sensor NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1010 of 2267

Diagnostic ProcedureNCEC0186

1 CHECK POWER SUPPLY

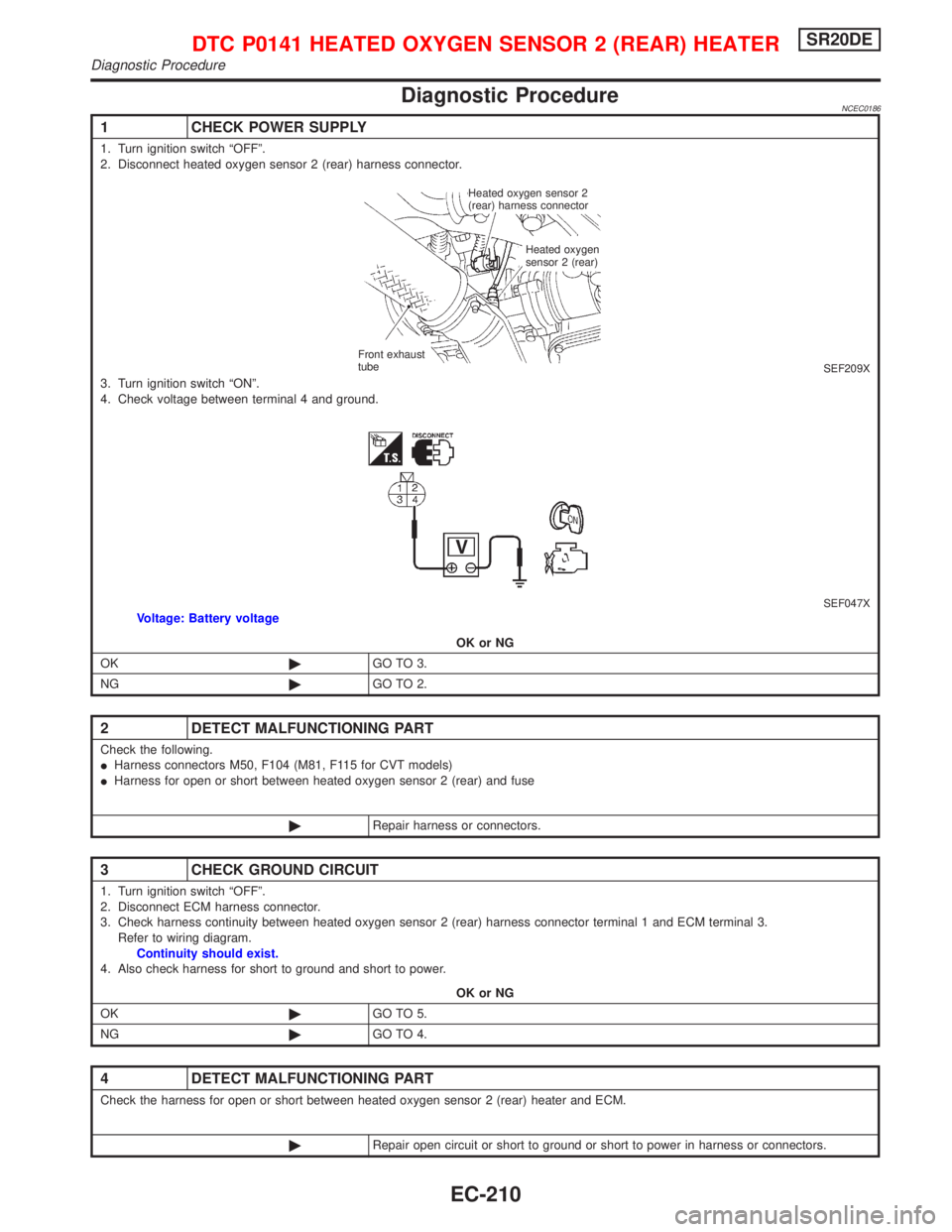

1. Turn ignition switch ªOFFº.

2. Disconnect heated oxygen sensor 2 (rear) harness connector.

SEF209X3. Turn ignition switch ªONº.

4. Check voltage between terminal 4 and ground.

SEF047XVoltage: Battery voltage

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M50, F104 (M81, F115 for CVT models)

IHarness for open or short between heated oxygen sensor 2 (rear) and fuse

©Repair harness or connectors.

3 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between heated oxygen sensor 2 (rear) harness connector terminal 1 and ECM terminal 3.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 DETECT MALFUNCTIONING PART

Check the harness for open or short between heated oxygen sensor 2 (rear) heater and ECM.

©Repair open circuit or short to ground or short to power in harness or connectors.

Heated oxygen sensor 2

(rear) harness connector

Heated oxygen

sensor 2 (rear)

