NISSAN PATROL 2006 Service Manual

Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 1191 of 1226

General Speci®cations

Power steering

Steering gear type PB69K

Turns of steering wheel on the vehicle

(Lock-to-lock)3.4

Steering gear ratio 17.0Steering wheel axial play

mm (in)0 (0)

Steering wheel play

mm (in)35 (1.38) or less

Steering damper

[at 0.3 m (1.0 ft)/sec.]

N (kg, lb)4,443 (453, 999) ...

Extended direction

3,315 (338, 745) ...

Compressed direction

Inspection and Adjustment

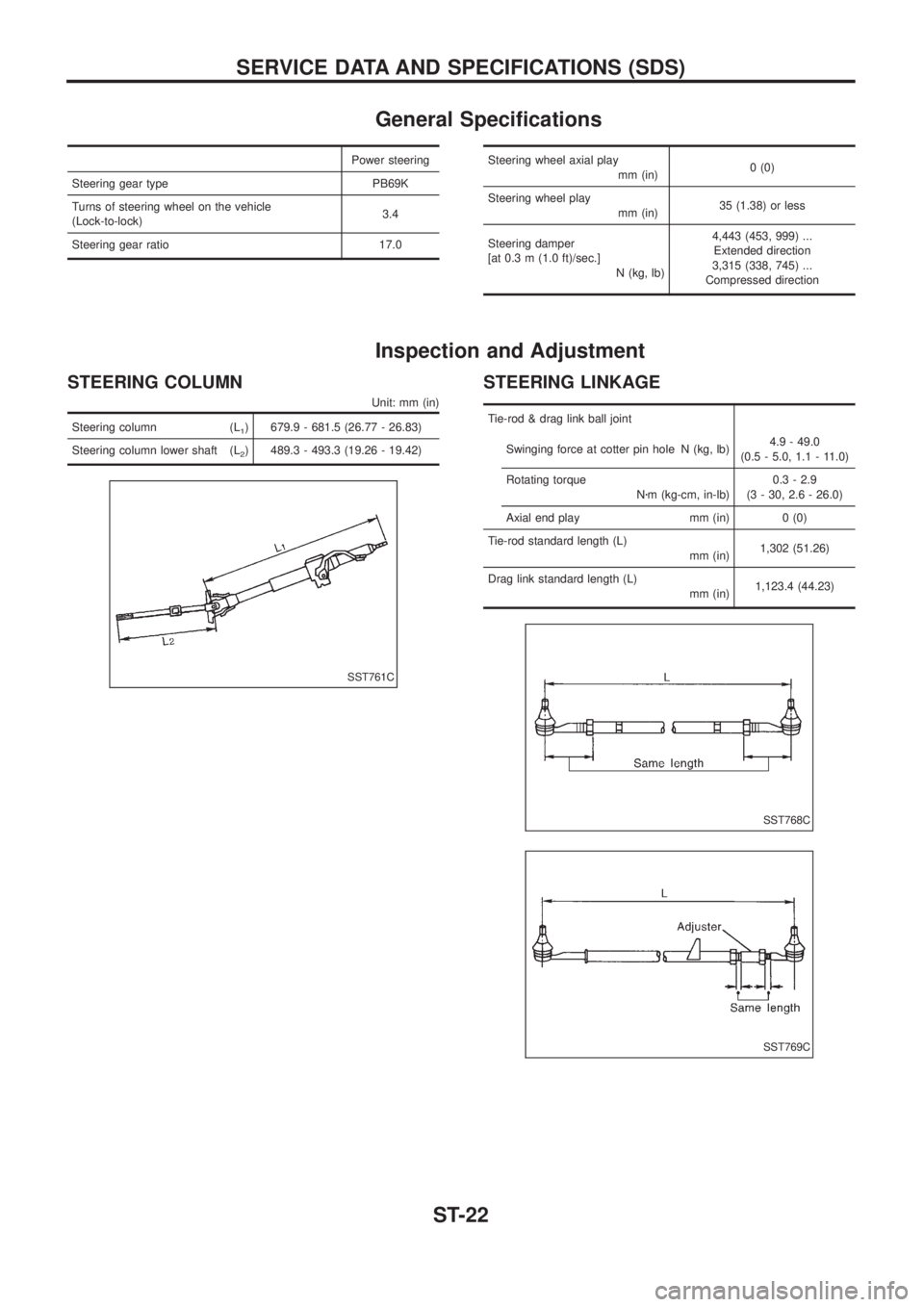

STEERING COLUMN

Unit: mm (in)

Steering column (L1) 679.9 - 681.5 (26.77 - 26.83)

Steering column lower shaft (L

2) 489.3 - 493.3 (19.26 - 19.42)

STEERING LINKAGE

Tie-rod & drag link ball joint

Swinging force at cotter pin hole N (kg, lb)4.9 - 49.0

(0.5 - 5.0, 1.1 - 11.0)

Rotating torque

Nzm (kg-cm, in-lb)0.3 - 2.9

(3 - 30, 2.6 - 26.0)

Axial end play mm (in) 0 (0)

