NISSAN PICK-UP 2001 Repair Manual

PICK-UP 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57372/w960_57372-0.png

NISSAN PICK-UP 2001 Repair Manual

Trending: tire pressure, transmission, carburetor, transmission fluid, stop start, check engine, gas type

Page 911 of 1306

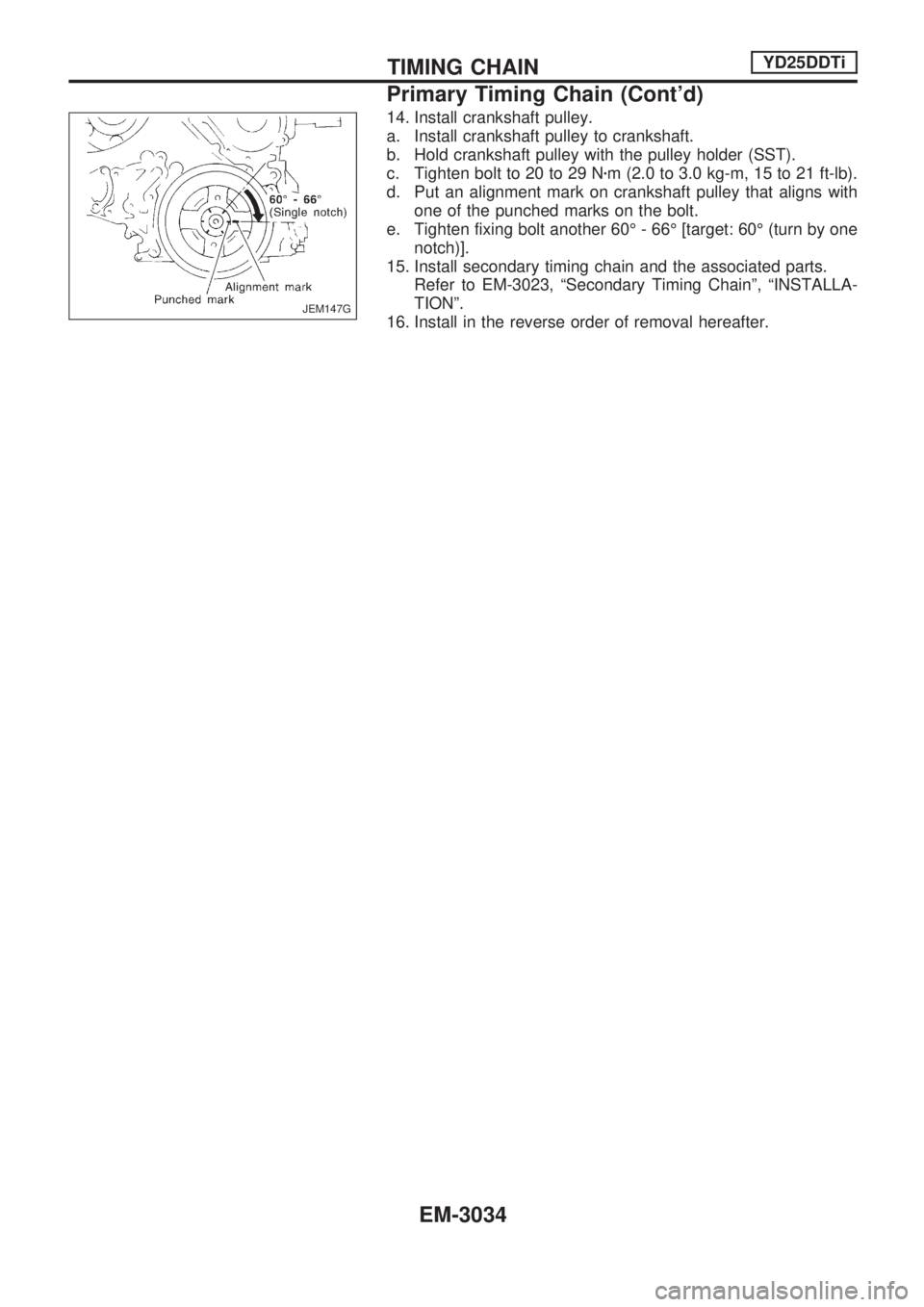

14. Install crankshaft pulley.

a. Install crankshaft pulley to crankshaft.

b. Hold crankshaft pulley with the pulley holder (SST).

c. Tighten bolt to 20 to 29 Nzm (2.0 to 3.0 kg-m, 15 to 21 ft-lb).

d. Put an alignment mark on crankshaft pulley that aligns with

one of the punched marks on the bolt.

e. Tighten fixing bolt another 60É - 66É [target: 60É (turn by one

notch)].

15. Install secondary timing chain and the associated parts.

Refer to EM-3023, ªSecondary Timing Chainº, ªINSTALLA-

TIONº.

16. Install in the reverse order of removal hereafter.

JEM147G

TIMING CHAINYD25DDTi

Primary Timing Chain (Cont'd)

