open hood NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 105 of 1659

Body Front End

lWhen removing or installing hood, place a cloth or other padding on hood. This prevents vehicle body

from being scratched.

lBumper fascia is made of plastic. Do not use excessive force and be sure to keep oil away from it.

lHood adjustment: Adjust at hinge portion.

lHood lock adjustment: After adjusting, check hood lock control operation. Apply a coat of grease to hood

locks engaging mechanism.

lHood opener: Do not attempt to bend cable forcibly. Doing so increases effort required to unlock hood.

REMOVAL Ð Front bumper assembly

V1Remove screws securing left and right combination lamps and remove the lamps.

V2Remove clips securing front grille and remove the front grille.

V3Remove bolts securing left and right bumper stays.

V4Remove bolts securing left and right bumper side brackets.

V5Remove bolts securing left and right bumper side stays.

V6Extract bumper assembly.

BODY END

BT-5

Page 178 of 1659

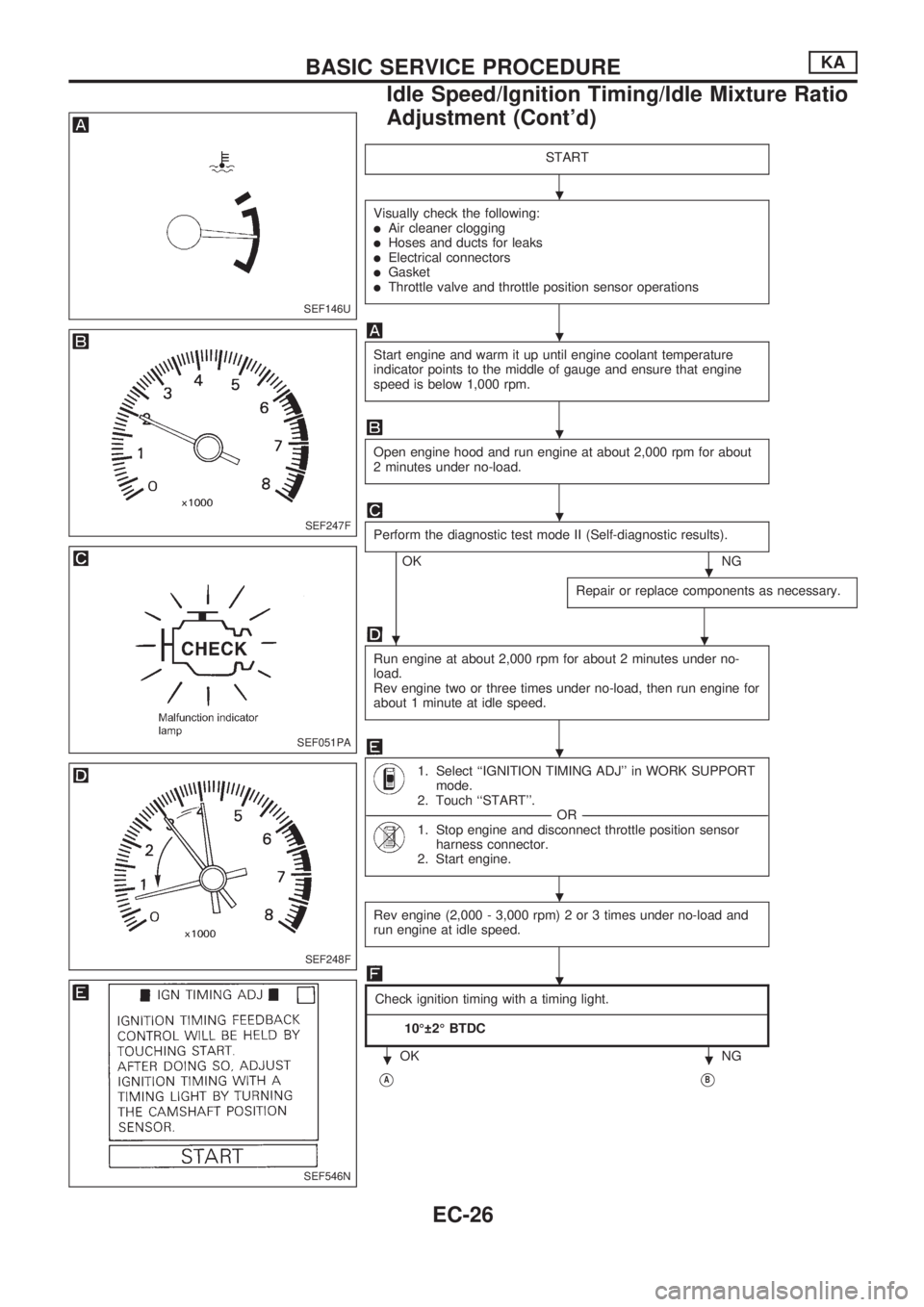

START

Visually check the following:lAir cleaner clogginglHoses and ducts for leakslElectrical connectorslGasketlThrottle valve and throttle position sensor operations

Start engine and warm it up until engine coolant temperature

indicator points to the middle of gauge and ensure that engine

speed is below 1,000 rpm.

