NISSAN PATROL 2006 Service Manual

Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 1171 of 1226

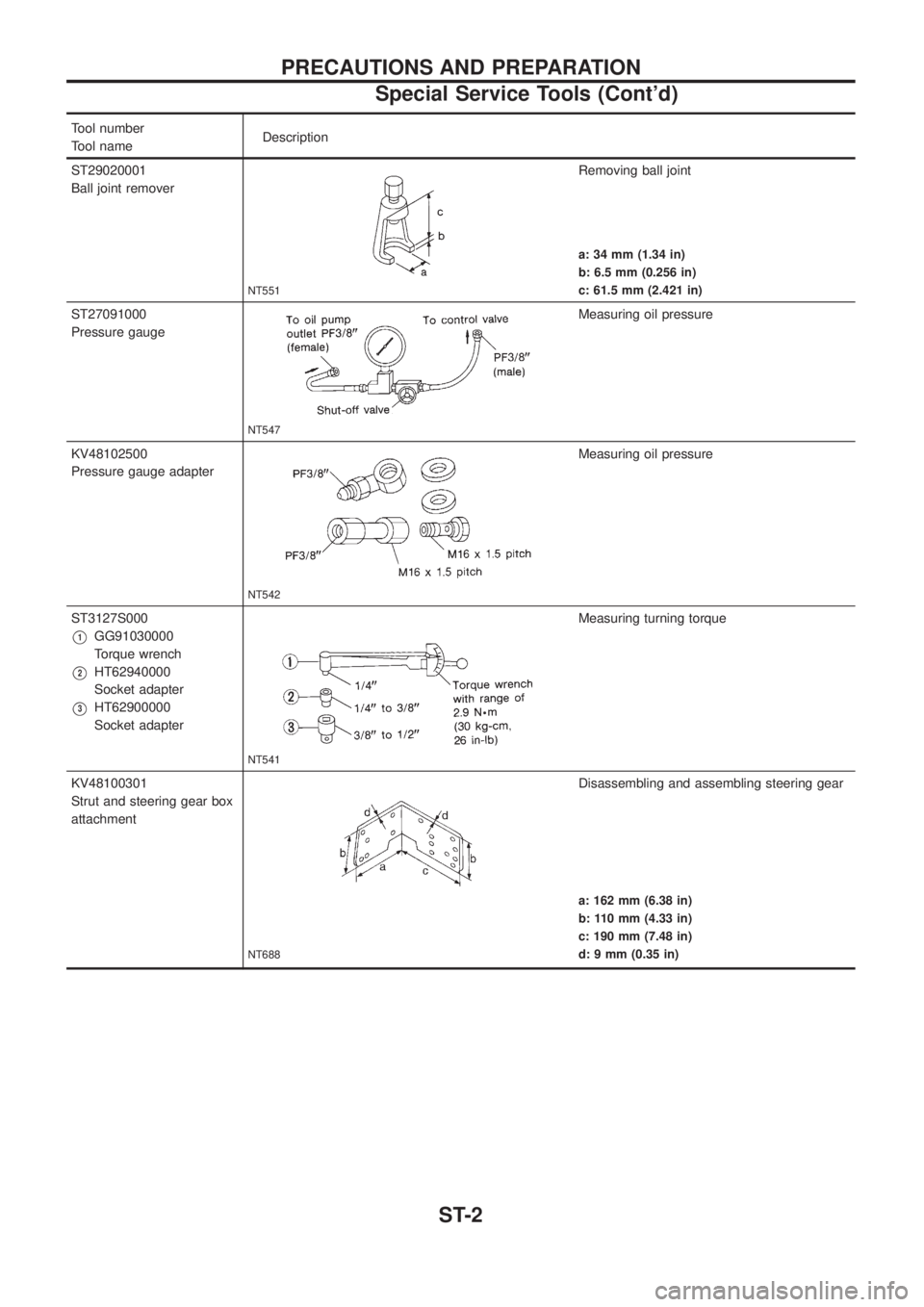

Tool number

Tool nameDescription

ST29020001

Ball joint remover

NT551

Removing ball joint

a: 34 mm (1.34 in)

b: 6.5 mm (0.256 in)

c: 61.5 mm (2.421 in)

ST27091000

Pressure gauge

NT547

Measuring oil pressure

KV48102500

Pressure gauge adapter

NT542

Measuring oil pressure

ST3127S000

V1GG91030000

Torque wrench

V2HT62940000

Socket adapter

V3HT62900000

Socket adapter

NT541

Measuring turning torque

KV48100301

Strut and steering gear box

attachment

NT688

Disassembling and assembling steering gear

a: 162 mm (6.38 in)

b: 110 mm (4.33 in)

c: 190 mm (7.48 in)

d: 9 mm (0.35 in)

PRECAUTIONS AND PREPARATION

Special Service Tools (Cont'd)