Tie-rod standard length (L)

mm (in)1,302 (51.26)

Drag link standard length (L)

mm (in)1,123.4 (44.23)

SST761C

SST768C

SST769C

SERVICE DATA AND SPECIFICATIONS (SDS)

ST-22

Page 1192 of 1226

POWER STEERING SYSTEM

(Model: PB69K)

Steering wheel turning force

(at 360É from neutral posi-

tion and circumference of

steering wheel) N (kg, lb)39 (4, 9) or less

Oil pump pressure

kPa (bar, kg/cm

2, psi)8,140 - 8,728

(81.4 - 87.3, 83 - 89, 1,180 - 1,266)

at idling

Fluid capacity

m!(Imp ¯ oz)Approximately 1,000 (35.2)

Normal operating tempera-

ture ÉC (ÉF)60 - 80 (140 - 176)

Steering gear turning torque

Nzm (kg-cm, in-lb)

360É position from

straight-ahead position0.15 - 0.78 (1.5 - 8.0, 1.3 - 6.9)

Straight-ahead position

(As compared with steer-

ing wheel turned 360É)0.2 - 0.5 (2 - 5, 1.7 - 4.3) higher

Maximum turning torque 0.44 - 1.18 (4.5 - 12, 3.9 - 10.4)

Backlash at pitman arm top

end (in a straight-

ahead position) mm (in)0 - 0.1 (0 - 0.004)

End play (at sector shaft

end in neutral position)

mm (in)0.1 (0.004) or less

SERVICE DATA AND SPECIFICATIONS (SDS)

Inspection and Adjustment (Cont'd)

ST-23

Page 1193 of 1226

TRANSFER

SECTION

TF

CONTENTS

PREPARATION................................................................1

Special Service Tools ..................................................1

Commercial Service Tools ...........................................2

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................3

NVH Troubleshooting Chart.........................................3

DESCRIPTION.................................................................4

Cross-sectional View ...................................................4

ON-VEHICLE SERVICE..................................................5

Replacing Oil Seal .......................................................5

Checking Position Switch ............................................7

REMOVAL AND INSTALLATION....................................8

Removal .......................................................................8

Installation ....................................................................8

TRANSFER GEAR CONTROL.......................................9

MAJOR OVERHAUL.....................................................10

Case Components .....................................................10

Gear Components ..................................................... 11Shift Control Components .........................................12

