NISSAN PATROL 2006 Service Manual

PATROL 2006

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57368/w960_57368-0.png

NISSAN PATROL 2006 Service Manual

Trending: ignition, jacking, front propeller axle, Break, brake pads, rear bumper, display

Page 691 of 1226

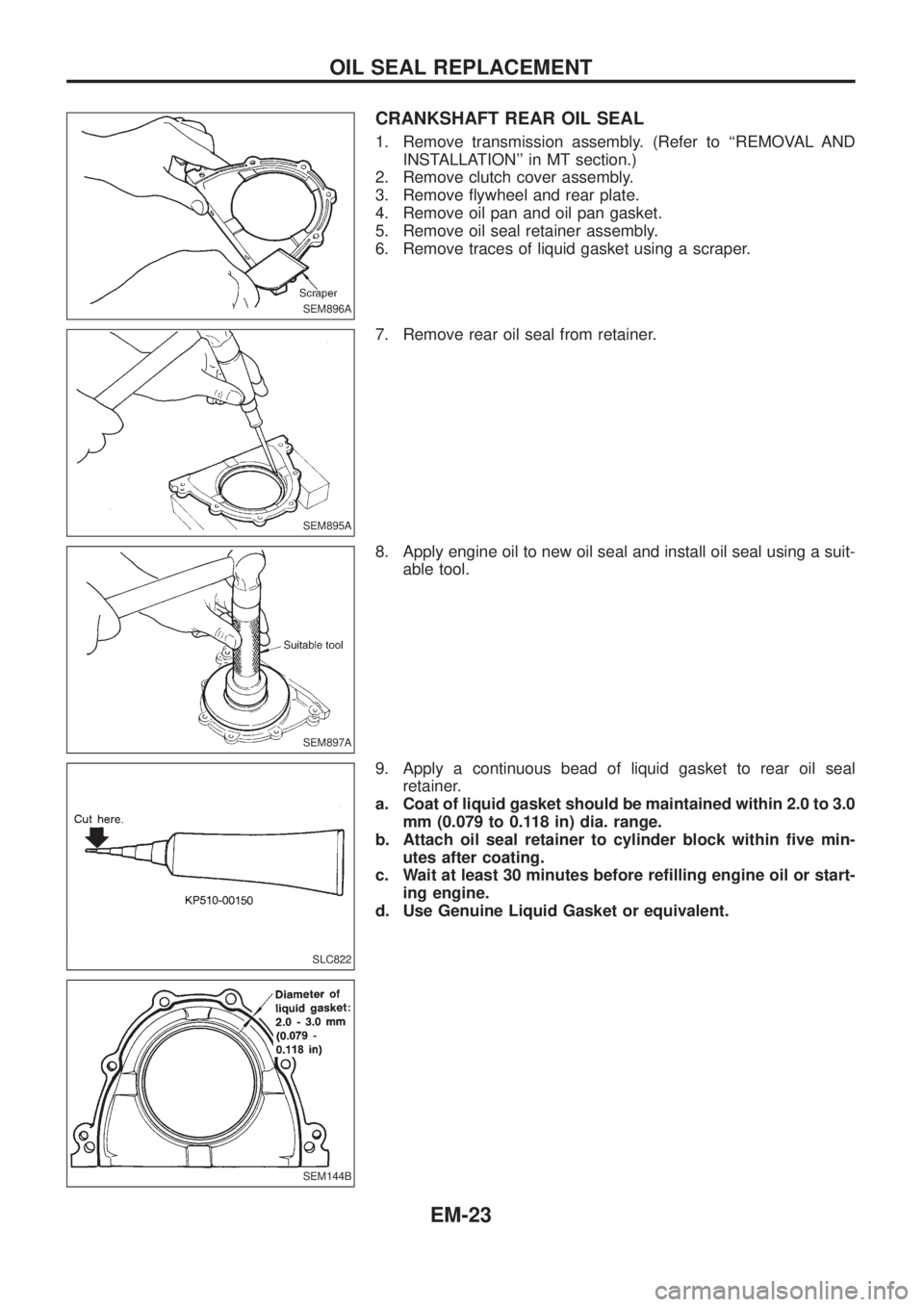

CRANKSHAFT REAR OIL SEAL

1. Remove transmission assembly. (Refer to ``REMOVAL AND

INSTALLATION'' in MT section.)

2. Remove clutch cover assembly.

3. Remove ¯ywheel and rear plate.

4. Remove oil pan and oil pan gasket.

5. Remove oil seal retainer assembly.

6. Remove traces of liquid gasket using a scraper.

7. Remove rear oil seal from retainer.

8. Apply engine oil to new oil seal and install oil seal using a suit-

able tool.

9. Apply a continuous bead of liquid gasket to rear oil seal

retainer.

a. Coat of liquid gasket should be maintained within 2.0 to 3.0

mm (0.079 to 0.118 in) dia. range.

b. Attach oil seal retainer to cylinder block within ®ve min-

utes after coating.

c. Wait at least 30 minutes before re®lling engine oil or start-

ing engine.

d. Use Genuine Liquid Gasket or equivalent.

