sensor NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1039 of 2267

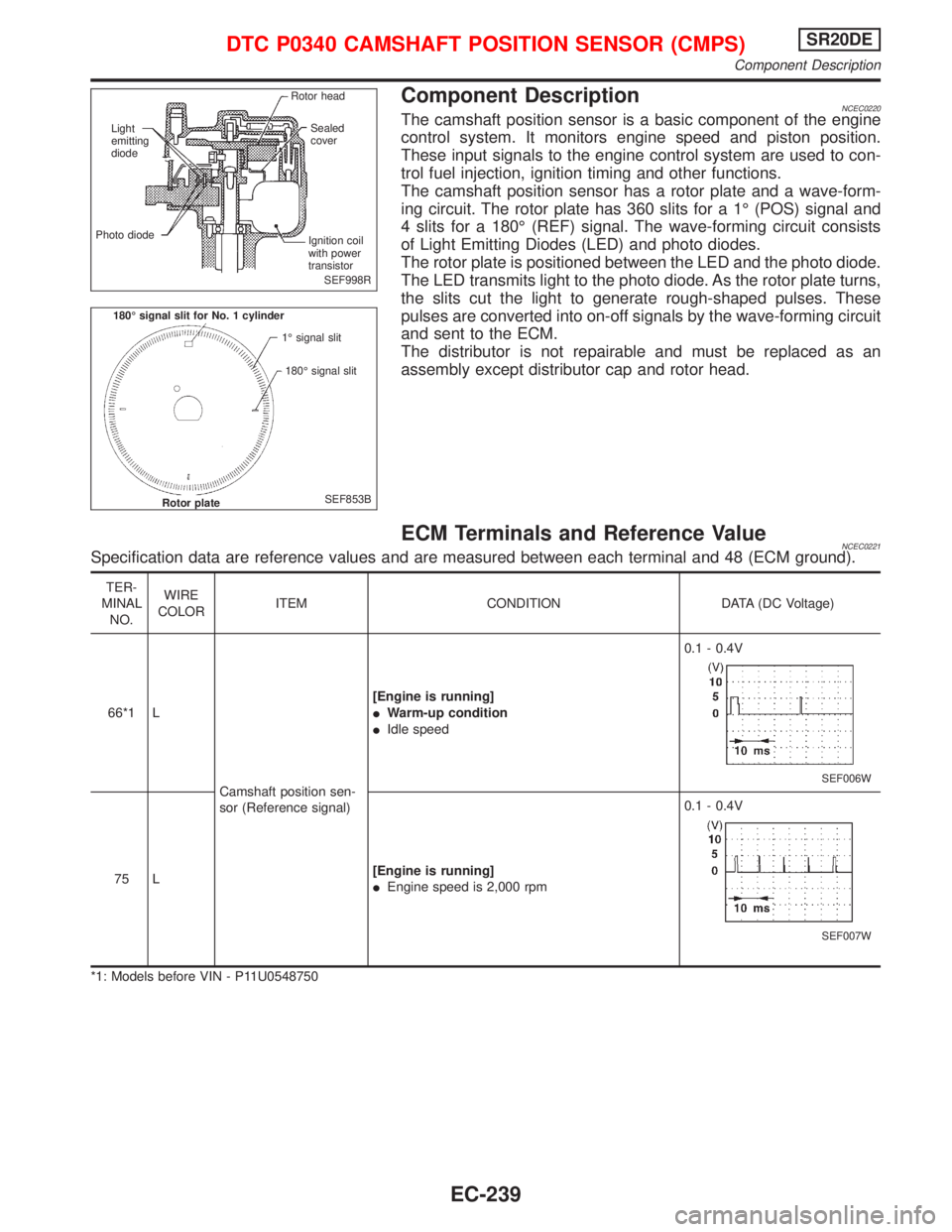

Component DescriptionNCEC0220The camshaft position sensor is a basic component of the engine

control system. It monitors engine speed and piston position.

These input signals to the engine control system are used to con-

trol fuel injection, ignition timing and other functions.

The camshaft position sensor has a rotor plate and a wave-form-

ing circuit. The rotor plate has 360 slits for a 1É (POS) signal and

4 slits for a 180É (REF) signal. The wave-forming circuit consists

of Light Emitting Diodes (LED) and photo diodes.

The rotor plate is positioned between the LED and the photo diode.

The LED transmits light to the photo diode. As the rotor plate turns,

the slits cut the light to generate rough-shaped pulses. These

pulses are converted into on-off signals by the wave-forming circuit

and sent to the ECM.

The distributor is not repairable and must be replaced as an

assembly except distributor cap and rotor head.

ECM Terminals and Reference ValueNCEC0221Specification data are reference values and are measured between each terminal and 48 (ECM ground).

