NISSAN PATROL 2006 Service Manual

PATROL 2006

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57368/w960_57368-0.png

NISSAN PATROL 2006 Service Manual

Trending: Break, fuse box diagram, transmission, rims, breaks, transmission oil, rear view mirror

Page 1211 of 1226

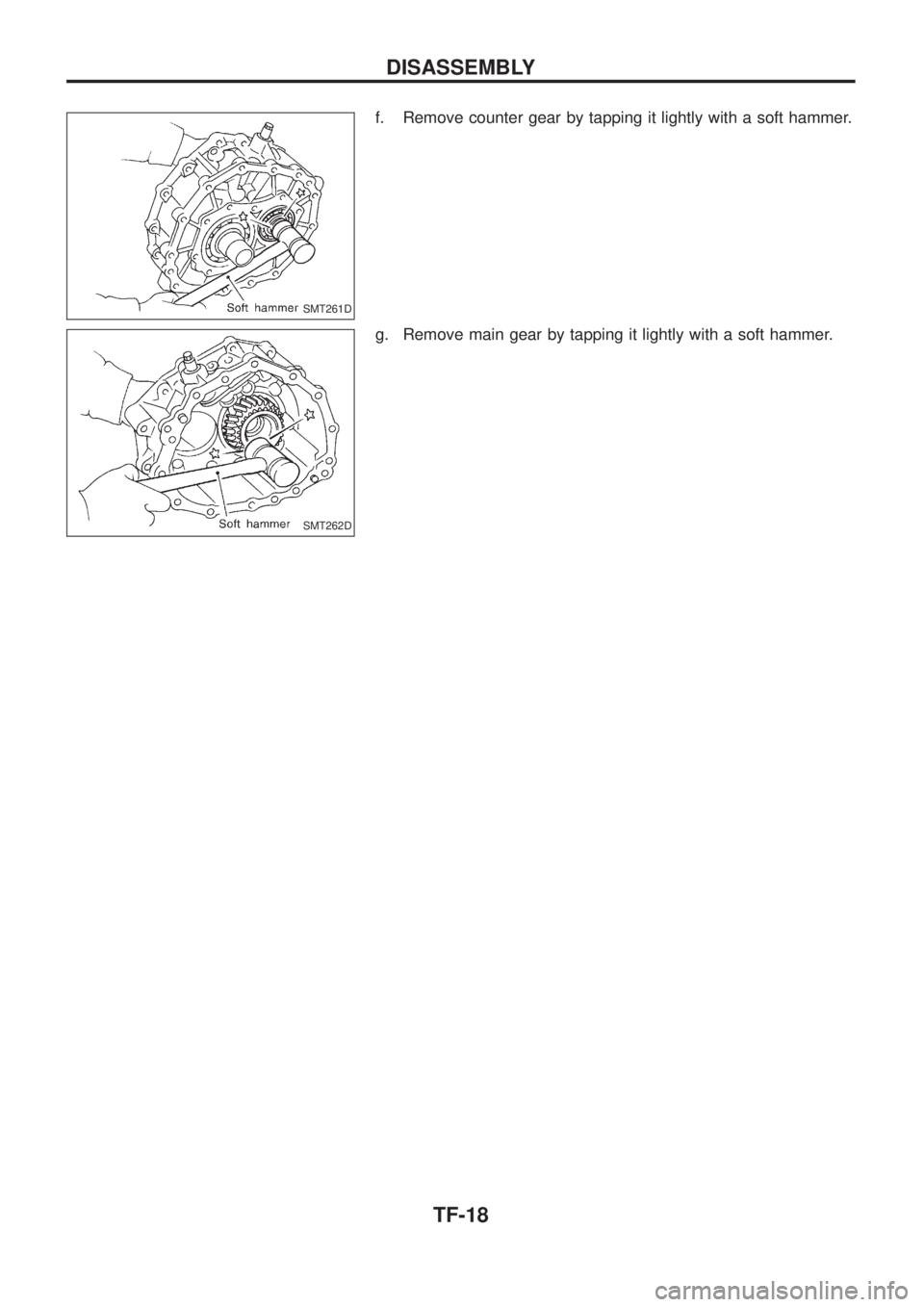

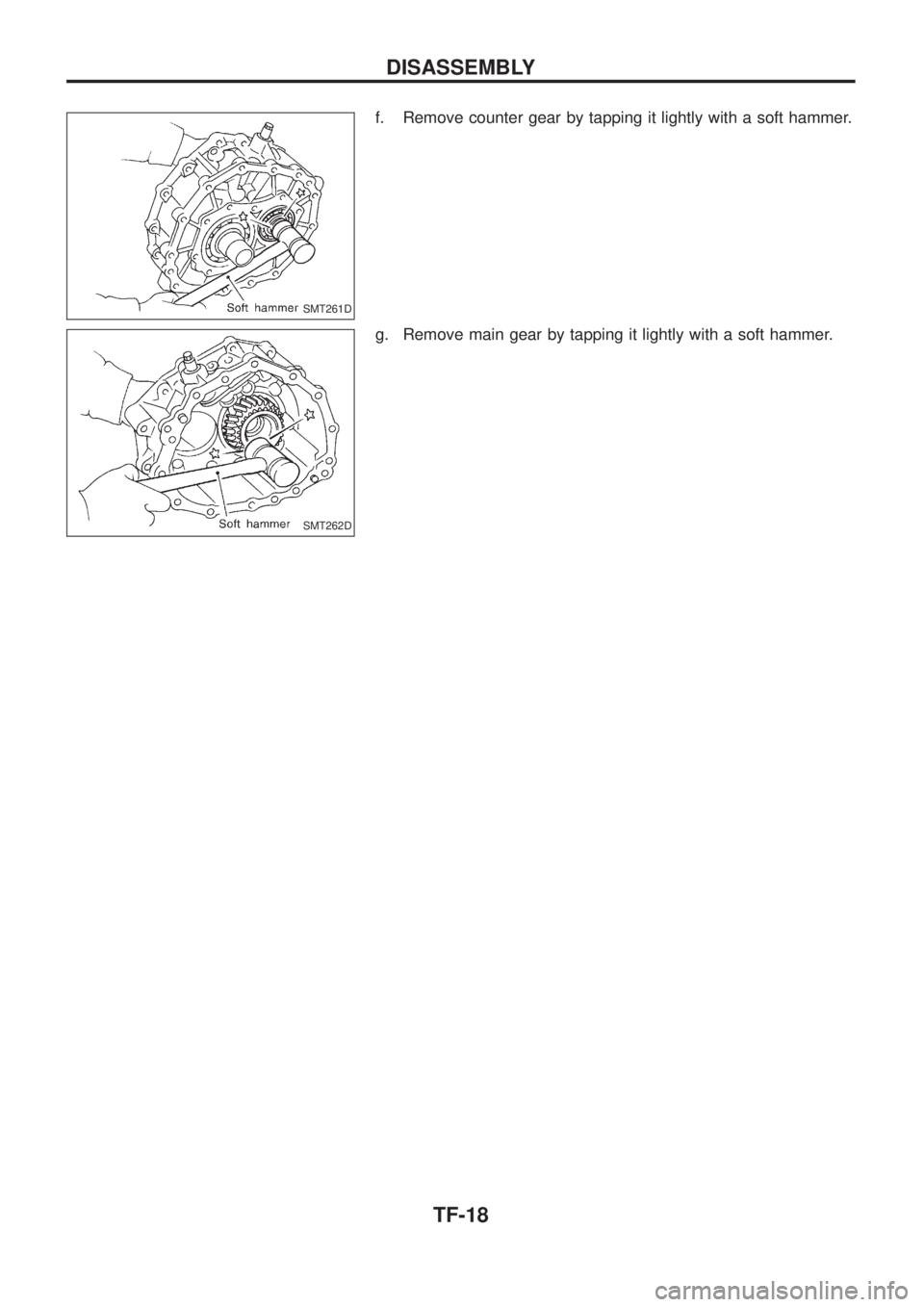

f. Remove counter gear by tapping it lightly with a soft hammer.

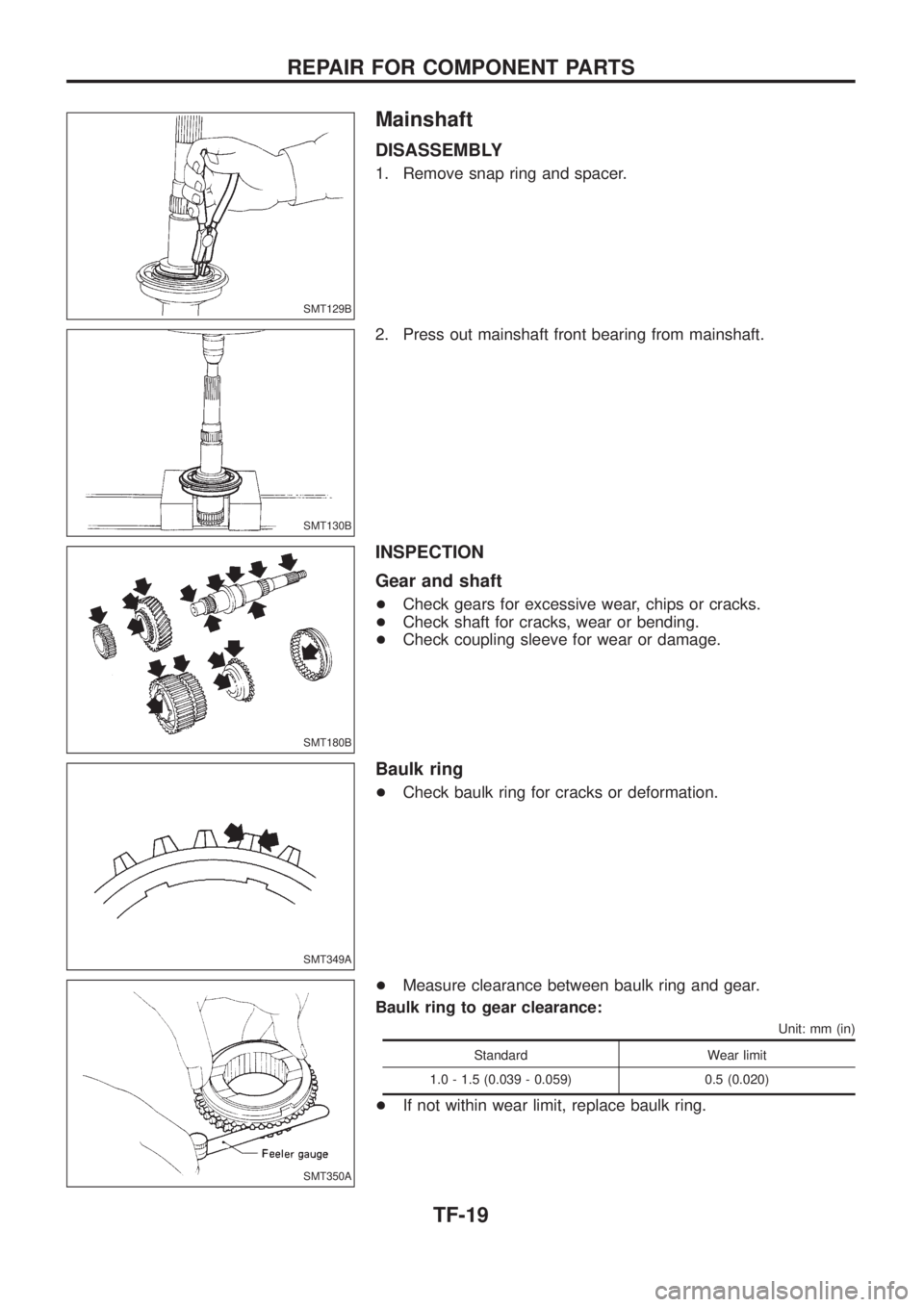

g. Remove main gear by tapping it lightly with a soft hammer.

