NISSAN PATROL 2006 Service Manual

Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 861 of 1226

CONTROL LINKAGE ADJUSTMENT

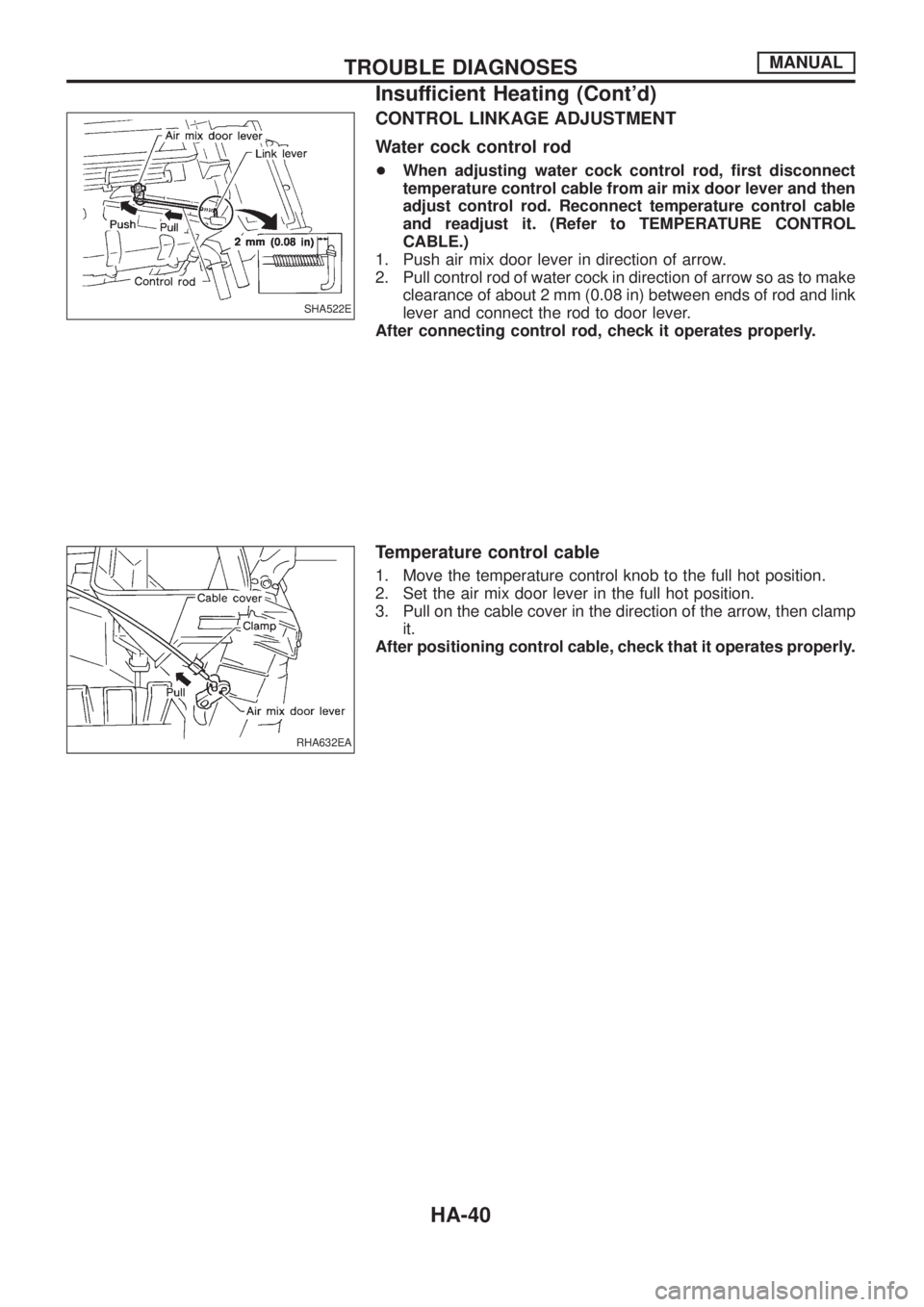

Water cock control rod

+When adjusting water cock control rod, ®rst disconnect

temperature control cable from air mix door lever and then

adjust control rod. Reconnect temperature control cable

and readjust it. (Refer to TEMPERATURE CONTROL

CABLE.)

1. Push air mix door lever in direction of arrow.

2. Pull control rod of water cock in direction of arrow so as to make

clearance of about 2 mm (0.08 in) between ends of rod and link

lever and connect the rod to door lever.

After connecting control rod, check it operates properly.

Temperature control cable

1. Move the temperature control knob to the full hot position.

2. Set the air mix door lever in the full hot position.

3. Pull on the cable cover in the direction of the arrow, then clamp

it.

After positioning control cable, check that it operates properly.

SHA522E

RHA632EA

TROUBLE DIAGNOSESMANUAL

Insufficient Heating (Cont'd)