EM-3034

Page 912 of 1306

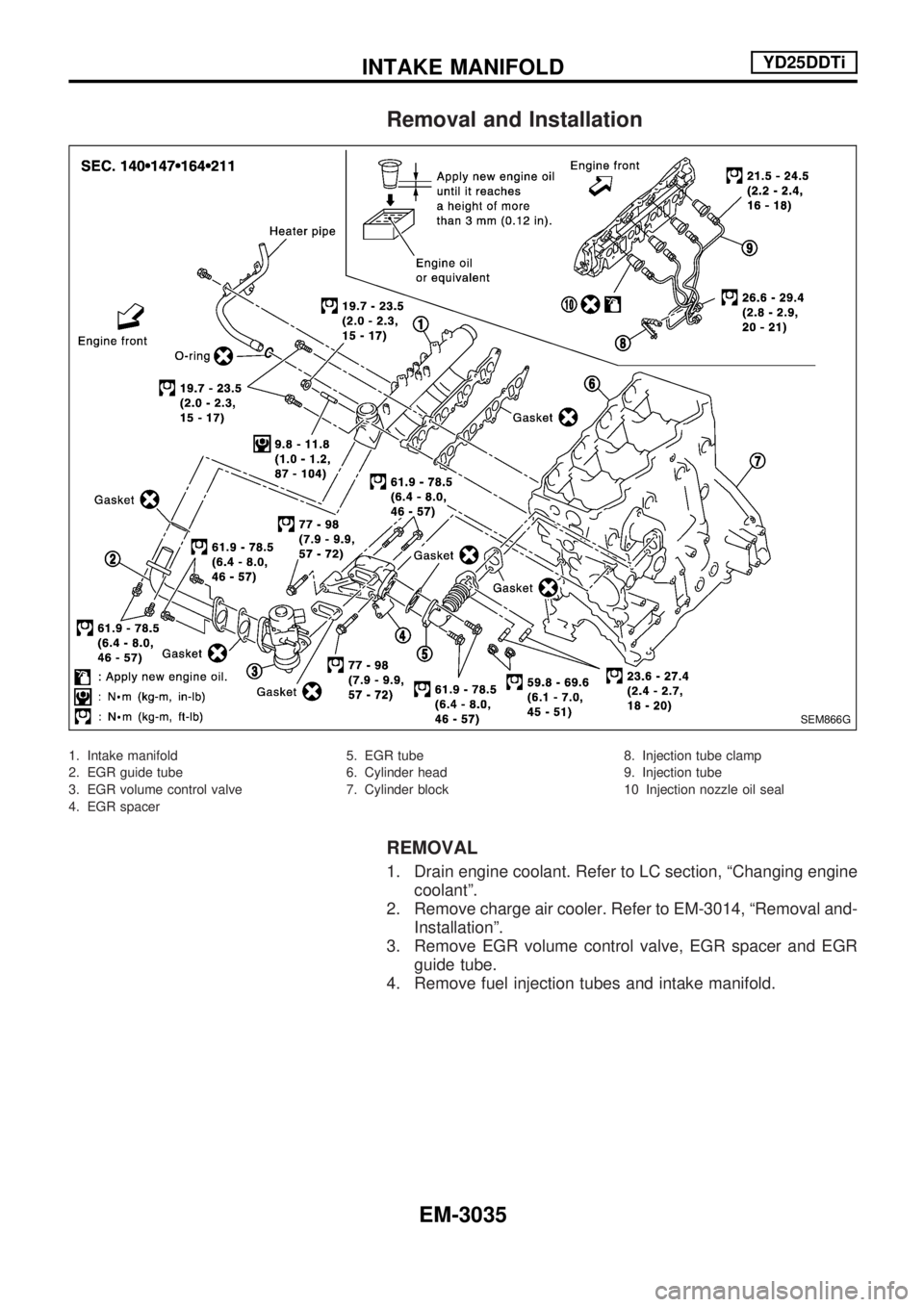

Removal and Installation

1. Intake manifold

2. EGR guide tube

3. EGR volume control valve

4. EGR spacer5. EGR tube

6. Cylinder head

7. Cylinder block8. Injection tube clamp

9. Injection tube

10 Injection nozzle oil seal

REMOVAL

1. Drain engine coolant. Refer to LC section, ªChanging engine

coolantº.

2. Remove charge air cooler. Refer to EM-3014, ªRemoval and-

Installationº.

3. Remove EGR volume control valve, EGR spacer and EGR

guide tube.

