NISSAN PICK-UP 2001 Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 901 of 1306

![NISSAN PICK-UP 2001 Repair Manual 3. Using a hexagon-head wrench [face to face: 6 mm (0.24 in),

SST], install timing chain slack guide.

4. Install chain tensioner.

a. Push the plunger of the chain tensioner. While holding it with

a pu NISSAN PICK-UP 2001 Repair Manual 3. Using a hexagon-head wrench [face to face: 6 mm (0.24 in),

SST], install timing chain slack guide.

4. Install chain tensioner.

a. Push the plunger of the chain tensioner. While holding it with

a pu](/img/5/57372/w960_57372-900.png)

3. Using a hexagon-head wrench [face to face: 6 mm (0.24 in),

SST], install timing chain slack guide.

4. Install chain tensioner.

a. Push the plunger of the chain tensioner. While holding it with

a push pin, install the chain tensioner.

b. Using a hexagon-head wrench [face to face: 5 mm (0.20 in),

SST], tighten bolts.

c. Pull out the push pin, etc. holding the plunger.

+Check again that the alignment marks on the sprockets

and the colored alignment marks on the timing chain are

aligned.

5. Install front chain case.

a. Install tension guide on the back surface of front chain case.

+Hold front chain case vertically when installing. Tension

guide may come off if front chain case is tilted.

b. Apply specified liquid gasket (Refer to EM-3003, ªLiquid Gas-

ket

Application Procedureº.) on both ends of arched area (loca-

tions where rear chain case is adjoined) as shown in the fig-

ure.

c. Install new chain case gasket to chain case groove.

d. Install front chain case.

+When installing, align dowel pin on oil pump case with the pin

hole.

+Install all bolts with the rubber washer to the front chain case.

e. Tighten fixing bolts in the numerical order shown in the fig-

ure.

f. After tightening all the bolts, re-tighten in the No. 1, 2, and 6

bolts.

SBIA0228E

SBIA0227E

SBIA0189E

JEM129G

JEM121G

TIMING CHAINYD25DDTi

Secondary Timing Chain (Cont'd)

EM-3024

Page 902 of 1306

6. Hereafter, install in the reverse order of removal.

TIMING CHAINYD25DDTi

Secondary Timing Chain (Cont'd)

