NISSAN PICK-UP 2001 Repair Manual

PICK-UP 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57372/w960_57372-0.png

NISSAN PICK-UP 2001 Repair Manual

Trending: keyless, display, reset, wheelbase, battery replacement, belt, trailer

Page 391 of 1306

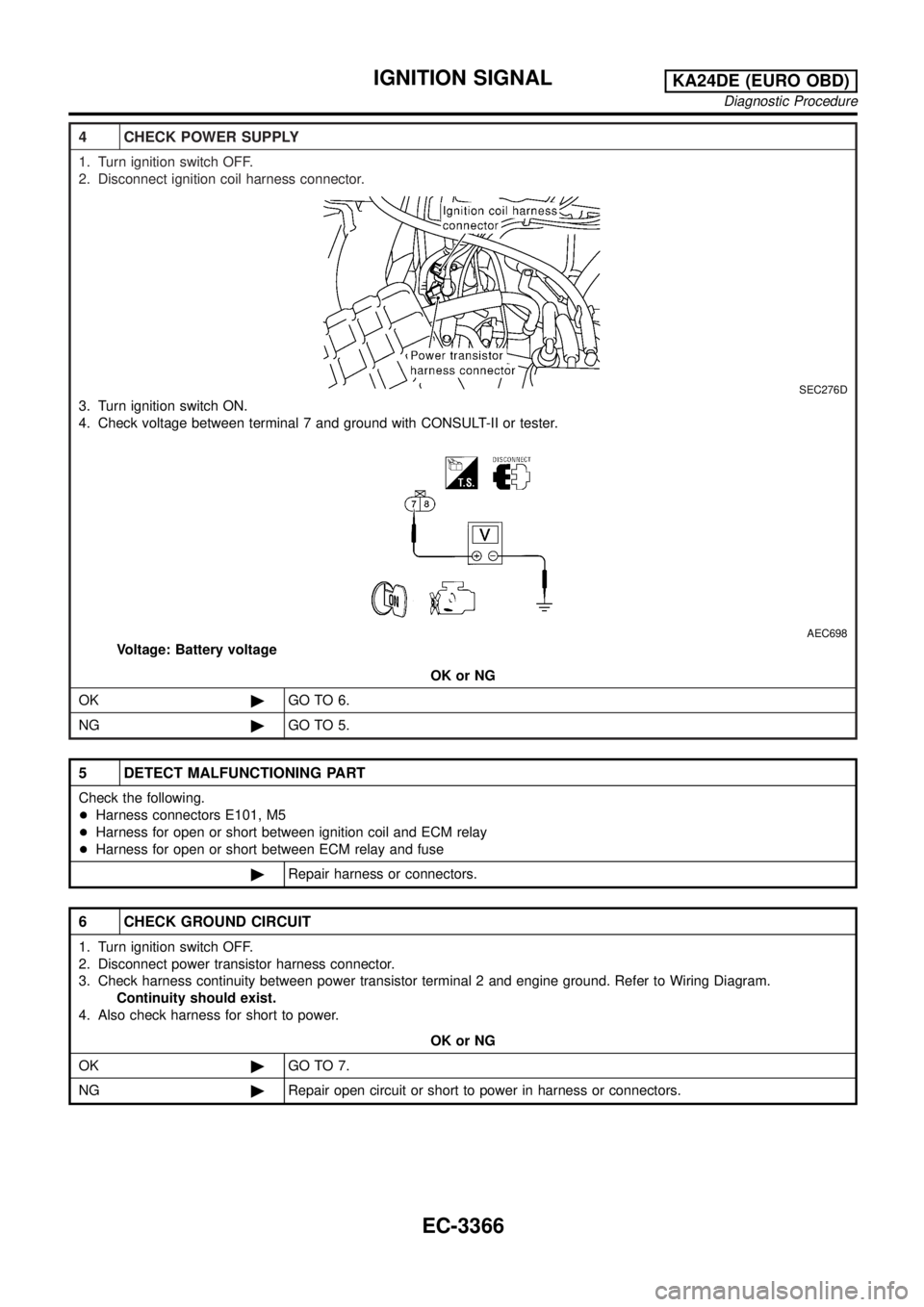

4 CHECK POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect ignition coil harness connector.

SEC276D

3. Turn ignition switch ON.

4. Check voltage between terminal 7 and ground with CONSULT-II or tester.

AEC698

Voltage: Battery voltage

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E101, M5

+Harness for open or short between ignition coil and ECM relay

+Harness for open or short between ECM relay and fuse

©Repair harness or connectors.

6 CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect power transistor harness connector.

3. Check harness continuity between power transistor terminal 2 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to power.

OK or NG

OK©GO TO 7.

NG©Repair open circuit or short to power in harness or connectors.

IGNITION SIGNALKA24DE (EURO OBD)