4. Remove fuel injection tubes and intake manifold.

SEM866G

INTAKE MANIFOLDYD25DDTi

EM-3035

Page 913 of 1306

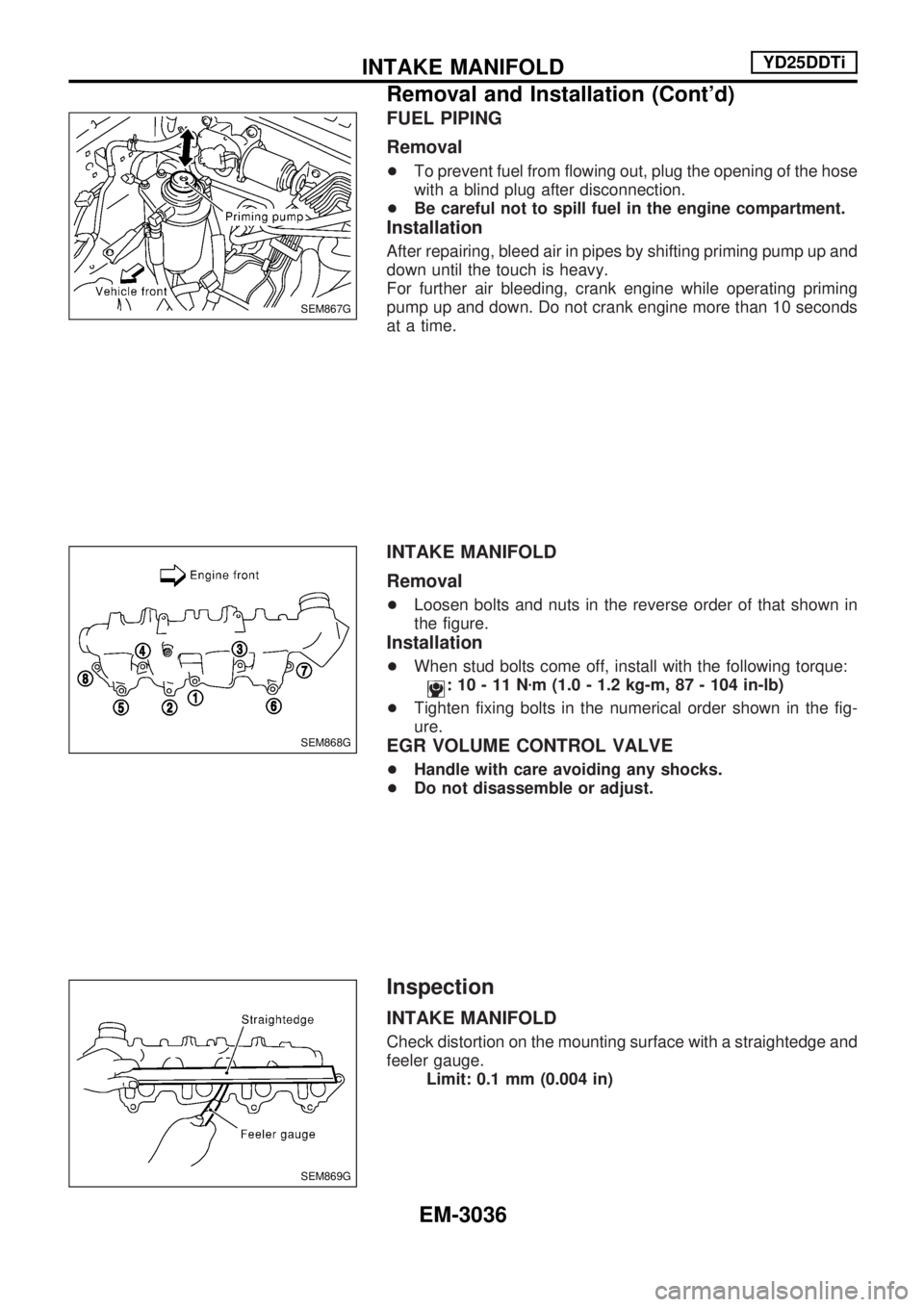

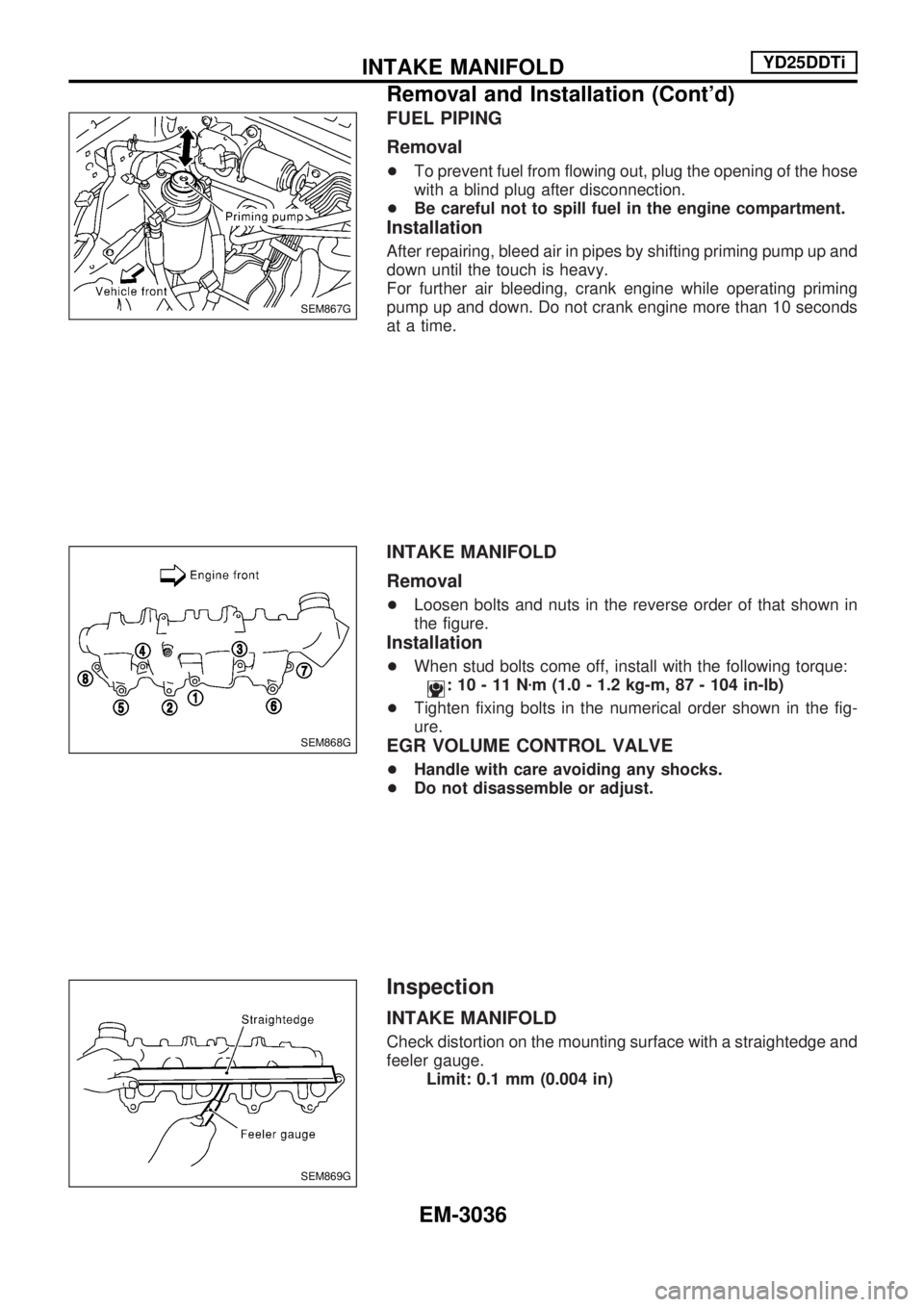

FUEL PIPING

Removal

+To prevent fuel from flowing out, plug the opening of the hose

with a blind plug after disconnection.

+Be careful not to spill fuel in the engine compartment.

Installation

After repairing, bleed air in pipes by shifting priming pump up and

down until the touch is heavy.

For further air bleeding, crank engine while operating priming

pump up and down. Do not crank engine more than 10 seconds

at a time.

INTAKE MANIFOLD

Removal

+Loosen bolts and nuts in the reverse order of that shown in

the figure.

Installation

+When stud bolts come off, install with the following torque:

:10-11Nzm (1.0 - 1.2 kg-m, 87 - 104 in-lb)

+Tighten fixing bolts in the numerical order shown in the fig-

ure.

EGR VOLUME CONTROL VALVE

+Handle with care avoiding any shocks.

+Do not disassemble or adjust.

Inspection

INTAKE MANIFOLD

Check distortion on the mounting surface with a straightedge and

feeler gauge.

Limit: 0.1 mm (0.004 in)

SEM867G

SEM868G

SEM869G

INTAKE MANIFOLDYD25DDTi

Removal and Installation (Cont'd)