SEM896A

SEM895A

SEM897A

SLC822

SEM144B

OIL SEAL REPLACEMENT

EM-23

Page 692 of 1226

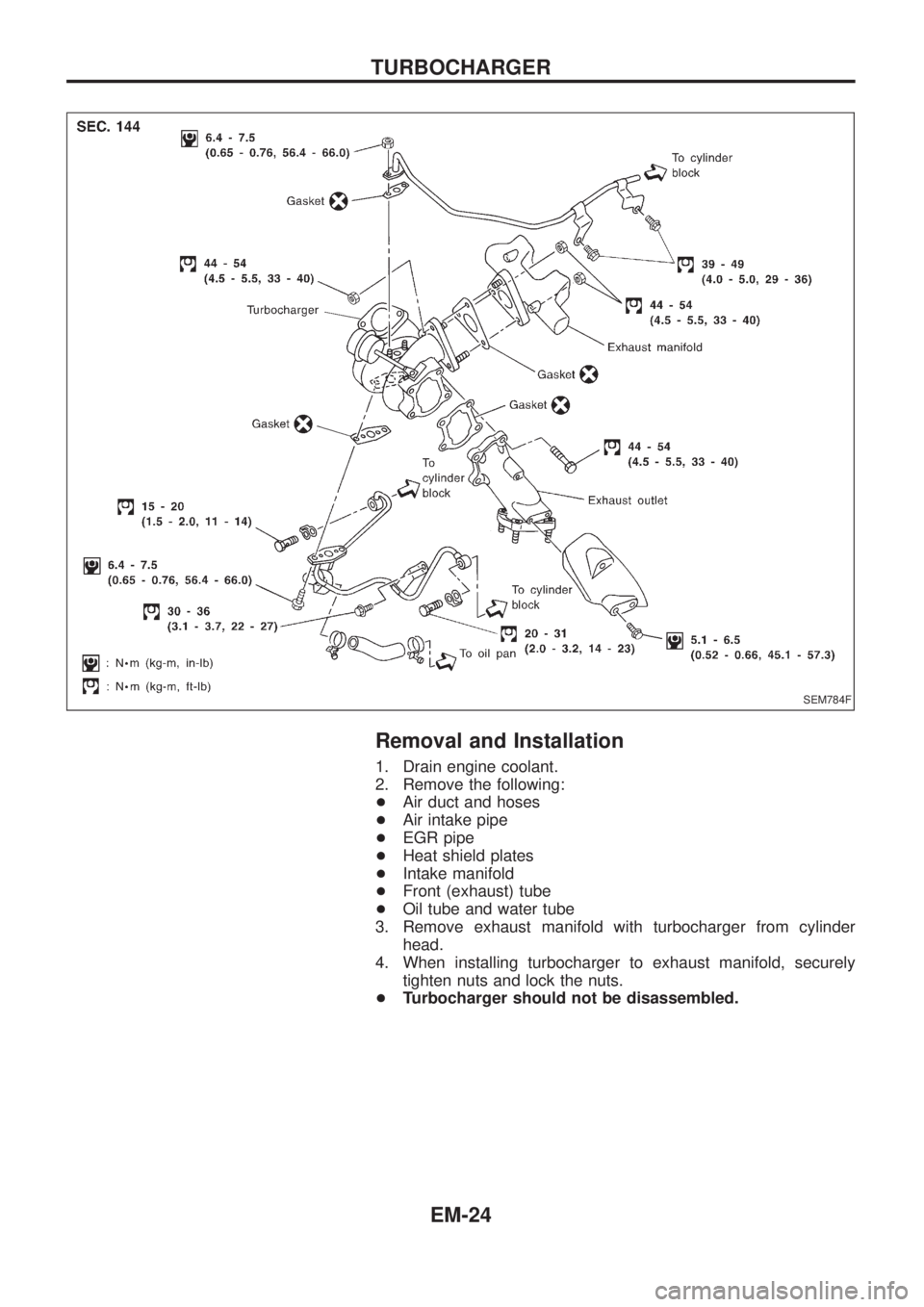

Removal and Installation

1. Drain engine coolant.

2. Remove the following:

+Air duct and hoses

+Air intake pipe

+EGR pipe

+Heat shield plates

+Intake manifold

+Front (exhaust) tube

+Oil tube and water tube

3. Remove exhaust manifold with turbocharger from cylinder

head.

4. When installing turbocharger to exhaust manifold, securely

tighten nuts and lock the nuts.

+Turbocharger should not be disassembled.