Open engine hood and run engine at about 2,000 rpm for about

2 minutes under no-load.

Perform the diagnostic test mode II (Self-diagnostic results).

OKNG

Repair or replace components as necessary.

.

Run engine at about 2,000 rpm for about 2 minutes under no-

load.

Rev engine two or three times under no-load, then run engine for

about 1 minute at idle speed.

1. Select ``IGNITION TIMING ADJ'' in WORK SUPPORT

mode.

2. Touch ``START''.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Stop engine and disconnect throttle position sensor

harness connector.

2. Start engine.

Rev engine (2,000 - 3,000 rpm) 2 or 3 times under no-load and

run engine at idle speed.

Check ignition timing with a timing light.

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

10É 2É BTDC

OK NG

VAVB

SEF146U

SEF247F

SEF051PA

SEF248F

SEF546N

.

.

.

.

.

.

.

.

.

..

BASIC SERVICE PROCEDUREKA

Idle Speed/Ignition Timing/Idle Mixture Ratio

Adjustment (Cont'd)

EC-26

Page 184 of 1659

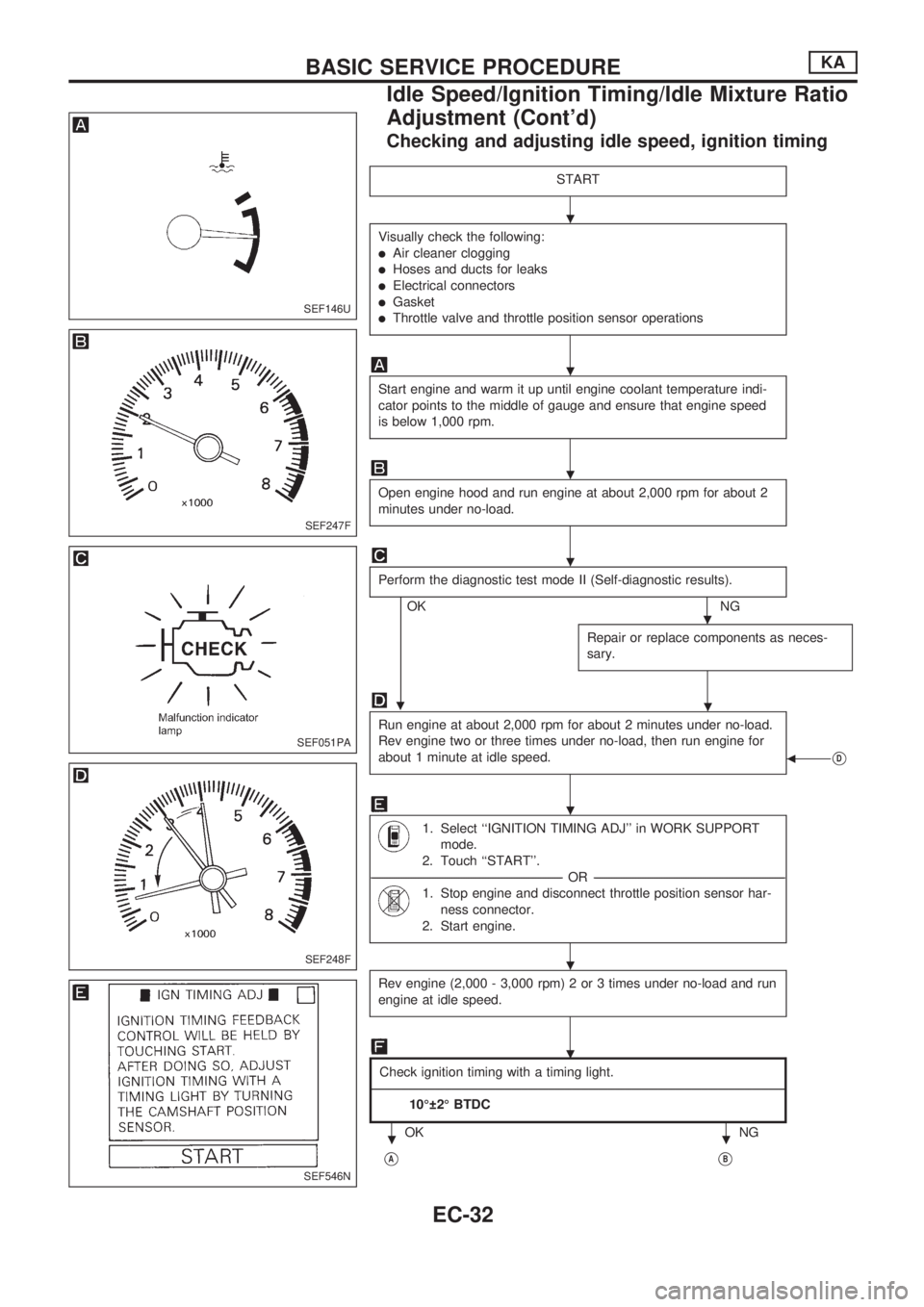

Checking and adjusting idle speed, ignition timing

START

Visually check the following:

lAir cleaner clogging

lHoses and ducts for leaks

lElectrical connectors

lGasket

lThrottle valve and throttle position sensor operations

Start engine and warm it up until engine coolant temperature indi-

cator points to the middle of gauge and ensure that engine speed

is below 1,000 rpm.

Open engine hood and run engine at about 2,000 rpm for about 2

minutes under no-load.

Perform the diagnostic test mode II (Self-diagnostic results).

OKNG

Repair or replace components as neces-

sary.

.

Run engine at about 2,000 rpm for about 2 minutes under no-load.

Rev engine two or three times under no-load, then run engine for

about 1 minute at idle speed.

bVD

1. Select ``IGNITION TIMING ADJ'' in WORK SUPPORT

mode.

2. Touch ``START''.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Stop engine and disconnect throttle position sensor har-

ness connector.

2. Start engine.

Rev engine (2,000 - 3,000 rpm) 2 or 3 times under no-load and run

engine at idle speed.

Check ignition timing with a timing light.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

10É 2É BTDC

OK NG

VAVB

SEF146U

SEF247F

SEF051PA

SEF248F

SEF546N

.

.

.

.

.

.

.

.

.

..

BASIC SERVICE PROCEDUREKA

Idle Speed/Ignition Timing/Idle Mixture Ratio

Adjustment (Cont'd)

