NISSAN PICK-UP 2001 Repair Manual

PICK-UP 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57372/w960_57372-0.png

NISSAN PICK-UP 2001 Repair Manual

Trending: service indicator, radio, check oil, ESP, service reset, octane, brake light

Page 881 of 1306

Special Service Tools (YD25DDTi engine)

Tool number

Tool nameDescription

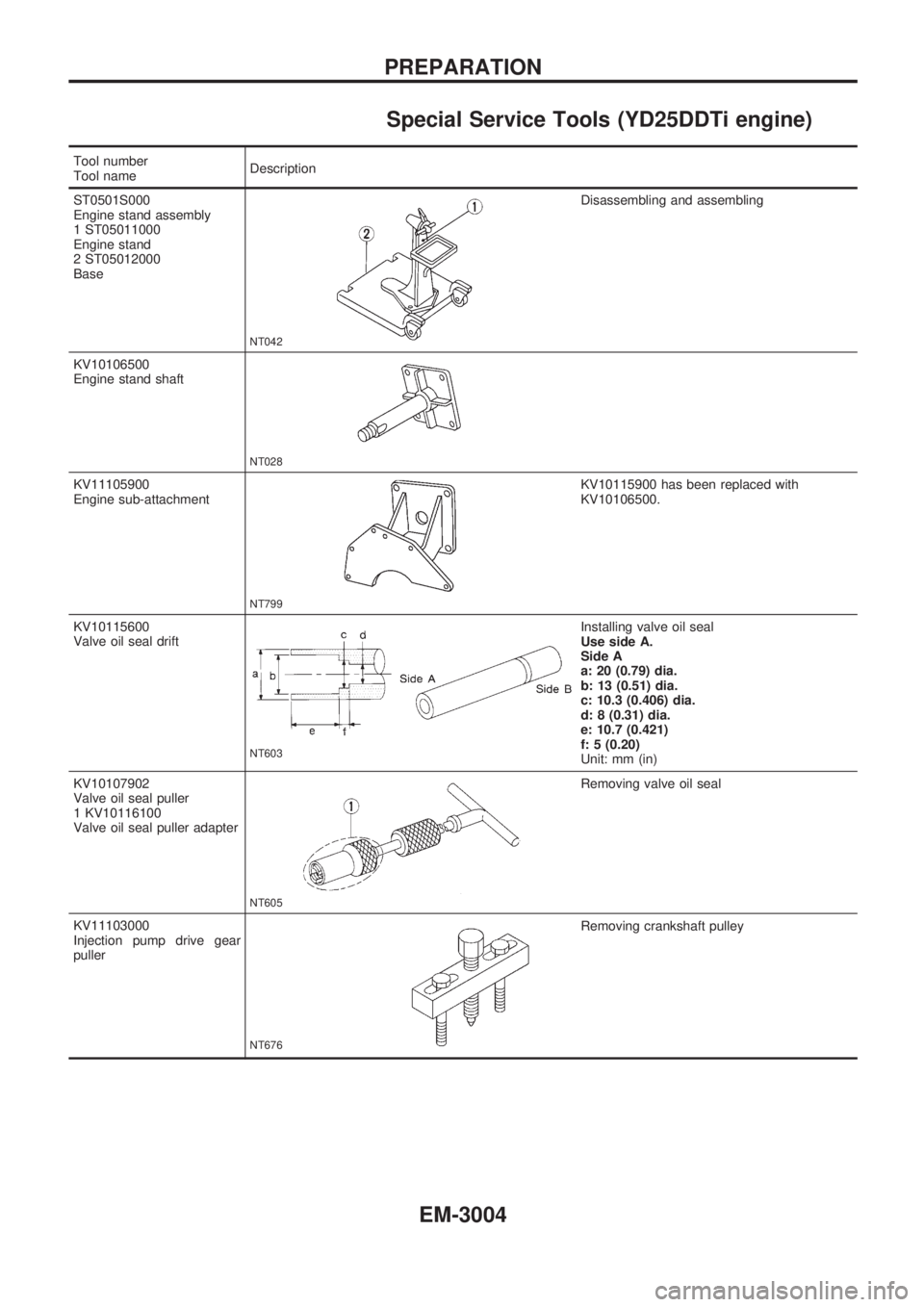

ST0501S000

Engine stand assembly

1 ST05011000

Engine stand

2 ST05012000

Base

NT042

Disassembling and assembling

KV10106500

Engine stand shaft

NT028

KV11105900

Engine sub-attachment

NT799

KV10115900 has been replaced with

KV10106500.

KV10115600

Valve oil seal drift

NT603

Installing valve oil seal

Use side A.

Side A

a: 20 (0.79) dia.

b: 13 (0.51) dia.

c: 10.3 (0.406) dia.

d: 8 (0.31) dia.

e: 10.7 (0.421)

f: 5 (0.20)

Unit: mm (in)