SMT261D

SMT262D

DISASSEMBLY

TF-18

Page 1212 of 1226

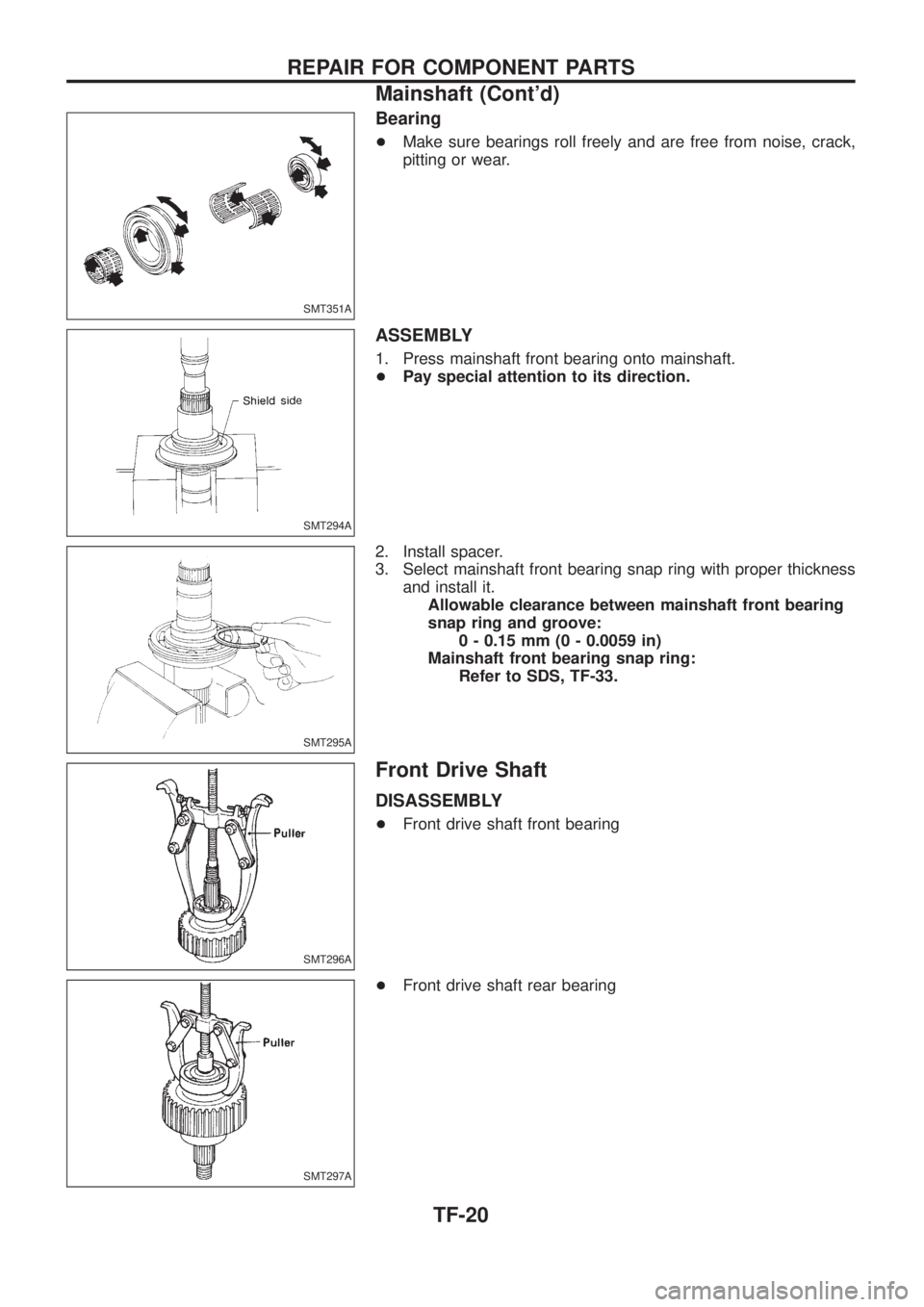

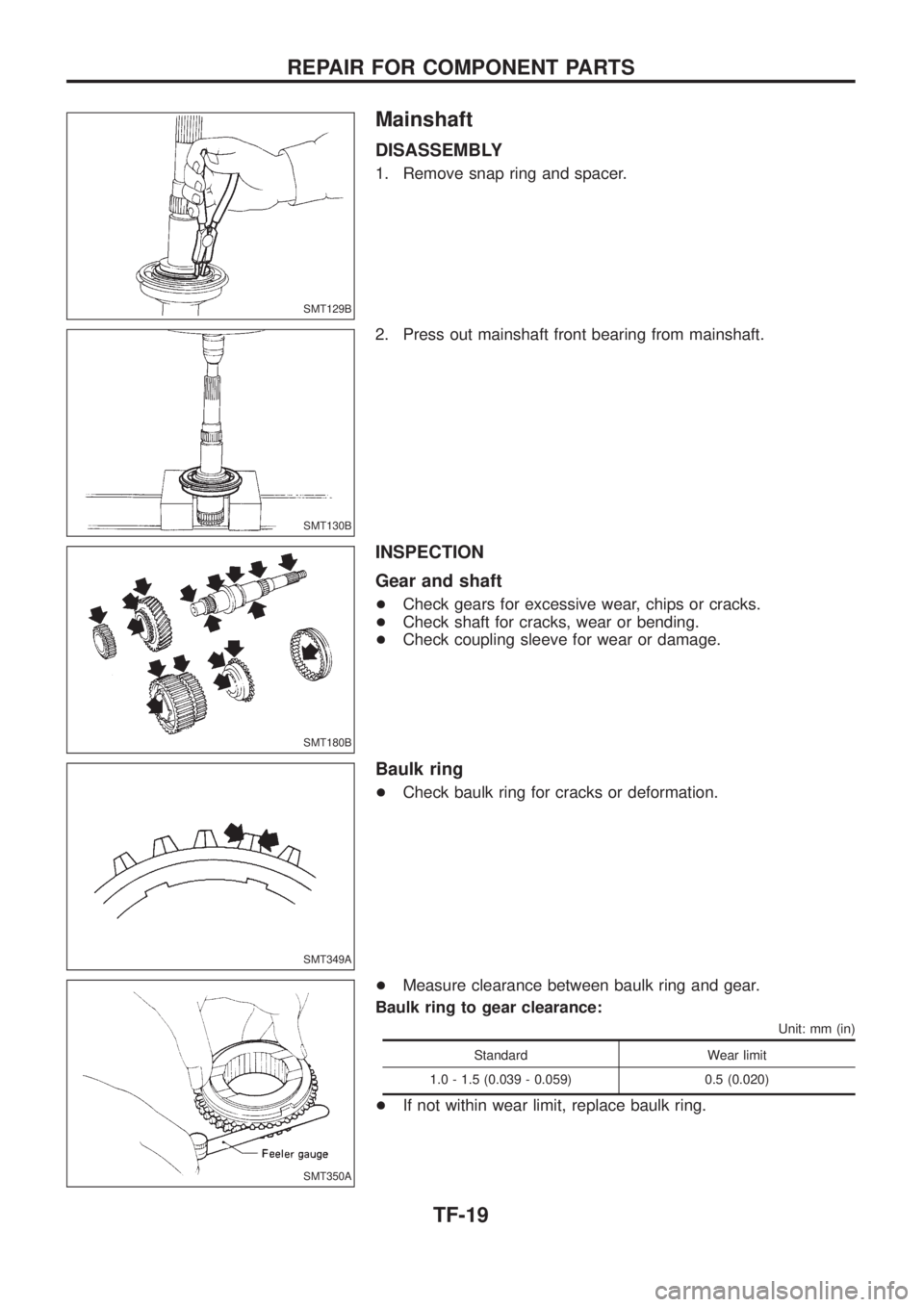

Mainshaft

DISASSEMBLY

1. Remove snap ring and spacer.

2. Press out mainshaft front bearing from mainshaft.

INSPECTION

Gear and shaft

+Check gears for excessive wear, chips or cracks.

+Check shaft for cracks, wear or bending.

+Check coupling sleeve for wear or damage.

Baulk ring

+Check baulk ring for cracks or deformation.

+Measure clearance between baulk ring and gear.

Baulk ring to gear clearance:

Unit: mm (in)

Standard Wear limit

1.0 - 1.5 (0.039 - 0.059) 0.5 (0.020)

+If not within wear limit, replace baulk ring.