SEM784F

TURBOCHARGER

EM-24

Page 693 of 1226

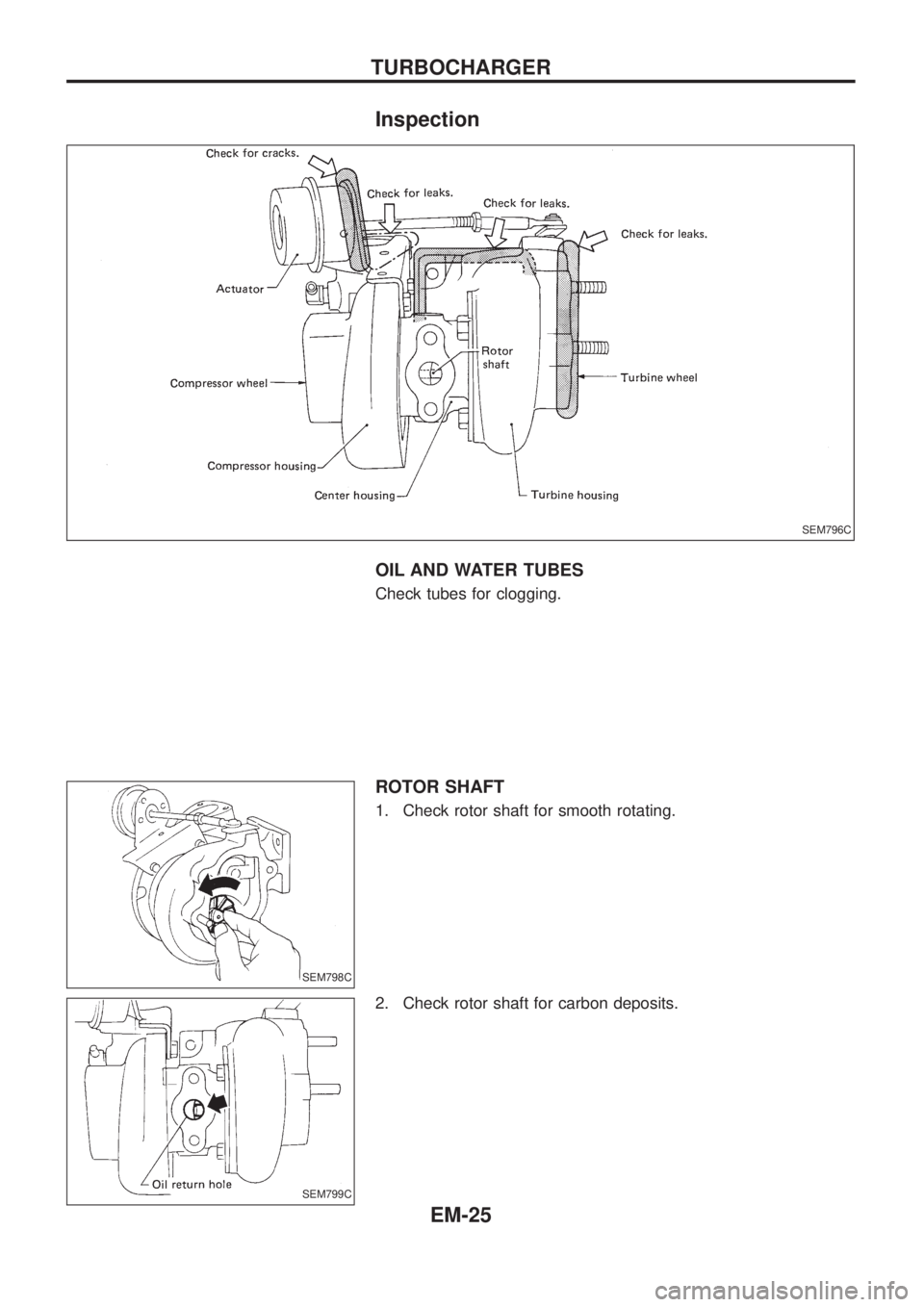

Inspection

OIL AND WATER TUBES

Check tubes for clogging.

ROTOR SHAFT

1. Check rotor shaft for smooth rotating.

2. Check rotor shaft for carbon deposits.

SEM796C

SEM798C

SEM799C

TURBOCHARGER

EM-25

Page 694 of 1226

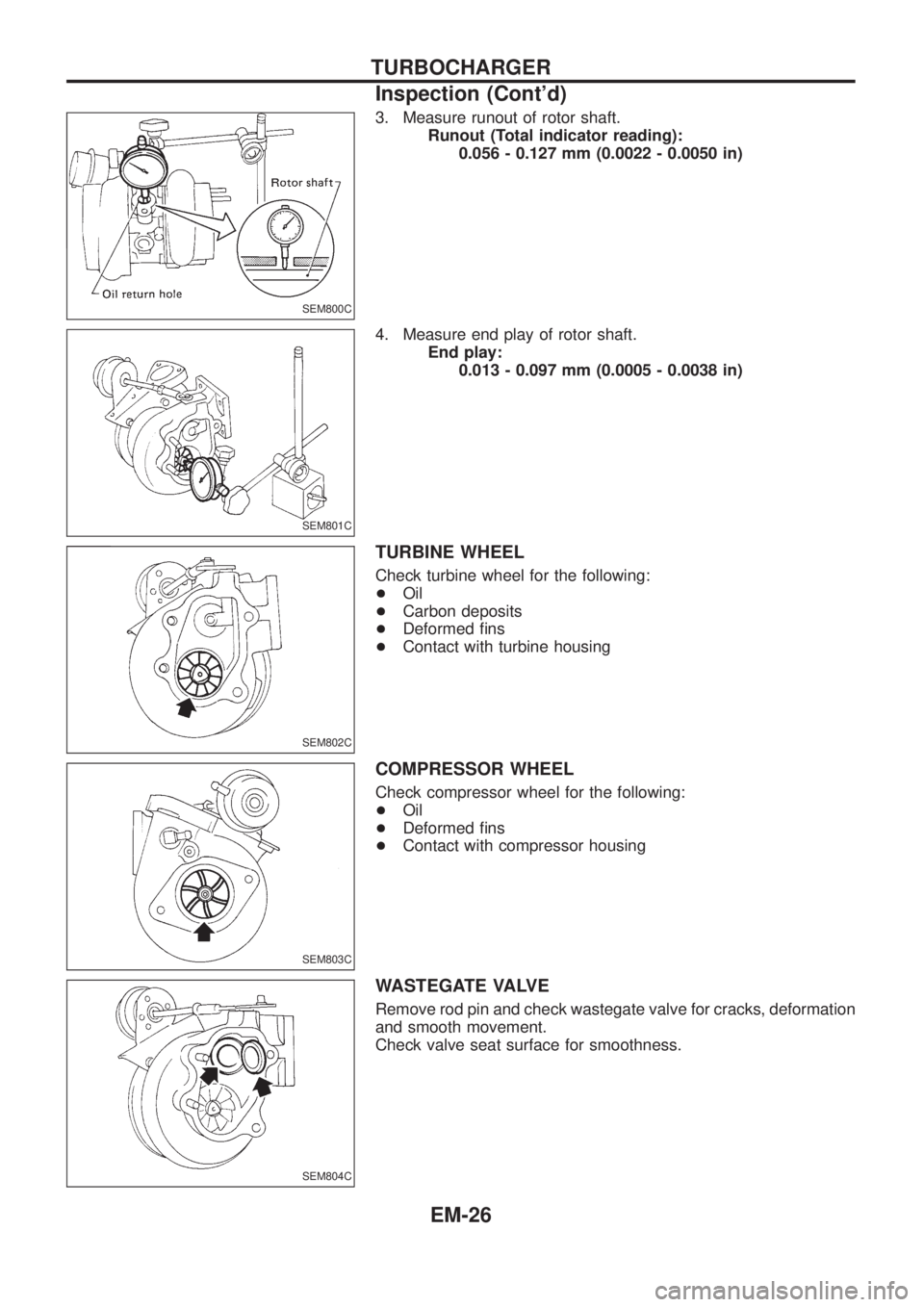

3. Measure runout of rotor shaft.

Runout (Total indicator reading):

0.056 - 0.127 mm (0.0022 - 0.0050 in)

4. Measure end play of rotor shaft.

End play:

0.013 - 0.097 mm (0.0005 - 0.0038 in)

TURBINE WHEEL

Check turbine wheel for the following:

+Oil

+Carbon deposits

+Deformed ®ns

+Contact with turbine housing

COMPRESSOR WHEEL

Check compressor wheel for the following:

+Oil

+Deformed ®ns

+Contact with compressor housing

WASTEGATE VALVE

Remove rod pin and check wastegate valve for cracks, deformation

and smooth movement.

Check valve seat surface for smoothness.