KV10107902

Valve oil seal puller

1 KV10116100

Valve oil seal puller adapter

NT605

Removing valve oil seal

KV11103000

Injection pump drive gear

puller

NT676

Removing crankshaft pulley

PREPARATION

EM-3004

Page 882 of 1306

Tool number

Tool nameDescription

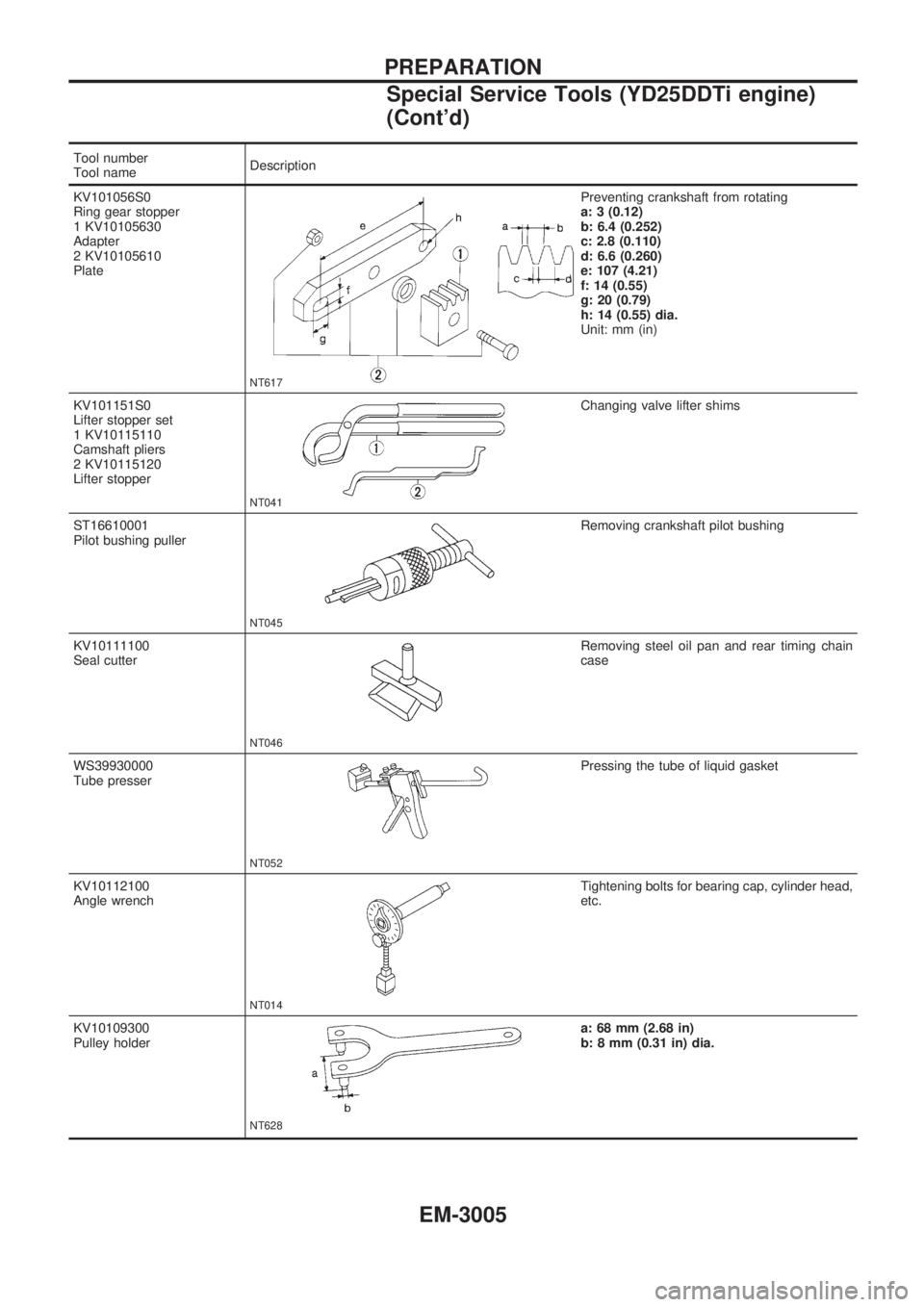

KV101056S0

Ring gear stopper

1 KV10105630

Adapter

2 KV10105610

Plate

NT617

Preventing crankshaft from rotating

a: 3 (0.12)

b: 6.4 (0.252)

c: 2.8 (0.110)

d: 6.6 (0.260)

e: 107 (4.21)

f: 14 (0.55)

g: 20 (0.79)

h: 14 (0.55) dia.

Unit: mm (in)

KV101151S0

Lifter stopper set

1 KV10115110

Camshaft pliers

2 KV10115120

Lifter stopper

NT041

Changing valve lifter shims

ST16610001

Pilot bushing puller

NT045

Removing crankshaft pilot bushing

KV10111100

Seal cutter

NT046

Removing steel oil pan and rear timing chain

case

WS39930000

Tube presser

NT052

Pressing the tube of liquid gasket

KV10112100

Angle wrench

NT014

Tightening bolts for bearing cap, cylinder head,

etc.

KV10109300

Pulley holder

NT628

a: 68 mm (2.68 in)

b: 8 mm (0.31 in) dia.

PREPARATION

Special Service Tools (YD25DDTi engine)

(Cont'd)

EM-3005

Page 883 of 1306

Tool number

Tool nameDescription

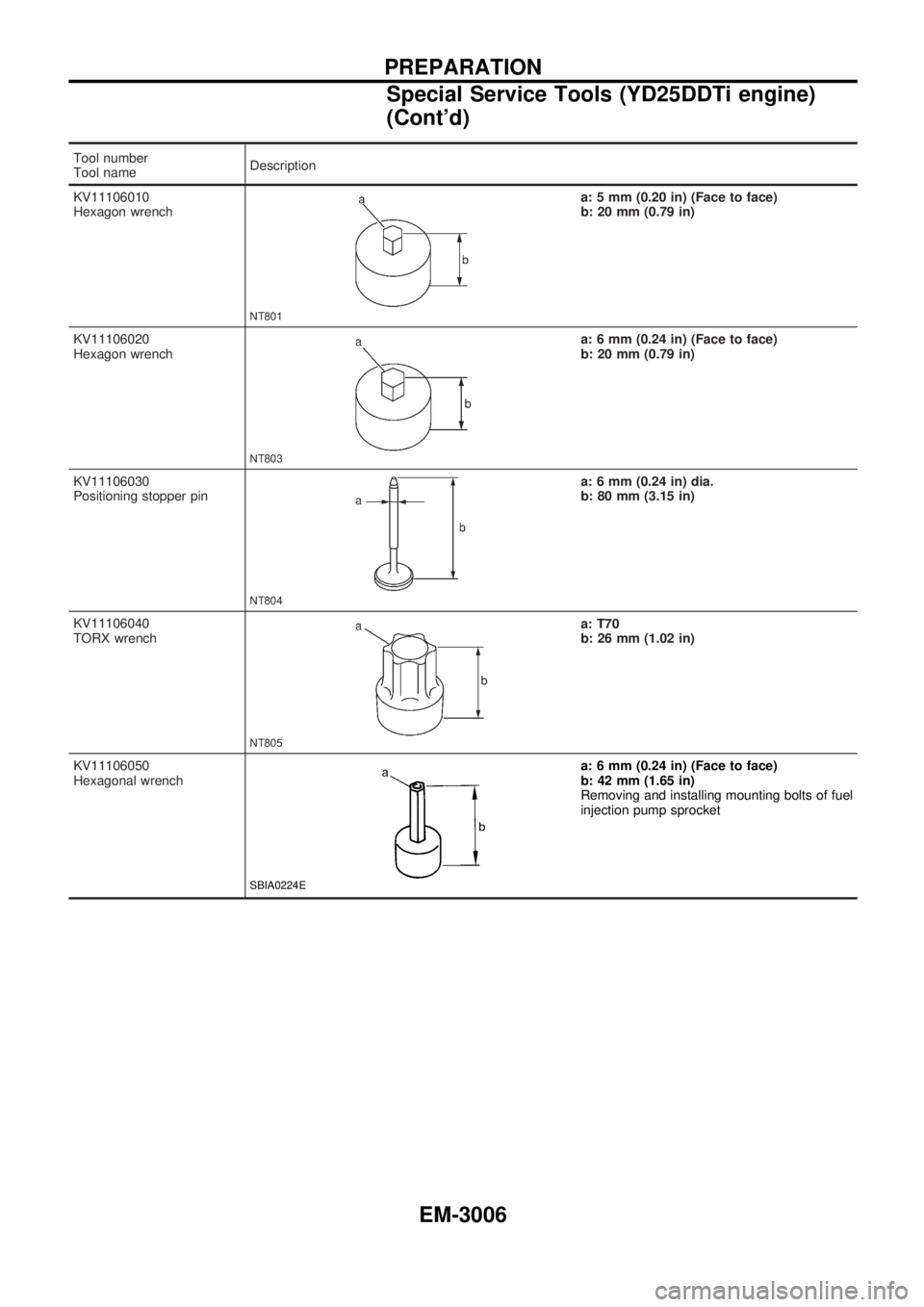

KV11106010

Hexagon wrench

NT801

a: 5 mm (0.20 in) (Face to face)

b: 20 mm (0.79 in)

