sensor NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1091 of 2267

DTC Confirmation ProcedureNCEC0330NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 5 seconds

before conducting the next test.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

with CONSULT-II.

2) Start engine and run it for at least 4 minutes at idle speed.

3) If 1st trip DTC is detected, go to ªDiagnostic Procedureº, EC-

SR-293.

With GST

Follow the procedure ªWith CONSULT-IIº above.

NEF068A

DTC P1336 CRANKSHAFT POSITION SENSOR

(CKPS) (OBD) (COG)SR20DE

DTC Confirmation Procedure

EC-291

Page 1092 of 2267

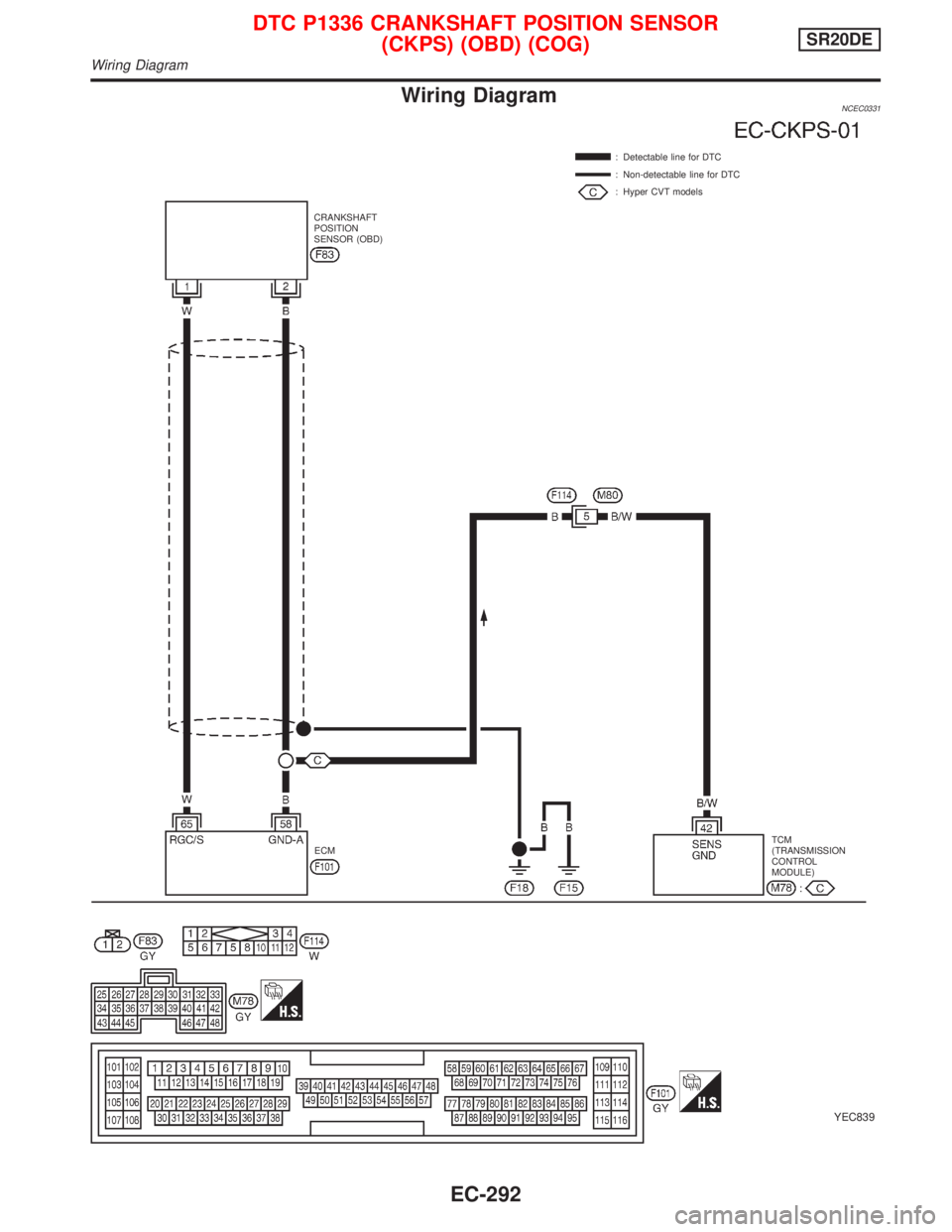

Wiring DiagramNCEC0331

YEC839

: Detectable line for DTC

: Non-detectable line for DTC

: Hyper CVT models

ECMTCM

(TRANSMISSION

CONTROL

MODULE) CRANKSHAFT

POSITION

SENSOR (OBD)

DTC P1336 CRANKSHAFT POSITION SENSOR

(CKPS) (OBD) (COG)SR20DE

Wiring Diagram

EC-292

Page 1093 of 2267

Diagnostic ProcedureNCEC0332

1 RETIGHTEN GROUND SCREWS

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

©GO TO 2.