EM-3025

Page 903 of 1306

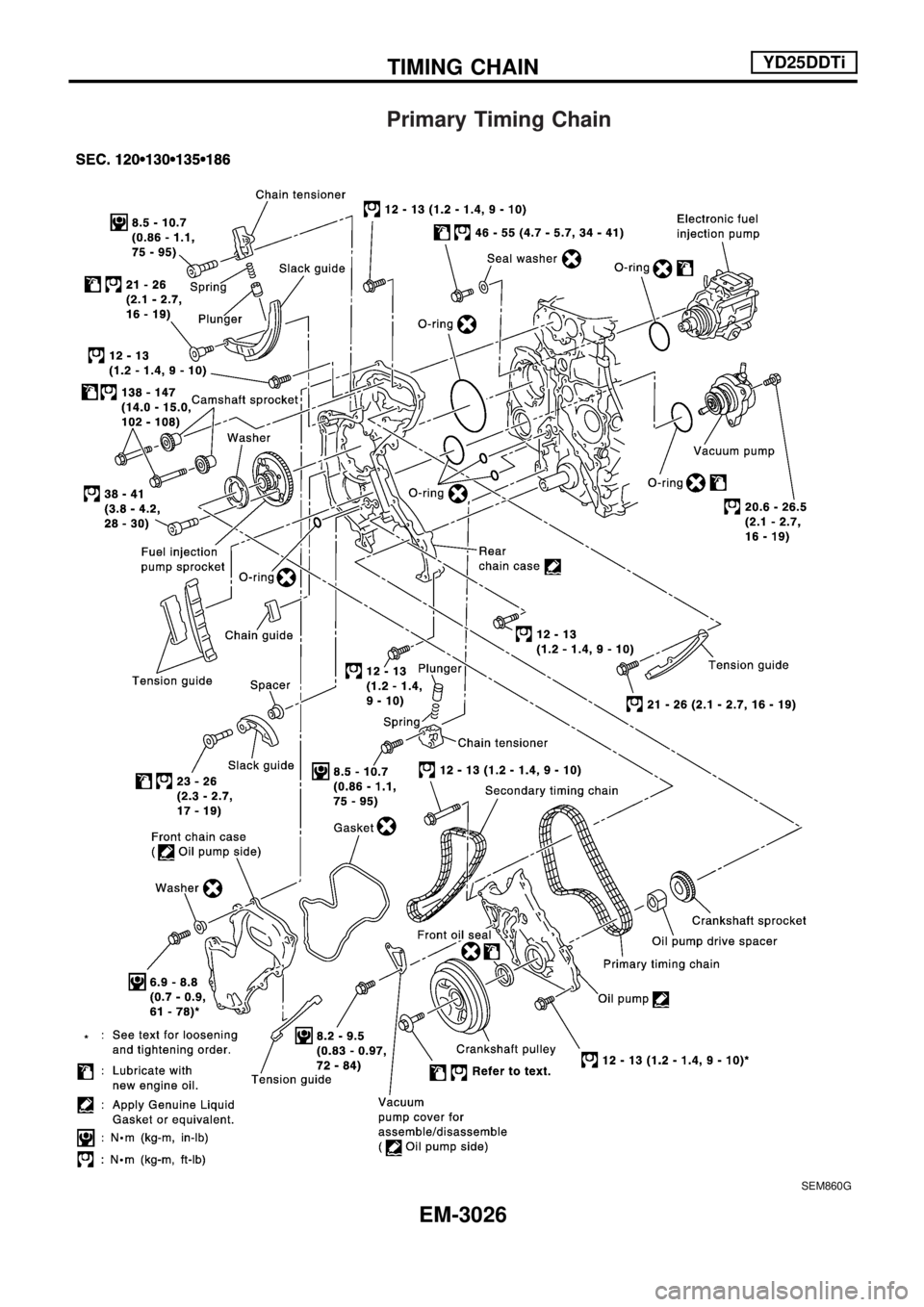

Primary Timing Chain

SEM860G

TIMING CHAINYD25DDTi

EM-3026

Page 904 of 1306

CAUTION:

+After removing timing chain, do not turn crankshaft and

camshaft separately, or valves will strike piston heads.

+When installing camshafts, chain tensioners, oil seals,

or other sliding parts, lubricate contacting surfaces with

new engine oil.

+Apply new engine oil to bolt threads and seat surfaces

when installing camshaft sprockets, crankshaft pulley,

and camshaft brackets.

+Do not spill engine coolant on drive belts.

REMOVAL

1. Remove charge air cooler and bracket.

2. Remove rocker cover. Refer to EM-3045, ªRemoval and

Installationº, ªROCKER COVERº.

3. Remove EGR guide tube.

4. Remove radiator shroud and radiator. Refer to LC section,

ªREMOVAL AND INSTALLATIONº, ªRadiatorº.

5. Remove idler pulley, idler pulley bracket and drive belts.

6. Remove upper and lower oil pans. Refer to EM-3015,

ªRemoval

and Installationº, ªOIL PANº.

7. Remove injection tube.

Refer to EC section, ªInjection Tube and Injection Nozzleº.

8. Remove secondary timing chain and associated parts.

Refer to EM-3021, ªSecondary Timing Chainº.

9. When removing rear chain case, remove camshaft sprock-

ets.

Refer to EM-3047, ªCAMSHAFTº.