KV11106020

Hexagon wrench

NT803

a: 6 mm (0.24 in) (Face to face)

b: 20 mm (0.79 in)

KV11106030

Positioning stopper pin

NT804

a: 6 mm (0.24 in) dia.

b: 80 mm (3.15 in)

KV11106040

TORX wrench

NT805

a: T70

b: 26 mm (1.02 in)

KV11106050

Hexagonal wrench

SBIA0224E

a: 6 mm (0.24 in) (Face to face)

b: 42 mm (1.65 in)

Removing and installing mounting bolts of fuel

injection pump sprocket

PREPARATION

Special Service Tools (YD25DDTi engine)

(Cont'd)

EM-3006

Page 884 of 1306

Commercial Service Tools (YD25DDTi

engine)

Tool name Description

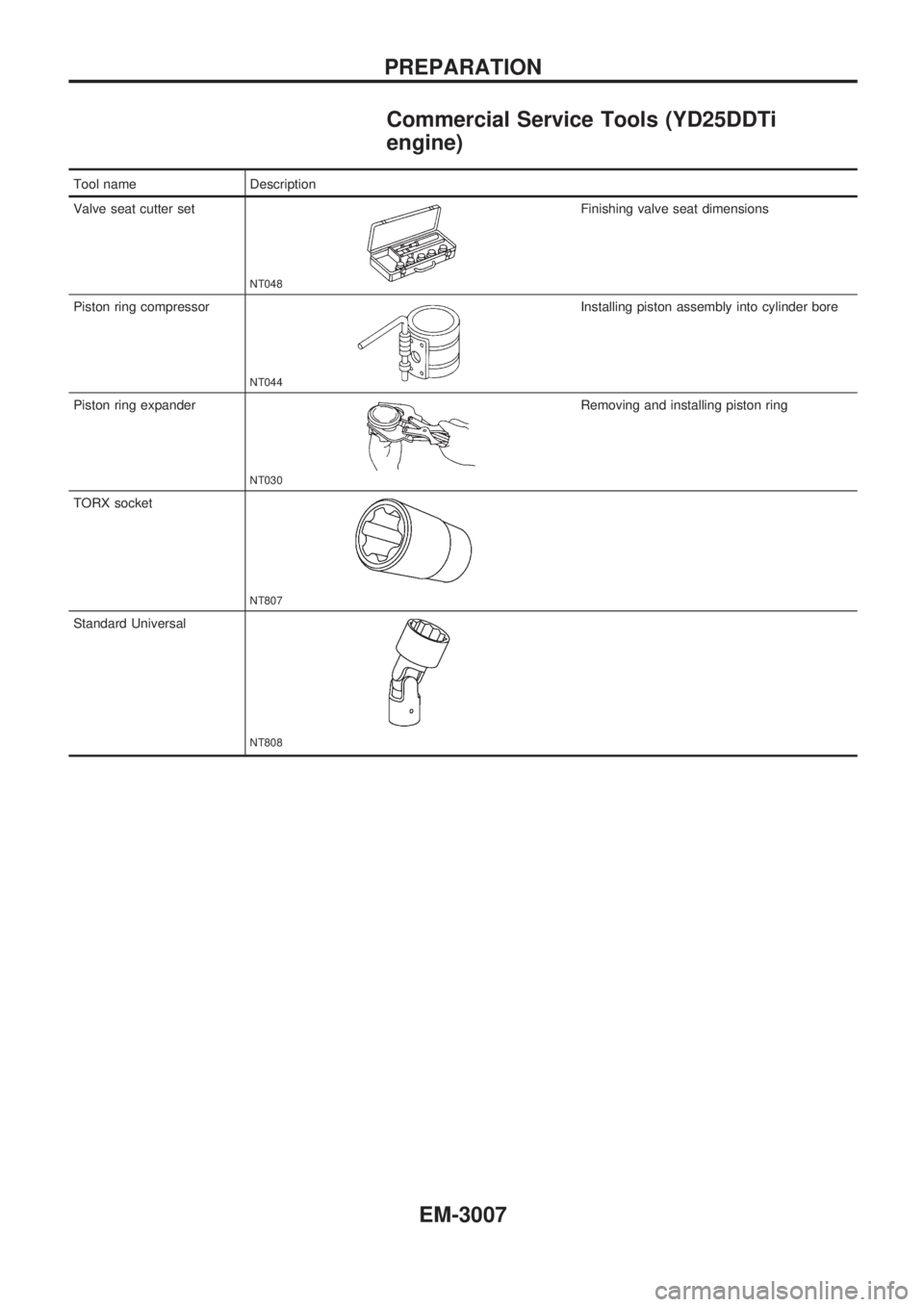

Valve seat cutter set