HA-40

Page 862 of 1226

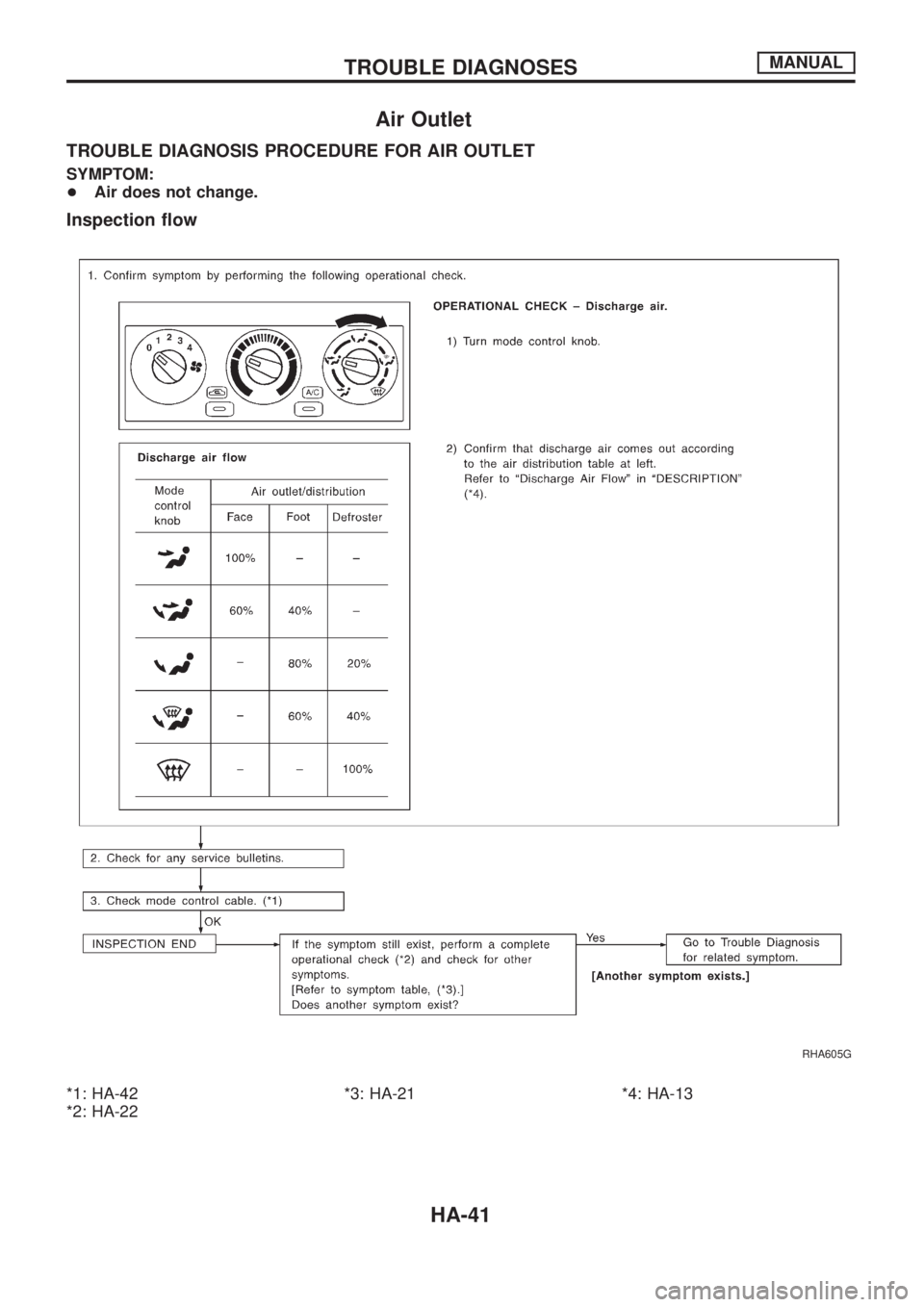

Air Outlet

TROUBLE DIAGNOSIS PROCEDURE FOR AIR OUTLET

SYMPTOM:

+Air does not change.

Inspection ¯ow

*1: HA-42

*2: HA-22*3: HA-21 *4: HA-13

RHA605G

TROUBLE DIAGNOSESMANUAL

HA-41

Page 863 of 1226

CONTROL LINKAGE ADJUSTMENT

Mode control cable

1. Turn the mode control knob to the DEF position.

2. Set the side link in the DEF position by hand.

3. Pull on the cable cover in the direction of the arrow, then clamp

it.

After positioning control cable, check that it operates properly.

RHA630EA

TROUBLE DIAGNOSESMANUAL

Air Outlet (Cont'd)