SEM800C

SEM801C

SEM802C

SEM803C

SEM804C

TURBOCHARGER

Inspection (Cont'd)

EM-26

Page 695 of 1226

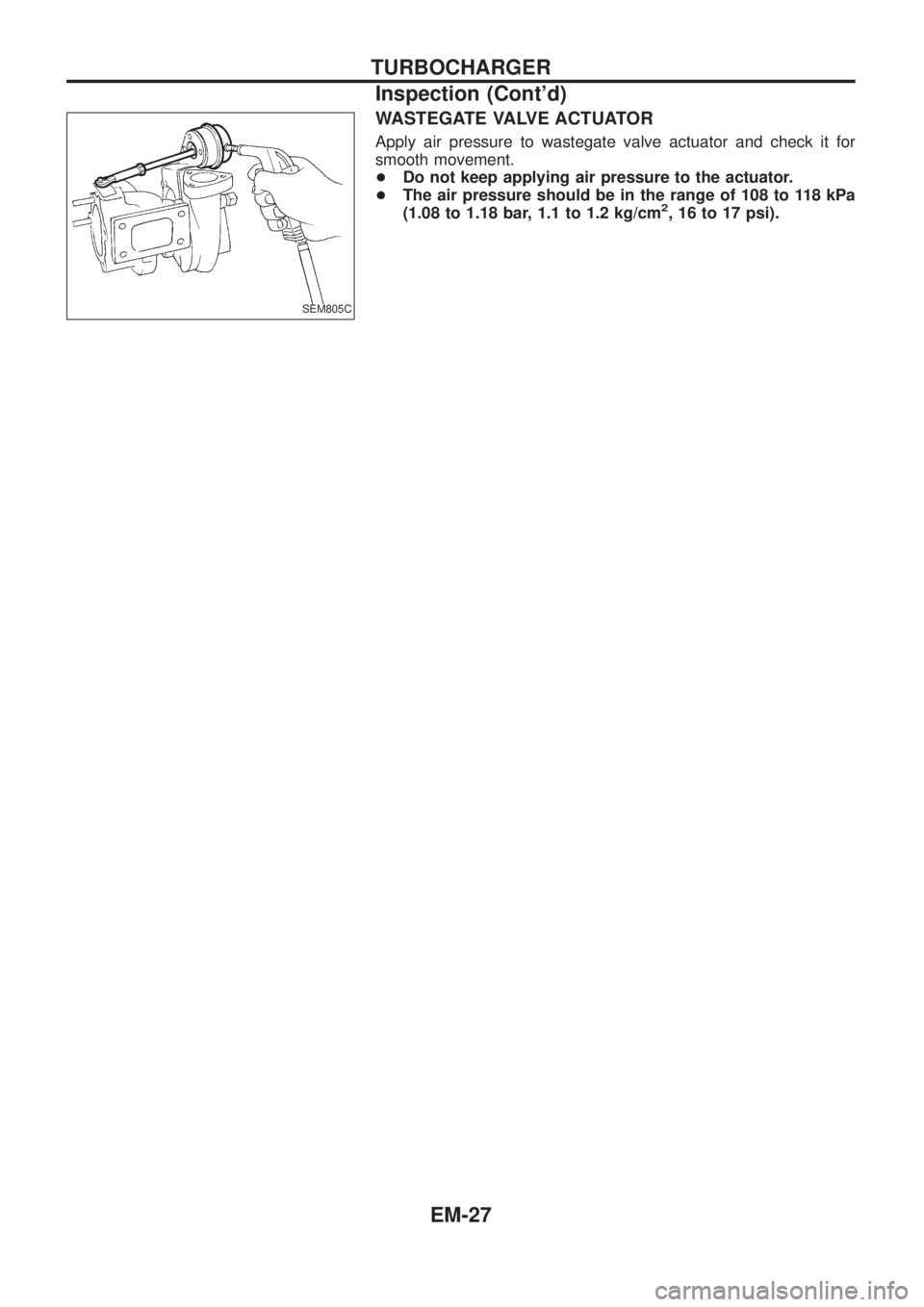

WASTEGATE VALVE ACTUATOR

Apply air pressure to wastegate valve actuator and check it for

smooth movement.

+Do not keep applying air pressure to the actuator.

+The air pressure should be in the range of 108 to 118 kPa

(1.08 to 1.18 bar, 1.1 to 1.2 kg/cm

2, 16 to 17 psi).

SEM805C

TURBOCHARGER

Inspection (Cont'd)