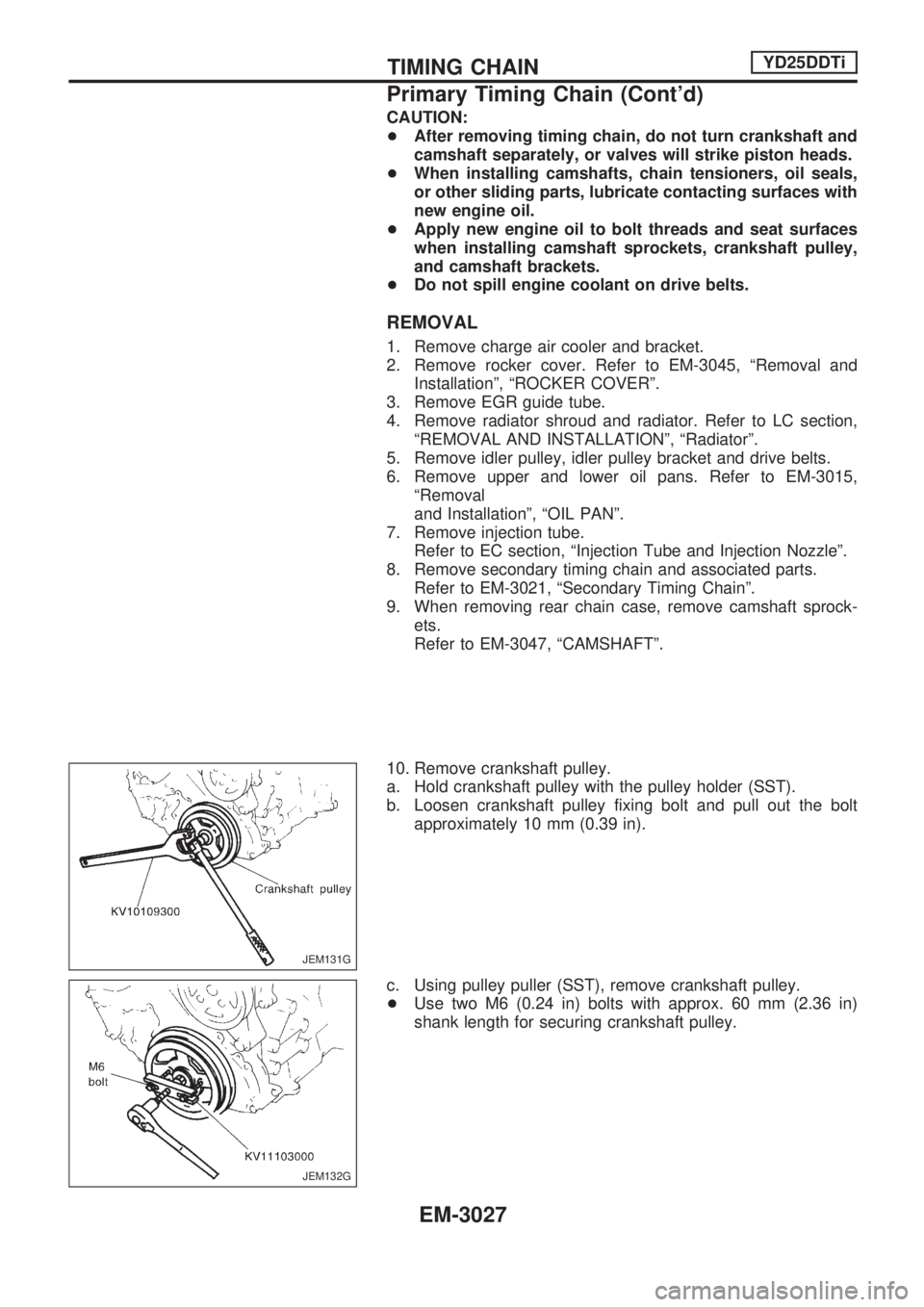

10. Remove crankshaft pulley.

a. Hold crankshaft pulley with the pulley holder (SST).

b. Loosen crankshaft pulley fixing bolt and pull out the bolt

approximately 10 mm (0.39 in).

c. Using pulley puller (SST), remove crankshaft pulley.

+Use two M6 (0.24 in) bolts with approx. 60 mm (2.36 in)

shank length for securing crankshaft pulley.

JEM131G

JEM132G

TIMING CHAINYD25DDTi

Primary Timing Chain (Cont'd)

EM-3027

Page 905 of 1306

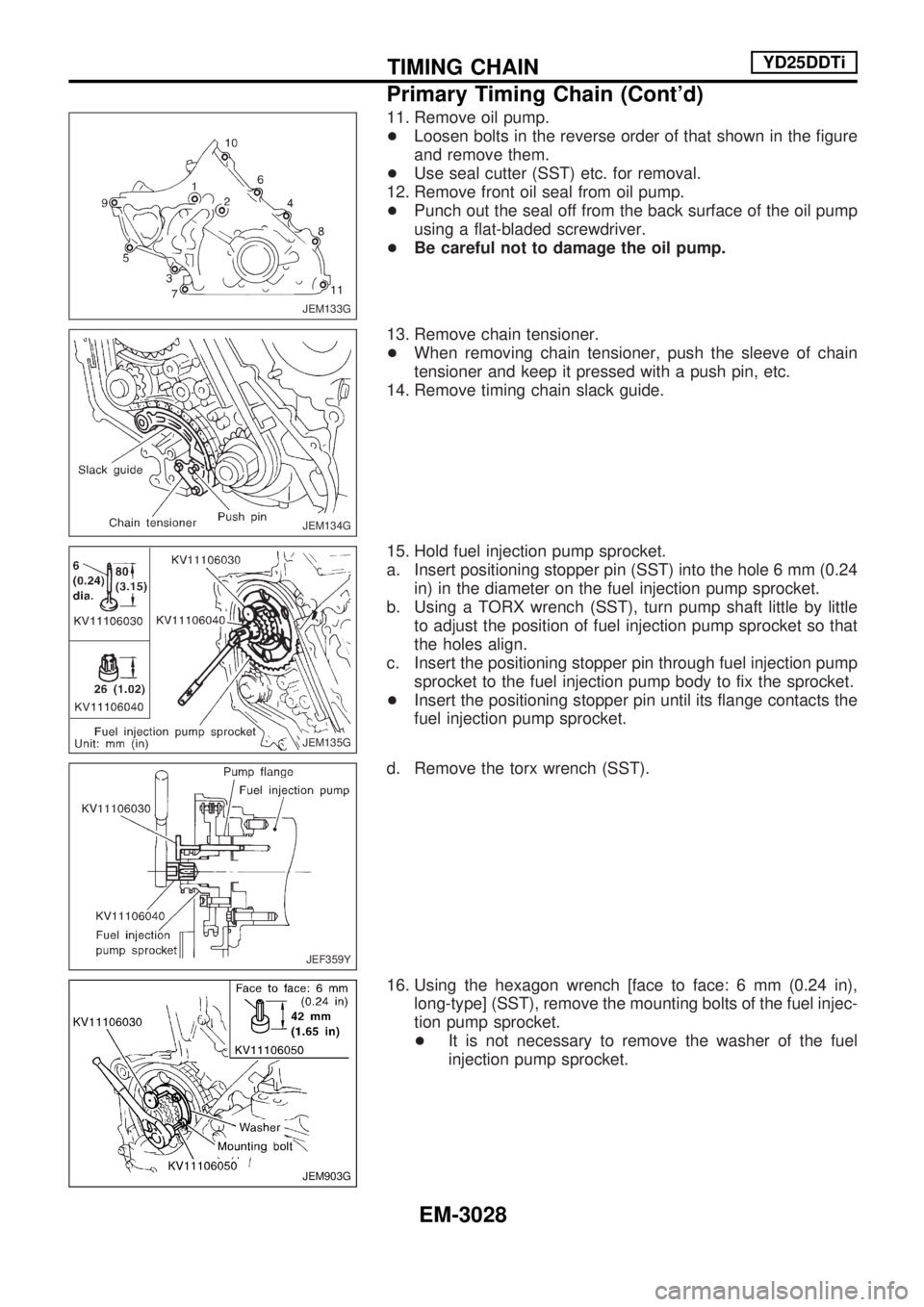

11. Remove oil pump.

+Loosen bolts in the reverse order of that shown in the figure

and remove them.