DISASSEMBLY..............................................................13

REPAIR FOR COMPONENT PARTS............................19

Mainshaft ...................................................................19

Front Drive Shaft .......................................................20

Counter Gear .............................................................21

Main Gear ..................................................................22

Front Case .................................................................24

Front Case Cover ......................................................24

Center Case...............................................................24

Bearing Retainer ........................................................25

Rear Case..................................................................25

Shift Control Components .........................................26

ASSEMBLY....................................................................27

SERVICE DATA AND SPECIFICATIONS (SDS)..........33

General Speci®cations ...............................................33

Inspection and Adjustment ........................................33

TF

Page 1194 of 1226

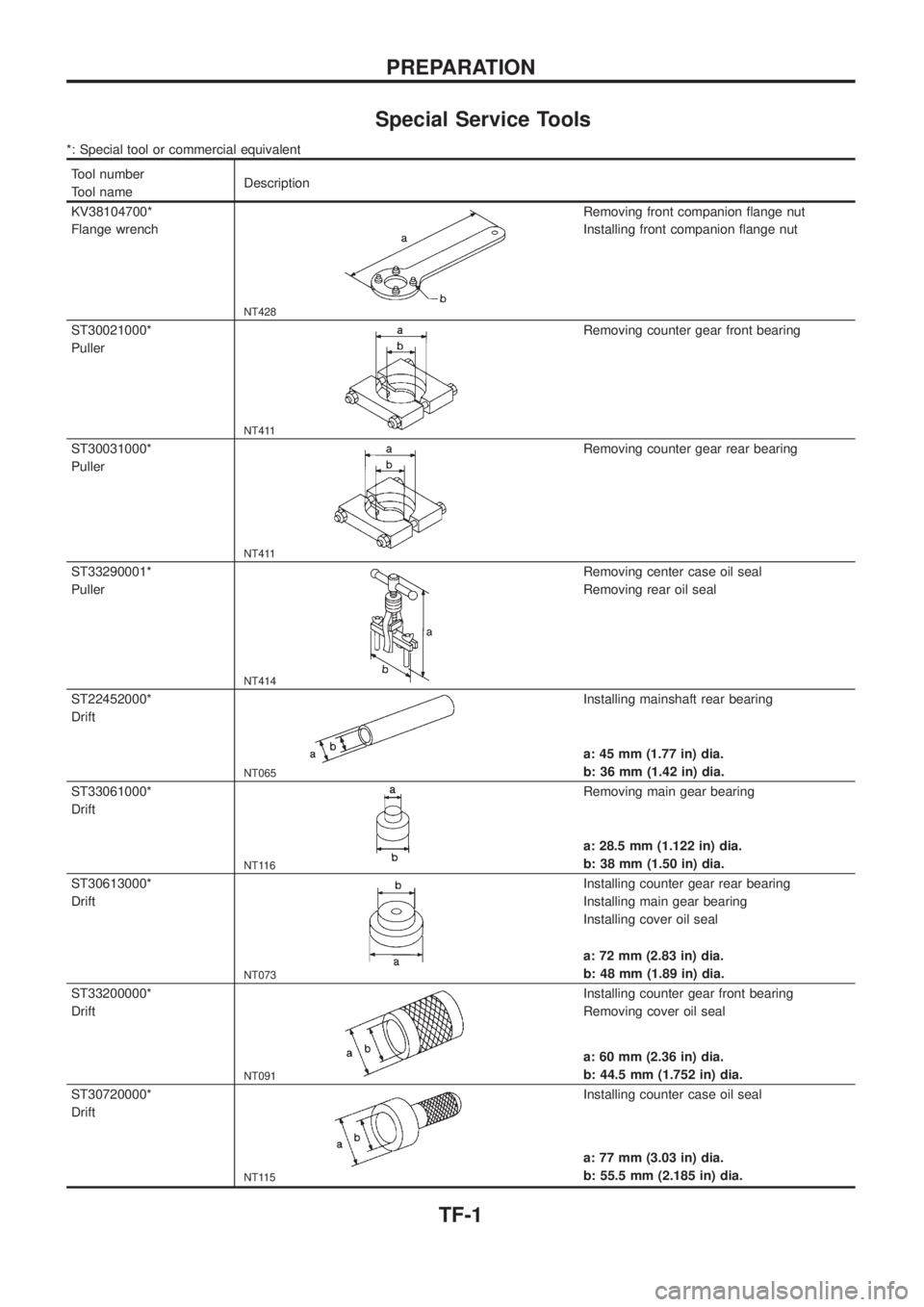

Special Service Tools

*: Special tool or commercial equivalent

Tool number

Tool nameDescription

KV38104700*

Flange wrench

NT428

Removing front companion ¯ange nut

Installing front companion ¯ange nut

ST30021000*

Puller

NT411

Removing counter gear front bearing

ST30031000*

Puller

NT411

Removing counter gear rear bearing

ST33290001*

Puller

NT414

Removing center case oil seal

Removing rear oil seal

ST22452000*

Drift

NT065

Installing mainshaft rear bearing

a: 45 mm (1.77 in) dia.

b: 36 mm (1.42 in) dia.

ST33061000*

Drift

NT116

Removing main gear bearing

a: 28.5 mm (1.122 in) dia.

b: 38 mm (1.50 in) dia.

ST30613000*

Drift

NT073

Installing counter gear rear bearing

Installing main gear bearing

Installing cover oil seal

a: 72 mm (2.83 in) dia.

b: 48 mm (1.89 in) dia.

ST33200000*

Drift

NT091

Installing counter gear front bearing

Removing cover oil seal

a: 60 mm (2.36 in) dia.

b: 44.5 mm (1.752 in) dia.

