearance

Camshaft runoutEM-37

Crankshaft

pulley

Cylinder

block (Side

of engine)

Oil panSlap or

knockÐAÐB BÐPiston pin

noisePiston and piston pin clear-

ance

Connecting rod bushing

clearanceEM-47, 53

Slap or rap A Ð Ð B B APiston slap

noisePiston-to-bore clearance

Piston ring side clearance

Piston ring end gap

Connecting rod bend and

torsionEM-48, 49

Knock A B C B B BConnecting

rod bearing

noiseConnecting rod bushing

clearance (Small end)

Connecting rod bearing

clearance (Big end)EM-52, 53

Knock A B Ð A B CMain bear-

ing noiseMain bearing oil clearance

Crankshaft runoutEM-51

Timing belt

coverWhine or

hissingCAÐAAÐTiming belt

noise (too

tight)

Loose timing belt

Belt contacting caseEM-18

Clatter A B Ð C A ÐTiming belt

noise (too

loose)

Front of

engineSqueaking

or ®zzingABÐBÐCOther drive

belts

(Sticking or

slipping)Drive belts de¯ection

*1

CreakingABABABOther drive

belts (Slip-

ping)Idler pulley bearing operation

Squall

CreakABÐBABWater pump

noiseWater pump operation *2

A: Closely related B: Related C: Sometimes related Ð: Not related

*1: MA section (``Checking Drive Belts'', ``ENGINE MAINTENANCE'')

*2: LC section (``Water Pump Inspection'', ``ENGINE COOLING SYSTEM'')