+Use seal cutter (SST) etc. for removal.

12. Remove front oil seal from oil pump.

+Punch out the seal off from the back surface of the oil pump

using a flat-bladed screwdriver.

+Be careful not to damage the oil pump.

13. Remove chain tensioner.

+When removing chain tensioner, push the sleeve of chain

tensioner and keep it pressed with a push pin, etc.

14. Remove timing chain slack guide.

15. Hold fuel injection pump sprocket.

a. Insert positioning stopper pin (SST) into the hole 6 mm (0.24

in) in the diameter on the fuel injection pump sprocket.

b. Using a TORX wrench (SST), turn pump shaft little by little

to adjust the position of fuel injection pump sprocket so that

the holes align.

c. Insert the positioning stopper pin through fuel injection pump

sprocket to the fuel injection pump body to fix the sprocket.

+Insert the positioning stopper pin until its flange contacts the

fuel injection pump sprocket.

d. Remove the torx wrench (SST).

16. Using the hexagon wrench [face to face: 6 mm (0.24 in),

long-type] (SST), remove the mounting bolts of the fuel injec-

tion pump sprocket.

+It is not necessary to remove the washer of the fuel

injection pump sprocket.

JEM133G

JEM134G

JEM135G

JEF359Y

JEM903G

TIMING CHAINYD25DDTi

Primary Timing Chain (Cont'd)

EM-3028

Page 906 of 1306

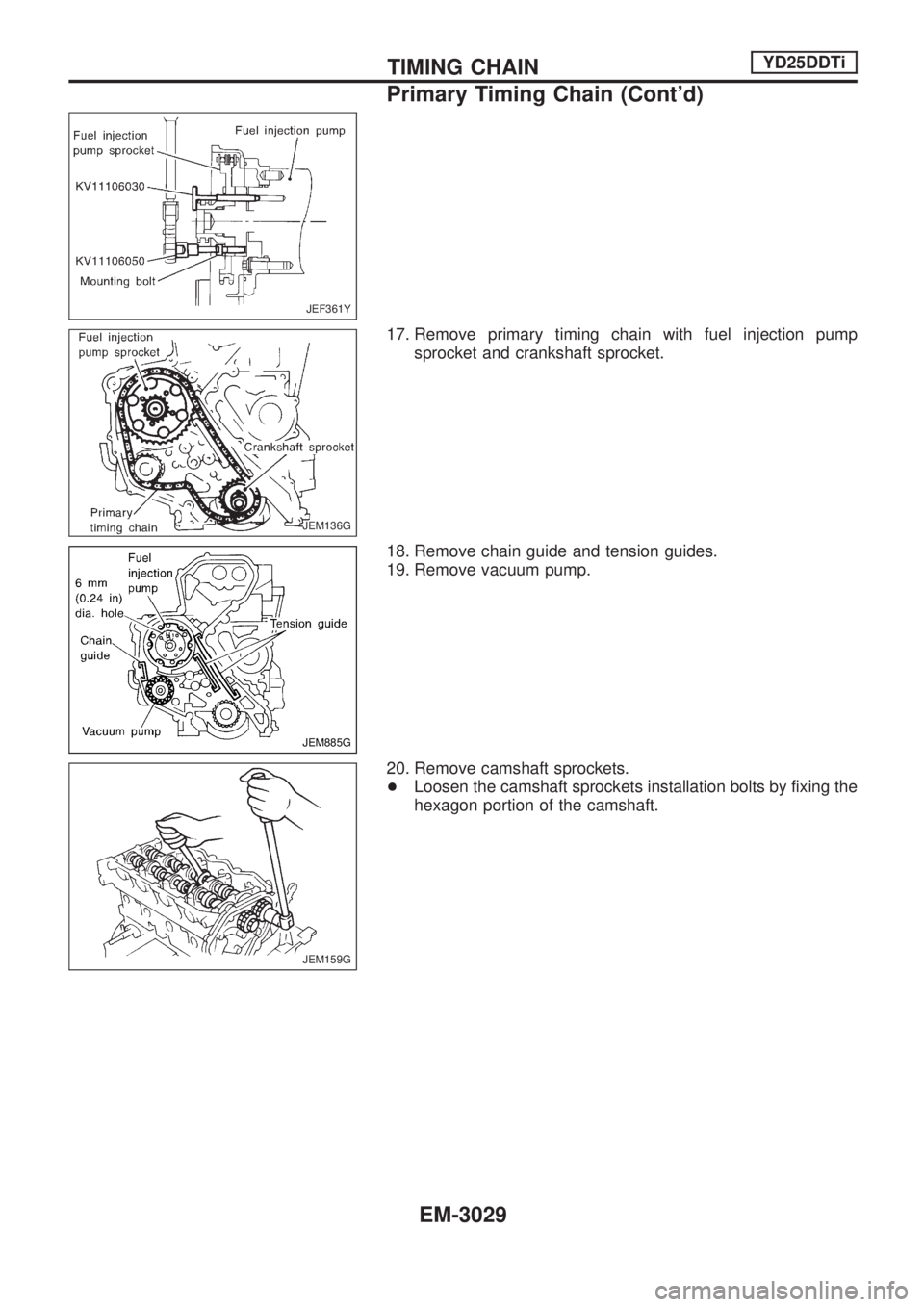

17. Remove primary timing chain with fuel injection pump

sprocket and crankshaft sprocket.