ST30720000*

Drift

NT115

Installing counter case oil seal

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

PREPARATION

TF-1

Page 1195 of 1226

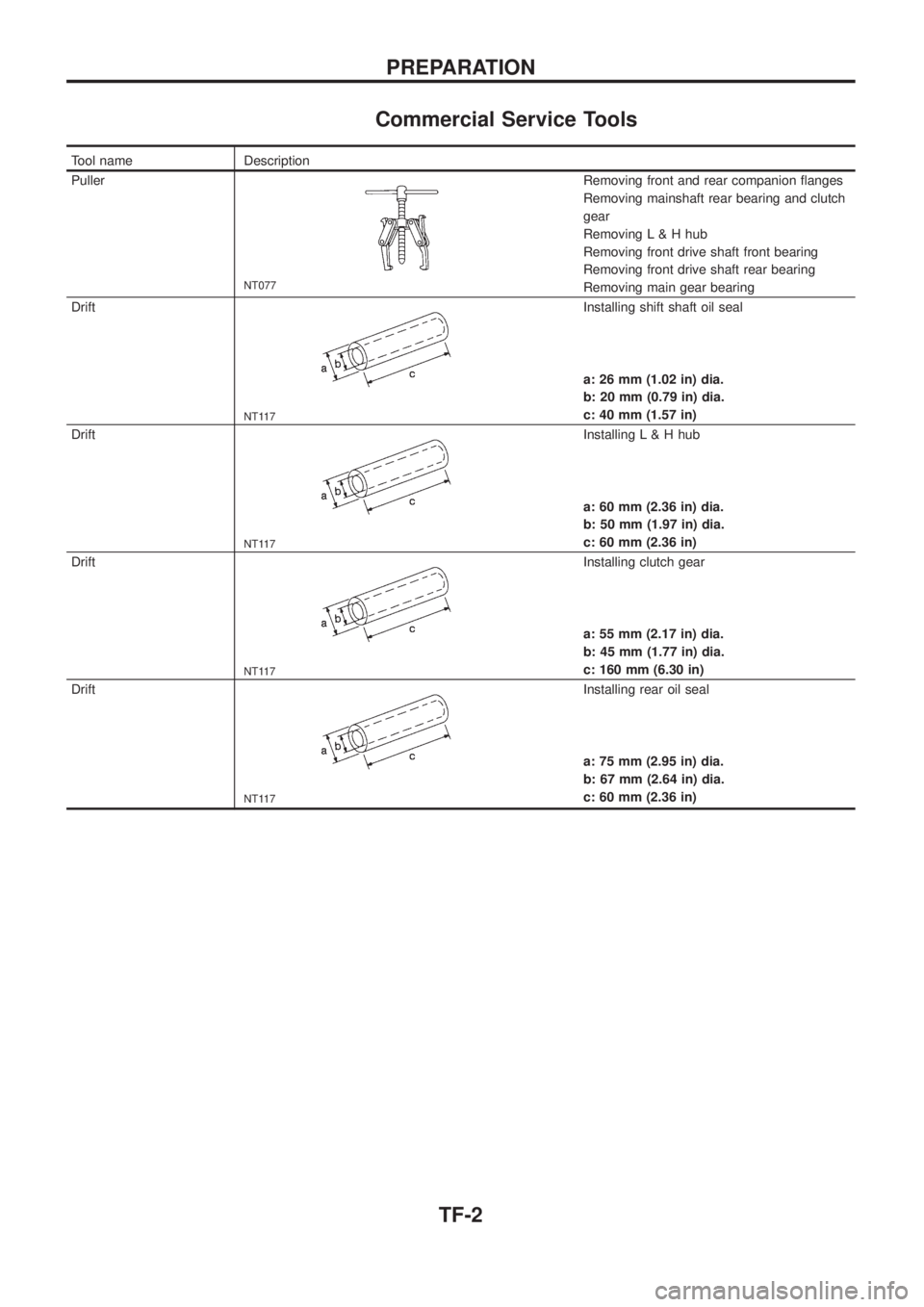

Commercial Service Tools

Tool name Description

Puller

NT077

Removing front and rear companion ¯anges

Removing mainshaft rear bearing and clutch

gear

Removing L & H hub

Removing front drive shaft front bearing

Removing front drive shaft rear bearing

Removing main gear bearing

Drift

NT117

Installing shift shaft oil seal

a: 26 mm (1.02 in) dia.

b: 20 mm (0.79 in) dia.

c: 40 mm (1.57 in)

Drift

NT117

Installing L & H hub

a: 60 mm (2.36 in) dia.

b: 50 mm (1.97 in) dia.

c: 60 mm (2.36 in)

Drift

NT117

Installing clutch gear

a: 55 mm (2.17 in) dia.

b: 45 mm (1.77 in) dia.

c: 160 mm (6.30 in)

Drift

NT117

Installing rear oil seal

a: 75 mm (2.95 in) dia.

b: 67 mm (2.64 in) dia.

c: 60 mm (2.36 in)