Front exhaust

tube

DTC P0141 HEATED OXYGEN SENSOR 2 (REAR) HEATERSR20DE

Diagnostic Procedure

EC-210

Page 1011 of 2267

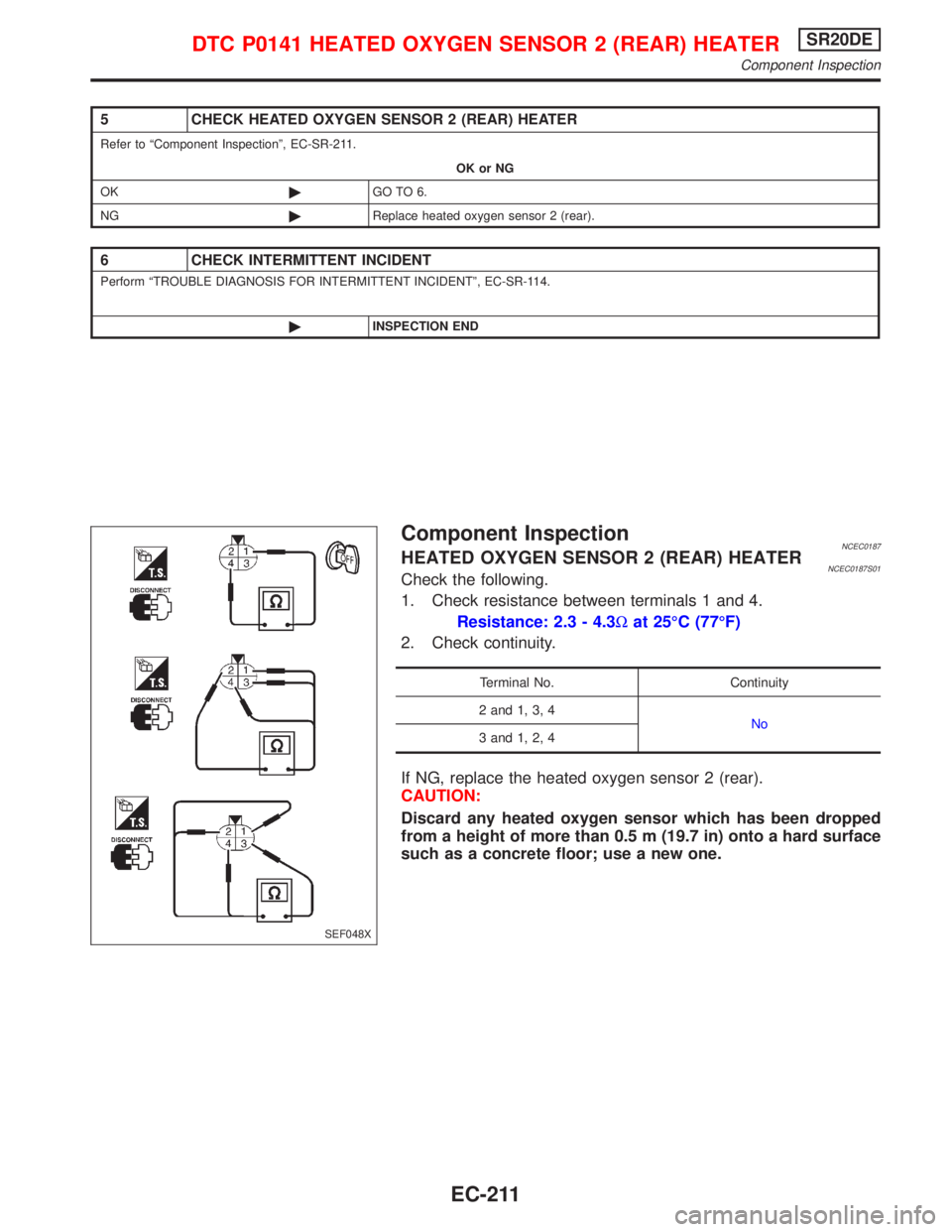

Component InspectionNCEC0187HEATED OXYGEN SENSOR 2 (REAR) HEATERNCEC0187S01Check the following.

1. Check resistance between terminals 1 and 4.

Resistance: 2.3 - 4.3Wat 25ÉC (77ÉF)

2. Check continuity.

Terminal No. Continuity

2 and 1, 3, 4

No

3 and 1, 2, 4

If NG, replace the heated oxygen sensor 2 (rear).

CAUTION:

Discard any heated oxygen sensor which has been dropped

from a height of more than 0.5 m (19.7 in) onto a hard surface

such as a concrete floor; use a new one.

5 CHECK HEATED OXYGEN SENSOR 2 (REAR) HEATER

Refer to ªComponent Inspectionº, EC-SR-211.

OK or NG

OK©GO TO 6.

NG©Replace heated oxygen sensor 2 (rear).

6 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-SR-114.

©INSPECTION END

SEF048X

DTC P0141 HEATED OXYGEN SENSOR 2 (REAR) HEATERSR20DE

Component Inspection

EC-211

Page 1012 of 2267

On Board Diagnosis LogicNCEC0188With the Air/Fuel Mixture Ratio Self-Learning Control, the actual mixture ratio can be brought closely to the

theoretical mixture ratio based on the mixture ratio feedback signal from the heated oxygen sensor 1 (front).

The ECM calculates the necessary compensation to correct the offset between the actual and the theoretical

ratios.

In case the amount of the compensation value is extremely large (The actual mixture ratio is too lean.), the

ECM judges the condition as the fuel injection system malfunction and lights up the MI (2 trip detection logic).

Sensor Input Signal to ECMECM func-

tionActuator

Heated oxygen sensor 1 (front)Density of oxygen in exhaust gas

(Mixture ratio feedback signal)Fuel injec-

tion & mix-

ture ratio

controlInjectors

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0171

0171IFuel injection system does not operate properly.

IThe amount of mixture ratio compensation is too large.

(The mixture ratio is too lean.)IIntake air leaks

IHeated oxygen sensor 1 (front)

IInjectors

IExhaust gas leaks

IIncorrect fuel pressure

ILack of fuel

IMass air flow sensor

DTC Confirmation ProcedureNCEC0189NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

TESTING CONDITION:

IAlways perform at a temperature above þ10ÉC (14ÉF).