EM-3036

Page 914 of 1306

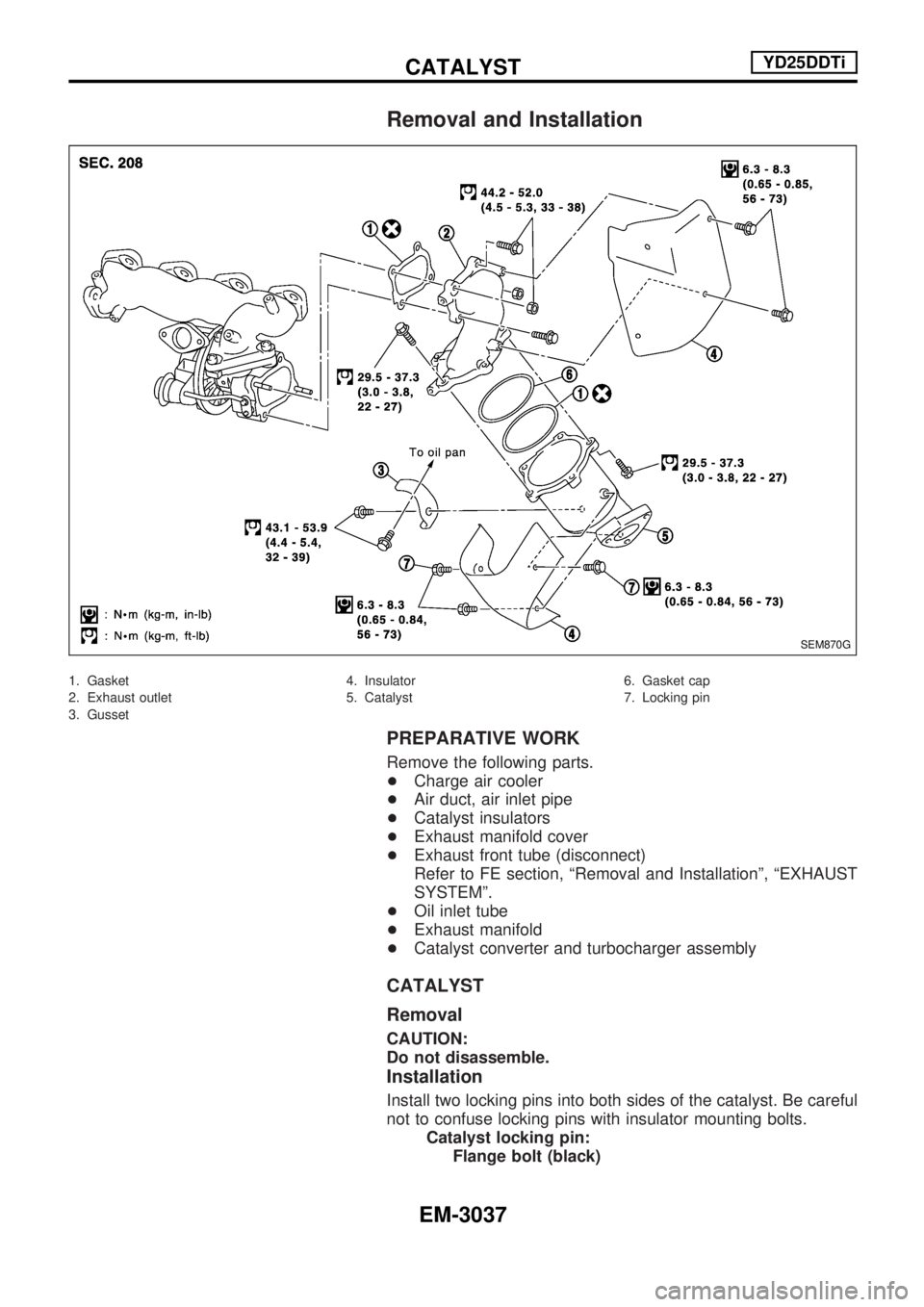

Removal and Installation

1. Gasket

2. Exhaust outlet

3. Gusset4. Insulator

5. Catalyst6. Gasket cap

7. Locking pin

PREPARATIVE WORK

Remove the following parts.

+Charge air cooler

+Air duct, air inlet pipe

+Catalyst insulators

+Exhaust manifold cover

+Exhaust front tube (disconnect)

Refer to FE section, ªRemoval and Installationº, ªEXHAUST

SYSTEMº.

+Oil inlet tube

+Exhaust manifold

+Catalyst converter and turbocharger assembly

CATALYST

Removal

CAUTION:

Do not disassemble.

Installation

Install two locking pins into both sides of the catalyst. Be careful

not to confuse locking pins with insulator mounting bolts.

Catalyst locking pin:

Flange bolt (black)

SEM870G

CATALYSTYD25DDTi

EM-3037

Page 915 of 1306

Insulator mounting bolt:

Washer bolt (silver or yellow)

GUSSET

Installation

Pushing gussets against the oil pan and the catalyst, temporarily

tighten the mounting bolt. And then tighten it to the specified

torque.

CATALYSTYD25DDTi

Removal and Installation (Cont'd)