HA-42

Page 864 of 1226

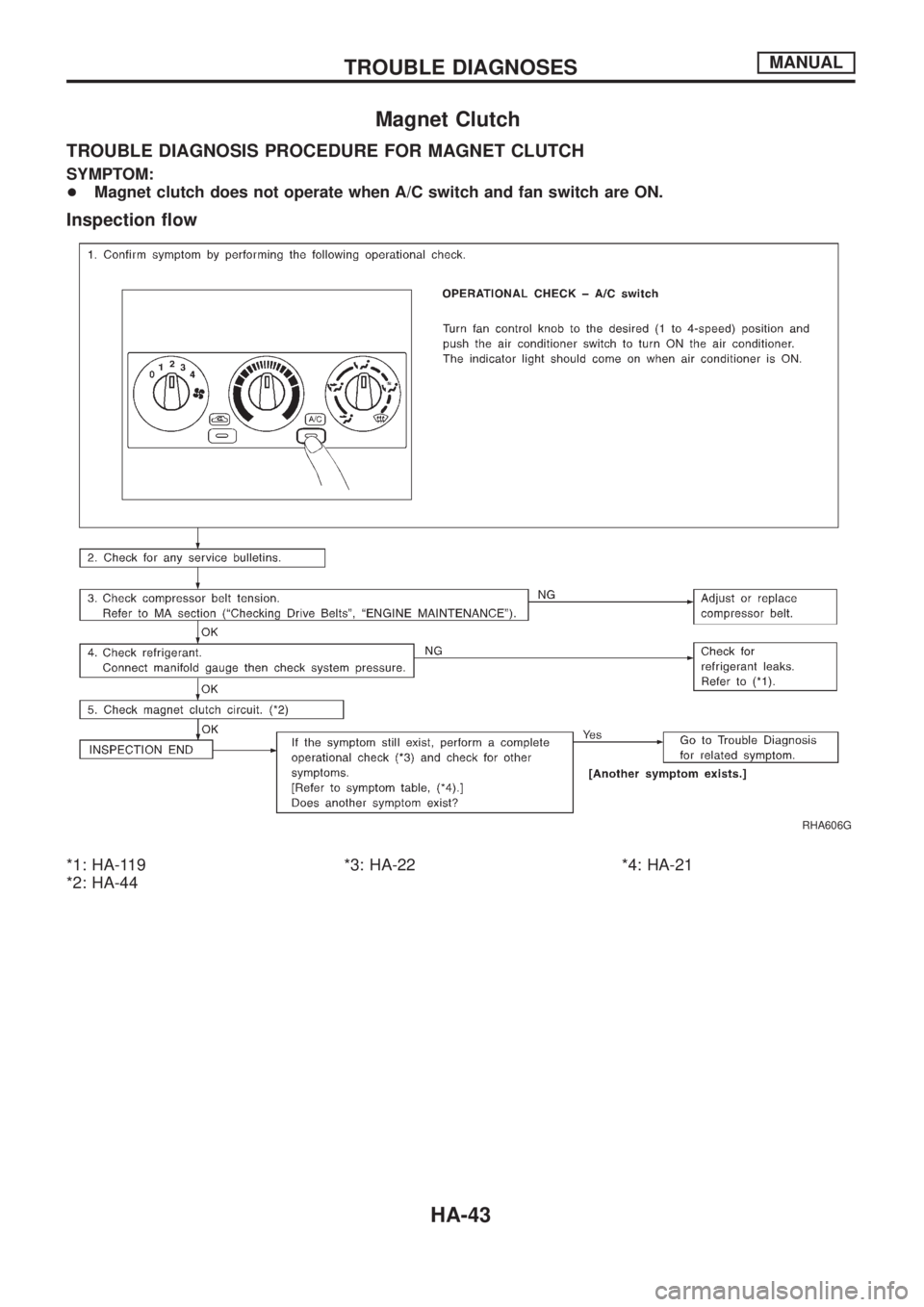

Magnet Clutch

TROUBLE DIAGNOSIS PROCEDURE FOR MAGNET CLUTCH

SYMPTOM:

+Magnet clutch does not operate when A/C switch and fan switch are ON.