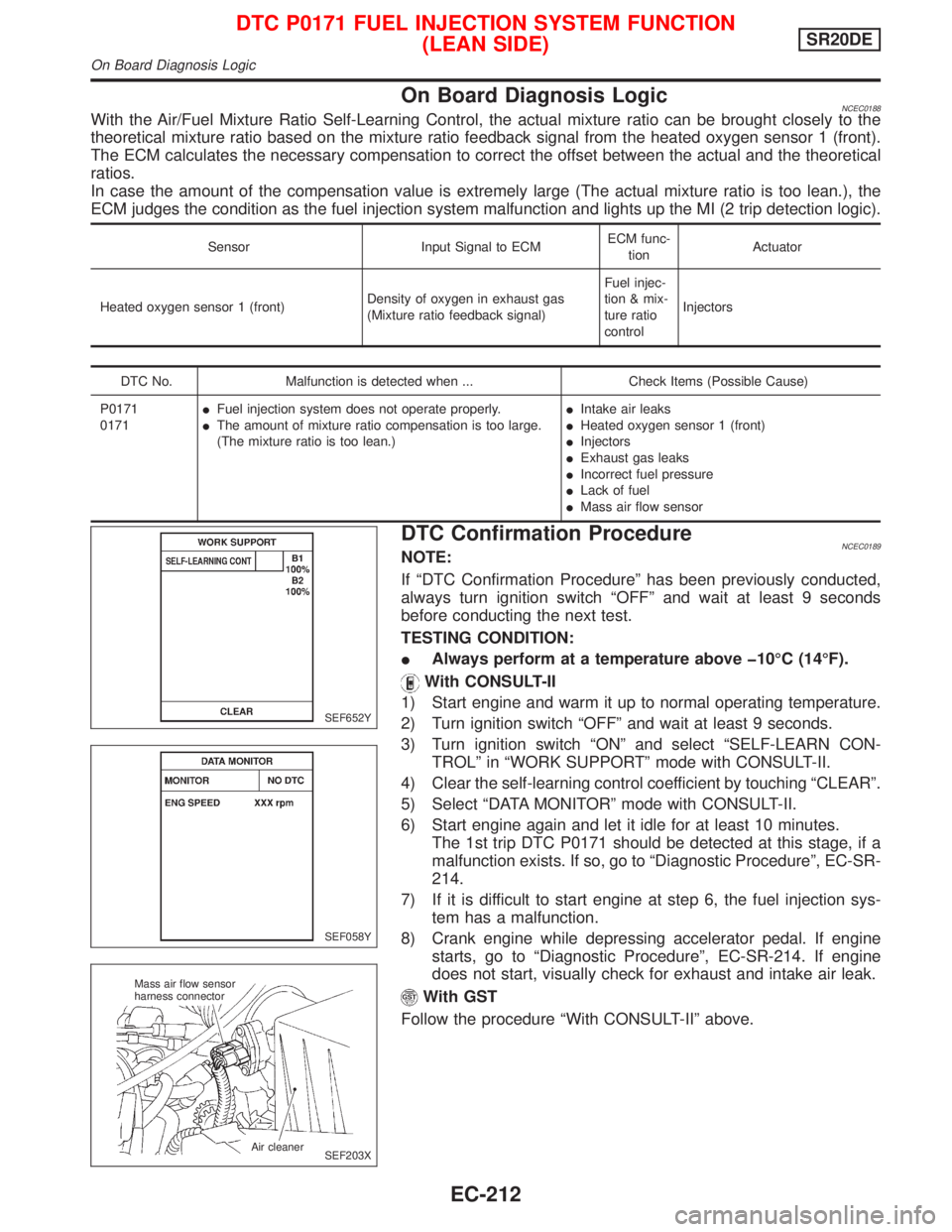

With CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Turn ignition switch ªOFFº and wait at least 9 seconds.

3) Turn ignition switch ªONº and select ªSELF-LEARN CON-

TROLº in ªWORK SUPPORTº mode with CONSULT-II.

4) Clear the self-learning control coefficient by touching ªCLEARº.

5) Select ªDATA MONITORº mode with CONSULT-II.

6) Start engine again and let it idle for at least 10 minutes.

The 1st trip DTC P0171 should be detected at this stage, if a

malfunction exists. If so, go to ªDiagnostic Procedureº, EC-SR-

214.

7) If it is difficult to start engine at step 6, the fuel injection sys-

tem has a malfunction.

8) Crank engine while depressing accelerator pedal. If engine

starts, go to ªDiagnostic Procedureº, EC-SR-214. If engine

does not start, visually check for exhaust and intake air leak.

With GST

Follow the procedure ªWith CONSULT-IIº above.

SEF652Y

SEF058Y

SEF203X Mass air flow sensor

harness connector

Air cleaner

DTC P0171 FUEL INJECTION SYSTEM FUNCTION

(LEAN SIDE)SR20DE

On Board Diagnosis Logic

EC-212

Page 1014 of 2267

Diagnostic ProcedureNCEC0191

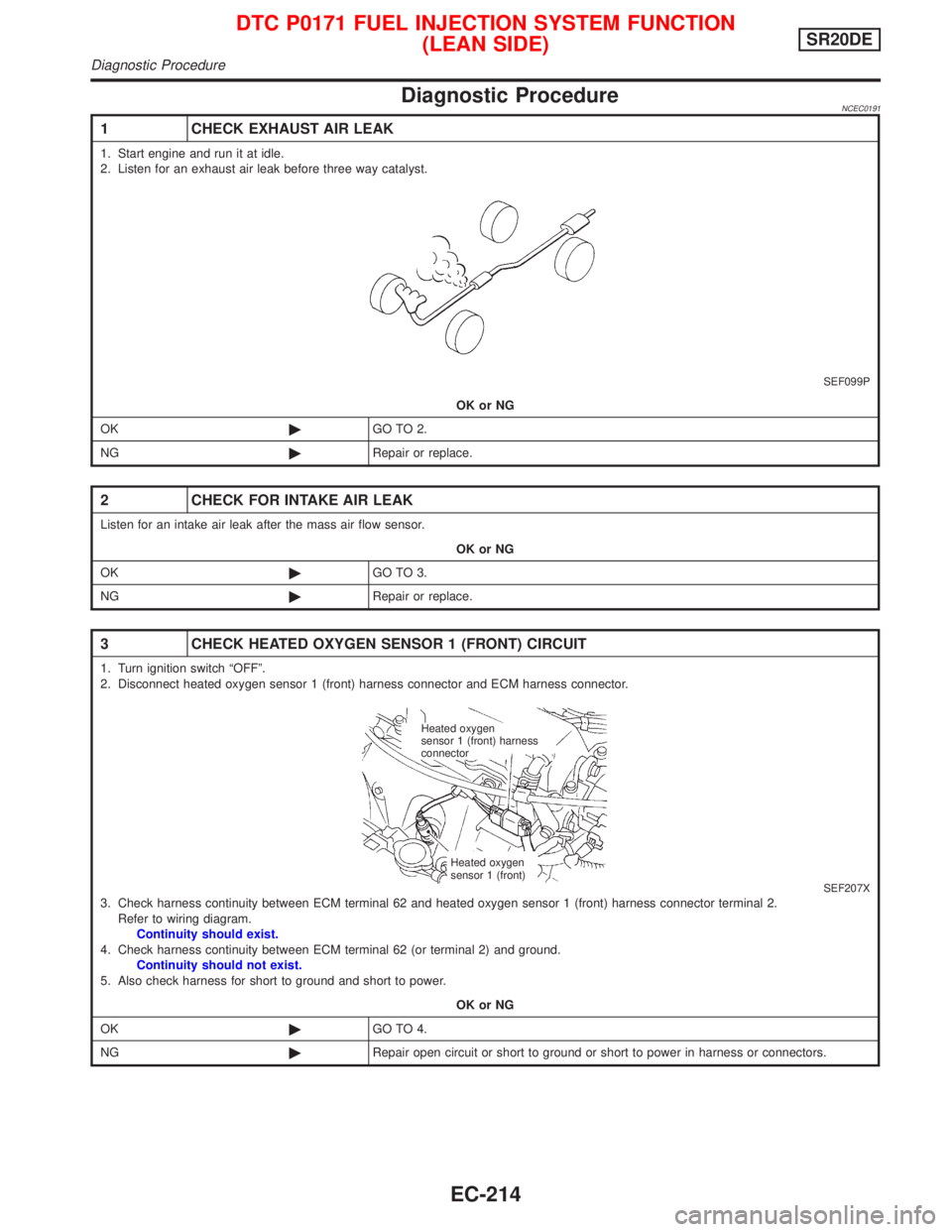

1 CHECK EXHAUST AIR LEAK

1. Start engine and run it at idle.

2. Listen for an exhaust air leak before three way catalyst.

SEF099P

OK or NG

OK©GO TO 2.

NG©Repair or replace.

2 CHECK FOR INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK©GO TO 3.

NG©Repair or replace.

