NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 191 of 2267

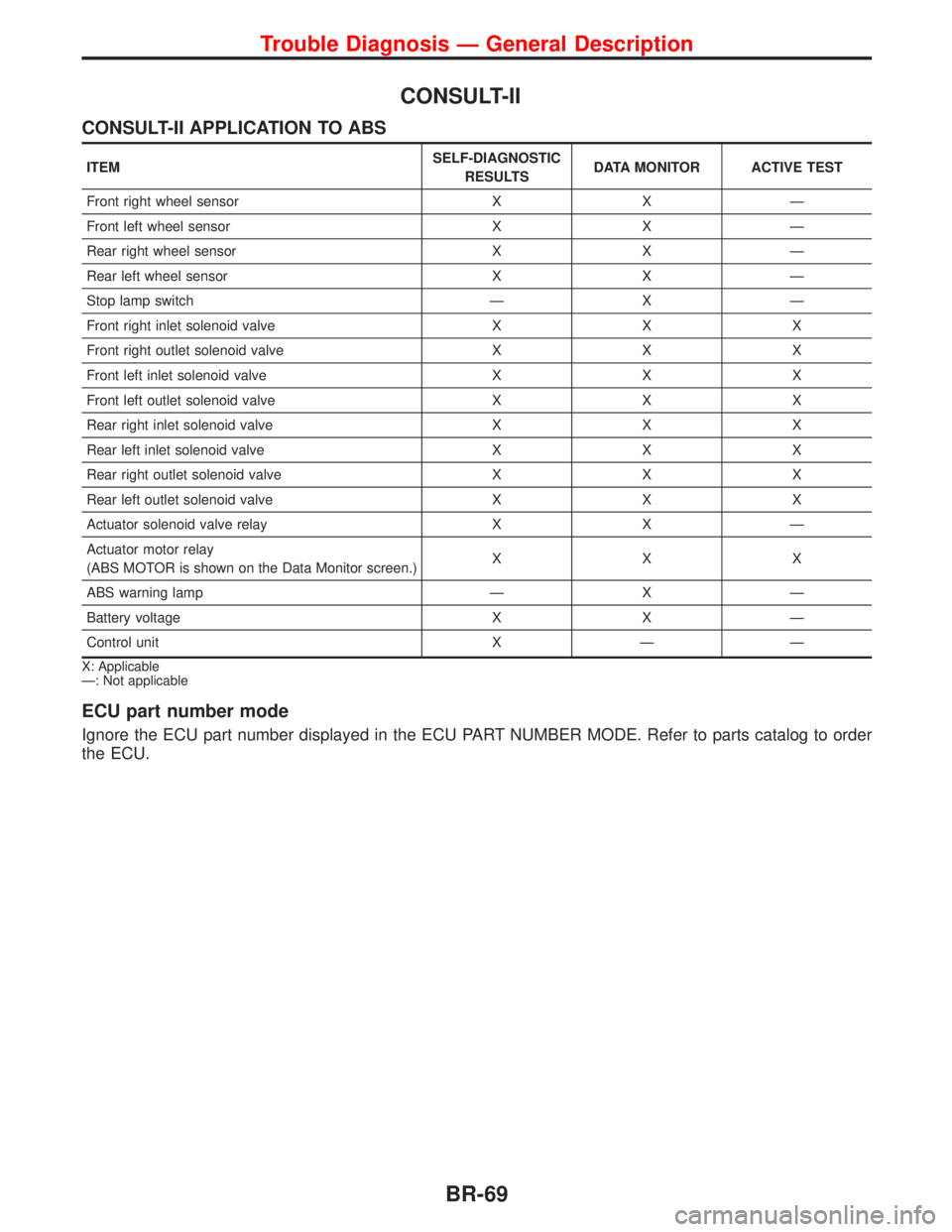

CONSULT-II

CONSULT-II APPLICATION TO ABS

ITEMSELF-DIAGNOSTIC

RESULTSDATA MONITOR ACTIVE TEST

Front right wheel sensor X X Ð

Front left wheel sensor X X Ð

Rear right wheel sensor X X Ð

Rear left wheel sensor X X Ð

Stop lamp switch Ð X Ð

Front right inlet solenoid valve X X X

Front right outlet solenoid valve X X X

Front left inlet solenoid valve X X X

Front left outlet solenoid valve X X X

Rear right inlet solenoid valve X X X

Rear left inlet solenoid valve X X X

Rear right outlet solenoid valve X X X

Rear left outlet solenoid valve X X X

Actuator solenoid valve relay X X Ð

Actuator motor relay

(ABS MOTOR is shown on the Data Monitor screen.)XXX

ABS warning lamp Ð X Ð

Battery voltage X X Ð

Control unit X Ð Ð

X: Applicable

Ð: Not applicable

ECU part number mode

Ignore the ECU part number displayed in the ECU PART NUMBER MODE. Refer to parts catalog to order

the ECU.