NT048

Finishing valve seat dimensions

Piston ring compressor

NT044

Installing piston assembly into cylinder bore

Piston ring expander

NT030

Removing and installing piston ring

TORX socket

NT807

Standard Universal

NT808

PREPARATION

EM-3007

Page 885 of 1306

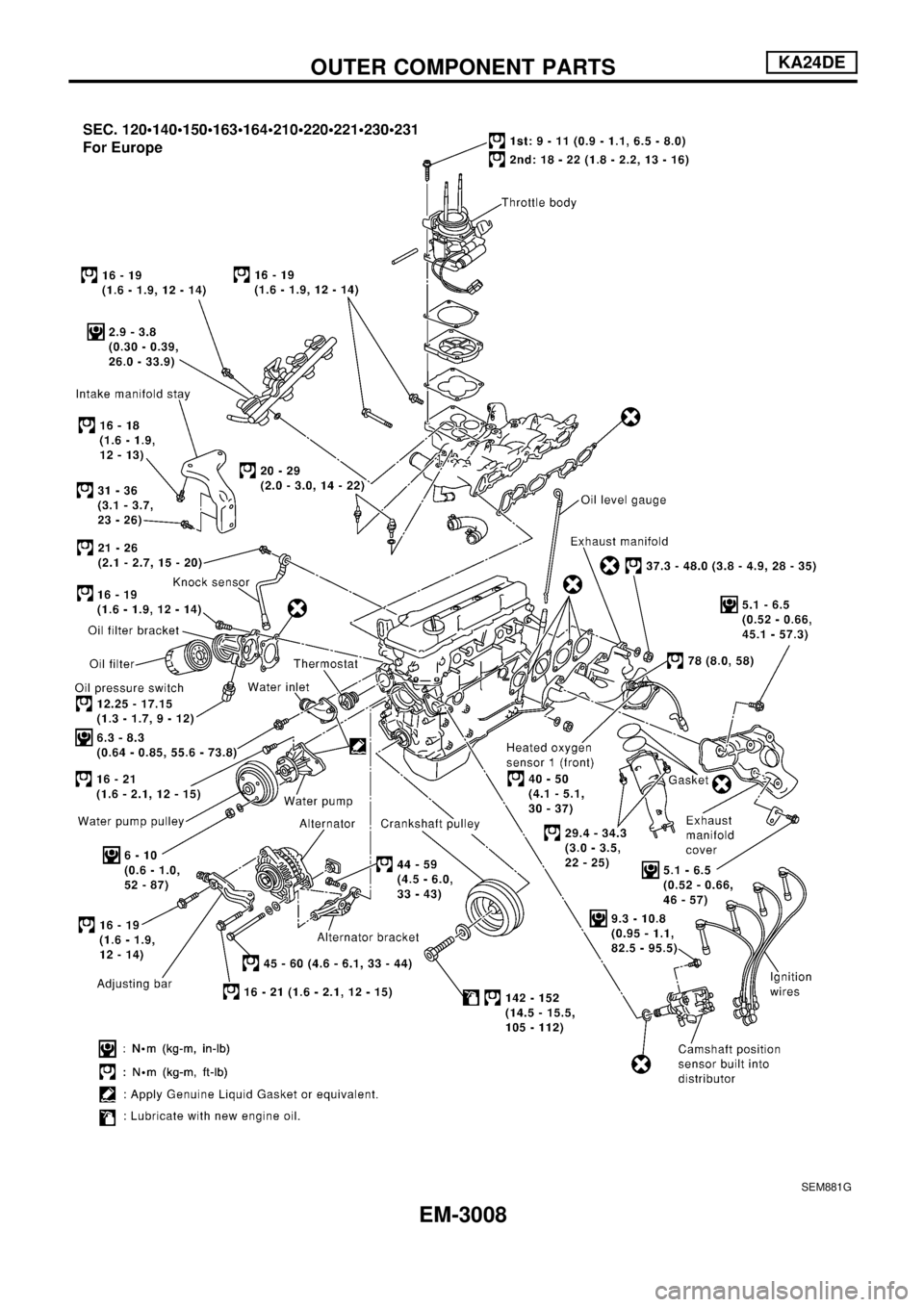

SEM881G

OUTER COMPONENT PARTSKA24DE

EM-3008

Page 886 of 1306

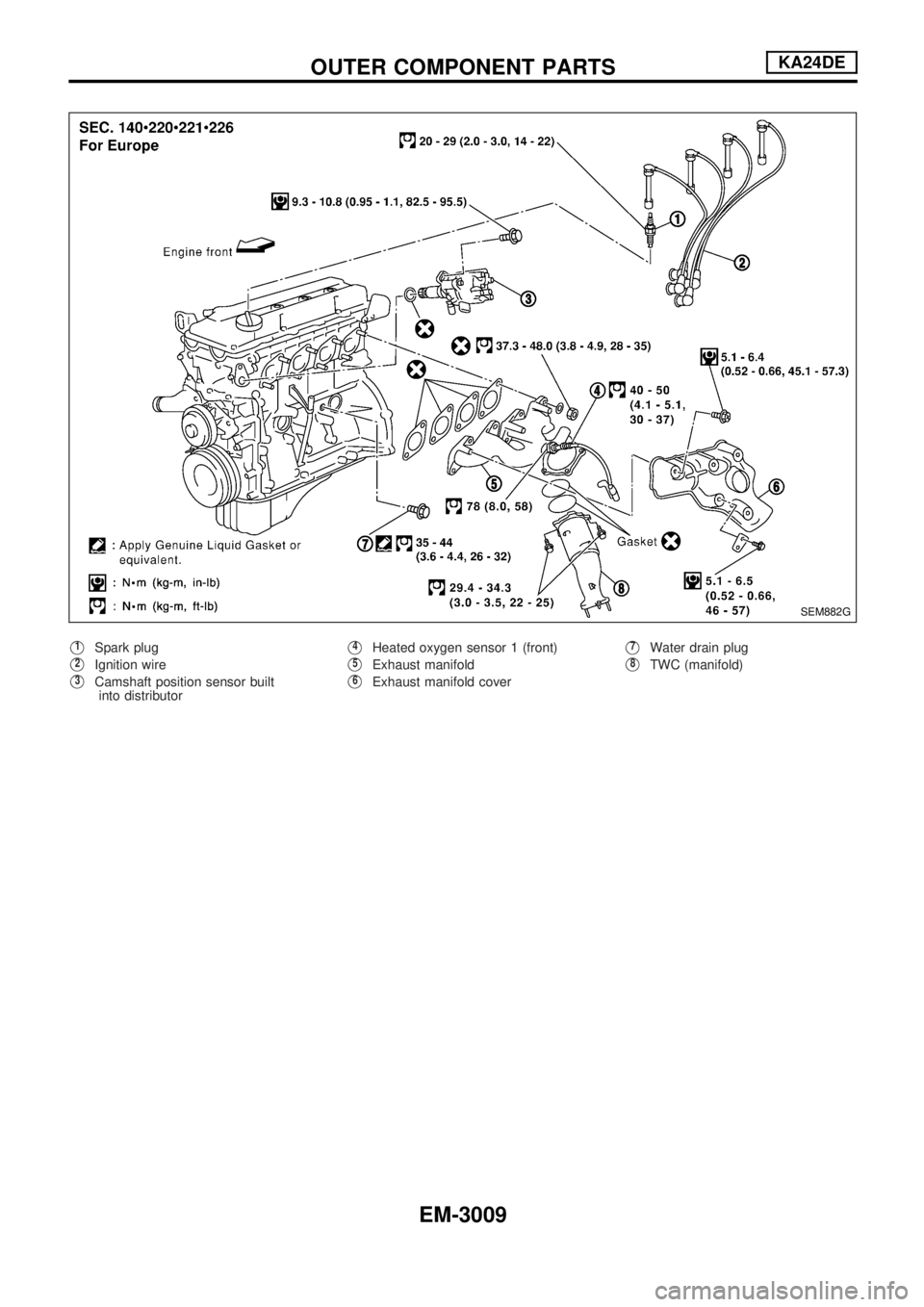

V1Spark plug

V2Ignition wire

V3Camshaft position sensor built

into distributor

V4Heated oxygen sensor 1 (front)

V5Exhaust manifold

V6Exhaust manifold cover

V7Water drain plug

V8TWC (manifold)