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

66*1 L

Camshaft position sen-

sor (Reference signal)[Engine is running]

IWarm-up condition

IIdle speed0.1 - 0.4V

SEF006W

75 L[Engine is running]

IEngine speed is 2,000 rpm0.1 - 0.4V

SEF007W

*1: Models before VIN - P11U0548750

SEF998R Rotor head

Sealed

cover

Ignition coil

with power

transistor Light

emitting

diode

Photo diode

SEF853B 180É signal slit for No. 1 cylinder

1É signal slit

180É signal slit

Rotor plate

DTC P0340 CAMSHAFT POSITION SENSOR (CMPS)SR20DE

Component Description

EC-239

Page 1040 of 2267

![NISSAN PRIMERA 1999 Electronic Repair Manual TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

85 B/WCamshaft position sen-

sor (Position signal)[Engine is running]

IWarm-up condition

IIdle speedApproximately 2.5V

0.2 ms

SEF004W

[Engine i NISSAN PRIMERA 1999 Electronic Repair Manual TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

85 B/WCamshaft position sen-

sor (Position signal)[Engine is running]

IWarm-up condition

IIdle speedApproximately 2.5V

0.2 ms

SEF004W

[Engine i](/img/5/57377/w960_57377-1039.png)

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

85 B/WCamshaft position sen-

sor (Position signal)[Engine is running]

IWarm-up condition

IIdle speedApproximately 2.5V

0.2 ms

SEF004W

[Engine is running]

IEngine speed is 2,000 rpmApproximately 2.4V

0.2 ms

SEF005W

On Board Diagnosis LogicNCEC0222

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0340

0340A) Either 1É or 180É signal is not sent to ECM for the

first few seconds during engine cranking.IHarness or connectors

(The camshaft position sensor circuit is open or

shorted.)

ICamshaft position sensor

IStarter motor (Refer to EL section.)

IStarting system circuit (Refer to EL section.)

IDead (Weak) battery B) Either 1É or 180É signal is not sent to ECM often

enough while the engine speed is higher than the

specified engine speed.

C) The relation between 1É and 180É signal is not in

the normal range during the specified engine speed.

DTC Confirmation ProcedureNCEC0223Perform ªProcedure for malfunction Aº first. If DTC cannot be

confirmed, perform ªProcedure for malfunction B and Cº.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is more than 10.5V.

PROCEDURE FOR MALFUNCTION ANCEC0223S01With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Crank engine for at least 2 seconds.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº, EC-

SR-243.

With GST

Follow the procedure ªWith CONSULT-IIº above.

NEF068A

DTC P0340 CAMSHAFT POSITION SENSOR (CMPS)SR20DE

ECM Terminals and Reference Value (Cont'd)

EC-240

Page 1041 of 2267

PROCEDURE FOR MALFUNCTION B AND CNCEC0223S02With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and run it for at least 2 seconds at idle speed.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº, EC-

SR-243.

With GST

Follow the procedure ªWith CONSULT-IIº above.

NEF068A

DTC P0340 CAMSHAFT POSITION SENSOR (CMPS)SR20DE

DTC Confirmation Procedure (Cont'd)