Trouble Diagnosis Ð General Description

BR-69

Page 192 of 2267

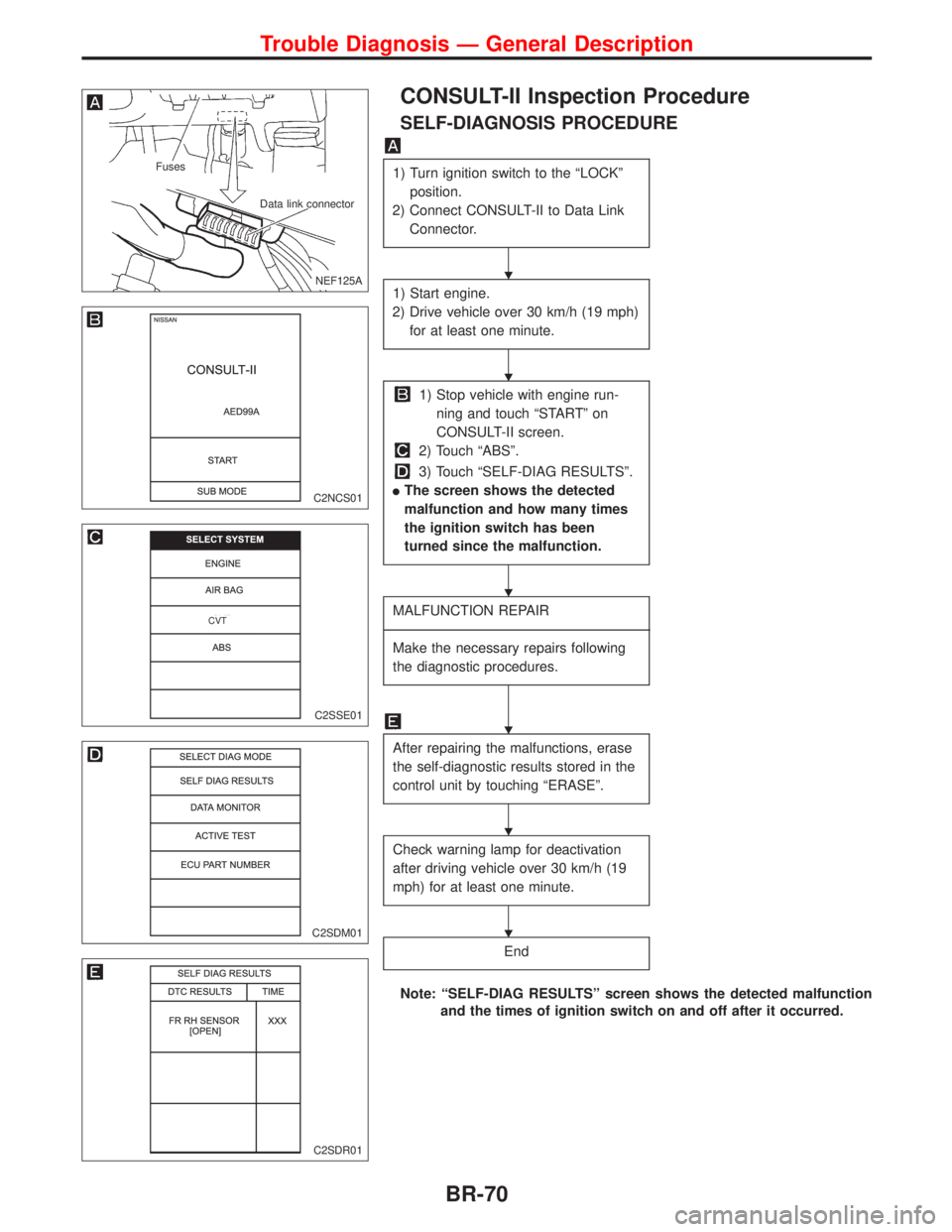

CONSULT-II Inspection Procedure

SELF-DIAGNOSIS PROCEDURE

1) Turn ignition switch to the ªLOCKº

position.

2) Connect CONSULT-II to Data Link

Connector.

1) Start engine.

2) Drive vehicle over 30 km/h (19 mph)

for at least one minute.

1) Stop vehicle with engine run-

ning and touch ªSTARTº on

CONSULT-II screen.

2) Touch ªABSº.

3) Touch ªSELF-DIAG RESULTSº.

lThe screen shows the detected

malfunction and how many times

the ignition switch has been

turned since the malfunction.

MALFUNCTION REPAIR

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Make the necessary repairs following

the diagnostic procedures.

After repairing the malfunctions, erase

the self-diagnostic results stored in the

control unit by touching ªERASEº.

Check warning lamp for deactivation

after driving vehicle over 30 km/h (19

mph) for at least one minute.

End

Note: ªSELF-DIAG RESULTSº screen shows the detected malfunction

and the times of ignition switch on and off after it occurred.

.NEF125A

Fuses

Data link connector

C2NCS01

C2SSE01

.CVT

C2SDM01

C2SDR01

H

H

H

H

H

H

Trouble Diagnosis Ð General Description

BR-70

Page 193 of 2267

![NISSAN PRIMERA 1999 Electronic Repair Manual SELF-DIAGNOSTIC RESULTS MODE

Diagnostic item Diagnostic item is detected when...Diagnostic

procedure

FR RH SENSORH

[OPEN]

lCircuit for front right wheel sensor is open.

(An abnormally high input volta NISSAN PRIMERA 1999 Electronic Repair Manual SELF-DIAGNOSTIC RESULTS MODE

Diagnostic item Diagnostic item is detected when...Diagnostic

procedure

FR RH SENSORH

[OPEN]

lCircuit for front right wheel sensor is open.

(An abnormally high input volta](/img/5/57377/w960_57377-192.png)

SELF-DIAGNOSTIC RESULTS MODE

Diagnostic item Diagnostic item is detected when...Diagnostic

procedure

FR RH SENSORH

[OPEN]

lCircuit for front right wheel sensor is open.

(An abnormally high input voltage is entered.)1

FR LH SENSORH

[OPEN]

lCircuit for front left wheel sensor is open.

(An abnormally high input voltage is entered.)1

RR RH SENSORH

[OPEN]

lCircuit for rear right sensor is open.

(An abnormally high input voltage is entered.)1

RR LH SENSORH

[OPEN]

lCircuit for rear left sensor is open.

(An abnormally high input voltage is entered.)1

FR RH SENSORH

[SHORT]

lCircuit for front right wheel sensor is shorted.

(An abnormally low input voltage is entered.)1

FR LH SENSORH

[SHORT]

lCircuit for front left wheel sensor is shorted.

(An abnormally low input voltage is entered.)1

RR RH SENSORH

[SHORT]

lCircuit for rear right sensor is shorted.

(An abnormally low input voltage is entered.)1

RR LH SENSOR

[SHORT]

lCircuit for rear left sensor is shorted.

(An abnormally low input voltage is entered.)1

ABS SENSORH

[ABNORMAL SIGNAL]

lTeeth damage on sensor rotor or improper installation of wheel sensor.

(Abnormal wheel sensor signal is entered.)1

FR RH IN ABS SOL

[OPEN]

lCircuit for front right inlet solenoid valve is open.

(An abnormally low output voltage is entered.)2

FR LH IN ABS SOL

[OPEN]

lCircuit for front left inlet solenoid valve is open.

(An abnormally low output voltage is entered.)2

RR RH IN ABS SOL

[OPEN]

lCircuit for rear right inlet solenoid valve is open.

(An abnormally low output voltage is entered.)2

RR LH IN ABS SOL

[OPEN]

lCircuit for rear left inlet solenoid valve is open.