EM-27

Page 696 of 1226

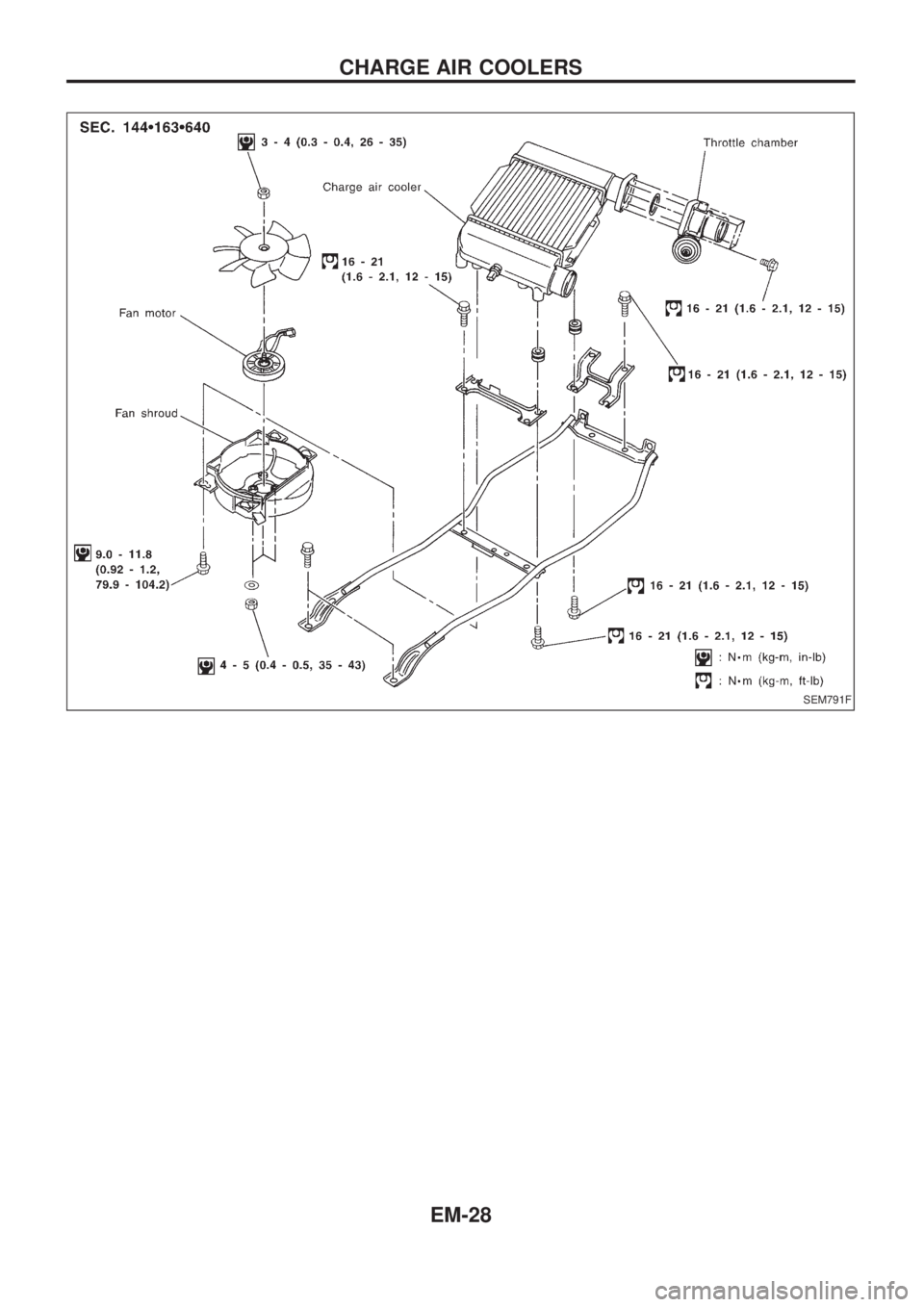

SEM791F

CHARGE AIR COOLERS

EM-28

Page 697 of 1226

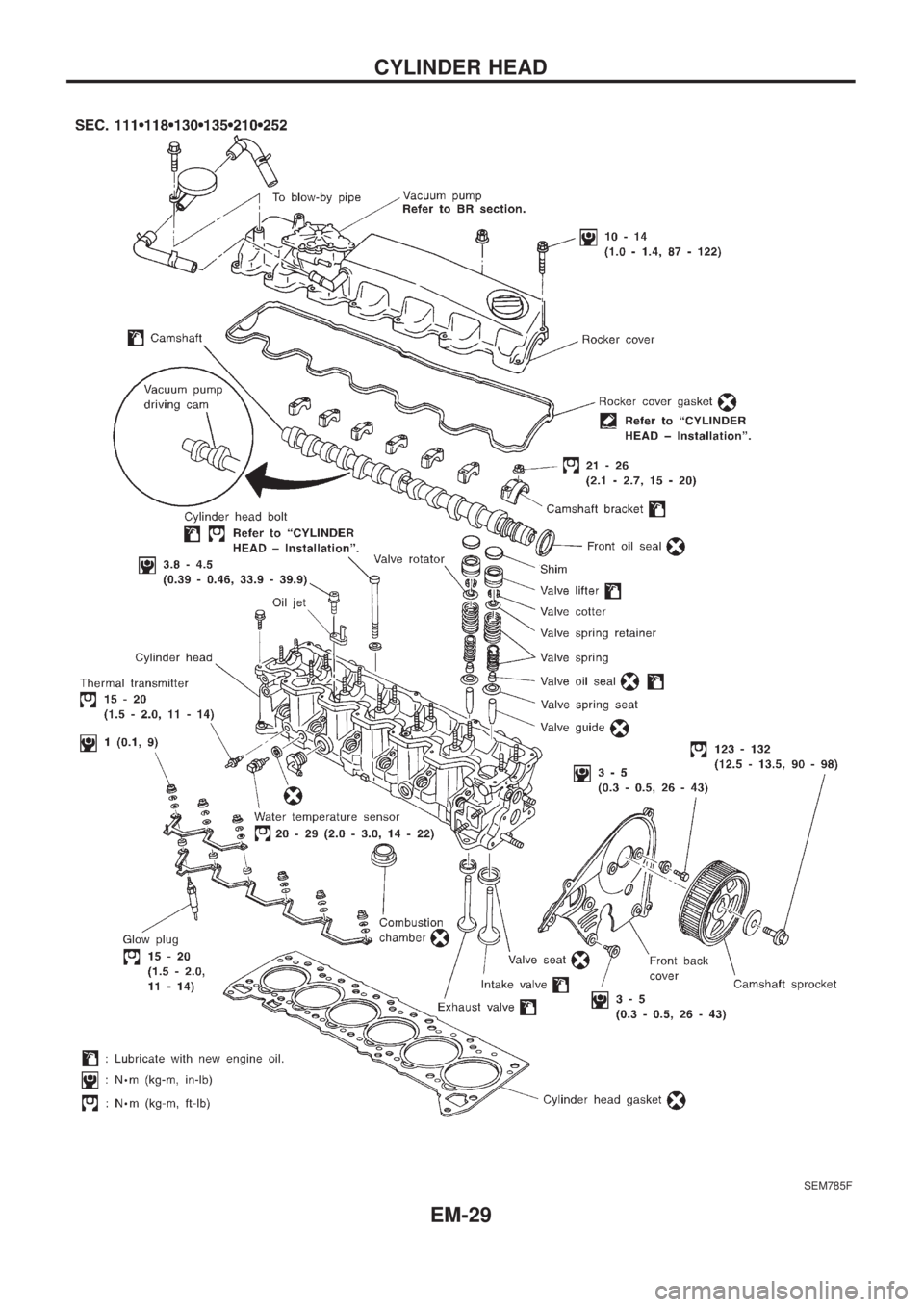

SEM785F

CYLINDER HEAD

EM-29

Page 698 of 1226

CAUTION:

+When installing sliding parts such as camshaft and oil

seal, be sure to apply new engine oil on their sliding sur-

faces.

+When tightening cylinder head bolts, apply new engine oil

to thread portions and seat surfaces of bolts.