3 CHECK HEATED OXYGEN SENSOR 1 (FRONT) CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect heated oxygen sensor 1 (front) harness connector and ECM harness connector.

SEF207X3. Check harness continuity between ECM terminal 62 and heated oxygen sensor 1 (front) harness connector terminal 2.

Refer to wiring diagram.

Continuity should exist.

4. Check harness continuity between ECM terminal 62 (or terminal 2) and ground.

Continuity should not exist.

5. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

Heated oxygen

sensor 1 (front) harness

connector

Heated oxygen

sensor 1 (front)

DTC P0171 FUEL INJECTION SYSTEM FUNCTION

(LEAN SIDE)SR20DE

Diagnostic Procedure

EC-214

Page 1015 of 2267

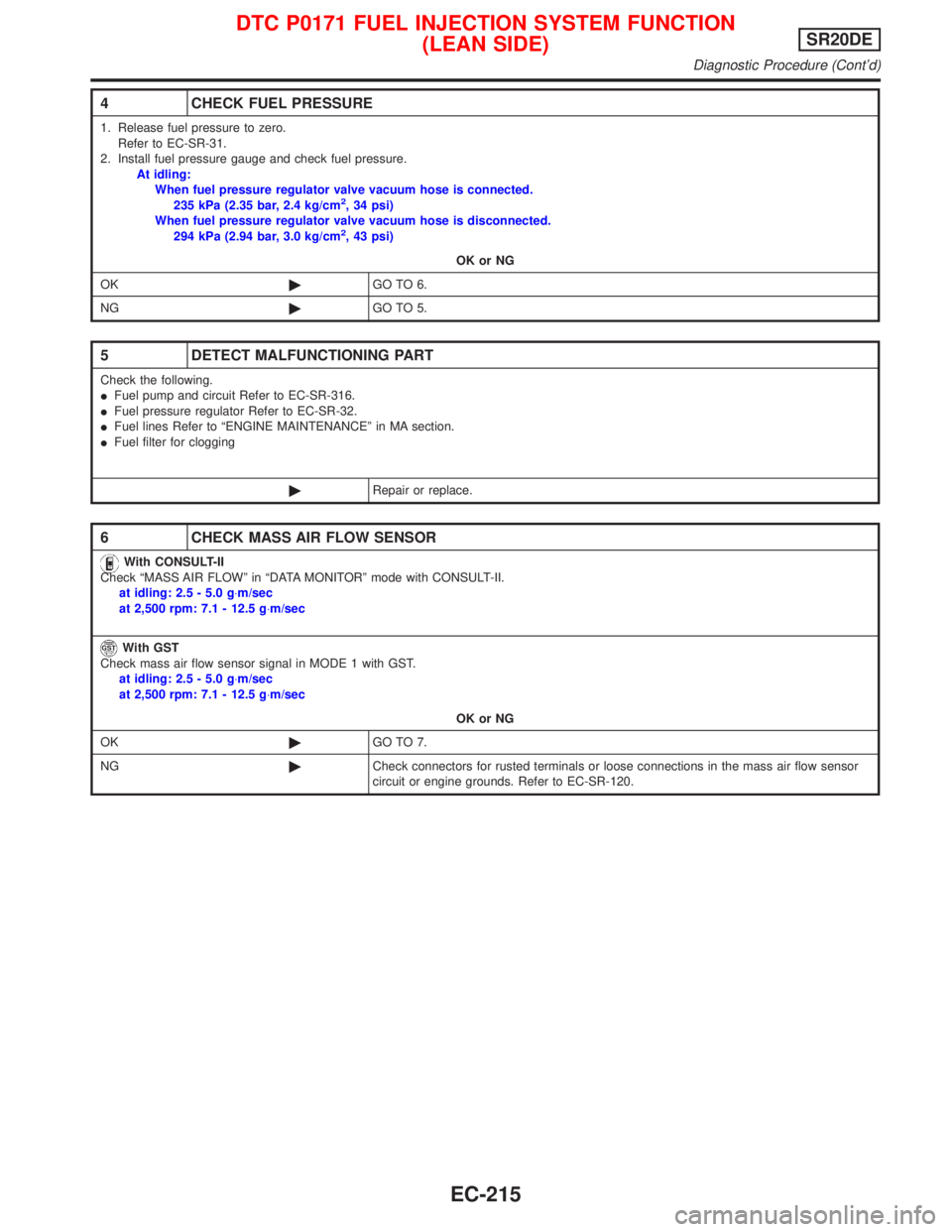

4 CHECK FUEL PRESSURE

1. Release fuel pressure to zero.

Refer to EC-SR-31.

2. Install fuel pressure gauge and check fuel pressure.

At idling:

When fuel pressure regulator valve vacuum hose is connected.

235 kPa (2.35 bar, 2.4 kg/cm

2, 34 psi)

When fuel pressure regulator valve vacuum hose is disconnected.

294 kPa (2.94 bar, 3.0 kg/cm

2, 43 psi)

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

IFuel pump and circuit Refer to EC-SR-316.

IFuel pressure regulator Refer to EC-SR-32.

IFuel lines Refer to ªENGINE MAINTENANCEº in MA section.

IFuel filter for clogging

©Repair or replace.

6 CHECK MASS AIR FLOW SENSOR

With CONSULT-II

Check ªMASS AIR FLOWº in ªDATA MONITORº mode with CONSULT-II.

at idling: 2.5 - 5.0 g×m/sec

at 2,500 rpm: 7.1 - 12.5 g×m/sec

With GST

Check mass air flow sensor signal in MODE 1 with GST.

at idling: 2.5 - 5.0 g×m/sec

at 2,500 rpm: 7.1 - 12.5 g×m/sec

OK or NG

OK©GO TO 7.

NG©Check connectors for rusted terminals or loose connections in the mass air flow sensor

circuit or engine grounds. Refer to EC-SR-120.