EC-241

Page 1042 of 2267

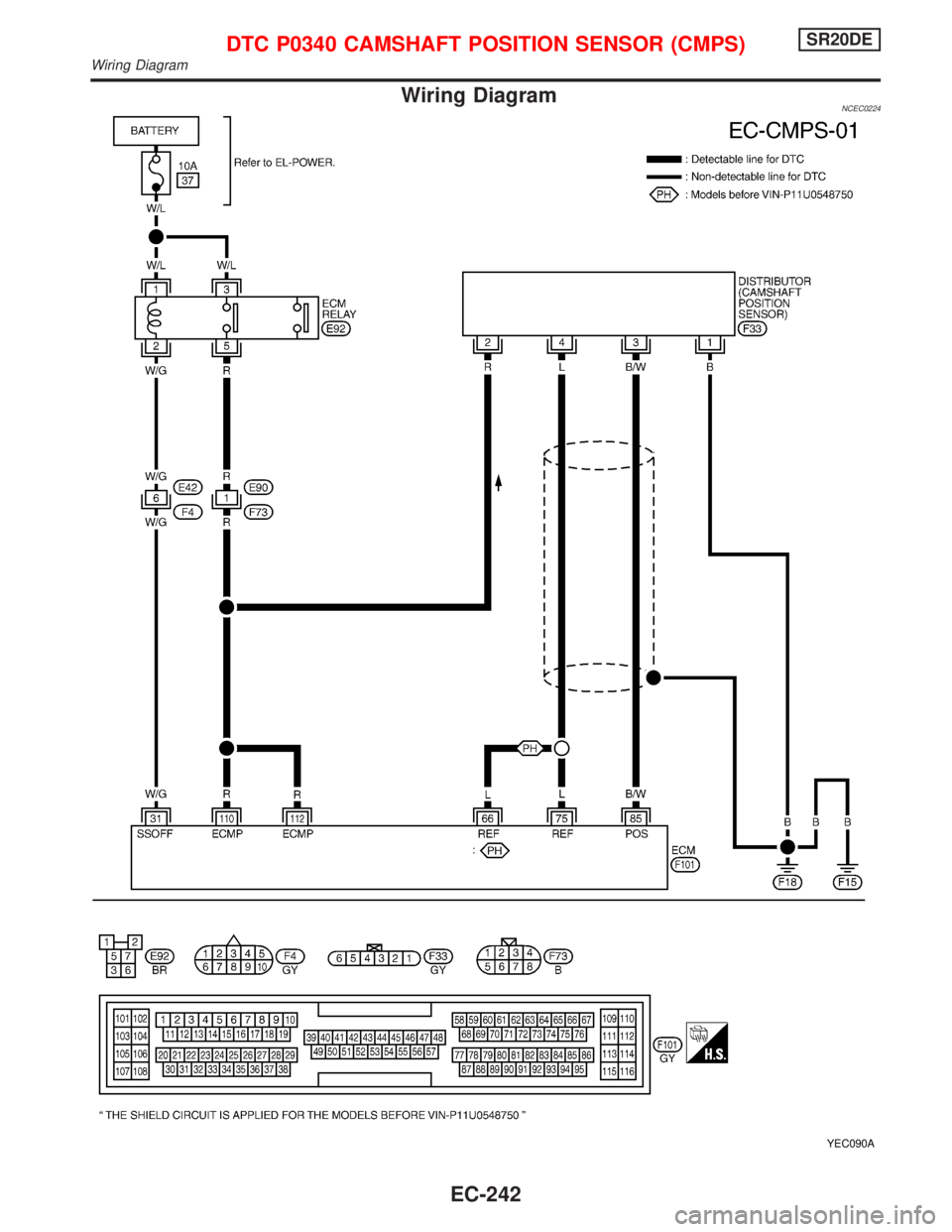

Wiring DiagramNCEC0224

YEC090A

DTC P0340 CAMSHAFT POSITION SENSOR (CMPS)SR20DE

Wiring Diagram

EC-242

Page 1043 of 2267

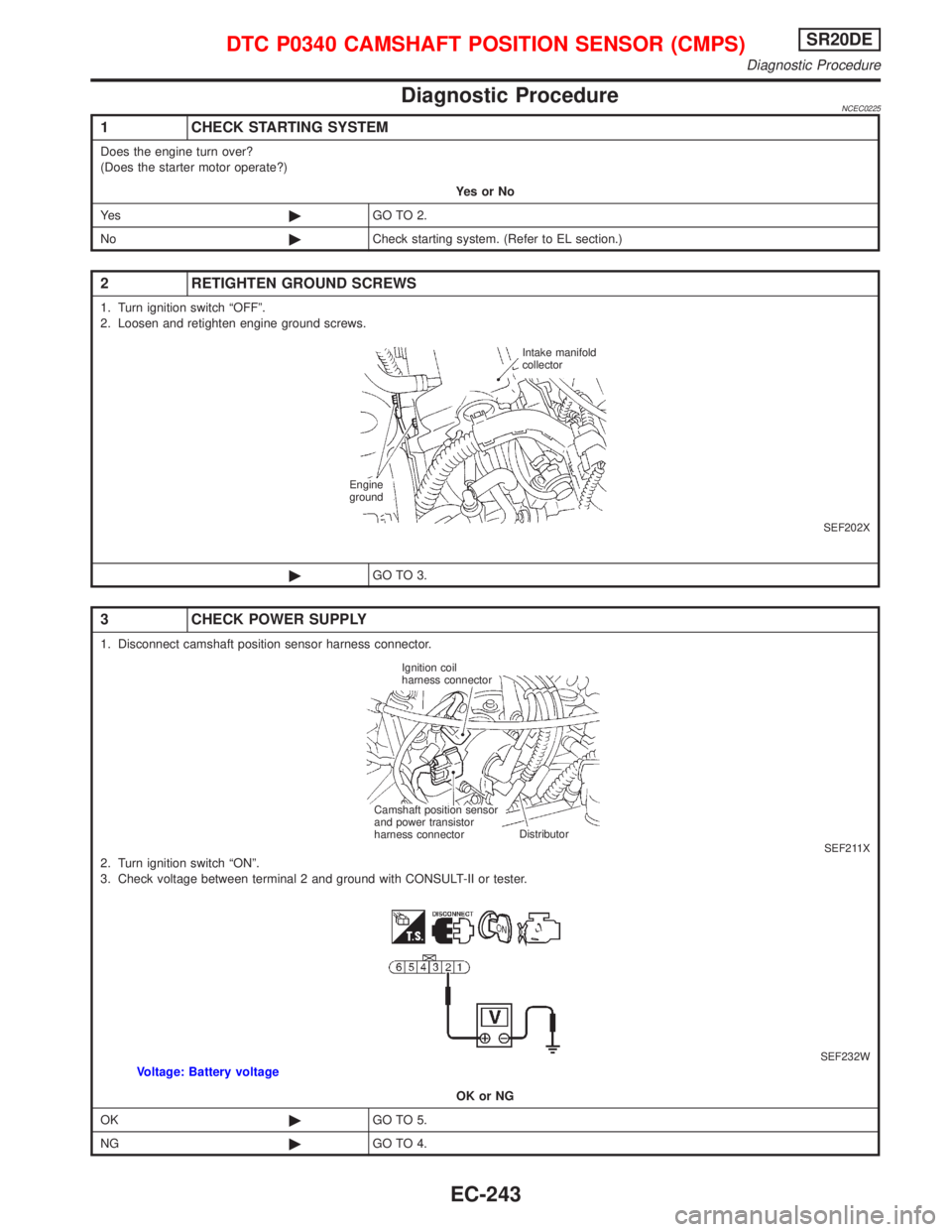

Diagnostic ProcedureNCEC0225

1 CHECK STARTING SYSTEM

Does the engine turn over?