18. Remove chain guide and tension guides.

19. Remove vacuum pump.

20. Remove camshaft sprockets.

+Loosen the camshaft sprockets installation bolts by fixing the

hexagon portion of the camshaft.

JEF361Y

JEM136G

JEM885G

JEM159G

TIMING CHAINYD25DDTi

Primary Timing Chain (Cont'd)

EM-3029

Page 907 of 1306

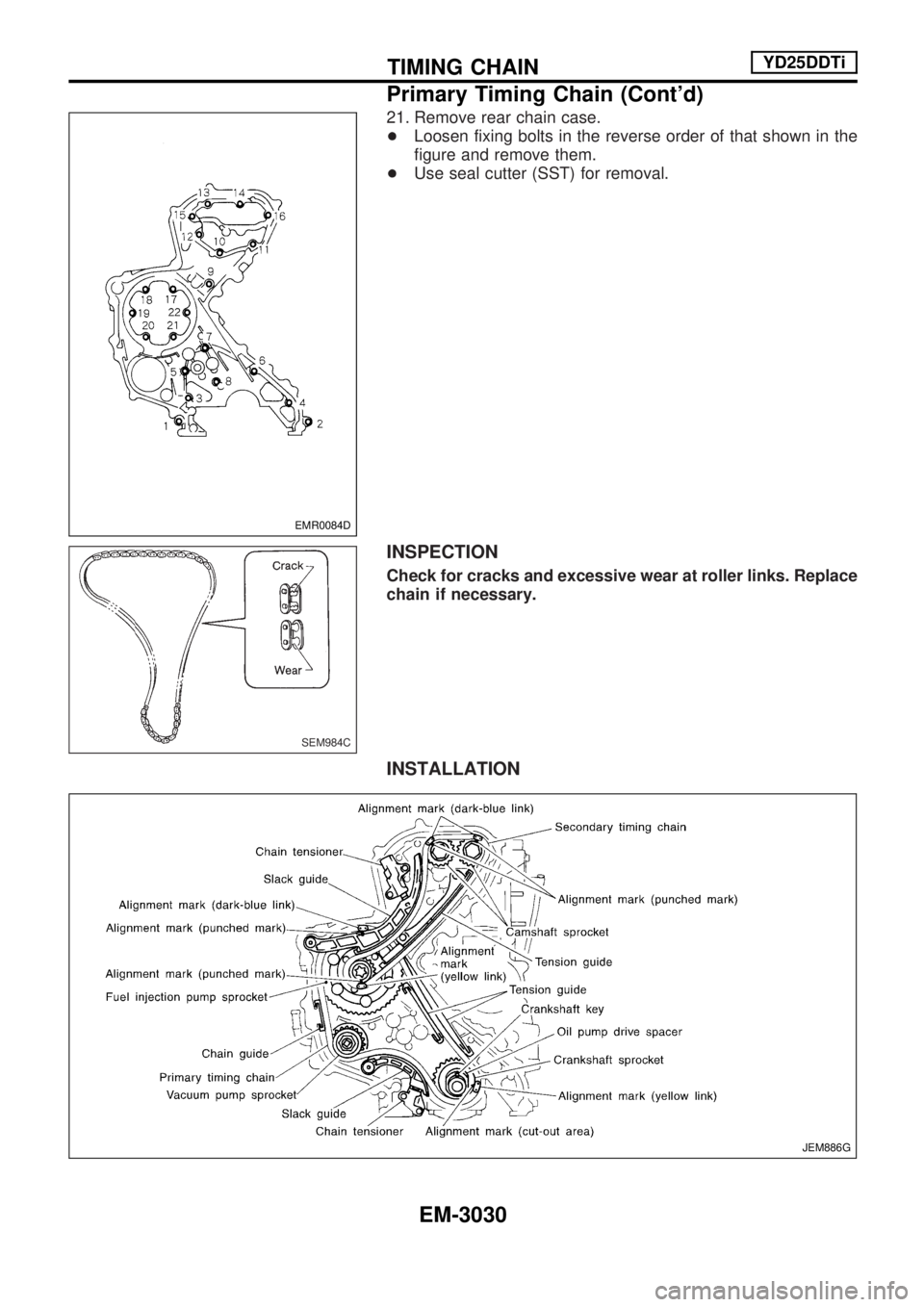

21. Remove rear chain case.

+Loosen fixing bolts in the reverse order of that shown in the

figure and remove them.

+Use seal cutter (SST) for removal.

INSPECTION

Check for cracks and excessive wear at roller links. Replace

chain if necessary.

INSTALLATION

EMR0084D

SEM984C

JEM886G

TIMING CHAINYD25DDTi

Primary Timing Chain (Cont'd)