Diagnostic Procedure

EC-3366

Page 392 of 1306

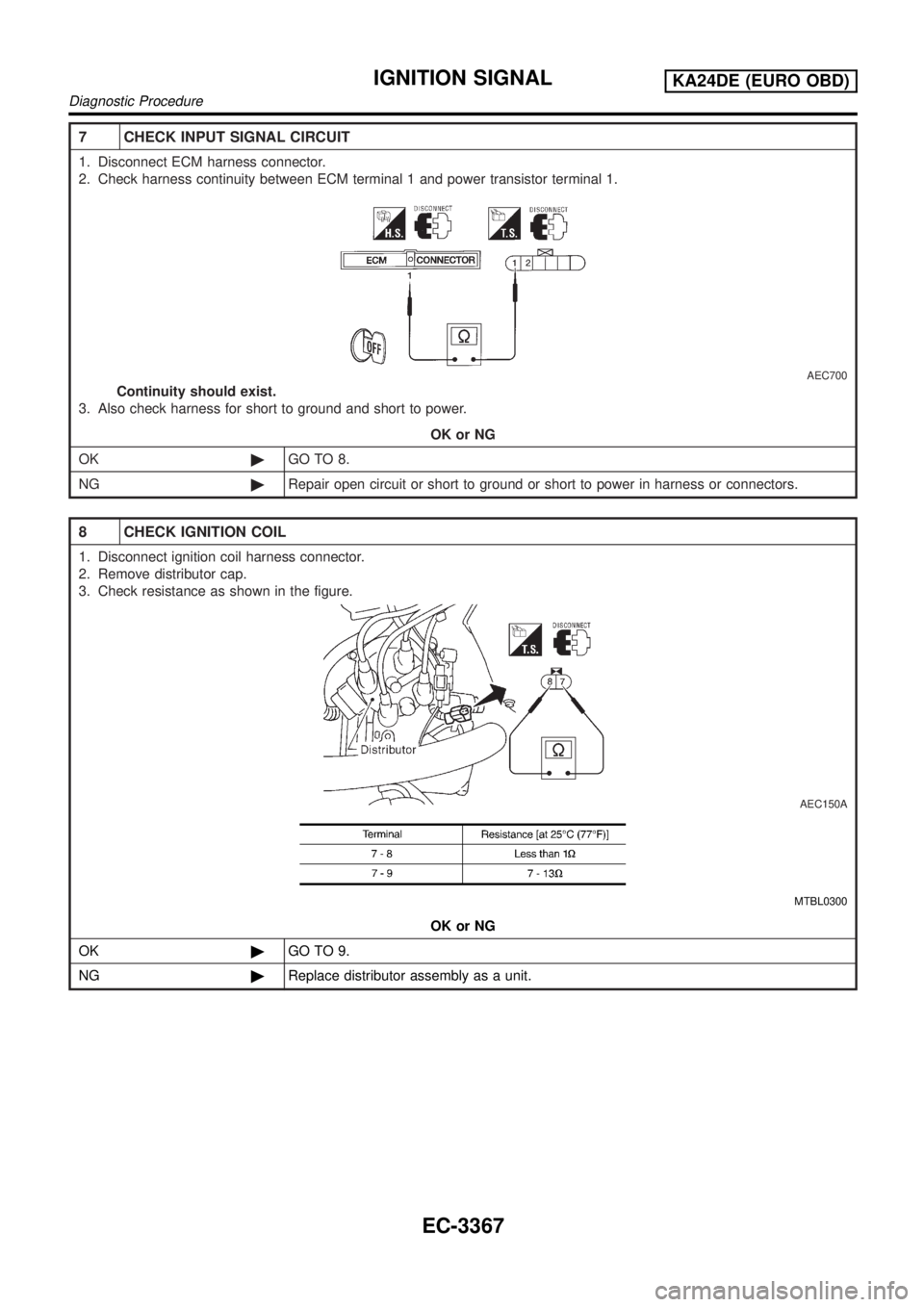

7 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 1 and power transistor terminal 1.

AEC700

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 8.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

8 CHECK IGNITION COIL

1. Disconnect ignition coil harness connector.

2. Remove distributor cap.

3. Check resistance as shown in the figure.

AEC150A

MTBL0300

OK or NG

OK©GO TO 9.

NG©Replace distributor assembly as a unit.

IGNITION SIGNALKA24DE (EURO OBD)