SMT129B

SMT130B

SMT180B

SMT349A

SMT350A

REPAIR FOR COMPONENT PARTS

TF-19

Page 1213 of 1226

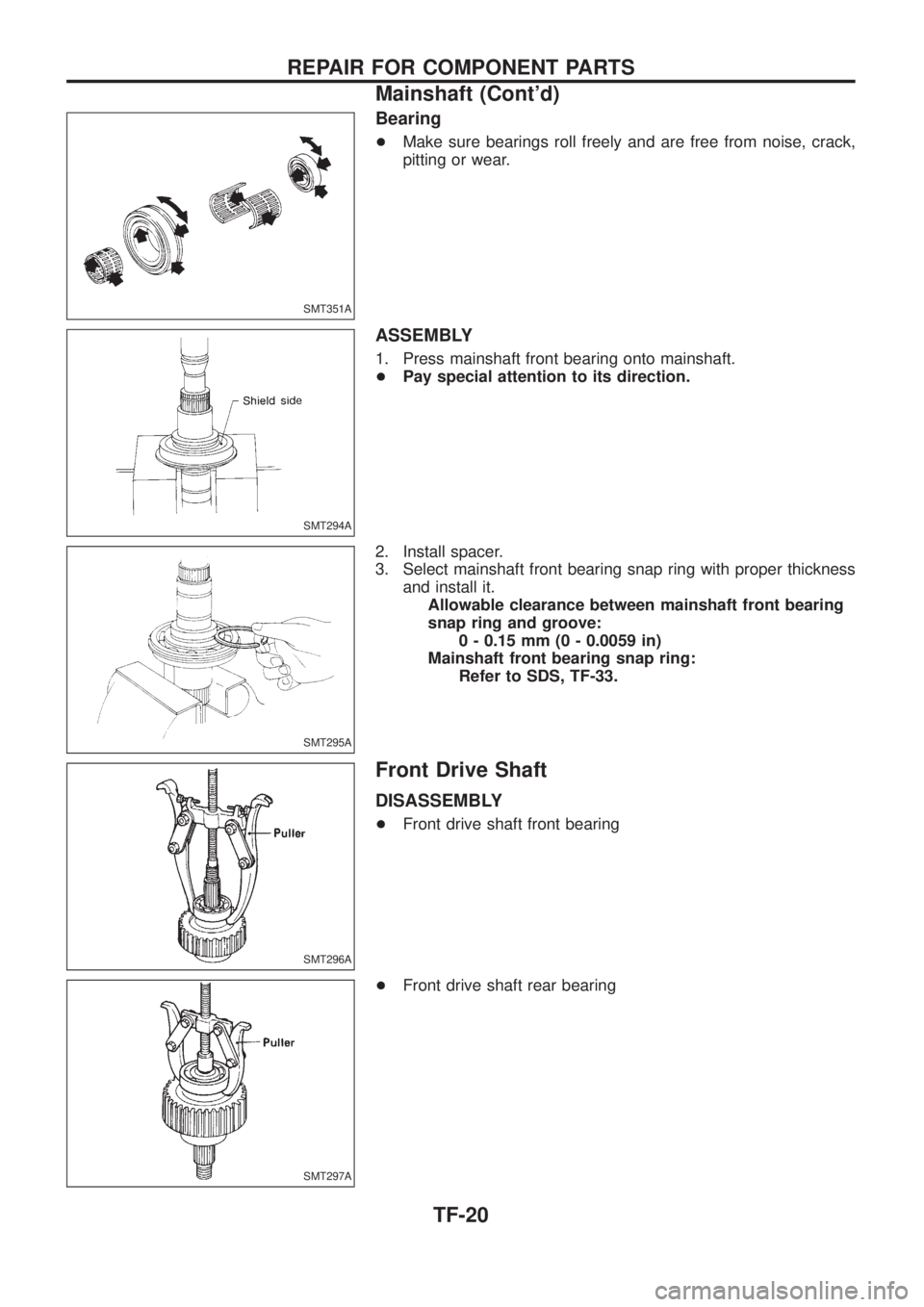

Bearing

+Make sure bearings roll freely and are free from noise, crack,

pitting or wear.

ASSEMBLY

1. Press mainshaft front bearing onto mainshaft.

+Pay special attention to its direction.

2. Install spacer.

3. Select mainshaft front bearing snap ring with proper thickness

and install it.

Allowable clearance between mainshaft front bearing

snap ring and groove:

0 - 0.15 mm (0 - 0.0059 in)

Mainshaft front bearing snap ring:

Refer to SDS, TF-33.

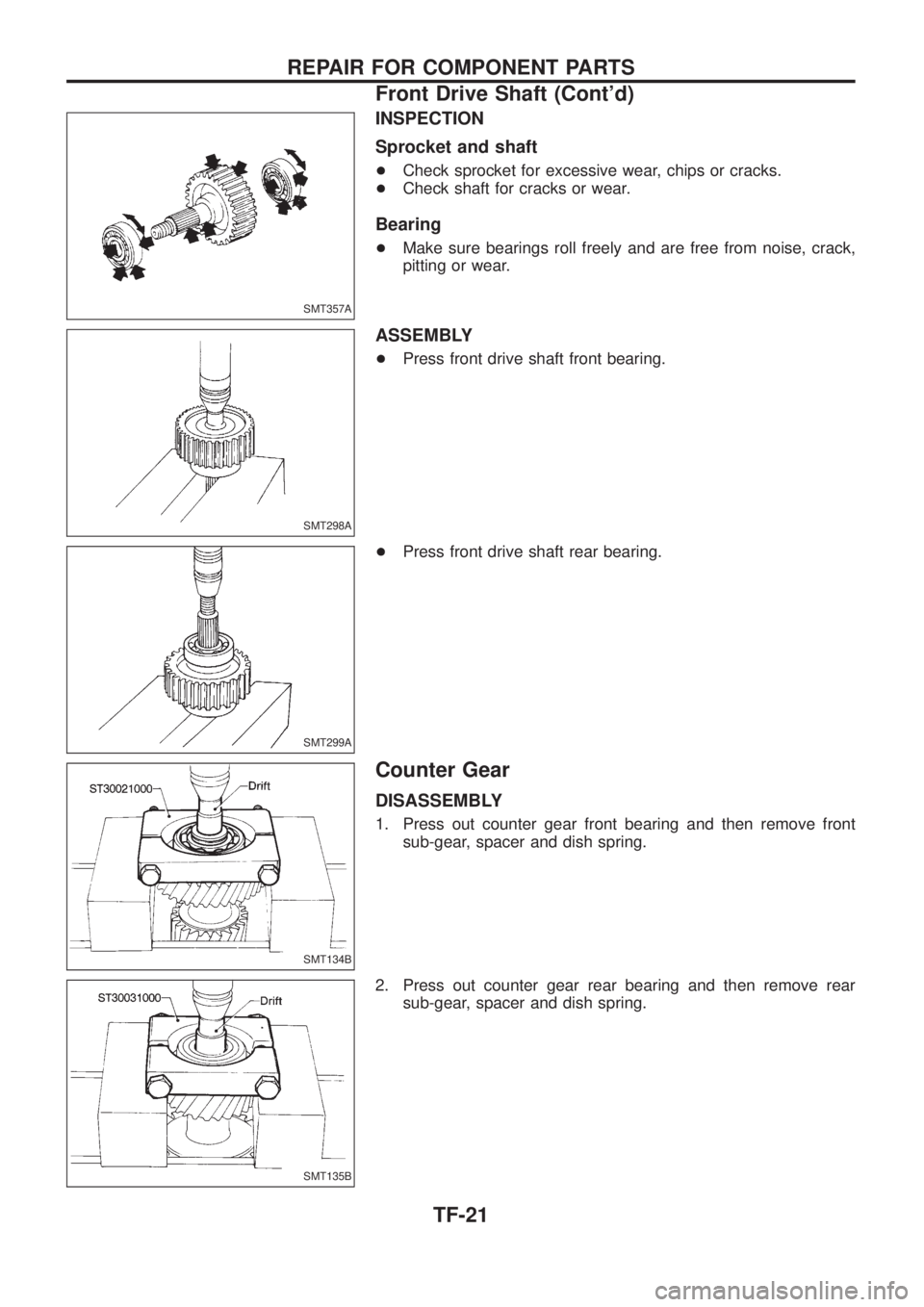

Front Drive Shaft

DISASSEMBLY

+Front drive shaft front bearing

+Front drive shaft rear bearing

SMT351A

SMT294A

SMT295A

SMT296A

SMT297A

REPAIR FOR COMPONENT PARTS

Mainshaft (Cont'd)

TF-20

Page 1214 of 1226

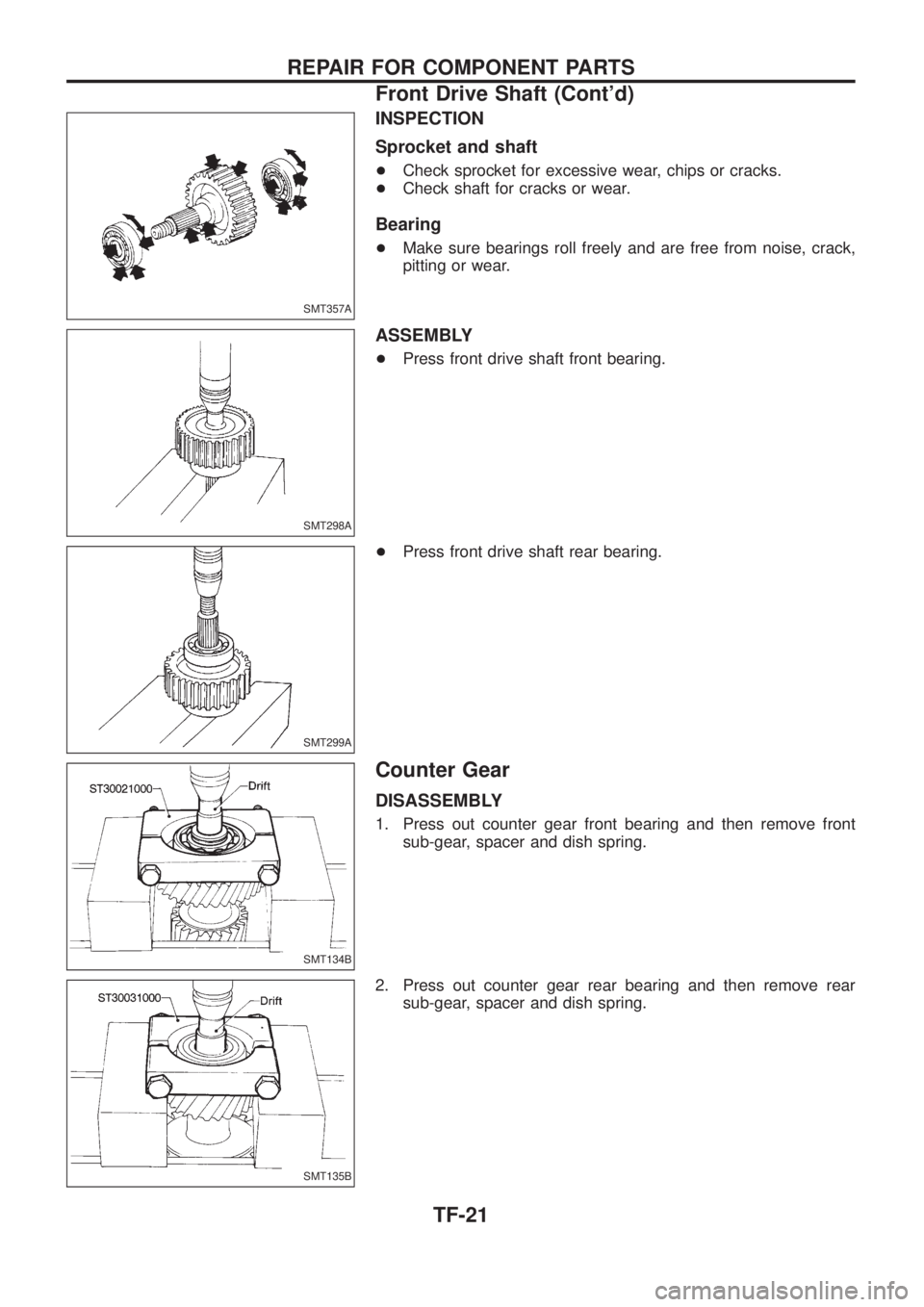

INSPECTION

Sprocket and shaft

+Check sprocket for excessive wear, chips or cracks.

