check engine NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1077 of 2267

Component DescriptionNCEC0295The ECM consists of a microcomputer, diagnostic test mode

selector, and connectors for signal input and output and for power

supply. The ECM controls the engine.

On Board Diagnosis LogicNCEC0296

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0605

0605IECM calculation function is malfunctioning.IECM

DTC Confirmation ProcedureNCEC0297NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine.

4) Run engine for at least 1 second at idle speed.

5) If 1st trip DTC is detected, go to ªDiagnostic Procedureº, EC-

SR-278.

With GST

Follow the procedure ªWith CONSULT-IIº above.

SEF093X

NEF068A

DTC P0605 ECMSR20DE

Component Description

EC-277

Page 1080 of 2267

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0486Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

AIR COND SIGIEngine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates)ON

COOLING FANIAfter warming up engine, idle the

engine.

IAir conditioner switch: OFFEngine coolant temperature is 94ÉC

(201ÉF) or lessOFF

Engine coolant temperature is between

95ÉC (203ÉF) and 104ÉC (219ÉF)LOW

Engine coolant temperature is 105ÉC

(221ÉF) or moreHIGH

ECM Terminals and Reference ValueNCEC0487Specification data are reference values and are measured between each terminal and 48 (ECM ground).

TERMI-

NAL NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

13 LG/R Cooling fan relay[Engine is running]

ICooling fan is not operatingBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

ICooling fan is operatingApproximately 0V

23 Ð Air conditioner switch[Engine is running]

IBoth air conditioner switch and blower switch are

ªONº (Compressor operates)Approximately 0V

[Engine is running]

IAir conditioner switch is ªOFFºBATTERY VOLTAGE

(11 - 14V)

74 R/LRefrigerant pressure

sensor[Engine is running]

IWarm-up condition

IIdle speed

IAir conditioner is ªONºMore than 1.5V

On Board Diagnosis LogicNCE0488If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

DTC No. Malfunction is detected when ...Check Items

(Possible Cause)

P1217

1217ICooling fan does not operate properly (Overheat).

ICooling fan system does not operate properly (Overheat).

IEngine coolant was not added to the system using the

proper filling method.IHarness or connectors

(The cooling fan circuit is open or shorted).

ICooling fan

IRadiator hose

IRadiator

IRadiator cap

IWater pump

IThermostat

For more information, refer to ªMAIN 12 CAUSES

OF OVERHEATINGº, EC-SR-288.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in the MA

section (ªChanging Engine Coolantº, ªENGINE MAINTENANCEº). Also, replace the engine oil.

1)Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to

use coolant with the proper mixture ratio. Refer to MA section (ªAnti-freeze Coolant Mixture Ratioº,

ªRECOMMENDED FLUIDS AND LUBRICANTSº).

2)After refilling coolant, run engine to ensure that no water-flow noise is emitted.

DTC P1217 OVERHEAT (COOLING SYSTEM)SR20DE

CONSULT-II Reference Value in Data Monitor Mode

EC-280

Page 1081 of 2267

Overall Function CheckNCEC0489Use this procedure to check the overall function of the cooling fan.

During this check, a DTC might not be confirmed.

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could be caused by high pressure fluid escaping from

the radiator.

Wrap a thick cloth around cap. Carefully remove the cap by

turning it a quarter turn to allow built-up pressure to escape.

Then turn the cap all the way off.

With CONSULT-II

1) Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to ªDiagnos-

tic Procedureº, EC-SR-284.

2) Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go to ªDiagnos-

tic Procedureº, EC-SR-284.

3) Turn ignition switch ªONº.

4) Perform ªCOOLING FANº in ªACTIVE TESTº mode with CON-

SULT-II.

5) If the results are NG, go to ªDiagnostic Procedureº, EC-SR-

284.