Diagnostic Procedure

EC-3367

Page 393 of 1306

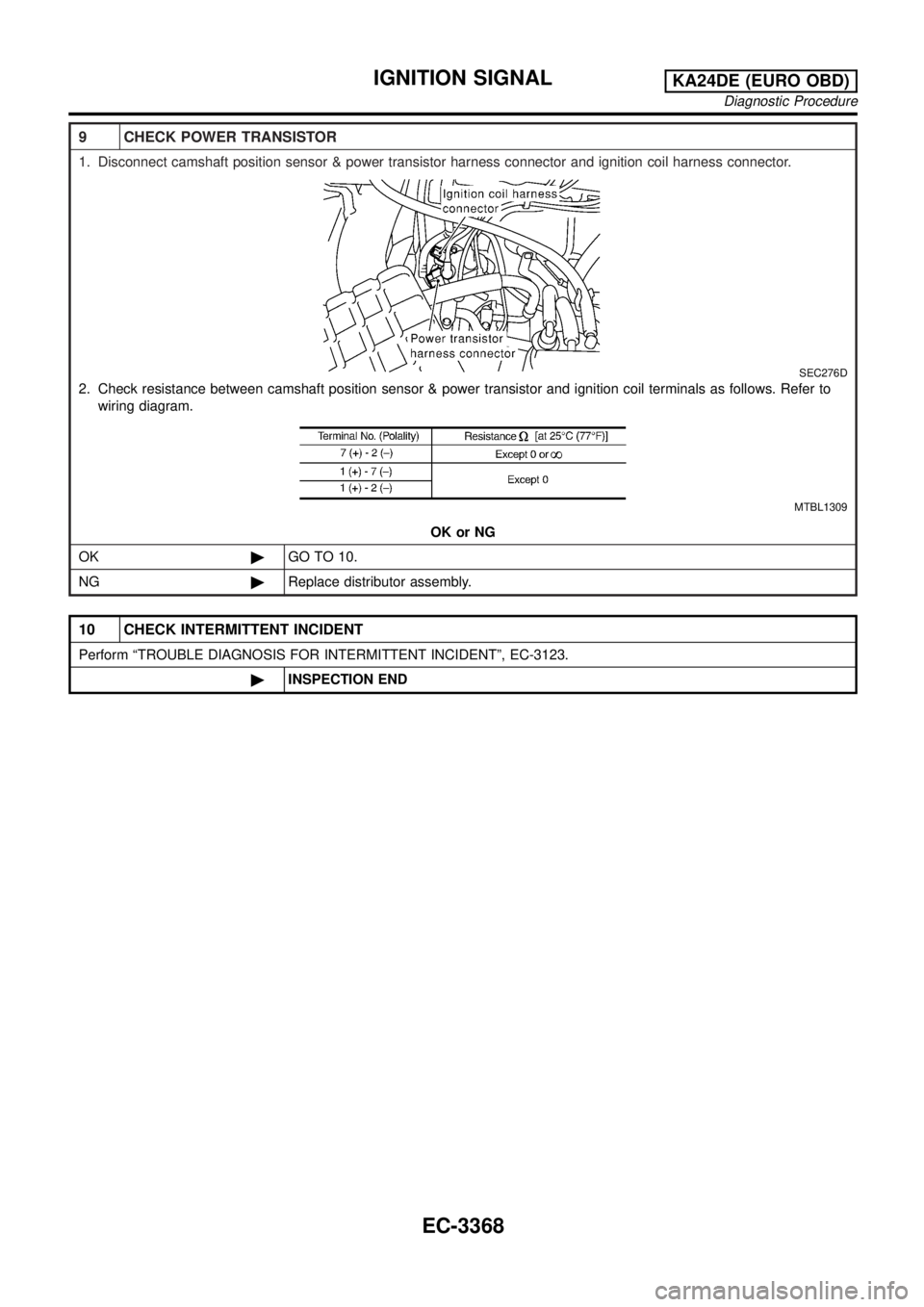

9 CHECK POWER TRANSISTOR

1. Disconnect camshaft position sensor & power transistor harness connector and ignition coil harness connector.

SEC276D

2. Check resistance between camshaft position sensor & power transistor and ignition coil terminals as follows. Refer to

wiring diagram.

MTBL1309

OK or NG

OK©GO TO 10.

NG©Replace distributor assembly.

10 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-3123.

©INSPECTION END

IGNITION SIGNALKA24DE (EURO OBD)

