manual transmission NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 808 of 1659

lAfter disconnecting vacuum or air hoses, attach a tag to

indicate the proper connection.

lUse only the fluids and lubricants specified in this manual.

lUse approved bonding agent, sealants or their equivalents

when required.

lUse tools and recommended special tools where specified

for safe and efficient service repairs.

lWhen repairing the fuel, oil, water, vacuum or exhaust

systems, check all affected lines for leaks.

lDispose of drained oil or the solvent used for cleaning parts

in an appropriate manner.

WARNING:

To prevent ECM from storing the diagnostic trouble codes,

do not carelessly disconnect the harness connectors which

are related to the ECCS system and TCM (Transmission

Control Module) system. The connectors should be discon-

nected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC section.

Precautions for Multiport Fuel Injection

System or ECCS Engine

lBefore connecting or disconnecting any harness connector

for the multiport fuel injection system or ECM (Engine Con-

trol Module):

Turn ignition switch to ``OFF'' position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

lBefore disconnecting pressurized fuel line from fuel pump to

injectors, be sure to release fuel pressure.

lBe careful not to jar components such as ECM and mass air

flow sensor.

Precautions for Three Way Catalyst

(If so equipped)

If a large amount of unburned fuel flows into the catalyst, the

catalyst temperature will be excessively high. To prevent this,

follow the instructions below:

lUse unleaded gasoline only. Leaded gasoline will seriously

damage the three way catalyst.

lWhen checking for ignition spark or measuring engine

compression, make tests quickly and only when necessary.

lDo not run engine when the fuel tank level is low, otherwise

the engine may misfire causing damage to the catalyst.

Do not place the vehicle on flammable material. Keep flammable

material off the exhaust pipe and the three way catalyst.

Precautions for Engine Oils

Prolonged and repeated contact with used engine oil may cause

skin cancer. Try to avoid direct skin contact with used oil.

SGI787

PRECAUTIONS

General Precautions (Cont'd)

GI-4

Page 811 of 1659

lALPHABETICAL INDEXis provided at the end of this manual so that you can rapidly find the item and

page you are searching for.

lA QUICK REFERENCE INDEX,a black tab (e.g.) is provided on the first page. You can quickly

find the first page of each section by mating it to the section's black tab.

lTHE CONTENTSare listed on the first page of each section.

lTHE TITLEis indicated on the upper portion of each page and shows the part or system.

lTHE PAGE NUMBERof each section consists of two letters which designate the particular section and

a number (e.g. ``BR-5'').

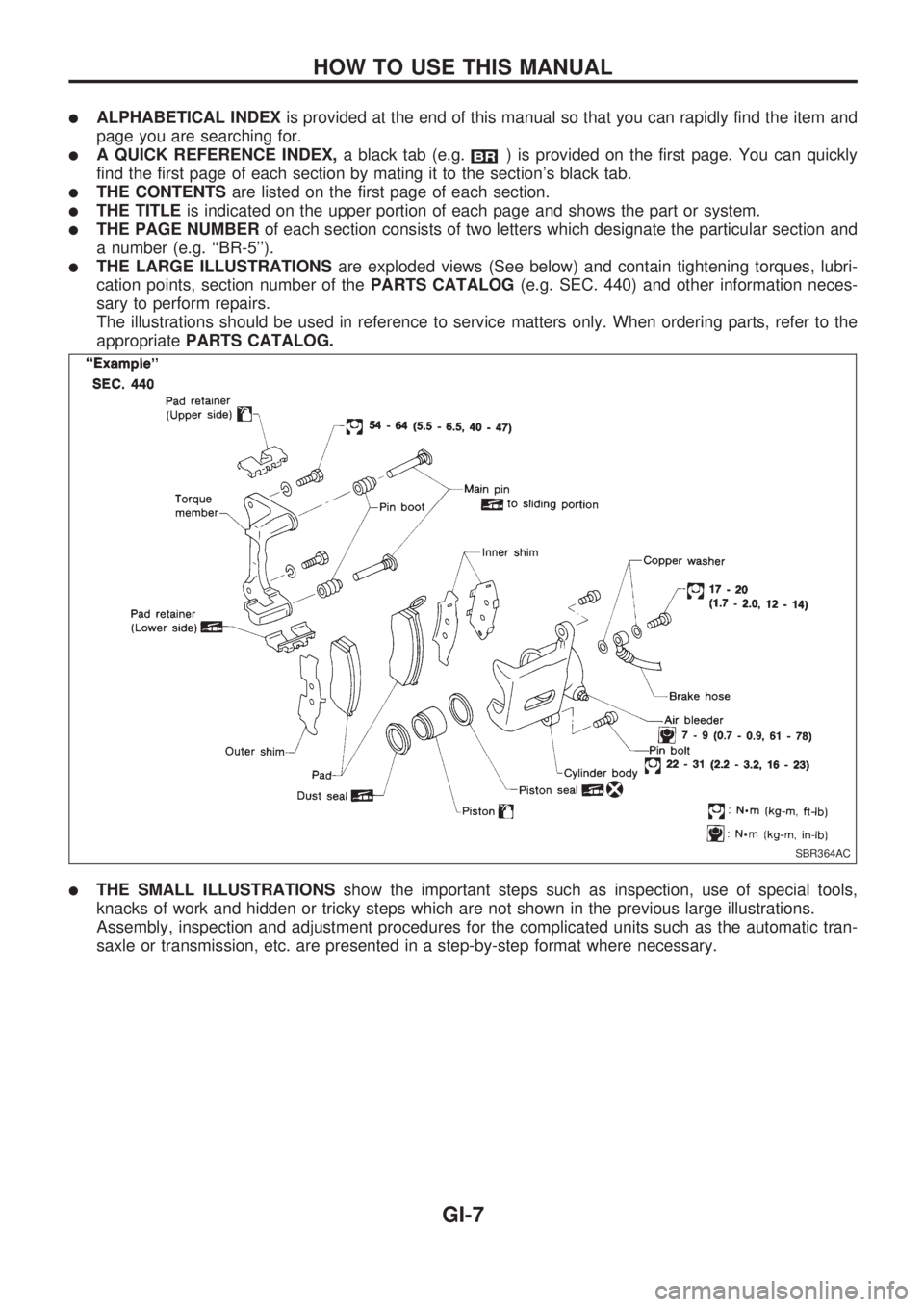

lTHE LARGE ILLUSTRATIONSare exploded views (See below) and contain tightening torques, lubri-

cation points, section number of thePARTS CATALOG(e.g. SEC. 440) and other information neces-

sary to perform repairs.

The illustrations should be used in reference to service matters only. When ordering parts, refer to the

appropriatePARTS CATALOG.

lTHE SMALL ILLUSTRATIONSshow the important steps such as inspection, use of special tools,

knacks of work and hidden or tricky steps which are not shown in the previous large illustrations.

Assembly, inspection and adjustment procedures for the complicated units such as the automatic tran-

saxle or transmission, etc. are presented in a step-by-step format where necessary.

SBR364AC

HOW TO USE THIS MANUAL

GI-7

Page 812 of 1659

lThe followingSYMBOLS AND ABBREVIATIONSare used:

,: Tightening torque

: Should be lubricated with grease.