(Does the starter motor operate?)

YesorNo

Ye s©GO TO 2.

No©Check starting system. (Refer to EL section.)

2 RETIGHTEN GROUND SCREWS

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

SEF202X

©GO TO 3.

3 CHECK POWER SUPPLY

1. Disconnect camshaft position sensor harness connector.

SEF211X2. Turn ignition switch ªONº.

3. Check voltage between terminal 2 and ground with CONSULT-II or tester.

SEF232WVoltage: Battery voltage

OK or NG

OK©GO TO 5.

NG©GO TO 4.

Intake manifold

collector

Engine

ground

Ignition coil

harness connector

Distributor Camshaft position sensor

and power transistor

harness connector

DTC P0340 CAMSHAFT POSITION SENSOR (CMPS)SR20DE

Diagnostic Procedure

EC-243

Page 1044 of 2267

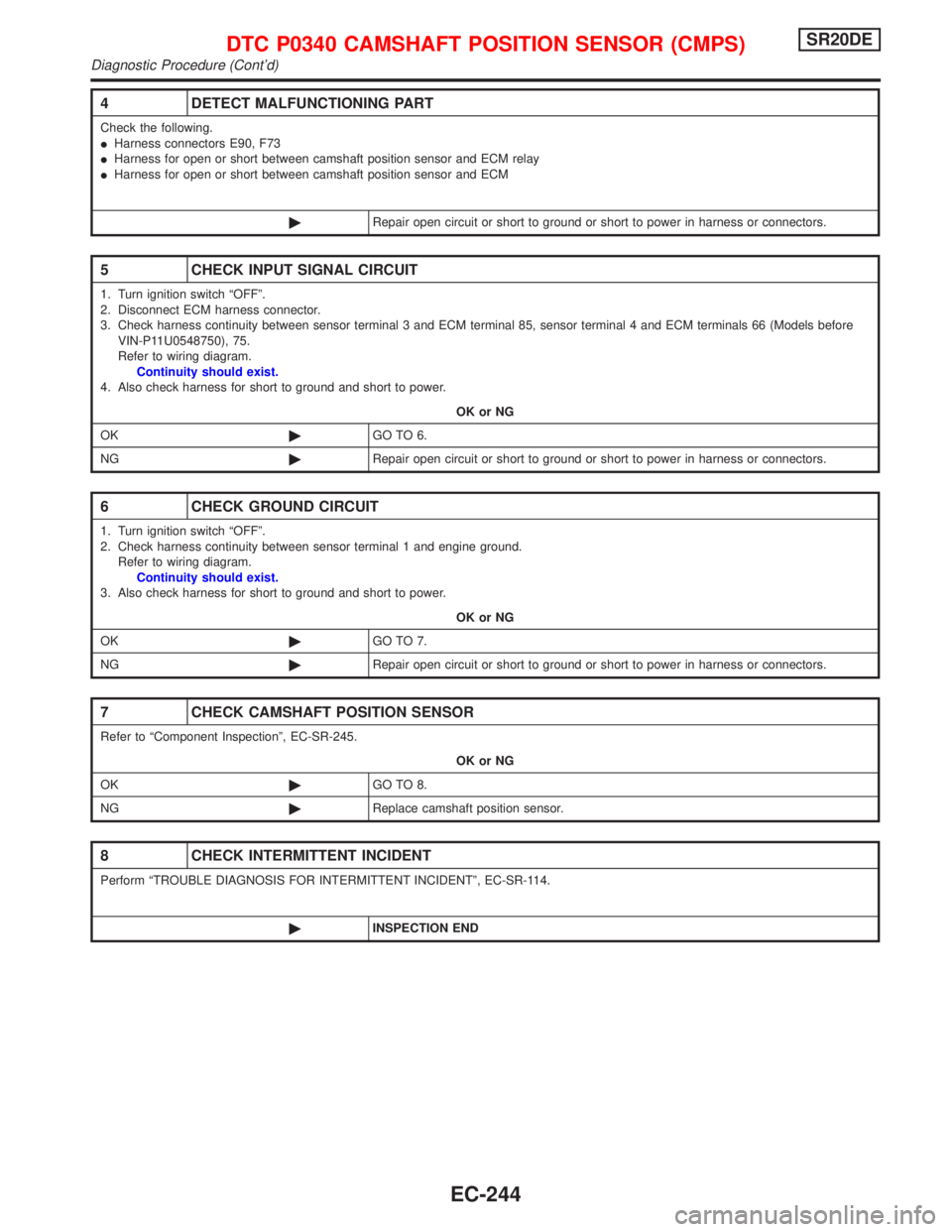

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E90, F73

IHarness for open or short between camshaft position sensor and ECM relay

IHarness for open or short between camshaft position sensor and ECM

©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK INPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between sensor terminal 3 and ECM terminal 85, sensor terminal 4 and ECM terminals 66 (Models before

VIN-P11U0548750), 75.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between sensor terminal 1 and engine ground.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 7.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

7 CHECK CAMSHAFT POSITION SENSOR

Refer to ªComponent Inspectionº, EC-SR-245.

OK or NG

OK©GO TO 8.