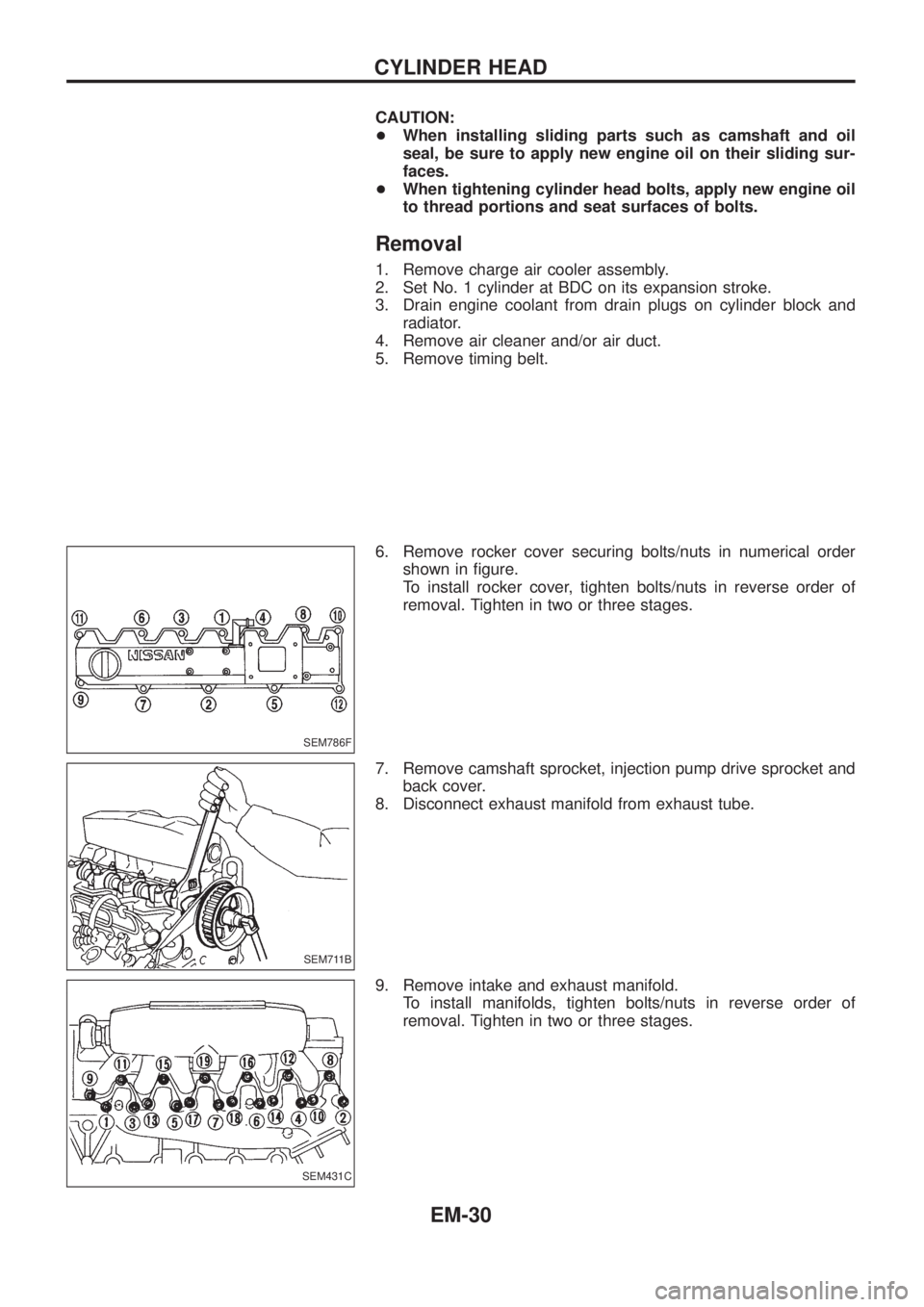

Removal

1. Remove charge air cooler assembly.

2. Set No. 1 cylinder at BDC on its expansion stroke.

3. Drain engine coolant from drain plugs on cylinder block and

radiator.

4. Remove air cleaner and/or air duct.

5. Remove timing belt.

6. Remove rocker cover securing bolts/nuts in numerical order

shown in ®gure.

To install rocker cover, tighten bolts/nuts in reverse order of

removal. Tighten in two or three stages.

7. Remove camshaft sprocket, injection pump drive sprocket and

back cover.

8. Disconnect exhaust manifold from exhaust tube.

9. Remove intake and exhaust manifold.

To install manifolds, tighten bolts/nuts in reverse order of

removal. Tighten in two or three stages.