Diagnostic Procedure

EC-3368

Page 394 of 1306

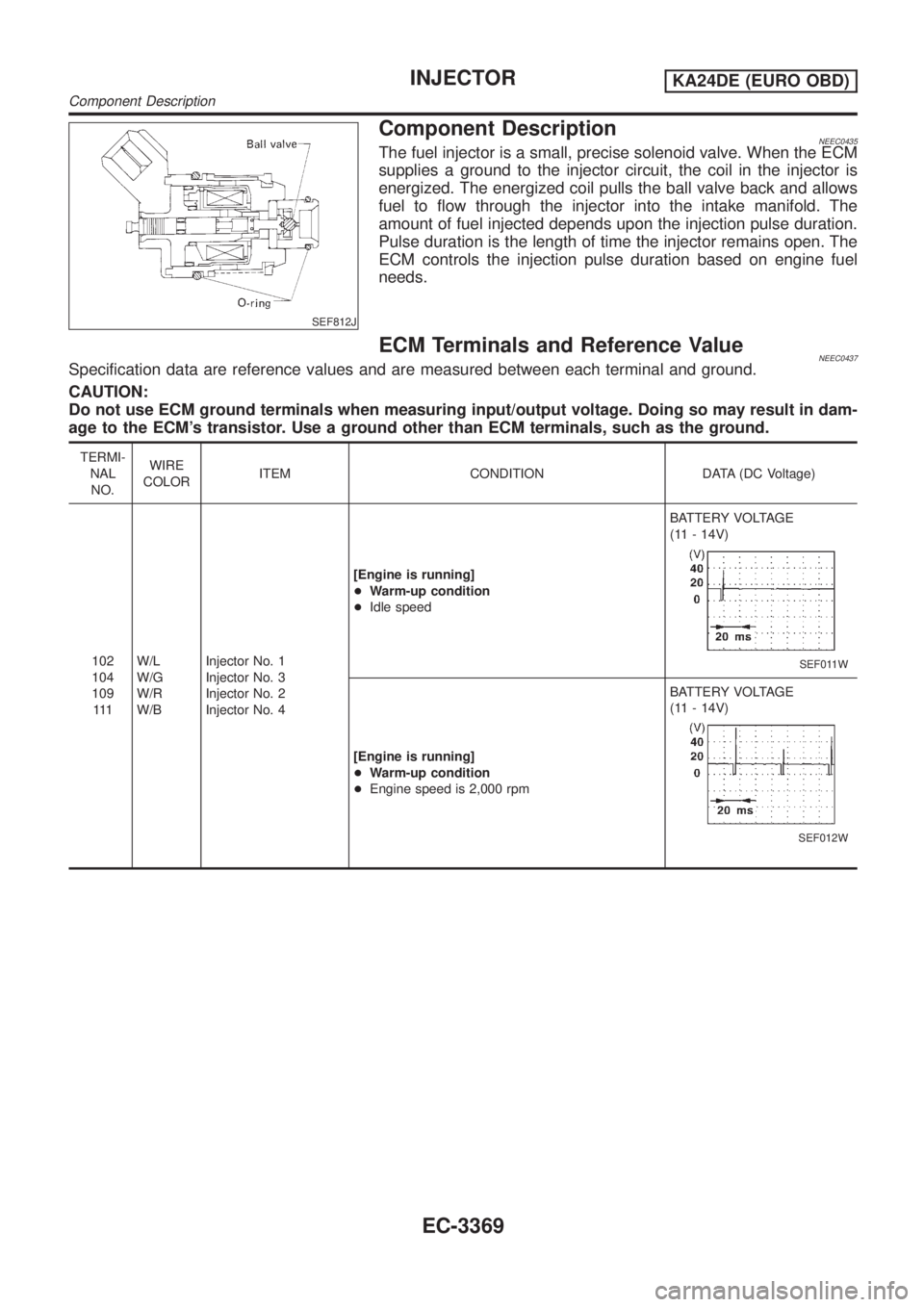

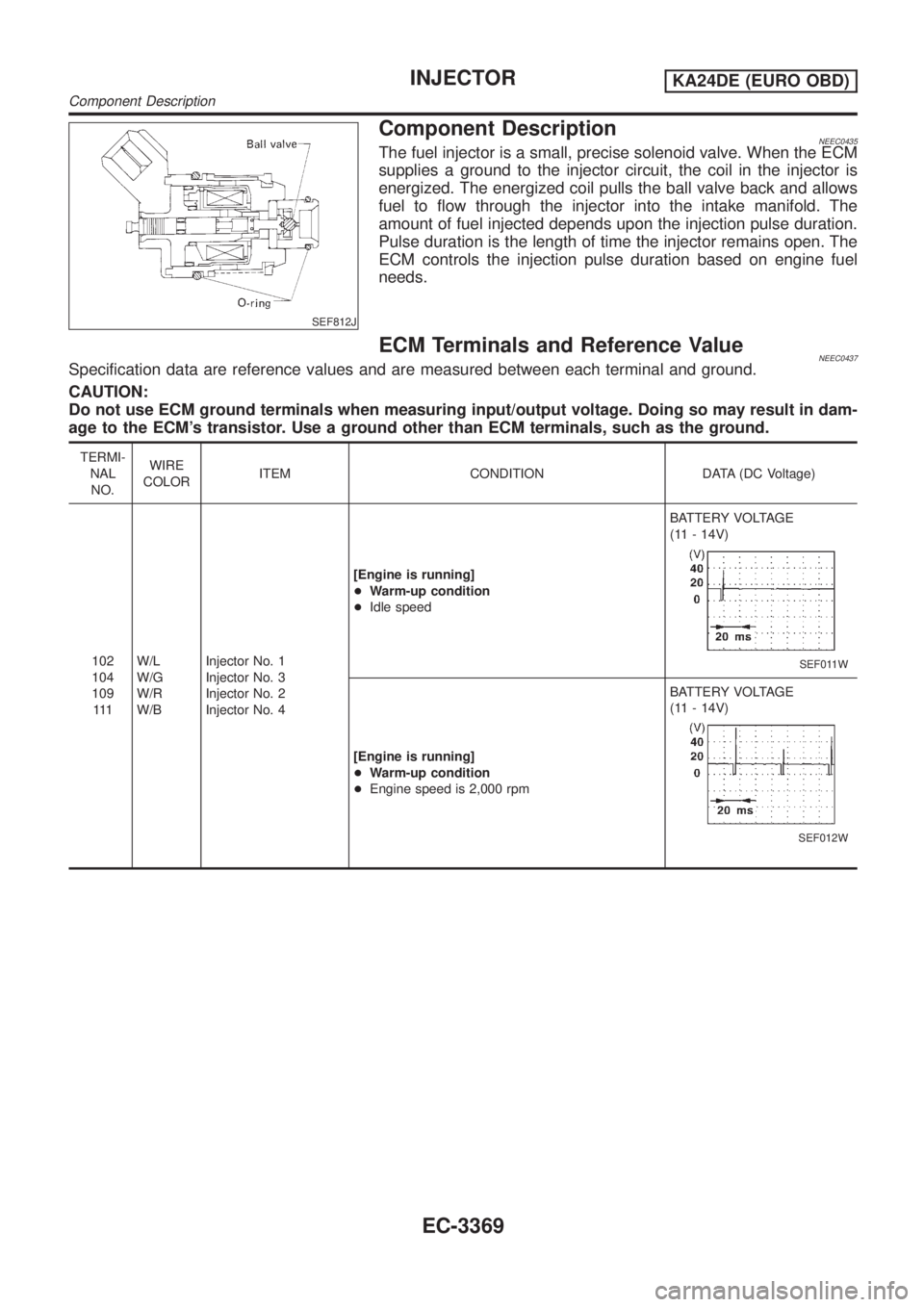

SEF812J

Component DescriptionNEEC0435The fuel injector is a small, precise solenoid valve. When the ECM

supplies a ground to the injector circuit, the coil in the injector is

energized. The energized coil pulls the ball valve back and allows

fuel to flow through the injector into the intake manifold. The

amount of fuel injected depends upon the injection pulse duration.

Pulse duration is the length of time the injector remains open. The

ECM controls the injection pulse duration based on engine fuel

needs.