ST-2

Page 1172 of 1226

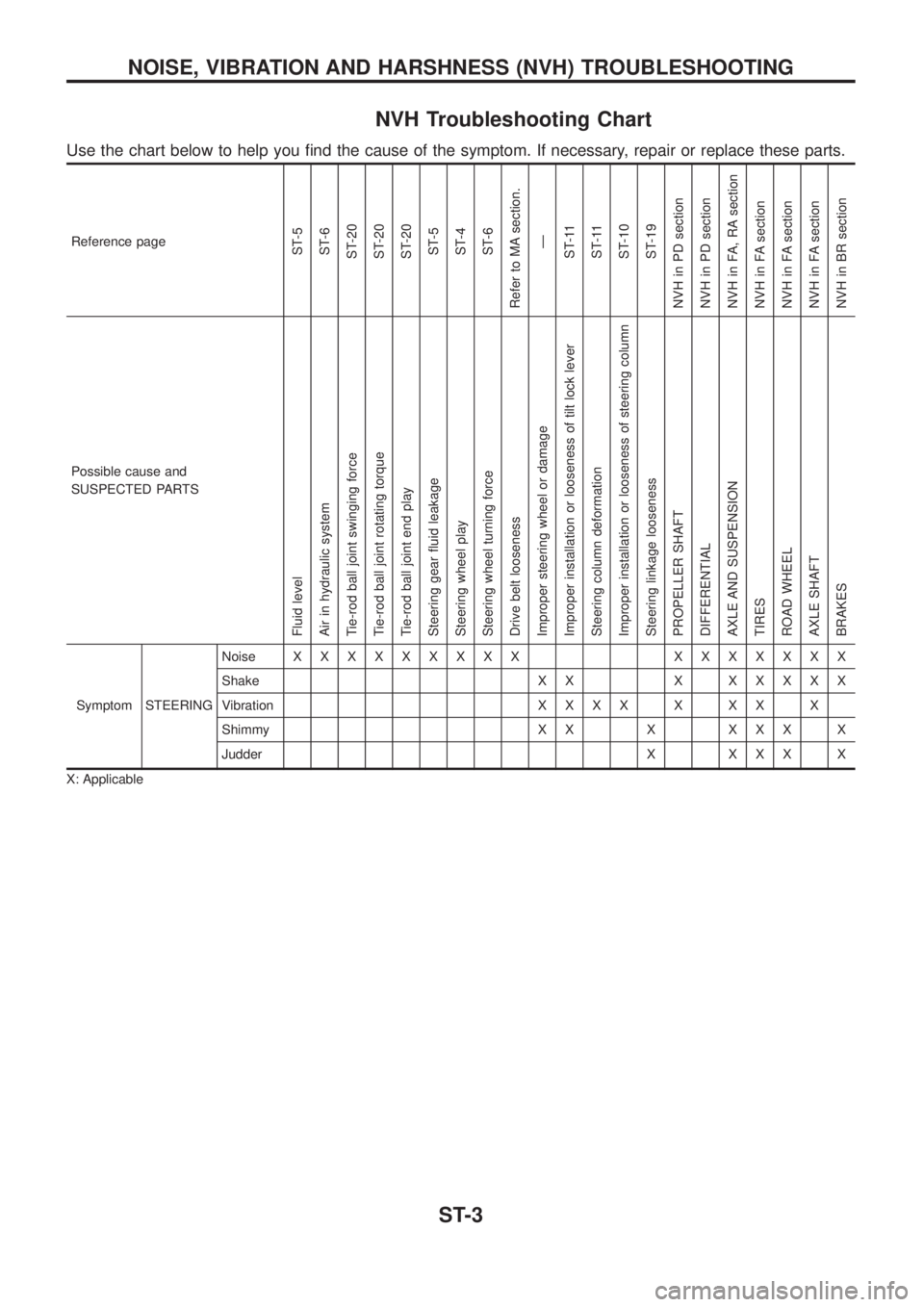

NVH Troubleshooting Chart

Use the chart below to help you ®nd the cause of the symptom. If necessary, repair or replace these parts.

Reference pageST-5

ST-6

ST-20

ST-20

ST-20

ST-5

ST-4

ST-6

Refer to MA section.