NG©Replace camshaft position sensor.

8 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-SR-114.

©INSPECTION END

DTC P0340 CAMSHAFT POSITION SENSOR (CMPS)SR20DE

Diagnostic Procedure (Cont'd)

EC-244

Page 1045 of 2267

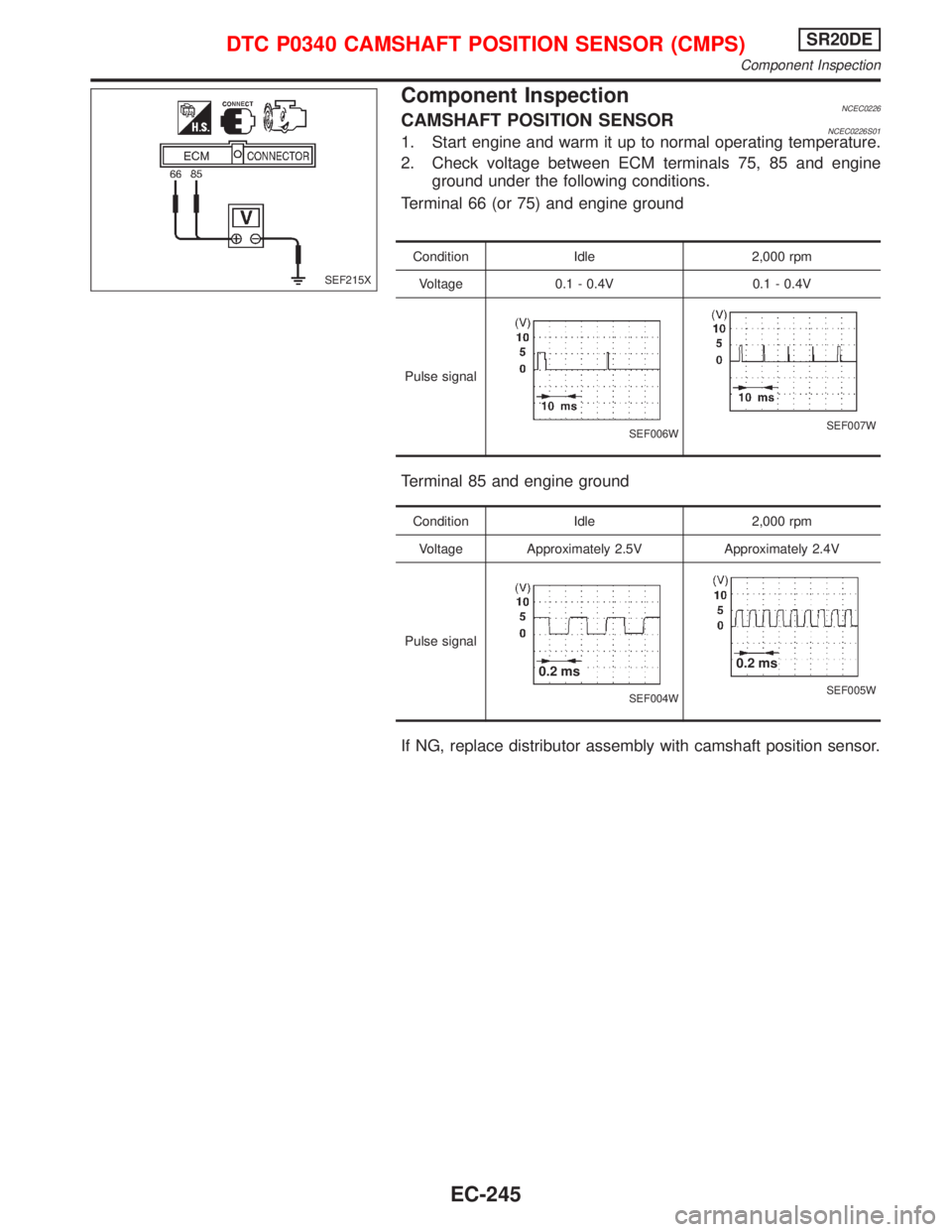

Component InspectionNCEC0226CAMSHAFT POSITION SENSORNCEC0226S011. Start engine and warm it up to normal operating temperature.

2. Check voltage between ECM terminals 75, 85 and engine

ground under the following conditions.

Terminal 66 (or 75) and engine ground

Condition Idle 2,000 rpm

Voltage 0.1 - 0.4V 0.1 - 0.4V

Pulse signal

SEF006WSEF007W

Terminal 85 and engine ground

Condition Idle 2,000 rpm

Voltage Approximately 2.5V Approximately 2.4V

Pulse signal

SEF004W

0.2 ms

SEF005W

0.2 ms

If NG, replace distributor assembly with camshaft position sensor.