DTC P0171 FUEL INJECTION SYSTEM FUNCTION

(LEAN SIDE)SR20DE

Diagnostic Procedure (Cont'd)

EC-215

Page 1018 of 2267

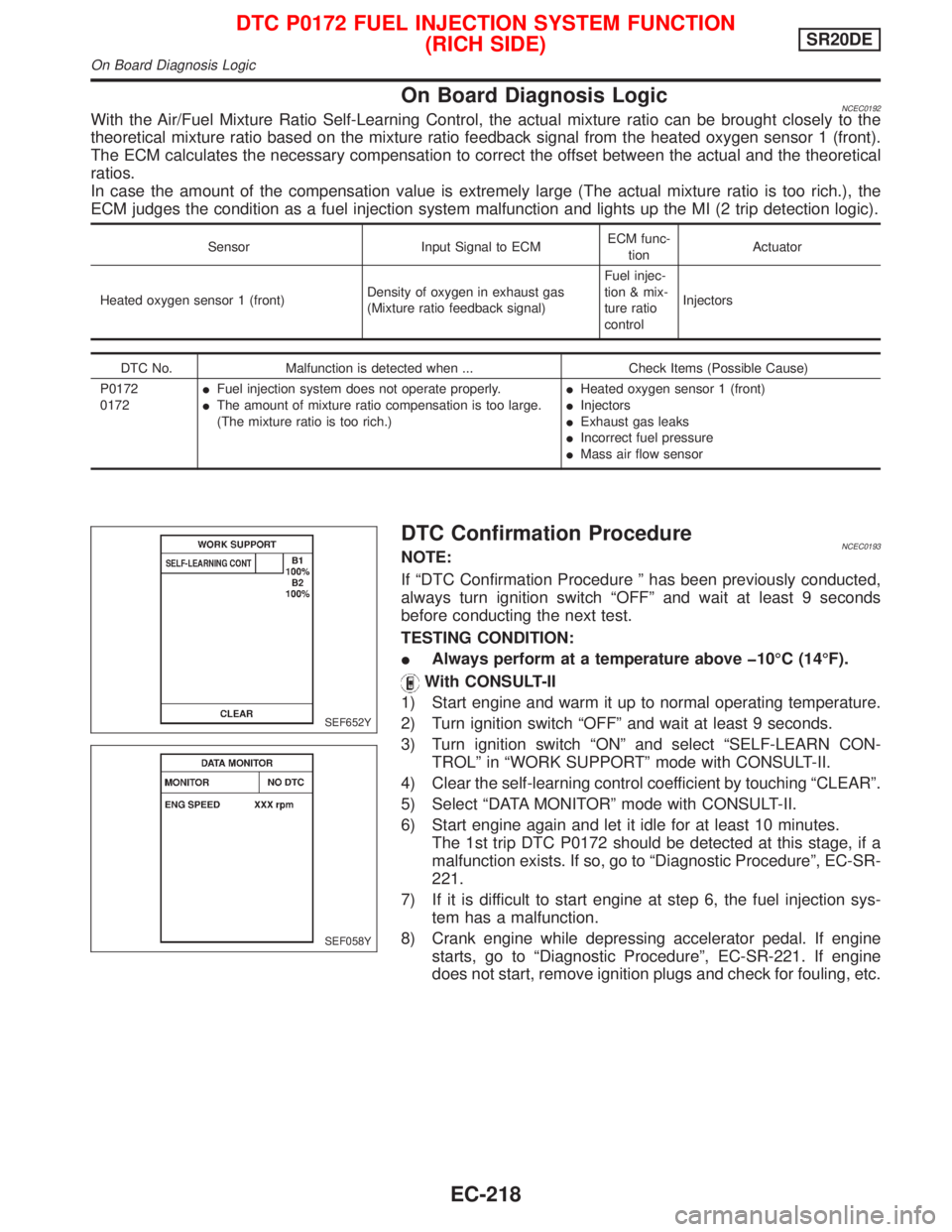

On Board Diagnosis LogicNCEC0192With the Air/Fuel Mixture Ratio Self-Learning Control, the actual mixture ratio can be brought closely to the

theoretical mixture ratio based on the mixture ratio feedback signal from the heated oxygen sensor 1 (front).

The ECM calculates the necessary compensation to correct the offset between the actual and the theoretical

ratios.

In case the amount of the compensation value is extremely large (The actual mixture ratio is too rich.), the

ECM judges the condition as a fuel injection system malfunction and lights up the MI (2 trip detection logic).

Sensor Input Signal to ECMECM func-

tionActuator

Heated oxygen sensor 1 (front)Density of oxygen in exhaust gas

(Mixture ratio feedback signal)Fuel injec-

tion & mix-

ture ratio

controlInjectors

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0172

0172IFuel injection system does not operate properly.

IThe amount of mixture ratio compensation is too large.

(The mixture ratio is too rich.)IHeated oxygen sensor 1 (front)

IInjectors

IExhaust gas leaks

IIncorrect fuel pressure

IMass air flow sensor

DTC Confirmation ProcedureNCEC0193NOTE:

If ªDTC Confirmation Procedure º has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

TESTING CONDITION:

IAlways perform at a temperature above þ10ÉC (14ÉF).

With CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Turn ignition switch ªOFFº and wait at least 9 seconds.

3) Turn ignition switch ªONº and select ªSELF-LEARN CON-

TROLº in ªWORK SUPPORTº mode with CONSULT-II.

4) Clear the self-learning control coefficient by touching ªCLEARº.

5) Select ªDATA MONITORº mode with CONSULT-II.

6) Start engine again and let it idle for at least 10 minutes.

The 1st trip DTC P0172 should be detected at this stage, if a

malfunction exists. If so, go to ªDiagnostic Procedureº, EC-SR-

221.

7) If it is difficult to start engine at step 6, the fuel injection sys-

tem has a malfunction.

8) Crank engine while depressing accelerator pedal. If engine

starts, go to ªDiagnostic Procedureº, EC-SR-221. If engine

does not start, remove ignition plugs and check for fouling, etc.