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

EM-8

Page 685 of 1226

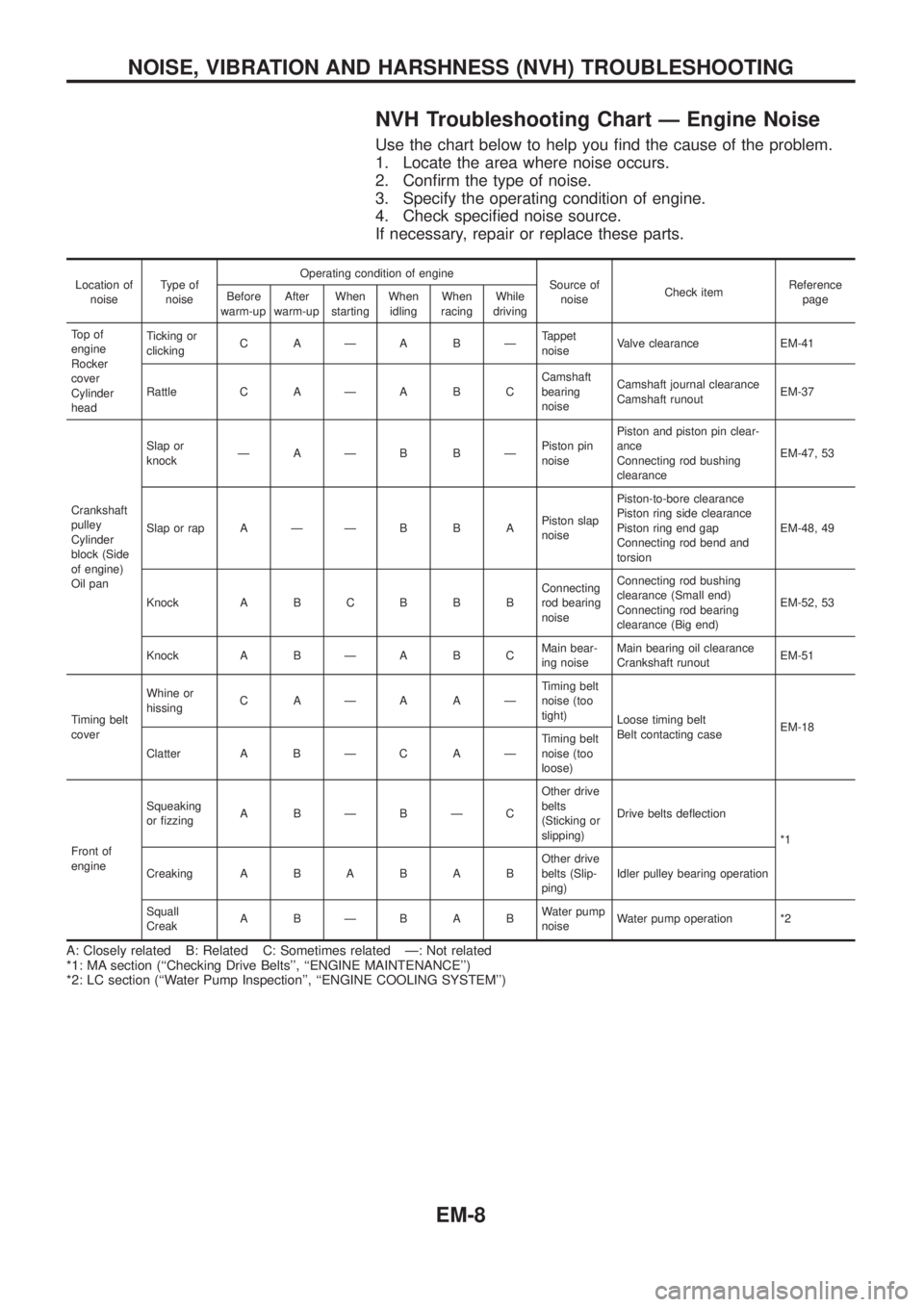

4. Set No. 1 cylinder at bottom dead center (BDC) on its expan-

sion stroke, as shown.

5. Remove the starter motor and wipe off the liquid gasket remain-

ing on the connecting part.

6. Install the ring gear stopper using the bolt holes for ®xing the

starter motor.

7. Remove crankshaft pulley using puller.

Be sure to securely attach puller jaws. Attach jaws only to the

rear side of pulley.