Ð

ST-11

ST-11

ST-10

ST-19

NVH in PD section

NVH in PD section

NVH in FA, RA section

NVH in FA section

NVH in FA section

NVH in FA section

NVH in BR section

Possible cause and

SUSPECTED PARTS

Fluid level

Air in hydraulic system

Tie-rod ball joint swinging force

Tie-rod ball joint rotating torque

Tie-rod ball joint end play

Steering gear ¯uid leakage

Steering wheel play

Steering wheel turning force

Drive belt looseness

Improper steering wheel or damage

Improper installation or looseness of tilt lock lever

Steering column deformation

Improper installation or looseness of steering column

Steering linkage looseness

PROPELLER SHAFT

DIFFERENTIAL

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

AXLE SHAFT

BRAKES

Symptom STEERINGNoiseXXXXXXXXX XXXXXXX

Shake X X XXXXXX

VibrationXXXXXXXX

Shimmy X X X X X X X

Judder X X X X X

X: Applicable

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

ST-3

Page 1173 of 1226

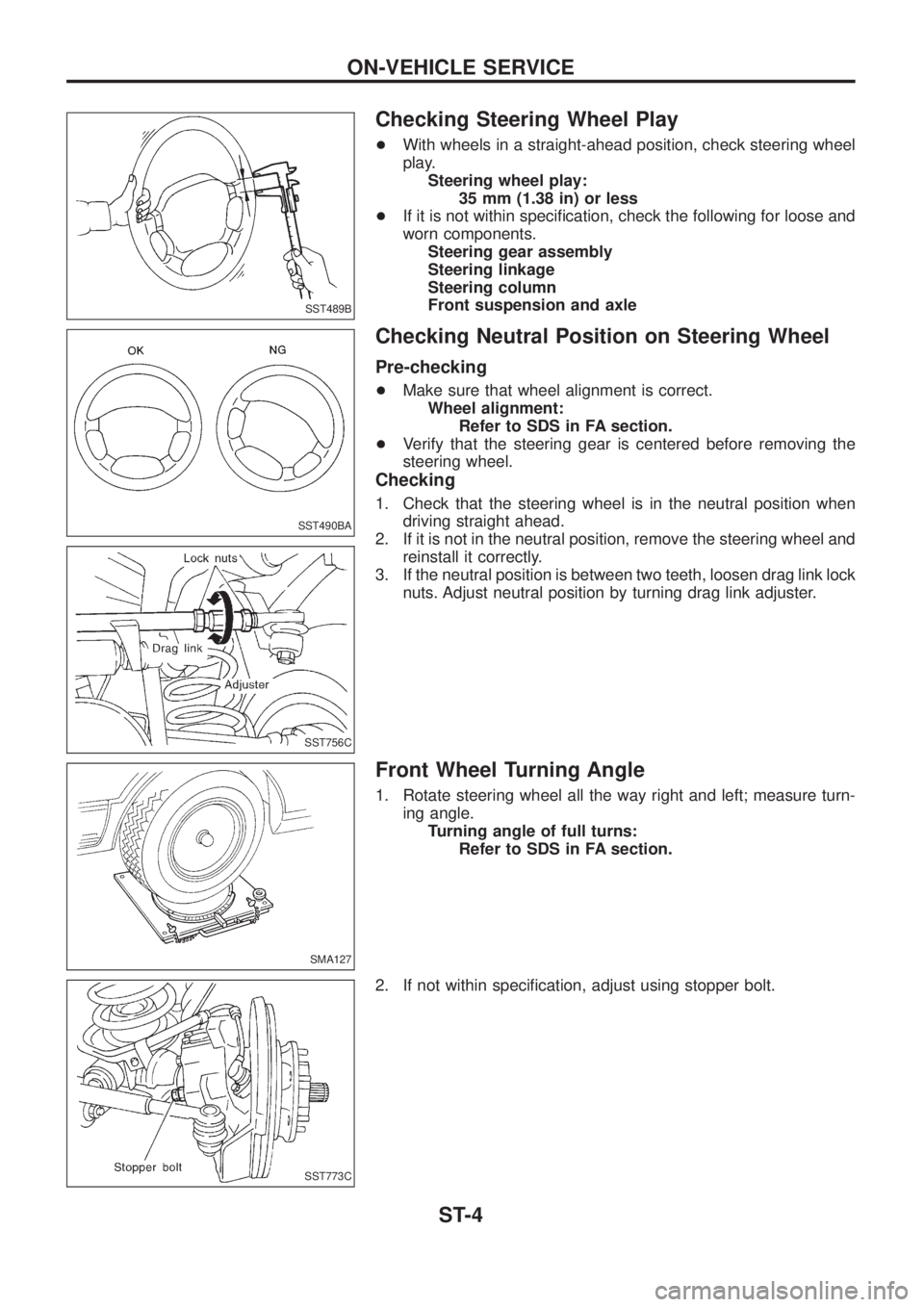

Checking Steering Wheel Play

+With wheels in a straight-ahead position, check steering wheel

play.

Steering wheel play:

35 mm (1.38 in) or less

+If it is not within speci®cation, check the following for loose and

worn components.

Steering gear assembly

Steering linkage

Steering column

Front suspension and axle

Checking Neutral Position on Steering Wheel

Pre-checking

+Make sure that wheel alignment is correct.

Wheel alignment:

Refer to SDS in FA section.

+Verify that the steering gear is centered before removing the

steering wheel.

Checking

1. Check that the steering wheel is in the neutral position when

driving straight ahead.

2. If it is not in the neutral position, remove the steering wheel and

reinstall it correctly.

3. If the neutral position is between two teeth, loosen drag link lock

nuts. Adjust neutral position by turning drag link adjuster.

Front Wheel Turning Angle

1. Rotate steering wheel all the way right and left; measure turn-

ing angle.

Turning angle of full turns:

Refer to SDS in FA section.

2. If not within speci®cation, adjust using stopper bolt.

SST489B

SST490BA

SST756C

SMA127

SST773C

ON-VEHICLE SERVICE

ST-4

Page 1174 of 1226

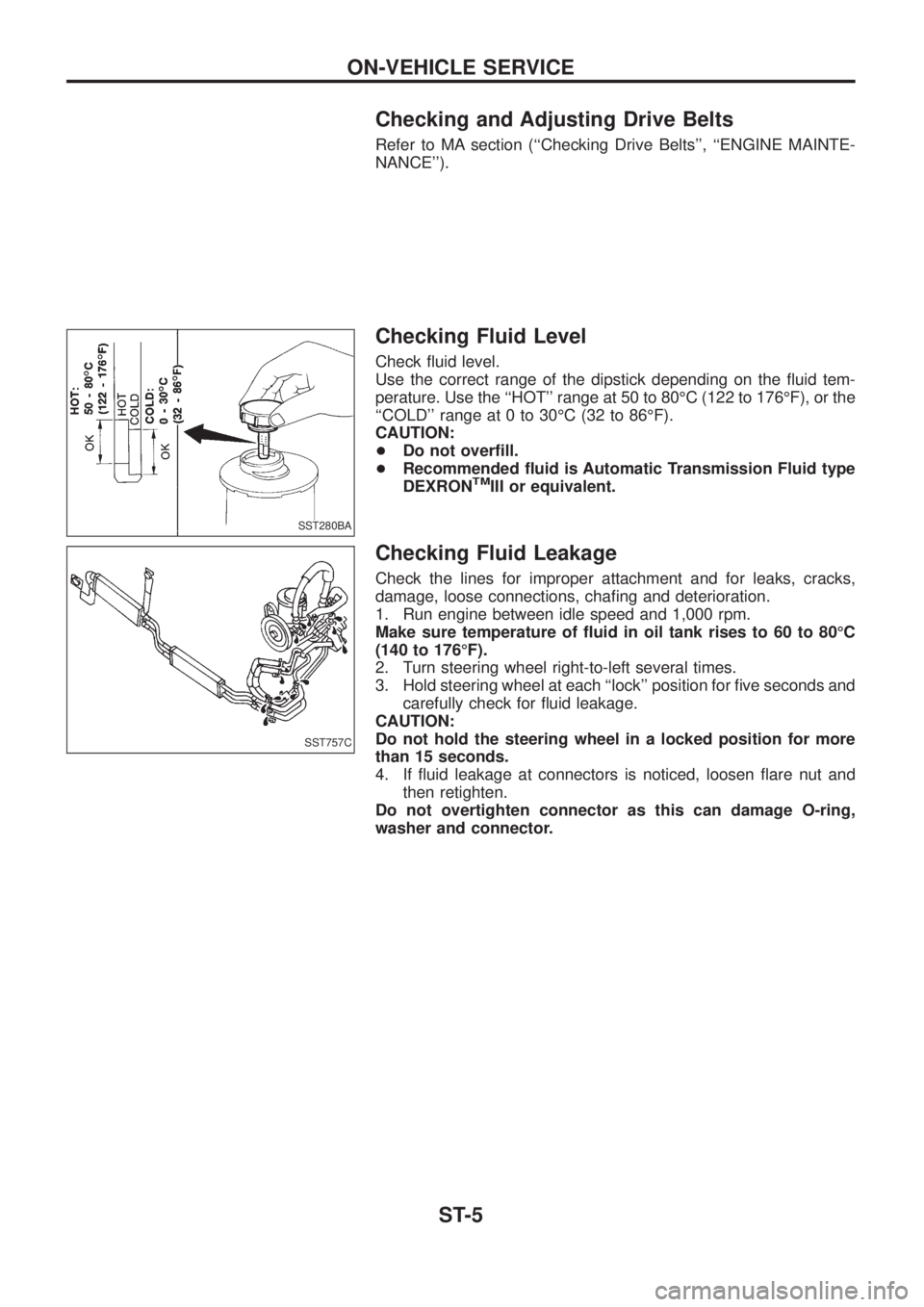

Checking and Adjusting Drive Belts

Refer to MA section (``Checking Drive Belts'', ``ENGINE MAINTE-

NANCE'').