+Check shaft for cracks or wear.

Bearing

+Make sure bearings roll freely and are free from noise, crack,

pitting or wear.

ASSEMBLY

+Press front drive shaft front bearing.

+Press front drive shaft rear bearing.

Counter Gear

DISASSEMBLY

1. Press out counter gear front bearing and then remove front

sub-gear, spacer and dish spring.

2. Press out counter gear rear bearing and then remove rear

sub-gear, spacer and dish spring.

SMT357A

SMT298A

SMT299A

SMT134B

SMT135B

REPAIR FOR COMPONENT PARTS

Front Drive Shaft (Cont'd)

TF-21

Page 1215 of 1226

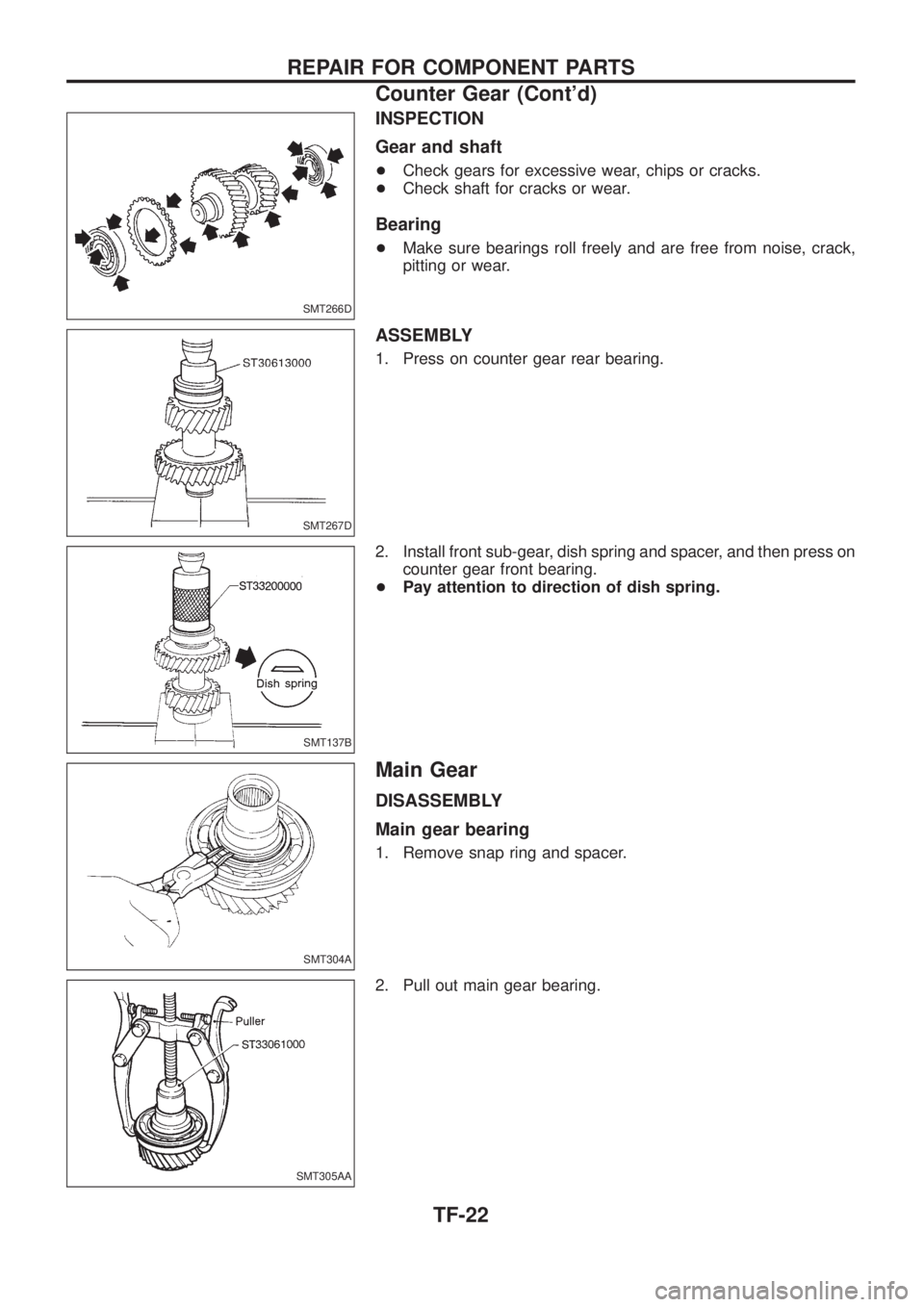

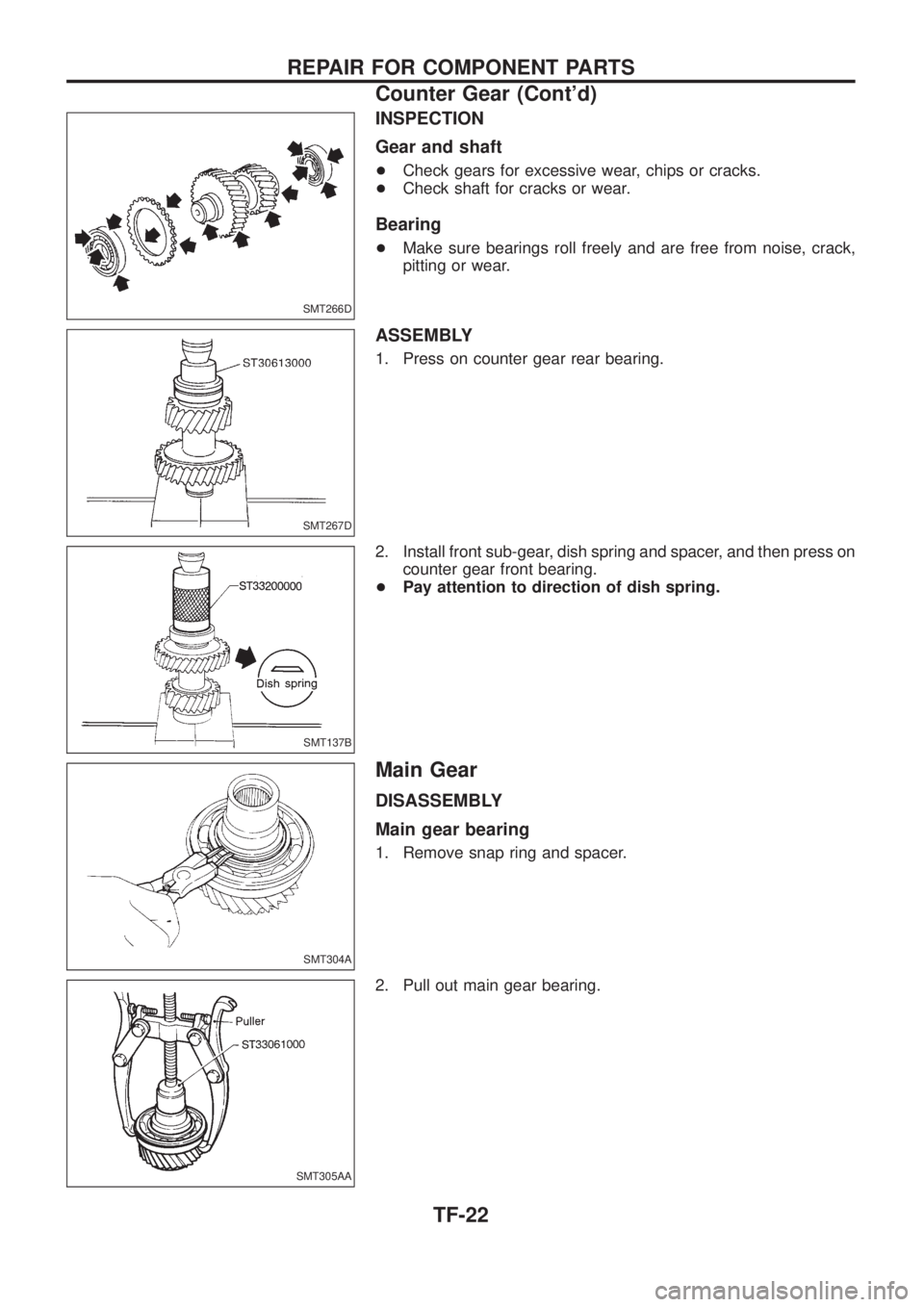

INSPECTION

Gear and shaft

+Check gears for excessive wear, chips or cracks.

+Check shaft for cracks or wear.

Bearing

+Make sure bearings roll freely and are free from noise, crack,

pitting or wear.

ASSEMBLY

1. Press on counter gear rear bearing.

2. Install front sub-gear, dish spring and spacer, and then press on

counter gear front bearing.

+Pay attention to direction of dish spring.