Inspection ¯ow

*1: HA-119

*2: HA-44*3: HA-22 *4: HA-21

RHA606G

TROUBLE DIAGNOSESMANUAL

HA-43

Page 865 of 1226

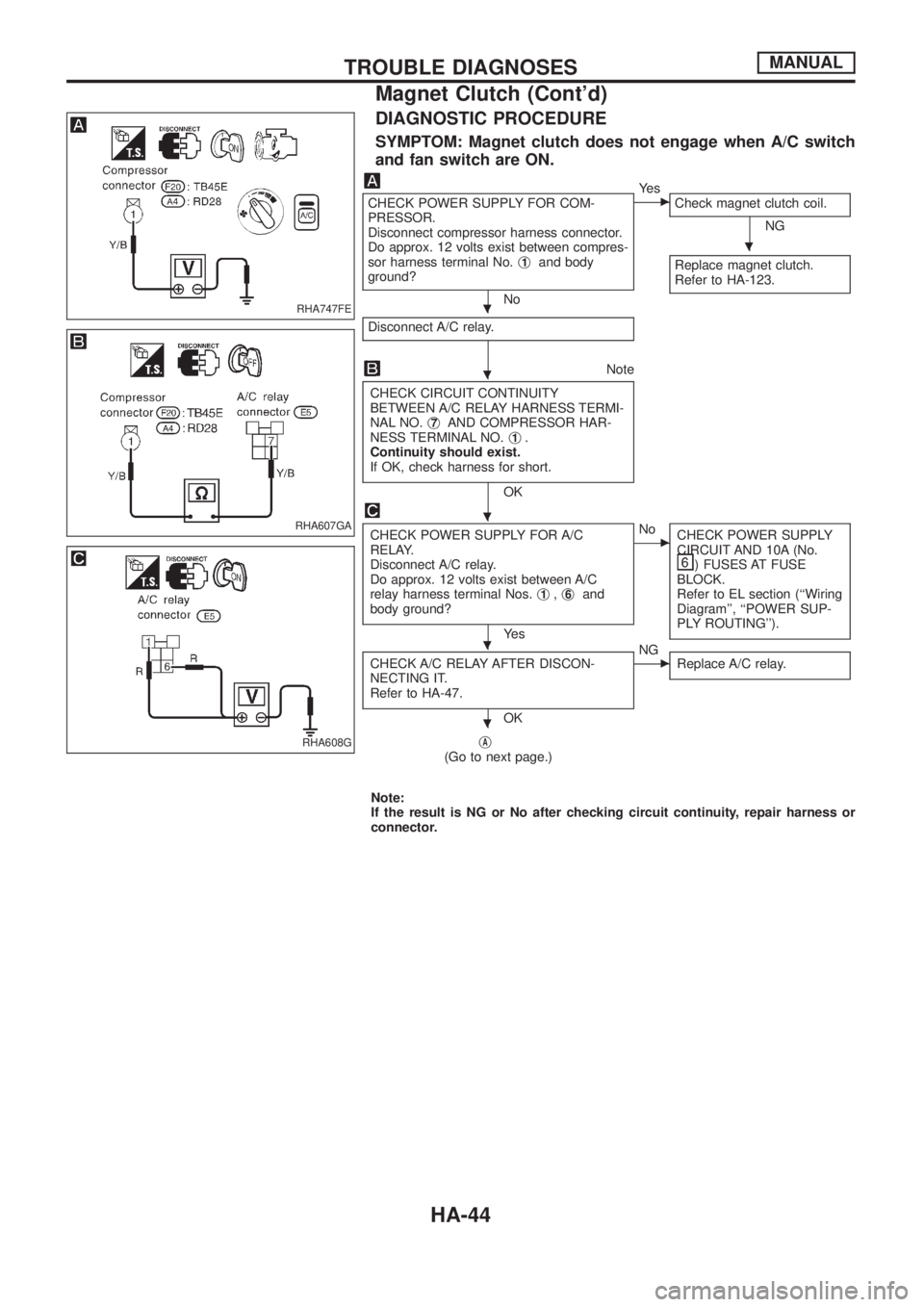

DIAGNOSTIC PROCEDURE

SYMPTOM: Magnet clutch does not engage when A/C switch

and fan switch are ON.

CHECK POWER SUPPLY FOR COM-

PRESSOR.

Disconnect compressor harness connector.

Do approx. 12 volts exist between compres-

sor harness terminal No.j

1and body

ground?

No

cYe s

Check magnet clutch coil.

NG

Replace magnet clutch.

Refer to HA-123.

Disconnect A/C relay.

Note

CHECK CIRCUIT CONTINUITY

BETWEEN A/C RELAY HARNESS TERMI-

NAL NO.j

7AND COMPRESSOR HAR-

NESS TERMINAL NO.j1.

Continuity should exist.

If OK, check harness for short.

OK

CHECK POWER SUPPLY FOR A/C

RELAY.

Disconnect A/C relay.

Do approx. 12 volts exist between A/C

relay harness terminal Nos.j

1,j6and

body ground?

Ye s

cNo

CHECK POWER SUPPLY

CIRCUIT AND 10A (No.

) FUSES AT FUSE

BLOCK.

Refer to EL section (``Wiring

Diagram'', ``POWER SUP-

PLY ROUTING'').

CHECK A/C RELAY AFTER DISCON-

NECTING IT.

Refer to HA-47.

OK

cNG

Replace A/C relay.

jA(Go to next page.)

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

RHA747FE

RHA607GA

RHA608G

.

.

.

.

.

.

TROUBLE DIAGNOSESMANUAL

Magnet Clutch (Cont'd)

HA-44

Page 866 of 1226

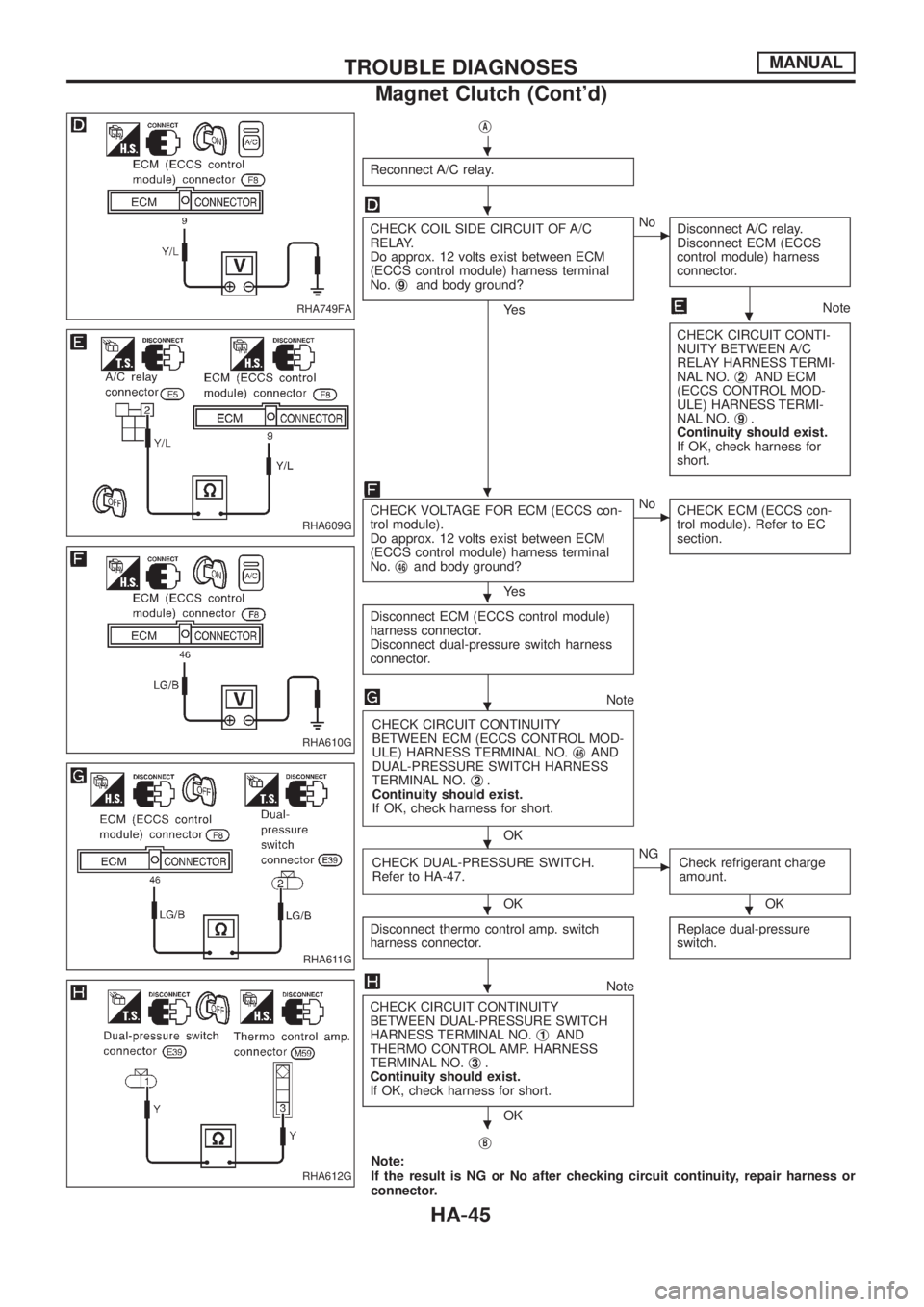

jA

Reconnect A/C relay.