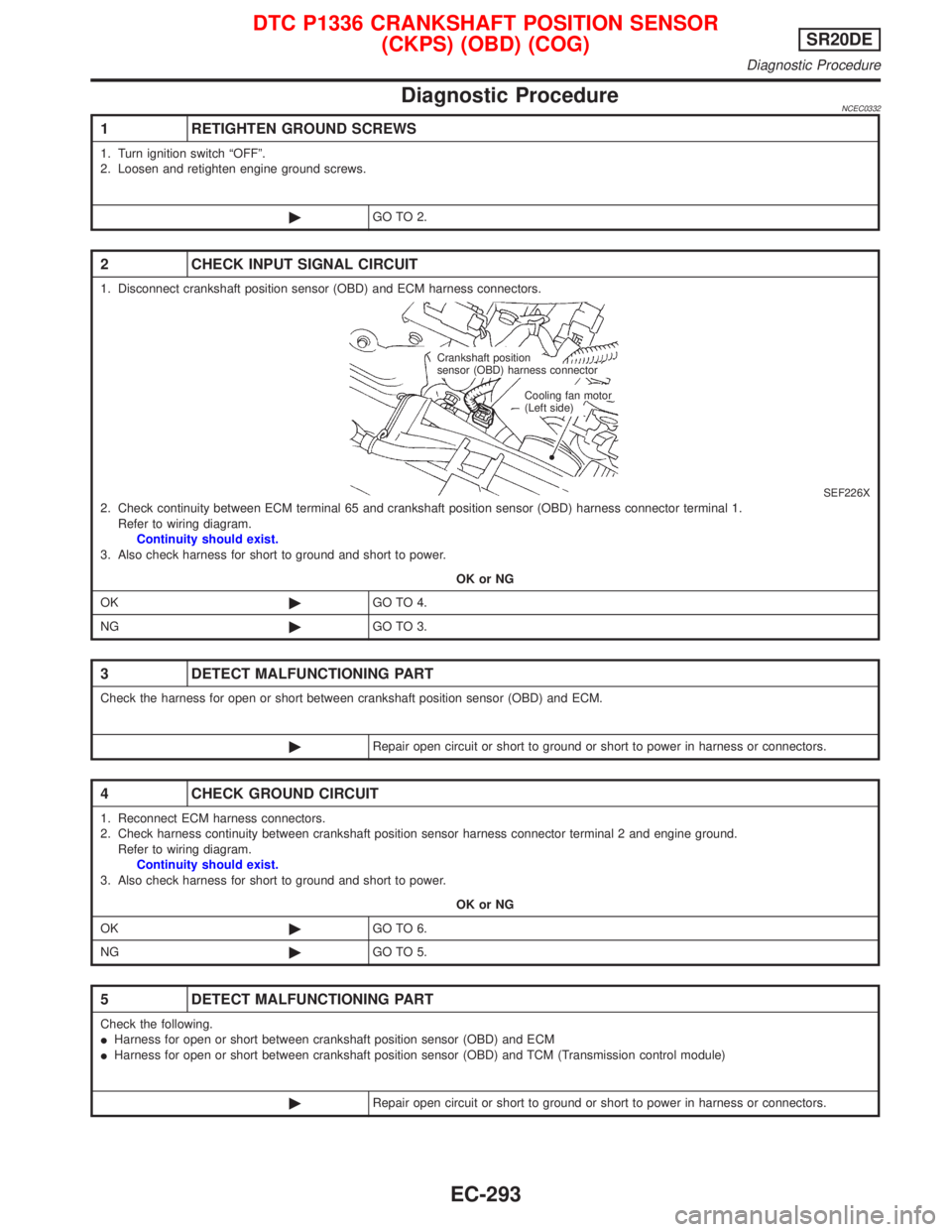

2 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect crankshaft position sensor (OBD) and ECM harness connectors.

SEF226X2. Check continuity between ECM terminal 65 and crankshaft position sensor (OBD) harness connector terminal 1.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the harness for open or short between crankshaft position sensor (OBD) and ECM.

©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK GROUND CIRCUIT

1. Reconnect ECM harness connectors.

2. Check harness continuity between crankshaft position sensor harness connector terminal 2 and engine ground.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

IHarness for open or short between crankshaft position sensor (OBD) and ECM

IHarness for open or short between crankshaft position sensor (OBD) and TCM (Transmission control module)

©Repair open circuit or short to ground or short to power in harness or connectors.

Crankshaft position

sensor (OBD) harness connector

Cooling fan motor

(Left side)