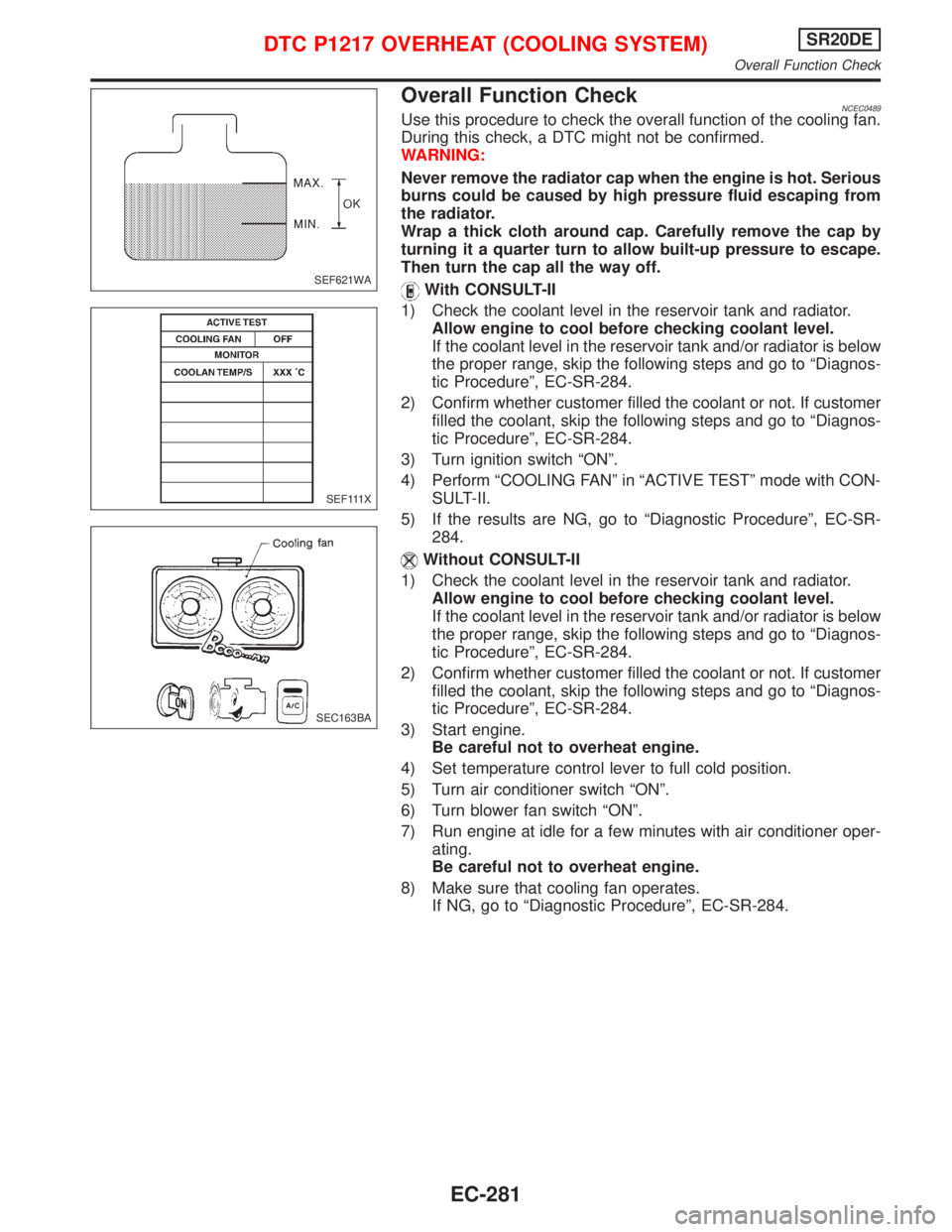

Without CONSULT-II

1) Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to ªDiagnos-

tic Procedureº, EC-SR-284.

2) Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go to ªDiagnos-

tic Procedureº, EC-SR-284.

3) Start engine.

Be careful not to overheat engine.

4) Set temperature control lever to full cold position.

5) Turn air conditioner switch ªONº.

6) Turn blower fan switch ªONº.

7) Run engine at idle for a few minutes with air conditioner oper-

ating.

Be careful not to overheat engine.

8) Make sure that cooling fan operates.

If NG, go to ªDiagnostic Procedureº, EC-SR-284.

SEF621WA

SEF111X

SEC163BA

DTC P1217 OVERHEAT (COOLING SYSTEM)SR20DE

Overall Function Check

EC-281

Page 1084 of 2267

Diagnostic ProcedureNCEC0491

1 CHECK COOLING FAN OPERATION

1. Start engine and let it idle.

2. Set temperature lever at full cold position.

3. Turn air conditioner switch ªONº.

4. Turn blower fan switch ªONº.

5. Make sure that cooling fans-1 and -2 operate.

SEC163BA

OK or NG

OK©GO TO 11.

NG©GO TO 2.

2 CHECK AIR CONDITIONER OPERATION

Is air conditioner operating?

(Check operation of compressor and blower motor.)

OK or NG

OK©GO TO 3.

NG©Check for failure of air conditioner to operate. Refer to HA section.