EM-3038

Page 916 of 1306

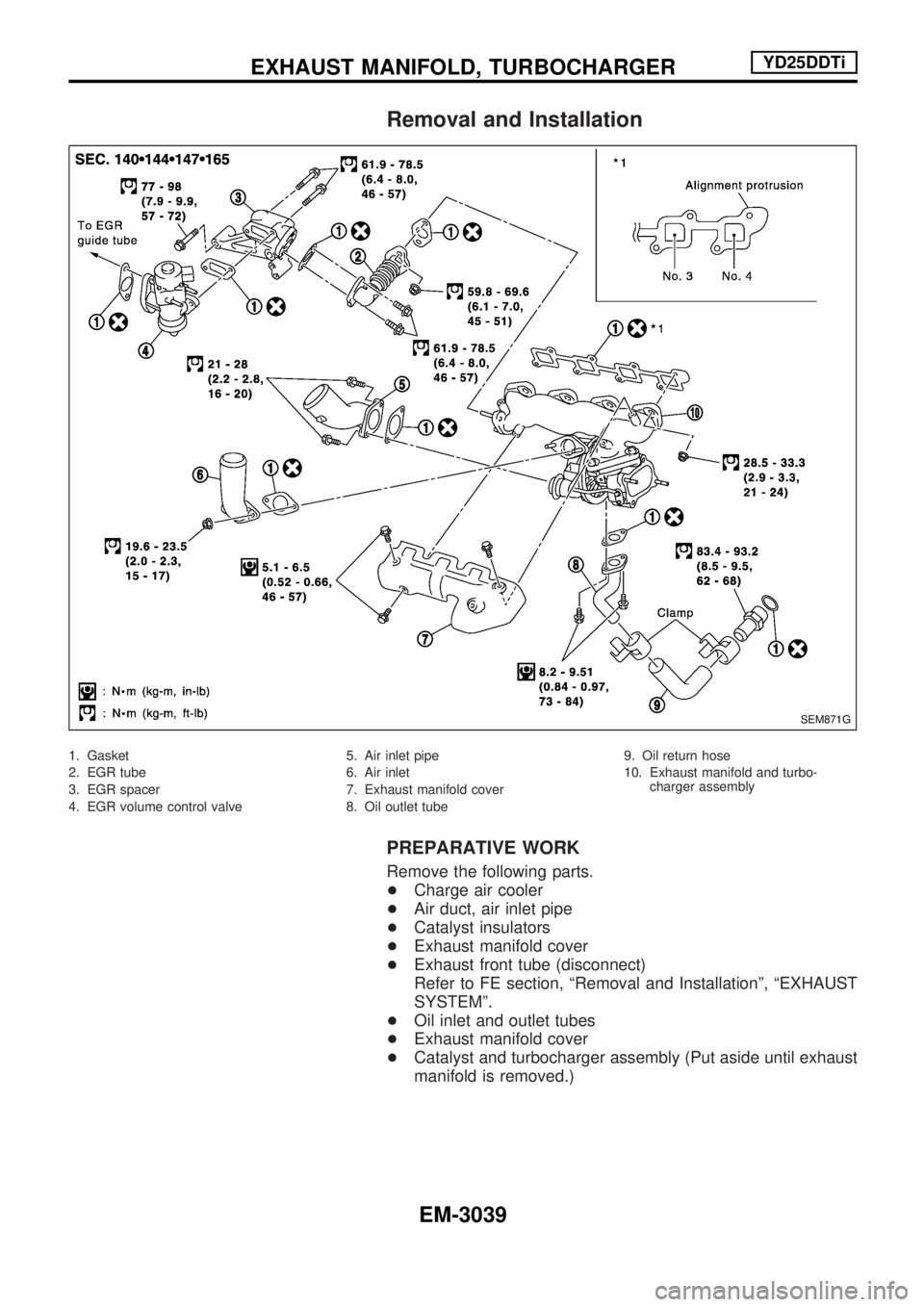

Removal and Installation

1. Gasket

2. EGR tube

3. EGR spacer

4. EGR volume control valve5. Air inlet pipe

6. Air inlet

7. Exhaust manifold cover

8. Oil outlet tube9. Oil return hose

10. Exhaust manifold and turbo-

charger assembly

PREPARATIVE WORK

Remove the following parts.

+Charge air cooler

+Air duct, air inlet pipe

+Catalyst insulators

+Exhaust manifold cover

+Exhaust front tube (disconnect)

Refer to FE section, ªRemoval and Installationº, ªEXHAUST

SYSTEMº.

+Oil inlet and outlet tubes

+Exhaust manifold cover

+Catalyst and turbocharger assembly (Put aside until exhaust

manifold is removed.)

SEM871G

EXHAUST MANIFOLD, TURBOCHARGERYD25DDTi

EM-3039

Page 917 of 1306

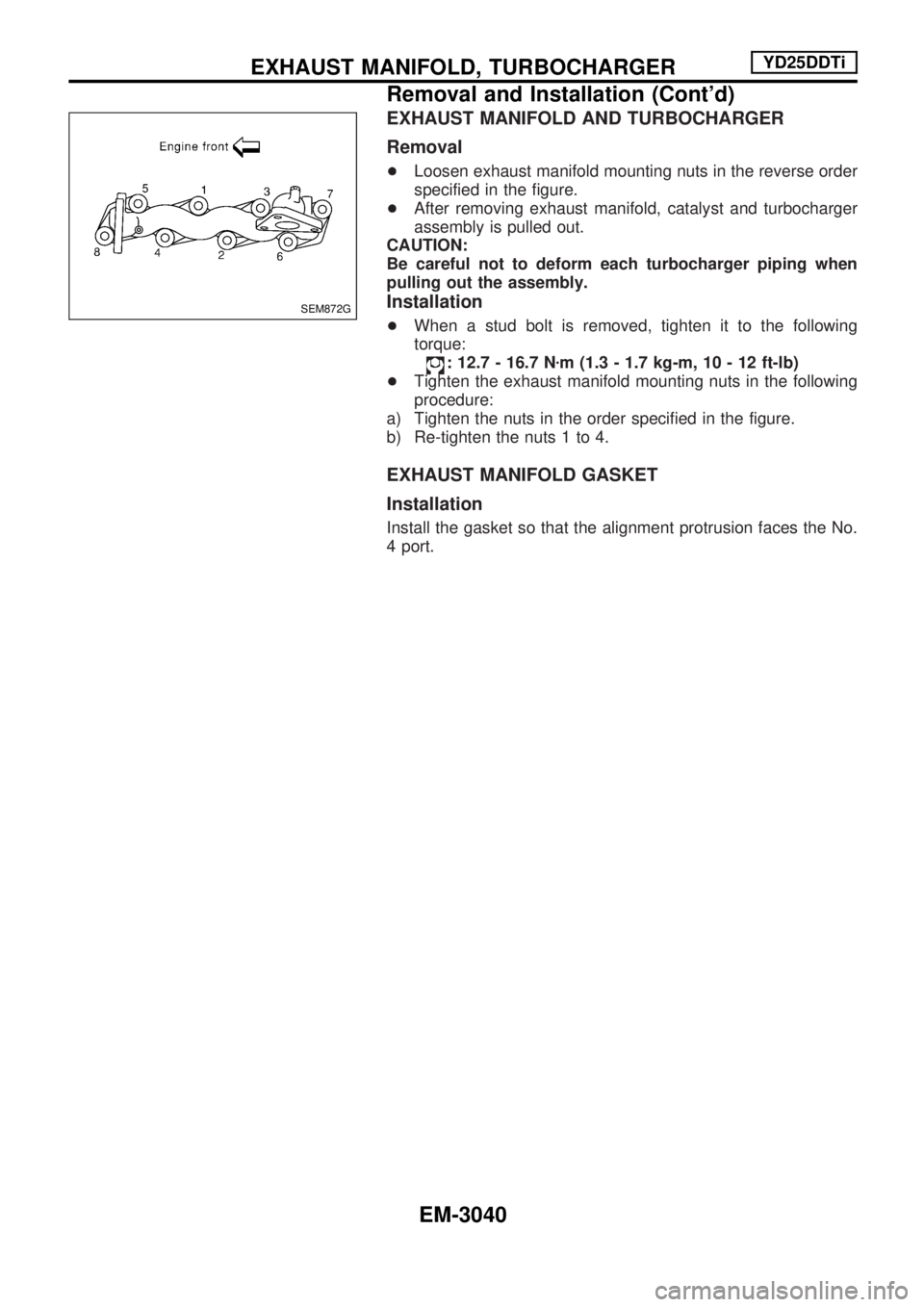

EXHAUST MANIFOLD AND TURBOCHARGER

Removal

+Loosen exhaust manifold mounting nuts in the reverse order

specified in the figure.