Checking Fluid Level

Check ¯uid level.

Use the correct range of the dipstick depending on the ¯uid tem-

perature. Use the ``HOT'' range at 50 to 80ÉC (122 to 176ÉF), or the

``COLD'' range at 0 to 30ÉC (32 to 86ÉF).

CAUTION:

+Do not over®ll.

+Recommended ¯uid is Automatic Transmission Fluid type

DEXRON

TMIII or equivalent.

Checking Fluid Leakage

Check the lines for improper attachment and for leaks, cracks,

damage, loose connections, cha®ng and deterioration.

1. Run engine between idle speed and 1,000 rpm.

Make sure temperature of ¯uid in oil tank rises to 60 to 80ÉC

(140 to 176ÉF).

2. Turn steering wheel right-to-left several times.

3. Hold steering wheel at each ``lock'' position for ®ve seconds and

carefully check for ¯uid leakage.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 15 seconds.

4. If ¯uid leakage at connectors is noticed, loosen ¯are nut and

then retighten.

Do not overtighten connector as this can damage O-ring,

washer and connector.

SST280BA

SST757C

ON-VEHICLE SERVICE

ST-5

Page 1175 of 1226

Bleeding Hydraulic System

1. Raise front end of vehicle until wheels are clear of the ground.

2. Add ¯uid into oil tank to speci®ed level. Then, quickly turn steer-

ing wheel fully to right and left and lightly touch steering stop-

pers.

Repeat steering wheel operation until ¯uid level no longer

decreases.

3. Start engine.

Repeat step 2 above.

+Incomplete air bleeding will cause the following to occur. When

this happens, bleed air again.

a. Air bubbles in reservoir tank

b. Clicking noise in oil pump

c. Excessive buzzing in oil pump

Fluid noise may occur in the valve or oil pump. This is common

when the vehicle is stationary or while turning steering wheel

slowly. This does not affect performance or durability of the system.

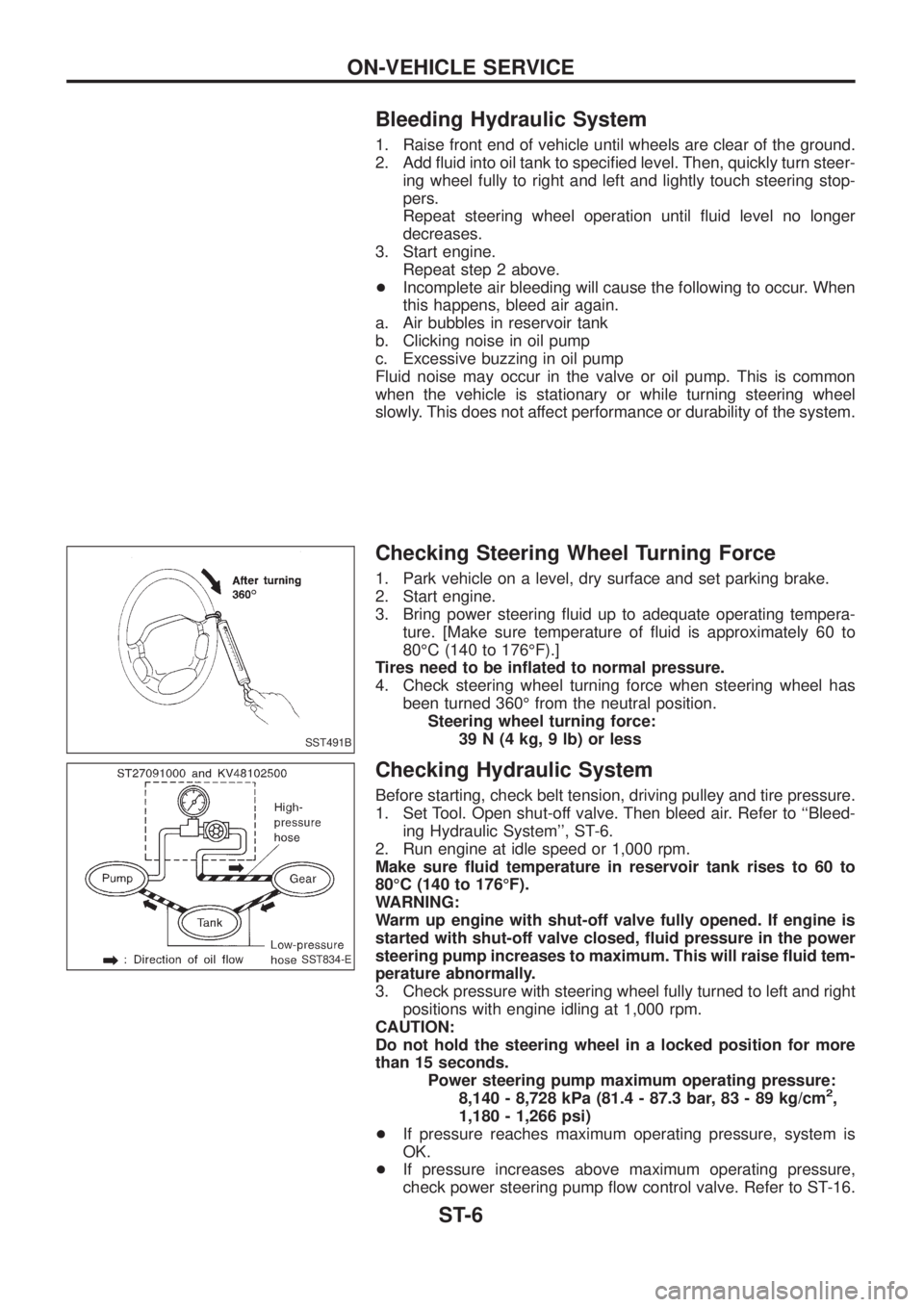

Checking Steering Wheel Turning Force

1. Park vehicle on a level, dry surface and set parking brake.

2. Start engine.

3. Bring power steering ¯uid up to adequate operating tempera-

ture. [Make sure temperature of ¯uid is approximately 60 to

80ÉC (140 to 176ÉF).]