Unless otherwise indicated, use

recommended multi-purpose

grease.

: Should be lubricated with oil.

: Sealing point

: Checking point

: Always replace after every disas-

sembly.

VP: Apply petroleum jelly.

: Apply ATF.

.: Select with proper thickness.

>: Adjustment is required.

SDS : Service Data and Specifications

LH, RH : Left-Hand, Right-Hand

FR, RR : Front, Rear

M/T : Manual Transaxle/Transmission

A/T : Automatic Transaxle/Transmission

,

4WD : 4-Wheel Drive

2WD : 2-Wheel Drive

A/C : Air Conditioner

P/S : Power Steering

SST : Special Service Tools

SAE : Society of Automotive Engineers,

Inc.

ATF : Automatic Transmission Fluid

D

1: Drive range 1st gear

D

2: Drive range 2nd gear

D

3: Drive range 3rd gear

D

4: Drive range 4th gear

OD : Overdrive

2

2: 2nd range 2nd gear

2

1: 2nd range 1st gear

1

2: 1st range 2nd gear

1

1: 1st range 1st gear

lTheUNITSgiven in this manual are primarily expressed as the SI UNIT (International System of Unit),

and alternatively expressed in the metric system and in the yard/pound system.

``Example''

Tightening torque:

59 - 78 N´m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

lTROUBLE DIAGNOSESare included in sections dealing with complicated components.

lSERVICE DATA AND SPECIFICATIONSare contained at the end of each section for quick reference

of data.

lThe captionsWARNINGandCAUTIONwarn you of steps that must be followed to prevent personal

injury and/or damage to some part of the vehicle.

WARNINGindicates the possibility of personal injury if instructions are not followed.

CAUTIONindicates the possibility of component damage if instructions are not followed.

BOLD TYPED STATEMENTSexceptWARNINGandCAUTIONgive you helpful information.

HOW TO USE THIS MANUAL

GI-8

Page 825 of 1659

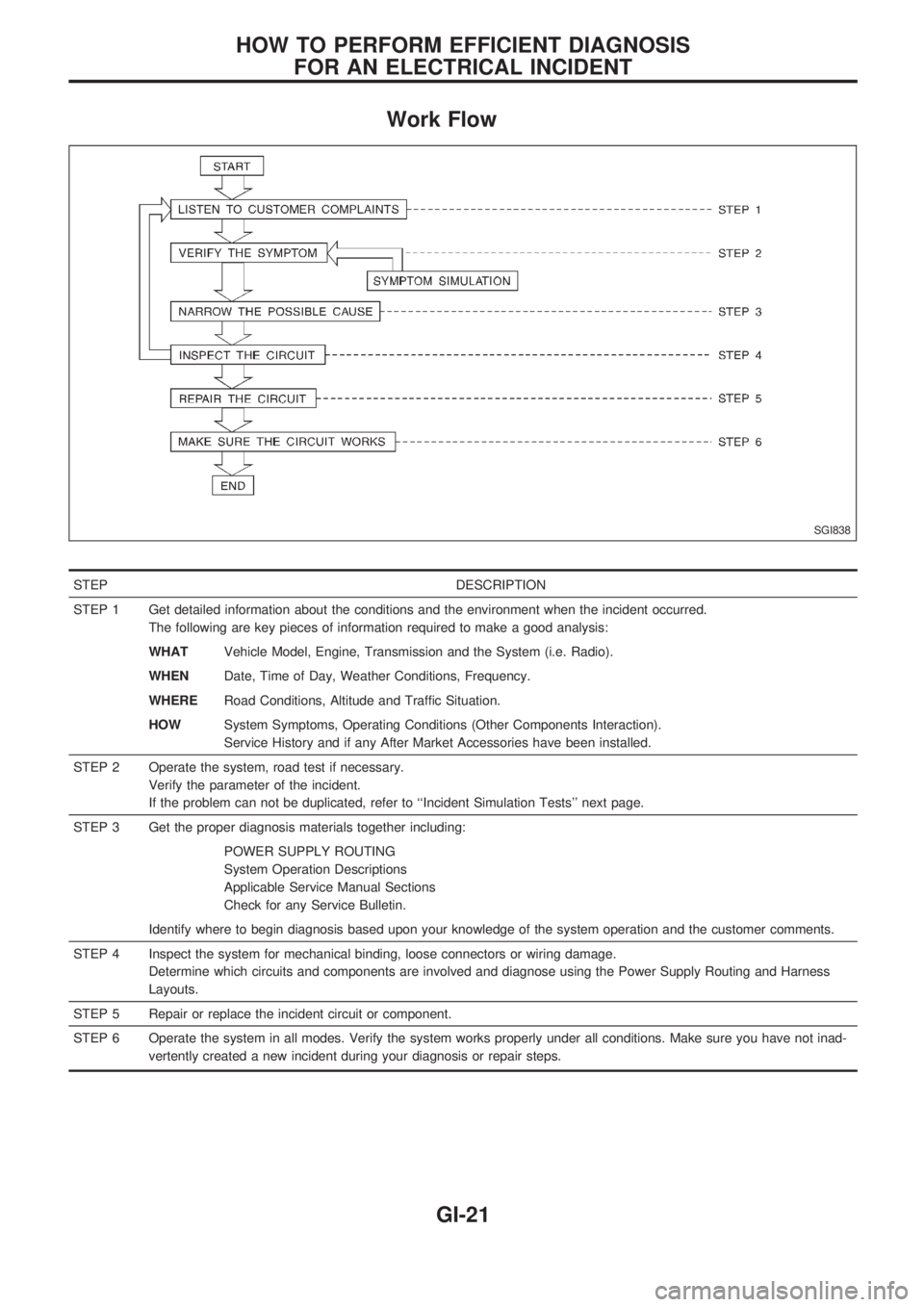

Work Flow

STEP DESCRIPTION

STEP 1 Get detailed information about the conditions and the environment when the incident occurred.

The following are key pieces of information required to make a good analysis:

WHATVehicle Model, Engine, Transmission and the System (i.e. Radio).

WHENDate, Time of Day, Weather Conditions, Frequency.

WHERERoad Conditions, Altitude and Traffic Situation.

HOWSystem Symptoms, Operating Conditions (Other Components Interaction).

Service History and if any After Market Accessories have been installed.

STEP 2 Operate the system, road test if necessary.

Verify the parameter of the incident.

If the problem can not be duplicated, refer to ``Incident Simulation Tests'' next page.

STEP 3 Get the proper diagnosis materials together including:

POWER SUPPLY ROUTING

System Operation Descriptions

Applicable Service Manual Sections

Check for any Service Bulletin.

Identify where to begin diagnosis based upon your knowledge of the system operation and the customer comments.

STEP 4 Inspect the system for mechanical binding, loose connectors or wiring damage.

Determine which circuits and components are involved and diagnose using the Power Supply Routing and Harness

Layouts.

STEP 5 Repair or replace the incident circuit or component.

STEP 6 Operate the system in all modes. Verify the system works properly under all conditions. Make sure you have not inad-

vertently created a new incident during your diagnosis or repair steps.