8. Remove front cover.

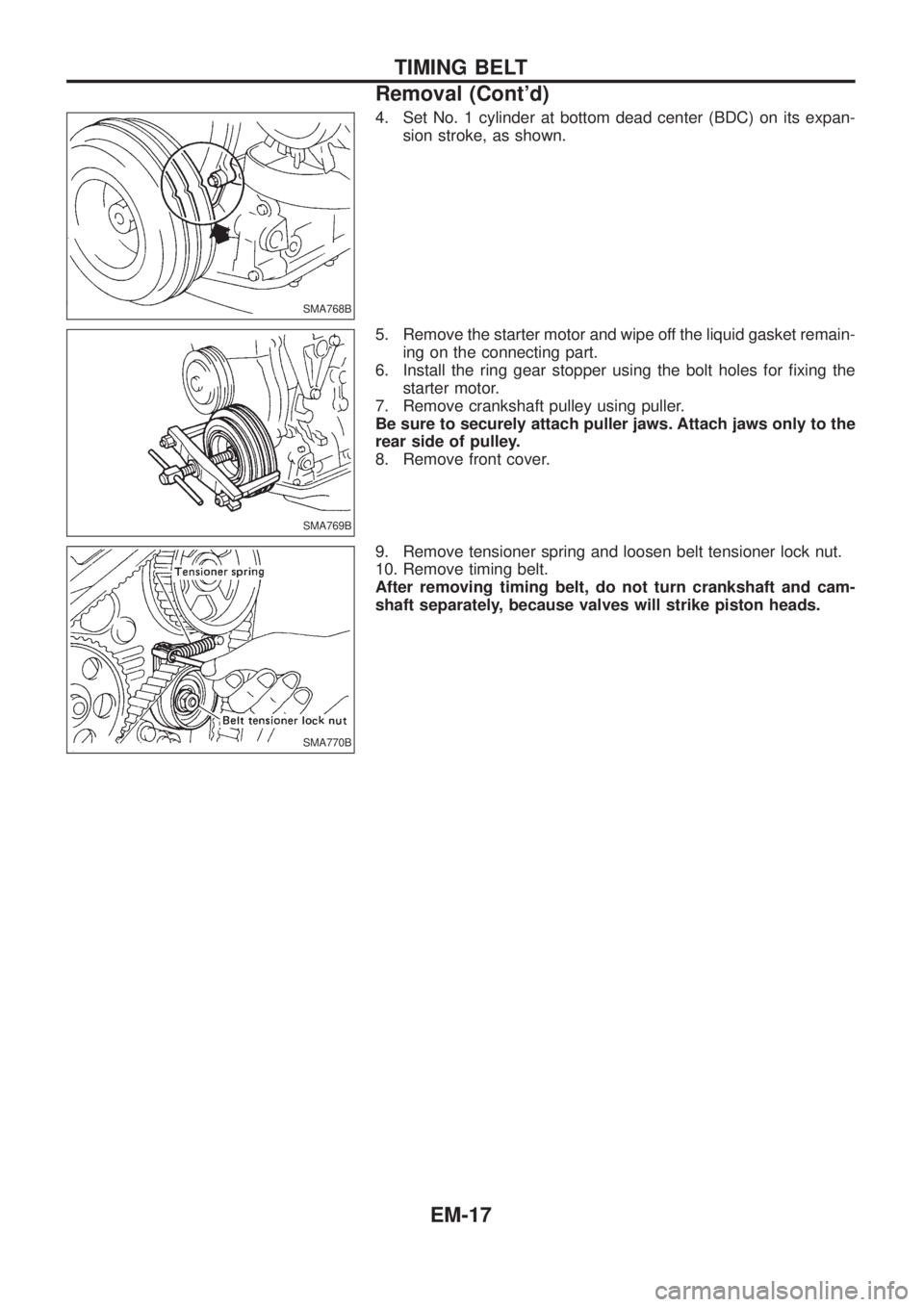

9. Remove tensioner spring and loosen belt tensioner lock nut.

10. Remove timing belt.

After removing timing belt, do not turn crankshaft and cam-

shaft separately, because valves will strike piston heads.

SMA768B

SMA769B

SMA770B

TIMING BELT

Removal (Cont'd)