CHECK COIL SIDE CIRCUIT OF A/C

RELAY.

Do approx. 12 volts exist between ECM

(ECCS control module) harness terminal

No.j

9and body ground?

Ye s

cNo

Disconnect A/C relay.

Disconnect ECM (ECCS

control module) harness

connector.

Note

CHECK CIRCUIT CONTI-

NUITY BETWEEN A/C

RELAY HARNESS TERMI-

NAL NO.j

2AND ECM

(ECCS CONTROL MOD-

ULE) HARNESS TERMI-

NAL NO.j

9.

Continuity should exist.

If OK, check harness for

short.

CHECK VOLTAGE FOR ECM (ECCS con-

trol module).

Do approx. 12 volts exist between ECM

(ECCS control module) harness terminal

No.j

46and body ground?

Ye s

cNo

CHECK ECM (ECCS con-

trol module). Refer to EC

section.

Disconnect ECM (ECCS control module)

harness connector.

Disconnect dual-pressure switch harness

connector.

Note

CHECK CIRCUIT CONTINUITY

BETWEEN ECM (ECCS CONTROL MOD-

ULE) HARNESS TERMINAL NO.j

46AND

DUAL-PRESSURE SWITCH HARNESS

TERMINAL NO.j

2.

Continuity should exist.

If OK, check harness for short.

OK

CHECK DUAL-PRESSURE SWITCH.

Refer to HA-47.

OK

cNG

Check refrigerant charge

amount.

OK

Disconnect thermo control amp. switch

harness connector.

Replace dual-pressure

switch.

Note

CHECK CIRCUIT CONTINUITY

BETWEEN DUAL-PRESSURE SWITCH

HARNESS TERMINAL NO.j

1AND

THERMO CONTROL AMP. HARNESS

TERMINAL NO.j

3.

Continuity should exist.

If OK, check harness for short.

OK

j

B

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

RHA749FA

RHA609G

RHA610G

RHA611G

RHA612G

.

.

.

.

.

.

.

..

.

.

TROUBLE DIAGNOSESMANUAL

Magnet Clutch (Cont'd)