EC-32

Page 210 of 1659

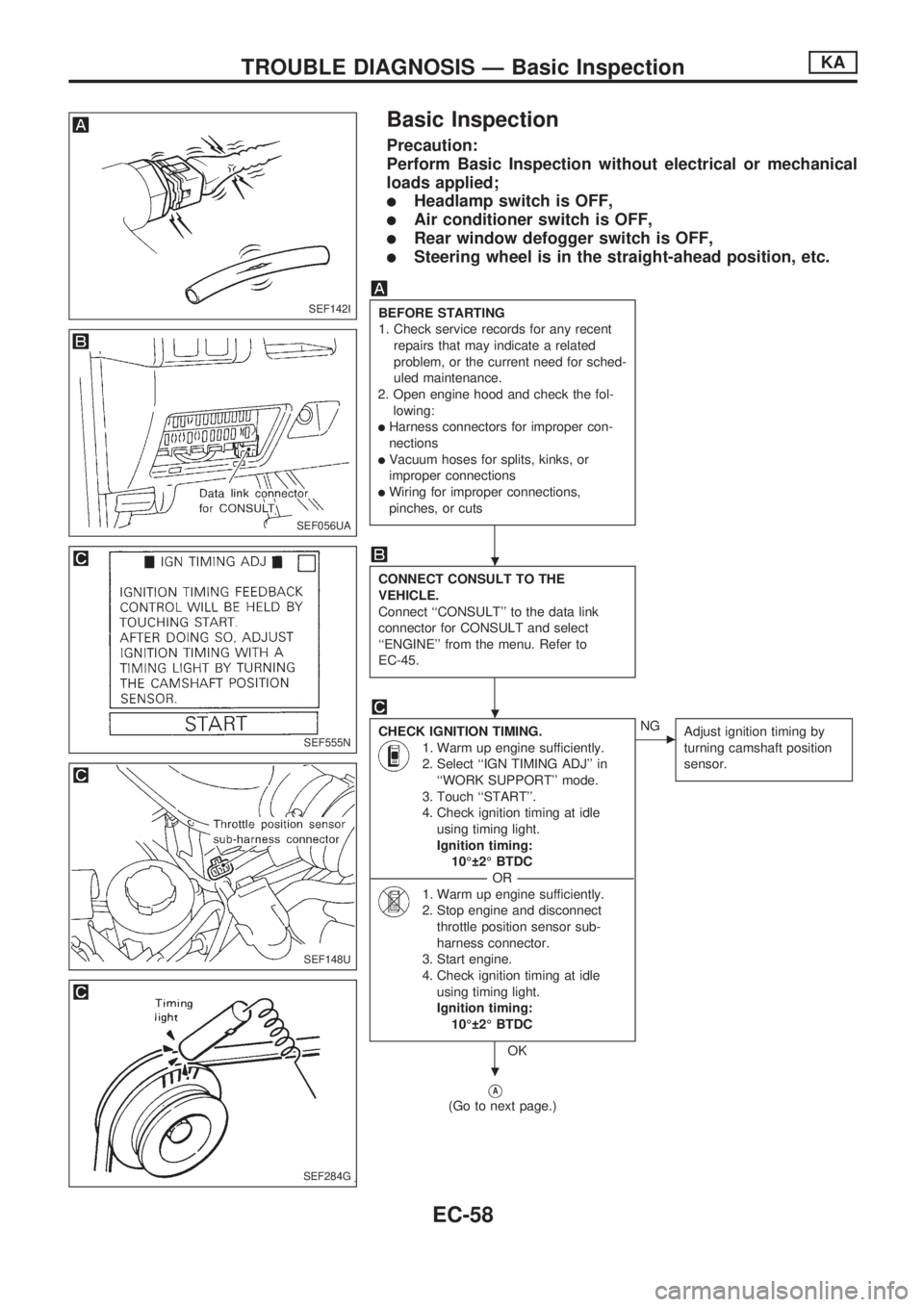

Basic Inspection

Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

lHeadlamp switch is OFF,

lAir conditioner switch is OFF,

lRear window defogger switch is OFF,

lSteering wheel is in the straight-ahead position, etc.

BEFORE STARTING

1. Check service records for any recent

repairs that may indicate a related

problem, or the current need for sched-

uled maintenance.

2. Open engine hood and check the fol-

lowing:

lHarness connectors for improper con-

nections

lVacuum hoses for splits, kinks, or

improper connections

lWiring for improper connections,

pinches, or cuts

CONNECT CONSULT TO THE

VEHICLE.

Connect ``CONSULT'' to the data link

connector for CONSULT and select

``ENGINE'' from the menu. Refer to

EC-45.

CHECK IGNITION TIMING.

1. Warm up engine sufficiently.

2. Select ``IGN TIMING ADJ'' in

``WORK SUPPORT'' mode.

3. Touch ``START''.

4. Check ignition timing at idle

using timing light.

Ignition timing:

10É 2É BTDC

----------------------------------------------------------------------------------------------------------------------------------OR----------------------------------------------------------------------------------------------------------------------------------

1. Warm up engine sufficiently.

2. Stop engine and disconnect

throttle position sensor sub-

harness connector.

3. Start engine.

4. Check ignition timing at idle

using timing light.

Ignition timing:

10É 2É BTDC

OK

cNG

Adjust ignition timing by

turning camshaft position

sensor.

VA

(Go to next page.)

SEF142I

SEF056UA

SEF555N

SEF148U

SEF284G

.

.

.