DTC P1336 CRANKSHAFT POSITION SENSOR

(CKPS) (OBD) (COG)SR20DE

Diagnostic Procedure

EC-293

Page 1094 of 2267

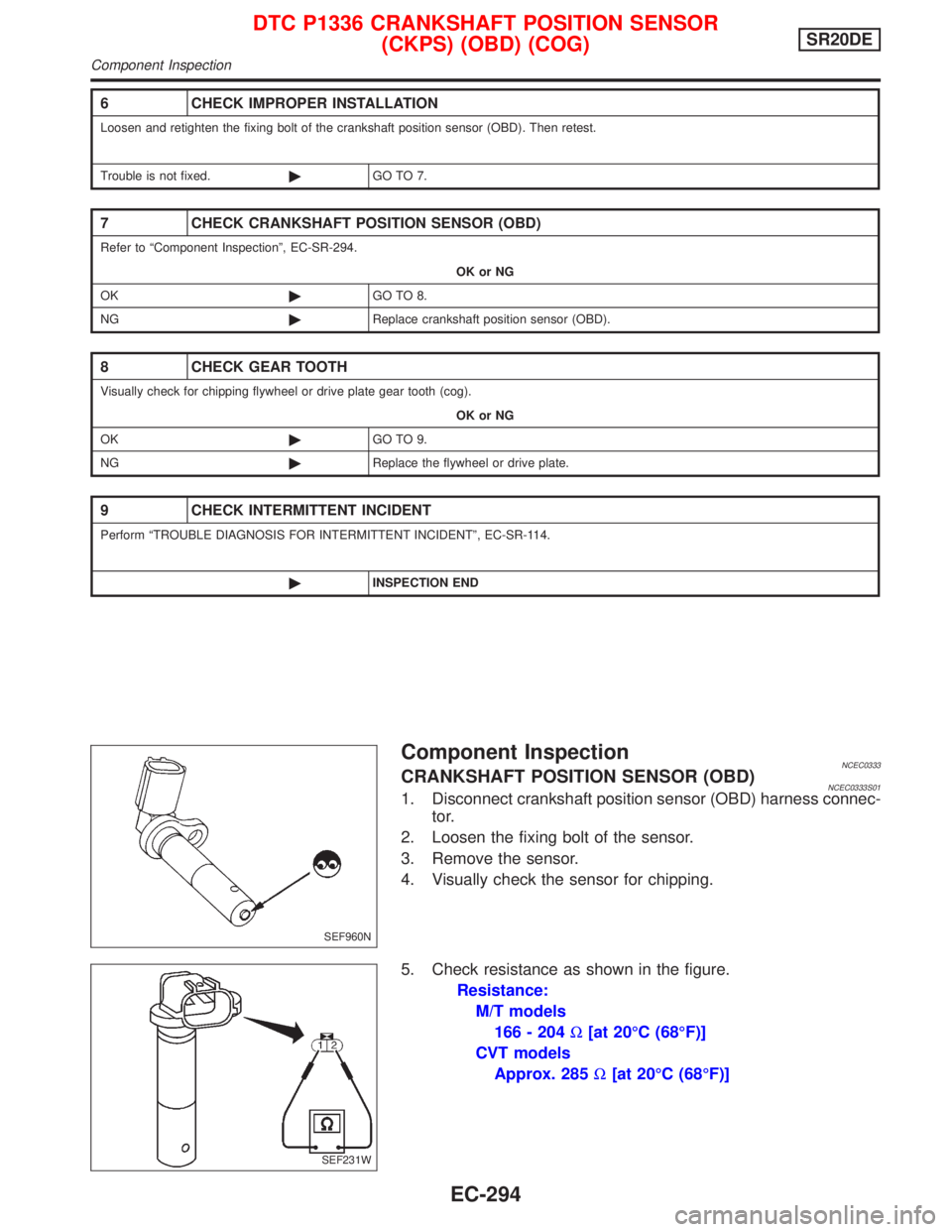

Component InspectionNCEC0333CRANKSHAFT POSITION SENSOR (OBD)NCEC0333S011. Disconnect crankshaft position sensor (OBD) harness connec-

tor.

2. Loosen the fixing bolt of the sensor.

3. Remove the sensor.

4. Visually check the sensor for chipping.

5. Check resistance as shown in the figure.

Resistance:

M/T models

166 - 204W[at 20ÉC (68ÉF)]

CVT models

Approx. 285W[at 20ÉC (68ÉF)]

6 CHECK IMPROPER INSTALLATION

Loosen and retighten the fixing bolt of the crankshaft position sensor (OBD). Then retest.

Trouble is not fixed.©GO TO 7.

7 CHECK CRANKSHAFT POSITION SENSOR (OBD)

Refer to ªComponent Inspectionº, EC-SR-294.

OK or NG

OK©GO TO 8.

NG©Replace crankshaft position sensor (OBD).

8 CHECK GEAR TOOTH

Visually check for chipping flywheel or drive plate gear tooth (cog).

OK or NG

OK©GO TO 9.

NG©Replace the flywheel or drive plate.

9 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-SR-114.