SGI838

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

GI-21

Page 843 of 1659

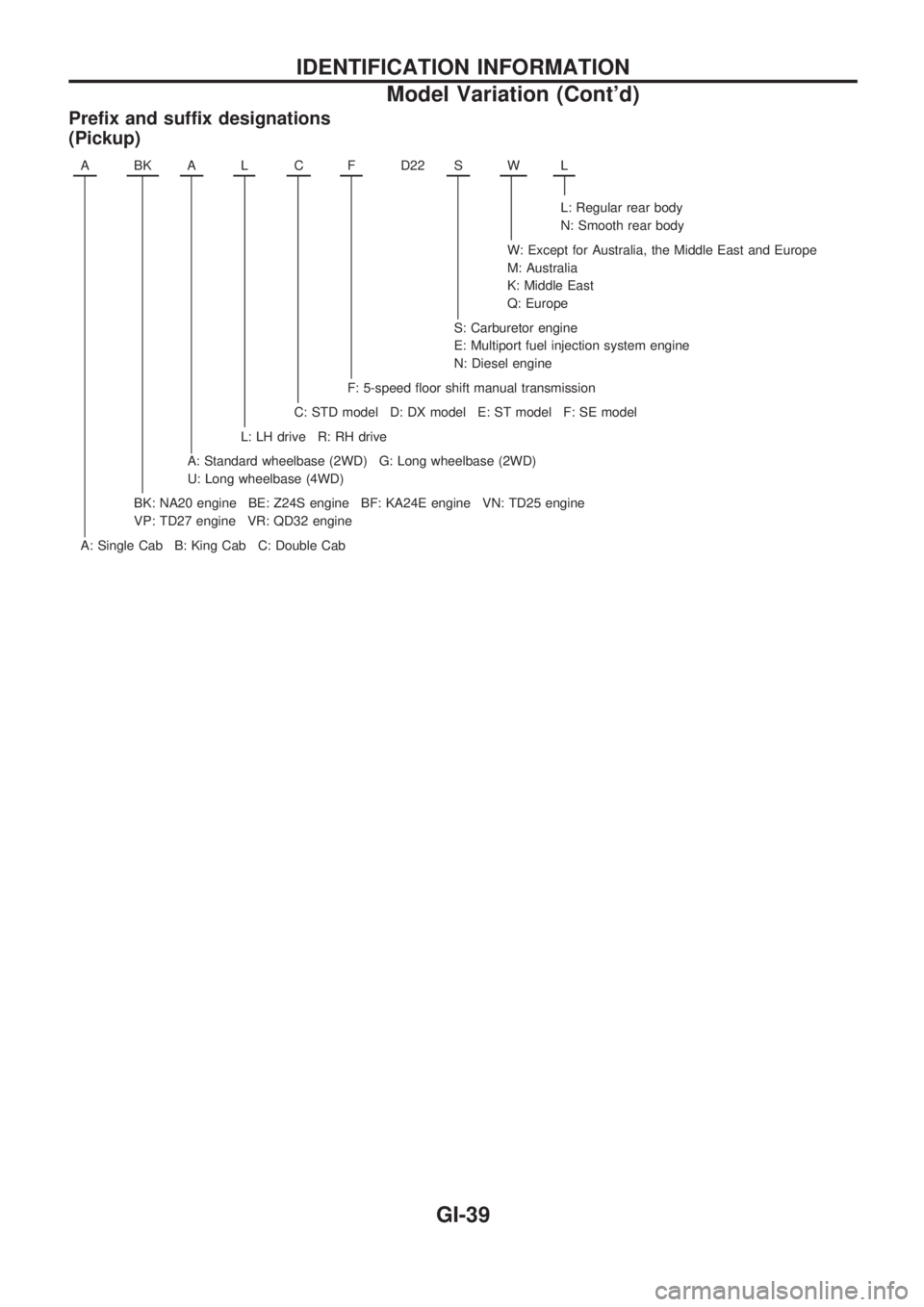

Prefix and suffix designations

(Pickup)

ABKALCFD22 SWL

L: Regular rear body

N: Smooth rear body

W: Except for Australia, the Middle East and Europe

M: Australia

K: Middle East

Q: Europe

S: Carburetor engine

E: Multiport fuel injection system engine

N: Diesel engine

F: 5-speed floor shift manual transmission

C: STD model D: DX model E: ST model F: SE model

L: LH drive R: RH drive

A: Standard wheelbase (2WD) G: Long wheelbase (2WD)

U: Long wheelbase (4WD)

BK: NA20 engine BE: Z24S engine BF: KA24E engine VN: TD25 engine

VP: TD27 engine VR: QD32 engine

A: Single Cab B: King Cab C: Double Cab

IDENTIFICATION INFORMATION

Model Variation (Cont'd)