ECM Terminals and Reference ValueNEEC0437Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

102

104

109

111W/L

W/G

W/R

W/BInjector No. 1

Injector No. 3

Injector No. 2

Injector No. 4[Engine is running]

+Warm-up condition

+Idle speedBATTERY VOLTAGE

(11 - 14V)

SEF011W

[Engine is running]

+Warm-up condition

+Engine speed is 2,000 rpmBATTERY VOLTAGE

(11 - 14V)

SEF012W

INJECTORKA24DE (EURO OBD)

Component Description

EC-3369

Page 395 of 1306

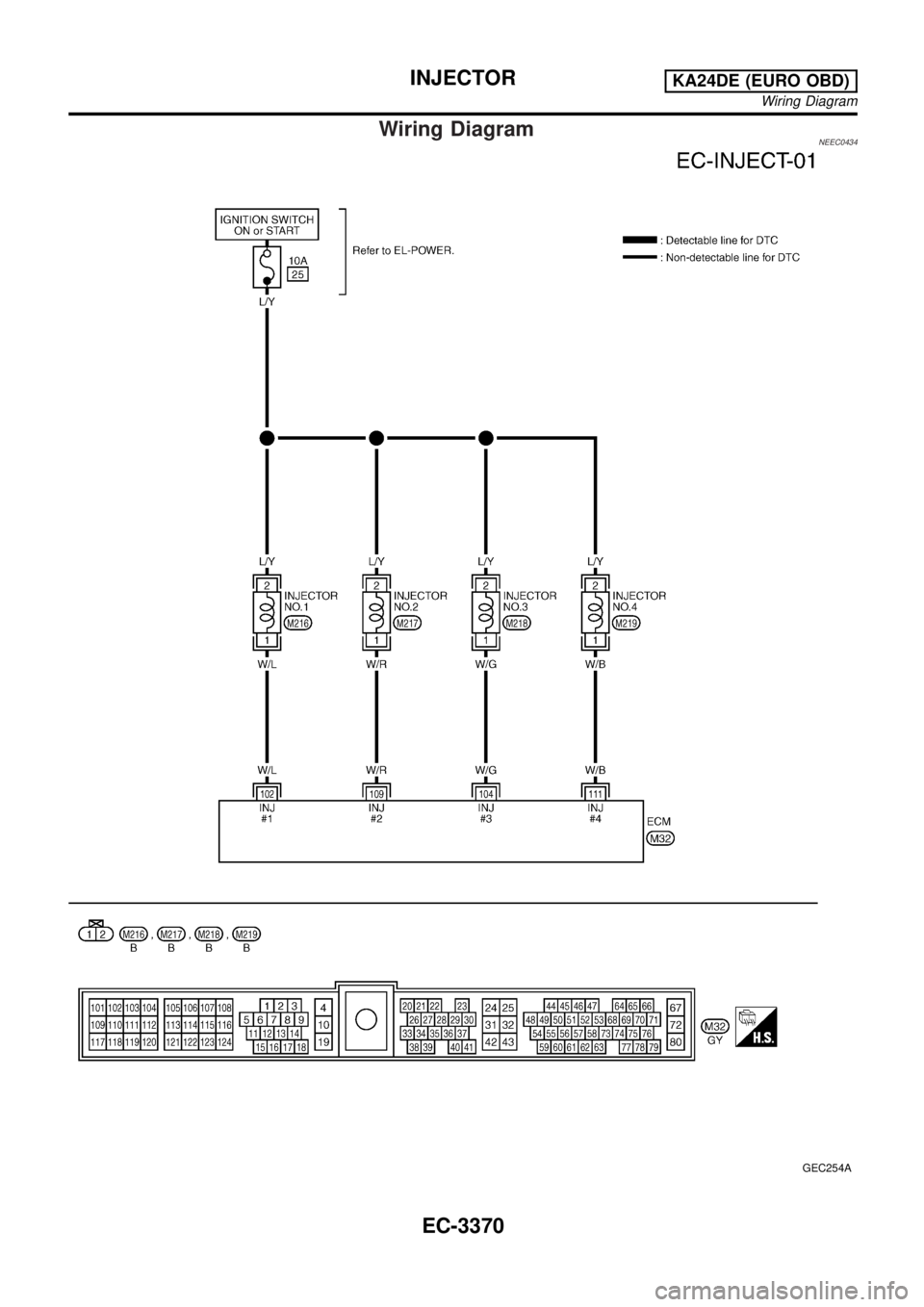

Wiring DiagramNEEC0434

GEC254A

INJECTORKA24DE (EURO OBD)