©INSPECTION END

SEF960N

SEF231W

DTC P1336 CRANKSHAFT POSITION SENSOR

(CKPS) (OBD) (COG)SR20DE

Component Inspection

EC-294

Page 1106 of 2267

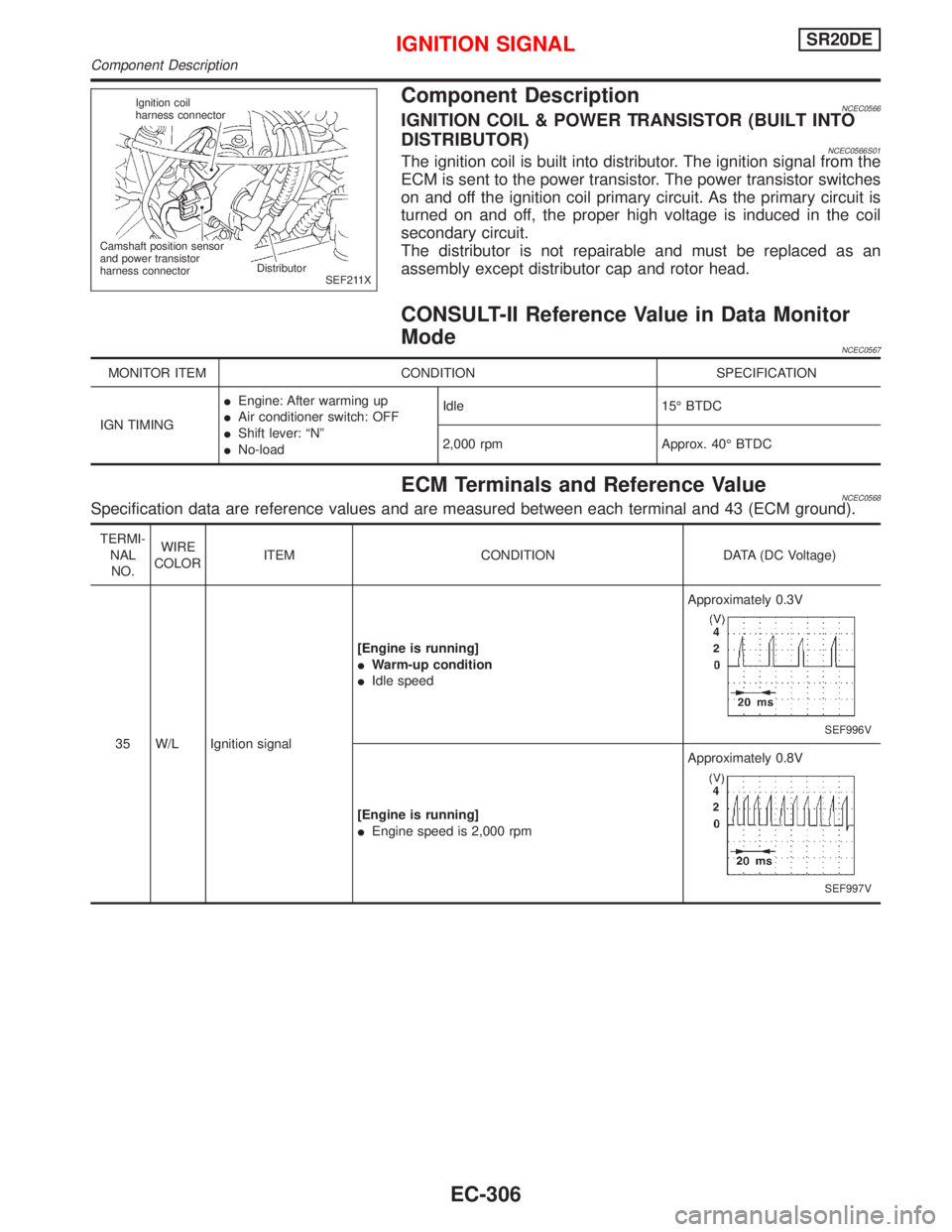

Component DescriptionNCEC0566IGNITION COIL & POWER TRANSISTOR (BUILT INTO

DISTRIBUTOR)

NCEC0566S01The ignition coil is built into distributor. The ignition signal from the

ECM is sent to the power transistor. The power transistor switches

on and off the ignition coil primary circuit. As the primary circuit is

turned on and off, the proper high voltage is induced in the coil

secondary circuit.

The distributor is not repairable and must be replaced as an

assembly except distributor cap and rotor head.

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0567

MONITOR ITEM CONDITION SPECIFICATION

IGN TIMINGIEngine: After warming up

IAir conditioner switch: OFF

IShift lever: ªNº

INo-loadIdle 15É BTDC

2,000 rpm Approx. 40É BTDC

ECM Terminals and Reference ValueNCEC0568Specification data are reference values and are measured between each terminal and 43 (ECM ground).

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

35 W/L Ignition signal[Engine is running]

IWarm-up condition

IIdle speedApproximately 0.3V

SEF996V

[Engine is running]

IEngine speed is 2,000 rpmApproximately 0.8V

SEF997V

SEF211XDistributor Camshaft position sensor

and power transistor

harness connectorIgnition coil

harness connector

IGNITION SIGNALSR20DE

Component Description

EC-306

Page 1109 of 2267

Diagnostic ProcedureNCEC0572

1 CHECK ENGINE START

Turn ignition switch ªOFFº, and restart engine.

Is engine running?

YesorNo

Ye s©GO TO 7.

No©GO TO 2.

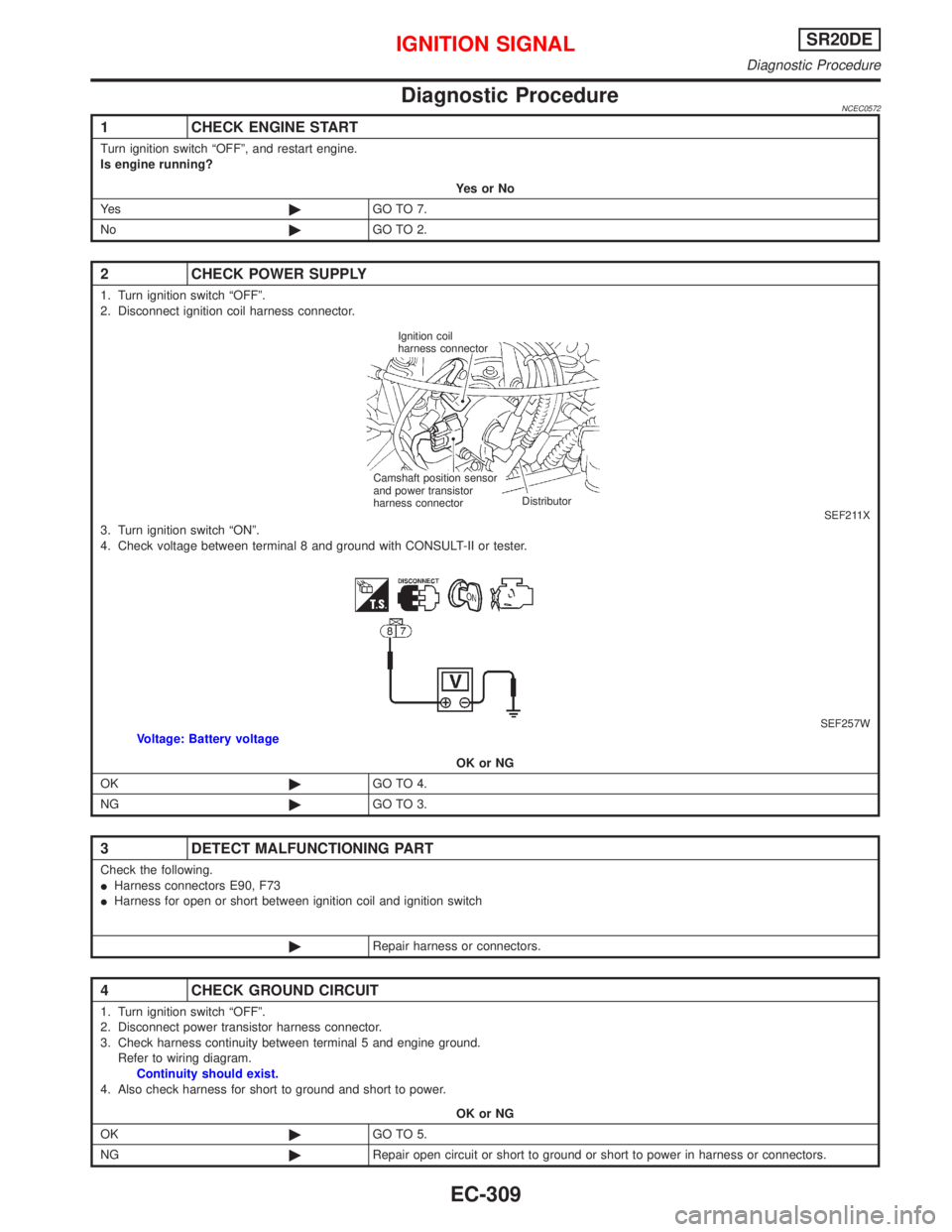

2 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect ignition coil harness connector.