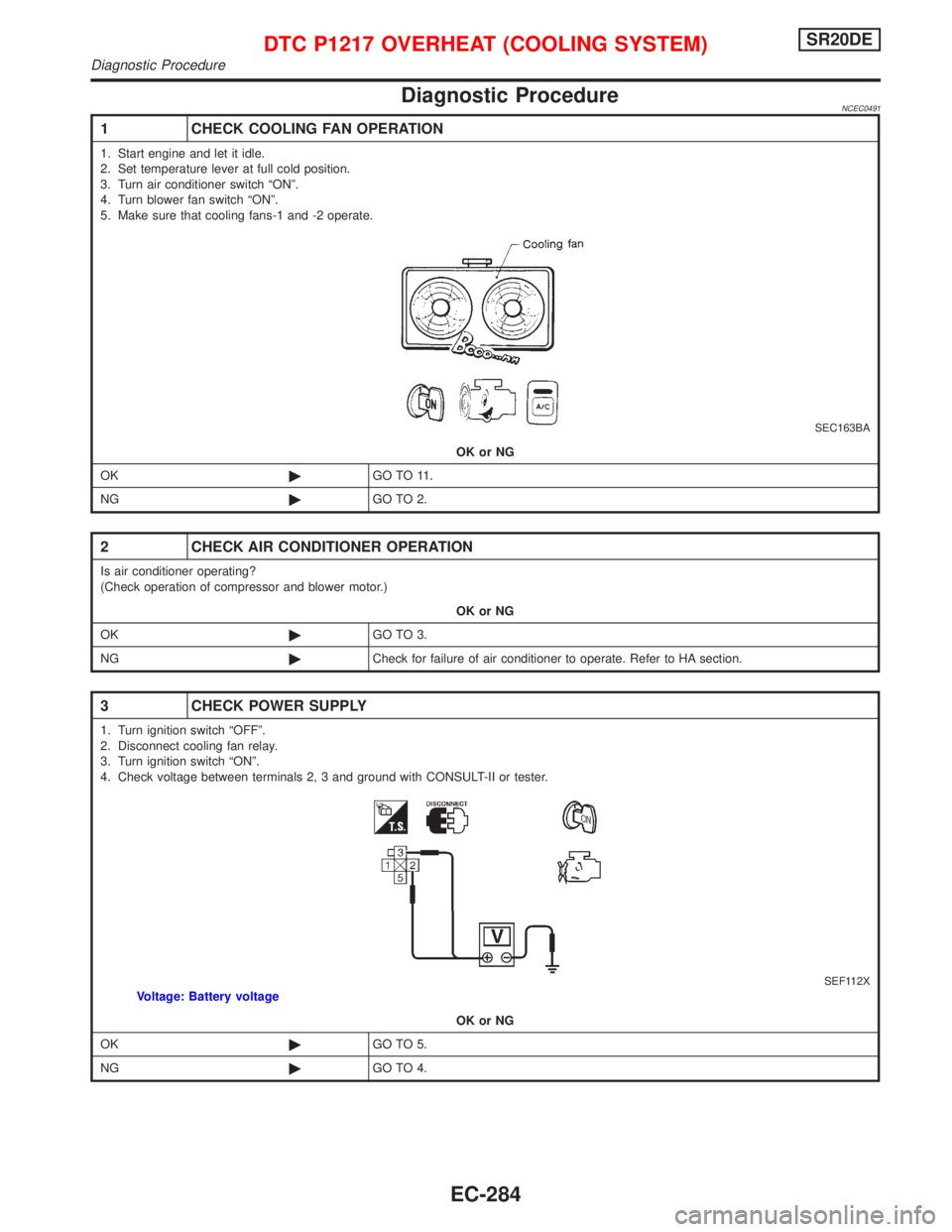

3 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect cooling fan relay.

3. Turn ignition switch ªONº.

4. Check voltage between terminals 2, 3 and ground with CONSULT-II or tester.

SEF112XVoltage: Battery voltage

OK or NG

OK©GO TO 5.

NG©GO TO 4.