EM-3030

Page 908 of 1306

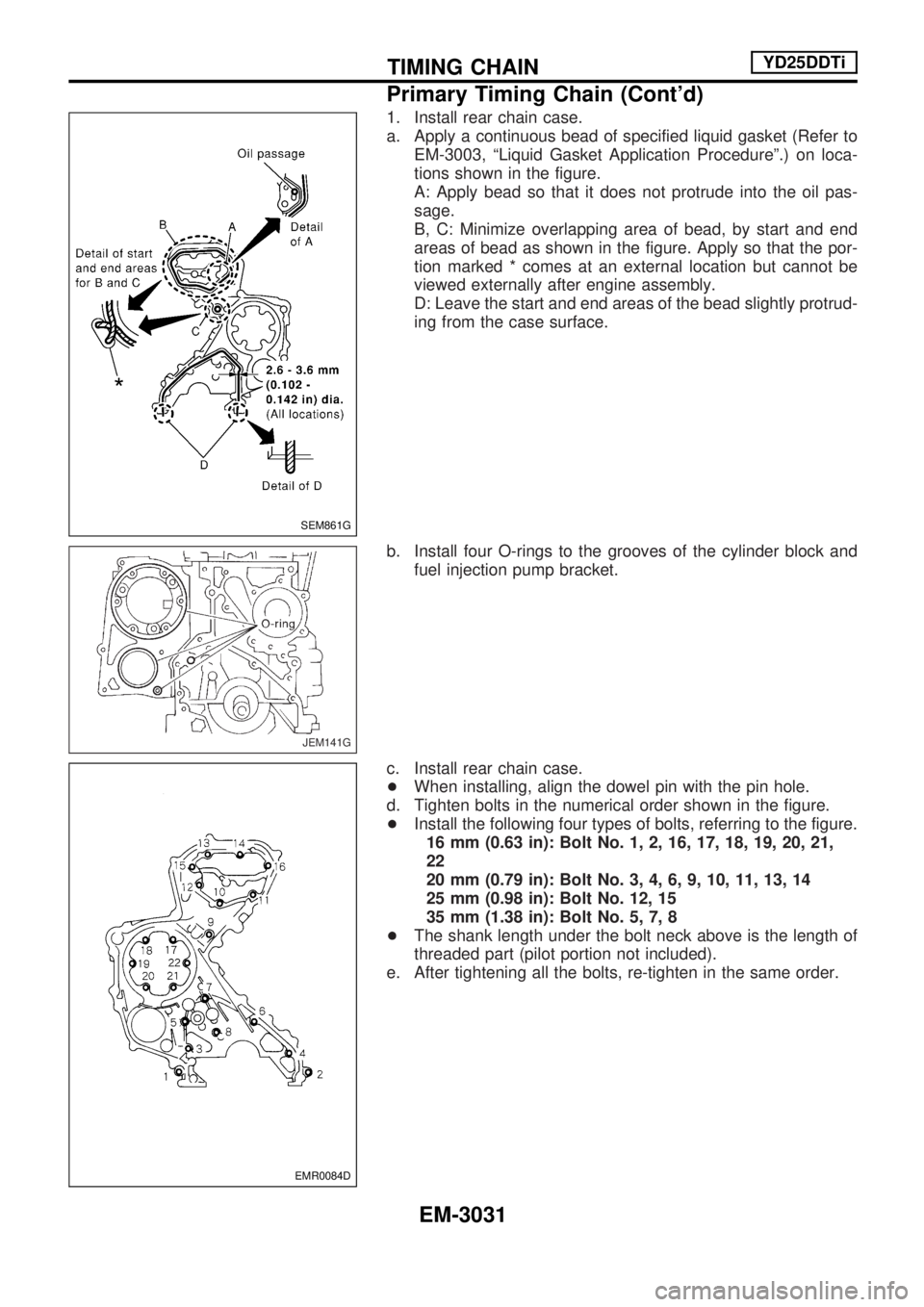

1. Install rear chain case.

a. Apply a continuous bead of specified liquid gasket (Refer to

EM-3003, ªLiquid Gasket Application Procedureº.) on loca-

tions shown in the figure.

A: Apply bead so that it does not protrude into the oil pas-

sage.

B, C: Minimize overlapping area of bead, by start and end

areas of bead as shown in the figure. Apply so that the por-

tion marked * comes at an external location but cannot be

viewed externally after engine assembly.

D: Leave the start and end areas of the bead slightly protrud-

ing from the case surface.

b. Install four O-rings to the grooves of the cylinder block and

fuel injection pump bracket.

c. Install rear chain case.

+When installing, align the dowel pin with the pin hole.

d. Tighten bolts in the numerical order shown in the figure.

+Install the following four types of bolts, referring to the figure.

16 mm (0.63 in): Bolt No. 1, 2, 16, 17, 18, 19, 20, 21,

22

20 mm (0.79 in): Bolt No. 3, 4, 6, 9, 10, 11, 13, 14

25 mm (0.98 in): Bolt No. 12, 15

35 mm (1.38 in): Bolt No. 5, 7, 8

+The shank length under the bolt neck above is the length of

threaded part (pilot portion not included).

e. After tightening all the bolts, re-tighten in the same order.

SEM861G

JEM141G

EMR0084D

TIMING CHAINYD25DDTi

Primary Timing Chain (Cont'd)