Main Gear

DISASSEMBLY

Main gear bearing

1. Remove snap ring and spacer.

2. Pull out main gear bearing.

SMT266D

SMT267D

SMT137B

SMT304A

SMT305AA

REPAIR FOR COMPONENT PARTS

Counter Gear (Cont'd)

TF-22

Page 1216 of 1226

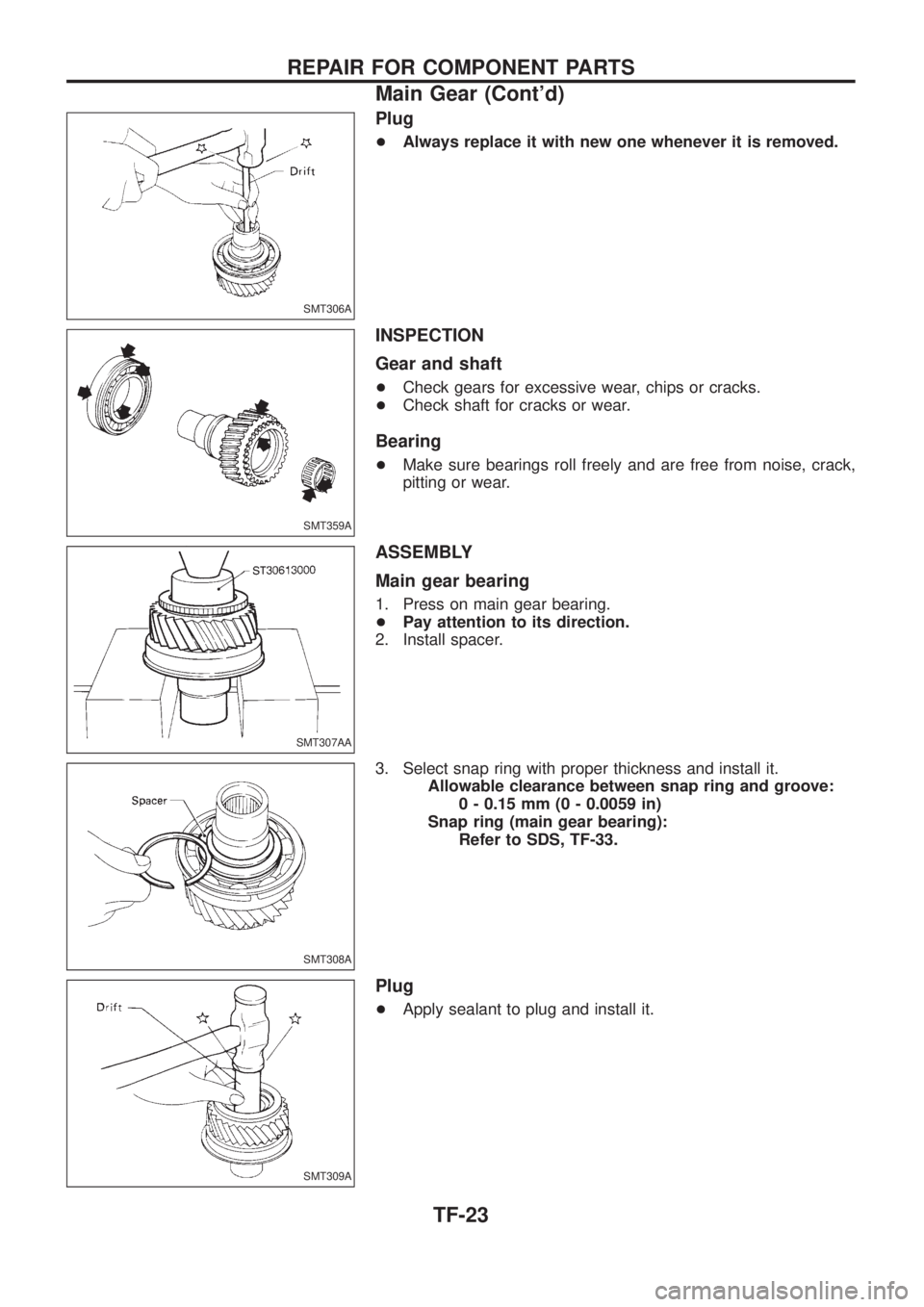

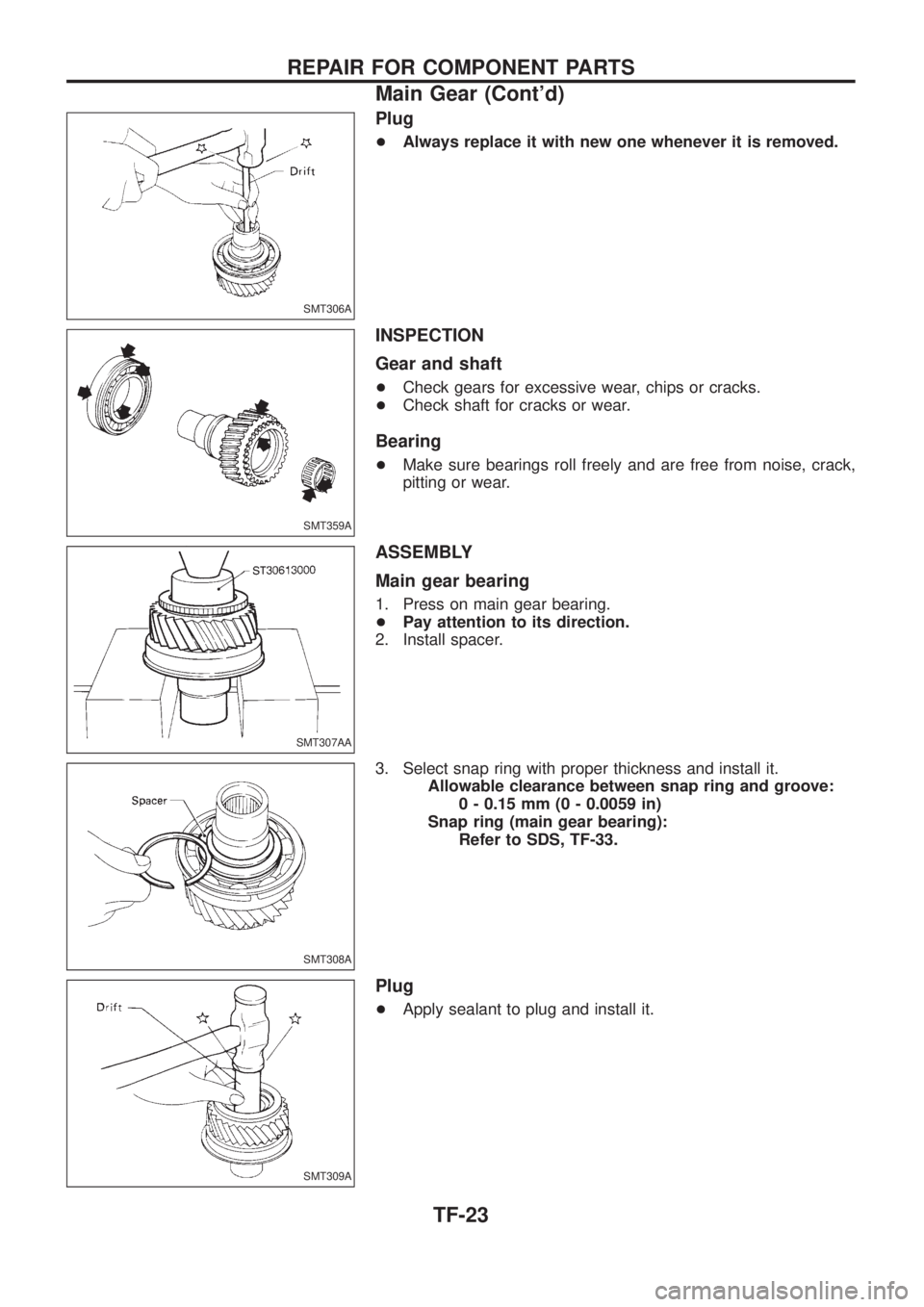

Plug

+Always replace it with new one whenever it is removed.

INSPECTION

Gear and shaft

+Check gears for excessive wear, chips or cracks.

+Check shaft for cracks or wear.

Bearing

+Make sure bearings roll freely and are free from noise, crack,

pitting or wear.

ASSEMBLY

Main gear bearing

1. Press on main gear bearing.

+Pay attention to its direction.

2. Install spacer.

3. Select snap ring with proper thickness and install it.

Allowable clearance between snap ring and groove:

0 - 0.15 mm (0 - 0.0059 in)

Snap ring (main gear bearing):

Refer to SDS, TF-33.

Plug

+Apply sealant to plug and install it.

SMT306A

SMT359A

SMT307AA

SMT308A

SMT309A

REPAIR FOR COMPONENT PARTS

Main Gear (Cont'd)