DTC P1217 OVERHEAT (COOLING SYSTEM)SR20DE

Diagnostic Procedure

EC-284

Page 1087 of 2267

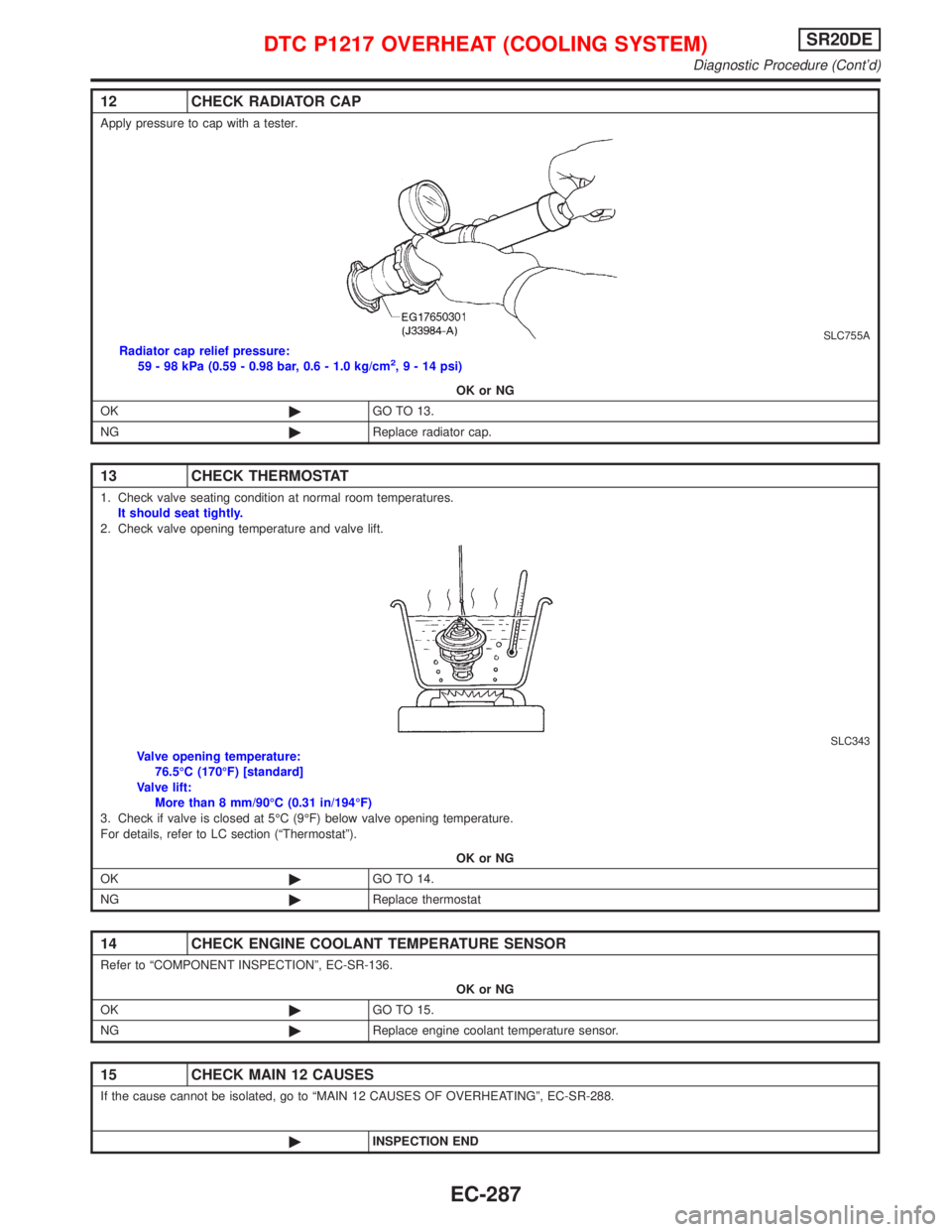

12 CHECK RADIATOR CAP

Apply pressure to cap with a tester.

SLC755ARadiator cap relief pressure:

59 - 98 kPa (0.59 - 0.98 bar, 0.6 - 1.0 kg/cm2,9-14psi)

OK or NG

OK©GO TO 13.

NG©Replace radiator cap.

13 CHECK THERMOSTAT

1. Check valve seating condition at normal room temperatures.

It should seat tightly.

2. Check valve opening temperature and valve lift.

SLC343Valve opening temperature:

76.5ÉC (170ÉF) [standard]

Valve lift:

More than 8 mm/90ÉC (0.31 in/194ÉF)

3. Check if valve is closed at 5ÉC (9ÉF) below valve opening temperature.

For details, refer to LC section (ªThermostatº).

OK or NG

OK©GO TO 14.

NG©Replace thermostat

14 CHECK ENGINE COOLANT TEMPERATURE SENSOR

Refer to ªCOMPONENT INSPECTIONº, EC-SR-136.

OK or NG

OK©GO TO 15.

NG©Replace engine coolant temperature sensor.

15 CHECK MAIN 12 CAUSES

If the cause cannot be isolated, go to ªMAIN 12 CAUSES OF OVERHEATINGº, EC-SR-288.

©INSPECTION END

DTC P1217 OVERHEAT (COOLING SYSTEM)SR20DE

Diagnostic Procedure (Cont'd)