SEF211X3. Turn ignition switch ªONº.

4. Check voltage between terminal 8 and ground with CONSULT-II or tester.

SEF257WVoltage: Battery voltage

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E90, F73

IHarness for open or short between ignition coil and ignition switch

©Repair harness or connectors.

4 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect power transistor harness connector.

3. Check harness continuity between terminal 5 and engine ground.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

Ignition coil

harness connector

Distributor Camshaft position sensor

and power transistor

harness connector

IGNITION SIGNALSR20DE

Diagnostic Procedure

EC-309

Page 1116 of 2267

System DescriptionNCEC0444

Sensor Input Signal to ECMECM func-

tionActuator

Camshaft position sensor (REF) Engine speed

ECM Fuel pump relay

Ignition switch Start signal

The ECM activates the fuel pump for several seconds after the ignition switch is turned on to improve engine

startability. If the ECM receives a 180É signal from the camshaft position sensor, it knows that the engine is

rotating, and causes the pump to perform. If the 180É signal is not received when the ignition switch is on, the

engine stalls. The ECM stops pump operation and prevents battery discharging, thereby improving safety. The

ECM does not directly drive the fuel pump. It controls the ON/OFF fuel pump relay, which in turn controls the

fuel pump.

Condition Fuel pump operation

Ignition switch is turned to ON. Operates for 2 seconds

Engine running and cranking Operates

When engine is stopped Stops in 1.5 seconds

Except as shown aboveStops

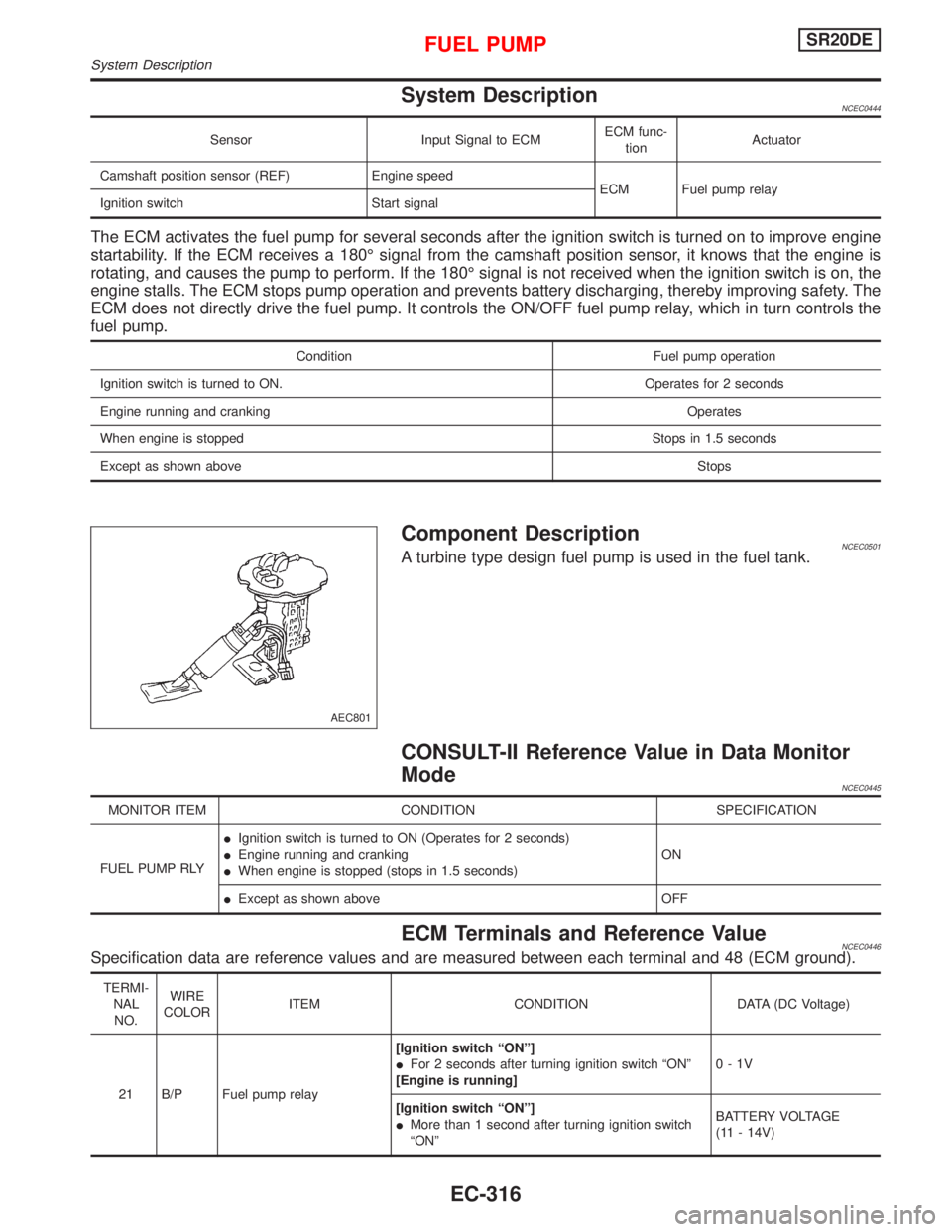

Component DescriptionNCEC0501A turbine type design fuel pump is used in the fuel tank.