+After removing exhaust manifold, catalyst and turbocharger

assembly is pulled out.

CAUTION:

Be careful not to deform each turbocharger piping when

pulling out the assembly.

Installation

+When a stud bolt is removed, tighten it to the following

torque:

: 12.7 - 16.7 Nzm (1.3 - 1.7 kg-m, 10 - 12 ft-lb)

+Tighten the exhaust manifold mounting nuts in the following

procedure:

a) Tighten the nuts in the order specified in the figure.

b) Re-tighten the nuts 1 to 4.

EXHAUST MANIFOLD GASKET

Installation

Install the gasket so that the alignment protrusion faces the No.

4 port.

SEM872G

EXHAUST MANIFOLD, TURBOCHARGERYD25DDTi

Removal and Installation (Cont'd)

EM-3040

Page 918 of 1306

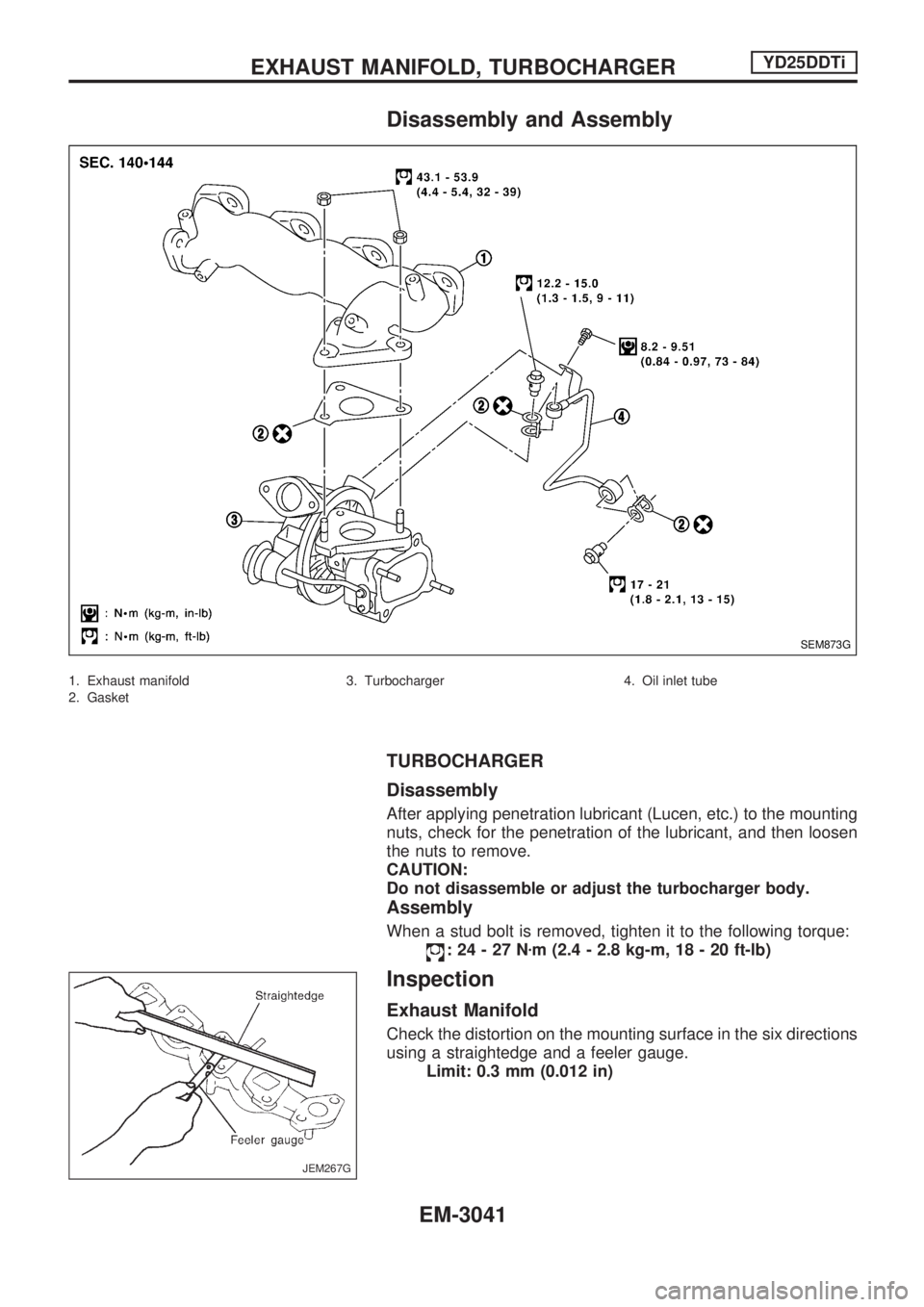

Disassembly and Assembly

1. Exhaust manifold

2. Gasket3. Turbocharger 4. Oil inlet tube

TURBOCHARGER

Disassembly

After applying penetration lubricant (Lucen, etc.) to the mounting

nuts, check for the penetration of the lubricant, and then loosen

the nuts to remove.

CAUTION:

Do not disassemble or adjust the turbocharger body.

Assembly

When a stud bolt is removed, tighten it to the following torque:

:24-27Nzm (2.4 - 2.8 kg-m, 18 - 20 ft-lb)

Inspection

Exhaust Manifold

Check the distortion on the mounting surface in the six directions

using a straightedge and a feeler gauge.

Limit: 0.3 mm (0.012 in)