EM-3031

Page 909 of 1306

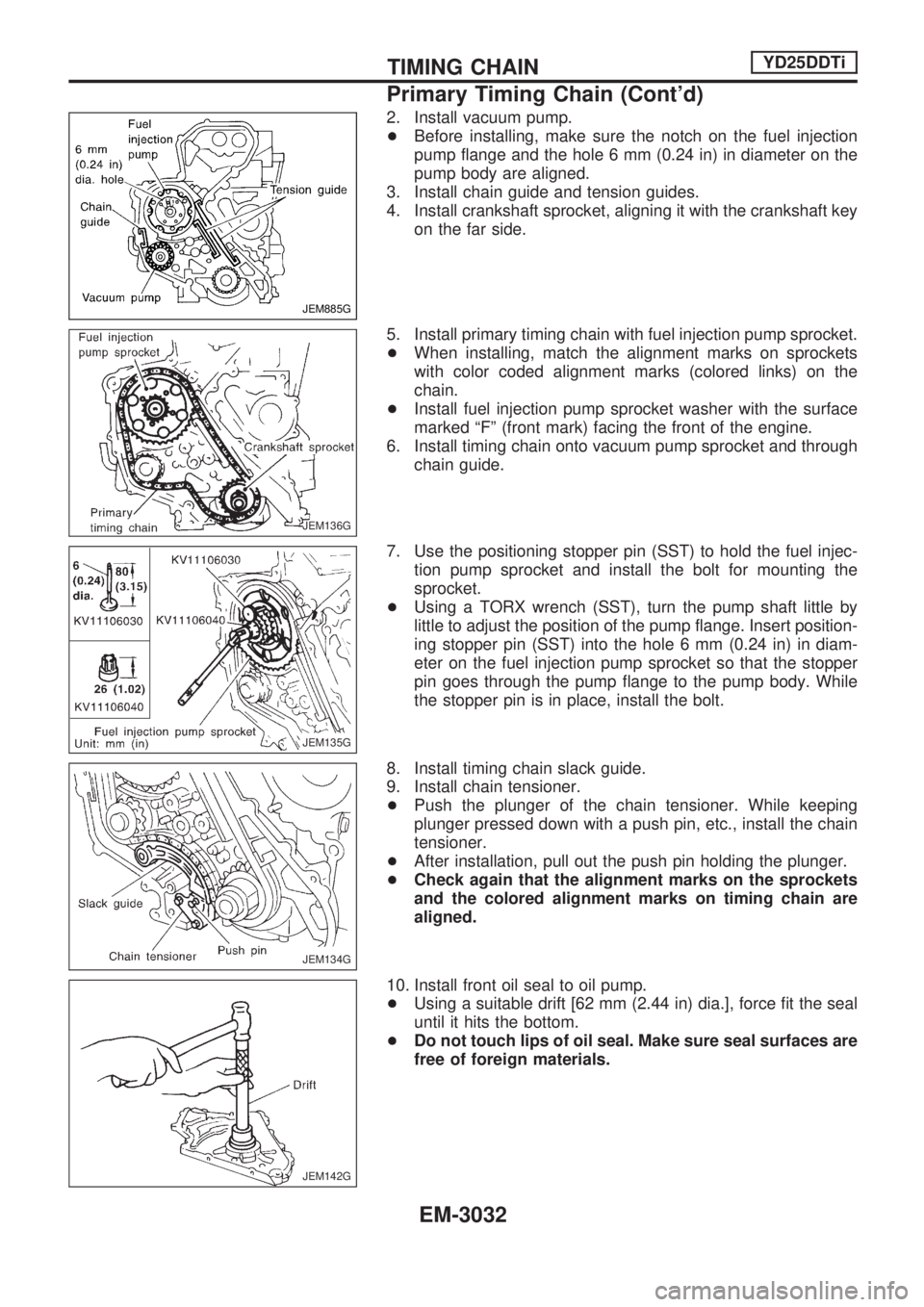

2. Install vacuum pump.

+Before installing, make sure the notch on the fuel injection

pump flange and the hole 6 mm (0.24 in) in diameter on the

pump body are aligned.

3. Install chain guide and tension guides.

4. Install crankshaft sprocket, aligning it with the crankshaft key

on the far side.

5. Install primary timing chain with fuel injection pump sprocket.

+When installing, match the alignment marks on sprockets

with color coded alignment marks (colored links) on the

chain.

+Install fuel injection pump sprocket washer with the surface

marked ªFº (front mark) facing the front of the engine.

6. Install timing chain onto vacuum pump sprocket and through

chain guide.

7. Use the positioning stopper pin (SST) to hold the fuel injec-

tion pump sprocket and install the bolt for mounting the

sprocket.

+Using a TORX wrench (SST), turn the pump shaft little by

little to adjust the position of the pump flange. Insert position-

ing stopper pin (SST) into the hole 6 mm (0.24 in) in diam-

eter on the fuel injection pump sprocket so that the stopper

pin goes through the pump flange to the pump body. While

the stopper pin is in place, install the bolt.

8. Install timing chain slack guide.

9. Install chain tensioner.

+Push the plunger of the chain tensioner. While keeping

plunger pressed down with a push pin, etc., install the chain

tensioner.

+After installation, pull out the push pin holding the plunger.

+Check again that the alignment marks on the sprockets

and the colored alignment marks on timing chain are

aligned.

10. Install front oil seal to oil pump.

+Using a suitable drift [62 mm (2.44 in) dia.], force fit the seal

until it hits the bottom.

+Do not touch lips of oil seal. Make sure seal surfaces are

free of foreign materials.