PREPARATION

TF-2

Page 1196 of 1226

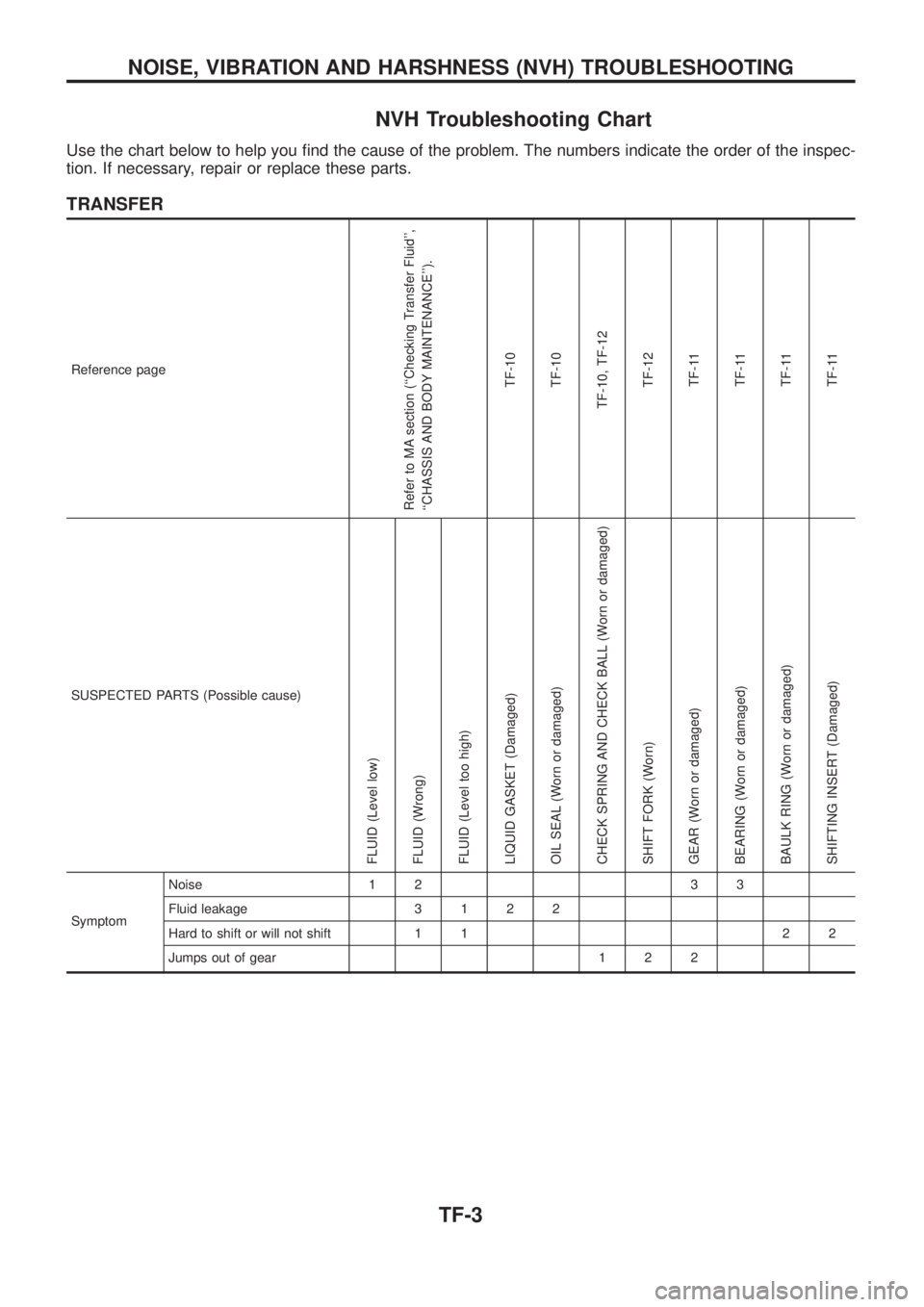

NVH Troubleshooting Chart

Use the chart below to help you ®nd the cause of the problem. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

TRANSFER

Reference page

Refer to MA section (``Checking Transfer Fluid'',

``CHASSIS AND BODY MAINTENANCE'').

TF-10

TF-10

TF-10, TF-12

TF-12

TF-11

TF-11

TF-11

TF-11

SUSPECTED PARTS (Possible cause)

FLUID (Level low)

FLUID (Wrong)

FLUID (Level too high)

LIQUID GASKET (Damaged)

OIL SEAL (Worn or damaged)

CHECK SPRING AND CHECK BALL (Worn or damaged)

SHIFT FORK (Worn)

GEAR (Worn or damaged)

BEARING (Worn or damaged)

BAULK RING (Worn or damaged)

SHIFTING INSERT (Damaged)