EC-287

Page 1088 of 2267

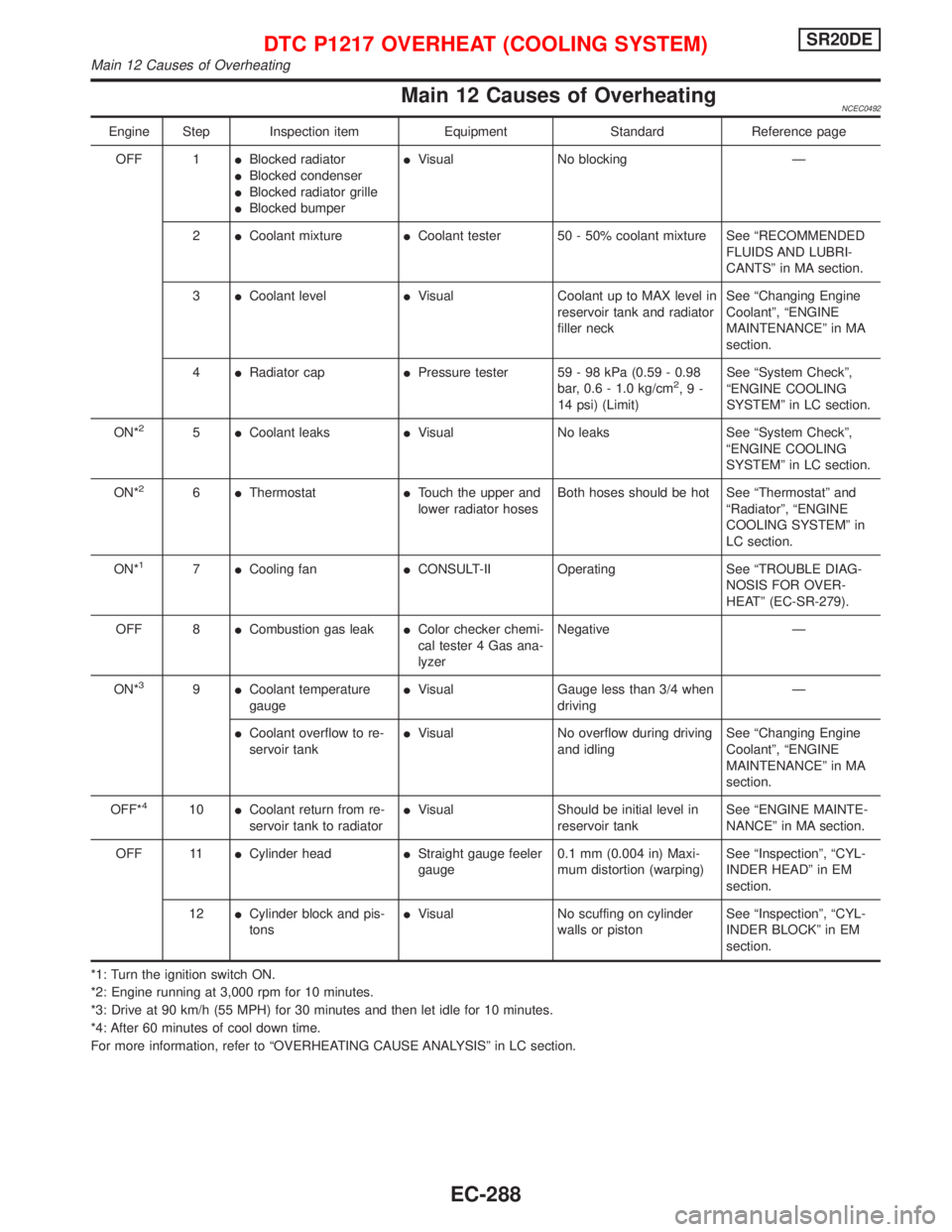

Main 12 Causes of OverheatingNCEC0492

Engine Step Inspection item Equipment Standard Reference page

OFF 1IBlocked radiator

IBlocked condenser

IBlocked radiator grille

IBlocked bumperIVisual No blocking Ð

2ICoolant mixtureICoolant tester 50 - 50% coolant mixture See ªRECOMMENDED

FLUIDS AND LUBRI-

CANTSº in MA section.

3ICoolant levelIVisual Coolant up to MAX level in

reservoir tank and radiator

filler neckSee ªChanging Engine

Coolantº, ªENGINE

MAINTENANCEº in MA

section.

4IRadiator capIPressure tester 59 - 98 kPa (0.59 - 0.98

bar, 0.6 - 1.0 kg/cm

2,9-

14 psi) (Limit)See ªSystem Checkº,

ªENGINE COOLING

SYSTEMº in LC section.

ON*

25ICoolant leaksIVisual No leaks See ªSystem Checkº,

ªENGINE COOLING

SYSTEMº in LC section.

ON*

26IThermostatITouch the upper and

lower radiator hosesBoth hoses should be hot See ªThermostatº and

ªRadiatorº, ªENGINE

COOLING SYSTEMº in

LC section.

ON*

17ICooling fanICONSULT-II Operating See ªTROUBLE DIAG-

NOSIS FOR OVER-

HEATº (EC-SR-279).

OFF 8ICombustion gas leakIColor checker chemi-

cal tester 4 Gas ana-

lyzerNegative Ð

ON*

39ICoolant temperature

gaugeIVisual Gauge less than 3/4 when

drivingÐ

ICoolant overflow to re-

servoir tankIVisual No overflow during driving

and idlingSee ªChanging Engine

Coolantº, ªENGINE

MAINTENANCEº in MA

section.

OFF*

410ICoolant return from re-

servoir tank to radiatorIVisual Should be initial level in

reservoir tankSee ªENGINE MAINTE-

NANCEº in MA section.

OFF 11ICylinder headIStraight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See ªInspectionº, ªCYL-

INDER HEADº in EM

section.

12ICylinder block and pis-

tonsIVisual No scuffing on cylinder

walls or pistonSee ªInspectionº, ªCYL-

INDER BLOCKº in EM

section.

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to ªOVERHEATING CAUSE ANALYSISº in LC section.