SEM882G

OUTER COMPONENT PARTSKA24DE

EM-3009

Page 887 of 1306

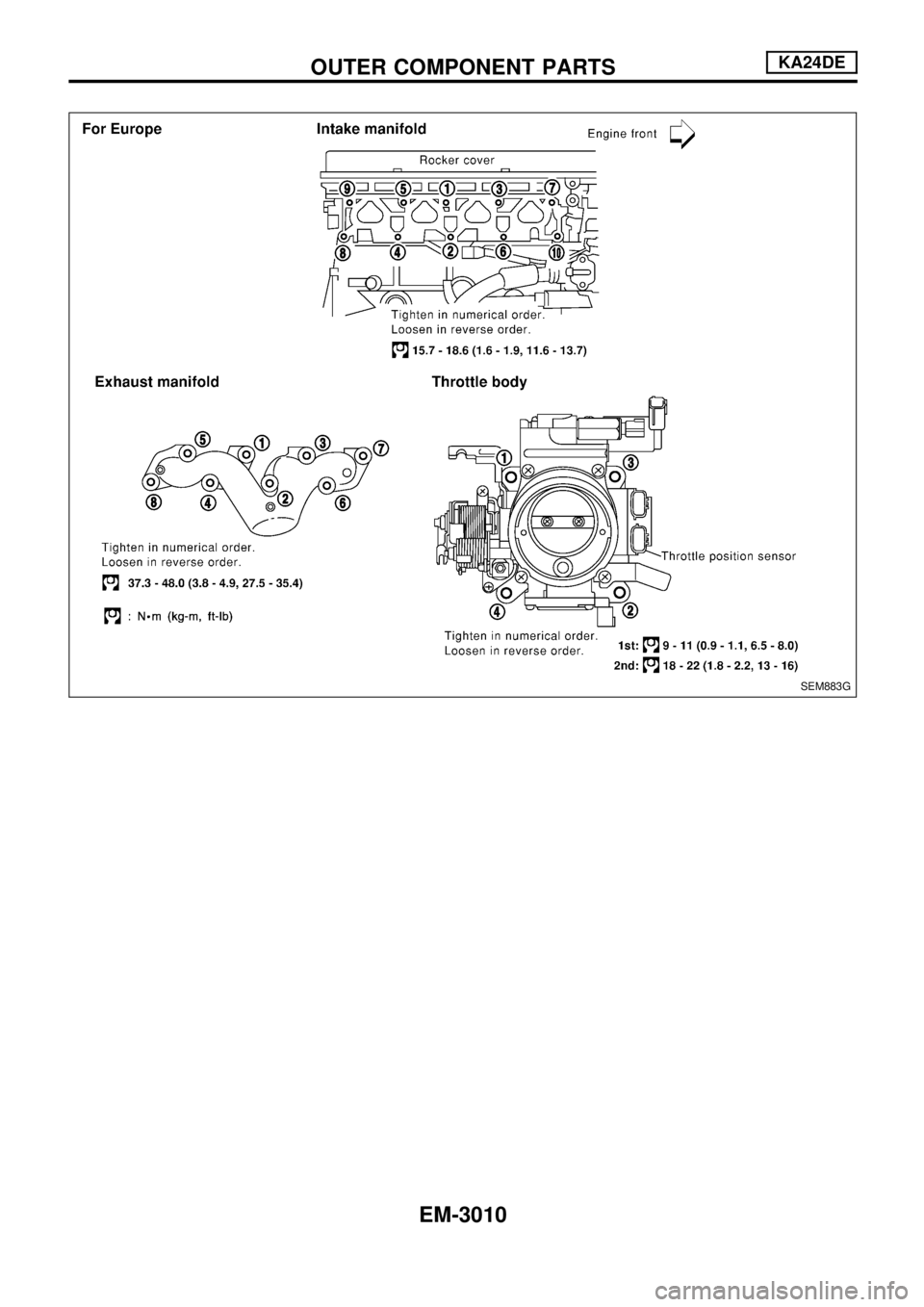

SEM883G

OUTER COMPONENT PARTSKA24DE

EM-3010

Page 888 of 1306

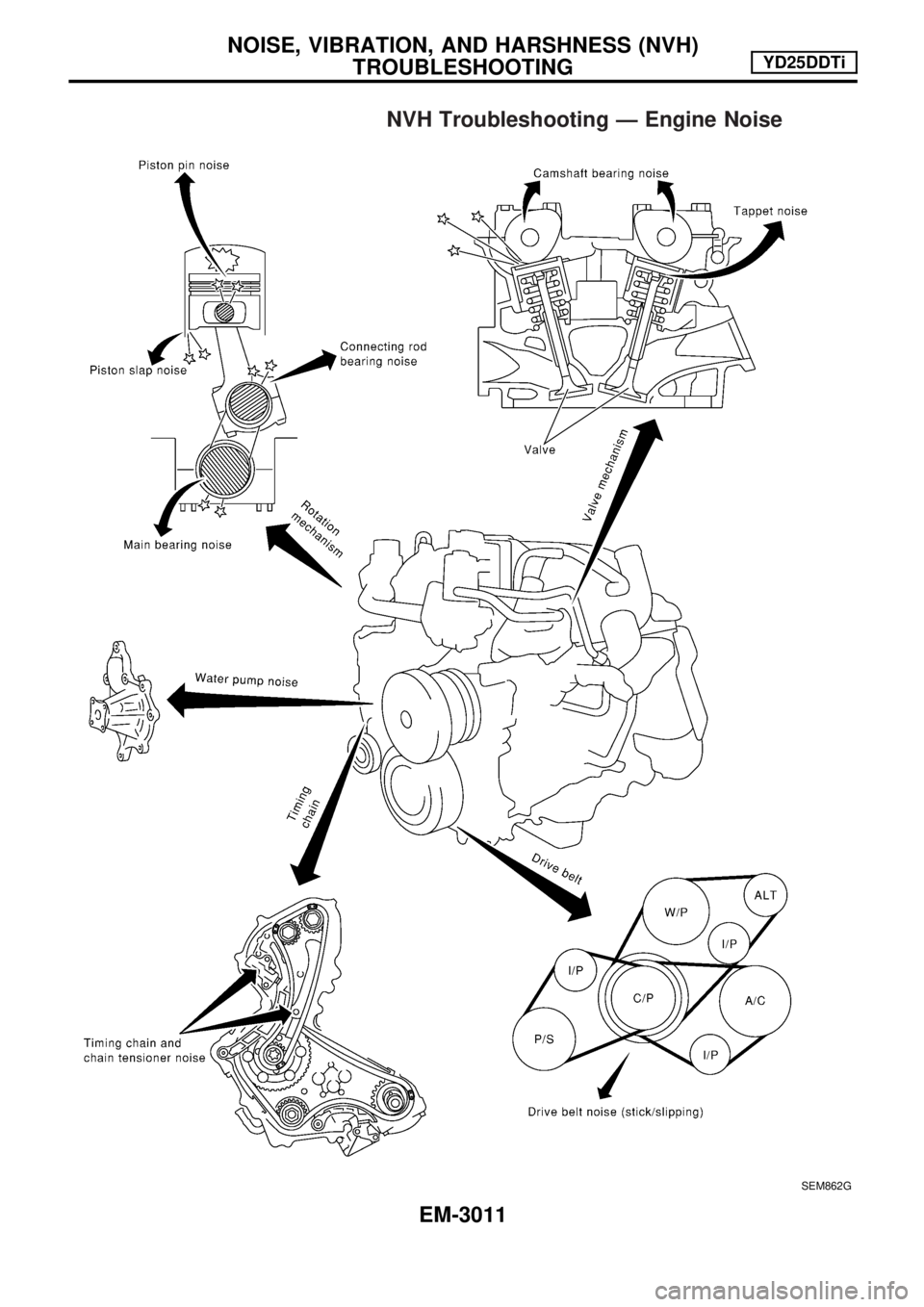

NVH Troubleshooting Ð Engine Noise

SEM862G

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTINGYD25DDTi

EM-3011

Page 889 of 1306

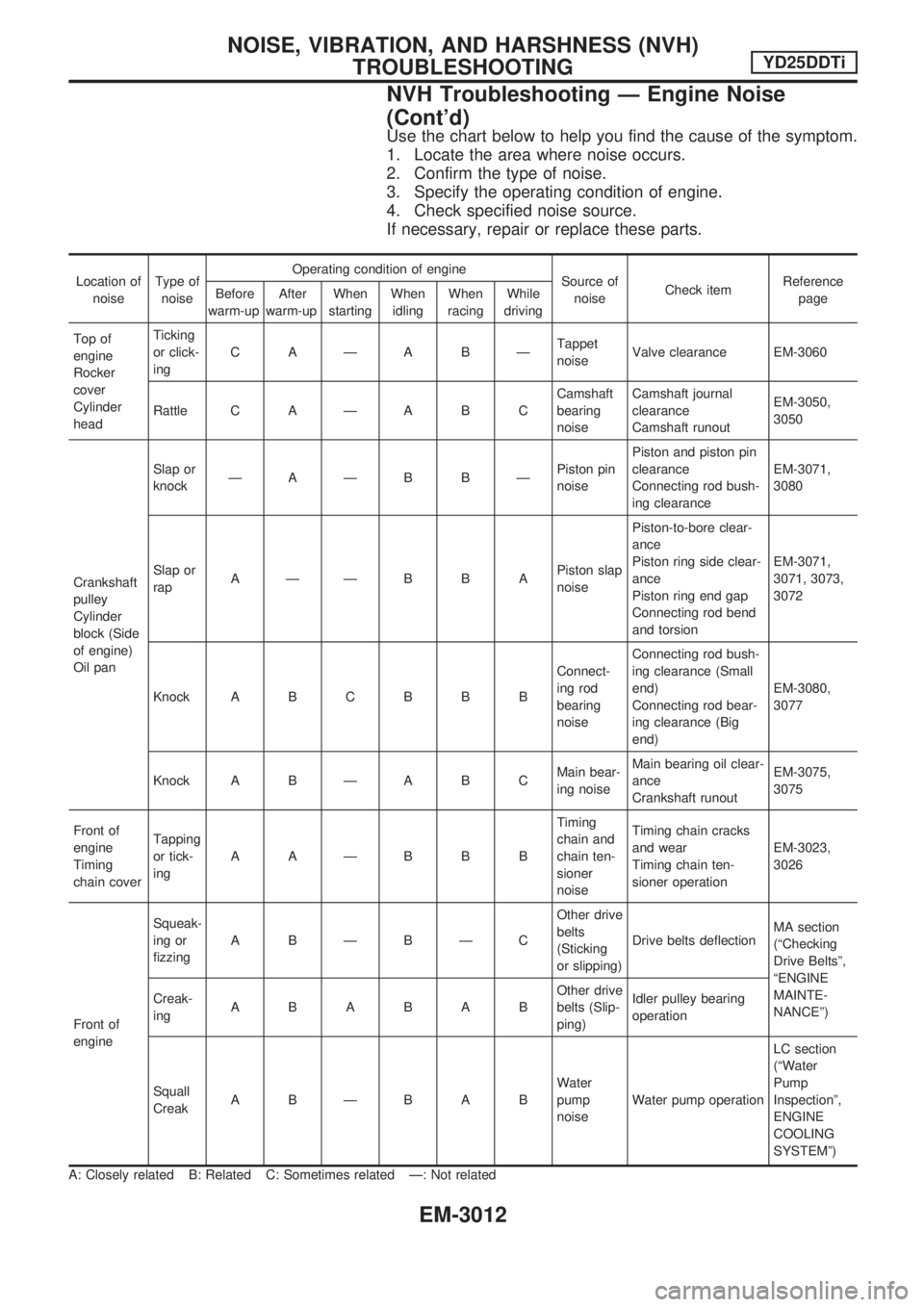

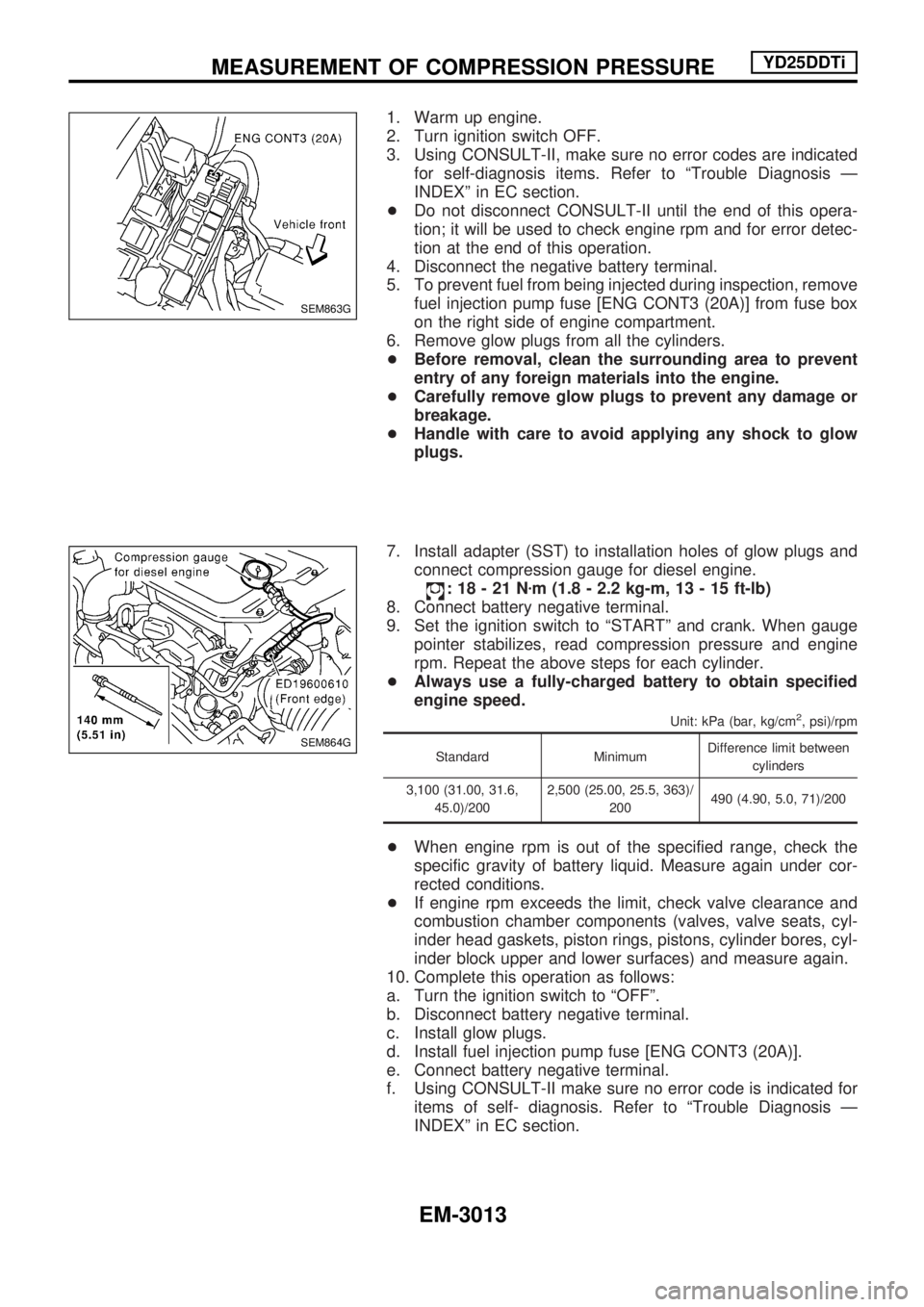

Use the chart below to help you find the cause of the symptom.

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

Location of

noiseType of

noiseOperating condition of engine

Source of

noiseCheck itemReference

page Before

warm-upAfter

warm-upWhen

startingWhen

idlingWhen

racingWhile

driving

Top of

engine

Rocker

cover