Tires need to be in¯ated to normal pressure.

4. Check steering wheel turning force when steering wheel has

been turned 360É from the neutral position.

Steering wheel turning force:

39 N (4 kg, 9 lb) or less

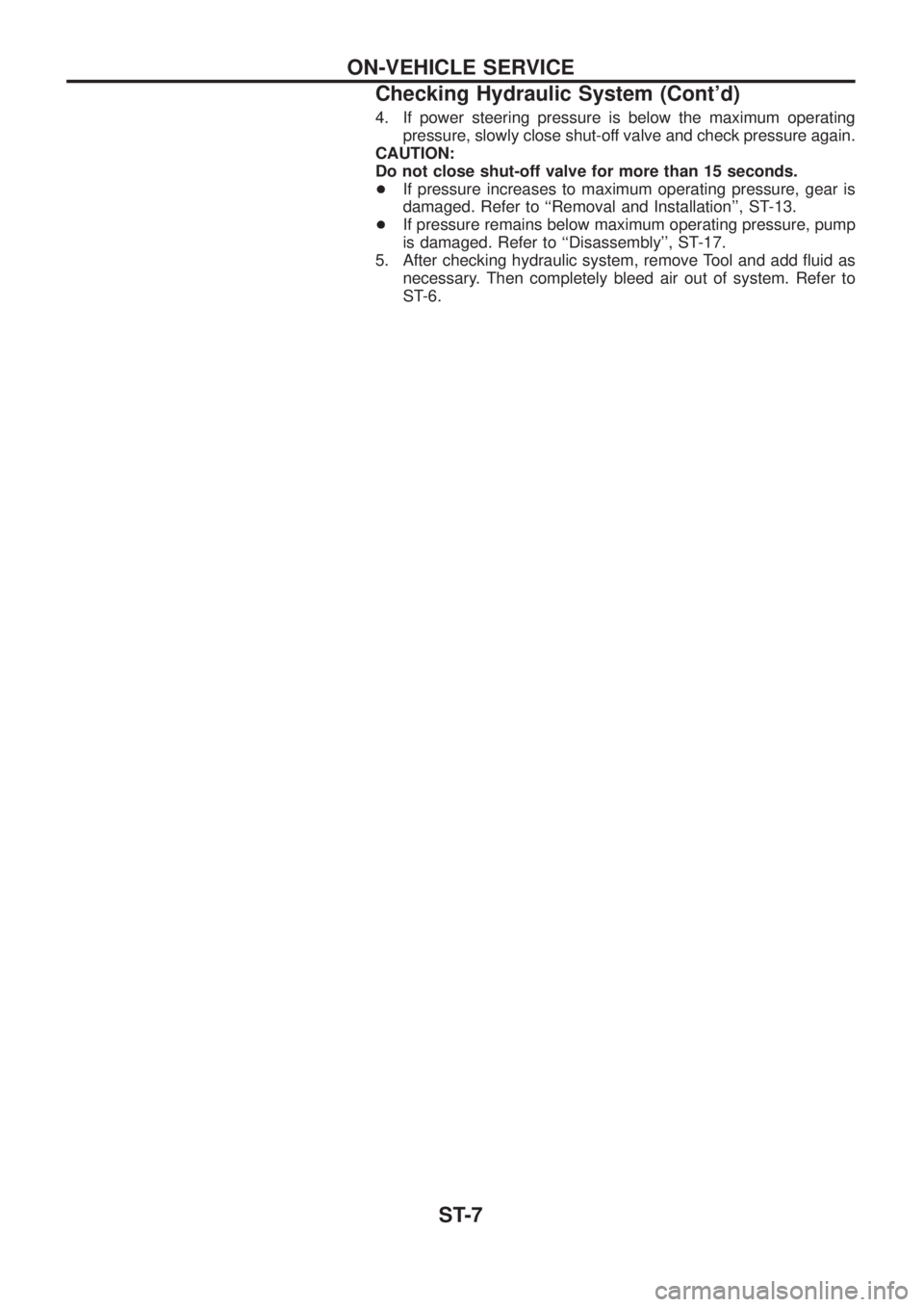

Checking Hydraulic System

Before starting, check belt tension, driving pulley and tire pressure.

1. Set Tool. Open shut-off valve. Then bleed air. Refer to ``Bleed-

ing Hydraulic System'', ST-6.

2. Run engine at idle speed or 1,000 rpm.

Make sure ¯uid temperature in reservoir tank rises to 60 to

80ÉC (140 to 176ÉF).

WARNING:

Warm up engine with shut-off valve fully opened. If engine is

started with shut-off valve closed, ¯uid pressure in the power

steering pump increases to maximum. This will raise ¯uid tem-

perature abnormally.

3. Check pressure with steering wheel fully turned to left and right

positions with engine idling at 1,000 rpm.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 15 seconds.

Power steering pump maximum operating pressure:

8,140 - 8,728 kPa (81.4 - 87.3 bar, 83 - 89 kg/cm

2,

1,180 - 1,266 psi)

+If pressure reaches maximum operating pressure, system is

OK.

+If pressure increases above maximum operating pressure,

check power steering pump ¯ow control valve. Refer to ST-16.

SST491B

SST834-E

ON-VEHICLE SERVICE

ST-6

Page 1176 of 1226

4. If power steering pressure is below the maximum operating

pressure, slowly close shut-off valve and check pressure again.

CAUTION:

Do not close shut-off valve for more than 15 seconds.

+If pressure increases to maximum operating pressure, gear is

damaged. Refer to ``Removal and Installation'', ST-13.

+If pressure remains below maximum operating pressure, pump

is damaged. Refer to ``Disassembly'', ST-17.

5. After checking hydraulic system, remove Tool and add ¯uid as

necessary. Then completely bleed air out of system. Refer to

ST-6.