SEF215X

DTC P0340 CAMSHAFT POSITION SENSOR (CMPS)SR20DE

Component Inspection

EC-245

Page 1046 of 2267

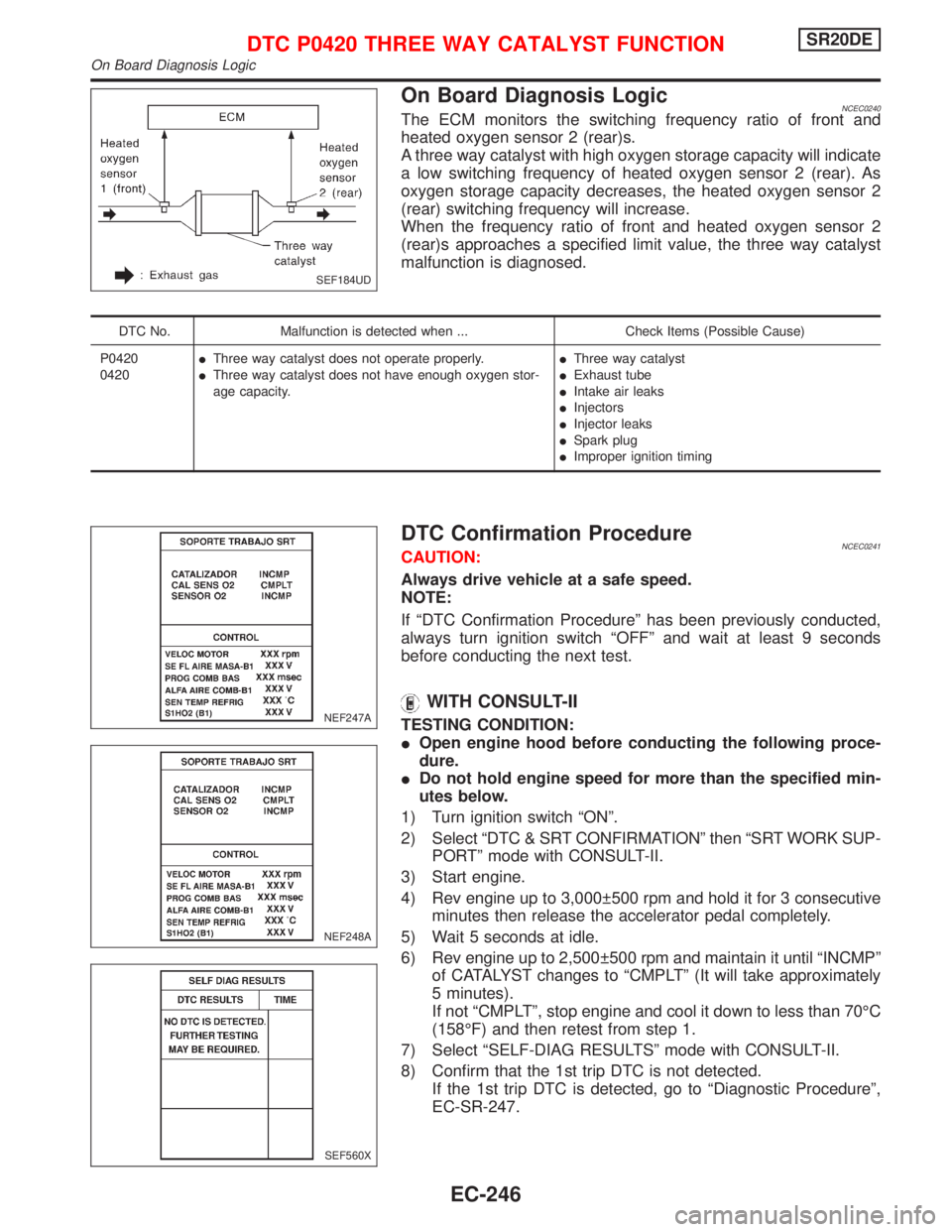

On Board Diagnosis LogicNCEC0240The ECM monitors the switching frequency ratio of front and

heated oxygen sensor 2 (rear)s.

A three way catalyst with high oxygen storage capacity will indicate

a low switching frequency of heated oxygen sensor 2 (rear). As

oxygen storage capacity decreases, the heated oxygen sensor 2

(rear) switching frequency will increase.

When the frequency ratio of front and heated oxygen sensor 2

(rear)s approaches a specified limit value, the three way catalyst

malfunction is diagnosed.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0420

0420IThree way catalyst does not operate properly.

IThree way catalyst does not have enough oxygen stor-

age capacity.IThree way catalyst

IExhaust tube

IIntake air leaks

IInjectors

IInjector leaks

ISpark plug

IImproper ignition timing

DTC Confirmation ProcedureNCEC0241CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

WITH CONSULT-II

TESTING CONDITION:

IOpen engine hood before conducting the following proce-

dure.

IDo not hold engine speed for more than the specified min-

utes below.

1) Turn ignition switch ªONº.

2) Select ªDTC & SRT CONFIRMATIONº then ªSRT WORK SUP-

PORTº mode with CONSULT-II.

3) Start engine.

4) Rev engine up to 3,000 500 rpm and hold it for 3 consecutive

minutes then release the accelerator pedal completely.

5) Wait 5 seconds at idle.

6) Rev engine up to 2,500 500 rpm and maintain it until ªINCMPº

of CATALYST changes to ªCMPLTº (It will take approximately

5 minutes).

If not ªCMPLTº, stop engine and cool it down to less than 70ÉC

(158ÉF) and then retest from step 1.

7) Select ªSELF-DIAG RESULTSº mode with CONSULT-II.

8) Confirm that the 1st trip DTC is not detected.

If the 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-SR-247.