SEF652Y

SEF058Y

DTC P0172 FUEL INJECTION SYSTEM FUNCTION

(RICH SIDE)SR20DE

On Board Diagnosis Logic

EC-218

Page 1019 of 2267

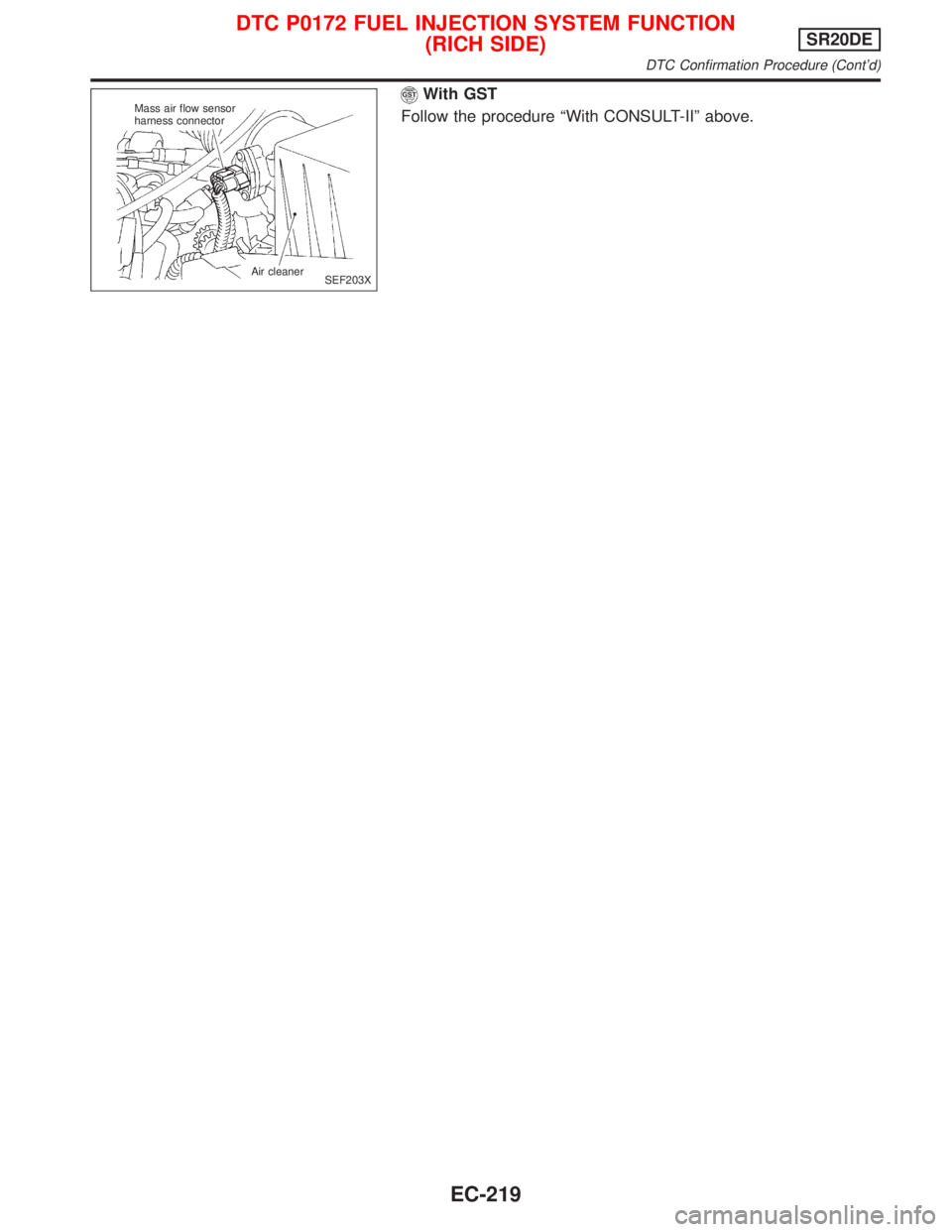

With GST

Follow the procedure ªWith CONSULT-IIº above.

SEF203X Mass air flow sensor

harness connector

Air cleaner

DTC P0172 FUEL INJECTION SYSTEM FUNCTION

(RICH SIDE)SR20DE

DTC Confirmation Procedure (Cont'd)

EC-219

Page 1021 of 2267

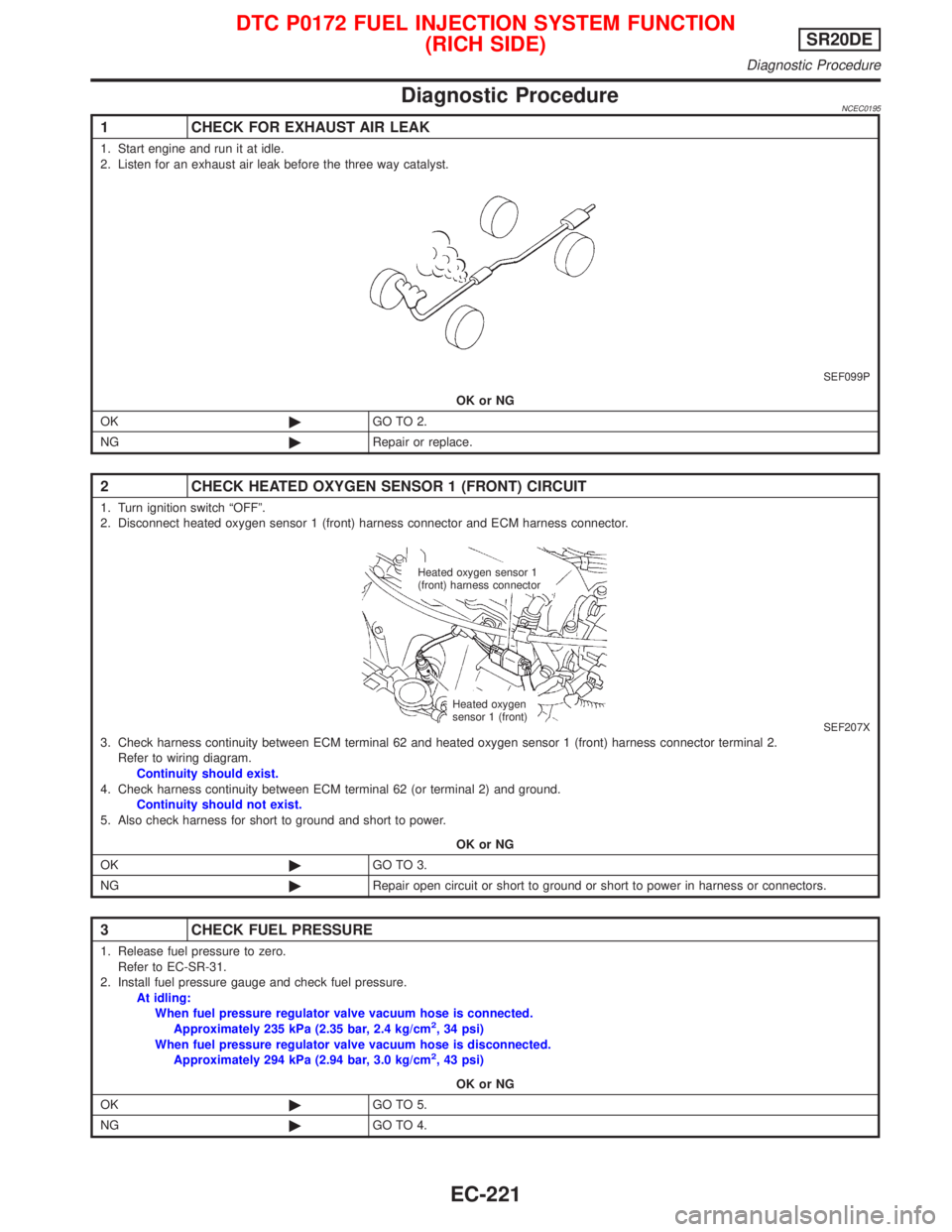

Diagnostic ProcedureNCEC0195

1 CHECK FOR EXHAUST AIR LEAK

1. Start engine and run it at idle.

2. Listen for an exhaust air leak before the three way catalyst.

SEF099P

OK or NG

OK©GO TO 2.