ON-VEHICLE SERVICE

Checking Hydraulic System (Cont'd)

ST-7

Page 1177 of 1226

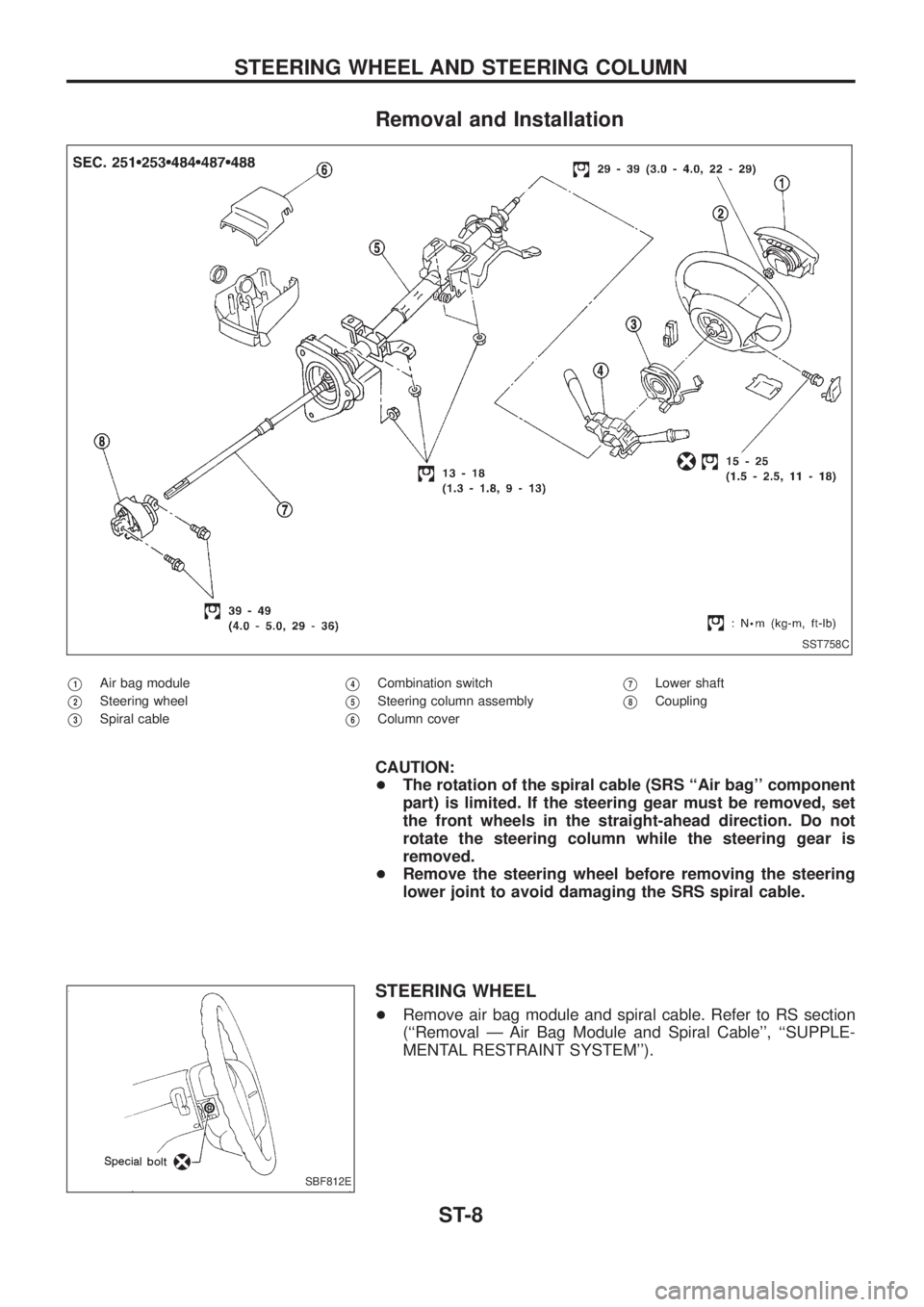

Removal and Installation

V1Air bag module

V2Steering wheel

V3Spiral cable

V4Combination switch

V5Steering column assembly

V6Column cover

V7Lower shaft

V8Coupling

CAUTION:

+The rotation of the spiral cable (SRS ``Air bag'' component

part) is limited. If the steering gear must be removed, set

the front wheels in the straight-ahead direction. Do not

rotate the steering column while the steering gear is

removed.

+Remove the steering wheel before removing the steering

lower joint to avoid damaging the SRS spiral cable.

STEERING WHEEL

+Remove air bag module and spiral cable. Refer to RS section

(``Removal Ð Air Bag Module and Spiral Cable'', ``SUPPLE-

MENTAL RESTRAINT SYSTEM'').