TF-23

Page 1217 of 1226

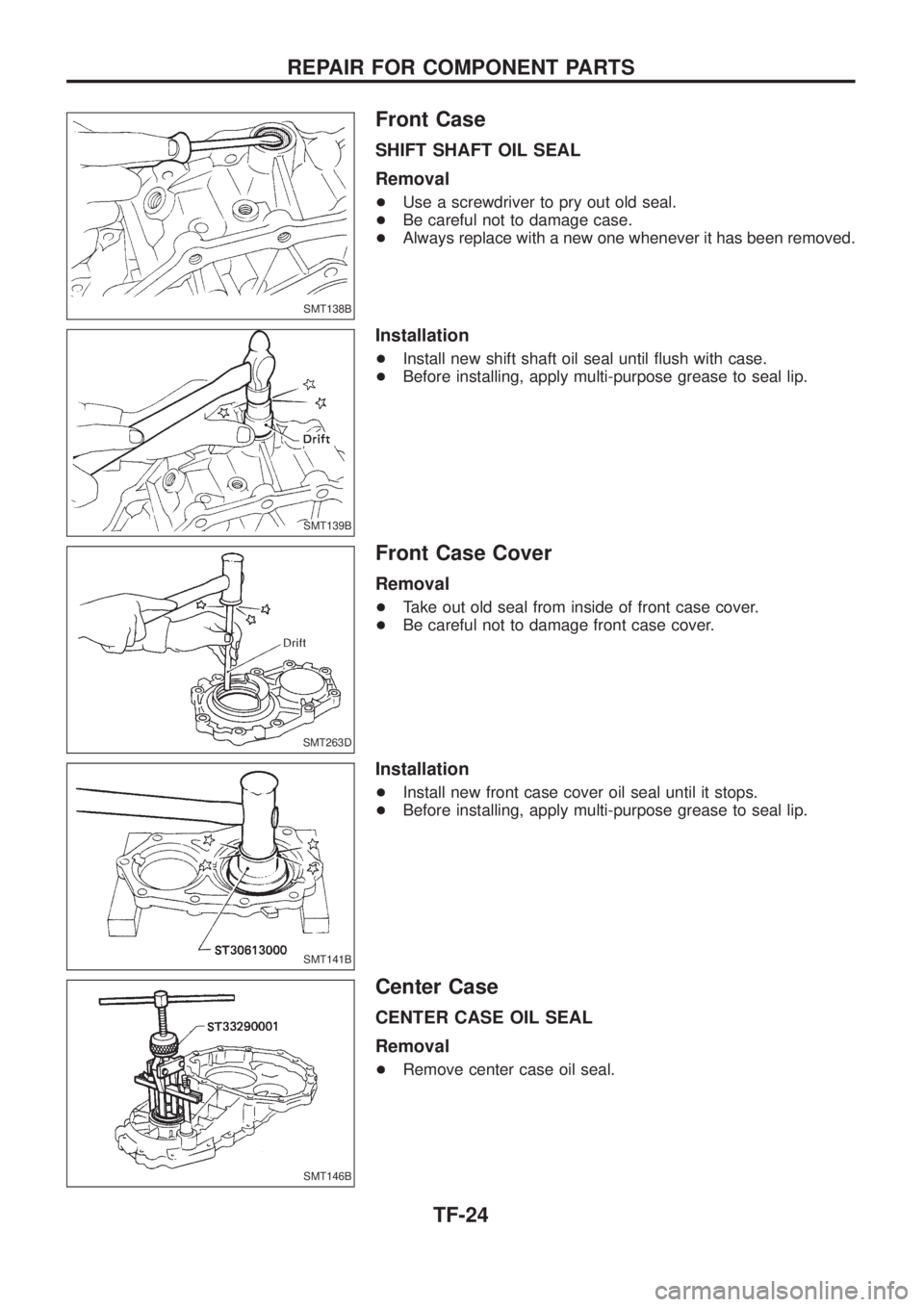

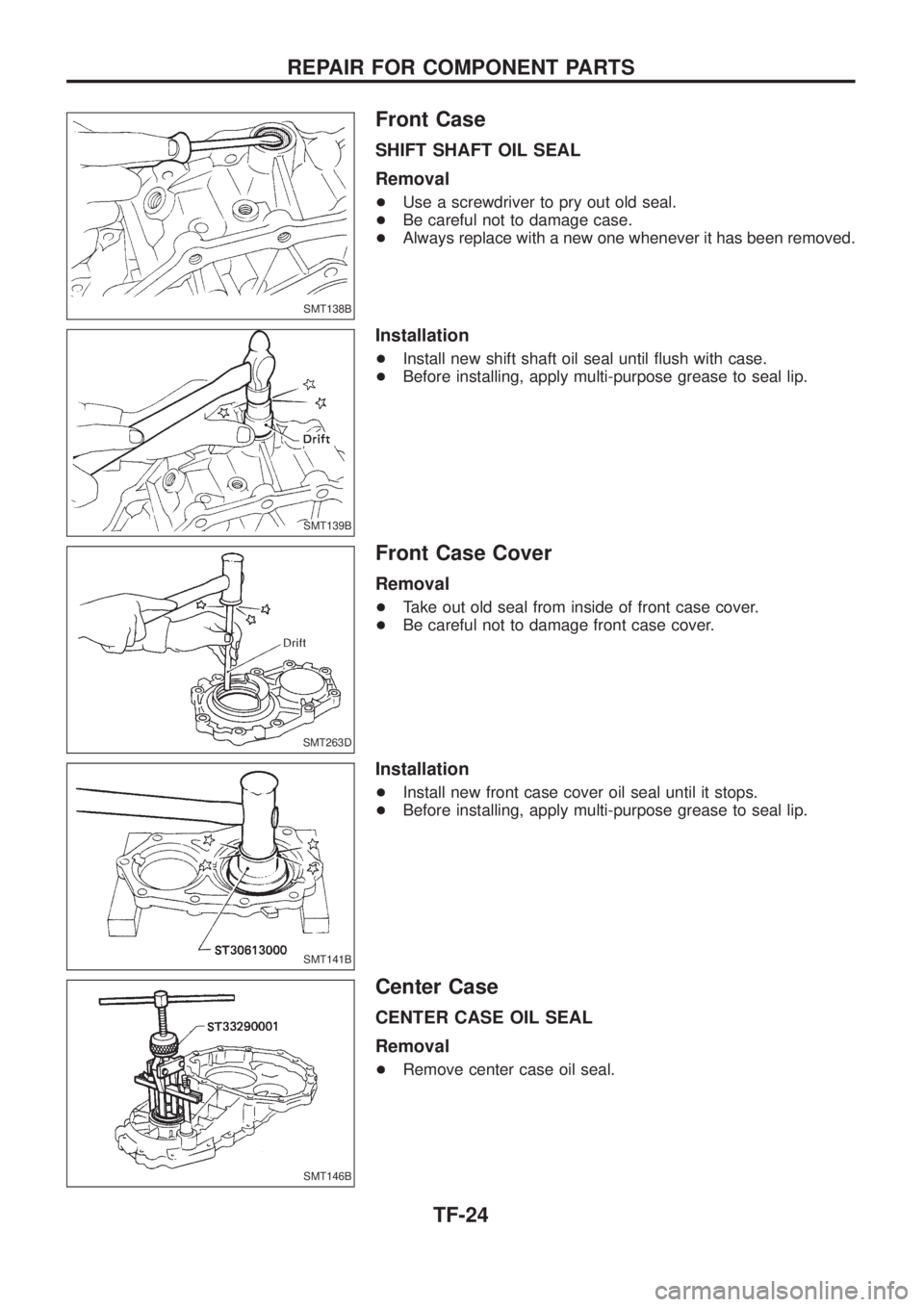

Front Case

SHIFT SHAFT OIL SEAL

Removal

+Use a screwdriver to pry out old seal.

+Be careful not to damage case.

+Always replace with a new one whenever it has been removed.

Installation

+Install new shift shaft oil seal until ¯ush with case.

+Before installing, apply multi-purpose grease to seal lip.

Front Case Cover

Removal

+Take out old seal from inside of front case cover.

+Be careful not to damage front case cover.

Installation

+Install new front case cover oil seal until it stops.

+Before installing, apply multi-purpose grease to seal lip.

Center Case

CENTER CASE OIL SEAL

Removal

+Remove center case oil seal.