DTC P1217 OVERHEAT (COOLING SYSTEM)SR20DE

Main 12 Causes of Overheating

EC-288

Page 1089 of 2267

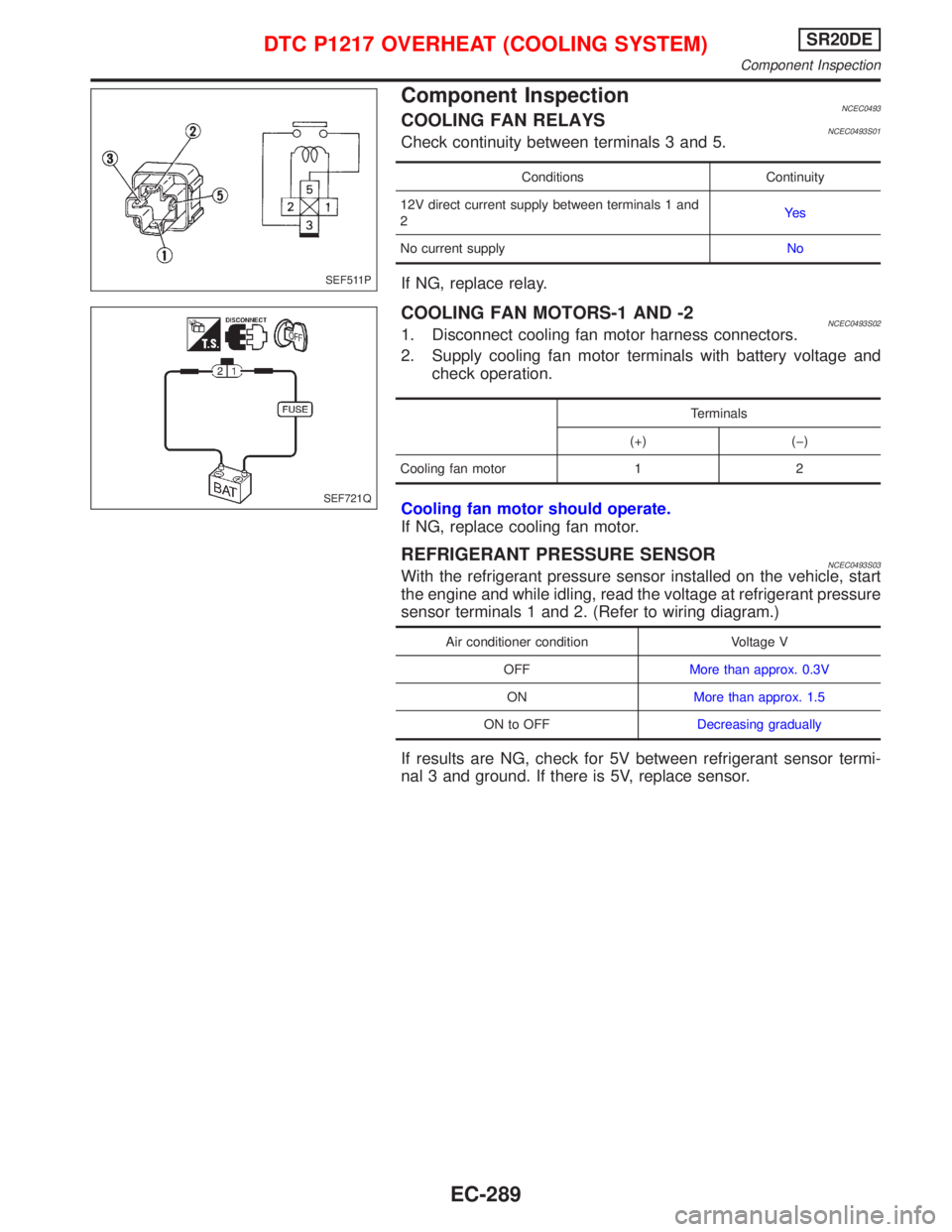

Component InspectionNCEC0493COOLING FAN RELAYSNCEC0493S01Check continuity between terminals 3 and 5.

Conditions Continuity

12V direct current supply between terminals 1 and

2Ye s

No current supplyNo

If NG, replace relay.

COOLING FAN MOTORS-1 AND -2NCEC0493S021. Disconnect cooling fan motor harness connectors.

2. Supply cooling fan motor terminals with battery voltage and

check operation.

Terminals

(+) (þ)

Cooling fan motor 1 2

Cooling fan motor should operate.

If NG, replace cooling fan motor.

REFRIGERANT PRESSURE SENSORNCEC0493S03With the refrigerant pressure sensor installed on the vehicle, start

the engine and while idling, read the voltage at refrigerant pressure

sensor terminals 1 and 2. (Refer to wiring diagram.)

Air conditioner condition Voltage V

OFFMore than approx. 0.3V

ONMore than approx. 1.5

ON to OFFDecreasing gradually

If results are NG, check for 5V between refrigerant sensor termi-

nal 3 and ground. If there is 5V, replace sensor.