Wiring Diagram

EC-3370

Page 396 of 1306

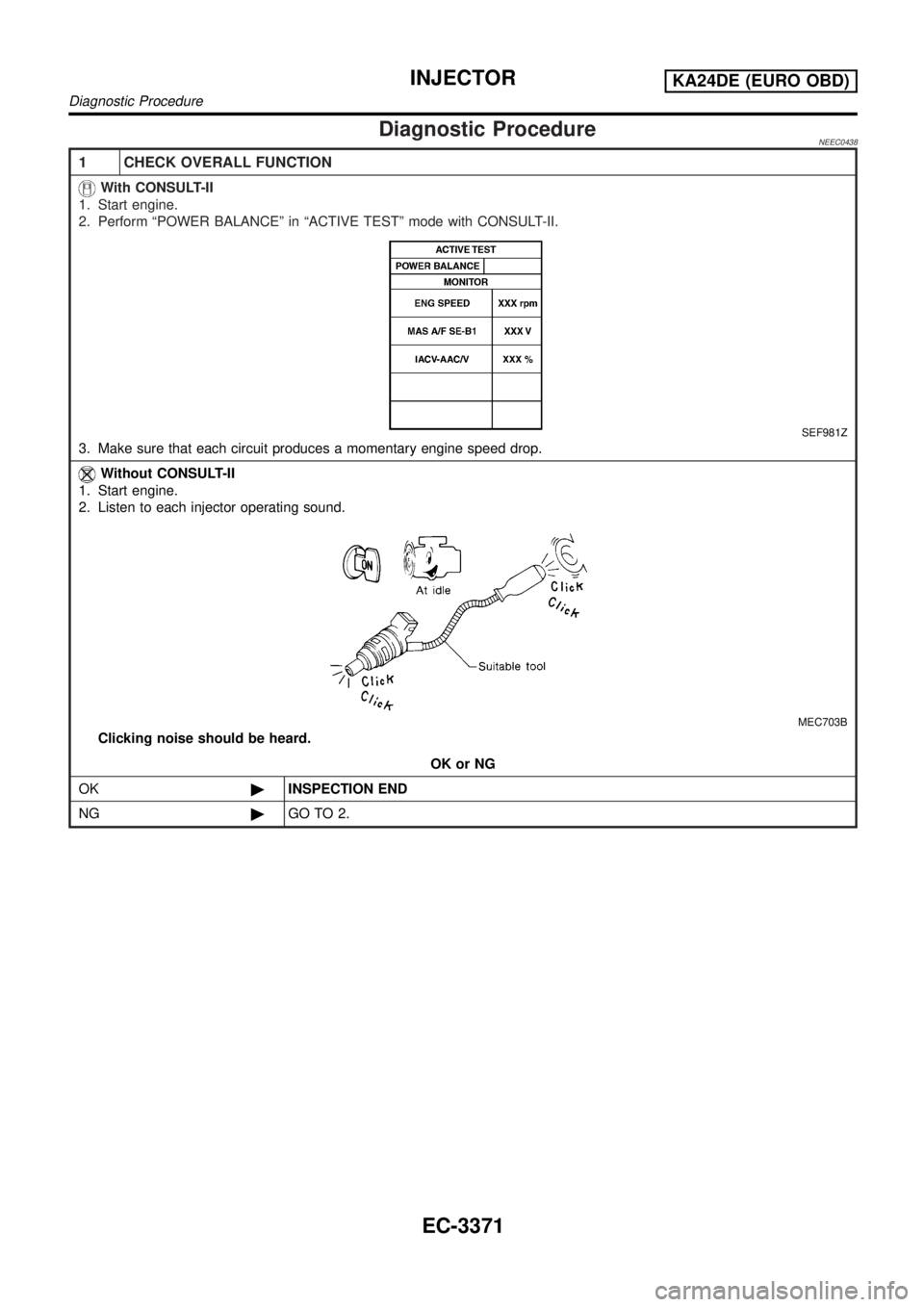

Diagnostic ProcedureNEEC0438

1 CHECK OVERALL FUNCTION

With CONSULT-II

1. Start engine.

2. Perform ªPOWER BALANCEº in ªACTIVE TESTº mode with CONSULT-II.

SEF981Z

3. Make sure that each circuit produces a momentary engine speed drop.

Without CONSULT-II

1. Start engine.

2. Listen to each injector operating sound.

MEC703B

Clicking noise should be heard.

OK or NG

OK©INSPECTION END

NG©GO TO 2.

INJECTORKA24DE (EURO OBD)