HA-45

Page 867 of 1226

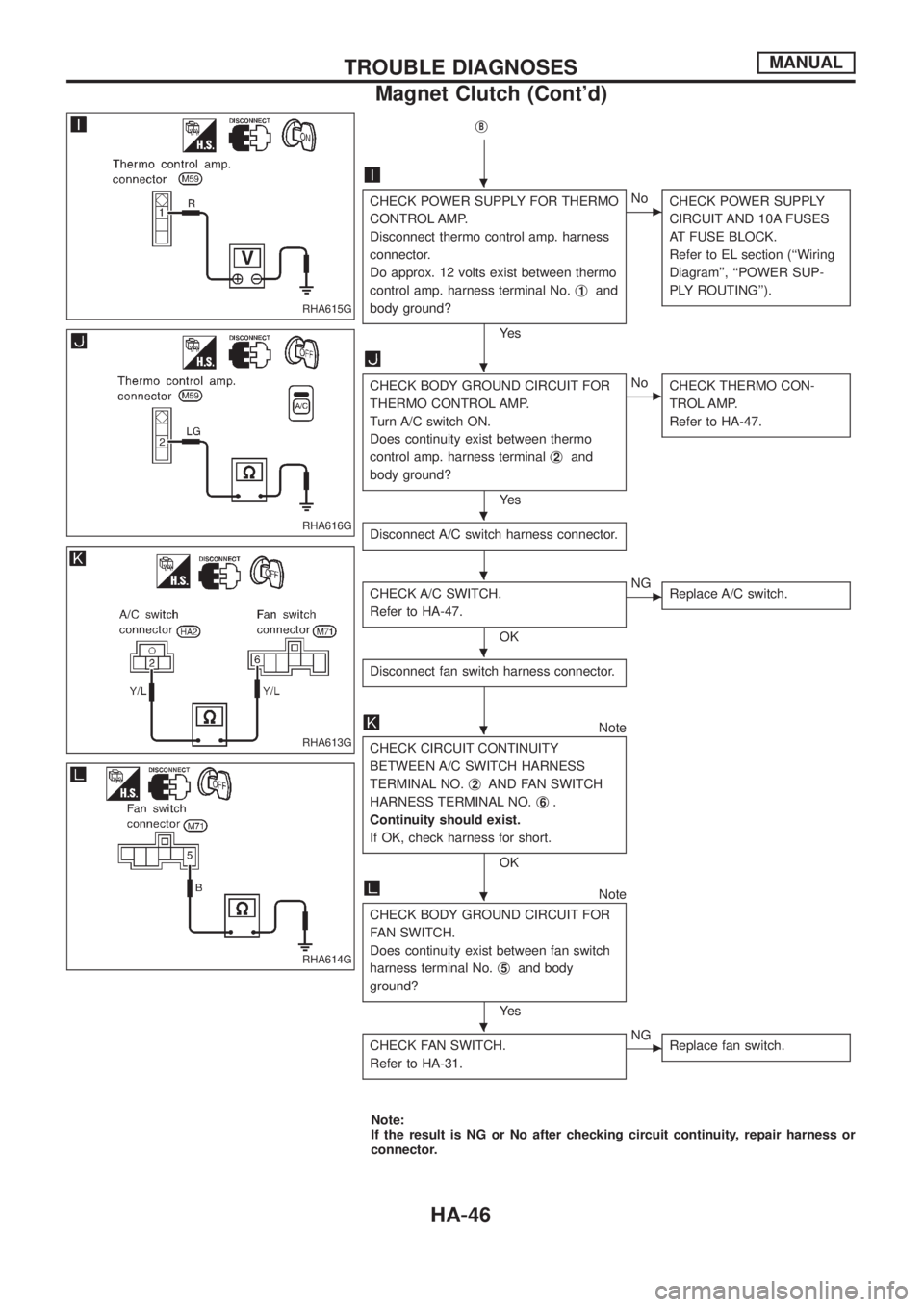

jB

CHECK POWER SUPPLY FOR THERMO

CONTROL AMP.

Disconnect thermo control amp. harness

connector.

Do approx. 12 volts exist between thermo

control amp. harness terminal No.j

1and

body ground?

Ye s

cNo

CHECK POWER SUPPLY

CIRCUIT AND 10A FUSES

AT FUSE BLOCK.

Refer to EL section (``Wiring

Diagram'', ``POWER SUP-

PLY ROUTING'').

CHECK BODY GROUND CIRCUIT FOR

THERMO CONTROL AMP.

Turn A/C switch ON.

Does continuity exist between thermo

control amp. harness terminalj

2and

body ground?

Ye s

cNo

CHECK THERMO CON-

TROL AMP.

Refer to HA-47.

Disconnect A/C switch harness connector.

CHECK A/C SWITCH.

Refer to HA-47.

OK

cNG

Replace A/C switch.

Disconnect fan switch harness connector.

Note

CHECK CIRCUIT CONTINUITY

BETWEEN A/C SWITCH HARNESS

TERMINAL NO.j

2AND FAN SWITCH

HARNESS TERMINAL NO.j

6.

Continuity should exist.

If OK, check harness for short.

OK

Note

CHECK BODY GROUND CIRCUIT FOR

FAN SWITCH.

Does continuity exist between fan switch

harness terminal No.j

5and body

ground?

Ye s

CHECK FAN SWITCH.

Refer to HA-31.

cNG

Replace fan switch.

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

RHA615G

RHA616G

RHA613G

RHA614G

.

.

.

.

.

.

.

.

TROUBLE DIAGNOSESMANUAL

Magnet Clutch (Cont'd)