GI-39

Page 868 of 1659

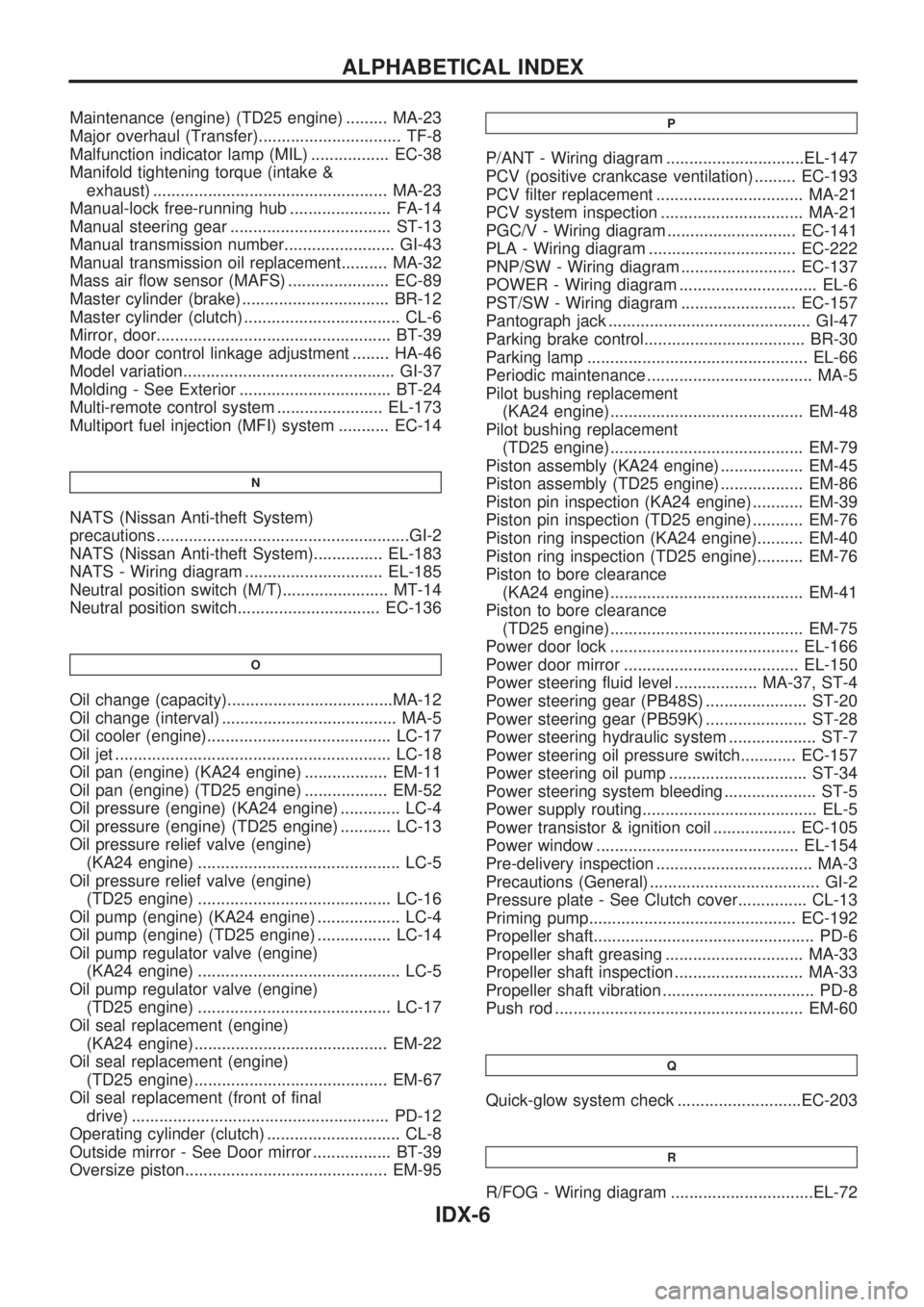

Maintenance (engine) (TD25 engine) ......... MA-23

Major overhaul (Transfer)............................... TF-8

Malfunction indicator lamp (MIL) ................. EC-38

Manifold tightening torque (intake &

exhaust) ................................................... MA-23

Manual-lock free-running hub ...................... FA-14

Manual steering gear ................................... ST-13

Manual transmission number........................ GI-43

Manual transmission oil replacement.......... MA-32

Mass air flow sensor (MAFS) ...................... EC-89

Master cylinder (brake) ................................ BR-12

Master cylinder (clutch) .................................. CL-6

Mirror, door................................................... BT-39

Mode door control linkage adjustment ........ HA-46

Model variation.............................................. GI-37

Molding - See Exterior ................................. BT-24

Multi-remote control system ....................... EL-173

Multiport fuel injection (MFI) system ........... EC-14

N

NATS (Nissan Anti-theft System)

precautions .......................................................GI-2

NATS (Nissan Anti-theft System)............... EL-183

NATS - Wiring diagram .............................. EL-185

Neutral position switch (M/T)....................... MT-14

Neutral position switch............................... EC-136

O

Oil change (capacity)....................................MA-12

Oil change (interval) ...................................... MA-5

Oil cooler (engine)........................................ LC-17

Oil jet ............................................................ LC-18

Oil pan (engine) (KA24 engine) .................. EM-11

Oil pan (engine) (TD25 engine) .................. EM-52

Oil pressure (engine) (KA24 engine) ............. LC-4

Oil pressure (engine) (TD25 engine) ........... LC-13

Oil pressure relief valve (engine)

(KA24 engine) ............................................ LC-5

Oil pressure relief valve (engine)

(TD25 engine) .......................................... LC-16

Oil pump (engine) (KA24 engine) .................. LC-4

Oil pump (engine) (TD25 engine) ................ LC-14

Oil pump regulator valve (engine)

(KA24 engine) ............................................ LC-5

Oil pump regulator valve (engine)

(TD25 engine) .......................................... LC-17

Oil seal replacement (engine)

(KA24 engine).......................................... EM-22

Oil seal replacement (engine)