Diagnostic Procedure

EC-3371

Page 397 of 1306

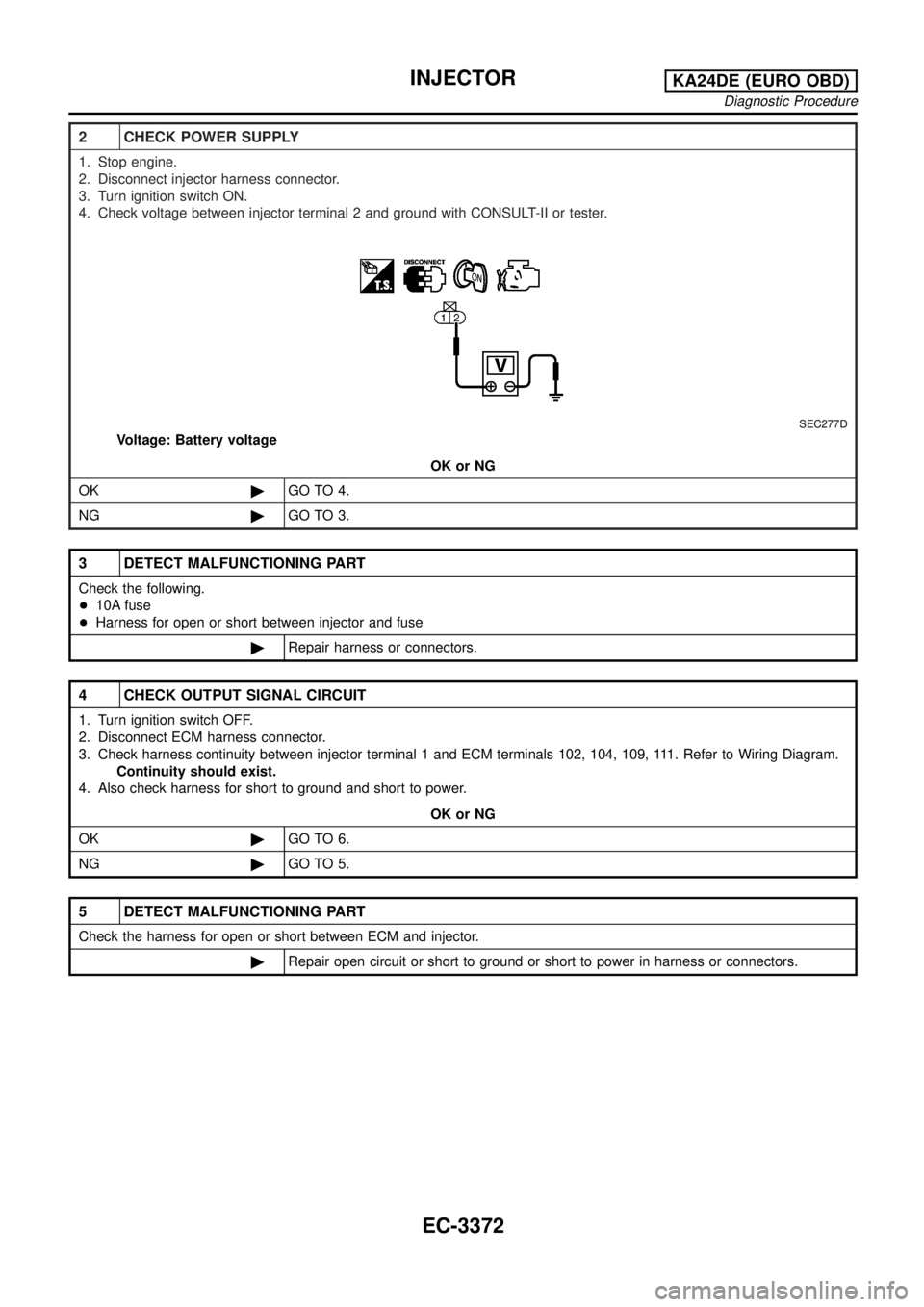

2 CHECK POWER SUPPLY

1. Stop engine.

2. Disconnect injector harness connector.

3. Turn ignition switch ON.

4. Check voltage between injector terminal 2 and ground with CONSULT-II or tester.

SEC277D

Voltage: Battery voltage

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

+10A fuse

+Harness for open or short between injector and fuse

©Repair harness or connectors.

4 CHECK OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between injector terminal 1 and ECM terminals 102, 104, 109, 111. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the harness for open or short between ECM and injector.

©Repair open circuit or short to ground or short to power in harness or connectors.

INJECTORKA24DE (EURO OBD)

Diagnostic Procedure

EC-3372

Page 398 of 1306

6 CHECK INJECTOR

1. Disconnect injector harness connector.

2. Check resistance between terminals as shown in the figure.

SEC278D

Resistance: 7.3 - 9.9W[at 25ÉC (77ÉF)]

OK or NG

OK©GO TO 7.

NG©Replace injector.

7 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-3123.

©INSPECTION END

INJECTORKA24DE (EURO OBD)

Diagnostic Procedure

EC-3373

Page 399 of 1306

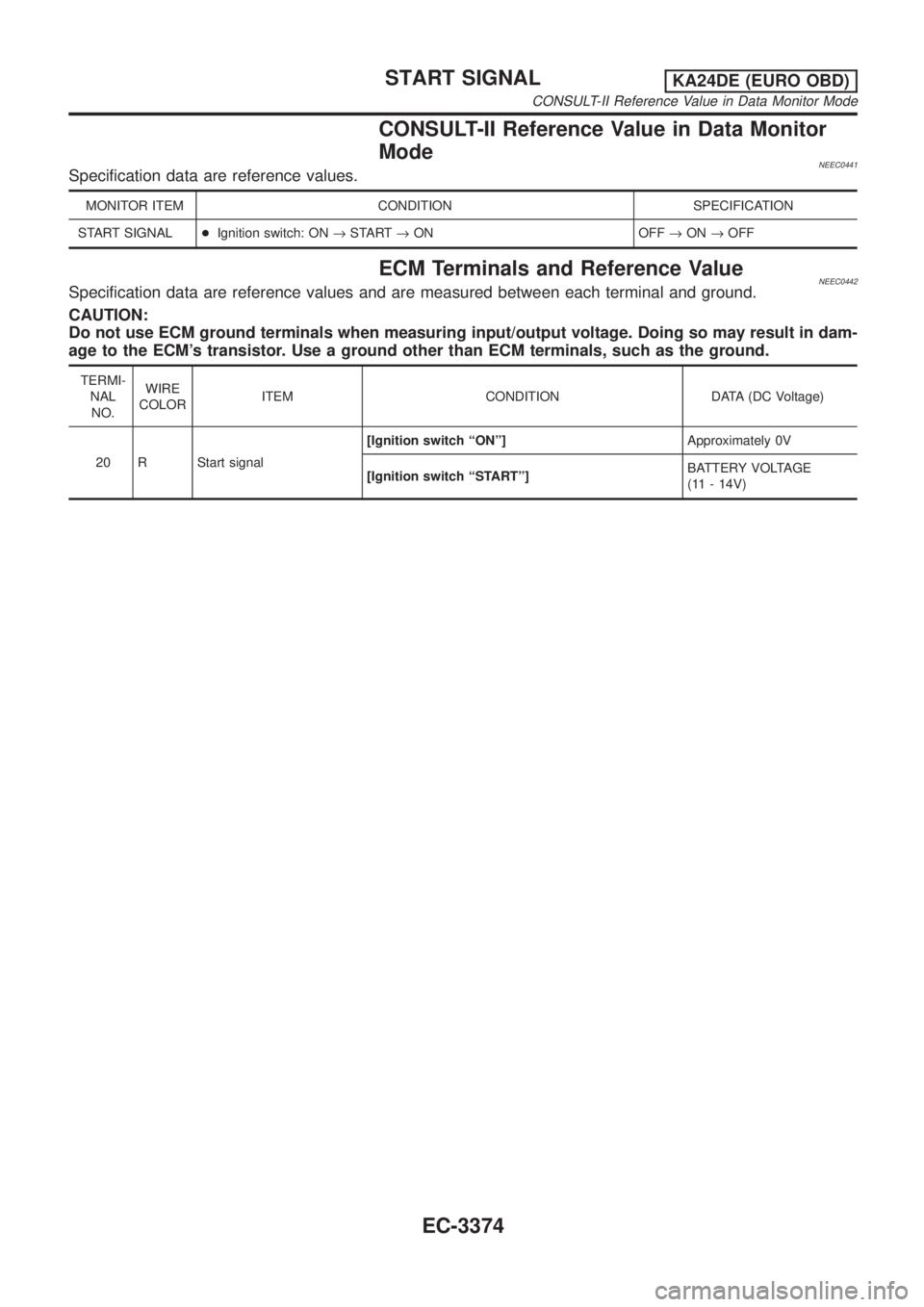

CONSULT-II Reference Value in Data Monitor

Mode

NEEC0441Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

START SIGNAL+Ignition switch: ON®START®ON OFF®ON®OFF

ECM Terminals and Reference ValueNEEC0442Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