EM-17

Page 688 of 1226

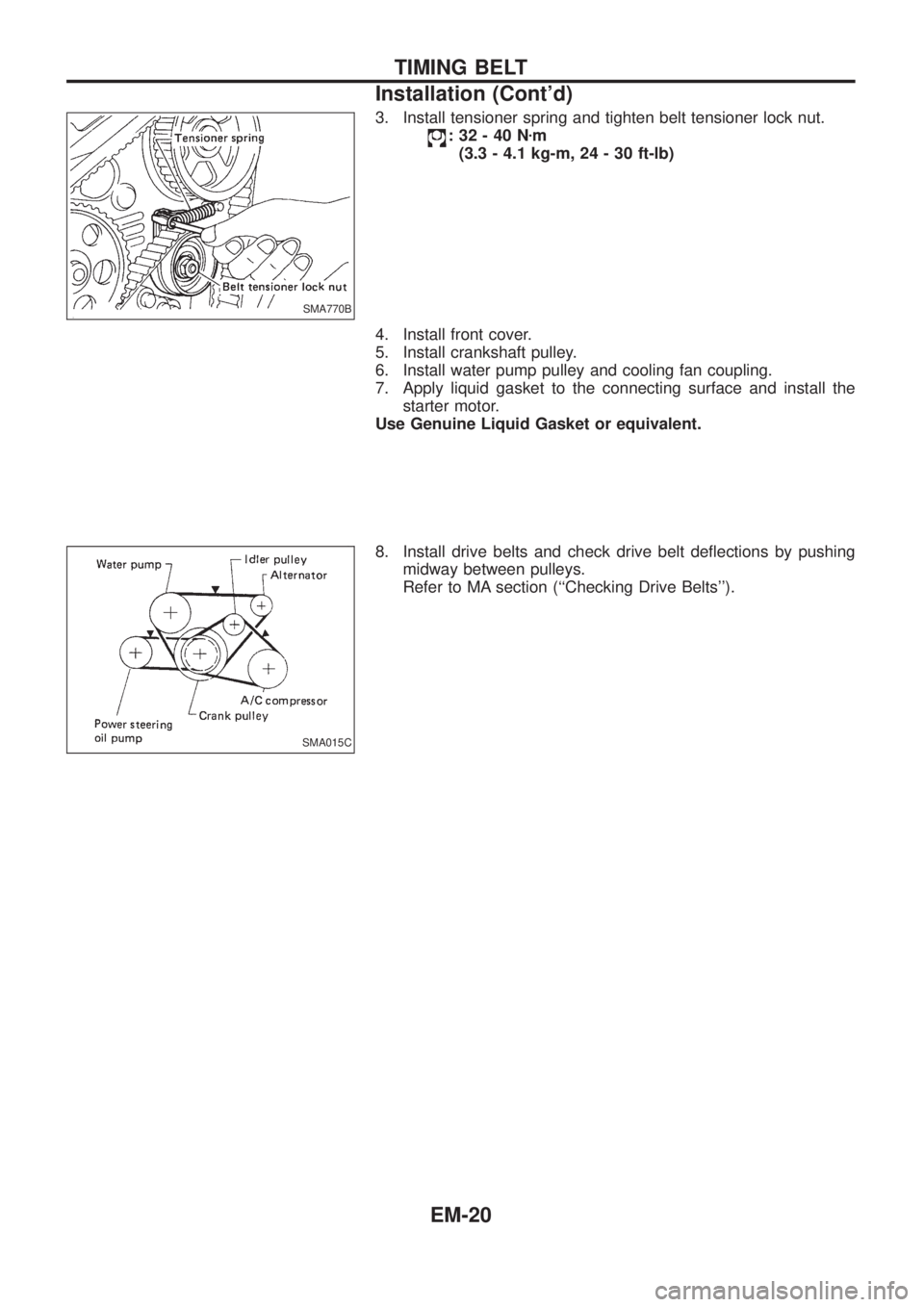

3. Install tensioner spring and tighten belt tensioner lock nut.

:32-40Nzm

(3.3 - 4.1 kg-m, 24 - 30 ft-lb)

4. Install front cover.

5. Install crankshaft pulley.

6. Install water pump pulley and cooling fan coupling.

7. Apply liquid gasket to the connecting surface and install the

starter motor.

Use Genuine Liquid Gasket or equivalent.

8. Install drive belts and check drive belt de¯ections by pushing

midway between pulleys.

Refer to MA section (``Checking Drive Belts'').

SMA770B

SMA015C

TIMING BELT

Installation (Cont'd)