(TD25 engine).......................................... EM-67

Oil seal replacement (front of final

drive) ........................................................ PD-12

Operating cylinder (clutch) ............................. CL-8

Outside mirror - See Door mirror ................. BT-39

Oversize piston............................................ EM-95

P

P/ANT - Wiring diagram ..............................EL-147

PCV (positive crankcase ventilation) ......... EC-193

PCV filter replacement ................................ MA-21

PCV system inspection ............................... MA-21

PGC/V - Wiring diagram ............................ EC-141

PLA - Wiring diagram ................................ EC-222

PNP/SW - Wiring diagram ......................... EC-137

POWER - Wiring diagram .............................. EL-6

PST/SW - Wiring diagram ......................... EC-157

Pantograph jack ............................................ GI-47

Parking brake control................................... BR-30

Parking lamp ................................................ EL-66

Periodic maintenance .................................... MA-5

Pilot bushing replacement

(KA24 engine).......................................... EM-48

Pilot bushing replacement

(TD25 engine).......................................... EM-79

Piston assembly (KA24 engine) .................. EM-45

Piston assembly (TD25 engine) .................. EM-86

Piston pin inspection (KA24 engine) ........... EM-39

Piston pin inspection (TD25 engine) ........... EM-76

Piston ring inspection (KA24 engine).......... EM-40

Piston ring inspection (TD25 engine).......... EM-76

Piston to bore clearance

(KA24 engine).......................................... EM-41

Piston to bore clearance

(TD25 engine).......................................... EM-75

Power door lock ......................................... EL-166

Power door mirror ...................................... EL-150

Power steering fluid level .................. MA-37, ST-4

Power steering gear (PB48S) ...................... ST-20

Power steering gear (PB59K) ...................... ST-28

Power steering hydraulic system ................... ST-7

Power steering oil pressure switch............ EC-157

Power steering oil pump .............................. ST-34

Power steering system bleeding .................... ST-5

Power supply routing...................................... EL-5

Power transistor & ignition coil .................. EC-105

Power window ............................................ EL-154

Pre-delivery inspection .................................. MA-3

Precautions (General) ..................................... GI-2

Pressure plate - See Clutch cover............... CL-13

Priming pump............................................. EC-192

Propeller shaft................................................ PD-6

Propeller shaft greasing .............................. MA-33

Propeller shaft inspection ............................ MA-33

Propeller shaft vibration ................................. PD-8

Push rod ...................................................... EM-60

Q

Quick-glow system check ...........................EC-203

R

R/FOG - Wiring diagram ...............................EL-72

ALPHABETICAL INDEX

IDX-6

Page 976 of 1659

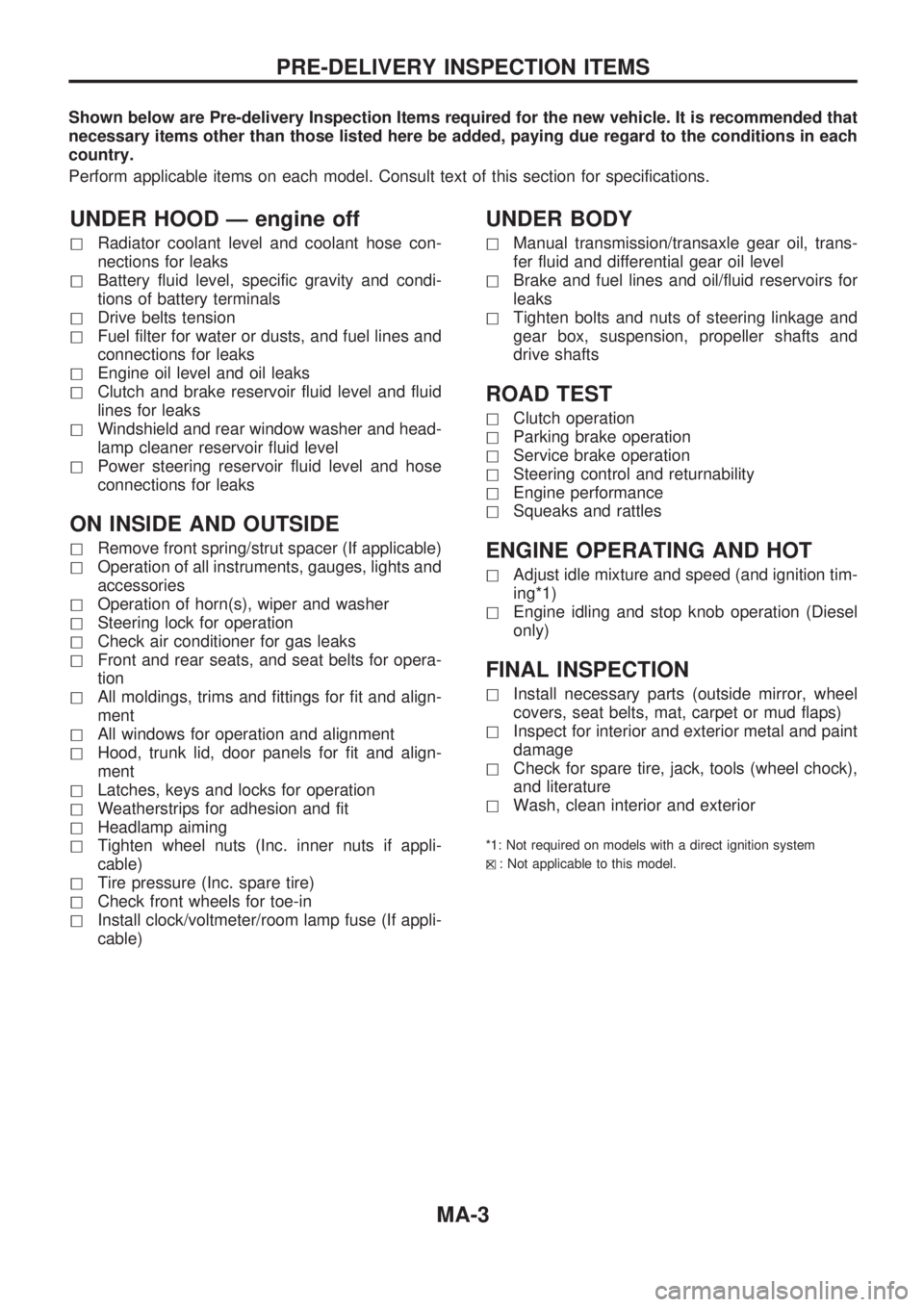

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD Ð engine off

hRadiator coolant level and coolant hose con-

nections for leaks

hBattery fluid level, specific gravity and condi-

tions of battery terminals

hDrive belts tension

hFuel filter for water or dusts, and fuel lines and

connections for leaks

hEngine oil level and oil leaks

hClutch and brake reservoir fluid level and fluid

lines for leaks

hWindshield and rear window washer and head-

lamp cleaner reservoir fluid level

hPower steering reservoir fluid level and hose

connections for leaks

ON INSIDE AND OUTSIDE

hRemove front spring/strut spacer (If applicable)

hOperation of all instruments, gauges, lights and

accessories

hOperation of horn(s), wiper and washer

hSteering lock for operation

hCheck air conditioner for gas leaks

hFront and rear seats, and seat belts for opera-

tion

hAll moldings, trims and fittings for fit and align-

ment

hAll windows for operation and alignment

hHood, trunk lid, door panels for fit and align-

ment

hLatches, keys and locks for operation

hWeatherstrips for adhesion and fit

hHeadlamp aiming

hTighten wheel nuts (Inc. inner nuts if appli-

cable)

hTire pressure (Inc. spare tire)

hCheck front wheels for toe-in

hInstall clock/voltmeter/room lamp fuse (If appli-

cable)

UNDER BODY

hManual transmission/transaxle gear oil, trans-

fer fluid and differential gear oil level

hBrake and fuel lines and oil/fluid reservoirs for

leaks

hTighten bolts and nuts of steering linkage and

gear box, suspension, propeller shafts and

drive shafts

ROAD TEST

hClutch operation

hParking brake operation

hService brake operation

hSteering control and returnability

hEngine performance

hSqueaks and rattles

ENGINE OPERATING AND HOT

hAdjust idle mixture and speed (and ignition tim-

ing*1)

hEngine idling and stop knob operation (Diesel

only)

FINAL INSPECTION

hInstall necessary parts (outside mirror, wheel

covers, seat belts, mat, carpet or mud flaps)

hInspect for interior and exterior metal and paint

damage

hCheck for spare tire, jack, tools (wheel chock),

and literature

hWash, clean interior and exterior

*1: Not required on models with a direct ignition system

h

X: Not applicable to this model.