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0445

MONITOR ITEM CONDITION SPECIFICATION

FUEL PUMP RLYIIgnition switch is turned to ON (Operates for 2 seconds)

IEngine running and cranking

IWhen engine is stopped (stops in 1.5 seconds)ON

IExcept as shown above OFF

ECM Terminals and Reference ValueNCEC0446Specification data are reference values and are measured between each terminal and 48 (ECM ground).

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

21 B/P Fuel pump relay[Ignition switch ªONº]

IFor 2 seconds after turning ignition switch ªONº

[Engine is running]0-1V

[Ignition switch ªONº]

IMore than 1 second after turning ignition switch

ªONºBATTERY VOLTAGE

(11 - 14V)

AEC801

FUEL PUMPSR20DE

System Description

EC-316

Page 1130 of 2267

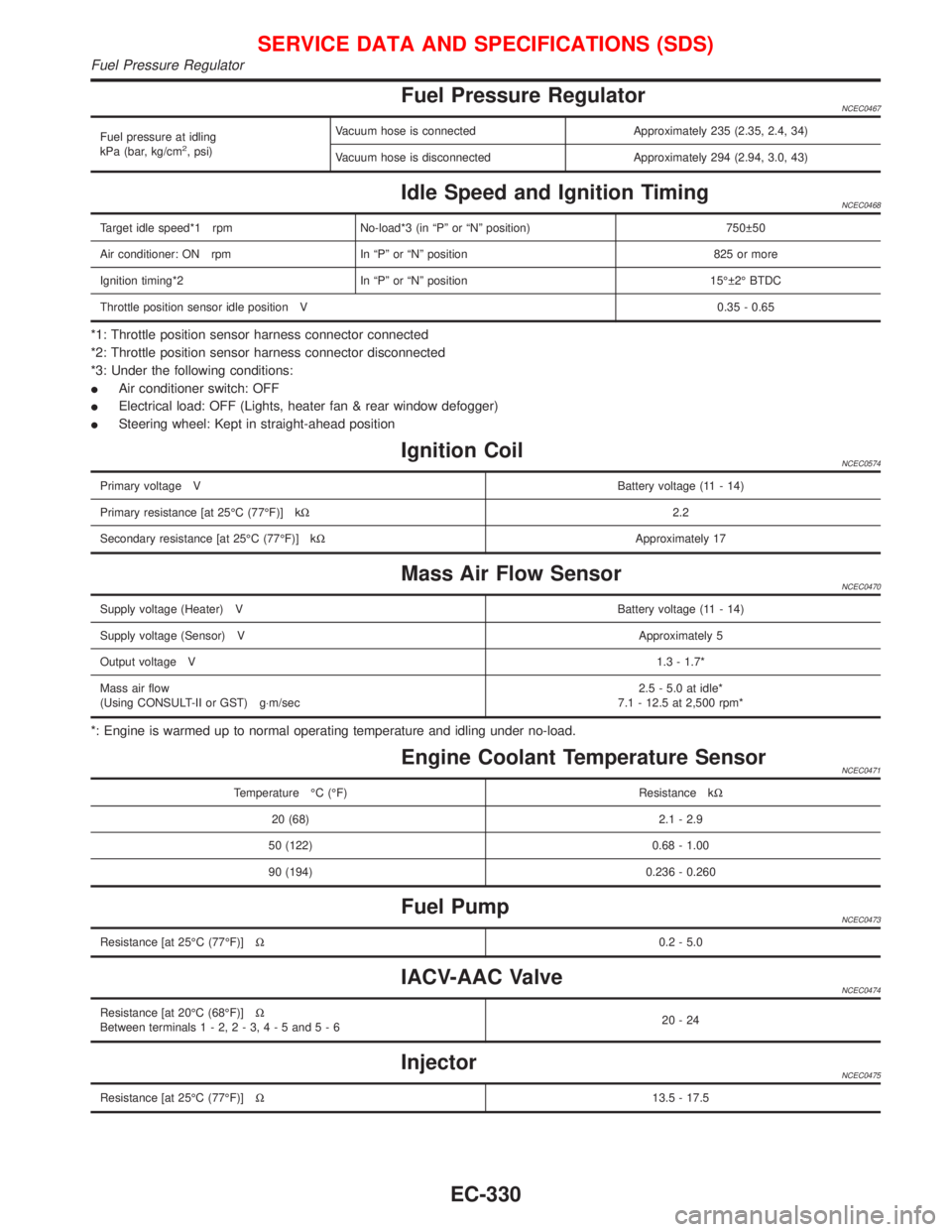

Fuel Pressure RegulatorNCEC0467

Fuel pressure at idling

kPa (bar, kg/cm2, psi)Vacuum hose is connected Approximately 235 (2.35, 2.4, 34)

Vacuum hose is disconnected Approximately 294 (2.94, 3.0, 43)

Idle Speed and Ignition TimingNCEC0468

Target idle speed*1 rpm No-load*3 (in ªPº or ªNº position) 750 50

Air conditioner: ON rpm In ªPº or ªNº position 825 or more

Ignition timing*2 In ªPº or ªNº position 15É 2É BTDC

Throttle position sensor idle position V0.35 - 0.65

*1: Throttle position sensor harness connector connected

*2: Throttle position sensor harness connector disconnected

*3: Under the following conditions:

IAir conditioner switch: OFF

IElectrical load: OFF (Lights, heater fan & rear window defogger)

ISteering wheel: Kept in straight-ahead position

Ignition CoilNCEC0574

Primary voltage VBattery voltage (11 - 14)

Primary resistance [at 25ÉC (77ÉF)] kW2.2

Secondary resistance [at 25ÉC (77ÉF)] kWApproximately 17

Mass Air Flow SensorNCEC0470

Supply voltage (Heater) VBattery voltage (11 - 14)

Supply voltage (Sensor) VApproximately 5

Output voltage V1.3 - 1.7*

Mass air flow

(Using CONSULT-II or GST) g×m/sec2.5 - 5.0 at idle*

7.1 - 12.5 at 2,500 rpm*

*: Engine is warmed up to normal operating temperature and idling under no-load.