(An abnormally low output voltage is entered.)2

FR RH IN ABS SOL

[SHORT]

lCircuit for front right inlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)2

FR LH IN ABS SOL

[SHORT]

lCircuit for front left inlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)2

RR RH IN ABS SOL

[SHORT]

lCircuit for rear right inlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)2

RR LH IN ABS SOL

[SHORT]

lCircuit for rear left inlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)2

FR RH OUT ABS SOL

[OPEN]

lCircuit for front right outlet solenoid valve is open.

(An abnormally low output voltage is entered.)2

FR LH OUT ABS SOL

[OPEN]

lCircuit for front left outlet solenoid valve is open.

(An abnormally low output voltage is entered.)2

RR RH OUT ABS SOL

[OPEN]

lCircuit for rear right outlet solenoid valve is open.

(An abnormally low output voltage is entered.)2

RR LH OUT ABS SOL

[OPEN]

lCircuit for rear left outlet solenoid valve is open.

(An abnormally low output voltage is entered.)2

FR RH OUT ABS SOL

[SHORT]

lCircuit for front right outlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)2

FR LH OUT ABS SOL

[SHORT]

lCircuit for front left outlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)2

RR RH OUT ABS SOL

[SHORT]

lCircuit for rear right outlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)2

RR LH OUT ABS SOL

[SHORT]

lCircuit for rear left outlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)2

ABS ACTUATOR RELAY

[ABNORMAL]

lActuator solenoid valve relay is ON, even control unit sends off signal.lActuator solenoid valve relay is OFF, even control unit sends on signal.2

ABS MOTOR RELAY

[ABNORMAL]

lCircuit for actuator motor is open or shorted.lActuator motor relay is stuck.lCircuit for actuator is open or shorted.3

BATTERY VOLT

[VB-LOW]

lPower source voltage supplied to ABS control unit is abnormally low. 4

CONTROL UNIT

lFunction of calculation in ABS control unit has failed. 5

H: If one or more wheels spin on a rough or slippery road for 40 seconds or more, the ABS warning lamp will illuminate. This does

not indicate a malfunction. Only in the case of the short-circuit after repair the ABS warning lamp also illuminates when the igni-

tion switch is turned ªONº. In this case, drive the vehicle at speeds greater than 30 km/h (19 MPH) for approximately 1 minute

as specified in ªSELF-DIAGNOSIS PROCEDUREº, BR-70. Check to ensure that the ABS warning lamp goes out while the

vehicle is being driven.

Trouble Diagnosis Ð General Description

CONSULT-II Inspection Procedure (Cont'd)

BR-71

Page 194 of 2267

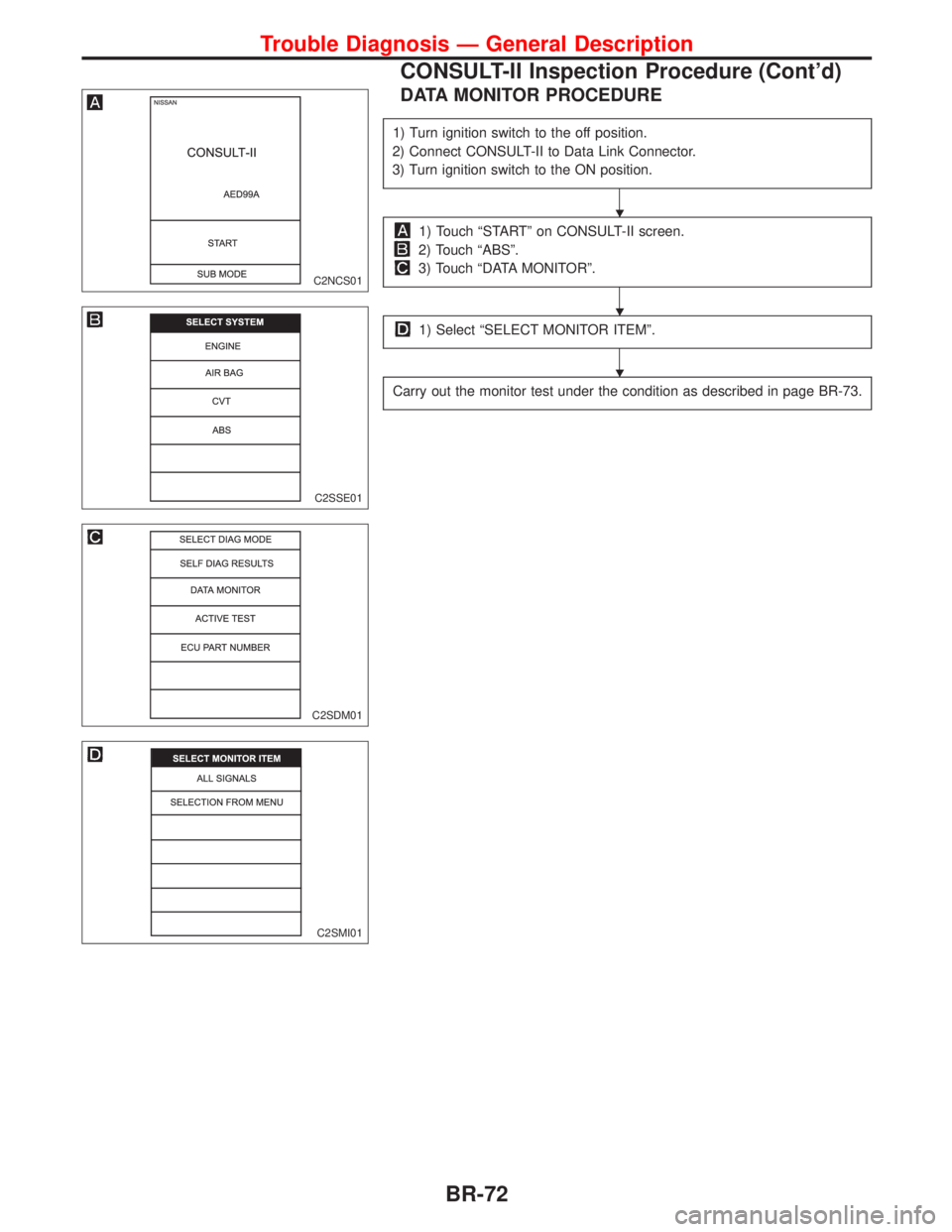

DATA MONITOR PROCEDURE

1) Turn ignition switch to the off position.