PRE-DELIVERY INSPECTION ITEMS

MA-3

Page 979 of 1659

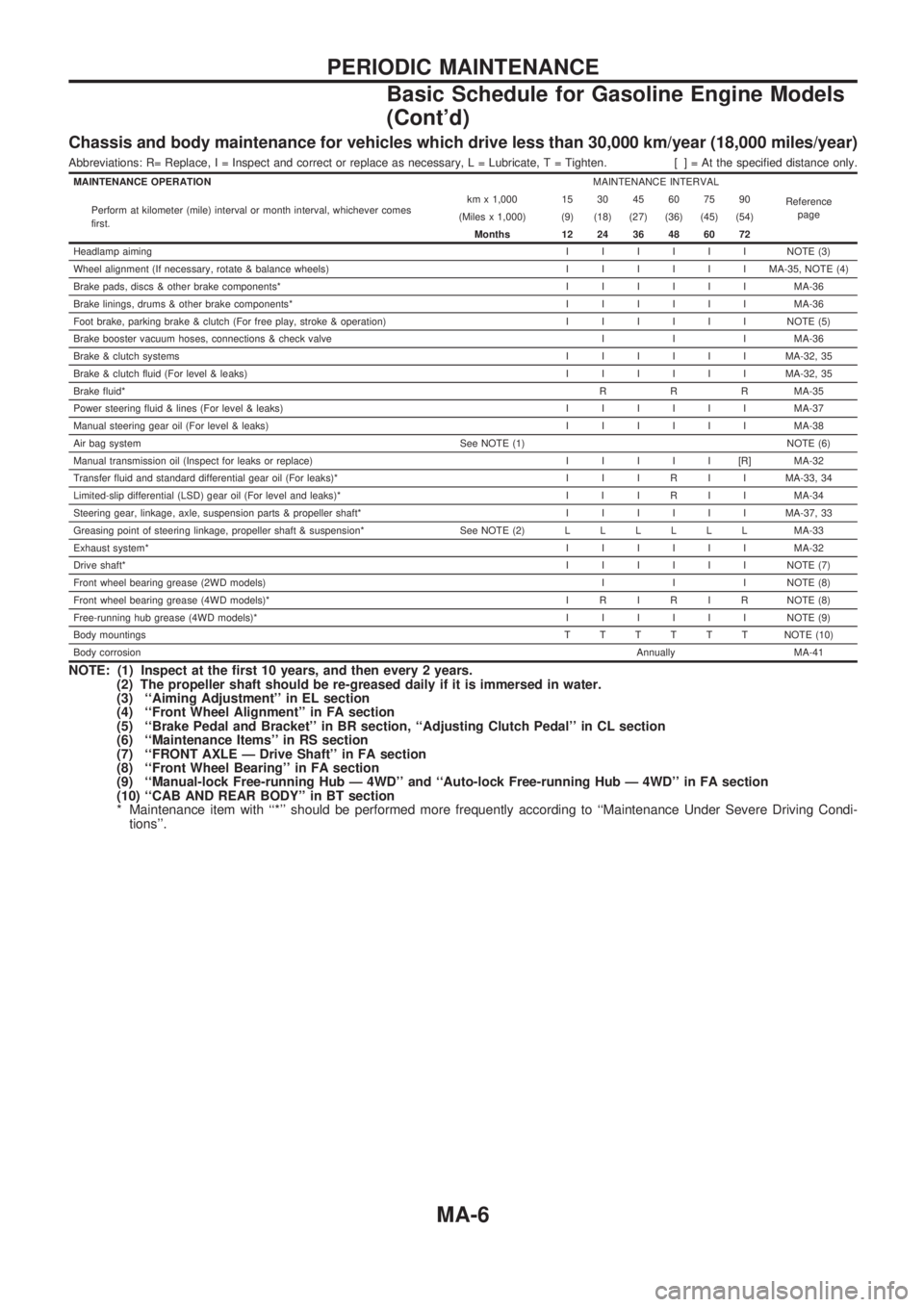

Chassis and body maintenance for vehicles which drive less than 30,000 km/year (18,000 miles/year)

Abbreviations: R= Replace, I = Inspect and correct or replace as necessary, L = Lubricate, T = Tighten. [ ] = At the specified distance only.

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform at kilometer (mile) interval or month interval, whichever comes

first.km x 1,000 15 30 45 60 75 90

(Miles x 1,000) (9) (18) (27) (36) (45) (54)

Months 12 24 36 48 60 72

Headlamp aimingIIIIIINOTE (3)

Wheel alignment (If necessary, rotate & balance wheels)IIIIIIMA-35, NOTE (4)

Brake pads, discs & other brake components*IIIIIIMA-36

Brake linings, drums & other brake components*IIIIIIMA-36

Foot brake, parking brake & clutch (For free play, stroke & operation)IIIIIINOTE (5)

Brake booster vacuum hoses, connections & check valve I I I MA-36

Brake & clutch systemsIIIIIIMA-32, 35

Brake & clutch fluid (For level & leaks)IIIIIIMA-32, 35

Brake fluid*R R R MA-35

Power steering fluid & lines (For level & leaks)IIIIIIMA-37

Manual steering gear oil (For level & leaks)IIIIIIMA-38

Air bag system See NOTE (1) NOTE (6)

Manual transmission oil (Inspect for leaks or replace)IIIII[R]MA-32

Transfer fluid and standard differential gear oil (For leaks)* I I I R I I MA-33, 34

Limited-slip differential (LSD) gear oil (For level and leaks)* I I I R I I MA-34

Steering gear, linkage, axle, suspension parts & propeller shaft*IIIIIIMA-37, 33

Greasing point of steering linkage, propeller shaft & suspension* See NOTE (2)LLLLLLMA-33

Exhaust system*IIIIIIMA-32

Drive shaft*IIIIIINOTE (7)

Front wheel bearing grease (2WD models)I I I NOTE (8)

Front wheel bearing grease (4WD models)* I R I R I R NOTE (8)

Free-running hub grease (4WD models)*IIIIIINOTE (9)

Body mountingsTTTTTTNOTE (10)

Body corrosionAnnually MA-41

NOTE: (1) Inspect at the first 10 years, and then every 2 years.

(2) The propeller shaft should be re-greased daily if it is immersed in water.

(3) ``Aiming Adjustment'' in EL section

(4) ``Front Wheel Alignment'' in FA section

(5) ``Brake Pedal and Bracket'' in BR section, ``Adjusting Clutch Pedal'' in CL section

(6) ``Maintenance Items'' in RS section

(7) ``FRONT AXLE Ð Drive Shaft'' in FA section

(8) ``Front Wheel Bearing'' in FA section

(9) ``Manual-lock Free-running Hub Ð 4WD'' and ``Auto-lock Free-running Hub Ð 4WD'' in FA section

(10) ``CAB AND REAR BODY'' in BT section

* Maintenance item with ``*'' should be performed more frequently according to ``Maintenance Under Severe Driving Condi-

tions''.

PERIODIC MAINTENANCE

Basic Schedule for Gasoline Engine Models

(Cont'd)