SEM873G

JEM267G

EXHAUST MANIFOLD, TURBOCHARGERYD25DDTi

EM-3041

Page 919 of 1306

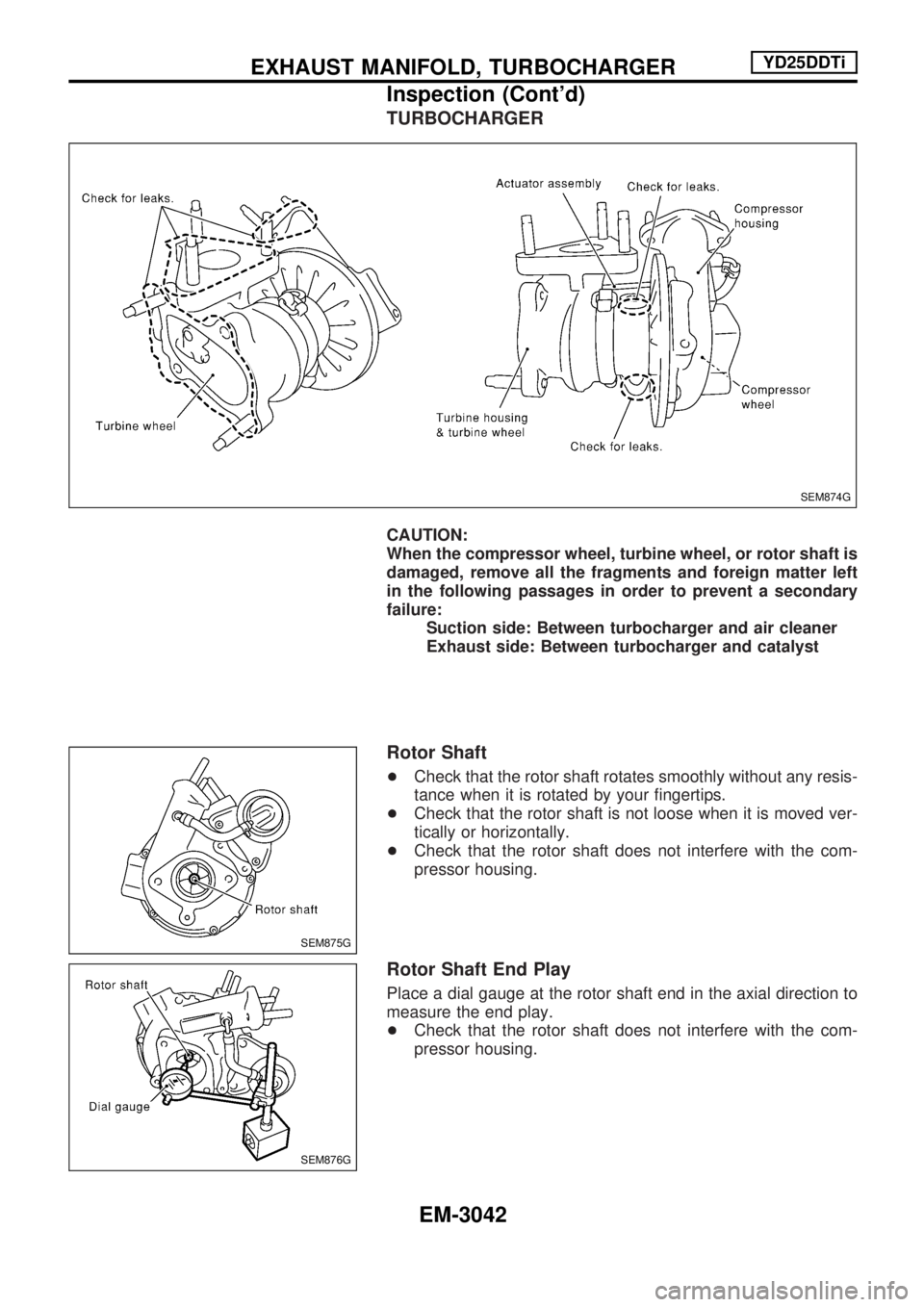

TURBOCHARGER

CAUTION:

When the compressor wheel, turbine wheel, or rotor shaft is

damaged, remove all the fragments and foreign matter left

in the following passages in order to prevent a secondary

failure:

Suction side: Between turbocharger and air cleaner

Exhaust side: Between turbocharger and catalyst

Rotor Shaft

+Check that the rotor shaft rotates smoothly without any resis-

tance when it is rotated by your fingertips.

+Check that the rotor shaft is not loose when it is moved ver-

tically or horizontally.

+Check that the rotor shaft does not interfere with the com-

pressor housing.

Rotor Shaft End Play

Place a dial gauge at the rotor shaft end in the axial direction to

measure the end play.

+Check that the rotor shaft does not interfere with the com-

pressor housing.

SEM874G

SEM875G

SEM876G

EXHAUST MANIFOLD, TURBOCHARGERYD25DDTi

Inspection (Cont'd)