2) Connect CONSULT-II to Data Link Connector.

3) Turn ignition switch to the ON position.

1) Touch ªSTARTº on CONSULT-II screen.

2) Touch ªABSº.

3) Touch ªDATA MONITORº.

1) Select ªSELECT MONITOR ITEMº.

Carry out the monitor test under the condition as described in page BR-73.

C2NCS01

C2SSE01

C2SDM01

C2SMI01

H

H

H

Trouble Diagnosis Ð General Description

CONSULT-II Inspection Procedure (Cont'd)

BR-72

Page 195 of 2267

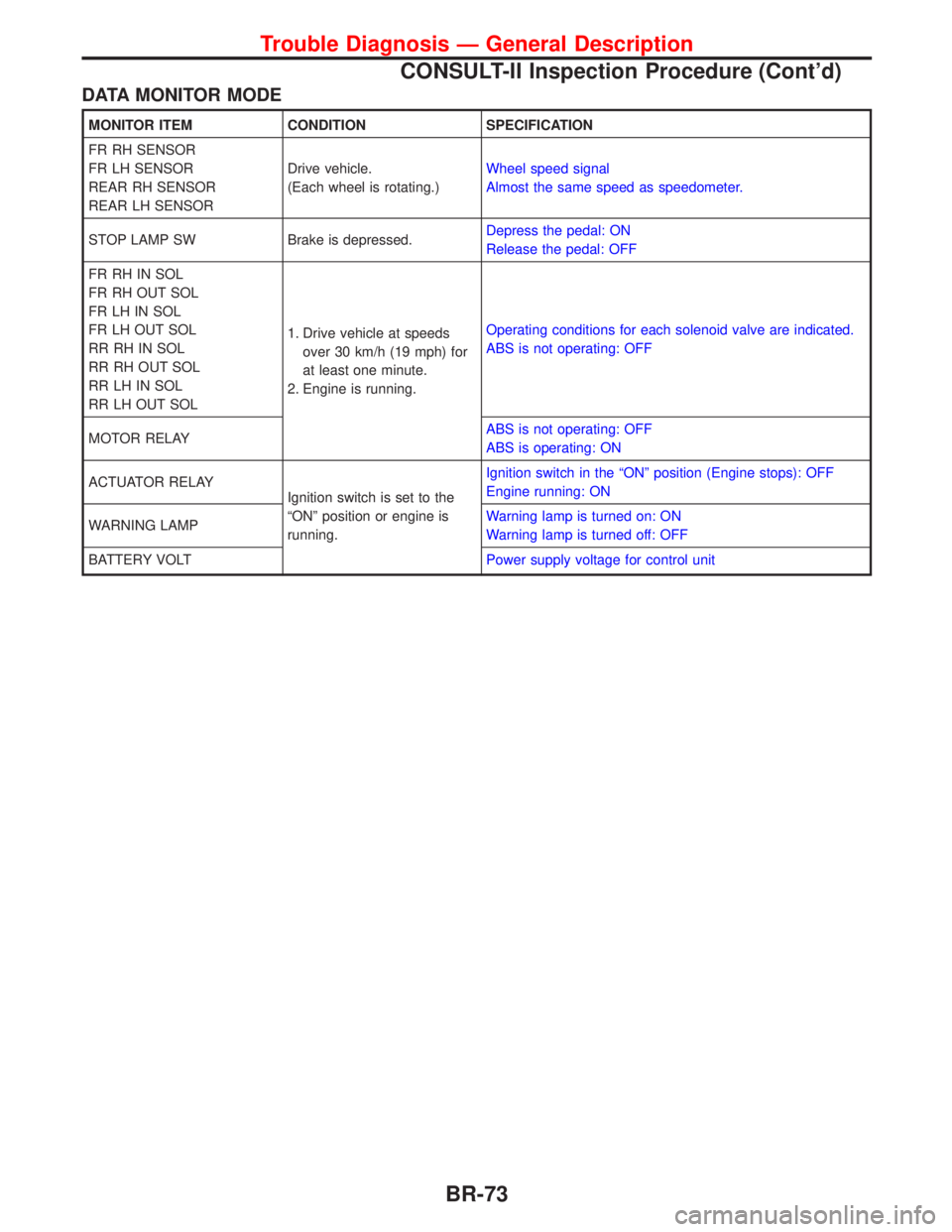

DATA MONITOR MODE

MONITOR ITEM CONDITION SPECIFICATION

FR RH SENSOR

FR LH SENSOR

REAR RH SENSOR

REAR LH SENSORDrive vehicle.

(Each wheel is rotating.)Wheel speed signal

Almost the same speed as speedometer.

STOP LAMP SW Brake is depressed.Depress the pedal: ON

Release the pedal: OFF

FR RH IN SOL

FR RH OUT SOL

FR LH IN SOL

FR LH OUT SOL

RR RH IN SOL

RR RH OUT SOL

RR LH IN SOL

RR LH OUT SOL1. Drive vehicle at speeds

over 30 km/h (19 mph) for

at least one minute.

2. Engine is running.Operating conditions for each solenoid valve are indicated.

ABS is not operating: OFF

MOTOR RELAYABS is not operating: OFF

ABS is operating: ON

ACTUATOR RELAY

Ignition switch is set to the

ªONº position or engine is

running.Ignition switch in the ªONº position (Engine stops): OFF

Engine running: ON

WARNING LAMPWarning lamp is turned on: ON

Warning lamp is turned off: OFF

BATTERY VOLTPower supply voltage for control unit

Trouble Diagnosis Ð General Description

CONSULT-II Inspection Procedure (Cont'd)