SymptomNoise 1 2 3 3

Fluid leakage3122

Hard to shift or will not shift 1 1 2 2

Jumps out of gear 1 2 2

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

TF-3

Page 1197 of 1226

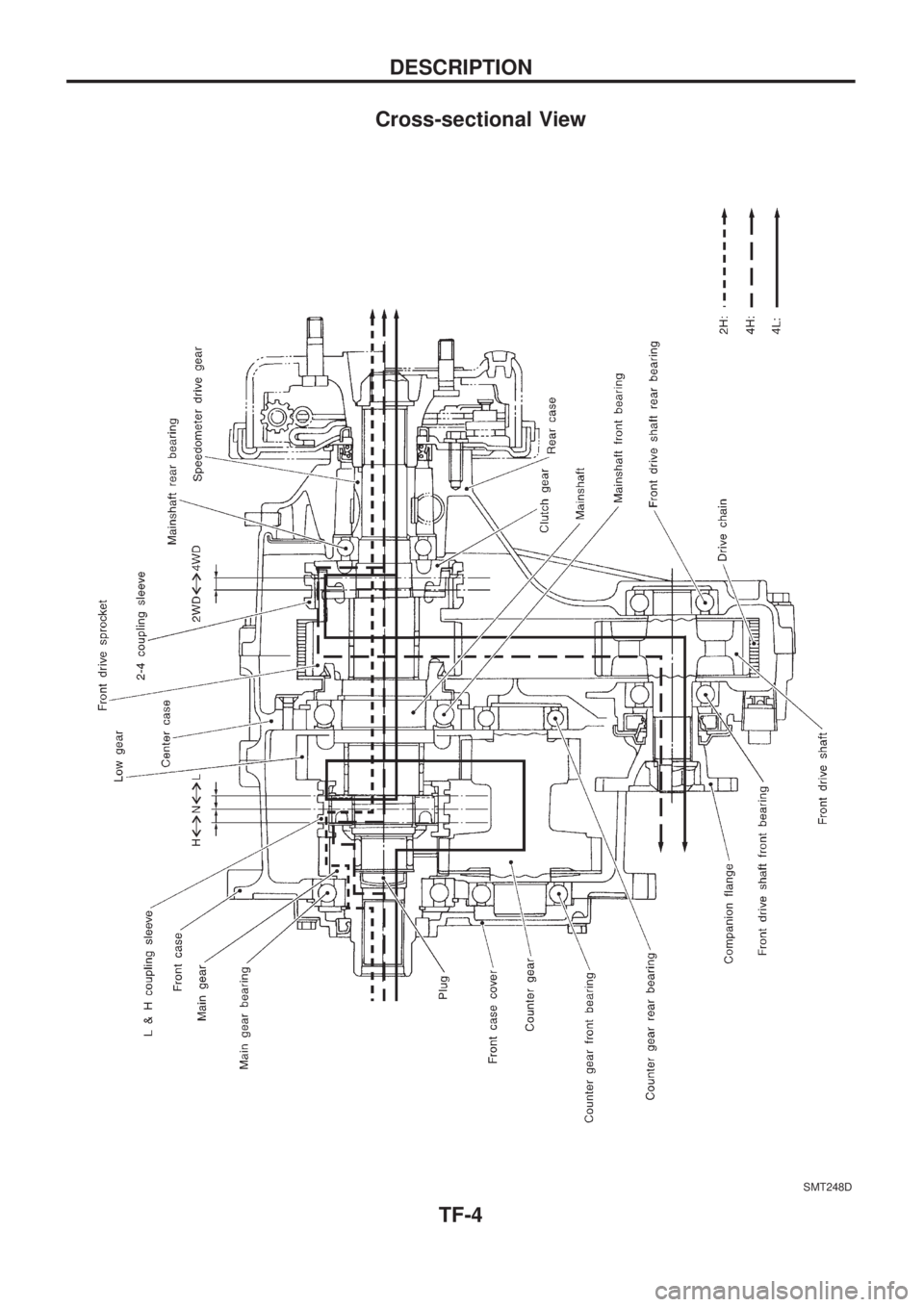

Cross-sectional View

SMT248D

DESCRIPTION

TF-4

Page 1198 of 1226

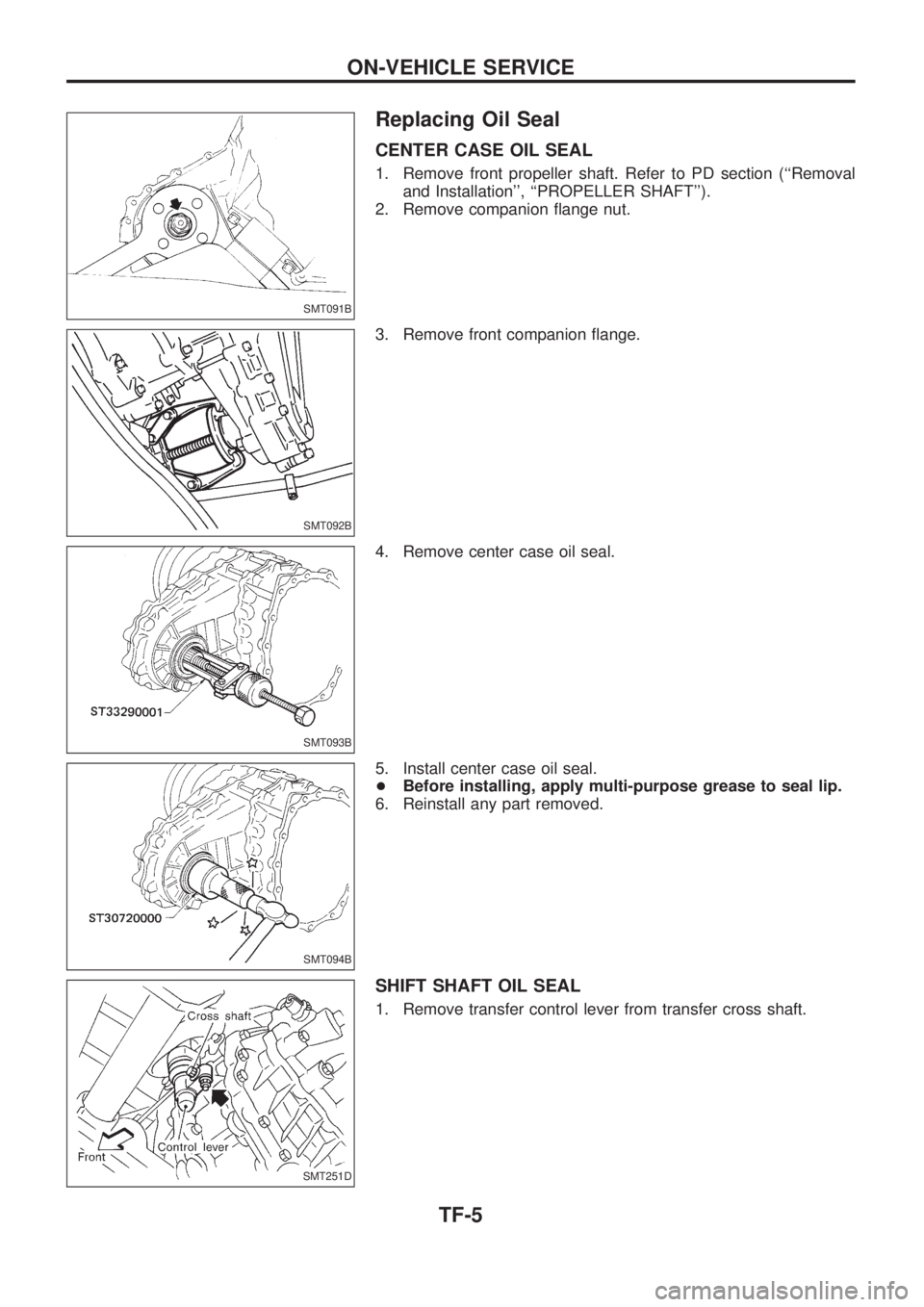

Replacing Oil Seal

CENTER CASE OIL SEAL

1. Remove front propeller shaft. Refer to PD section (``Removal

and Installation'', ``PROPELLER SHAFT'').