SMT138B

SMT139B

SMT263D

SMT141B

SMT146B

REPAIR FOR COMPONENT PARTS

TF-24

Page 1218 of 1226

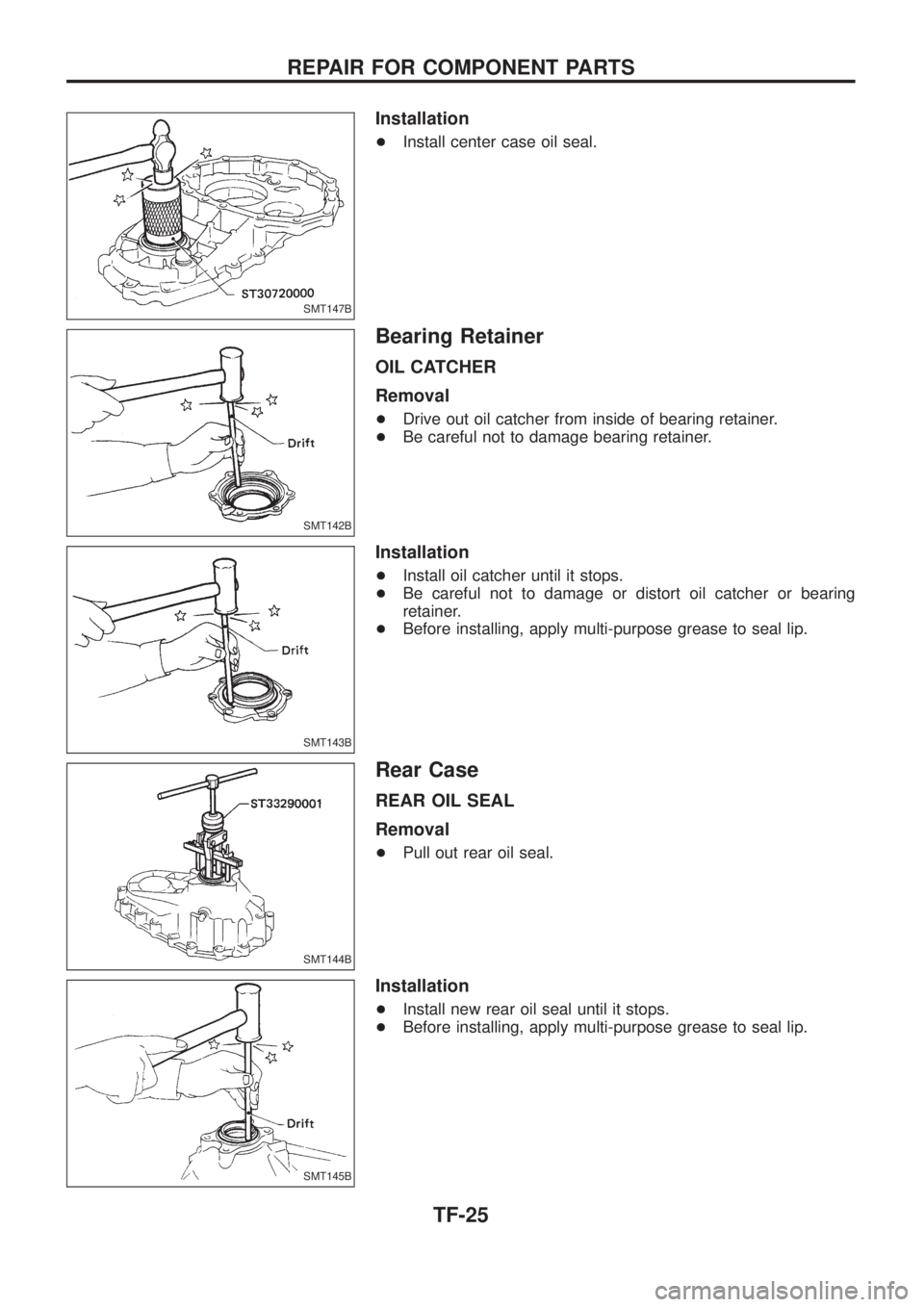

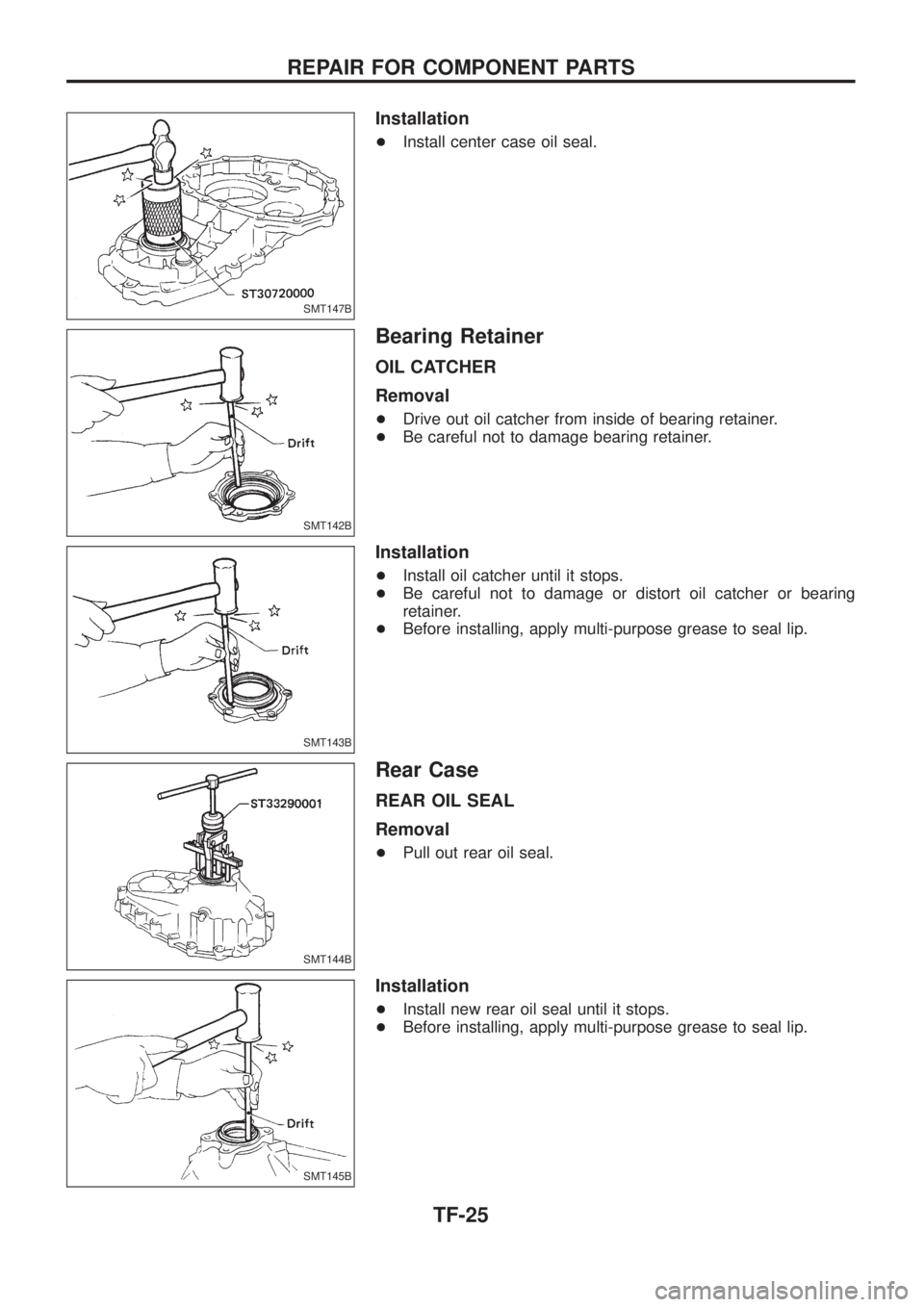

Installation

+Install center case oil seal.

Bearing Retainer

OIL CATCHER

Removal

+Drive out oil catcher from inside of bearing retainer.

+Be careful not to damage bearing retainer.

Installation

+Install oil catcher until it stops.

+Be careful not to damage or distort oil catcher or bearing

retainer.

+Before installing, apply multi-purpose grease to seal lip.

Rear Case

REAR OIL SEAL

Removal

+Pull out rear oil seal.

Installation

+Install new rear oil seal until it stops.

+Before installing, apply multi-purpose grease to seal lip.

SMT147B

SMT142B

SMT143B

SMT144B

SMT145B

REPAIR FOR COMPONENT PARTS

TF-25

Page 1219 of 1226

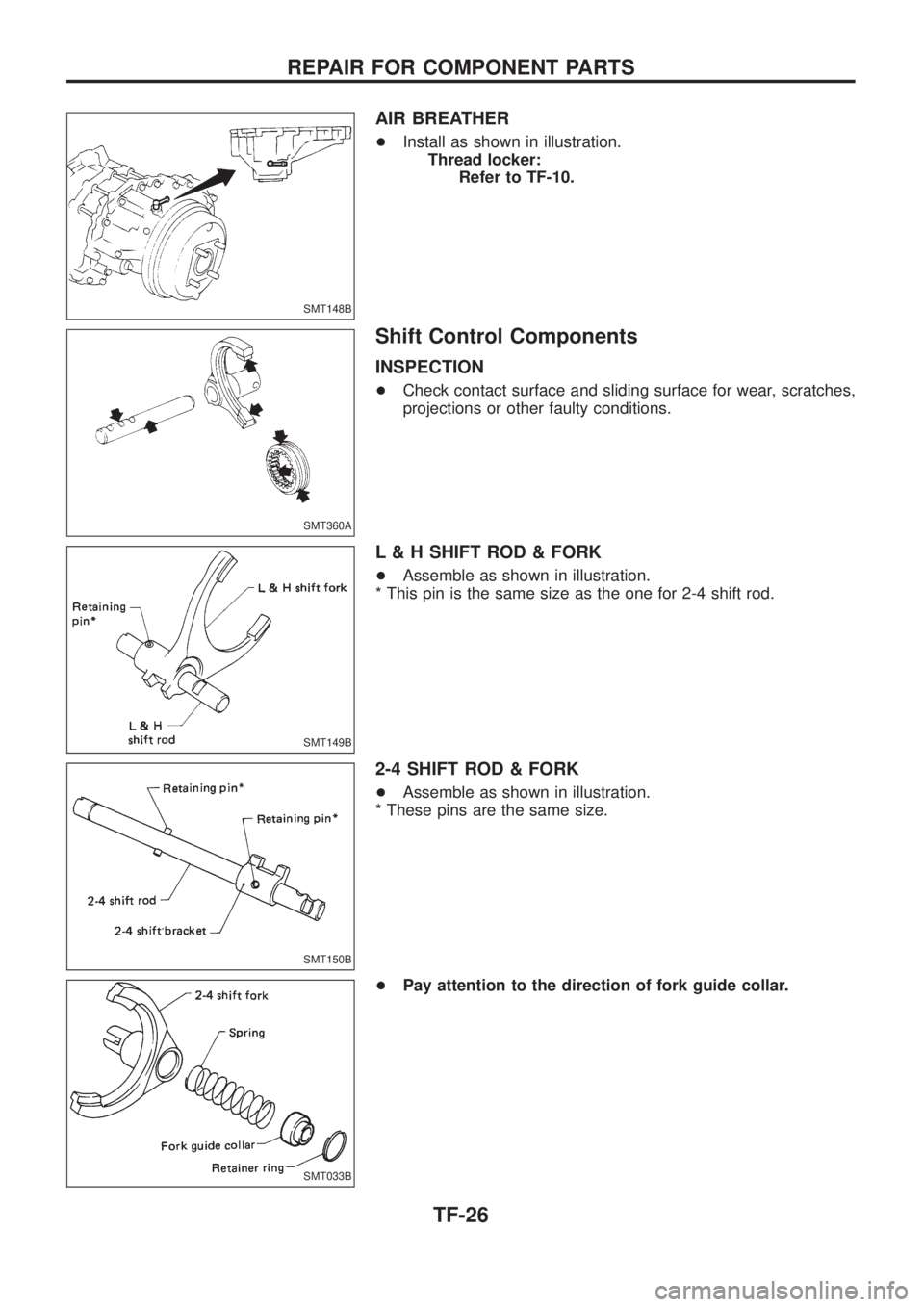

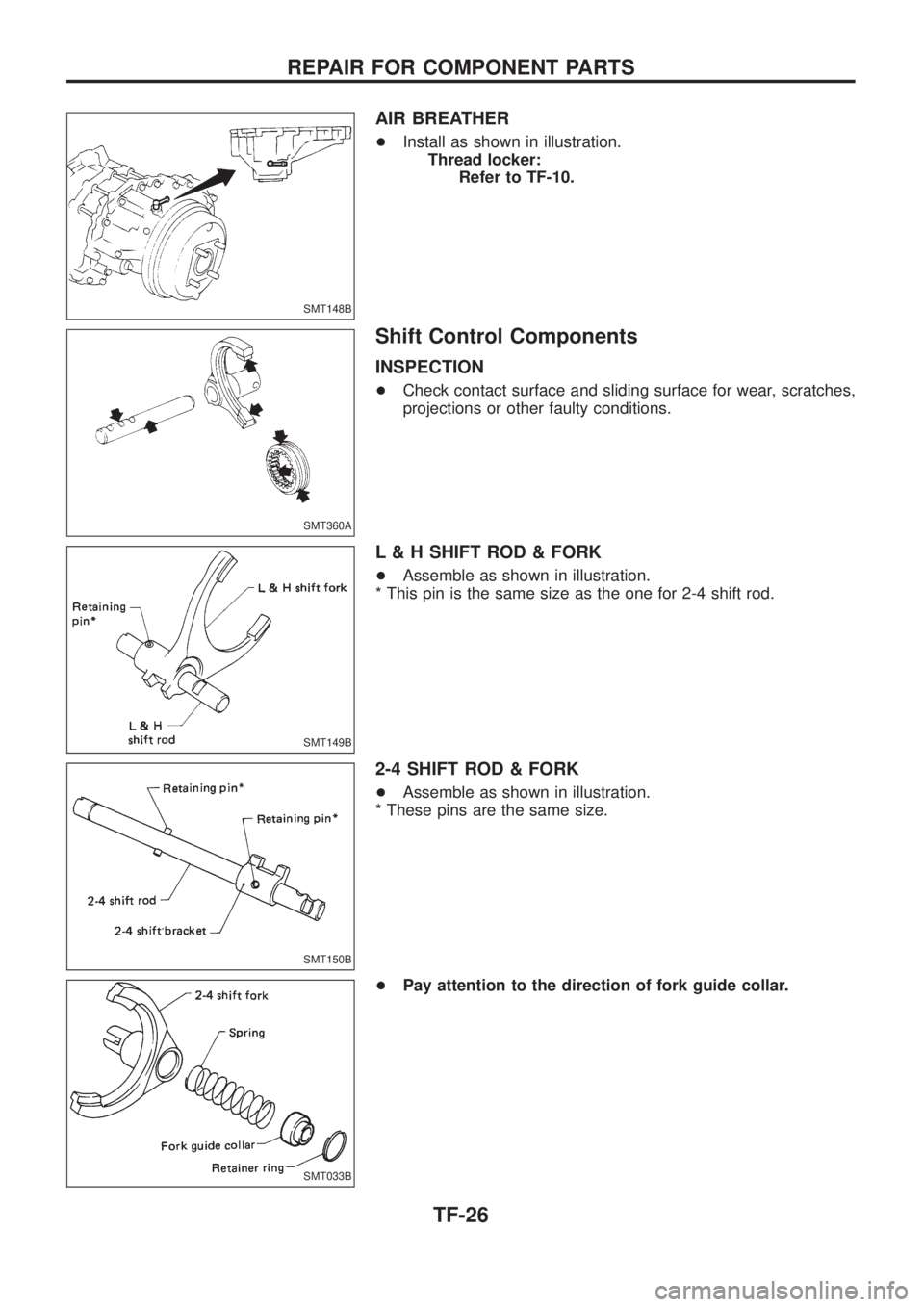

AIR BREATHER

+Install as shown in illustration.