EM-20

Page 691 of 1226

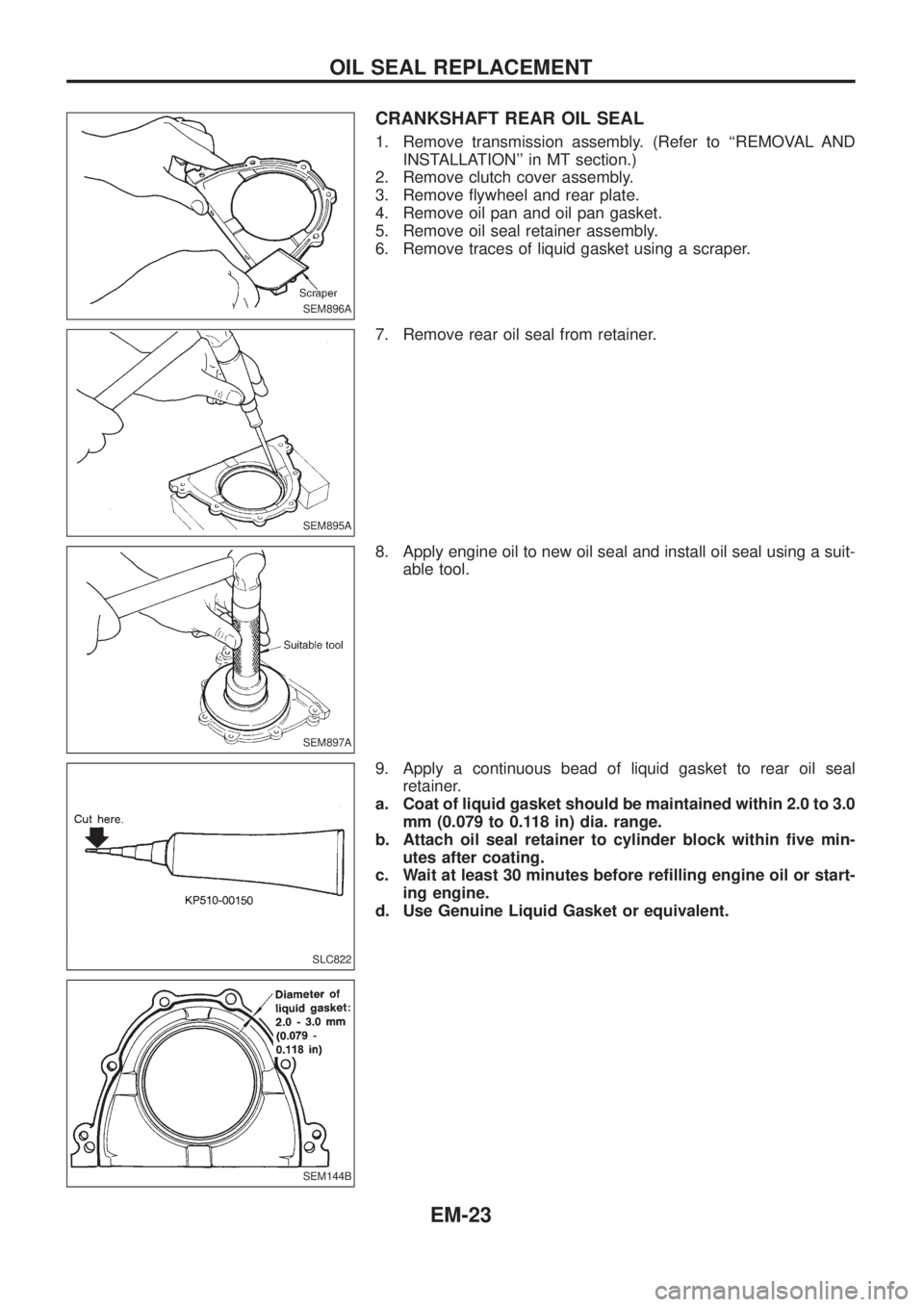

CRANKSHAFT REAR OIL SEAL

1. Remove transmission assembly. (Refer to ``REMOVAL AND

INSTALLATION'' in MT section.)

2. Remove clutch cover assembly.

3. Remove ¯ywheel and rear plate.

4. Remove oil pan and oil pan gasket.

5. Remove oil seal retainer assembly.

6. Remove traces of liquid gasket using a scraper.

7. Remove rear oil seal from retainer.

8. Apply engine oil to new oil seal and install oil seal using a suit-

able tool.

9. Apply a continuous bead of liquid gasket to rear oil seal

retainer.

a. Coat of liquid gasket should be maintained within 2.0 to 3.0

mm (0.079 to 0.118 in) dia. range.

b. Attach oil seal retainer to cylinder block within ®ve min-

utes after coating.

c. Wait at least 30 minutes before re®lling engine oil or start-

ing engine.

d. Use Genuine Liquid Gasket or equivalent.