SST758C

SBF812E

STEERING WHEEL AND STEERING COLUMN

ST-8

Page 1178 of 1226

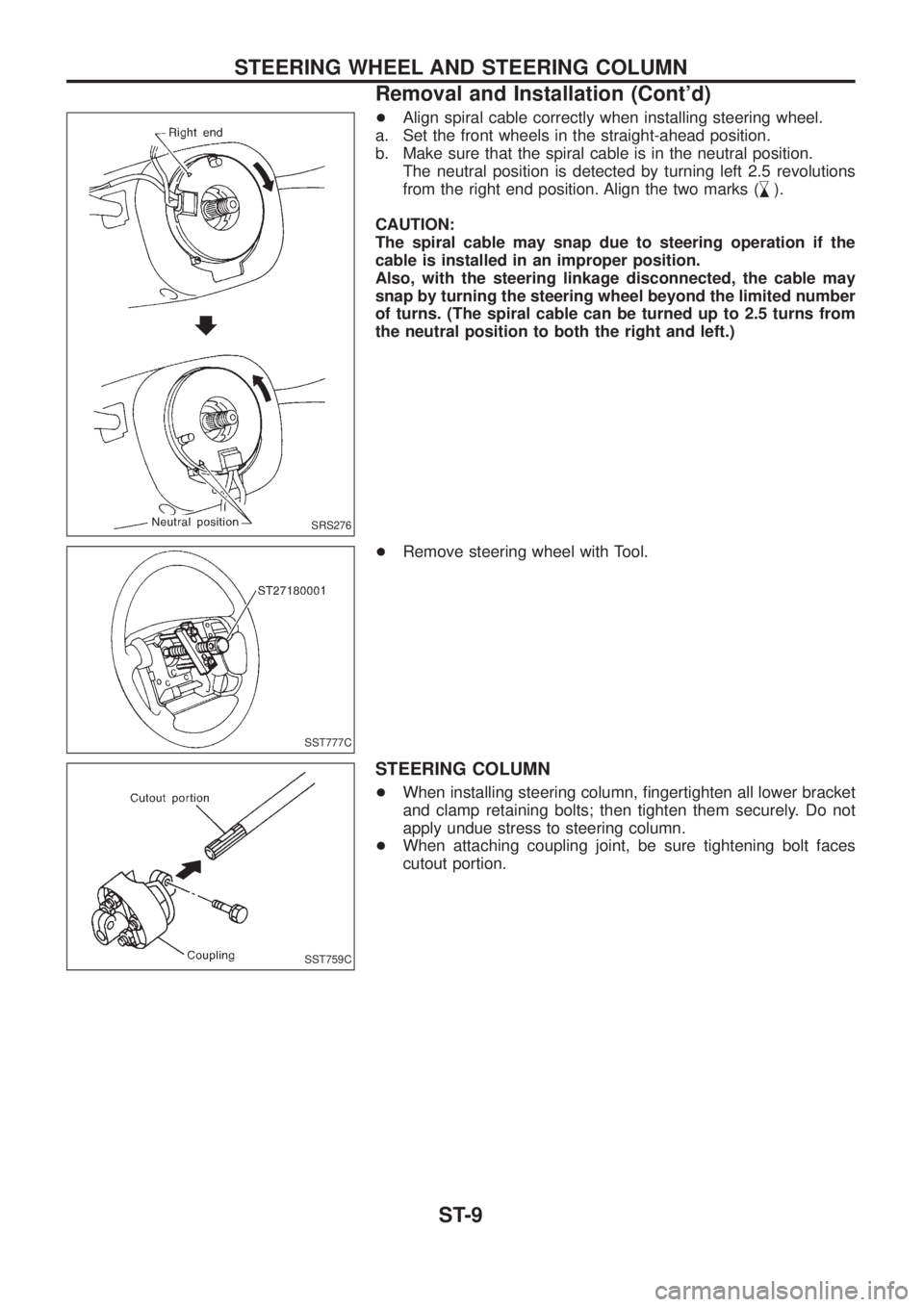

+Align spiral cable correctly when installing steering wheel.

a. Set the front wheels in the straight-ahead position.

b. Make sure that the spiral cable is in the neutral position.

The neutral position is detected by turning left 2.5 revolutions

from the right end position. Align the two marks (

,

m).

CAUTION:

The spiral cable may snap due to steering operation if the

cable is installed in an improper position.

Also, with the steering linkage disconnected, the cable may

snap by turning the steering wheel beyond the limited number

of turns. (The spiral cable can be turned up to 2.5 turns from

the neutral position to both the right and left.)

+Remove steering wheel with Tool.

STEERING COLUMN

+When installing steering column, ®ngertighten all lower bracket

and clamp retaining bolts; then tighten them securely. Do not

apply undue stress to steering column.

+When attaching coupling joint, be sure tightening bolt faces

cutout portion.

SRS276

SST777C

SST759C

STEERING WHEEL AND STEERING COLUMN

Removal and Installation (Cont'd)