SEF184UD

NEF247A

NEF248A

SEF560X

DTC P0420 THREE WAY CATALYST FUNCTIONSR20DE

On Board Diagnosis Logic

EC-246

Page 1047 of 2267

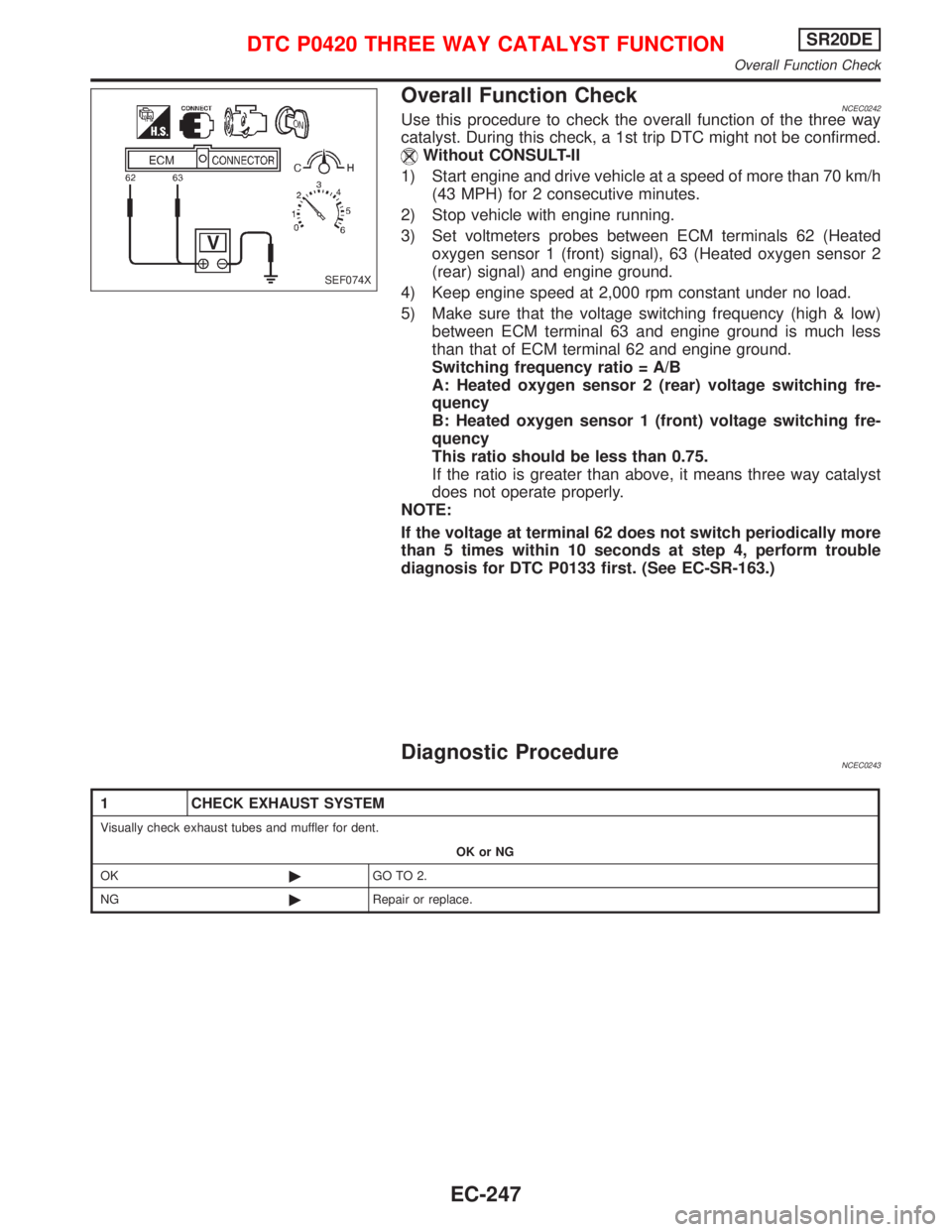

Overall Function CheckNCEC0242Use this procedure to check the overall function of the three way

catalyst. During this check, a 1st trip DTC might not be confirmed.

Without CONSULT-II

1) Start engine and drive vehicle at a speed of more than 70 km/h

(43 MPH) for 2 consecutive minutes.

2) Stop vehicle with engine running.

3) Set voltmeters probes between ECM terminals 62 (Heated

oxygen sensor 1 (front) signal), 63 (Heated oxygen sensor 2

(rear) signal) and engine ground.

4) Keep engine speed at 2,000 rpm constant under no load.

5) Make sure that the voltage switching frequency (high & low)

between ECM terminal 63 and engine ground is much less

than that of ECM terminal 62 and engine ground.

Switching frequency ratio = A/B

A: Heated oxygen sensor 2 (rear) voltage switching fre-

quency

B: Heated oxygen sensor 1 (front) voltage switching fre-

quency

This ratio should be less than 0.75.

If the ratio is greater than above, it means three way catalyst

does not operate properly.

NOTE:

If the voltage at terminal 62 does not switch periodically more

than 5 times within 10 seconds at step 4, perform trouble

diagnosis for DTC P0133 first. (See EC-SR-163.)