SEM896A

SEM895A

SEM897A

SLC822

SEM144B

OIL SEAL REPLACEMENT

EM-23

Page 692 of 1226

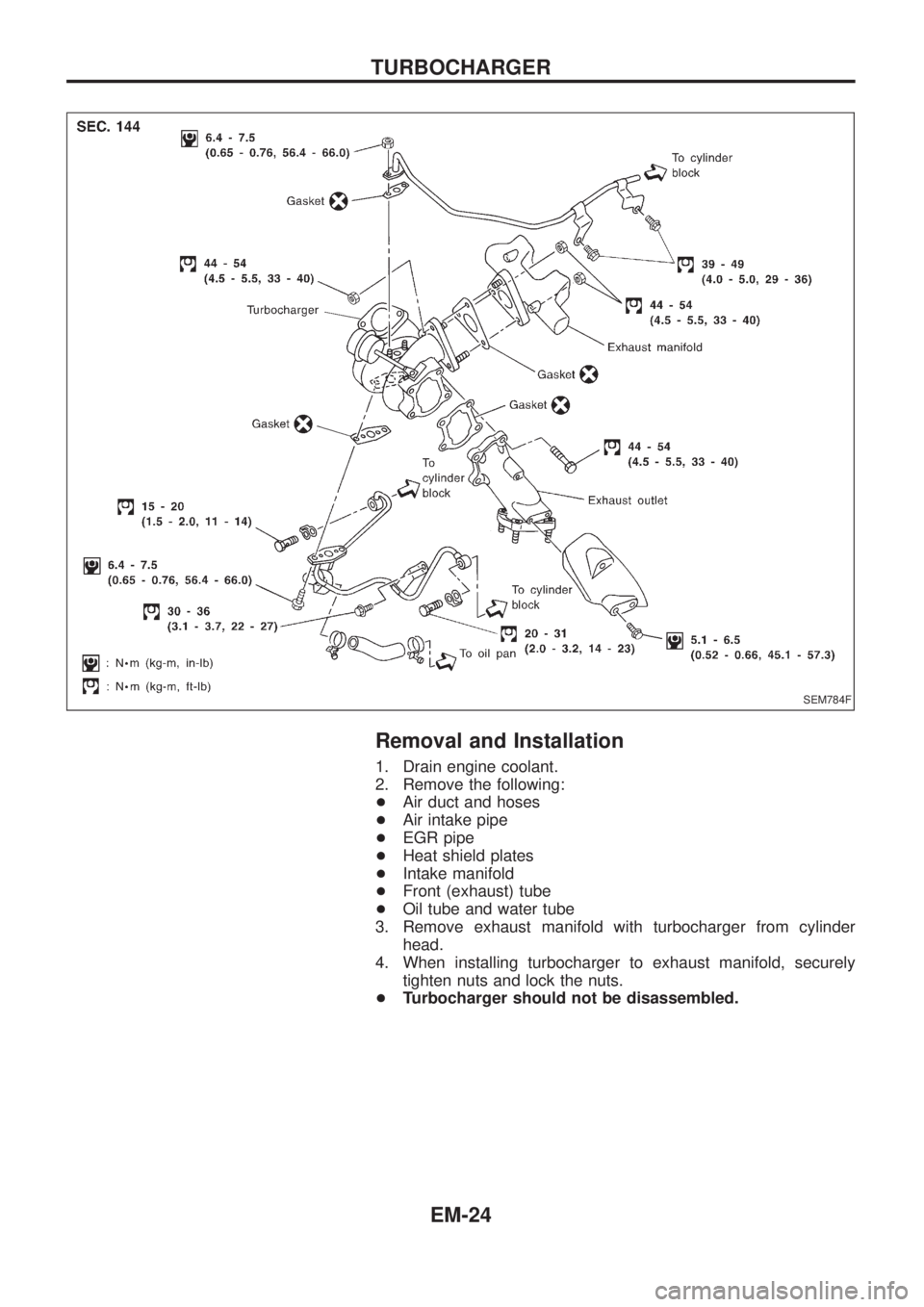

Removal and Installation

1. Drain engine coolant.

2. Remove the following:

+Air duct and hoses

+Air intake pipe

+EGR pipe

+Heat shield plates

+Intake manifold

+Front (exhaust) tube

+Oil tube and water tube

3. Remove exhaust manifold with turbocharger from cylinder

head.

4. When installing turbocharger to exhaust manifold, securely

tighten nuts and lock the nuts.

+Turbocharger should not be disassembled.

SEM784F

TURBOCHARGER

EM-24