HA-46

Page 868 of 1226

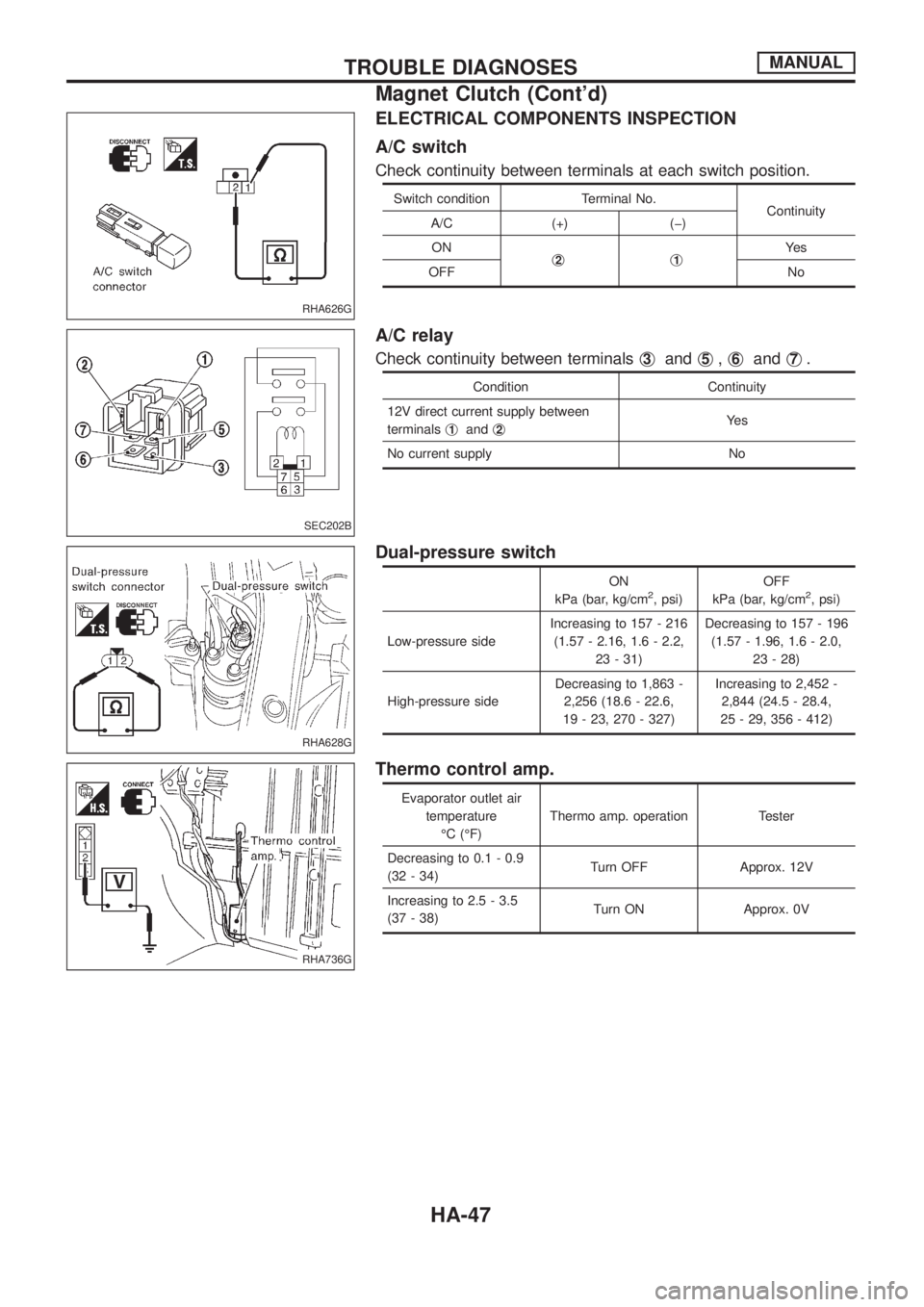

ELECTRICAL COMPONENTS INSPECTION

A/C switch

Check continuity between terminals at each switch position.

Switch condition Terminal No.

Continuity

A/C (+) (þ)

ON

j

2j1Ye s

OFF No

A/C relay

Check continuity between terminalsj3andj5,j6andj7.

Condition Continuity

12V direct current supply between

terminalsj

1andj2Ye s

No current supply No

Dual-pressure switch

ON

kPa (bar, kg/cm2, psi)OFF

kPa (bar, kg/cm2, psi)

Low-pressure sideIncreasing to 157 - 216

(1.57 - 2.16, 1.6 - 2.2,

23 - 31)Decreasing to 157 - 196

(1.57 - 1.96, 1.6 - 2.0,

23 - 28)

High-pressure sideDecreasing to 1,863 -

2,256 (18.6 - 22.6,

19 - 23, 270 - 327)Increasing to 2,452 -

2,844 (24.5 - 28.4,

25 - 29, 356 - 412)

Thermo control amp.

Evaporator outlet air

temperature

ÉC (ÉF)Thermo amp. operation Tester

Decreasing to 0.1 - 0.9

(32 - 34)Turn OFF Approx. 12V

Increasing to 2.5 - 3.5

(37 - 38)Turn ON Approx. 0V

RHA626G

SEC202B

RHA628G

RHA736G

TROUBLE DIAGNOSESMANUAL

Magnet Clutch (Cont'd)

HA-47

Page 869 of 1226

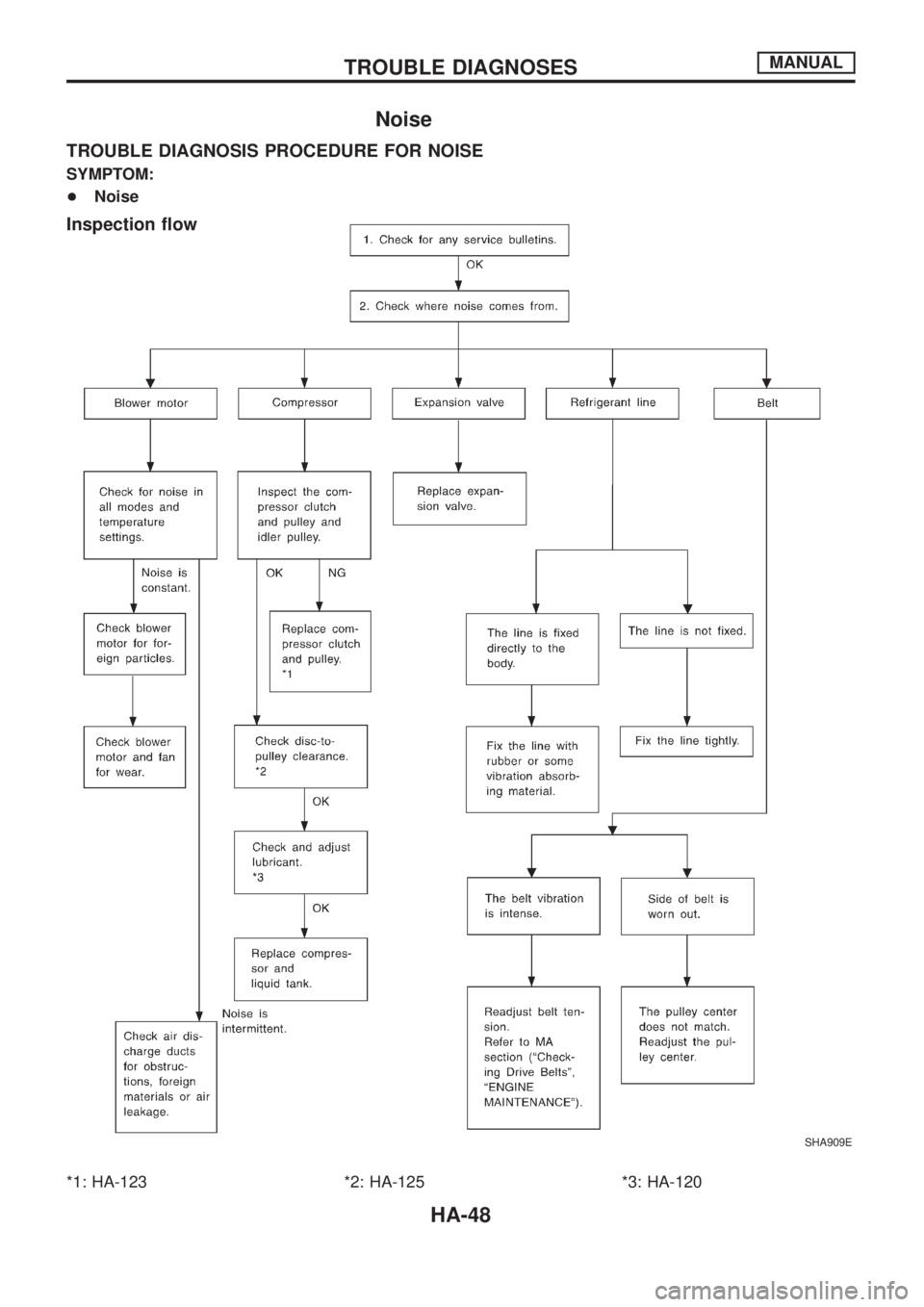

Noise

TROUBLE DIAGNOSIS PROCEDURE FOR NOISE

SYMPTOM:

+Noise

Inspection ¯ow

*1: HA-123 *2: HA-125 *3: HA-120

SHA909E

TROUBLE DIAGNOSESMANUAL

HA-48

Page 870 of 1226

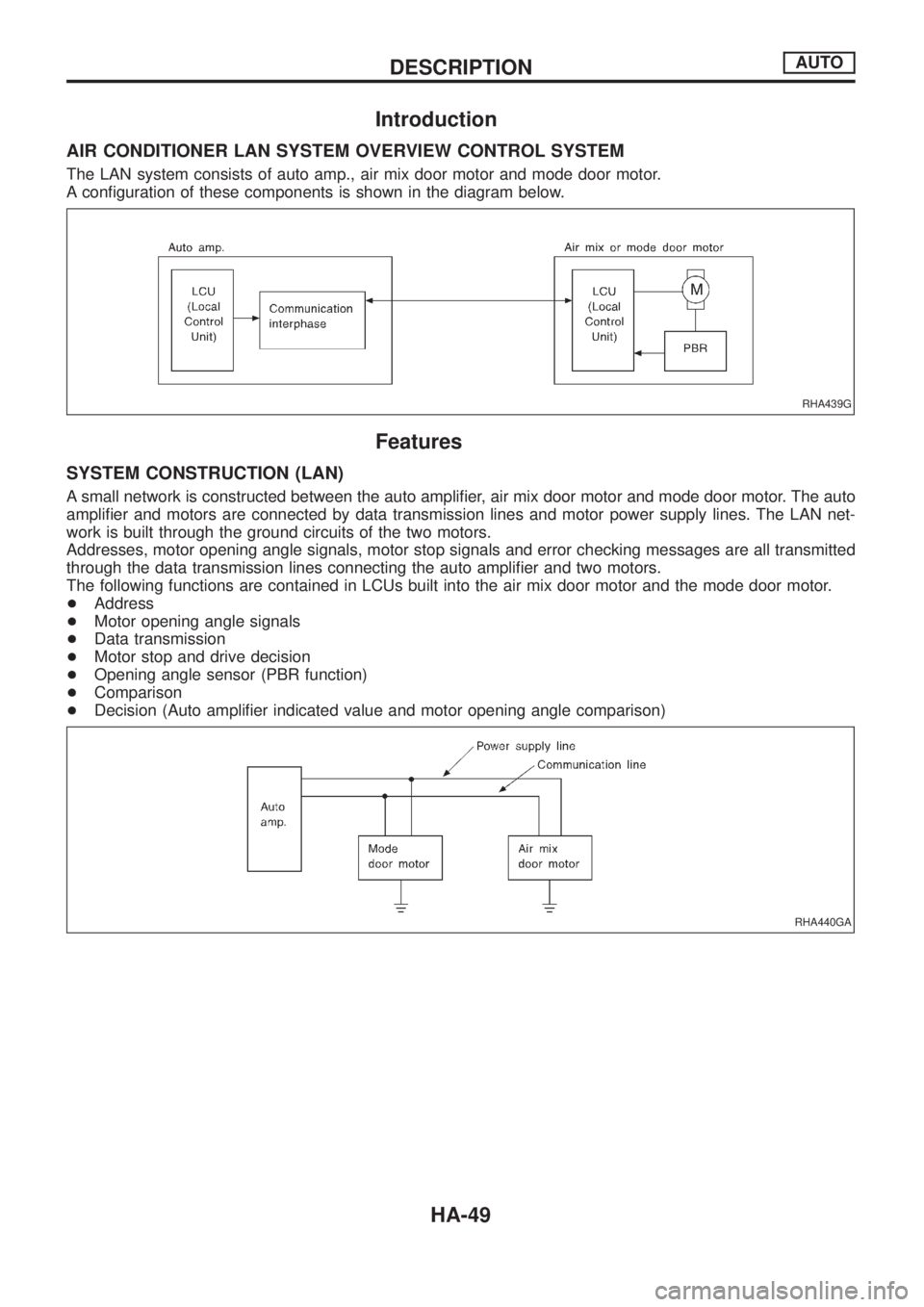

Introduction

AIR CONDITIONER LAN SYSTEM OVERVIEW CONTROL SYSTEM

The LAN system consists of auto amp., air mix door motor and mode door motor.

A con®guration of these components is shown in the diagram below.

Features

SYSTEM CONSTRUCTION (LAN)

A small network is constructed between the auto ampli®er, air mix door motor and mode door motor. The auto

ampli®er and motors are connected by data transmission lines and motor power supply lines. The LAN net-

work is built through the ground circuits of the two motors.

Addresses, motor opening angle signals, motor stop signals and error checking messages are all transmitted

through the data transmission lines connecting the auto ampli®er and two motors.

The following functions are contained in LCUs built into the air mix door motor and the mode door motor.

+Address

+Motor opening angle signals

+Data transmission

+Motor stop and drive decision

+Opening angle sensor (PBR function)

+Comparison

+Decision (Auto ampli®er indicated value and motor opening angle comparison)

RHA439G

RHA440GA

DESCRIPTIONAUTO

HA-49