JEM885G

JEM136G

JEM135G

JEM134G

JEM142G

TIMING CHAINYD25DDTi

Primary Timing Chain (Cont'd)

EM-3032

Page 910 of 1306

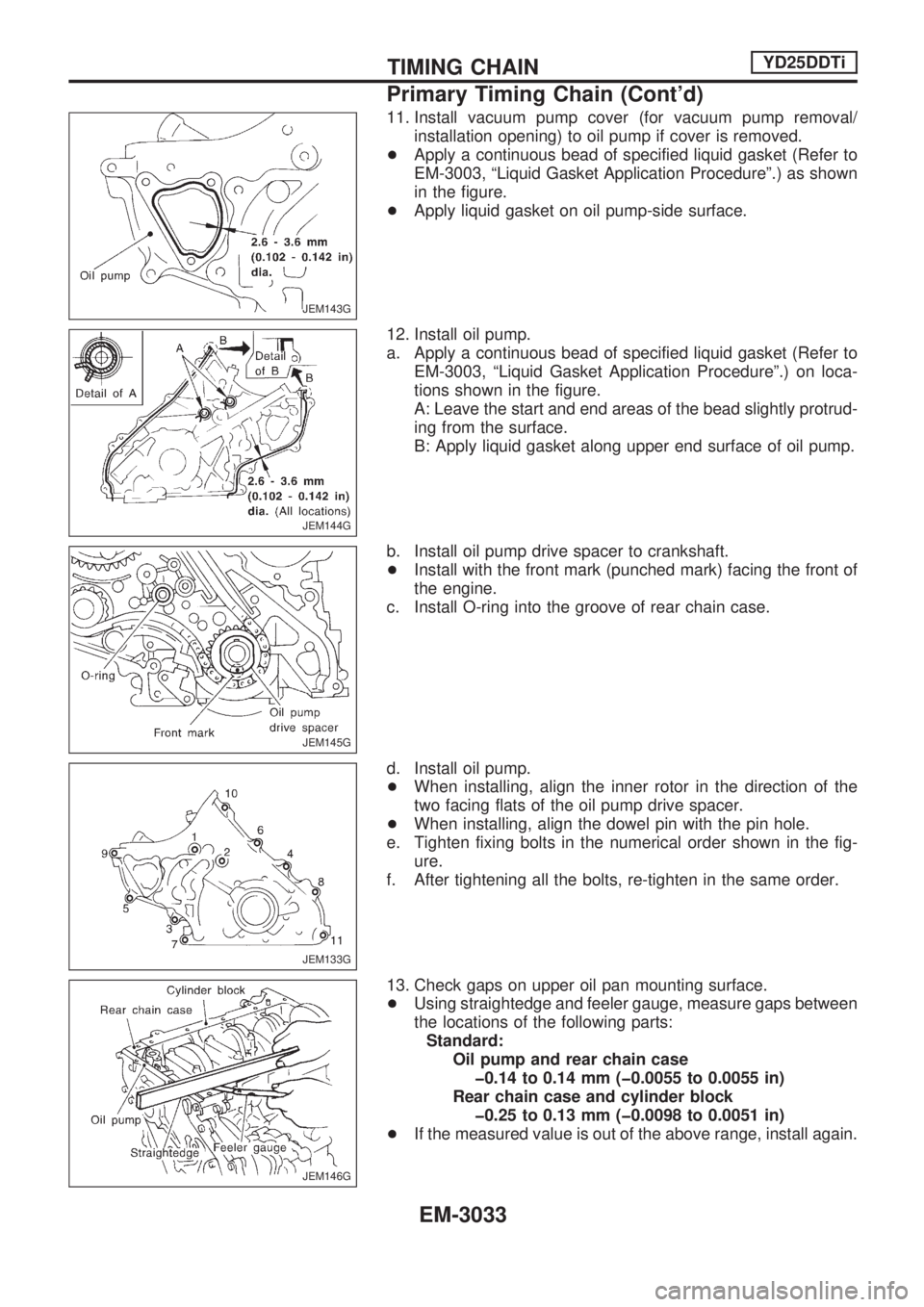

11. Install vacuum pump cover (for vacuum pump removal/

installation opening) to oil pump if cover is removed.

+Apply a continuous bead of specified liquid gasket (Refer to

EM-3003, ªLiquid Gasket Application Procedureº.) as shown

in the figure.

+Apply liquid gasket on oil pump-side surface.

12. Install oil pump.

a. Apply a continuous bead of specified liquid gasket (Refer to

EM-3003, ªLiquid Gasket Application Procedureº.) on loca-

tions shown in the figure.

A: Leave the start and end areas of the bead slightly protrud-

ing from the surface.

B: Apply liquid gasket along upper end surface of oil pump.

b. Install oil pump drive spacer to crankshaft.

+Install with the front mark (punched mark) facing the front of

the engine.

c. Install O-ring into the groove of rear chain case.

d. Install oil pump.

+When installing, align the inner rotor in the direction of the

two facing flats of the oil pump drive spacer.

+When installing, align the dowel pin with the pin hole.

e. Tighten fixing bolts in the numerical order shown in the fig-

ure.

f. After tightening all the bolts, re-tighten in the same order.

13. Check gaps on upper oil pan mounting surface.

+Using straightedge and feeler gauge, measure gaps between

the locations of the following parts:

Standard:

Oil pump and rear chain case

þ0.14 to 0.14 mm (þ0.0055 to 0.0055 in)

Rear chain case and cylinder block

þ0.25 to 0.13 mm (þ0.0098 to 0.0051 in)

+If the measured value is out of the above range, install again.

JEM143G

JEM144G

JEM145G

JEM133G

JEM146G

TIMING CHAINYD25DDTi

Primary Timing Chain (Cont'd)

EM-3033