BR-73

Page 196 of 2267

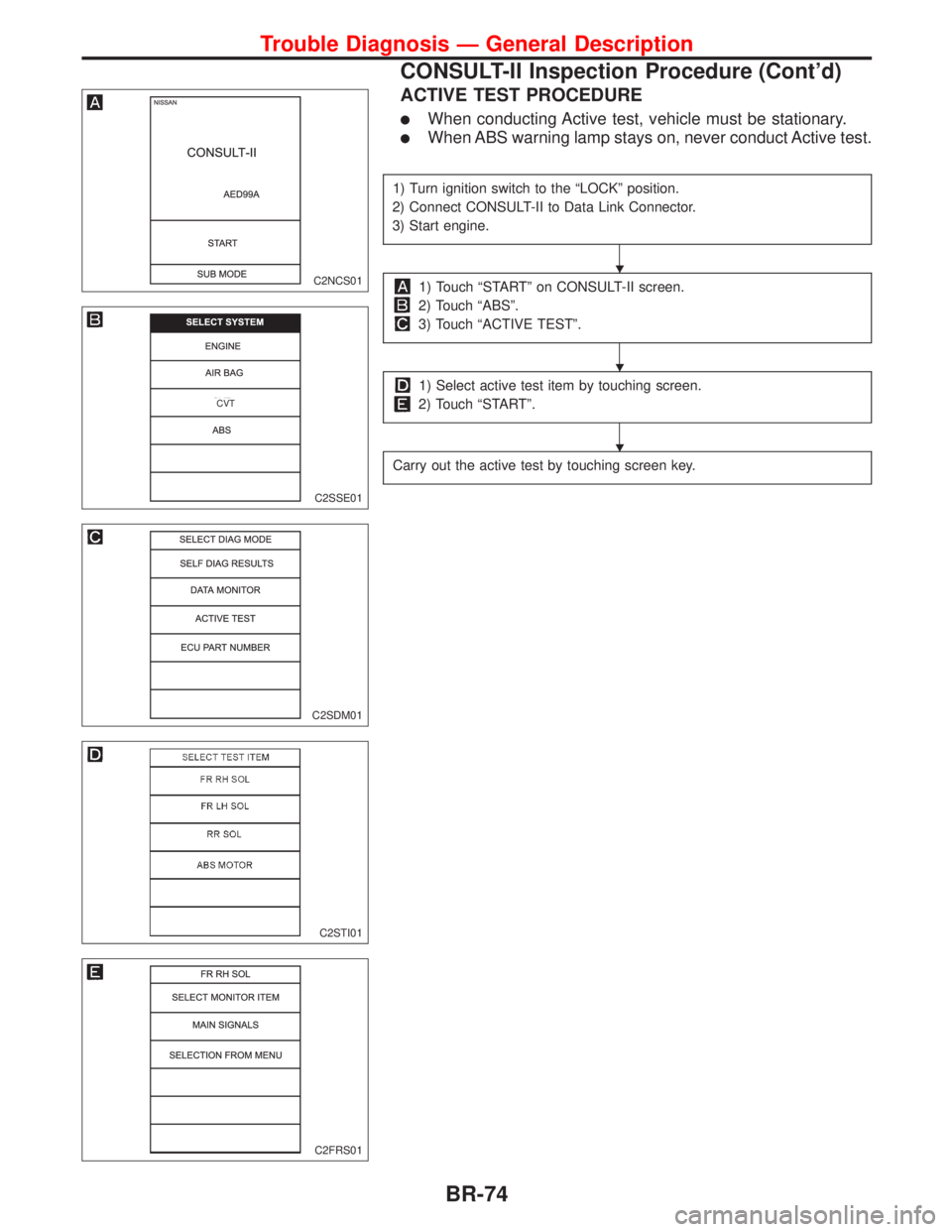

ACTIVE TEST PROCEDURE

lWhen conducting Active test, vehicle must be stationary.

lWhen ABS warning lamp stays on, never conduct Active test.

1) Turn ignition switch to the ªLOCKº position.

2) Connect CONSULT-II to Data Link Connector.

3) Start engine.

1) Touch ªSTARTº on CONSULT-II screen.

2) Touch ªABSº.

3) Touch ªACTIVE TESTº.

1) Select active test item by touching screen.

2) Touch ªSTARTº.

Carry out the active test by touching screen key.

C2NCS01

C2SSE01

.CVT

C2SDM01

C2STI01

C2FRS01

H

H

H

Trouble Diagnosis Ð General Description

CONSULT-II Inspection Procedure (Cont'd)