2. Remove companion ¯ange nut.

3. Remove front companion ¯ange.

4. Remove center case oil seal.

5. Install center case oil seal.

+Before installing, apply multi-purpose grease to seal lip.

6. Reinstall any part removed.

SHIFT SHAFT OIL SEAL

1. Remove transfer control lever from transfer cross shaft.

SMT091B

SMT092B

SMT093B

SMT094B

SMT251D

ON-VEHICLE SERVICE

TF-5

Page 1199 of 1226

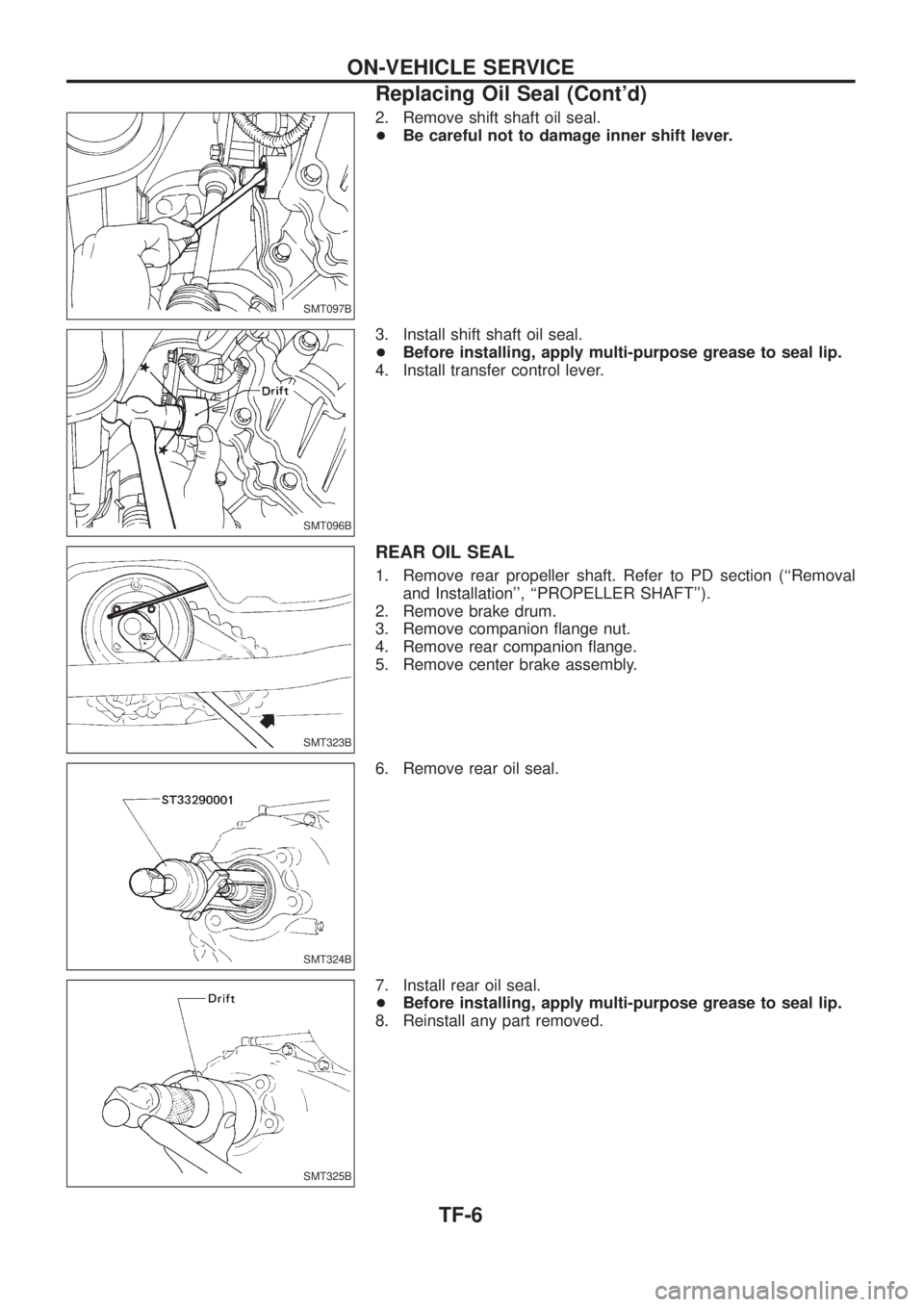

2. Remove shift shaft oil seal.

+Be careful not to damage inner shift lever.