MA-6

Page 980 of 1659

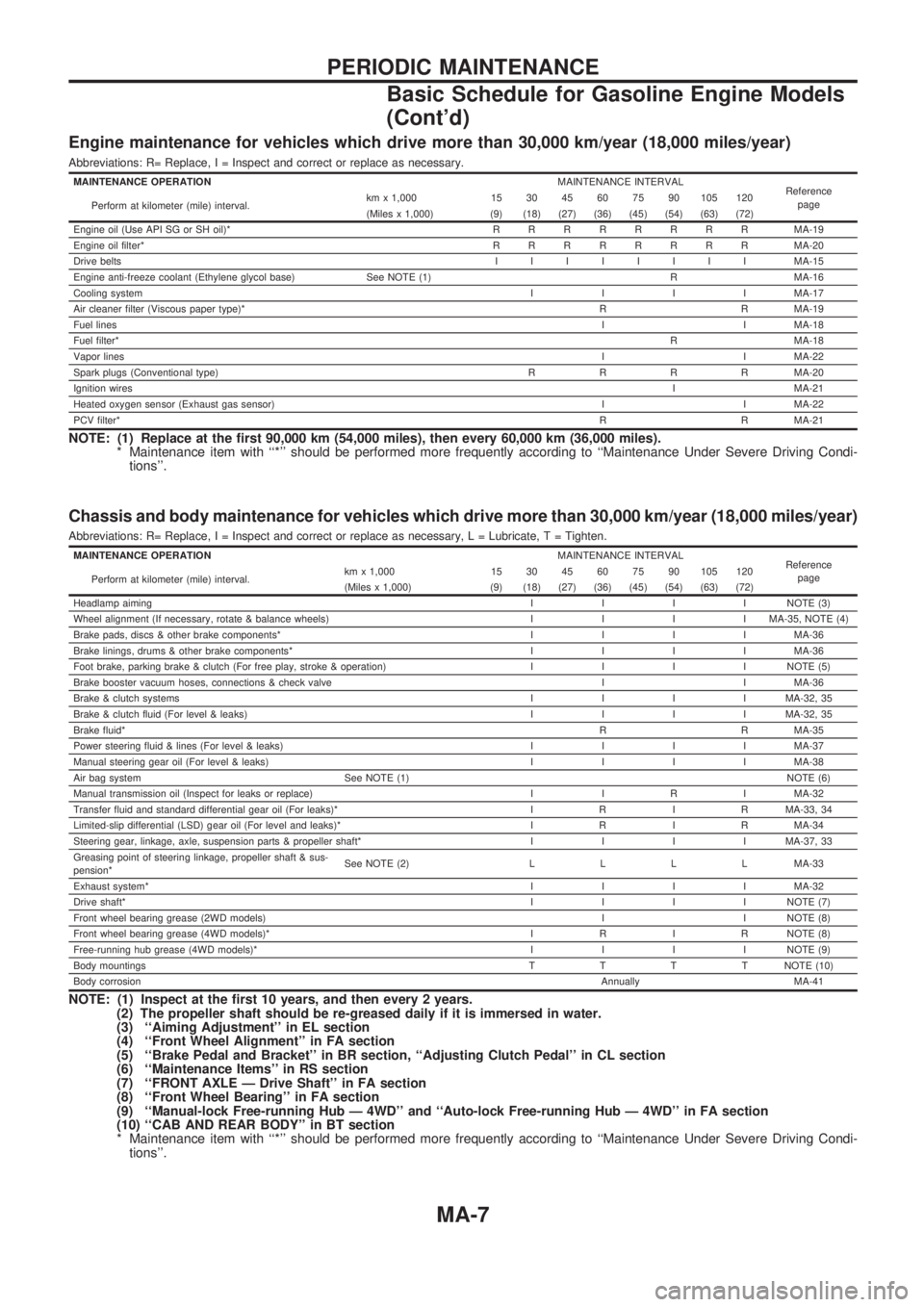

Engine maintenance for vehicles which drive more than 30,000 km/year (18,000 miles/year)

Abbreviations: R= Replace, I = Inspect and correct or replace as necessary.

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page

Perform at kilometer (mile) interval.km x 1,000 15 30 45 60 75 90 105 120

(Miles x 1,000) (9) (18) (27) (36) (45) (54) (63) (72)

Engine oil (Use API SG or SH oil)*RRRRRRRRMA-19

Engine oil filter*RRRRRRRRMA-20

Drive beltsIIIIIIIIMA-15

Engine anti-freeze coolant (Ethylene glycol base) See NOTE (1) R MA-16

Cooling systemIIIIMA-17

Air cleaner filter (Viscous paper type)*R R MA-19

Fuel linesI I MA-18

Fuel filter*R MA-18

Vapor linesI I MA-22

Spark plugs (Conventional type)RRRRMA-20

Ignition wiresI MA-21

Heated oxygen sensor (Exhaust gas sensor)I I MA-22

PCV filter*R R MA-21

NOTE: (1) Replace at the first 90,000 km (54,000 miles), then every 60,000 km (36,000 miles).

* Maintenance item with ``*'' should be performed more frequently according to ``Maintenance Under Severe Driving Condi-

tions''.

Chassis and body maintenance for vehicles which drive more than 30,000 km/year (18,000 miles/year)

Abbreviations: R= Replace, I = Inspect and correct or replace as necessary, L = Lubricate, T = Tighten.

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page

Perform at kilometer (mile) interval.km x 1,000 15 30 45 60 75 90 105 120

(Miles x 1,000) (9) (18) (27) (36) (45) (54) (63) (72)

Headlamp aimingIIIINOTE (3)

Wheel alignment (If necessary, rotate & balance wheels)IIIIMA-35, NOTE (4)

Brake pads, discs & other brake components*IIIIMA-36

Brake linings, drums & other brake components*IIIIMA-36

Foot brake, parking brake & clutch (For free play, stroke & operation)IIIINOTE (5)

Brake booster vacuum hoses, connections & check valve I I MA-36

Brake & clutch systemsIIIIMA-32, 35

Brake & clutch fluid (For level & leaks)IIIIMA-32, 35

Brake fluid*R R MA-35

Power steering fluid & lines (For level & leaks)IIIIMA-37

Manual steering gear oil (For level & leaks)IIIIMA-38

Air bag system See NOTE (1)NOTE (6)

Manual transmission oil (Inspect for leaks or replace) I I R I MA-32

Transfer fluid and standard differential gear oil (For leaks)* I R I R MA-33, 34

Limited-slip differential (LSD) gear oil (For level and leaks)* I R I R MA-34

Steering gear, linkage, axle, suspension parts & propeller shaft*IIIIMA-37, 33

Greasing point of steering linkage, propeller shaft & sus-

pension*See NOTE (2)LLLLMA-33

Exhaust system*IIIIMA-32

Drive shaft*IIIINOTE (7)

Front wheel bearing grease (2WD models)I I NOTE (8)

Front wheel bearing grease (4WD models)* I R I R NOTE (8)

Free-running hub grease (4WD models)*IIIINOTE (9)

Body mountingsTTTTNOTE (10)

Body corrosionAnnually MA-41

NOTE: (1) Inspect at the first 10 years, and then every 2 years.

(2) The propeller shaft should be re-greased daily if it is immersed in water.

(3) ``Aiming Adjustment'' in EL section

(4) ``Front Wheel Alignment'' in FA section

(5) ``Brake Pedal and Bracket'' in BR section, ``Adjusting Clutch Pedal'' in CL section

(6) ``Maintenance Items'' in RS section

(7) ``FRONT AXLE Ð Drive Shaft'' in FA section

(8) ``Front Wheel Bearing'' in FA section

(9) ``Manual-lock Free-running Hub Ð 4WD'' and ``Auto-lock Free-running Hub Ð 4WD'' in FA section

(10) ``CAB AND REAR BODY'' in BT section

* Maintenance item with ``*'' should be performed more frequently according to ``Maintenance Under Severe Driving Condi-

tions''.

PERIODIC MAINTENANCE

Basic Schedule for Gasoline Engine Models

(Cont'd)