Cylinder

headTicking

or click-

ingCAÐABÐTappet

noiseValve clearance EM-3060

Rattle C A Ð A B CCamshaft

bearing

noiseCamshaft journal

clearance

Camshaft runoutEM-3050,

3050

Crankshaft

pulley

Cylinder

block (Side

of engine)

Oil panSlap or

knockÐAÐB BÐPiston pin

noisePiston and piston pin

clearance

Connecting rod bush-

ing clearanceEM-3071,

3080

Slap or

rapAÐÐBBAPiston slap

noisePiston-to-bore clear-

ance

Piston ring side clear-

ance

Piston ring end gap

Connecting rod bend

and torsionEM-3071,

3071, 3073,

3072

Knock A B C B B BConnect-

ing rod

bearing

noiseConnecting rod bush-

ing clearance (Small

end)

Connecting rod bear-

ing clearance (Big

end)EM-3080,

3077

Knock A B Ð A B CMain bear-

ing noiseMain bearing oil clear-

ance

Crankshaft runoutEM-3075,

3075

Front of

engine

Timing

chain coverTapping

or tick-

ingAAÐBBBTiming

chain and

chain ten-

sioner

noiseTiming chain cracks

and wear

Timing chain ten-

sioner operationEM-3023,

3026

Front of

engineSqueak-

ing or

fizzingABÐBÐCOther drive

belts

(Sticking

or slipping)Drive belts deflectionMA section

(ªChecking

Drive Beltsº,

ªENGINE

MAINTE-

NANCEº) Creak-

ingABABABOther drive

belts (Slip-

ping)Idler pulley bearing

operation

Squall

CreakABÐBABWater

pump

noiseWater pump operationLC section

(ªWater

Pump

Inspectionº,

ENGINE

COOLING

SYSTEMº)

A: Closely related B: Related C: Sometimes related Ð: Not related

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTINGYD25DDTi

NVH Troubleshooting Ð Engine Noise

(Cont'd)