3. Install shift shaft oil seal.

+Before installing, apply multi-purpose grease to seal lip.

4. Install transfer control lever.

REAR OIL SEAL

1. Remove rear propeller shaft. Refer to PD section (``Removal

and Installation'', ``PROPELLER SHAFT'').

2. Remove brake drum.

3. Remove companion ¯ange nut.

4. Remove rear companion ¯ange.

5. Remove center brake assembly.

6. Remove rear oil seal.

7. Install rear oil seal.

+Before installing, apply multi-purpose grease to seal lip.

8. Reinstall any part removed.

SMT097B

SMT096B

SMT323B

SMT324B

SMT325B

ON-VEHICLE SERVICE

Replacing Oil Seal (Cont'd)

TF-6

Page 1200 of 1226

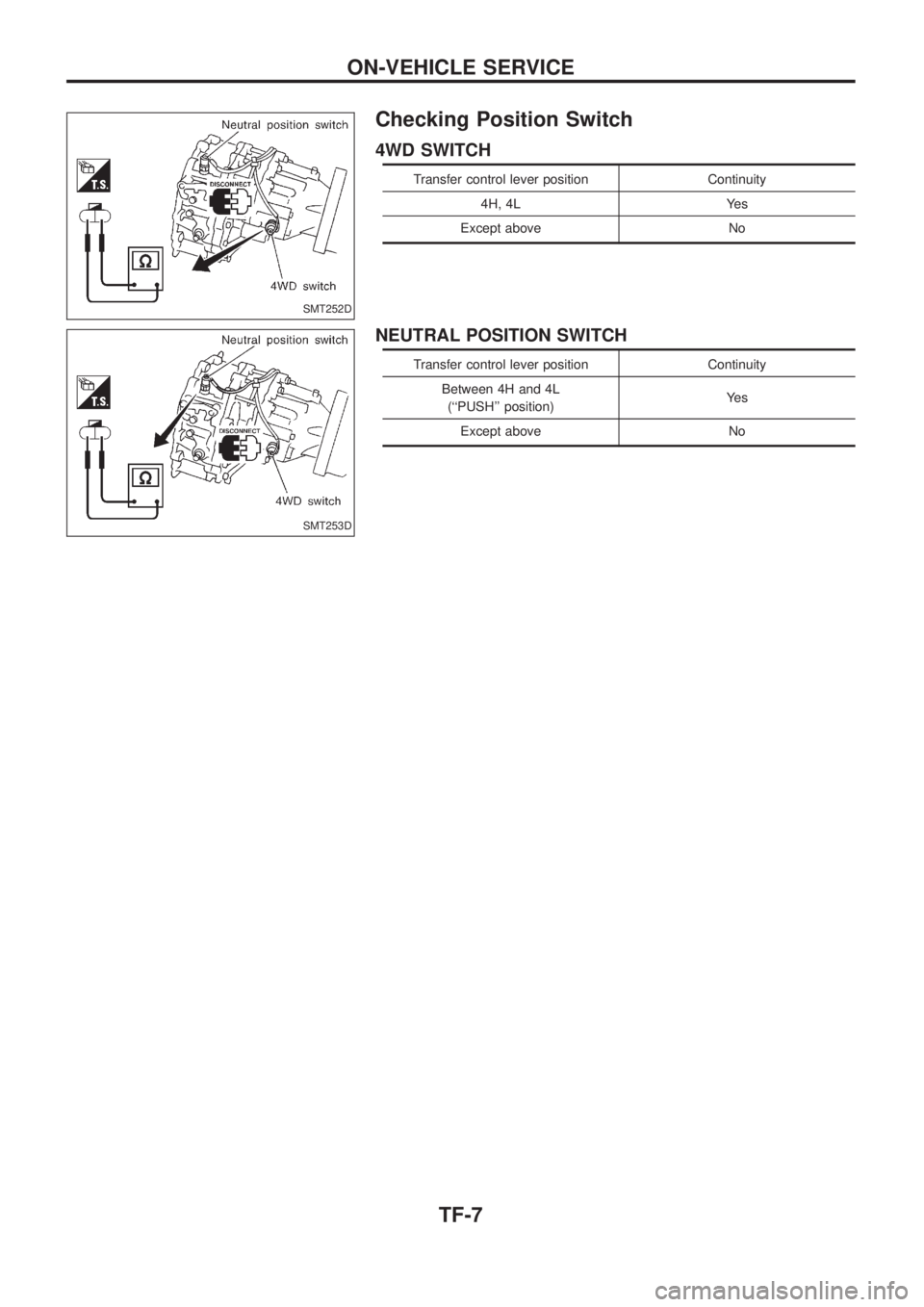

Checking Position Switch

4WD SWITCH

Transfer control lever position Continuity

4H, 4L Yes

Except above No

NEUTRAL POSITION SWITCH

Transfer control lever position Continuity

Between 4H and 4L

(``PUSH'' position)Ye s

Except above No

SMT252D

SMT253D

ON-VEHICLE SERVICE

TF-7