NG©Repair or replace.

2 CHECK HEATED OXYGEN SENSOR 1 (FRONT) CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect heated oxygen sensor 1 (front) harness connector and ECM harness connector.

SEF207X3. Check harness continuity between ECM terminal 62 and heated oxygen sensor 1 (front) harness connector terminal 2.

Refer to wiring diagram.

Continuity should exist.

4. Check harness continuity between ECM terminal 62 (or terminal 2) and ground.

Continuity should not exist.

5. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 3.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK FUEL PRESSURE

1. Release fuel pressure to zero.

Refer to EC-SR-31.

2. Install fuel pressure gauge and check fuel pressure.

At idling:

When fuel pressure regulator valve vacuum hose is connected.

Approximately 235 kPa (2.35 bar, 2.4 kg/cm

2, 34 psi)

When fuel pressure regulator valve vacuum hose is disconnected.

Approximately 294 kPa (2.94 bar, 3.0 kg/cm

2, 43 psi)

OK or NG

OK©GO TO 5.

NG©GO TO 4.

Heated oxygen sensor 1

(front) harness connector

Heated oxygen

sensor 1 (front)

DTC P0172 FUEL INJECTION SYSTEM FUNCTION

(RICH SIDE)SR20DE

Diagnostic Procedure

EC-221

Page 1022 of 2267

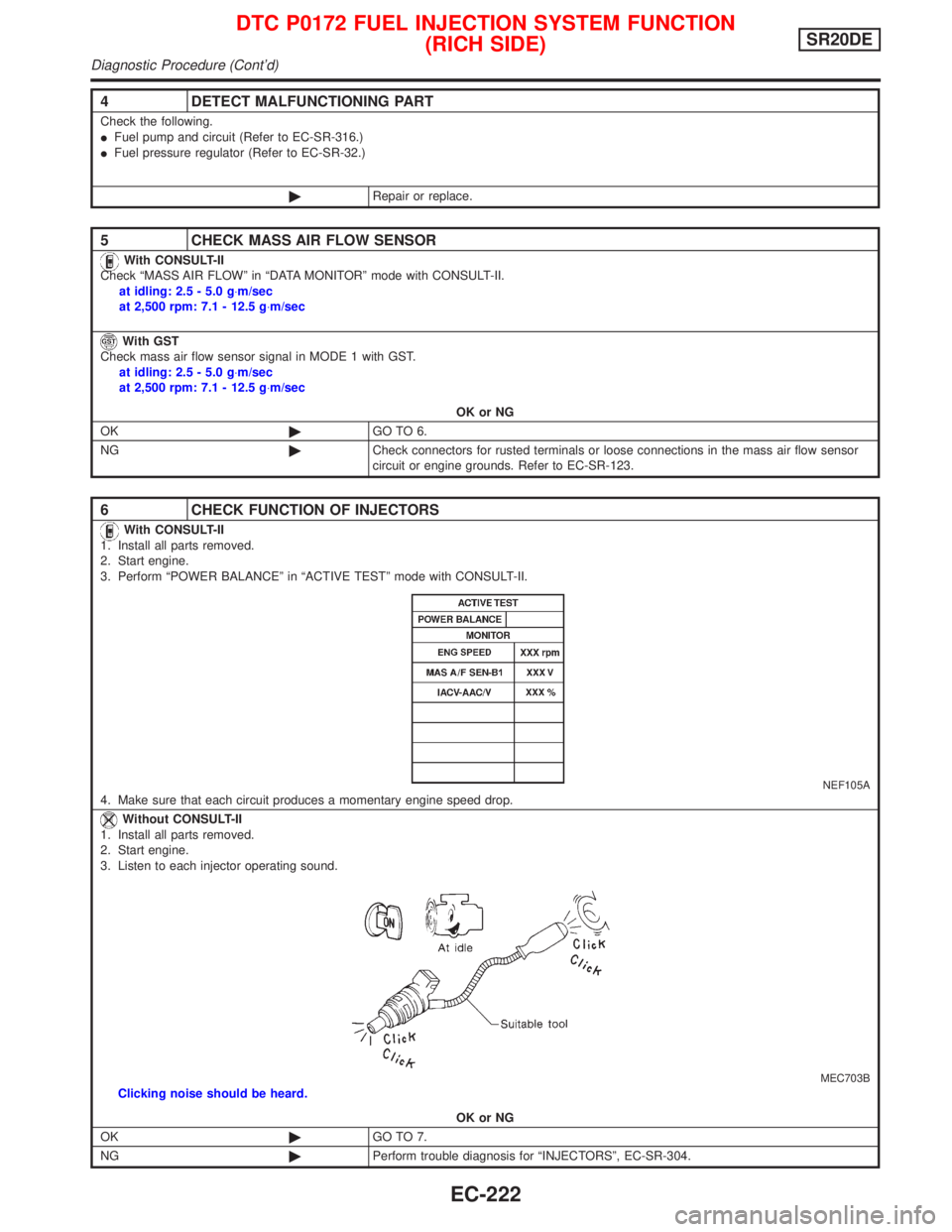

4 DETECT MALFUNCTIONING PART

Check the following.

IFuel pump and circuit (Refer to EC-SR-316.)

IFuel pressure regulator (Refer to EC-SR-32.)

©Repair or replace.

5 CHECK MASS AIR FLOW SENSOR

With CONSULT-II

Check ªMASS AIR FLOWº in ªDATA MONITORº mode with CONSULT-II.

at idling: 2.5 - 5.0 g×m/sec

at 2,500 rpm: 7.1 - 12.5 g×m/sec

With GST

Check mass air flow sensor signal in MODE 1 with GST.

at idling: 2.5 - 5.0 g×m/sec

at 2,500 rpm: 7.1 - 12.5 g×m/sec

OK or NG

OK©GO TO 6.

NG©Check connectors for rusted terminals or loose connections in the mass air flow sensor

circuit or engine grounds. Refer to EC-SR-123.

6 CHECK FUNCTION OF INJECTORS

With CONSULT-II

1. Install all parts removed.

2. Start engine.

3. Perform ªPOWER BALANCEº in ªACTIVE TESTº mode with CONSULT-II.

NEF105A4. Make sure that each circuit produces a momentary engine speed drop.

Without CONSULT-II

1. Install all parts removed.

2. Start engine.

3. Listen to each injector operating sound.

MEC703BClicking noise should be heard.

OK or NG

OK©GO TO 7.

NG©Perform trouble diagnosis for ªINJECTORSº, EC-SR-304.