EM-3012

Page 890 of 1306

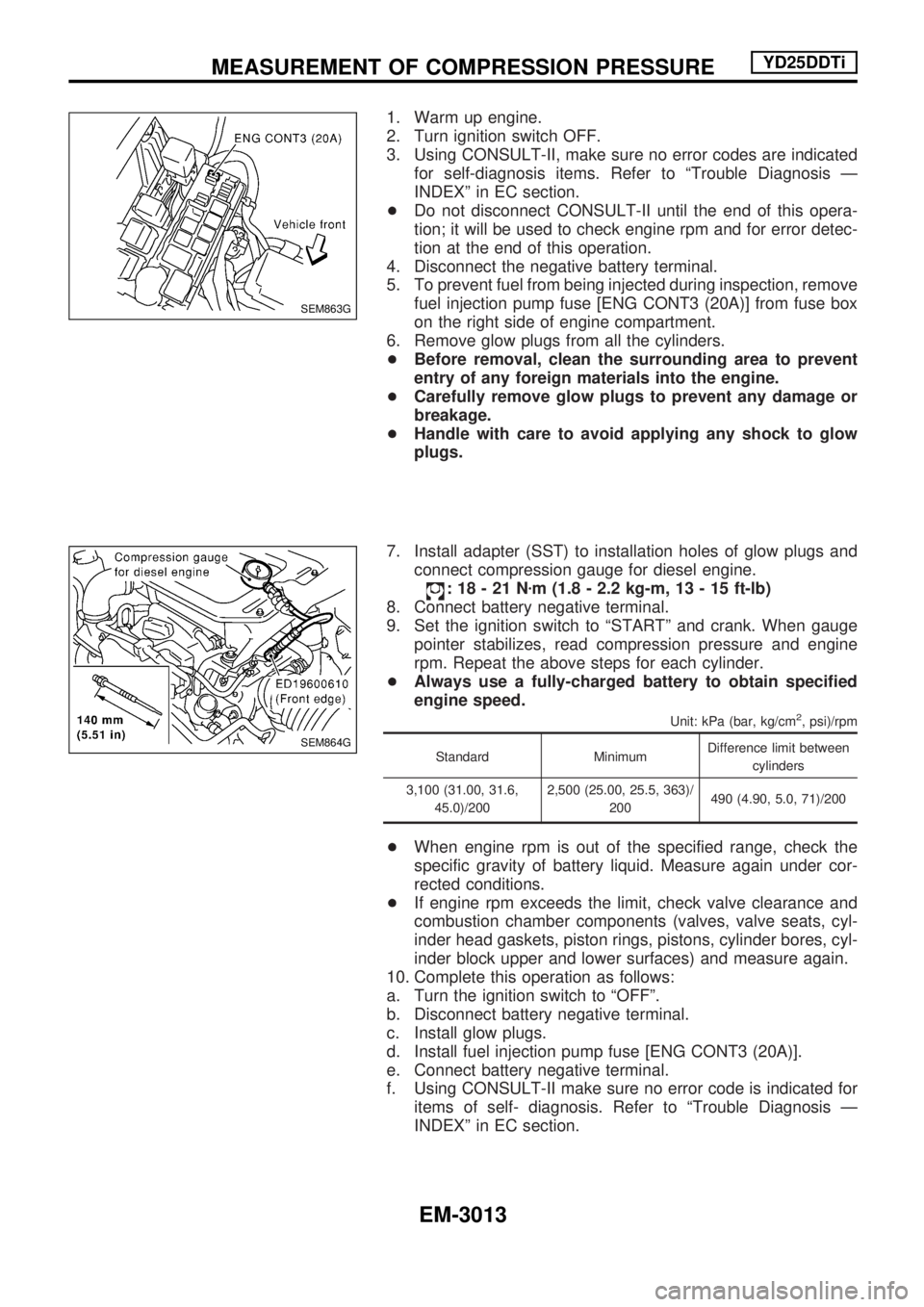

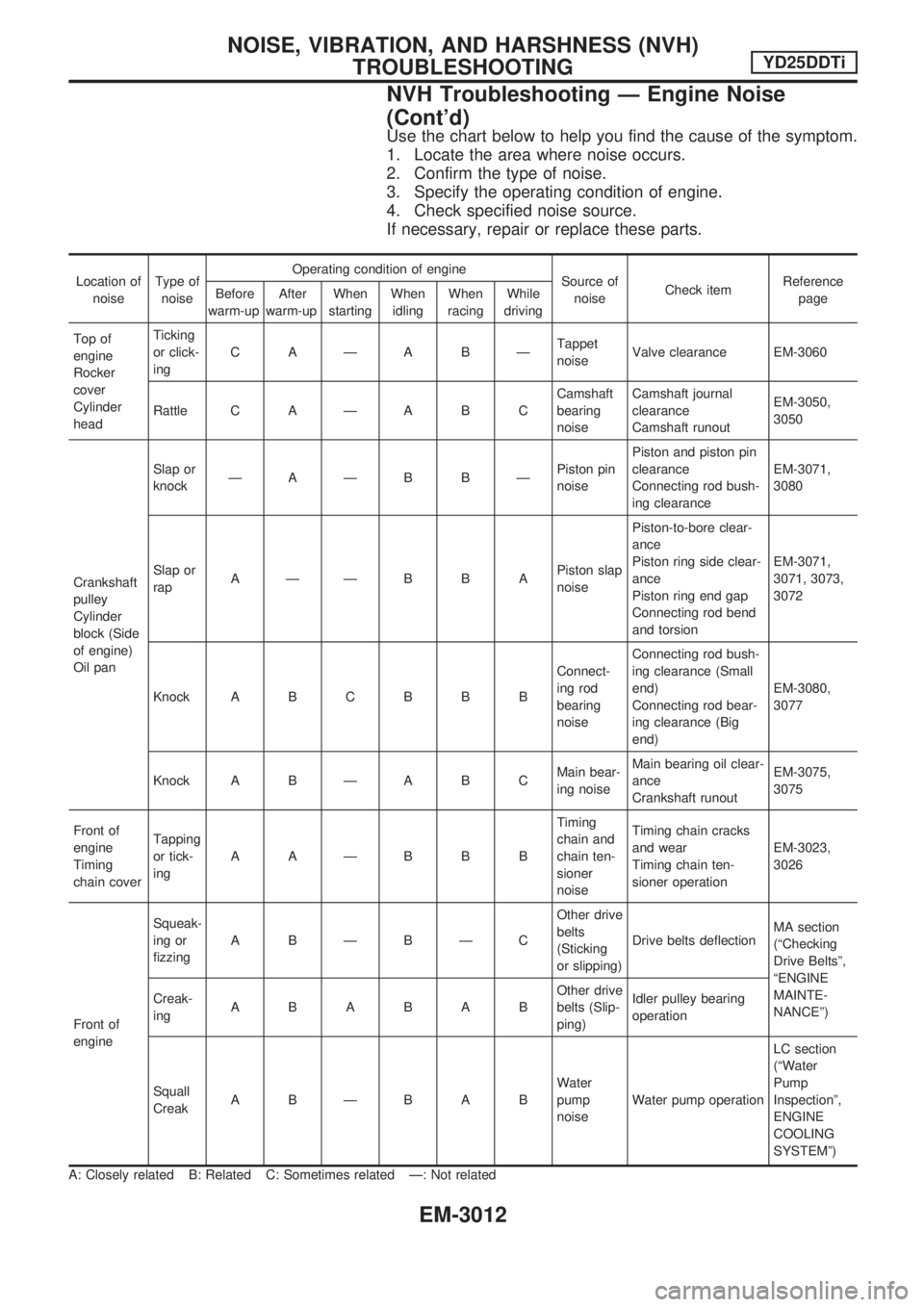

1. Warm up engine.

2. Turn ignition switch OFF.

3. Using CONSULT-II, make sure no error codes are indicated

for self-diagnosis items. Refer to ªTrouble Diagnosis Ð

INDEXº in EC section.

+Do not disconnect CONSULT-II until the end of this opera-

tion; it will be used to check engine rpm and for error detec-

tion at the end of this operation.

4. Disconnect the negative battery terminal.

5. To prevent fuel from being injected during inspection, remove

fuel injection pump fuse [ENG CONT3 (20A)] from fuse box

on the right side of engine compartment.

6. Remove glow plugs from all the cylinders.

+Before removal, clean the surrounding area to prevent

entry of any foreign materials into the engine.

+Carefully remove glow plugs to prevent any damage or

breakage.

+Handle with care to avoid applying any shock to glow

plugs.

7. Install adapter (SST) to installation holes of glow plugs and

connect compression gauge for diesel engine.

:18-21Nzm (1.8 - 2.2 kg-m, 13 - 15 ft-lb)

8. Connect battery negative terminal.

9. Set the ignition switch to ªSTARTº and crank. When gauge

pointer stabilizes, read compression pressure and engine

rpm. Repeat the above steps for each cylinder.

+Always use a fully-charged battery to obtain specified

engine speed.

Unit: kPa (bar, kg/cm2, psi)/rpm

Standard MinimumDifference limit between

cylinders

3,100 (31.00, 31.6,

45.0)/2002,500 (25.00, 25.5, 363)/

200490 (4.90, 5.0, 71)/200

+When engine rpm is out of the specified range, check the

specific gravity of battery liquid. Measure again under cor-

rected conditions.

+If engine rpm exceeds the limit, check valve clearance and

combustion chamber components (valves, valve seats, cyl-

inder head gaskets, piston rings, pistons, cylinder bores, cyl-

inder block upper and lower surfaces) and measure again.

10. Complete this operation as follows:

a. Turn the ignition switch to ªOFFº.

b. Disconnect battery negative terminal.

c. Install glow plugs.

d. Install fuel injection pump fuse [ENG CONT3 (20A)].

e. Connect battery negative terminal.

f. Using CONSULT-II make sure no error code is indicated for

items of self- diagnosis. Refer to ªTrouble Diagnosis Ð

INDEXº in EC section.

SEM863G

SEM864G

MEASUREMENT OF COMPRESSION PRESSUREYD25DDTi

EM-3013

Trending: manual transmission, flat tire, engine oil capacity, brake fluid, radiator, fuel, ignition