EM-3042

Page 920 of 1306

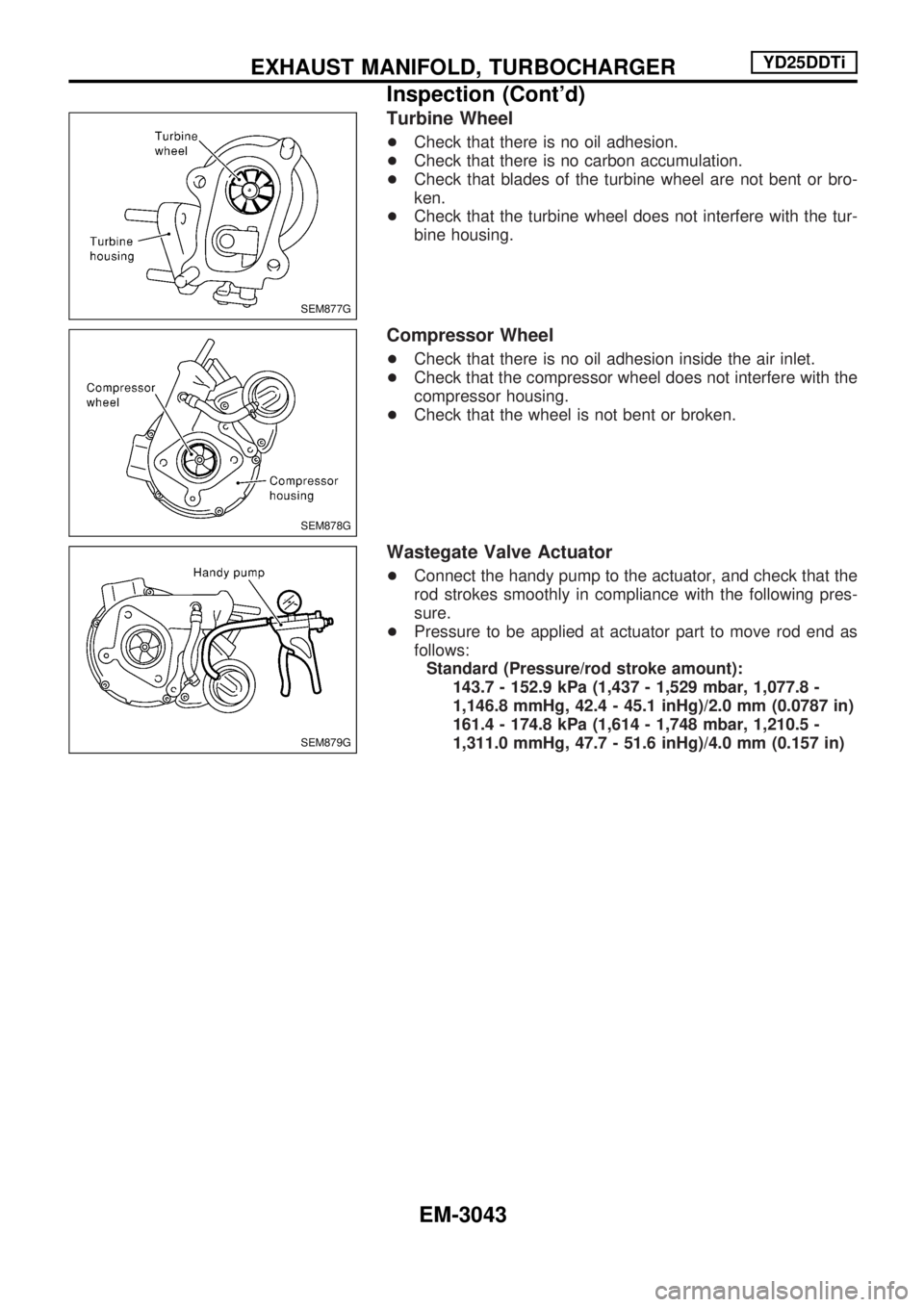

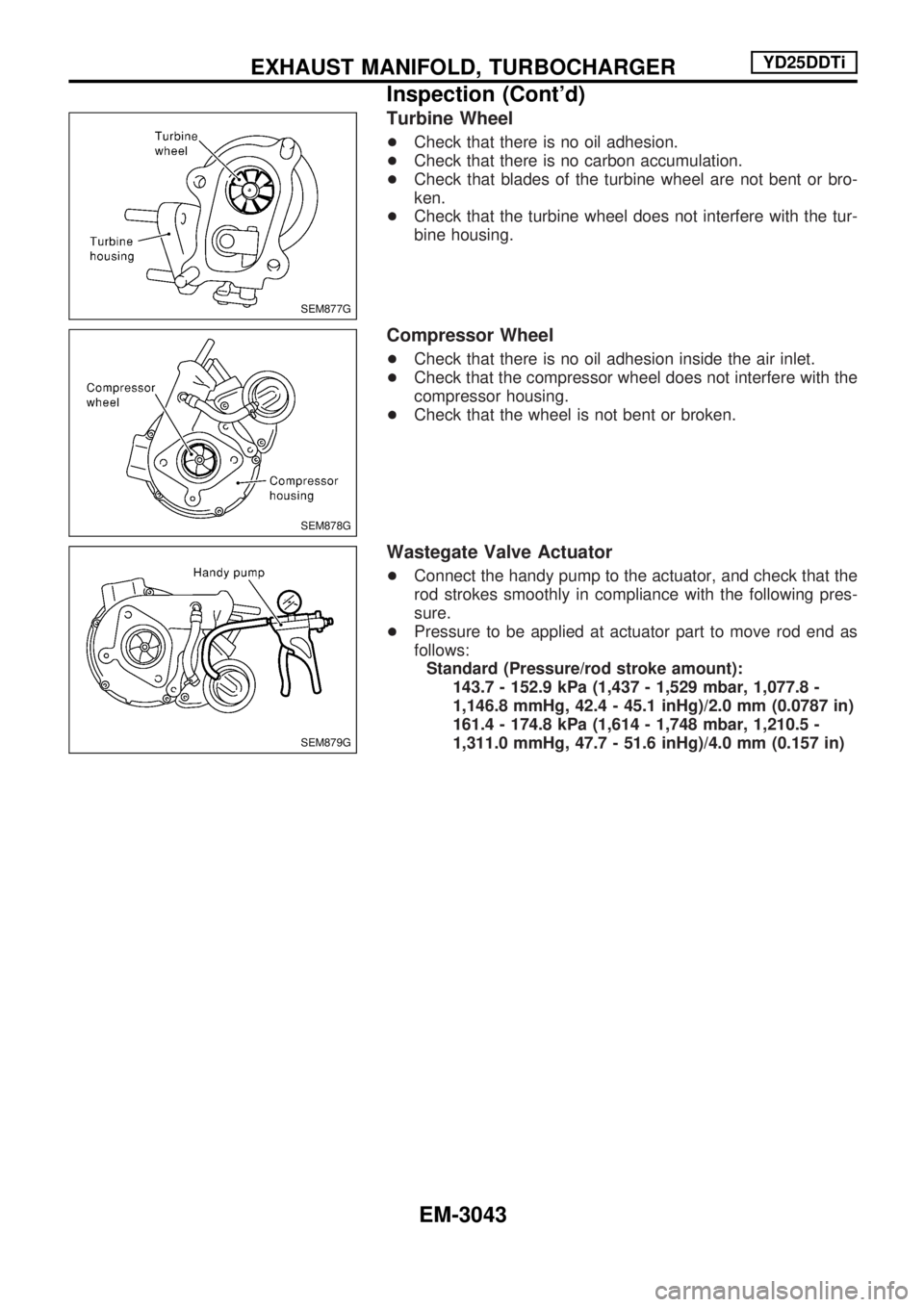

Turbine Wheel

+Check that there is no oil adhesion.

+Check that there is no carbon accumulation.

+Check that blades of the turbine wheel are not bent or bro-

ken.

+Check that the turbine wheel does not interfere with the tur-

bine housing.

Compressor Wheel

+Check that there is no oil adhesion inside the air inlet.

+Check that the compressor wheel does not interfere with the

compressor housing.

+Check that the wheel is not bent or broken.

Wastegate Valve Actuator

+Connect the handy pump to the actuator, and check that the

rod strokes smoothly in compliance with the following pres-

sure.

+Pressure to be applied at actuator part to move rod end as

follows:

Standard (Pressure/rod stroke amount):

143.7 - 152.9 kPa (1,437 - 1,529 mbar, 1,077.8 -

1,146.8 mmHg, 42.4 - 45.1 inHg)/2.0 mm (0.0787 in)

161.4 - 174.8 kPa (1,614 - 1,748 mbar, 1,210.5 -

1,311.0 mmHg, 47.7 - 51.6 inHg)/4.0 mm (0.157 in)

SEM877G

SEM878G

SEM879G

EXHAUST MANIFOLD, TURBOCHARGERYD25DDTi

Inspection (Cont'd)

EM-3043

Trending: tires, charging, oil change, ESP, seat adjustment, door lock, service indicator