ST-9

Page 1179 of 1226

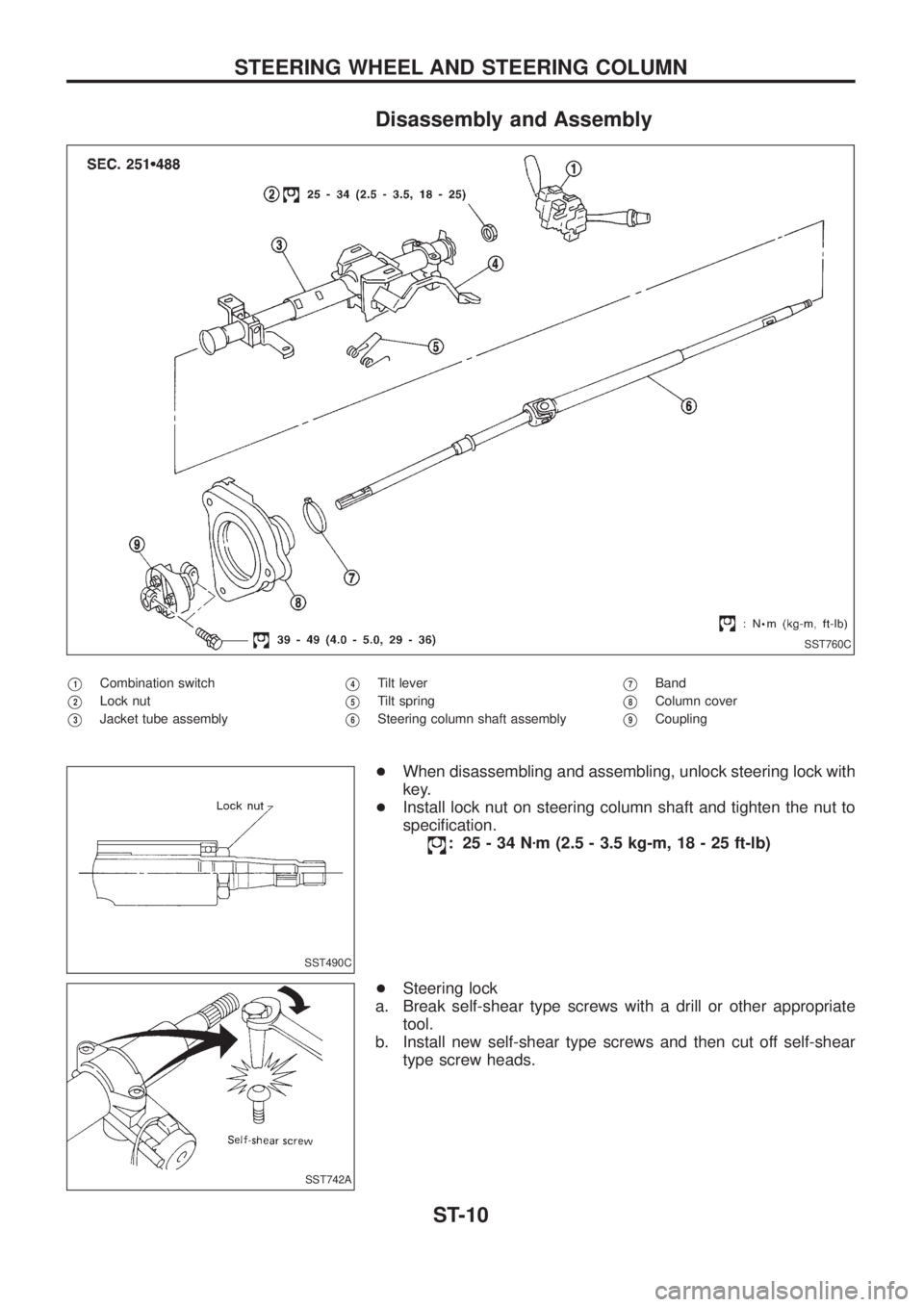

Disassembly and Assembly

V1Combination switch

V2Lock nut

V3Jacket tube assembly

V4Tilt lever

V5Tilt spring

V6Steering column shaft assembly

V7Band

V8Column cover

V9Coupling

+When disassembling and assembling, unlock steering lock with

key.

+Install lock nut on steering column shaft and tighten the nut to

speci®cation.

: 25-34Nzm (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

+Steering lock

a. Break self-shear type screws with a drill or other appropriate

tool.

b. Install new self-shear type screws and then cut off self-shear

type screw heads.

SST760C

SST490C

SST742A

STEERING WHEEL AND STEERING COLUMN

ST-10

Page 1180 of 1226

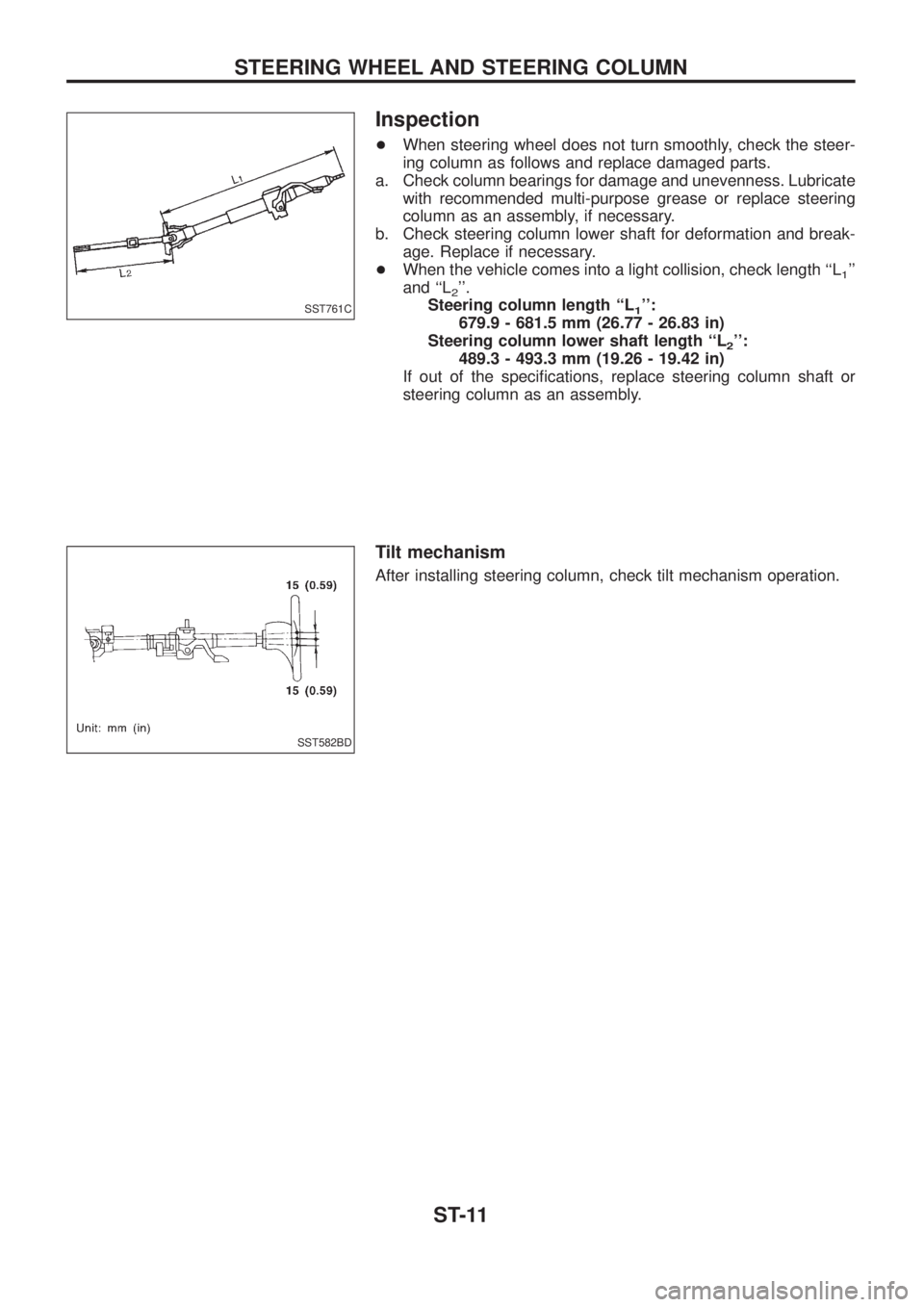

Inspection

+When steering wheel does not turn smoothly, check the steer-

ing column as follows and replace damaged parts.

a. Check column bearings for damage and unevenness. Lubricate

with recommended multi-purpose grease or replace steering

column as an assembly, if necessary.

b. Check steering column lower shaft for deformation and break-

age. Replace if necessary.

+When the vehicle comes into a light collision, check length ``L

1''

and ``L

2''.

Steering column length ``L

1'':

679.9 - 681.5 mm (26.77 - 26.83 in)

Steering column lower shaft length ``L

2'':

489.3 - 493.3 mm (19.26 - 19.42 in)

If out of the speci®cations, replace steering column shaft or

steering column as an assembly.

Tilt mechanism

After installing steering column, check tilt mechanism operation.

SST761C

SST582BD

STEERING WHEEL AND STEERING COLUMN

ST-11