SEF511P

SEF721Q

DTC P1217 OVERHEAT (COOLING SYSTEM)SR20DE

Component Inspection

EC-289

Page 1090 of 2267

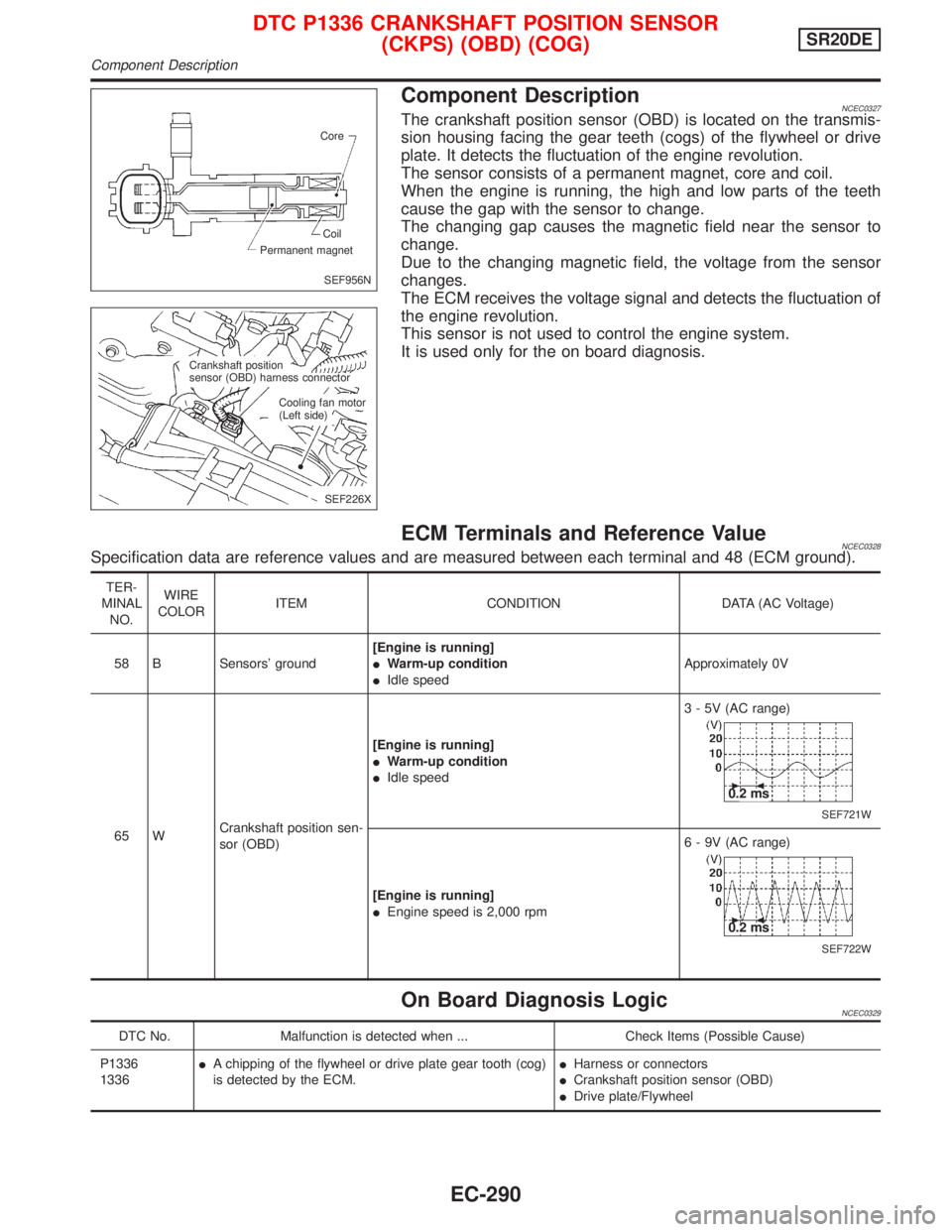

Component DescriptionNCEC0327The crankshaft position sensor (OBD) is located on the transmis-

sion housing facing the gear teeth (cogs) of the flywheel or drive

plate. It detects the fluctuation of the engine revolution.

The sensor consists of a permanent magnet, core and coil.

When the engine is running, the high and low parts of the teeth

cause the gap with the sensor to change.

The changing gap causes the magnetic field near the sensor to

change.

Due to the changing magnetic field, the voltage from the sensor

changes.

The ECM receives the voltage signal and detects the fluctuation of

the engine revolution.

This sensor is not used to control the engine system.

It is used only for the on board diagnosis.

ECM Terminals and Reference ValueNCEC0328Specification data are reference values and are measured between each terminal and 48 (ECM ground).

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (AC Voltage)

58 B Sensors' ground[Engine is running]

IWarm-up condition

IIdle speedApproximately 0V

65 WCrankshaft position sen-

sor (OBD)[Engine is running]

IWarm-up condition

IIdle speed3 - 5V (AC range)

SEF721W

0.2 ms

[Engine is running]

IEngine speed is 2,000 rpm6 - 9V (AC range)

SEF722W

0.2 ms

On Board Diagnosis LogicNCEC0329

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P1336

1336IA chipping of the flywheel or drive plate gear tooth (cog)

is detected by the ECM.IHarness or connectors

ICrankshaft position sensor (OBD)

IDrive plate/Flywheel

SEF956N Core

Permanent magnetCoil

SEF226X Crankshaft position

sensor (OBD) harness connector

Cooling fan motor

(Left side)

DTC P1336 CRANKSHAFT POSITION SENSOR

(CKPS) (OBD) (COG)SR20DE

Component Description

EC-290

Page 1093 of 2267

Diagnostic ProcedureNCEC0332

1 RETIGHTEN GROUND SCREWS

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

©GO TO 2.