Thread locker:

Refer to TF-10.

Shift Control Components

INSPECTION

+Check contact surface and sliding surface for wear, scratches,

projections or other faulty conditions.

L & H SHIFT ROD & FORK

+Assemble as shown in illustration.

* This pin is the same size as the one for 2-4 shift rod.

2-4 SHIFT ROD & FORK

+Assemble as shown in illustration.

* These pins are the same size.

+Pay attention to the direction of fork guide collar.

SMT148B

SMT360A

SMT149B

SMT150B

SMT033B

REPAIR FOR COMPONENT PARTS

TF-26

Page 1220 of 1226

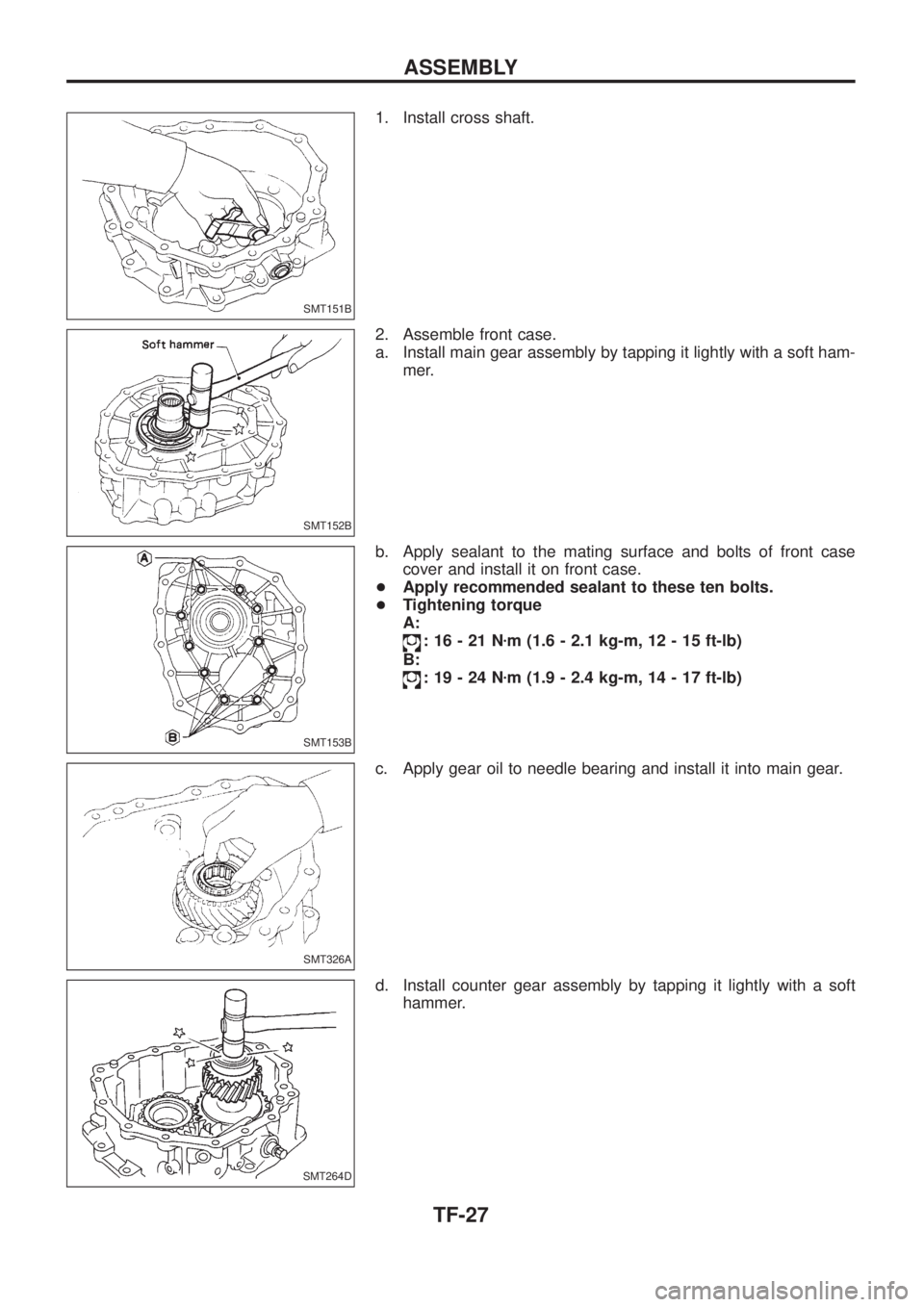

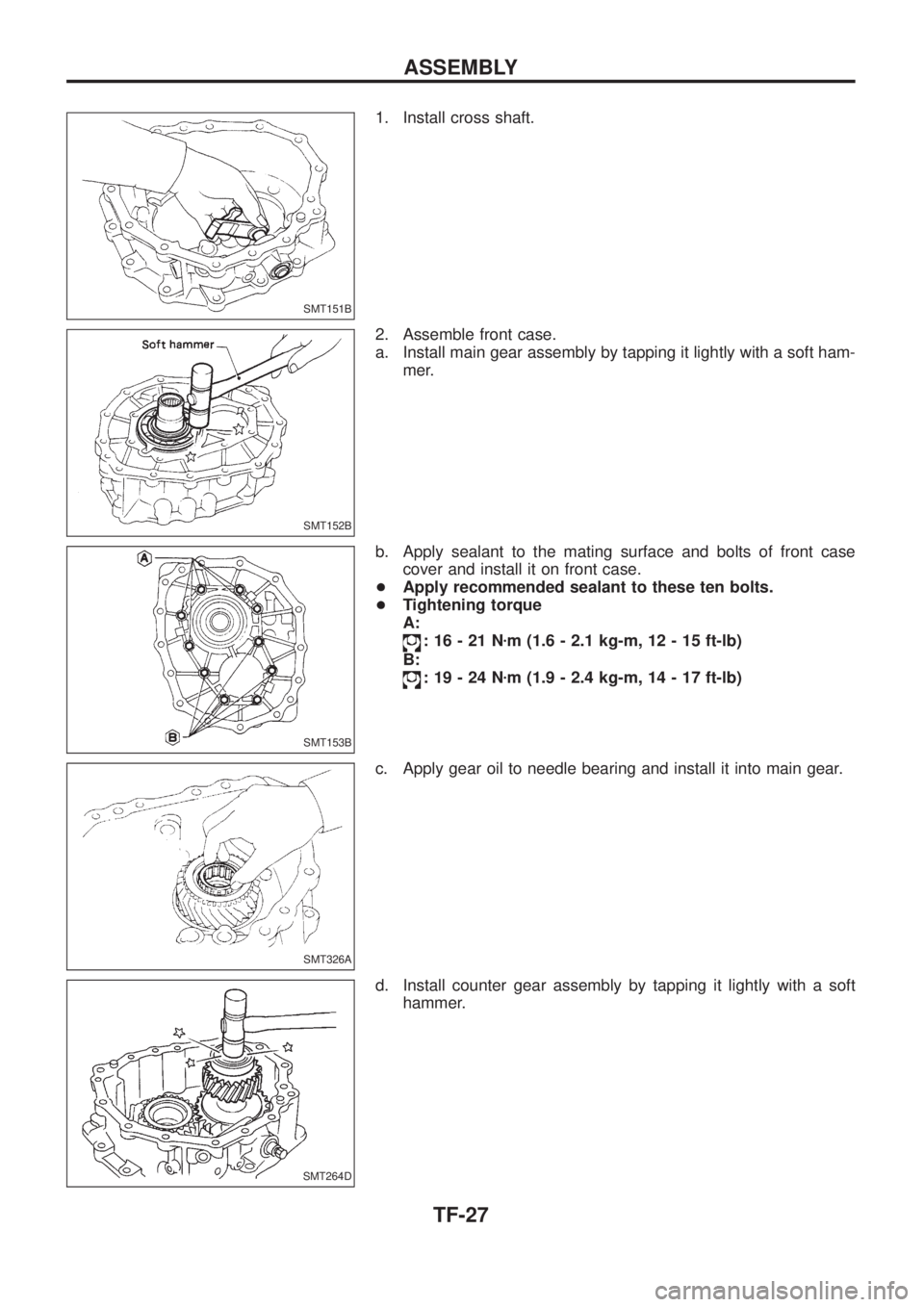

1. Install cross shaft.

2. Assemble front case.

a. Install main gear assembly by tapping it lightly with a soft ham-

mer.

b. Apply sealant to the mating surface and bolts of front case

cover and install it on front case.

+Apply recommended sealant to these ten bolts.

+Tightening torque

A:

:16-21Nzm (1.6 - 2.1 kg-m, 12 - 15 ft-lb)

B:

:19-24Nzm (1.9 - 2.4 kg-m, 14 - 17 ft-lb)

c. Apply gear oil to needle bearing and install it into main gear.

d. Install counter gear assembly by tapping it lightly with a soft

hammer.

SMT151B

SMT152B

SMT153B

SMT326A

SMT264D

ASSEMBLY

TF-27

Trending: airbag off, fuse chart, head, ignition coil, width, limit switch electrical circuit, main