BR-74

Page 197 of 2267

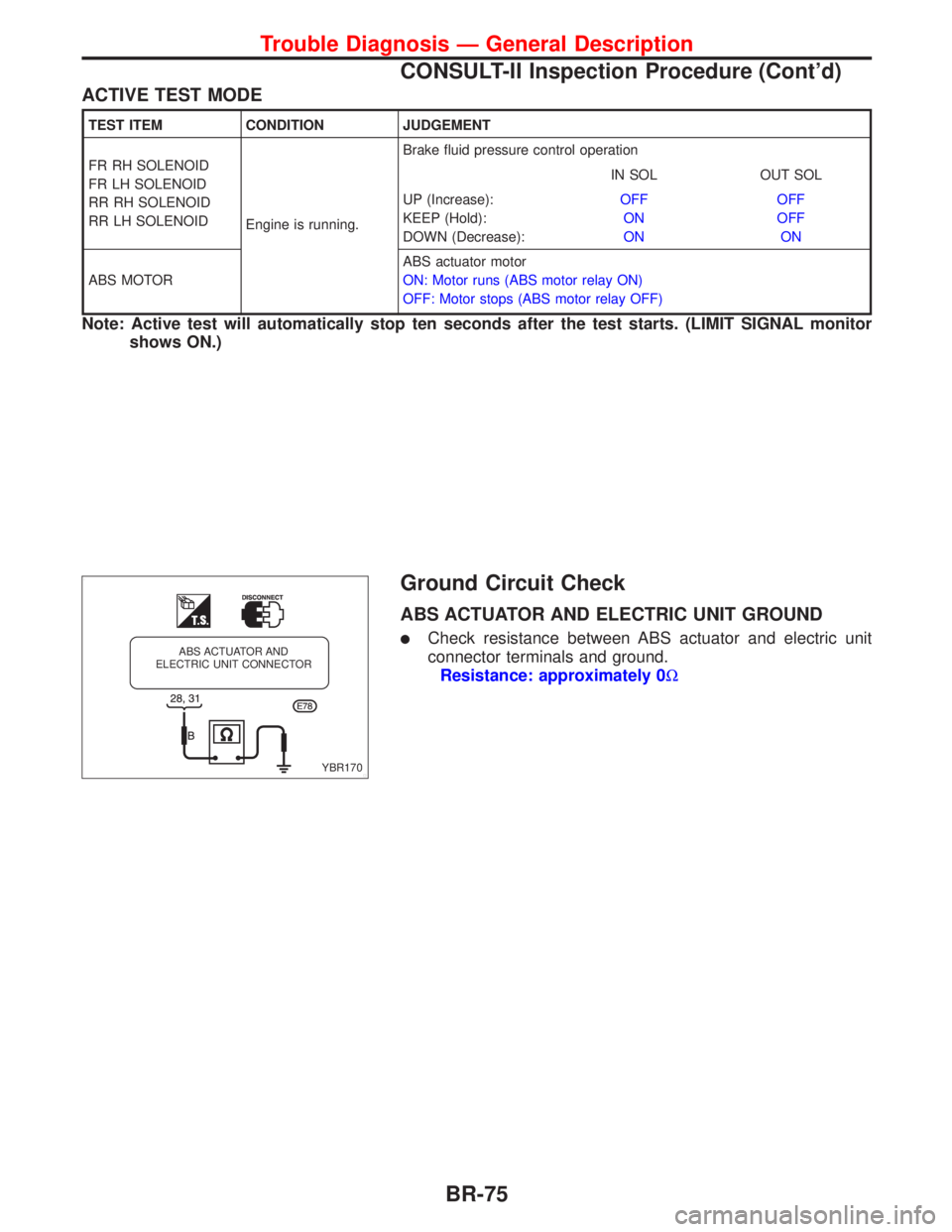

ACTIVE TEST MODE

TEST ITEM CONDITION JUDGEMENT

FR RH SOLENOID

FR LH SOLENOID

RR RH SOLENOID

RR LH SOLENOID

Engine is running.Brake fluid pressure control operation

IN SOL OUT SOL

UP (Increase):

KEEP (Hold):

DOWN (Decrease):OFF

ON

ONOFF

OFF

ON

ABS MOTORABS actuator motor

ON: Motor runs (ABS motor relay ON)

OFF: Motor stops (ABS motor relay OFF)

Note: Active test will automatically stop ten seconds after the test starts. (LIMIT SIGNAL monitor

shows ON.)

Ground Circuit Check

ABS ACTUATOR AND ELECTRIC UNIT GROUND

lCheck resistance between ABS actuator and electric unit

connector terminals and ground.

Resistance: approximately 0W

YBR170 ABS ACTUATOR AND

ELECTRIC UNIT CONNECTOR

Trouble Diagnosis Ð General Description

CONSULT-II Inspection Procedure (Cont'd)