SEM786F

SEM711B

SEM431C

CYLINDER HEAD

EM-30

Page 699 of 1226

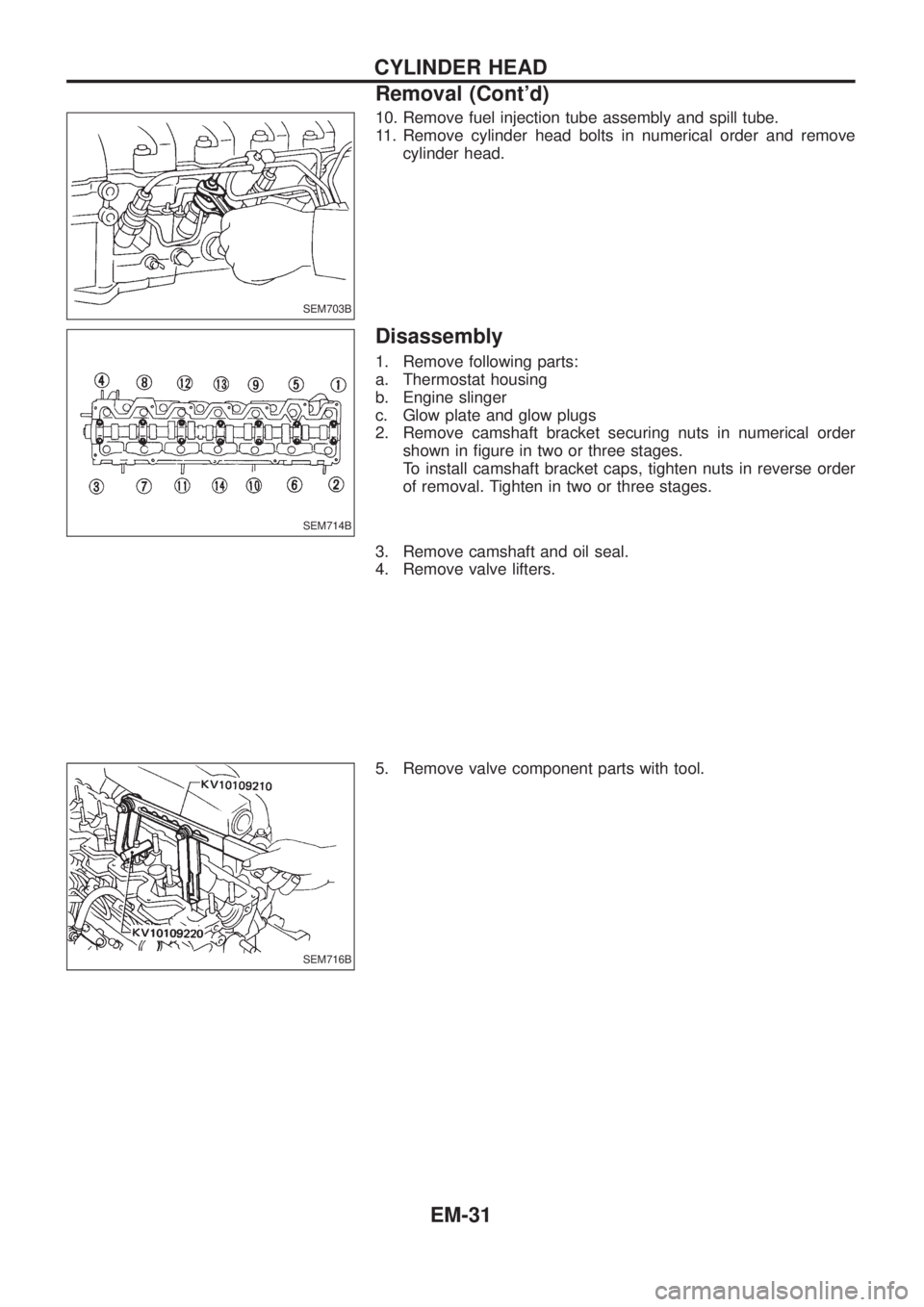

10. Remove fuel injection tube assembly and spill tube.

11. Remove cylinder head bolts in numerical order and remove

cylinder head.

Disassembly

1. Remove following parts:

a. Thermostat housing

b. Engine slinger

c. Glow plate and glow plugs

2. Remove camshaft bracket securing nuts in numerical order

shown in ®gure in two or three stages.

To install camshaft bracket caps, tighten nuts in reverse order

of removal. Tighten in two or three stages.

3. Remove camshaft and oil seal.

4. Remove valve lifters.

5. Remove valve component parts with tool.

SEM703B

SEM714B

SEM716B

CYLINDER HEAD

Removal (Cont'd)

EM-31

Page 700 of 1226

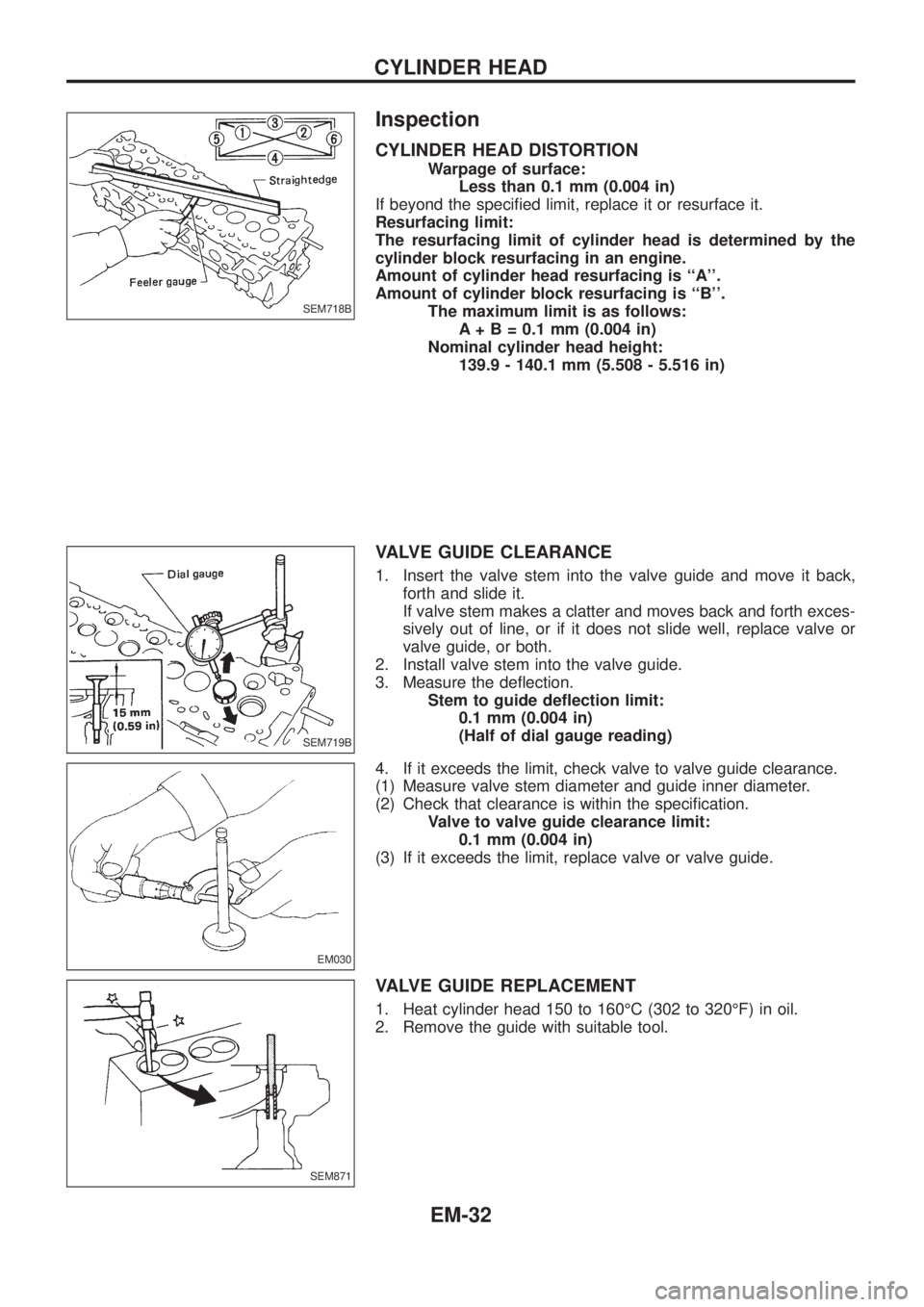

Inspection

CYLINDER HEAD DISTORTION

Warpage of surface:

Less than 0.1 mm (0.004 in)

If beyond the speci®ed limit, replace it or resurface it.