Diagnostic ProcedureNCEC0243

SEF074X

1 CHECK EXHAUST SYSTEM

Visually check exhaust tubes and muffler for dent.

OK or NG

OK©GO TO 2.

NG©Repair or replace.

DTC P0420 THREE WAY CATALYST FUNCTIONSR20DE

Overall Function Check

EC-247

Page 1048 of 2267

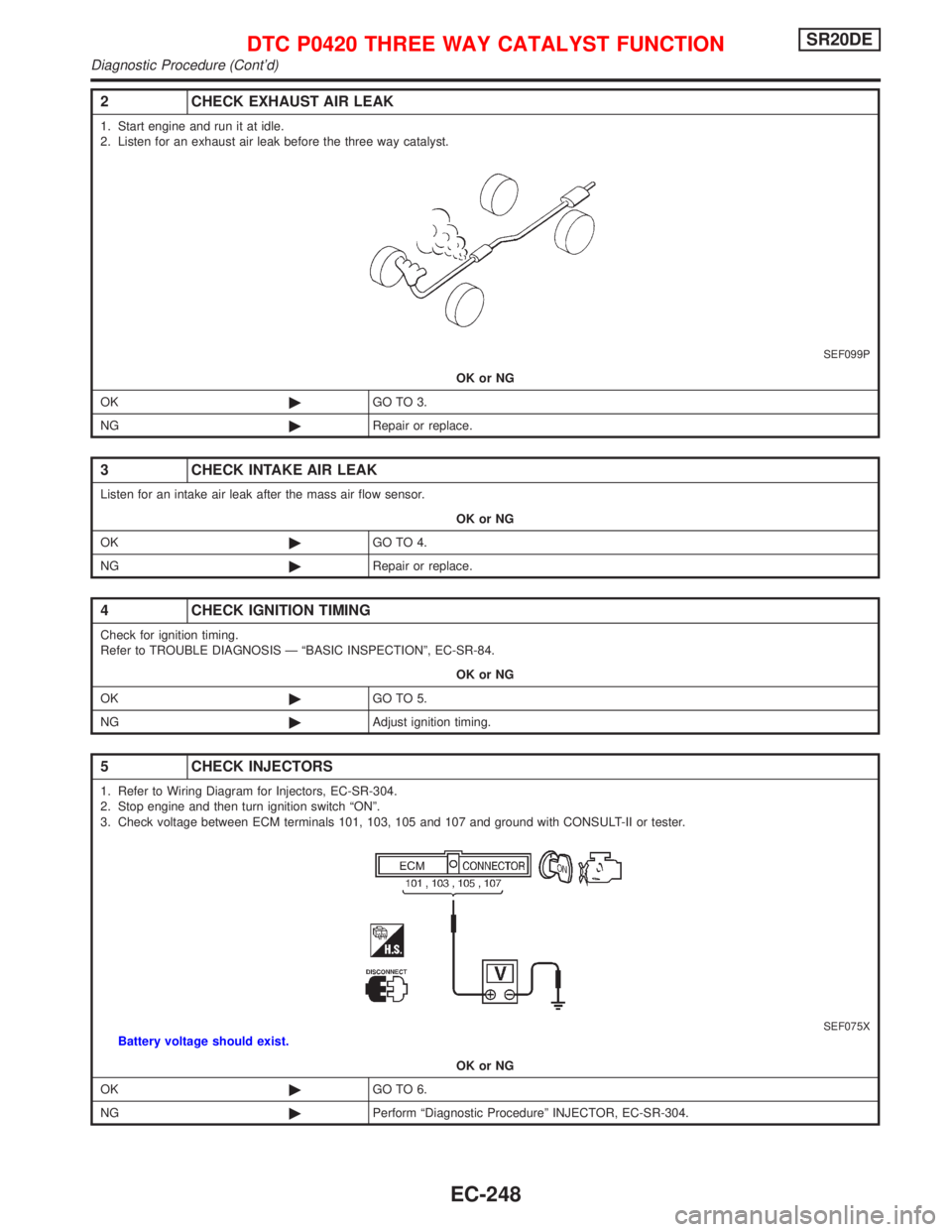

2 CHECK EXHAUST AIR LEAK

1. Start engine and run it at idle.

2. Listen for an exhaust air leak before the three way catalyst.

SEF099P

OK or NG

OK©GO TO 3.

NG©Repair or replace.

3 CHECK INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK©GO TO 4.

NG©Repair or replace.

4 CHECK IGNITION TIMING

Check for ignition timing.

Refer to TROUBLE DIAGNOSIS Ð ªBASIC INSPECTIONº, EC-SR-84.

OK or NG

OK©GO TO 5.

NG©Adjust ignition timing.

5 CHECK INJECTORS

1. Refer to Wiring Diagram for Injectors, EC-SR-304.

2. Stop engine and then turn ignition switch ªONº.

3. Check voltage between ECM terminals 101, 103, 105 and 107 and ground with CONSULT-II or tester.

SEF075XBattery voltage should exist.

OK or NG

OK©GO TO 6.

NG©Perform ªDiagnostic Procedureº INJECTOR, EC-SR-304.

DTC P0420 THREE WAY CATALYST FUNCTIONSR20DE

Diagnostic Procedure (Cont'd)

EC-248