TROUBLE DIAGNOSIS Ð Basic InspectionKA

EC-58

Page 897 of 1659

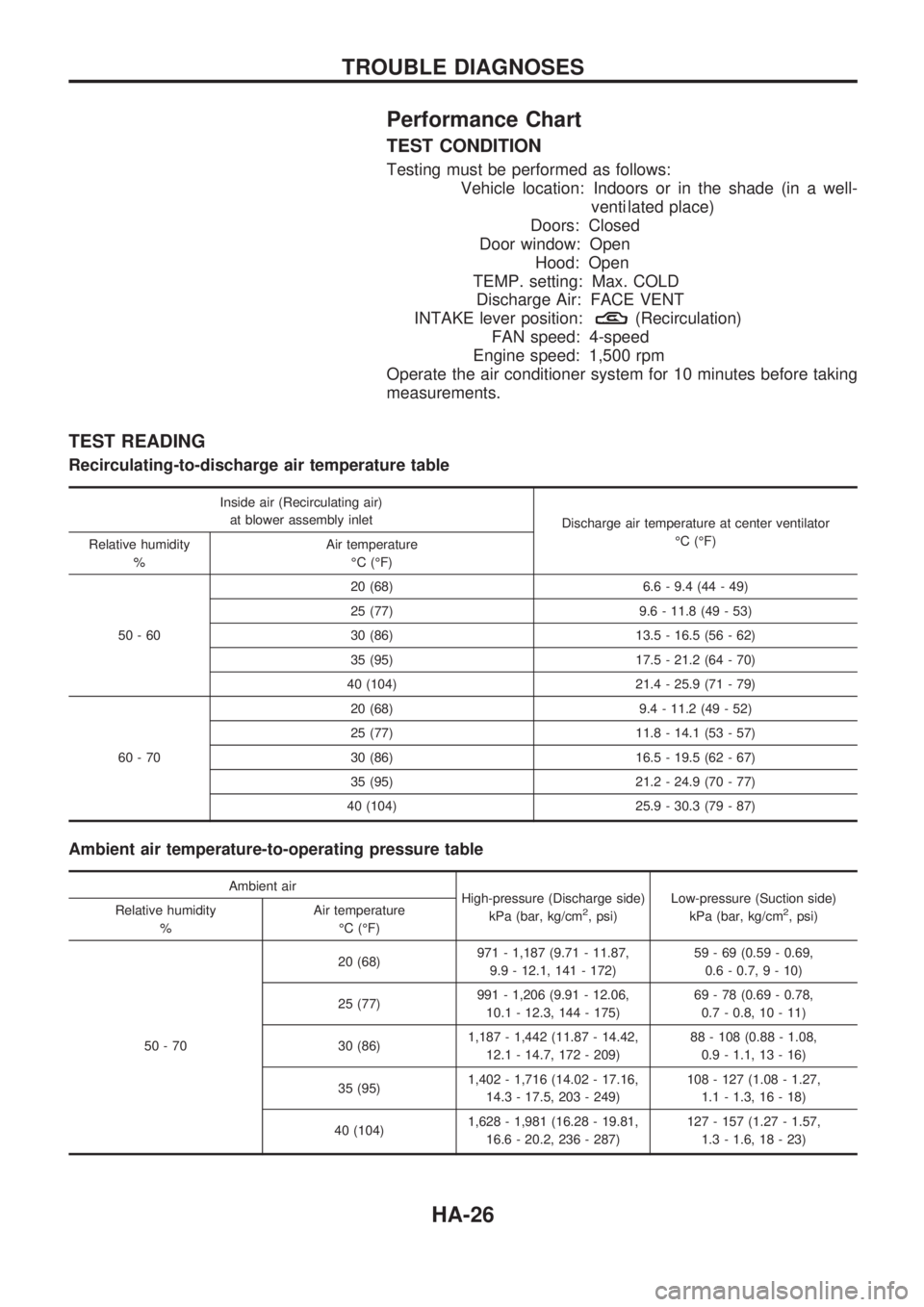

Performance Chart

TEST CONDITION

Testing must be performed as follows:

Vehicle location: Indoors or in the shade (in a well-

venti lated place)

Doors: Closed

Door window: Open

Hood: Open

TEMP. setting: Max. COLD

Discharge Air: FACE VENT

INTAKE lever position:

(Recirculation)

FAN speed: 4-speed

Engine speed: 1,500 rpm

Operate the air conditioner system for 10 minutes before taking

measurements.

TEST READING

Recirculating-to-discharge air temperature table

Inside air (Recirculating air)

at blower assembly inlet

Discharge air temperature at center ventilator

ÉC (ÉF)

Relative humidity

%Air temperature

ÉC (ÉF)

50-6020 (68) 6.6 - 9.4 (44 - 49)

25 (77) 9.6 - 11.8 (49 - 53)

30 (86) 13.5 - 16.5 (56 - 62)

35 (95) 17.5 - 21.2 (64 - 70)

40 (104) 21.4 - 25.9 (71 - 79)

60-7020 (68) 9.4 - 11.2 (49 - 52)

25 (77) 11.8 - 14.1 (53 - 57)

30 (86) 16.5 - 19.5 (62 - 67)

35 (95) 21.2 - 24.9 (70 - 77)