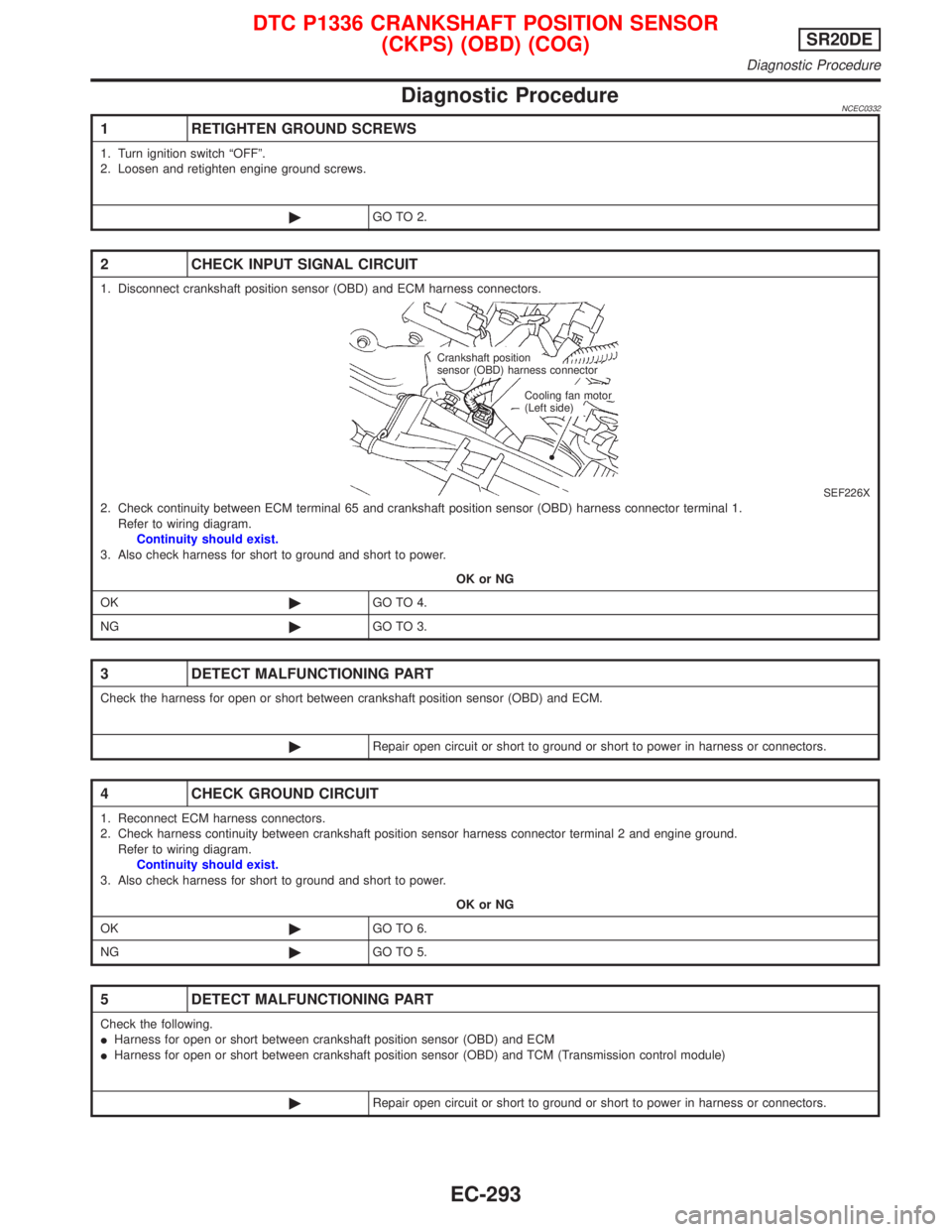

2 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect crankshaft position sensor (OBD) and ECM harness connectors.

SEF226X2. Check continuity between ECM terminal 65 and crankshaft position sensor (OBD) harness connector terminal 1.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the harness for open or short between crankshaft position sensor (OBD) and ECM.

©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK GROUND CIRCUIT

1. Reconnect ECM harness connectors.

2. Check harness continuity between crankshaft position sensor harness connector terminal 2 and engine ground.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

IHarness for open or short between crankshaft position sensor (OBD) and ECM

IHarness for open or short between crankshaft position sensor (OBD) and TCM (Transmission control module)

©Repair open circuit or short to ground or short to power in harness or connectors.

Crankshaft position

sensor (OBD) harness connector

Cooling fan motor

(Left side)

DTC P1336 CRANKSHAFT POSITION SENSOR

(CKPS) (OBD) (COG)SR20DE

Diagnostic Procedure

EC-293

Page 1095 of 2267

System DescriptionNCEC0560The malfunction information related to CVT is transferred through the line (circuit) from TCM (Transmission

Control Module) to ECM. Therefore, be sure to erase the malfunction information such as DTC not only in TCM

(Transmission Control Module) but also ECM after the CVT related repair.

ECM Terminals and Reference ValueNCEC0561Specification data are reference values and are measured between each terminal and 48 (ECM ground).

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

91 PU/Y CVT check signal[Ignition switch ªONº]

[Engine is running]0 - Approximately 5V

On Board Diagnosis LogicNCEC0562

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P1605

1605IAn incorrect signal from TCM (Transmission Control

Module) is sent to ECM.IHarness or connectors

[The communication line circuit between ECM and

TCM (Transmission Control Module) is open or

shorted.]

IDead (Weak) battery

ITCM (Transmission Control Module)

DTC Confirmation ProcedureNCEC0563NOTE:

If ªDTC CONFIRMATION PROCEDUREº has been previously

conducted, always turn ignition switch ªOFFº and wait at least 9

seconds before conducting the next test.

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and let it idle for at least 40 seconds.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº, EC-

SR-297.

With GST

Follow the procedure ªWith CONSULT-IIº above.

NEF068A

DTC P1605 A/T DIAGNOSIS COMMUNICATION LINESR20DE

System Description

EC-295