BR-75

Page 198 of 2267

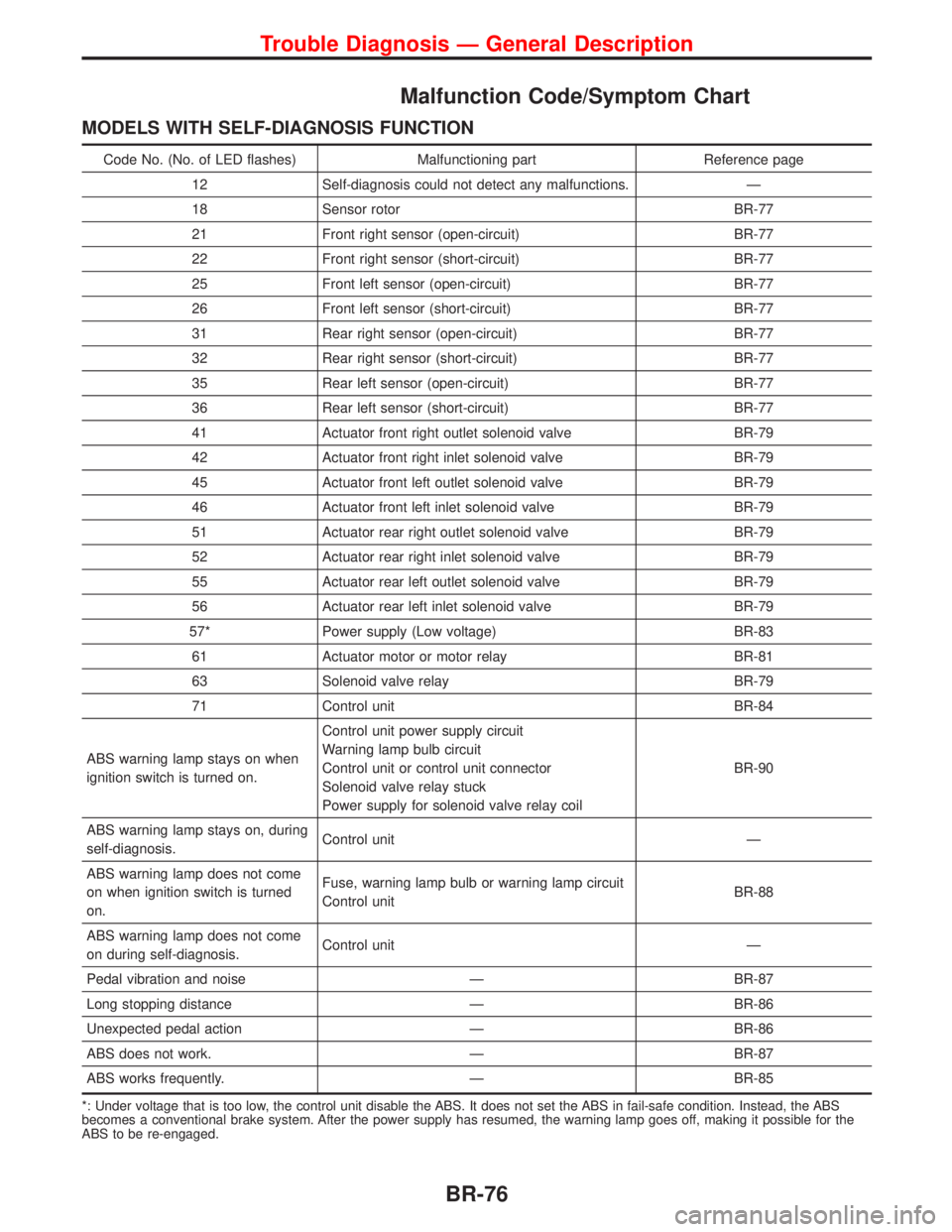

Malfunction Code/Symptom Chart

MODELS WITH SELF-DIAGNOSIS FUNCTION

Code No. (No. of LED flashes) Malfunctioning part Reference page

12 Self-diagnosis could not detect any malfunctions. Ð

18 Sensor rotor BR-77

21 Front right sensor (open-circuit) BR-77

22 Front right sensor (short-circuit) BR-77

25 Front left sensor (open-circuit) BR-77

26 Front left sensor (short-circuit) BR-77

31 Rear right sensor (open-circuit) BR-77

32 Rear right sensor (short-circuit) BR-77

35 Rear left sensor (open-circuit) BR-77

36 Rear left sensor (short-circuit) BR-77

41 Actuator front right outlet solenoid valve BR-79

42 Actuator front right inlet solenoid valve BR-79

45 Actuator front left outlet solenoid valve BR-79

46 Actuator front left inlet solenoid valve BR-79

51 Actuator rear right outlet solenoid valve BR-79

52 Actuator rear right inlet solenoid valve BR-79

55 Actuator rear left outlet solenoid valve BR-79

56 Actuator rear left inlet solenoid valve BR-79

57* Power supply (Low voltage) BR-83

61 Actuator motor or motor relay BR-81

63 Solenoid valve relay BR-79

71 Control unit BR-84

ABS warning lamp stays on when

ignition switch is turned on.Control unit power supply circuit

Warning lamp bulb circuit

Control unit or control unit connector

Solenoid valve relay stuck

Power supply for solenoid valve relay coilBR-90

ABS warning lamp stays on, during

self-diagnosis.Control unit Ð

ABS warning lamp does not come

on when ignition switch is turned

on.Fuse, warning lamp bulb or warning lamp circuit

Control unitBR-88

ABS warning lamp does not come

on during self-diagnosis.Control unit Ð

Pedal vibration and noise Ð BR-87

Long stopping distance Ð BR-86

Unexpected pedal action Ð BR-86

ABS does not work. Ð BR-87

ABS works frequently. Ð BR-85

*: Under voltage that is too low, the control unit disable the ABS. It does not set the ABS in fail-safe condition. Instead, the ABS

becomes a conventional brake system. After the power supply has resumed, the warning lamp goes off, making it possible for the

ABS to be re-engaged.

Trouble Diagnosis Ð General Description

BR-76

Page 199 of 2267

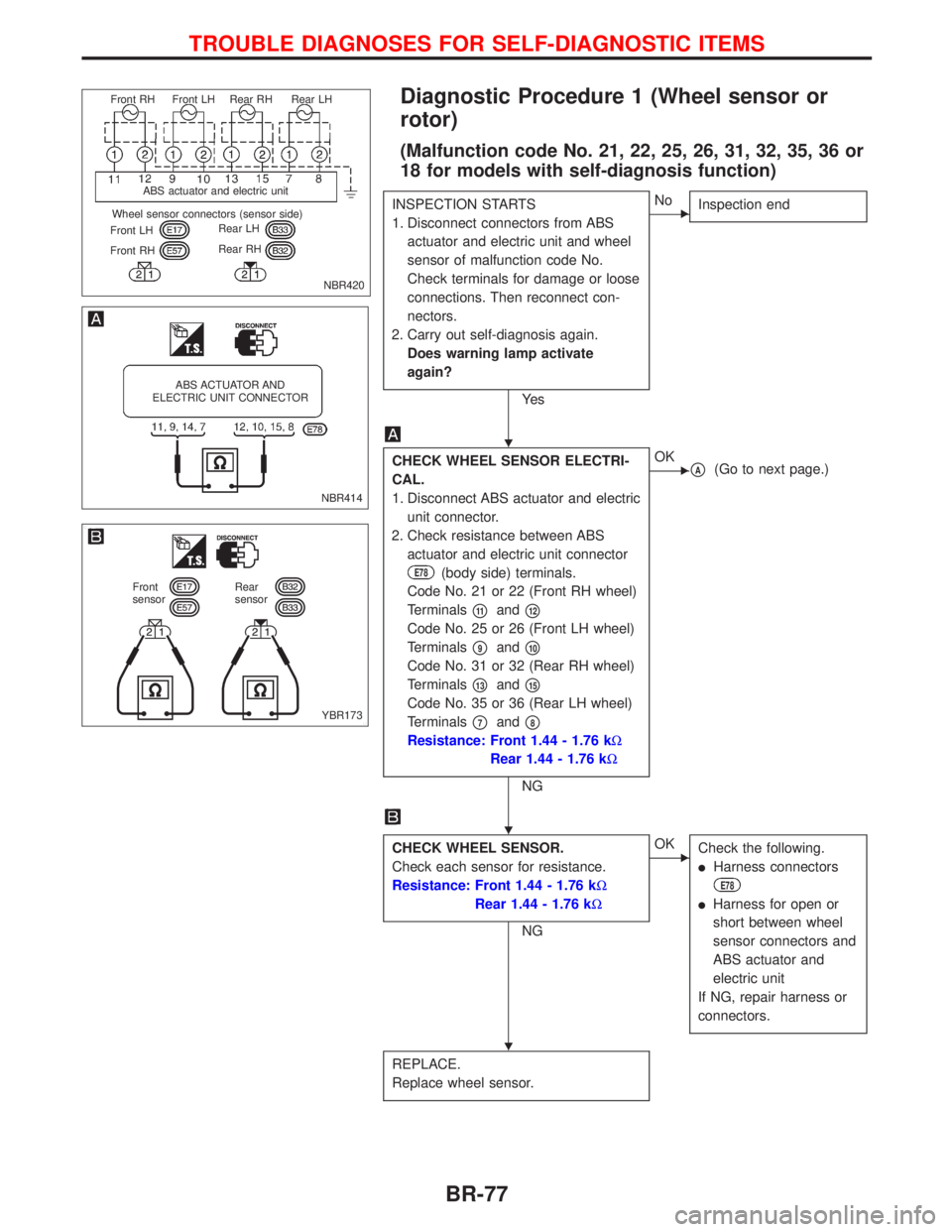

Diagnostic Procedure 1 (Wheel sensor or

rotor)

(Malfunction code No. 21, 22, 25, 26, 31, 32, 35, 36 or

18 for models with self-diagnosis function)

INSPECTION STARTS

1. Disconnect connectors from ABS

actuator and electric unit and wheel

sensor of malfunction code No.

Check terminals for damage or loose

connections. Then reconnect con-

nectors.

2. Carry out self-diagnosis again.

Does warning lamp activate

again?