Resurfacing limit:

The resurfacing limit of cylinder head is determined by the

cylinder block resurfacing in an engine.

Amount of cylinder head resurfacing is ``A''.

Amount of cylinder block resurfacing is ``B''.

The maximum limit is as follows:

A + B = 0.1 mm (0.004 in)

Nominal cylinder head height:

139.9 - 140.1 mm (5.508 - 5.516 in)

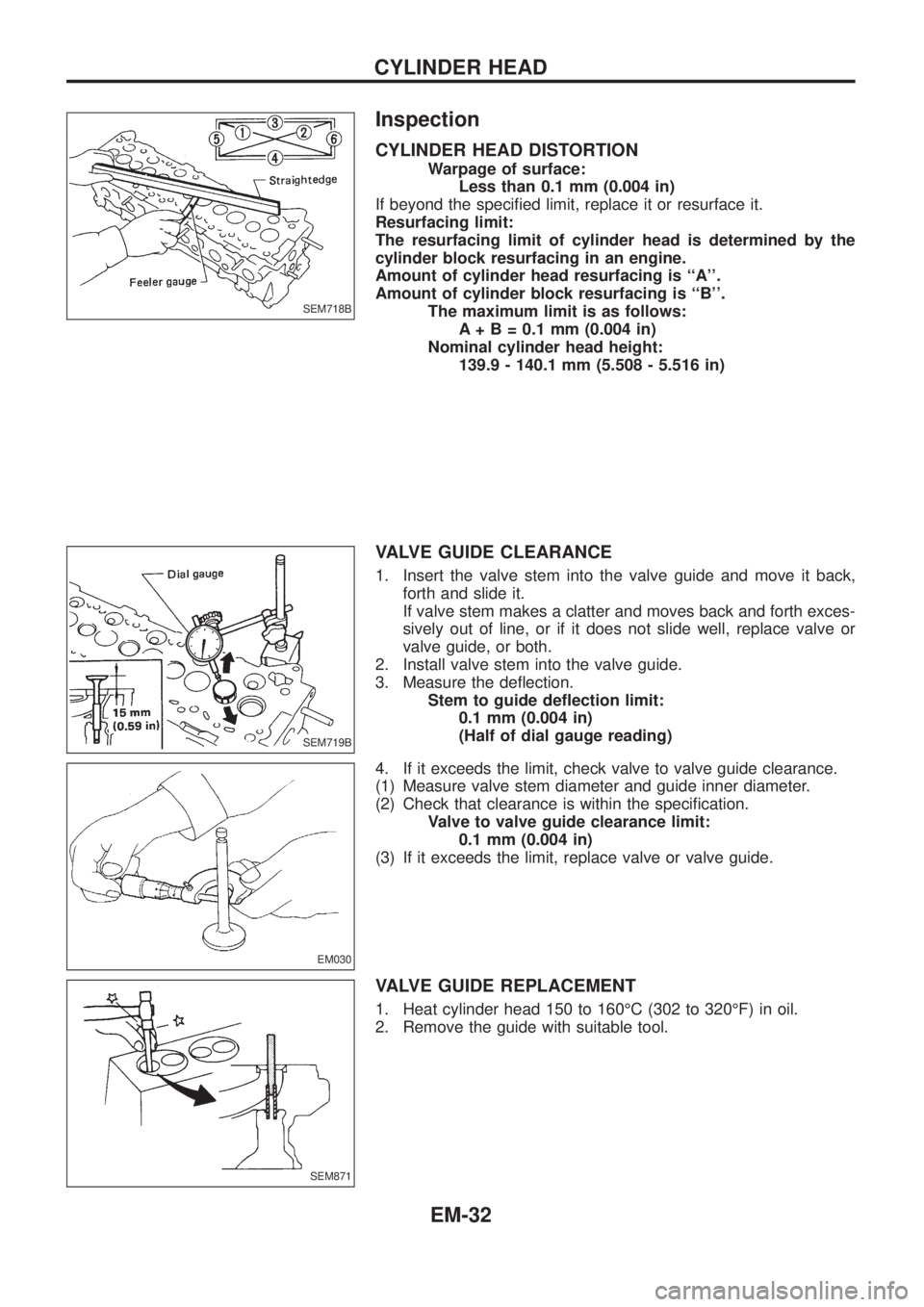

VALVE GUIDE CLEARANCE

1. Insert the valve stem into the valve guide and move it back,

forth and slide it.

If valve stem makes a clatter and moves back and forth exces-

sively out of line, or if it does not slide well, replace valve or

valve guide, or both.

2. Install valve stem into the valve guide.

3. Measure the de¯ection.

Stem to guide de¯ection limit:

0.1 mm (0.004 in)

(Half of dial gauge reading)

4. If it exceeds the limit, check valve to valve guide clearance.

(1) Measure valve stem diameter and guide inner diameter.

(2) Check that clearance is within the speci®cation.

Valve to valve guide clearance limit:

0.1 mm (0.004 in)

(3) If it exceeds the limit, replace valve or valve guide.

VALVE GUIDE REPLACEMENT

1. Heat cylinder head 150 to 160ÉC (302 to 320ÉF) in oil.

2. Remove the guide with suitable tool.

SEM718B

SEM719B

EM030

SEM871

CYLINDER HEAD

EM-32

Trending: radiator, airbag, adding oil, sunroof, trailer, hazard indicators, sensor