DTC P0172 FUEL INJECTION SYSTEM FUNCTION

(RICH SIDE)SR20DE

Diagnostic Procedure (Cont'd)

EC-222

Page 1024 of 2267

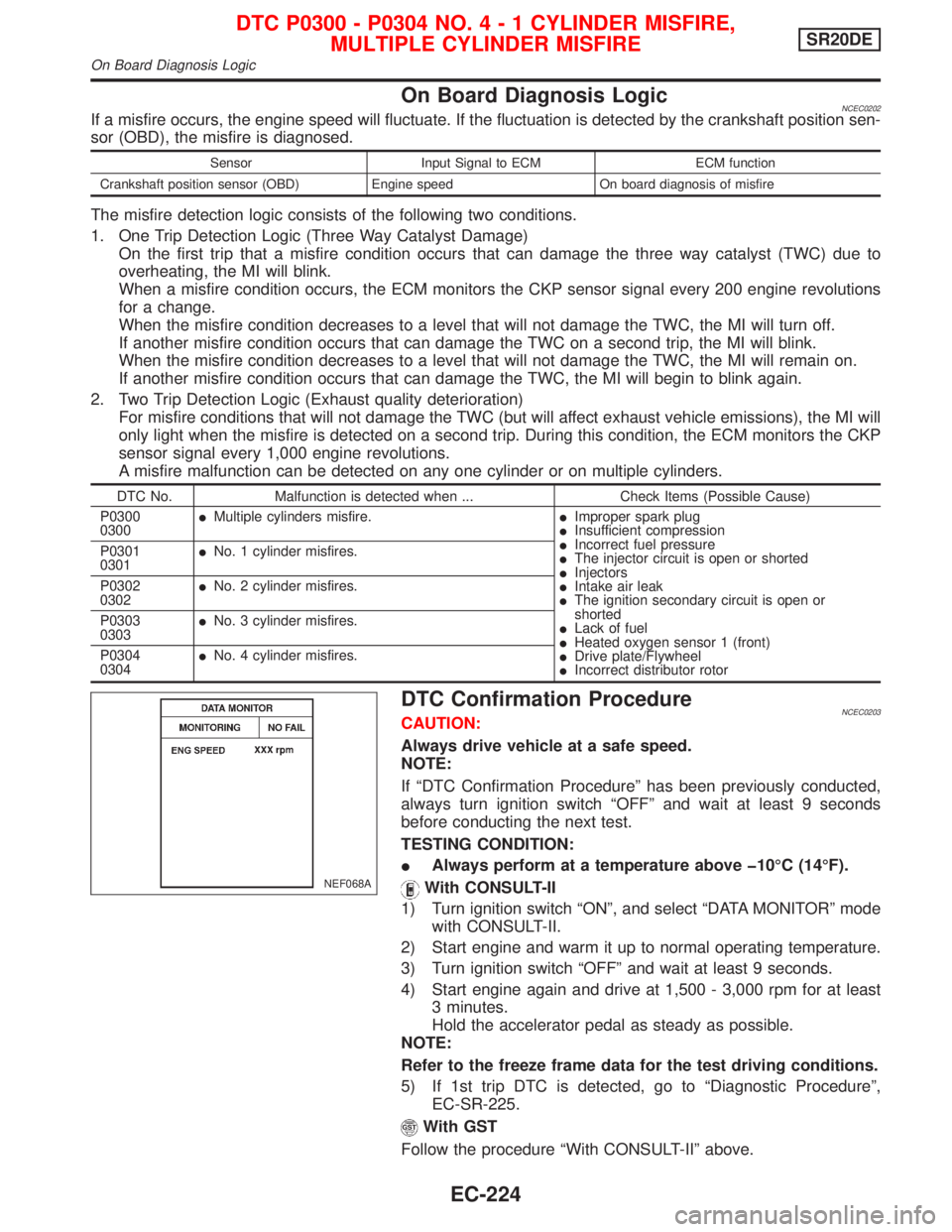

On Board Diagnosis LogicNCEC0202If a misfire occurs, the engine speed will fluctuate. If the fluctuation is detected by the crankshaft position sen-

sor (OBD), the misfire is diagnosed.

Sensor Input Signal to ECM ECM function

Crankshaft position sensor (OBD) Engine speed On board diagnosis of misfire

The misfire detection logic consists of the following two conditions.

1. One Trip Detection Logic (Three Way Catalyst Damage)

On the first trip that a misfire condition occurs that can damage the three way catalyst (TWC) due to

overheating, the MI will blink.

When a misfire condition occurs, the ECM monitors the CKP sensor signal every 200 engine revolutions

for a change.

When the misfire condition decreases to a level that will not damage the TWC, the MI will turn off.

If another misfire condition occurs that can damage the TWC on a second trip, the MI will blink.

When the misfire condition decreases to a level that will not damage the TWC, the MI will remain on.

If another misfire condition occurs that can damage the TWC, the MI will begin to blink again.

2. Two Trip Detection Logic (Exhaust quality deterioration)

For misfire conditions that will not damage the TWC (but will affect exhaust vehicle emissions), the MI will

only light when the misfire is detected on a second trip. During this condition, the ECM monitors the CKP

sensor signal every 1,000 engine revolutions.

A misfire malfunction can be detected on any one cylinder or on multiple cylinders.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0300

0300IMultiple cylinders misfire.IImproper spark plug

IInsufficient compression

IIncorrect fuel pressure

IThe injector circuit is open or shorted

IInjectors

IIntake air leak

IThe ignition secondary circuit is open or

shorted

ILack of fuel

IHeated oxygen sensor 1 (front)

IDrive plate/Flywheel

IIncorrect distributor rotor P0301

0301INo. 1 cylinder misfires.

P0302

0302INo. 2 cylinder misfires.

P0303

0303INo. 3 cylinder misfires.

P0304

0304INo. 4 cylinder misfires.

DTC Confirmation ProcedureNCEC0203CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

TESTING CONDITION:

IAlways perform at a temperature above þ10ÉC (14ÉF).

With CONSULT-II

1) Turn ignition switch ªONº, and select ªDATA MONITORº mode

with CONSULT-II.

2) Start engine and warm it up to normal operating temperature.

3) Turn ignition switch ªOFFº and wait at least 9 seconds.

4) Start engine again and drive at 1,500 - 3,000 rpm for at least

3 minutes.

Hold the accelerator pedal as steady as possible.

NOTE:

Refer to the freeze frame data for the test driving conditions.

5) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-SR-225.

With GST

Follow the procedure ªWith CONSULT-IIº above.

NEF068A

DTC P0300 - P0304 NO.4-1CYLINDER MISFIRE,

MULTIPLE CYLINDER MISFIRESR20DE

On Board Diagnosis Logic

EC-224