40 (104) 25.9 - 30.3 (79 - 87)

Ambient air temperature-to-operating pressure table

Ambient air

High-pressure (Discharge side)

kPa (bar, kg/cm

2, psi)Low-pressure (Suction side)

kPa (bar, kg/cm2, psi) Relative humidity

%Air temperature

ÉC (ÉF)

50-7020 (68)971 - 1,187 (9.71 - 11.87,

9.9 - 12.1, 141 - 172)59 - 69 (0.59 - 0.69,

0.6 - 0.7, 9 - 10)

25 (77)991 - 1,206 (9.91 - 12.06,

10.1 - 12.3, 144 - 175)69 - 78 (0.69 - 0.78,

0.7 - 0.8, 10 - 11)

30 (86)1,187 - 1,442 (11.87 - 14.42,

12.1 - 14.7, 172 - 209)88 - 108 (0.88 - 1.08,

0.9 - 1.1, 13 - 16)

35 (95)1,402 - 1,716 (14.02 - 17.16,

14.3 - 17.5, 203 - 249)108 - 127 (1.08 - 1.27,

1.1 - 1.3, 16 - 18)

40 (104)1,628 - 1,981 (16.28 - 19.81,

16.6 - 20.2, 236 - 287)127 - 157 (1.27 - 1.57,

1.3 - 1.6, 18 - 23)

TROUBLE DIAGNOSES

HA-26

Page 977 of 1659

General maintenance includes those items which should be checked during the normal day-to-day opera-

tion of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can per-

form the checks and inspections themselves or they can have their NISSAN dealers do them.

Item Reference pages

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise

specified.

TiresCheck the pressure with a gauge periodically when at a service station, including the

spare, and adjust to the specified pressure if necessary. Check carefully for damage, cuts or

excessive wear.Ð

Windshield wiper bladesCheck for cracks or wear if they do not wipe properly. Ð

Doors and engine hoodCheck that all doors, the engine hood, the trunk lid and back door

operate properly. Also ensure that all latches lock securely. Lubricate hinges, latches, rollers and

links if necessary. Make sure that the secondary latch keeps the hood from opening when the

primary latch is released.

When driving in areas using road salt or other corrosive materials, check for lubrication fre-

quently.MA-39

Tire rotationTires should be rotated every 10,000 km (6,000 miles) for 2WD models and every

5,000 km (3,000 miles) for 4WD models.MA-35

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when per-

forming periodic maintenance, cleaning the vehicle, etc.

LightsMake sure that the headlights, stop lights, tail lights, turn signal lights, and other lights

are all operating properly and installed securely. Also check headlight aim.Ð

Warning lights and chimesMake sure that all warning lights and chimes are operating prop-

erly.Ð

Steering wheelCheck for change in the steering conditions, such as excessive free play, hard

steering or strange noises.

Free play: Less than 35 mm (1.38 in)Ð

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the belt webbing for

cuts, fraying, wear or damage.MA-40

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the

engine oil or refuel.

Windshield washer fluidCheck that there is adequate fluid in the tank. Ð

Engine coolant levelCheck the coolant level when the engine is cold. MA-16, 25

Engine oil levelCheck the level after parking the vehicle on a level spot and turning off the

engine.MA-19, 24

Brake and clutch fluid levelMake sure that the brake and clutch fluid levels are between the

``MAX'' and ``MIN'' lines on the reservoir.MA-32, 35

BatteryCheck the fluid level in each cell. It should be between the ``MAX'' and ``MIN'' lines. Ð

GENERAL MAINTENANCE

MA-4

Page 1014 of 1659

Checking Body Corrosion

Visually check the body sheet metal panel for corrosion, paint damage (scratches, chipping, rubbing, etc.)

or damage to the anti-corrosion materials. In particular, check the following locations.

Hemmed portion

Hood front end, door lower end, trunk lid rear end, etc.

Panel joint

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut tower in engine

compartment, etc.

Panel edge

Trunk lid opening, sunroof opening, fender wheelarch flange, fuel filler lid flange, around holes in panel, etc.

Parts contact

Waist molding, windshield molding, bumper, etc.

Protectors

Damage or condition of mudguard, fender protector, chipping protector, etc.

Anti-corrosion materials

Damage or separation of anti-corrosion materials under the body.

Drain holes

Condition of drain holes at door and side sill.

When repairing corroded areas, refer to the Corrosion Repair Manual.

CHASSIS AND BODY MAINTENANCE

MA-41