Engine Coolant Temperature SensorNCEC0471

Temperature ÉC (ÉF) Resistance kW

20 (68) 2.1 - 2.9

50 (122) 0.68 - 1.00

90 (194) 0.236 - 0.260

Fuel PumpNCEC0473

Resistance [at 25ÉC (77ÉF)]W0.2 - 5.0

IACV-AAC ValveNCEC0474

Resistance [at 20ÉC (68ÉF)]W

Between terminals1-2,2-3,4-5and5-620-24

InjectorNCEC0475

Resistance [at 25ÉC (77ÉF)]W13.5 - 17.5

SERVICE DATA AND SPECIFICATIONS (SDS)

Fuel Pressure Regulator

EC-330

Page 1131 of 2267

![NISSAN PRIMERA 1999 Electronic Repair Manual Throttle Position SensorNCEC0477

Throttle valve conditions Resistance [at 25ÉC (77ÉF)]

Completely closedApproximately 0.6 kW

Partially open0.6 - 4.0 kW

Completely openApproximately 4.0 kW

Heated Oxy NISSAN PRIMERA 1999 Electronic Repair Manual Throttle Position SensorNCEC0477

Throttle valve conditions Resistance [at 25ÉC (77ÉF)]

Completely closedApproximately 0.6 kW

Partially open0.6 - 4.0 kW

Completely openApproximately 4.0 kW

Heated Oxy](/img/5/57377/w960_57377-1130.png)

Throttle Position SensorNCEC0477

Throttle valve conditions Resistance [at 25ÉC (77ÉF)]

Completely closedApproximately 0.6 kW

Partially open0.6 - 4.0 kW

Completely openApproximately 4.0 kW

Heated Oxygen Sensor 1 (Front) HeaterNCEC0478

Resistance [at 25ÉC (77ÉF)]W2.3 - 4.3

Intake Air Temperature SensorNCEC0480

Temperature ÉC (ÉF) Resistance kW

20 (68) 2.2 - 2.6

80 (176) 0.31 - 0.37

EVAP Canister Purge Volume Control ValveNCEC0481

Resistance [at 20ÉC (68ÉF)]W31-35

Heated Oxygen Sensor 1 (Rear) HeaterNCEC0483

Resistance [at 25ÉC (77ÉF)]W2.3 - 4.3

Crankshaft Position Sensor (OBD)NCEC0575

Resistance [at 25ÉC (77ÉF)]W166 - 204

SERVICE DATA AND SPECIFICATIONS (SDS)