Ye s

ENo

Inspection end

CHECK WHEEL SENSOR ELECTRI-

CAL.

1. Disconnect ABS actuator and electric

unit connector.

2. Check resistance between ABS

actuator and electric unit connector

E78(body side) terminals.

Code No. 21 or 22 (Front RH wheel)

Terminals

p11andp12

Code No. 25 or 26 (Front LH wheel)

Terminals

p9andp10

Code No. 31 or 32 (Rear RH wheel)

Terminals

p13andp15

Code No. 35 or 36 (Rear LH wheel)

Terminals

p7andp8

Resistance: Front 1.44 - 1.76 kW

Rear 1.44 - 1.76 kW

NG

EOKpA(Go to next page.)

CHECK WHEEL SENSOR.

Check each sensor for resistance.

Resistance: Front 1.44 - 1.76 kW

Rear 1.44 - 1.76 kW

NG

EOK

Check the following.

lHarness connectors

E78

lHarness for open or

short between wheel

sensor connectors and

ABS actuator and

electric unit

If NG, repair harness or

connectors.

REPLACE.

Replace wheel sensor.

NBR420 Front RH Front LH Rear RH Rear LH

ABS actuator and electric unit

Wheel sensor connectors (sensor side)

Front LH

Front RHRear LH

Rear RH

NBR414

ABS ACTUATOR AND

ELECTRIC UNIT CONNECTOR

YBR173

Front

sensorRear

sensor

H

H

H

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMS

BR-77

Page 200 of 2267

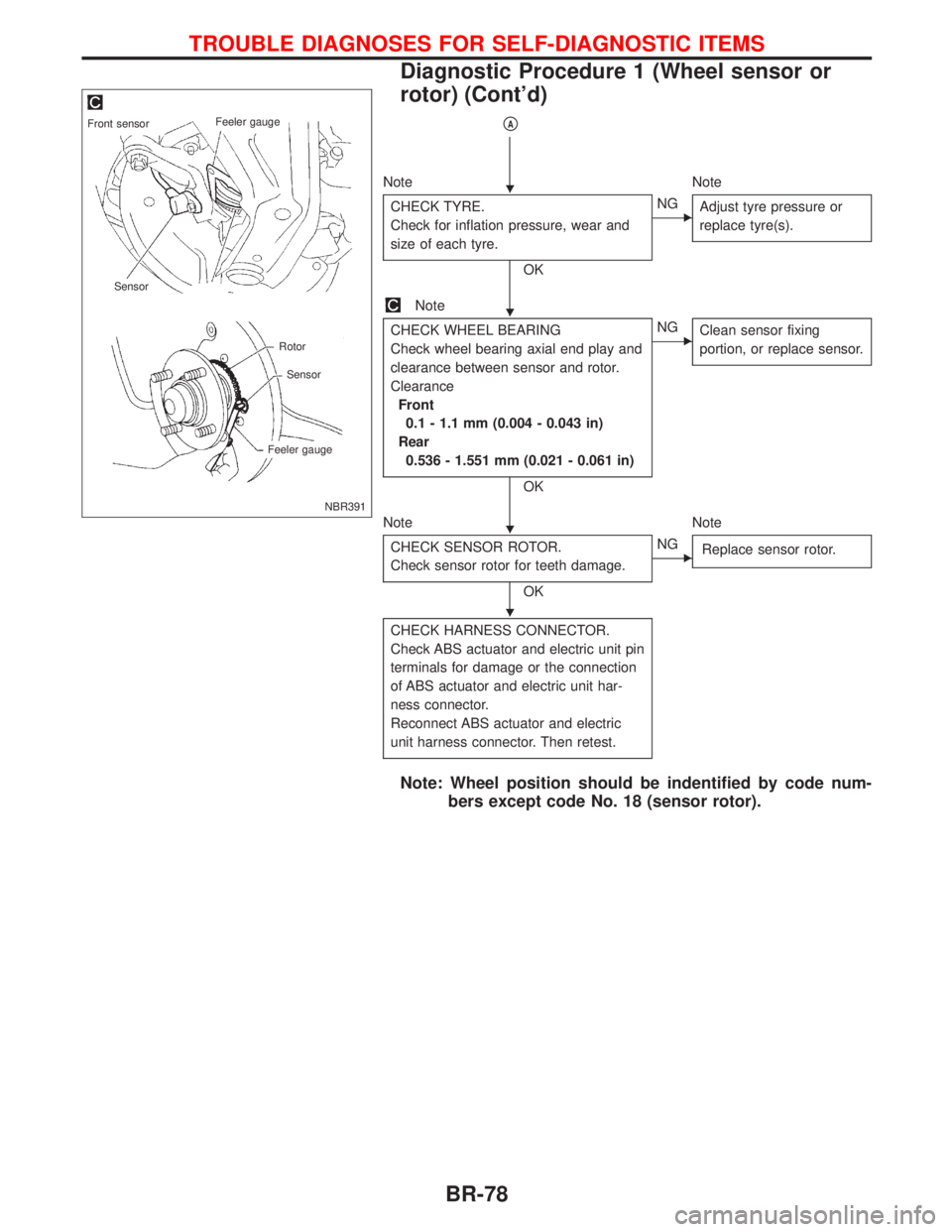

pA

Note Note

CHECK TYRE.

Check for inflation pressure, wear and

size of each tyre.

OK

ENG

Adjust tyre pressure or

replace tyre(s).

Note

CHECK WHEEL BEARING

Check wheel bearing axial end play and

clearance between sensor and rotor.

Clearance

Front

0.1 - 1.1 mm (0.004 - 0.043 in)

Rear

0.536 - 1.551 mm (0.021 - 0.061 in)

OK

ENG

Clean sensor fixing

portion, or replace sensor.

Note Note

CHECK SENSOR ROTOR.

Check sensor rotor for teeth damage.

OK

ENG

Replace sensor rotor.

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit pin

terminals for damage or the connection

of ABS actuator and electric unit har-

ness connector.

Reconnect ABS actuator and electric

unit harness connector. Then retest.

Note: Wheel position should be indentified by code num-

bers except code No. 18 (sensor rotor).

NBR391

Front sensorFeeler gauge

Sensor

Rotor

Sensor

Feeler gauge

H

H

H

H

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMS

Diagnostic Procedure 1 (Wheel sensor or

rotor) (Cont'd)

BR-78