20 R Start signal[Ignition switch ªONº]Approximately 0V

[Ignition switch ªSTARTº]BATTERY VOLTAGE

(11 - 14V)

START SIGNALKA24DE (EURO OBD)

CONSULT-II Reference Value in Data Monitor Mode

EC-3374

Page 400 of 1306

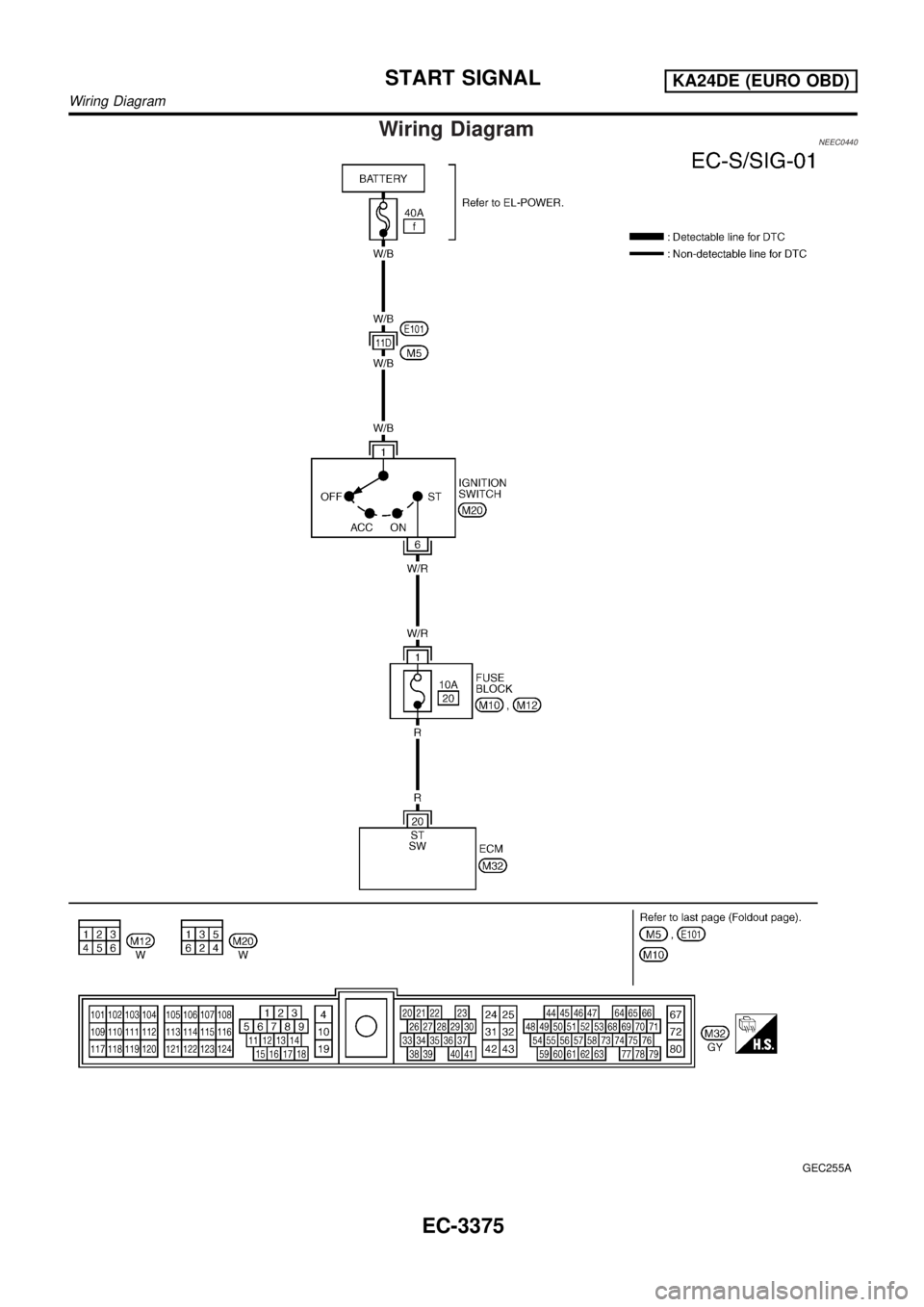

Wiring DiagramNEEC0440

GEC255A

START SIGNALKA24DE (EURO OBD)

Wiring Diagram

EC-3375

Trending: auxiliary battery, service reset, towing, washer fluid, engine oil capacity, keyless entry, service indicator

![NISSAN PICK-UP 2001 Repair Manual 6 CHECK INJECTOR

1. Disconnect injector harness connector.

2. Check resistance between terminals as shown in the figure.

SEC278D

Resistance: 7.3 - 9.9W[at 25ÉC (77ÉF)]

OK or NG

OK©GO TO 7.

NG©Repl NISSAN PICK-UP 2001 Repair Manual 6 CHECK INJECTOR

1. Disconnect injector harness connector.

2. Check resistance between terminals as shown in the figure.

SEC278D

Resistance: 7.3 - 9.9W[at 25ÉC (77ÉF)]

OK or NG

OK©GO TO 7.

NG©Repl](/img/5/57372/w960_57372-397.png)