MA-7

Page 981 of 1659

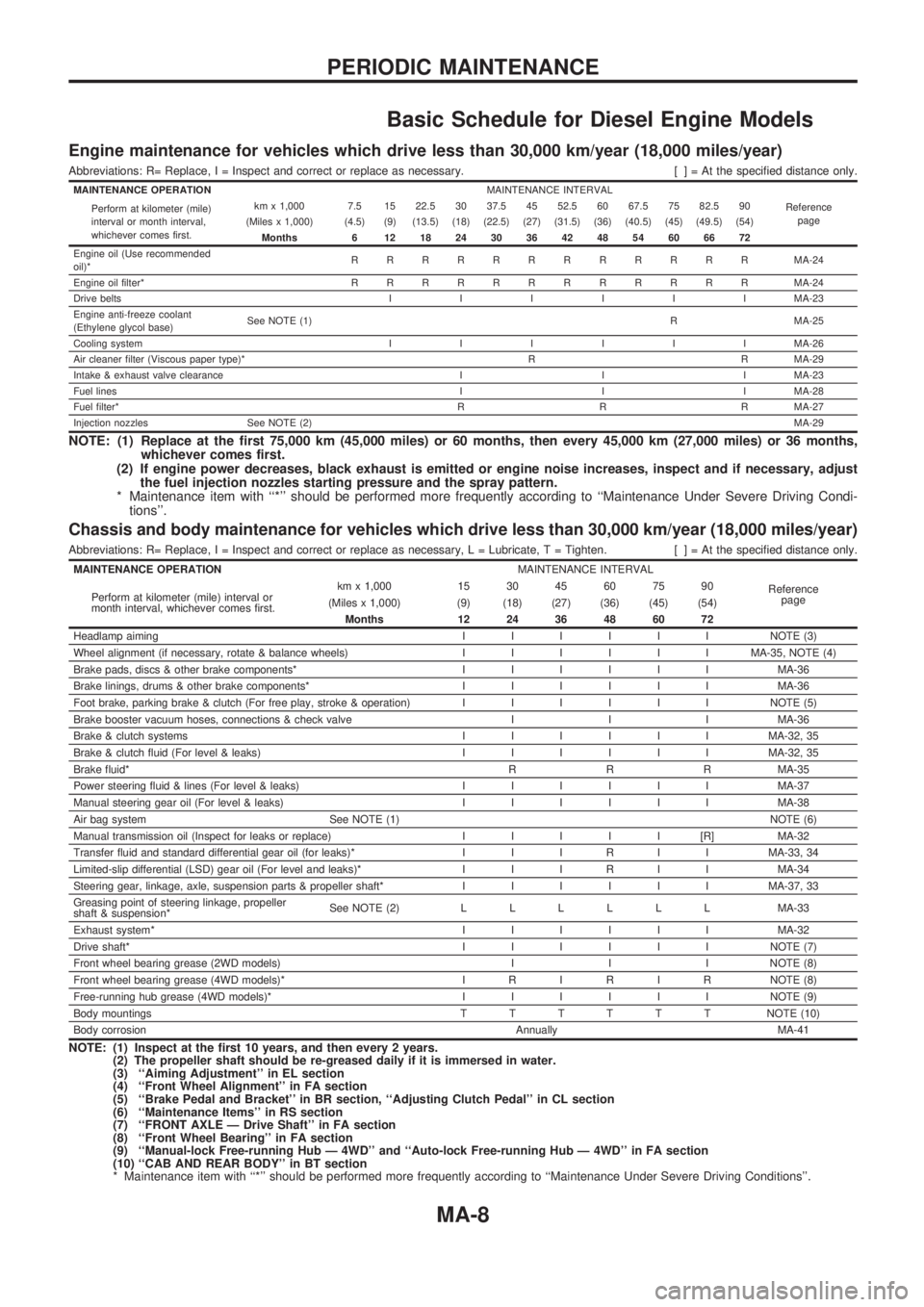

Basic Schedule for Diesel Engine Models

Engine maintenance for vehicles which drive less than 30,000 km/year (18,000 miles/year)

Abbreviations: R= Replace, I = Inspect and correct or replace as necessary. [ ] = At the specified distance only.

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform at kilometer (mile)

interval or month interval,

whichever comes first.km x 1,000 7.5 15 22.5 30 37.5 45 52.5 60 67.5 75 82.5 90

(Miles x 1,000) (4.5) (9) (13.5) (18) (22.5) (27) (31.5) (36) (40.5) (45) (49.5) (54)

Months 6 12 18 24 30 36 42 48 54 60 66 72

Engine oil (Use recommended

oil)*RRRRRRRRRRRRMA-24

Engine oil filter*RRRRRRRRRRRRMA-24

Drive beltsIIIIIIMA-23

Engine anti-freeze coolant

(Ethylene glycol base)See NOTE (1)R MA-25

Cooling systemIIIIIIMA-26

Air cleaner filter (Viscous paper type)* R R MA-29

Intake & exhaust valve clearance I I I MA-23

Fuel linesI I I MA-28

Fuel filter*R R R MA-27

Injection nozzles See NOTE (2)MA-29

NOTE: (1) Replace at the first 75,000 km (45,000 miles) or 60 months, then every 45,000 km (27,000 miles) or 36 months,

whichever comes first.

(2) If engine power decreases, black exhaust is emitted or engine noise increases, inspect and if necessary, adjust

the fuel injection nozzles starting pressure and the spray pattern.

* Maintenance item with ``*'' should be performed more frequently according to ``Maintenance Under Severe Driving Condi-

tions''.

Chassis and body maintenance for vehicles which drive less than 30,000 km/year (18,000 miles/year)

Abbreviations: R= Replace, I = Inspect and correct or replace as necessary, L = Lubricate, T = Tighten. [ ] = At the specified distance only.

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform at kilometer (mile) interval or

month interval, whichever comes first.km x 1,000 15 30 45 60 75 90

(Miles x 1,000) (9) (18) (27) (36) (45) (54)

Months 12 24 36 48 60 72

Headlamp aimingIIIIIINOTE (3)

Wheel alignment (if necessary, rotate & balance wheels)IIIIIIMA-35, NOTE (4)

Brake pads, discs & other brake components*IIIIIIMA-36

Brake linings, drums & other brake components*IIIIIIMA-36

Foot brake, parking brake & clutch (For free play, stroke & operation)IIIIIINOTE (5)

Brake booster vacuum hoses, connections & check valve I I I MA-36

Brake & clutch systemsIIIIIIMA-32, 35

Brake & clutch fluid (For level & leaks)IIIIIIMA-32, 35

Brake fluid*R R R MA-35

Power steering fluid & lines (For level & leaks)IIIIIIMA-37

Manual steering gear oil (For level & leaks)IIIIIIMA-38

Air bag system See NOTE (1)NOTE (6)

Manual transmission oil (Inspect for leaks or replace)IIIII[R]MA-32

Transfer fluid and standard differential gear oil (for leaks)* I I I R I I MA-33, 34

Limited-slip differential (LSD) gear oil (For level and leaks)* I I I R I I MA-34

Steering gear, linkage, axle, suspension parts & propeller shaft*IIIIIIMA-37, 33

Greasing point of steering linkage, propeller

shaft & suspension*See NOTE (2)LLLLLLMA-33

Exhaust system*IIIIIIMA-32

Drive shaft*IIIIIINOTE (7)

Front wheel bearing grease (2WD models) I I I NOTE (8)

Front wheel bearing grease (4WD models)* I R I R I R NOTE (8)

Free-running hub grease (4WD models)*IIIIIINOTE (9)

Body mountingsTTTTTTNOTE (10)

Body corrosionAnnually MA-41

NOTE: (1) Inspect at the first 10 years, and then every 2 years.

(2) The propeller shaft should be re-greased daily if it is immersed in water.

(3) ``Aiming Adjustment'' in EL section

(4) ``Front Wheel Alignment'' in FA section

(5) ``Brake Pedal and Bracket'' in BR section, ``Adjusting Clutch Pedal'' in CL section

(6) ``Maintenance Items'' in RS section

(7) ``FRONT AXLE Ð Drive Shaft'' in FA section

(8) ``Front Wheel Bearing'' in FA section

(9) ``Manual-lock Free-running Hub Ð 4WD'' and ``Auto-lock Free-running Hub Ð 4WD'' in FA section

(10) ``CAB AND REAR BODY'' in BT section

* Maintenance item with ``*'' should be performed more frequently according to ``Maintenance Under Severe Driving Conditions''.

PERIODIC MAINTENANCE

MA-8