Throttle Position Sensor

EC-331

Page 1134 of 2267

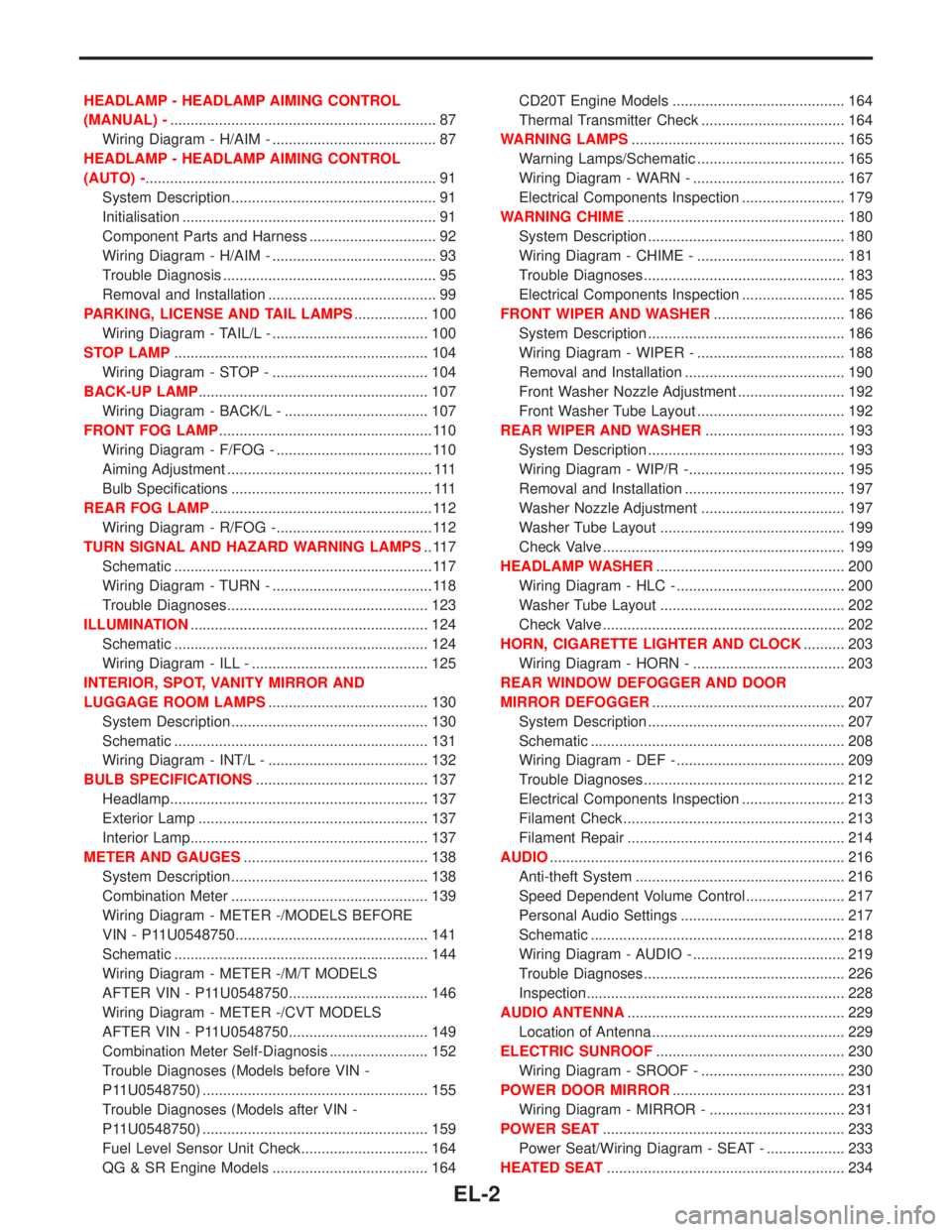

HEADLAMP - HEADLAMP AIMING CONTROL

(MANUAL) -................................................................. 87

Wiring Diagram - H/AIM - ........................................ 87

HEADLAMP - HEADLAMP AIMING CONTROL

(AUTO) -....................................................................... 91

System Description .................................................. 91

Initialisation .............................................................. 91

Component Parts and Harness ............................... 92

Wiring Diagram - H/AIM - ........................................ 93

Trouble Diagnosis .................................................... 95

Removal and Installation ......................................... 99

PARKING, LICENSE AND TAIL LAMPS.................. 100

Wiring Diagram - TAIL/L - ...................................... 100

STOP LAMP.............................................................. 104

Wiring Diagram - STOP - ...................................... 104

BACK-UP LAMP........................................................ 107

Wiring Diagram - BACK/L - ................................... 107

FRONT FOG LAMP.................................................... 110

Wiring Diagram - F/FOG - ...................................... 110

Aiming Adjustment .................................................. 111

Bulb Specifications ................................................. 111

REAR FOG LAMP...................................................... 112

Wiring Diagram - R/FOG -...................................... 112

TURN SIGNAL AND HAZARD WARNING LAMPS.. 117

Schematic ............................................................... 117

Wiring Diagram - TURN - ....................................... 118

Trouble Diagnoses................................................. 123

ILLUMINATION.......................................................... 124

Schematic .............................................................. 124

Wiring Diagram - ILL - ........................................... 125

INTERIOR, SPOT, VANITY MIRROR AND

LUGGAGE ROOM LAMPS....................................... 130

System Description ................................................ 130

Schematic .............................................................. 131

Wiring Diagram - INT/L - ....................................... 132

BULB SPECIFICATIONS.......................................... 137

Headlamp............................................................... 137

Exterior Lamp ........................................................ 137

Interior Lamp.......................................................... 137

METER AND GAUGES............................................. 138

System Description ................................................ 138

Combination Meter ................................................ 139

Wiring Diagram - METER -/MODELS BEFORE

VIN - P11U0548750............................................... 141

Schematic .............................................................. 144

Wiring Diagram - METER -/M/T MODELS

AFTER VIN - P11U0548750.................................. 146

Wiring Diagram - METER -/CVT MODELS

AFTER VIN - P11U0548750.................................. 149

Combination Meter Self-Diagnosis ........................ 152

Trouble Diagnoses (Models before VIN -

P11U0548750) ....................................................... 155

Trouble Diagnoses (Models after VIN -

P11U0548750) ....................................................... 159

Fuel Level Sensor Unit Check............................... 164

QG & SR Engine Models ...................................... 164CD20T Engine Models .......................................... 164

Thermal Transmitter Check ................................... 164

WARNING LAMPS.................................................... 165

Warning Lamps/Schematic .................................... 165

Wiring Diagram - WARN - ..................................... 167

Electrical Components Inspection ......................... 179

WARNING CHIME..................................................... 180

System Description ................................................ 180

Wiring Diagram - CHIME - .................................... 181

Trouble Diagnoses................................................. 183

Electrical Components Inspection ......................... 185

FRONT WIPER AND WASHER................................ 186

System Description ................................................ 186

Wiring Diagram - WIPER - .................................... 188

Removal and Installation ....................................... 190

Front Washer Nozzle Adjustment .......................... 192

Front Washer Tube Layout .................................... 192

REAR WIPER AND WASHER.................................. 193

System Description ................................................ 193

Wiring Diagram - WIP/R -...................................... 195

Removal and Installation ....................................... 197

Washer Nozzle Adjustment ................................... 197

Washer Tube Layout ............................................. 199

Check Valve ........................................................... 199

HEADLAMP WASHER.............................................. 200

Wiring Diagram - HLC - ......................................... 200

Washer Tube Layout ............................................. 202

Check Valve ........................................................... 202

HORN, CIGARETTE LIGHTER AND CLOCK.......... 203

Wiring Diagram - HORN - ..................................... 203

REAR WINDOW DEFOGGER AND DOOR

MIRROR DEFOGGER............................................... 207

System Description ................................................ 207

Schematic .............................................................. 208

Wiring Diagram - DEF - ......................................... 209

Trouble Diagnoses................................................. 212

Electrical Components Inspection ......................... 213

Filament Check ...................................................... 213

Filament Repair ..................................................... 214

AUDIO........................................................................ 216

Anti-theft System ................................................... 216

Speed Dependent Volume Control ........................ 217

Personal Audio Settings ........................................ 217

Schematic .............................................................. 218

Wiring Diagram - AUDIO - ..................................... 219

Trouble Diagnoses................................................. 226

Inspection............................................................... 228

AUDIO ANTENNA..................................................... 229

Location of Antenna ............................................... 229

ELECTRIC SUNROOF.............................................. 230

Wiring Diagram - SROOF - ................................... 230

POWER DOOR MIRROR.......................................... 231

Wiring Diagram - MIRROR - ................................. 231

POWER SEAT........................................................... 233

Power Seat/Wiring Diagram - SEAT - ................... 233

HEATED SEAT.......................................................... 234

EL-2